Occurrence of Acrylamide in Italian Baked Products and Dietary Exposure Assessment

Abstract

1. Introduction

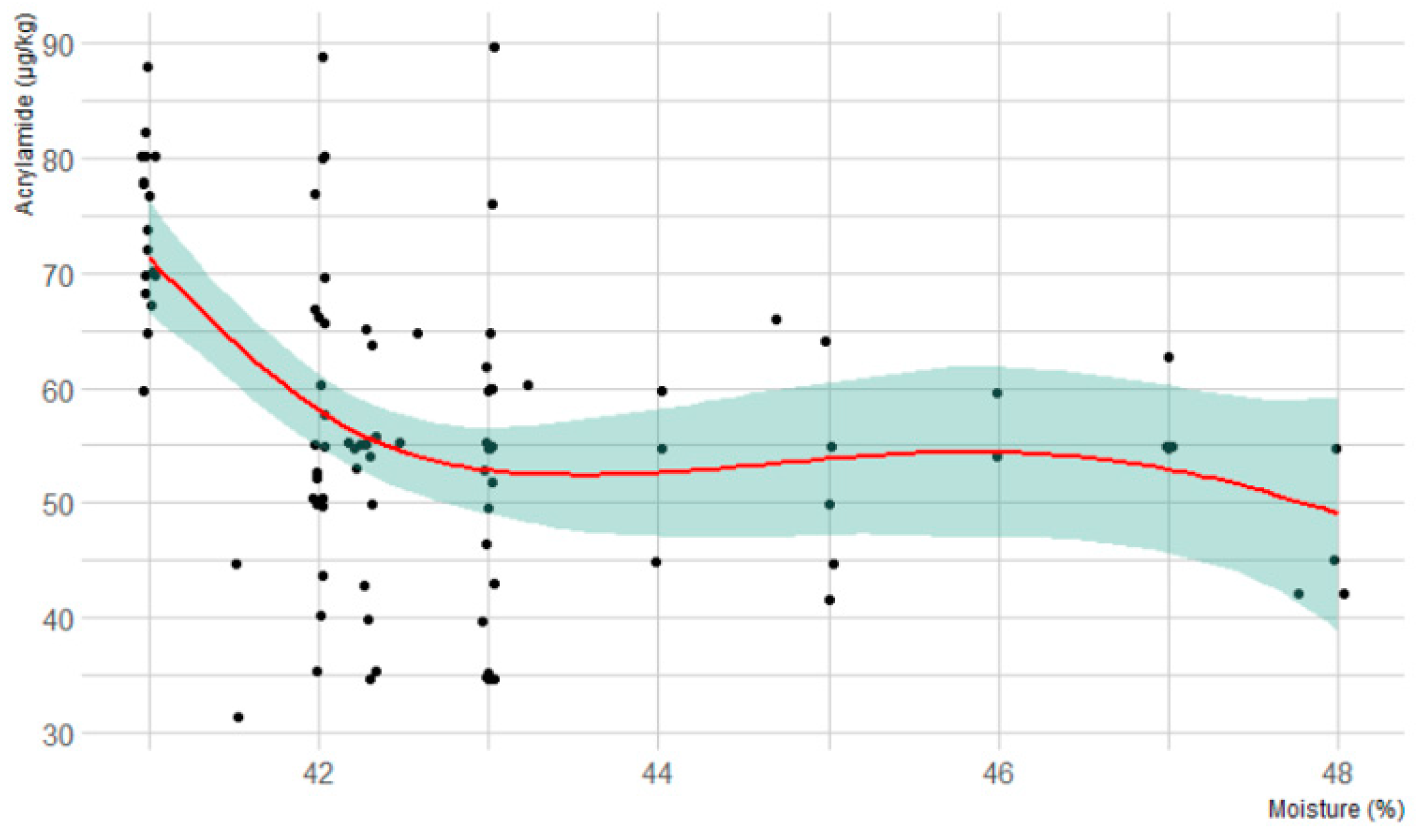

2. Results and Discussion

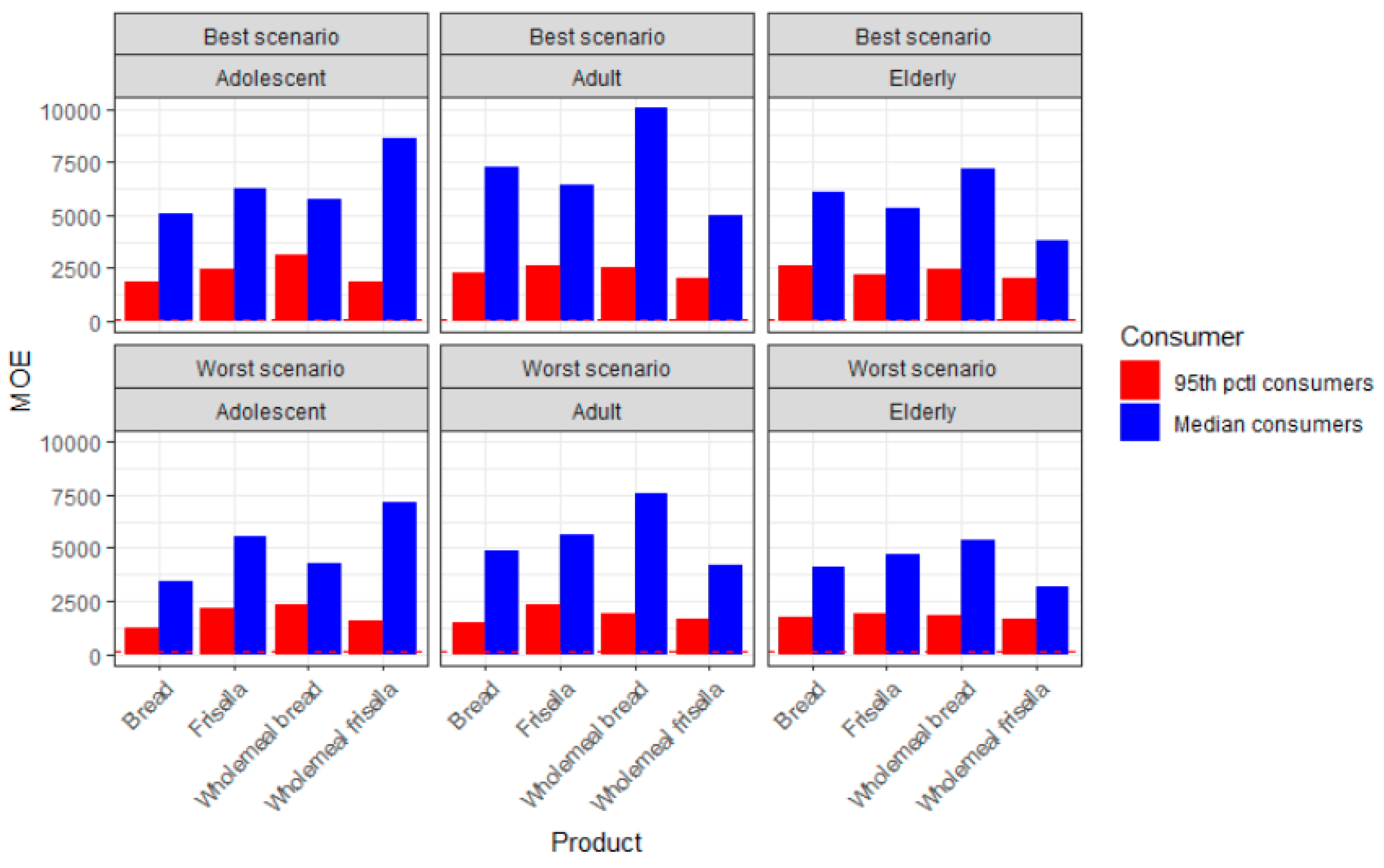

