Mechanochemical and Size Reduction Machines for Biorefining

Abstract

1. Introduction

2. Mechanochemical Equipments for Biorefining

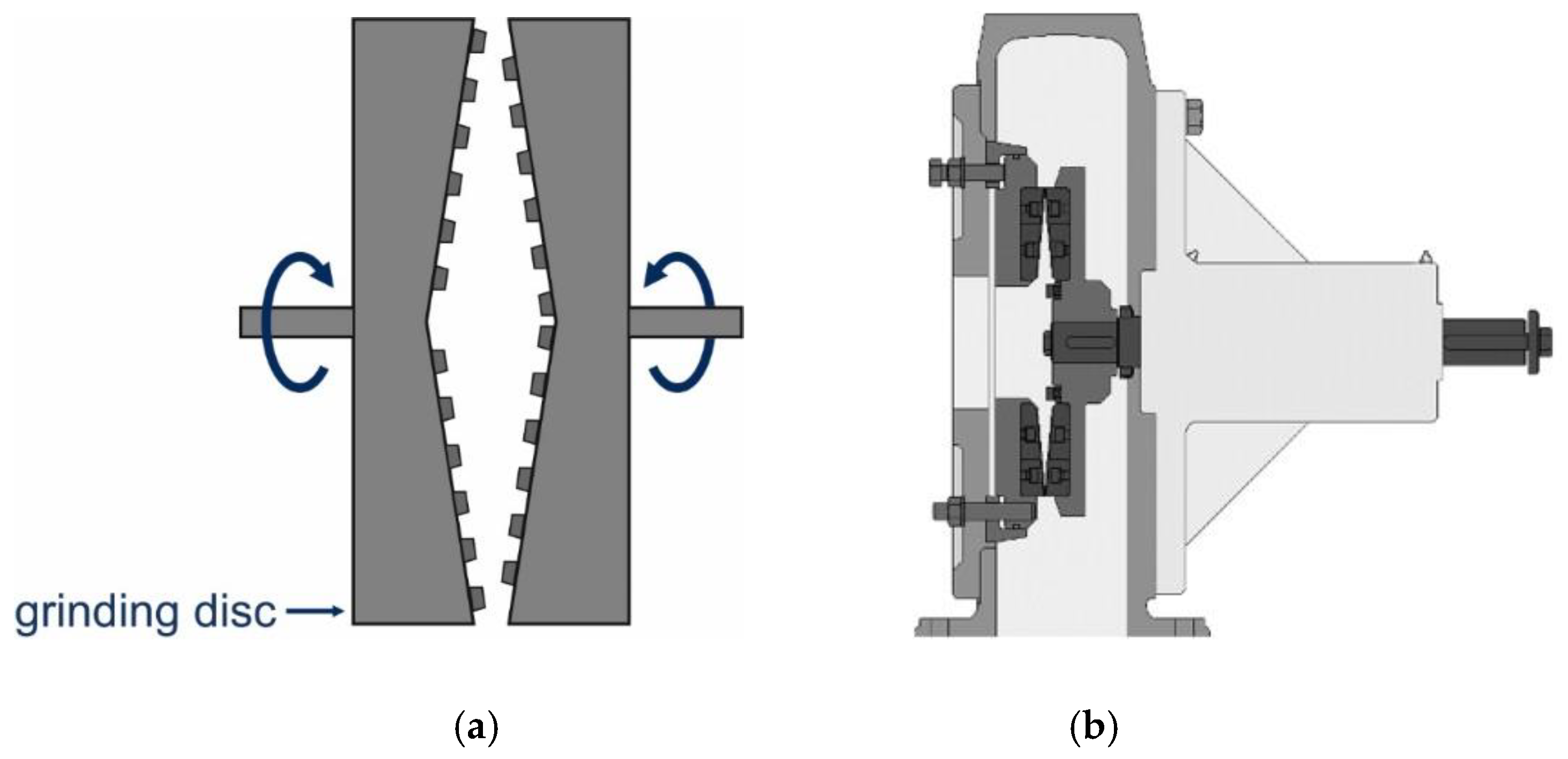

2.1. Disc Mills

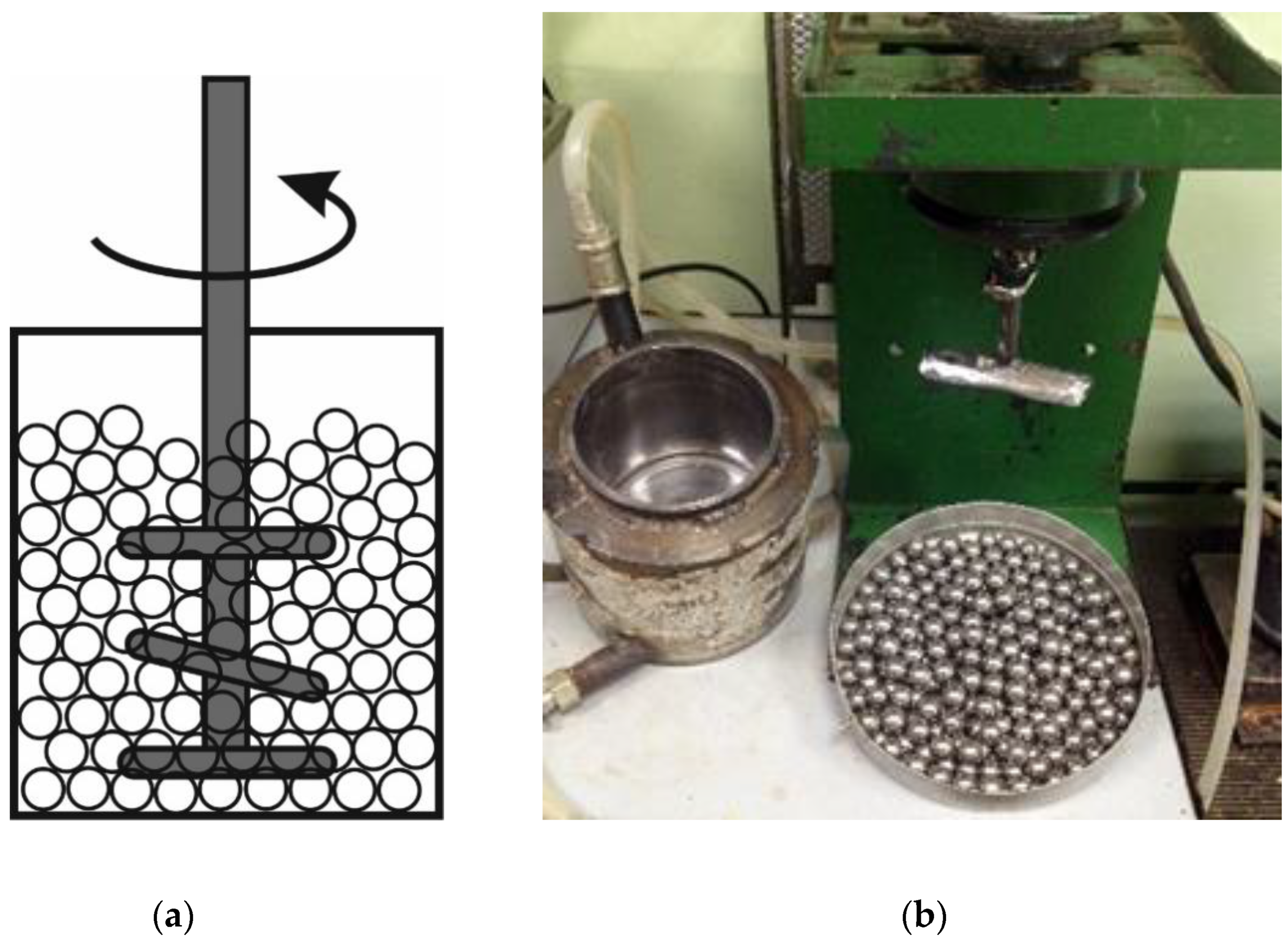

2.2. Attritors and Bead Mills

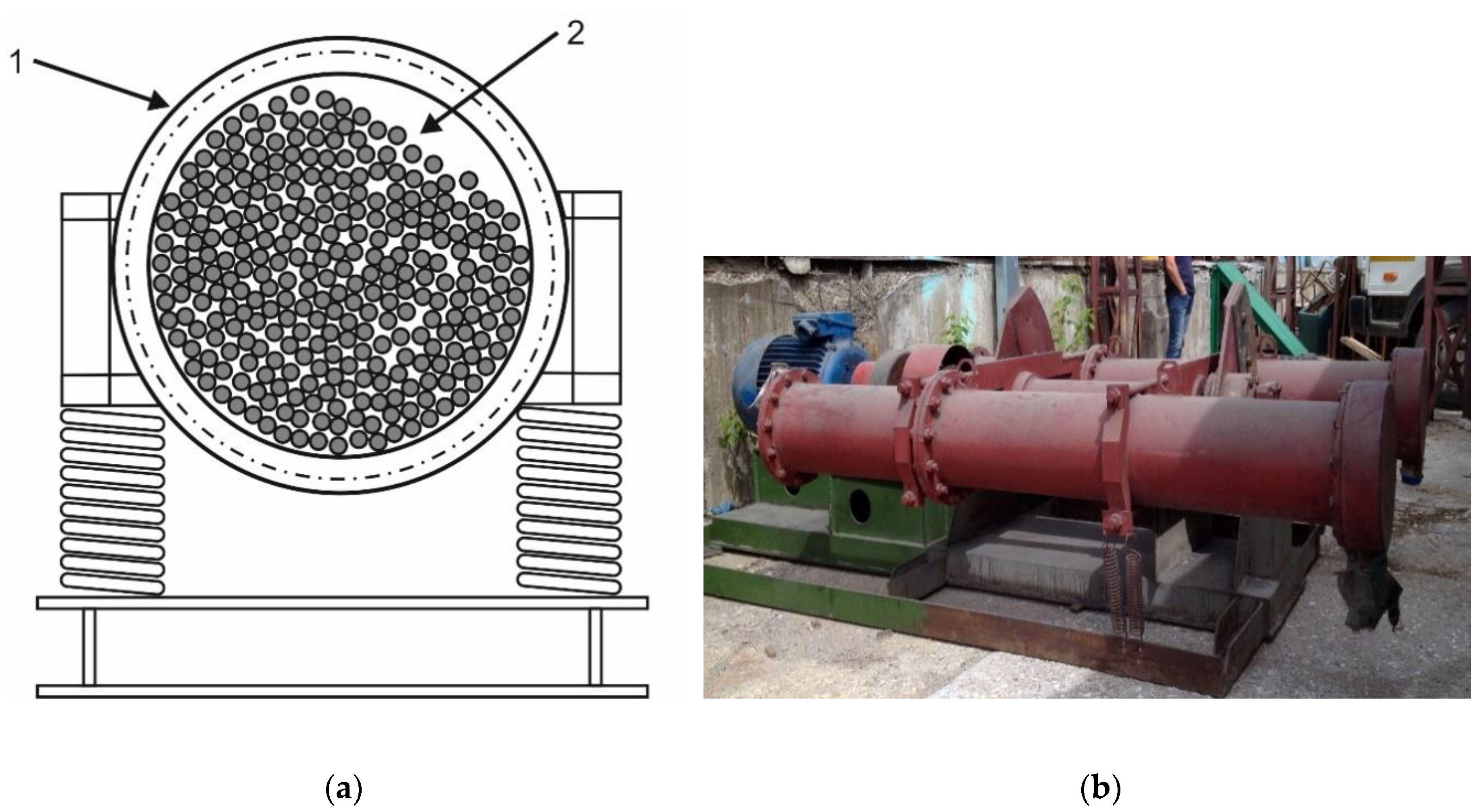

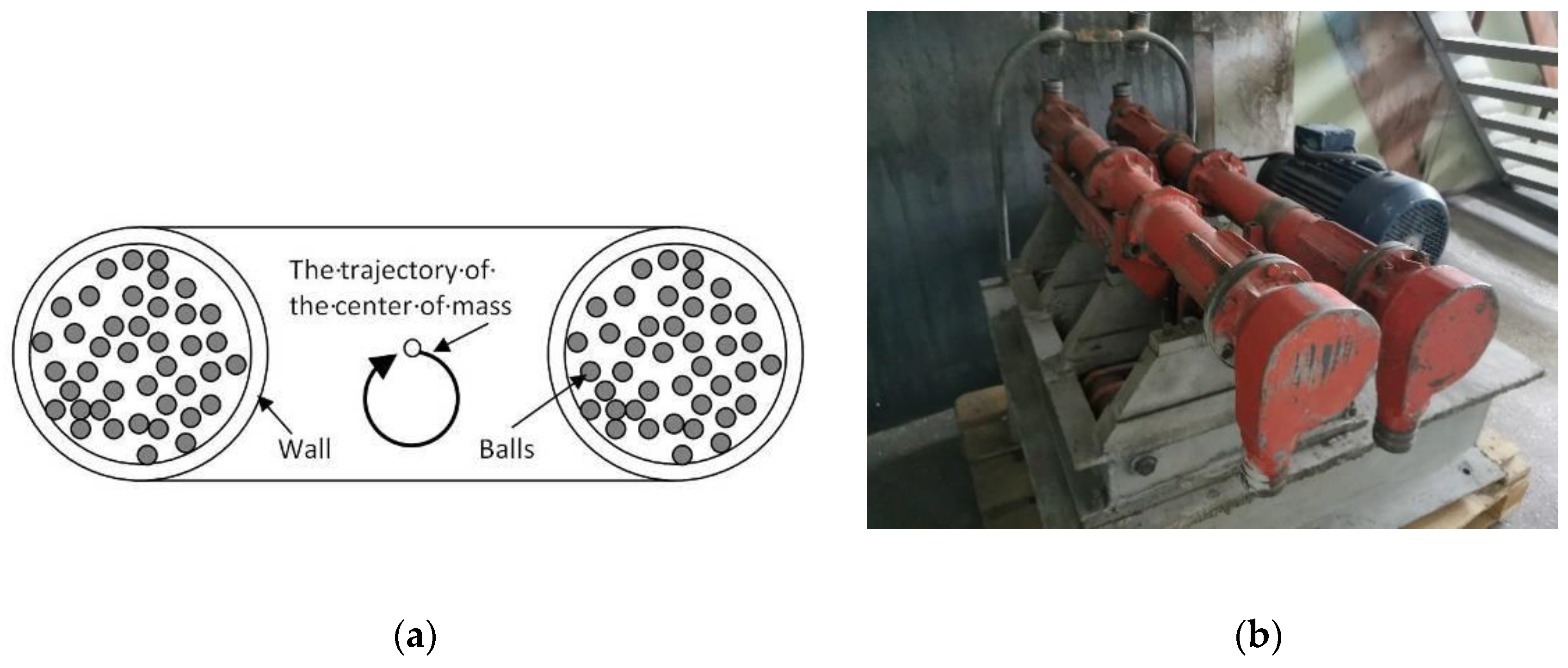

2.3. Ball Mills

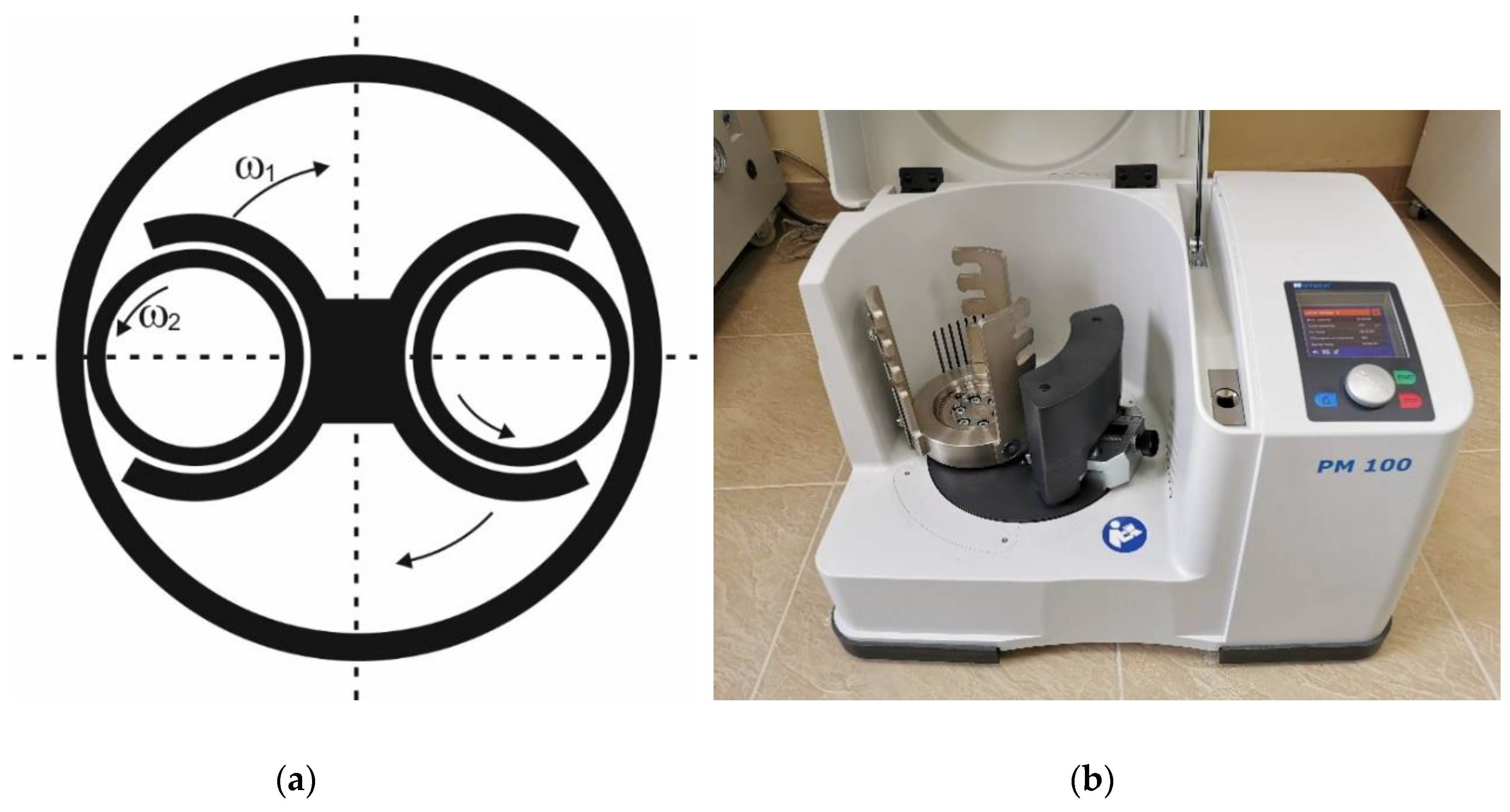

2.4. Planetary Mills

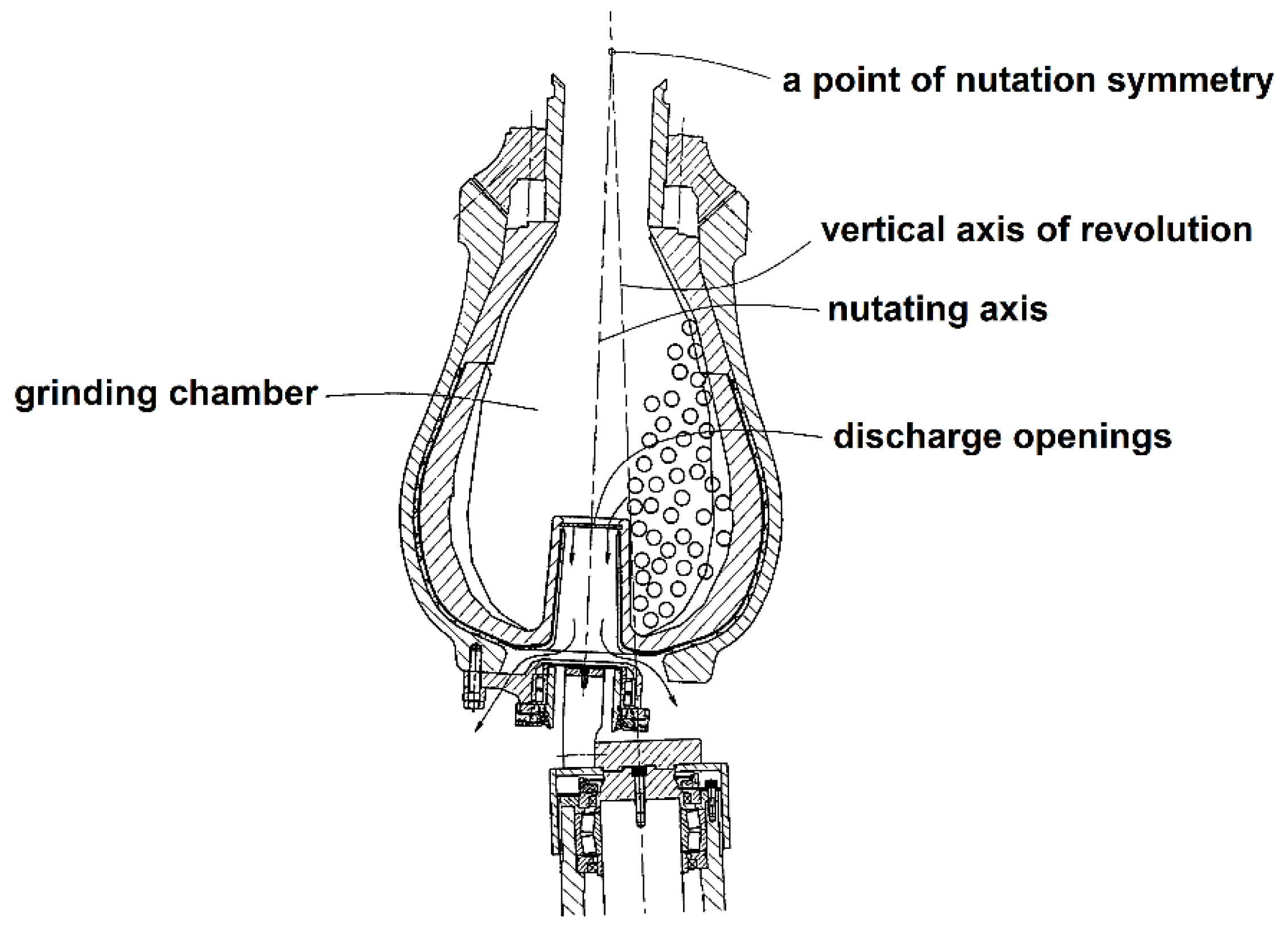

2.5. Vibration and Vibrocentrifugal Mills

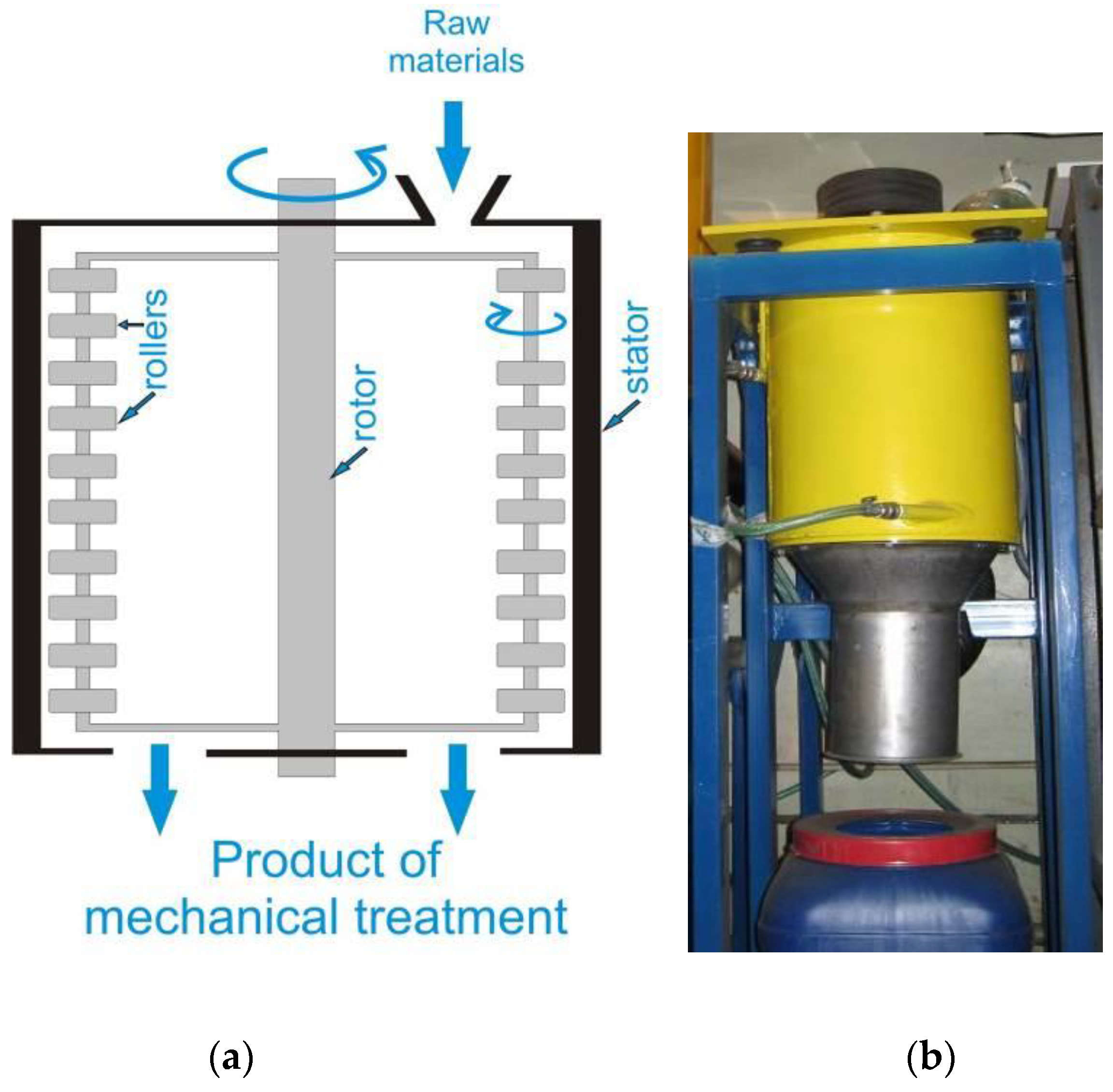

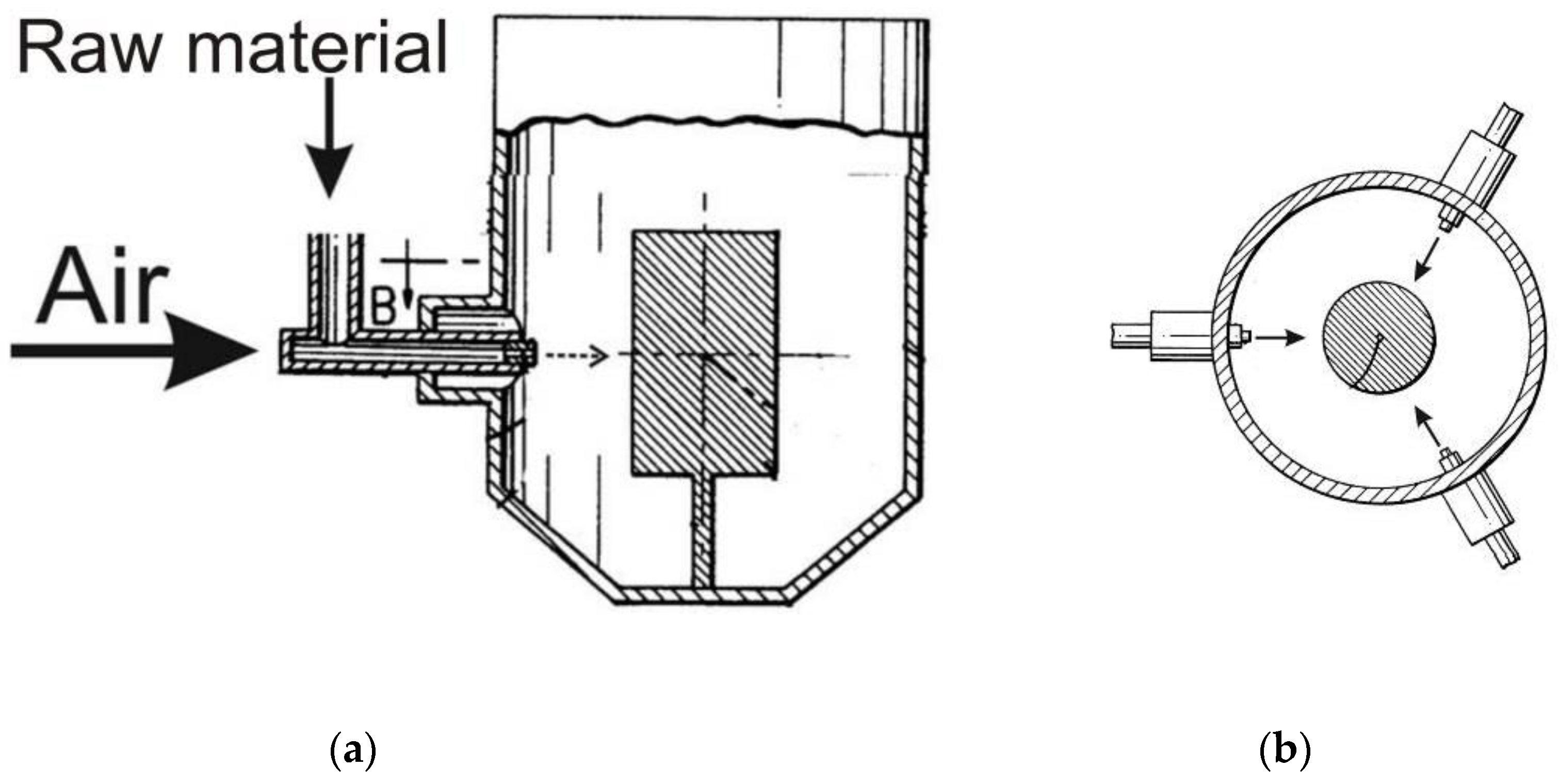

2.6. Roller and Centrifugal Roller Mills

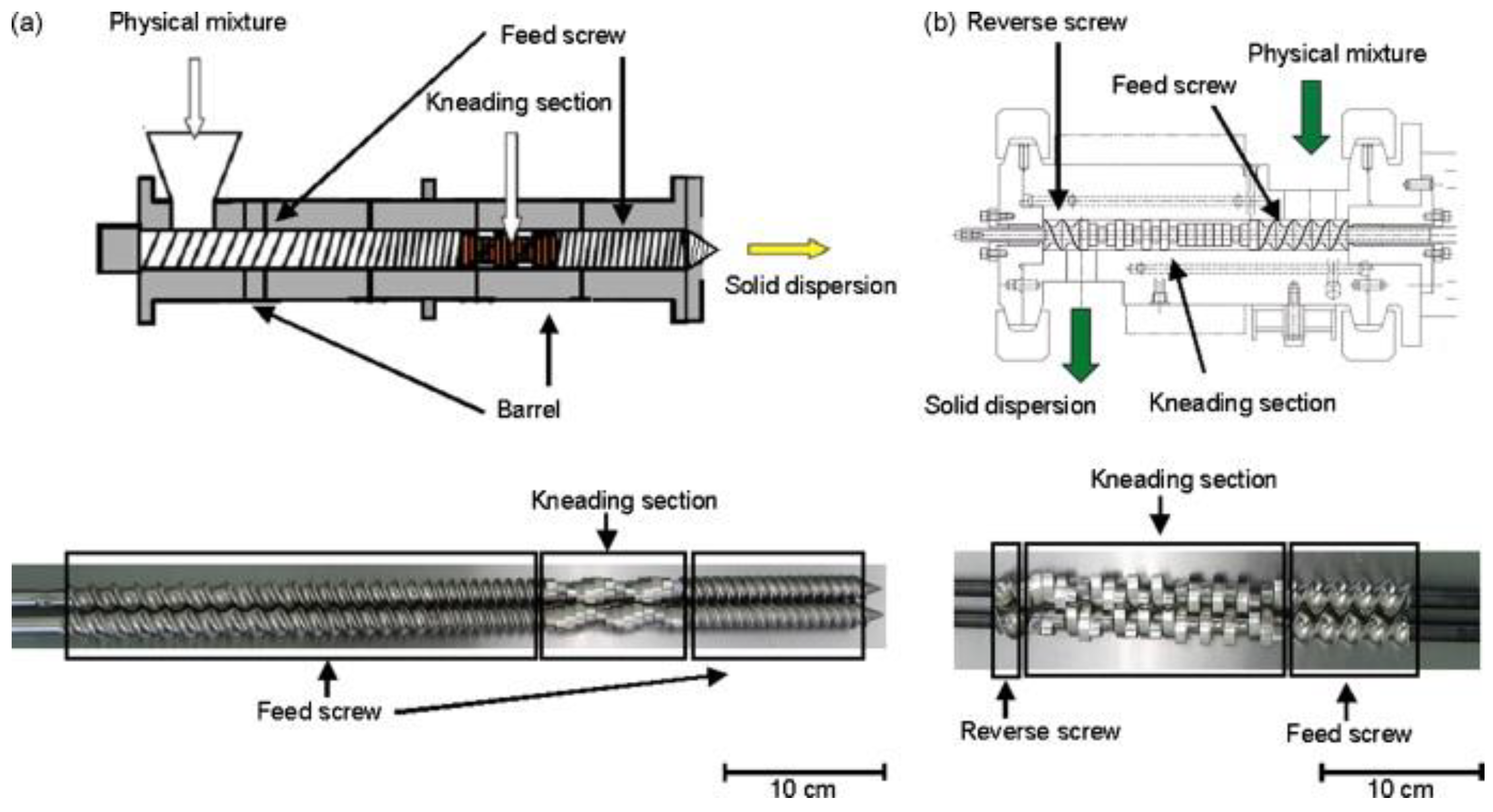

2.7. Extruders

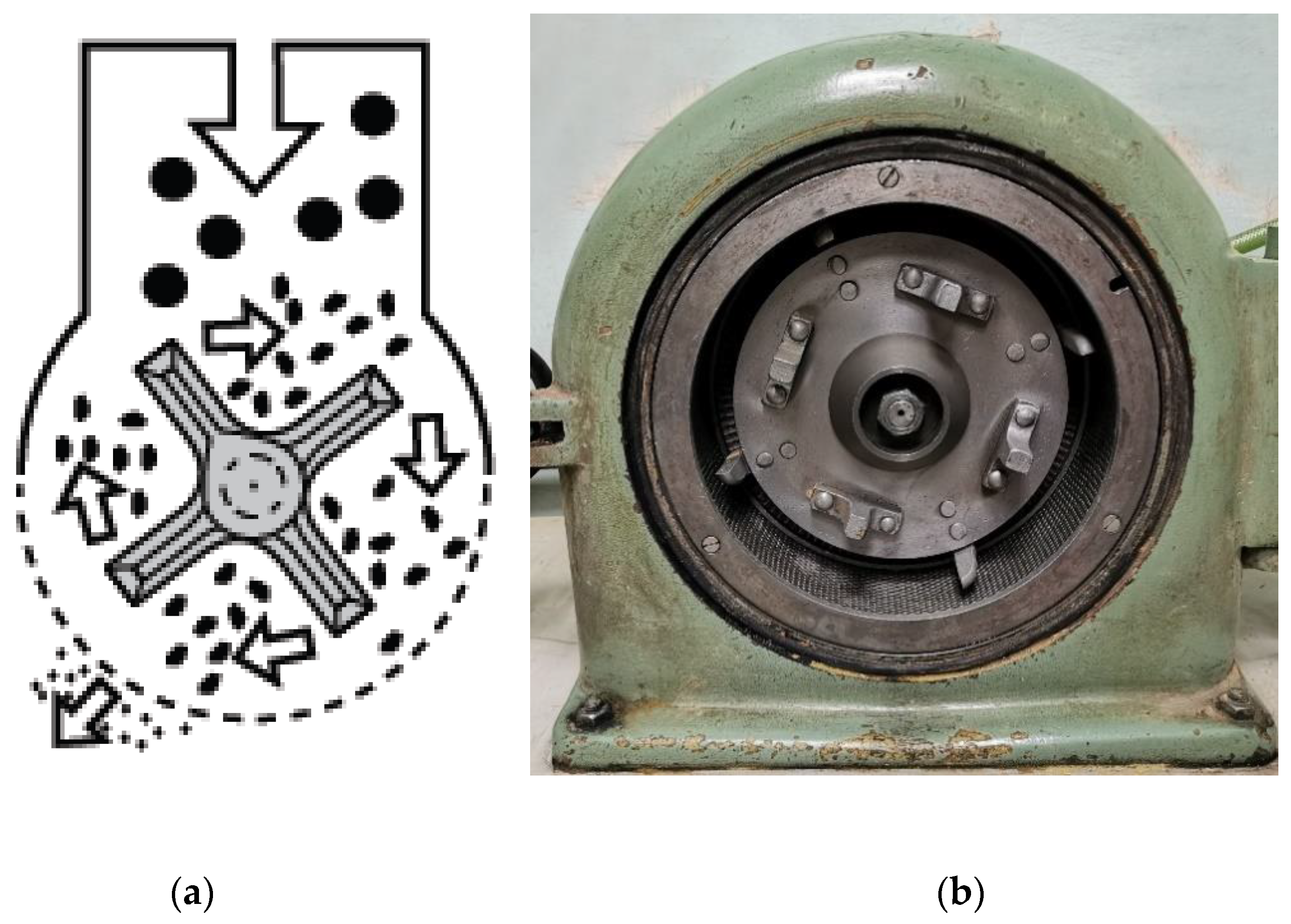

2.8. Hammer Mills, Knife Mills, Pin Mills, and Disintegrators

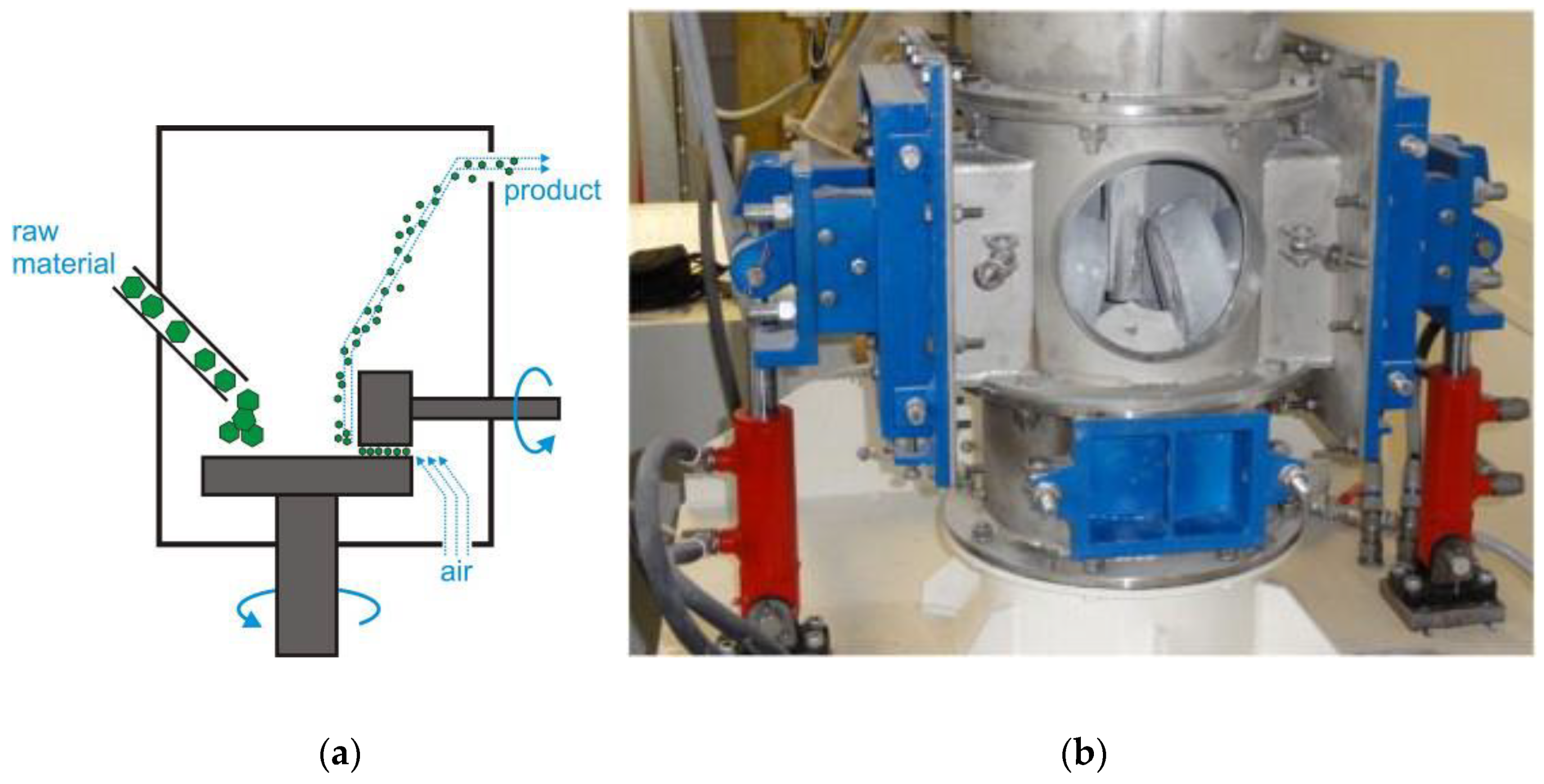

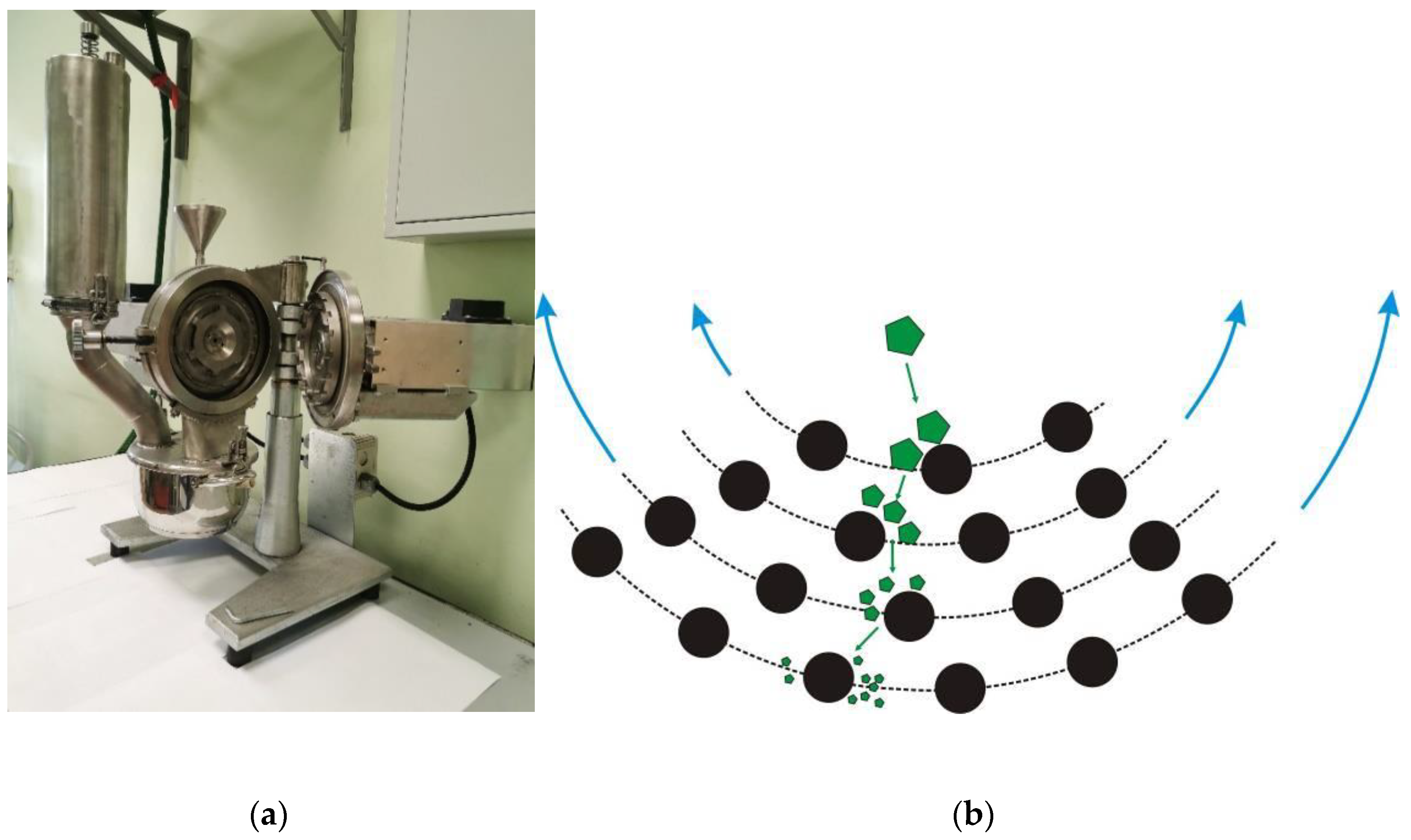

2.9. Jet Mills

2.10. Comparison of Machines of Different Types

3. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Efanov, M.V.; Kon’Shin, V.V.; Anan’Ina, I.V.; Sartakov, M.P. Acetylation of Peat by a Mechanochemical Method. Solid Fuel Chem. 2019, 53, 280–282. [Google Scholar] [CrossRef]

- Wu, K.; Xi, J. Mechanochemical-Assisted Extraction of Platycodin D from the Roots of Platycodon Grandiflorum with Solid Alkalis. Ind. Crop. Prod. 2020, 145, 112026. [Google Scholar] [CrossRef]

- Bychkov, A.L.; Podgorbunskikh, E.; Bychkova, E.S.; Lomovsky, O.I. Current Achievements in the Mechanically Pretreated Conversion of Plant Biomass. Biotechnol. Bioeng. 2019, 116, 1231–1244. [Google Scholar] [CrossRef]

- Zhang, Q.; Suntsova, L.; Chistyachenko, Y.S.; Evseenko, V.; Khvostov, M.V.; Polyakov, N.E.; Dushkin, A.V.; Su, W. Preparation, Physicochemical and Pharmacological Study of Curcumin Solid Dispersion with an Arabinogalactan Complexation Agent. Int. J. Biol. Macromol. 2019, 128, 158–166. [Google Scholar] [CrossRef]

- Bardakova, K.; Akopova, T.A.; Kurkov, A.V.; Goncharuk, G.P.; Butnaru, D.; Burdukovskii, V.; Antoshin, A.; Farion, I.A.; Zharikova, T.M.; Shekhter, A.B.; et al. From Aggregates to Porous Three-Dimensional Scaffolds through a Mechanochemical Approach to Design Photosensitive Chitosan Derivatives. Mar. Drugs 2019, 17, 48. [Google Scholar] [CrossRef]

- Xu, W.; Wen, M.; Yu, J.; Zhang, Q.; Polyakov, N.; Dushkin, A.V.; Su, W. Mechanochemical Preparation of Kaempferol Intermolecular Complexes for Enhancing the Solubility and Bioavailability. Drug Dev. Ind. Pharm. 2018, 44, 1924–1932. [Google Scholar] [CrossRef]

- Sapozhnikov, A.N.; Kopylova, A.V.; Krainova, Y.O.; Krainov, S.A. The Prospects of Using Spinach in Flour and Bakery Products. Proc. Voronezh State Univ. Eng. Technol. 2019, 80, 234–239. [Google Scholar] [CrossRef]

- Shen, F.; Xiong, X.; Fu, J.; Yang, J.; Qiu, M.; Qi, X.; Tsang, D.C.W. Recent Advances in Mechanochemical Production of Chemicals and Carbon Materials From Sustainable Biomass Resources. Renew. Sustain. Energy Rev. 2020, 130, 109944. [Google Scholar] [CrossRef]

- Mahmood, H.; Moniruzzaman, M.; Iqbal, T.; Khan, M.J. Recent Advances in the Pretreatment of Lignocellulosic Biomass for Biofuels and Value-Added Products. Curr. Opin. Green Sustain. Chem. 2019, 20, 18–24. [Google Scholar] [CrossRef]

- Matassa, S.; Esposito, G.; Pirozzi, F.; Papirio, S. Exploring the Biomethane Potential of Different Industrial Hemp (Cannabis sativa L.) Biomass Residues. Energies 2020, 13, 3361. [Google Scholar] [CrossRef]

- West, A. Solid State Chemistry and its Applications, 2nd ed.; Student Edition; John Wiley & Sons: Hoboken, NJ, USA, 2014; ISBN 978-1-119-94294-8. [Google Scholar]

- Semionescu, C.; Oprea, C.V. Mecanochimia Compuşilor Macromoleculari; Editura Academiei Republicii Socialiste România: Bucuresti, Romania, 1967. [Google Scholar]

- Simionescu, C.; Oprea, C.V.; Negulianu, C. Mechanochemical Syntheses. J. Polym. Sci. Polym. Symp. 2007, 64, 149–180. [Google Scholar] [CrossRef]

- Leibfarth, F.A.; Hawker, C.J. Mechanically Throwing a Reaction into Reverse. Science 2011, 333, 1582–1583. [Google Scholar] [CrossRef]

- Do, J.-L.; Friscic, T. Mechanochemistry: A Force of Synthesis. ACS Cent. Sci. 2017, 3, 13–19. [Google Scholar] [CrossRef]

- Skripkina, T.; Bychkov, A.; Tikhova, V.; Smolyakov, B.; Lomovsky, O. Mechanochemically Oxidized Brown Coal and the Effect of Its Application in Polluted Water. Environ. Technol. Innov. 2018, 11, 74–82. [Google Scholar] [CrossRef]

- Dabral, S.; Turberg, M.; Wanninger, A.; Bolm, C.; Hernández, J.G. Mechanochemical Lignin-Mediated Strecker Reaction. Molecules 2017, 22, 146. [Google Scholar] [CrossRef]

- Baláž, P.; Achimovičová, M.; Baláž, M.; Billik, P.; Cherkezova-Zheleva, Z.; Criado, J.M.; Delogu, F.; Dutková, E.; Gaffet, E.; Gotor, F.J.; et al. Hallmarks of Mechanochemistry: From Nanoparticles to Technology. Chem. Soc. Rev. 2013, 42, 7571–7637. [Google Scholar] [CrossRef]

- Jones, W.; Eddleston, M.D. Introductory Lecture: Mechanochemistry, a Versatile Synthesis Strategy for New Materials. Faraday Discuss. 2014, 170, 9–34. [Google Scholar] [CrossRef]

- Boldyreva, E. Mechanochemistry of Inorganic and Organic Systems: What Is Similar, What Is Different? Chem. Soc. Rev. 2013, 42, 7719–7738. [Google Scholar] [CrossRef]

- Tricker, A.W.; Samaras, G.; Hebisch, K.L.; Realff, M.J.; Sievers, C. Hot Spot Generation, Reactivity, and Decay in Mechanochemical Reactors. Chem. Eng. J. 2020, 382, 122954. [Google Scholar] [CrossRef]

- Cagnetta, G.; Robertson, J.; Huang, J.; Zhang, K.; Yu, G. Mechanochemical Destruction of Halogenated Organic Pollutants: A Critical Review. J. Hazard. Mater. 2016, 313, 85–102. [Google Scholar] [CrossRef]

- Ballantyne, G.; Powell, M. Benchmarking Comminution Energy Consumption for the Processing of Copper and Gold Ores. Miner. Eng. 2014, 65, 109–114. [Google Scholar] [CrossRef]

- Kwiatkowski, J.R.; McAloon, A.J.; Taylor, F.; Johnston, D.B. Modeling the Process and Costs of Fuel Ethanol Production by the Corn Dry-Grind Process. Ind. Crop. Prod. 2006, 23, 288–296. [Google Scholar] [CrossRef]

- Michalchuk, A.A.L.; Tumanov, I.A.; Boldyreva, E.V. Ball Size or Ball Mass–What Matters in Organic Mechanochemical Synthesis? CrystEngComm 2019, 21, 2174–2179. [Google Scholar] [CrossRef]

- Weißbach, U.; Dabral, S.; Konnert, L.; Bolm, C.; Hernández, J.G. Selective Enzymatic Esterification of Lignin Model Compounds in the Ball Mill. Beilstein J. Org. Chem. 2017, 13, 1788–1795. [Google Scholar] [CrossRef] [PubMed]

- Spence, K.L.; Venditti, R.A.; Rojas, O.J.; Habibi, Y.; Pawlak, J.J. A Comparative Study of Energy Consumption and Physical Properties of Microfibrillated Cellulose Produced by Different Processing Methods. Cellulose 2011, 18, 1097–1111. [Google Scholar] [CrossRef]

- Repellin, V.; Govin, A.; Rolland, M.; Guyonnet, R. Energy Requirement for Fine Grinding of Torrefied Wood. Biomass Bioenergy 2010, 34, 923–930. [Google Scholar] [CrossRef]

- Gu, Y.M.; Kim, S.; Sung, D.; Sang, B.-I.; Lee, J.H. Feasibility of Continuous Pretreatment of Corn Stover: A Comparison of Three Commercially Available Continuous Pulverizing Devices. Energies 2019, 12, 1422. [Google Scholar] [CrossRef]

- Broek, D. Elementary Engineering Fracture Mechanics; Springer Science and Business Media LLC: New York, NY, USA, 1982. [Google Scholar]

- Zhao, M.; Balachandran, B. Dynamics and Stability of Milling Process. Int. J. Solids Struct. 2001, 38, 2233–2248. [Google Scholar] [CrossRef]

- Nied, R. Chapter 5 Rotor Impact Mills. Handbook of Powder Technology 2007, 229–249. [Google Scholar] [CrossRef]

- Karbyshev, M.; Kozhukhov, V.; Alashkevich, Y. A Grinding of Fibrous Materials in Installation with Internal Movement of Grinding Bodies. Khimija Rastit. Syr’ja 2012, 3, 213–217. [Google Scholar]

- Smirnov, K.; Alashkevich, Y.; Kovalev, V. Determination of the Angle of Intersection of the Cutting Edges of the Circular Knives of the Grinding Set. Khimija Rastit. Syr’ja 2012, 1, 199–203. [Google Scholar]

- Qin, Y.; Qiu, X.; Zhu, J.Y. Understanding Longitudinal Wood Fiber Ultra-structure for Producing Cellulose Nanofibrils Using Disk Milling with Diluted Acid Prehydrolysis. Sci. Rep. 2016, 6, 35602. [Google Scholar] [CrossRef] [PubMed]

- Francis, D.W.; Towers, M.T.; Browne, T.C. Energy Cost Reduction in the Pulp and Paper Industry–An Energy Benchmarking Perspective; Pulp and Paper Technical Association Canada: Montreal, QC, Canada, 2002; p. 30. [Google Scholar]

- Rajkhowa, R.; Wang, L.; Kanwar, J.; Wang, X. Fabrication of Ultrafine Powder from Eri Silk Through Attritor and Jet Milling. Powder Technol. 2009, 191, 155–163. [Google Scholar] [CrossRef]

- Urakaev, F.K. Mechanochemical Synthesis of Nanoparticles by a Dilution Method: Determination of the Particle Mixing Coefficient in a Ball Mill. Mendeleev Commun. 2012, 22, 215–217. [Google Scholar] [CrossRef]

- Zhang, Q.; Polyakov, N.E.; Chistyachenko, Y.S.; Khvostov, M.V.; Frolova, T.S.; Tolstikova, T.G.; Dushkin, A.V.; Su, W. Preparation of Curcumin Self-Micelle Solid Dispersion With Enhanced Bioavailability and Cytotoxic Activity by Mechanochemistry. Drug Deliv. 2018, 25, 198–209. [Google Scholar] [CrossRef] [PubMed]

- Dushkin, A. V Potential of Mechanochemical Technology in Organic Synthesis and Synthesis of New Materials. Chem. Sustain. Dev. 2004, 12, 251–273. [Google Scholar]

- Mishra, B. A Review of Computer Simulation of Tumbling Mills by the Discrete Element Method: Part I—Contact Mechanics. Int. J. Miner. Process. 2003, 71, 73–93. [Google Scholar] [CrossRef]

- Neikov, O.D. Mechanical Crushing and Grinding. In Handbook of Non-Ferrous Metal Powders; Elsevier: Amsterdam, The Netherlands, 2009; pp. 47–62. [Google Scholar]

- Sun, Y.; Dong, M.; Mao, Y.; Fan, D. Analysis on grinding media motion in ball mill by discrete element method. Manuf. Eng. Qual. Prod. Syst. 2009, 1, 227–231. [Google Scholar]

- Tangsathitkulchai, C. Effects of Slurry Concentration and Powder Filling on the Net Mill Power of a Laboratory Ball Mill. Powder Technol. 2003, 137, 131–138. [Google Scholar] [CrossRef]

- Zeng, Y.; Forssberg, E. Monitoring Grinding Parameters by Signal Measurements for an Industrial Ball Mill. Int. J. Miner. Process. 1993, 40, 1–16. [Google Scholar] [CrossRef]

- Rosenkranz, S.; Breitung-Faes, S.; Kwade, A. Experimental Investigations and Modelling of the Ball Motion in Planetary Ball Mills. Powder Technol. 2011, 212, 224–230. [Google Scholar] [CrossRef]

- Fokina, E.L.; Budim, N.I.; Kochnev, V.G.; Chernik, G.G. Planetary Mills of Periodic and Continuous Action. J. Mater. Sci. 2004, 39, 5217–5221. [Google Scholar] [CrossRef]

- Skripkina, T.; Bychkov, A.L.; Tikhova, V.D.; Lomovsky, O. Mechanochemical Solid-Phase Reactions of Humic Acids from Brown Coal with Sodium Percarbonate. Solid Fuel Chem. 2018, 52, 356–360. [Google Scholar] [CrossRef]

- Cagnetta, G.; Huang, J.; Wang, B.; Deng, S.; Yu, G. A Comprehensive Kinetic Model for Mechanochemical Destruction of Persistent Organic Pollutants. Chem. Eng. J. 2016, 291, 30–38. [Google Scholar] [CrossRef]

- Streletskii, A.N.; Sivak, M.V.; Dolgoborodov, A.Y. Nature of High Reactivity of Metal/Solid Oxidizer Nanocomposites Prepared by Mechanoactivation: A Review. J. Mater. Sci. 2017, 52, 11810–11825. [Google Scholar] [CrossRef]

- Dabral, S.; Wotruba, H.; Hernández, J.G.; Bolm, C. Mechanochemical Oxidation and Cleavage of Lignin β-O-4 Model Compounds and Lignin. ACS Sustain. Chem. Eng. 2018, 6, 3242–3254. [Google Scholar] [CrossRef]

- Akopova, T.A.; Yablokov, M.Y.; Zelenetskii, A.N. Amphiphilic Systems Based on Polysaccharides Produced by Solid-Phase Synthesis—A Review. Fibre Chem. 2012, 44, 217–220. [Google Scholar] [CrossRef]

- Shalabayev, Z.; Baláž, M.; Daneu, N.; Dutkova, E.; Bujňáková, Z.; Kaňuchová, M.; Dankova, Z.; Balážová, Ľ.; Urakaev, F.K.; Tkáčiková, Ľ.; et al. Sulfur-Mediated Mechanochemical Synthesis of Spherical and Needle-Like Copper Sulfide Nanocrystals with Antibacterial Activity. ACS Sustain. Chem. Eng. 2019, 7, 12897–12909. [Google Scholar] [CrossRef]

- Urakaev, F.K.; Bulavchenko, A.I.; Uralbekov, B.M.; Massalimov, I.A.; Tatykayev, B.B.; Bolatov, A.K.; Dzharlykasimova, D.N.; Burkitbayev, M.M. Mechanochemical Synthesis of Colloidal Sulfur Particles in the Na2S2O3–H2(C4H4O4)–Na2SO3 System. Colloid J. 2016, 78, 210–219. [Google Scholar] [CrossRef]

- Urazova, T.S.; Bychkov, A.L.; Lomovskii, O.I. Mechanochemical Modification of the Structure of Brown Coal Humic Acids for Preparing a Sorbent for Heavy Metals. Russ. J. Appl. Chem. 2014, 87, 651–655. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical Alloying and Milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Innovative Research and Production Company. Technique and Technology of Disintegration, MP-4 Planetary Mill. Available online: http://ttd.spb.ru/catalog/mp-4 (accessed on 16 October 2020).

- Gock, E.; Kurrer, K.-E. Eccentric Vibratory Mills—Theory and Practice. Powder Technol. 1999, 105, 302–310. [Google Scholar] [CrossRef]

- Bilke, M.; Losch, P.; Vozniuk, O.; Bodach, A.; Schüth, F. Methane to Chloromethane by Mechanochemical Activation: A Selective Radical Pathway. J. Am. Chem. Soc. 2019, 141, 11212–11218. [Google Scholar] [CrossRef]

- NPO Novic. Novosibirsk Testing Center. Available online: http://www.novic-mill.ru/about.php (accessed on 16 October 2020).

- Ballantyne, G.R.; Powell, M.S.; Tiang, M. Proportion of Energy Attributable to Comminution. In Proceedings of the 11th Australasian Institute of Mining and Metallurgy Mill Operator’s Conference, Hobart, Tasmania, 29–31 October 2012; pp. 25–30. [Google Scholar]

- Trofimova, E.G.; Podgorbunskikh, E.M.; Skripkina, T.S.; Bychkov, A.L.; Lomovsky, O.I. Scaling of the Mechano-Chemical Process of Production of Silicon Chelates From Plant Raw Materials. Bulg. Chem. Commun. 2018, 50, 44–48. [Google Scholar]

- Cleary, P.W.; Owen, P. Using DEM to Understand Scale-up for a HICOM® Mill. Miner. Eng. 2016, 92, 86–109. [Google Scholar] [CrossRef]

- Cagnetta, G.; Intini, G.; Liberti, L.; Notarnicola, M.; Spinosa, L.; Stellacci, P. Mechanochemical and Biological Degradation of PCB in Contaminated Marine Sediments. J. Residuals Sci. Technol. 2009, 6, 139–144. [Google Scholar]

- Okada, G.; Hagiwara, T. Vertical Type Roller Mill. Patent US4606506A, 19 August 1986. [Google Scholar]

- Böhm, A.-P.D.-I.D.M.A.; Meissner, P.; Plochberger, T. An Energy Based Comparison of Vertical Roller Mills and Tumbling Mills. Int. J. Miner. Process. 2015, 136, 37–41. [Google Scholar] [CrossRef]

- Avvakumov, E.; Senna, M.; Kosova, N. Soft Mechanochemical Synthesis, A Basis for New Chemical Technologies; Springer: New York, NY, USA, 2001; ISBN 0306476460. [Google Scholar]

- Shibata, Y.; Fujii, M.; Sugamura, Y.; Yoshikawa, R.; Fujimoto, S.; Nakanishi, S.; Motosugi, Y.; Koizumi, N.; Yamada, M.; Ouchi, K.; et al. The Preparation of a Solid Dispersion Powder of Indomethacin with Crospovidone Using a Twin-Screw Extruder or Kneader. Int. J. Pharm. 2009, 365, 53–60. [Google Scholar] [CrossRef]

- Riaz, M.N.; Rokey, G.J. Extrusion Problems Solved: Food, Pet Food and Feed; Woodhead Publishing Limited: Cambridge, UK, 2011; ISBN 9780857095206. [Google Scholar]

- Guy, R. Extrusion Cooking Technologies and Applications; Woodhead Publishing: Cambridge, UK, 2001. [Google Scholar]

- Gomollón-Bel, F. Ten Chemical Innovations That Will Change Our World: IUPAC Identifies Emerging Technologies in Chemistry with Potential to Make Our Planet More Sustainable. Chem. Int. 2019, 41, 12–17. [Google Scholar] [CrossRef]

- Giles, H.F., Jr.; Wagner, J.R., Jr.; Mount, E.M., III. Extrusion: The Definitive Processing Guide and Handbook; William Andrew: New York, NY, USA, 2013. [Google Scholar]

- Bitra, V.S.; Womac, A.R.; Chevanan, N.; Miu, P.I.; Igathinathane, C.; Sokhansanj, S.; Smith, D.R. Direct Mechanical Energy Measures of Hammer Mill Comminution of Switchgrass, Wheat Straw, and Corn Stover and Analysis of Their Particle Size Distributions. Powder Technol. 2009, 193, 32–45. [Google Scholar] [CrossRef]

- Moiceanu, G.; Paraschiv, G.; Voicu, G.; Dinca, M.; Negoita, O.; Chitoiu, M.; Tudor, P. Energy Consumption at Size Reduction of Lignocellulose Biomass for Bioenergy. Sustainability 2019, 11, 2477. [Google Scholar] [CrossRef]

- Dey, S.K.; Dey, S.; Das, A. Comminution Features in an Impact Hammer Mill. Powder Technol. 2013, 235, 914–920. [Google Scholar] [CrossRef]

- Ghorbani, Z.; Masoumi, A.; Hemmat, A. Specific Energy Consumption for Reducing the Size of Alfalfa Chops Using a Hammer Mill. Biosyst. Eng. 2010, 105, 34–40. [Google Scholar] [CrossRef]

- Reece, F.N.; Lott, B.D.; Deaton, J.W. The Effects of Hammer Mill Screen Size on Ground Corn Particle Size, Pellet Durability, and Broiler Performance. Poult. Sci. 1986, 65, 1257–1261. [Google Scholar] [CrossRef]

- Peetsalu, P.; Goljandin, D.; Kulu, P.; Mikli, V. Micropowders Producted By Disintegrator Milling. Powder Metall. 2003, 3, 99–110. [Google Scholar]

- Kallakas, H.; Poltimäe, T.; Süld, T.-M.; Kers, J.; Krumme, A. The Influence of Accelerated Weathering on the Mechanical and Physical Properties of Wood-Plastic Composites. Proc. Est. Acad. Sci. 2015, 64, 94. [Google Scholar] [CrossRef]

- Kratky, L.; Jirout, T. Biomass Size Reduction Machines for Enhancing Biogas Production. Chem. Eng. Technol. 2011, 34, 391–399. [Google Scholar] [CrossRef]

- Kobayashi, N.; Guilin, P.; Kobayashi, J.; Hatano, S.; Itaya, Y.; Mori, S. A New Pulverized Biomass Utilization Technology. Powder Technol. 2008, 180, 272–283. [Google Scholar] [CrossRef]

- Cadoche, L.; López, G.D. Assessment of Size Reduction as a Preliminary Step in the Production of Ethanol from Lignocellulosic Wastes. Biol. Wastes 1989, 30, 153–157. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Grinding Performance and Physical Properties of Wheat and Barley Straws, Corn Stover and Switchgrass. Biomass Bioenergy 2004, 27, 339–352. [Google Scholar] [CrossRef]

- Podgorbunskikh, E.M.; Bychkov, A.L.; Bulina, N.V.; Lomovskii, O.I. Disordering of the Crystal Structure of Cellulose under Mechanical Activation. J. Struct. Chem. 2018, 59, 201–208. [Google Scholar] [CrossRef]

- Podgorbunskikh, E.; Bychkov, A.; Ryabchikova, E.; Lomovsky, O. The Effect of Thermomechanical Pretreatment on the Structure and Properties of Lignin-Rich Plant Biomass. Molecules 2020, 25, 995. [Google Scholar] [CrossRef] [PubMed]

- Podgorbunskikh, E.M.; Ryabchikova, E.; Bychkov, A.L.; Lomovskii, O.I. Changes in the Structure of Cell Wall Polymers in Thermomechanical Treatment of Highly Lignified Plant Feedstock. Dokl. Phys. Chem. 2017, 473, 49–51. [Google Scholar] [CrossRef]

- Hideno, A.; Inoue, H.; Tsukahara, K.; Fujimoto, S.; Minowa, T.; Inoue, S.; Endo, T.; Sawayama, S. Wet Disk Milling Pretreatment Without Sulfuric Acid for Enzymatic Hydrolysis of Rice Straw. Bioresour. Technol. 2009, 100, 2706–2711. [Google Scholar] [CrossRef] [PubMed]

- Licari, A.; Monlau, F.; Solhy, A.; Buche, P.; Barakat, A. Comparison of Various Milling Modes Combined to the Enzymatic Hydrolysis of Lignocellulosic Biomass for Bioenergy Production: Glucose Yield and Energy Efficiency. Energy 2016, 102, 335–342. [Google Scholar] [CrossRef]

- Moro, M.K.; Teixeira, R.S.S.; Da Silva, A.S.; Fujimoto, M.D.; Melo, P.A.; Secchi, A.; Bon, E.P.S. Continuous Pretreatment of Sugarcane Biomass Using a Twin-Screw Extruder. Ind. Crop. Prod. 2017, 97, 509–517. [Google Scholar] [CrossRef]

- Zhang, Z.; O’Hara, I.; Doherty, W. Pretreatment of Sugarcane Bagasse by Acid-Catalysed Process in Aqueous Ionic Liquid Solutions. Bioresour. Technol. 2012, 120, 149–156. [Google Scholar] [CrossRef]

- Da Silva, A.S.; Teixeira, R.S.S.; Endo, T.; Bon, E.P.S.; Lee, S.-H. Continuous Pretreatment of Sugarcane Bagasse at High Loading in an Ionic Liquid Using a Twin-Screw Extruder. Green Chem. 2013, 15, 1991–2001. [Google Scholar] [CrossRef]

- Zheng, J.; Rehmann, L. Extrusion Pretreatment of Lignocellulosic Biomass: A Review. Int. J. Mol. Sci. 2014, 15, 18967–18984. [Google Scholar] [CrossRef]

- Rincón, E.; Balu, A.M.; Luque, R.; Serrano, L. Mechanochemical Extraction of Antioxidant Phenolic Compounds From Mediterranean and Medicinal Laurus Nobilis: A Comparative Study With Other Traditional and Green Novel Techniques. Ind. Crop. Prod. 2019, 141, 111805. [Google Scholar] [CrossRef]

| Material | Equipment | Effect | Specific Energy Requirement, kWht−1 | Ref |

|---|---|---|---|---|

| Purpose: Size Reduction and/or Amorphization | ||||

| Hardwood, 6% wet | Disc Mills | Size reduction from 19.05 to 1.6 mm−1 | 200–400 | [80] |

| Hardwood, 11% wet | Vibration mill | from 22 to 0.15 mm | 800 | [81] |

| Hardwood, 4–7% wet | Hammer mill | from 22.4 to 1.6 mm | 130 | [82] |

| from 22.4 to 2.5 mm | 120 | |||

| from 22.4 3.2 mm | 115 | |||

| from 22.4 to 6.35 mm | 95 | |||

| Knife mill | from 22.4 to 1.6 mm | 130 | ||

| from 22.4 to 2.5 mm | 80 | |||

| from 22.4 3.2 mm | 50 | |||

| from 22.4 to 6.35 mm | 25 | |||

| from 22.4 to 9.5 mm | 15 | |||

| from 22.4 to 12.7 mm | 8 | |||

| Corn stover, 6.2% wet | Hammer mill | from 7.15 to 0.8 mm | 22.1 | [83] |

| from 7.15 to 1.6 mm | 14.8 | |||

| Corn stover, 12% wet | from 7.15 to 0.8 mm | 34.3 | ||

| from 7.15 to 1.6 mm | 19.9 | |||

| Corn stover, 4–7% wet | Hammer mill | from 22.4 to 1.6 mm | 14.0 | [82] |

| from 22.4 to 3.2 mm | 6 | |||

| Knife mill | from 22.4 to 3.2 mm | 20.0 | ||

| from 22.4 to 6.3 mm | 15.0 | |||

| from 22.4 to 9.5 mm | 3.2 | |||

| from 19.05 to 3.0 mm | 12.0 | [80] | ||

| Wheat straw, 4–7% wet | Hammer mill | from 19.05 to 1.6 mm | 42 | [82] |

| from 19.05 to 2.5 mm | 29 | |||

| from 19.05 to 3.2 mm | 21 | |||

| Knife mill | from 22.4 to 1.6 mm | 7.5 | ||

| from 22.4 to 2.5 mm | 6.4 | |||

| from 22.4 to 6.3 mm | 5.5 | |||

| Wheat straw, 5.4% wet | Planetary ball mill, 2 min | Size reduction from 0.24 mm to 0.19 mm, Crystallinity index, % (CrI, %) from 82 ± 2 to 78 ± 2 | About 150 * | [84] |

| Planetary ball mill, 10 min | Size reduction from 0.24 mm to 0.015 mm, CrI, % reduction from 82 ± 2 to 39 ± 5 | About 750 * | ||

| Centrifugal Roller Mill, activation mode 600 rpm | Size reduction from 0.24 mm to 0.17 mm, CrI, % reduction from 82 ± 2 to 64 ± 2 | 23 | ||

| Centrifugal Roller Mill, activation mode 1200 rpm | Size reduction from 0.24 mm to 0.038 mm, CrI, % reduction from 82 ± 2 to 65 ± 5 % | 87 | ||

| Purpose: Thermomechanical Pretreatment for Subsequent Heterogeneous Hydrolysis | ||||

| Lignin-rich plant biomass (reed biomass) | Attritor, 10 ℃, 20 min, 600 rpm | The yield of enzymatic hydrolysis increasing from 13.1 ± 0.3 to 20.8 ± 0.4, Size reduction from 1 mm to 0.070 ± 0.004 mm CrI, % reduction from 69 ± 6 to 42 ± 5 | - | [85,86] |

| Attritor, 180 ℃, 20 min, 600 rpm | The yield of enzymatic hydrolysis increasing from 13.1 ± 0.3 to 14.8 ± 0.4, Size reduction from 1 mm to 0.075 ± 0.005 mm CrI, % reduction from 69 ± 6 to 59 ± 5. Molten lignin leaves the cell wall structure, forming pores, and is accumulated on the surface of the cell walls, preventing enzymatic conversion | - | ||

| Rice straw | Wet disc milling, 1 round | Sugar yields, % increasing from 22.5 ± 1.3 to 39.3 ± 0.1 CrI, % reduction from 51.9 to 46.9 | 83.3 | [87] |

| Wet disc milling, 3 round | Sugar yields, % increasing from 22.5 ± 1.3 to 43.1 ± 5.2 CrI, % reduction from 51.9 to 50.8 | 250 | ||

| Wet disc milling, 5 round | Sugar yields, % increasing from 22.5 ± 1.3 to 51.3 ± 5.3 CrI, % reduction from 51.9 to 46.0 | 639 | ||

| Wet disc milling, 10 round | Sugar yields, % increasing from 22.5 ± 1.3 to 67.5 ± 5.1 CrI, % reduction from 51.9 to 48.6 | 1500 | ||

| Vibration mill, 1700 rpm, 5 min | Sugar yields, % increasing from 22.5 ± 1.3 to 67.5 ± 5.1 CrI, % reduction from 51.9 to 46.7 | 2500 | ||

| Vibration mill, 1700 rpm, 15 min | Sugar yields, % increasing from 22.5 ± 1.3 to 67.5 ± 5.1 CrI, % reduction from 51.9 to 35.0 | 7500 | ||

| Vibration mill, 1700 rpm, 30 min | Sugar yields, % increasing from 22.5 ± 1.3 to 67.5 ± 5.1 CrI, % reduction from 51.9 to 25.2 | 15,000 | ||

| Vibration mill, 1700 rpm, 60 min | Sugar yields, % increasing from 22.5 ± 1.3 to 67.5 ± 5.1 CrI, % reduction from 51.9 to 13.3 | 30,000 | ||

| Bagasse sugarcane | Vibration mill, 1 h | glucose yields of 69.8 %, CrI, % reduction from 64.5 to 28.9 | 11,720 | [88] |

| Vibration mill, 3 h | glucose yields of 95.2%, CrI, % reduction from 64.5 to 2.5 | 25,340 | ||

| Ball mill, 24 h | glucose yields of 55.2%, CrI, % reduction from 64.5 to 53.3 | 19,540 | ||

| Ball mill, 72 h | glucose yields of 75.2%, CrI, % reduction from 64.5 to 38.4 | 53,650 | ||

| Centrifugal mill screen size of 0.12 0.5 mm | glucose yields of 38.2%, CrI, % reduction from 64.5 to 60.8 | 1050 | ||

| Centrifugal mill, screen size of 0.12 mm | glucose yields of 53.9%, CrI, % reduction from 64.5 to 48.5 | 4980 | ||

| Jet mill, 4000 rpm, 15 min | glucose yields of 60.0%, CrI, % reduction from 64.5 to 58.1 | 66,780 | ||

| Jet mill, 5000 rpm, 15 min | glucose yields of 61%, CrI, % reduction from 64.5 to 53.5 | 66,850 | ||

| Twin-screw extruder | straw hydrolysis yield of 68.2%, CrI reduction from 57.3 ± 1.25% to 54.0 ± 0.23% | 5600–8500 | [89] | |

| Twin-screw extruder, alkali-combine pretreatment combined with ionic liquids | Glucose yields of 90% | - | [90,91,92] | |

| Mechanochemical Assisted Extraction (MAE) of Different Bioactive Compounds | ||||

| Bay leaves (Laurus nobilis L.) | Planetary ball mill, 400 rpm, 10 min | The total extraction time—an reduction of more than 10-fold | - | [93] |

| Platycodon grandiflorum | Planetary ball mill | Extraction time and temperature reduction, the yield of platycodin D increasing (7.16 ± 0.14 compared to 4.18 ± 0.11 mg/g), water instead of organic solvent | - | [2] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lomovskiy, I.; Bychkov, A.; Lomovsky, O.; Skripkina, T. Mechanochemical and Size Reduction Machines for Biorefining. Molecules 2020, 25, 5345. https://doi.org/10.3390/molecules25225345

Lomovskiy I, Bychkov A, Lomovsky O, Skripkina T. Mechanochemical and Size Reduction Machines for Biorefining. Molecules. 2020; 25(22):5345. https://doi.org/10.3390/molecules25225345

Chicago/Turabian StyleLomovskiy, Igor, Aleksey Bychkov, Oleg Lomovsky, and Tatiana Skripkina. 2020. "Mechanochemical and Size Reduction Machines for Biorefining" Molecules 25, no. 22: 5345. https://doi.org/10.3390/molecules25225345

APA StyleLomovskiy, I., Bychkov, A., Lomovsky, O., & Skripkina, T. (2020). Mechanochemical and Size Reduction Machines for Biorefining. Molecules, 25(22), 5345. https://doi.org/10.3390/molecules25225345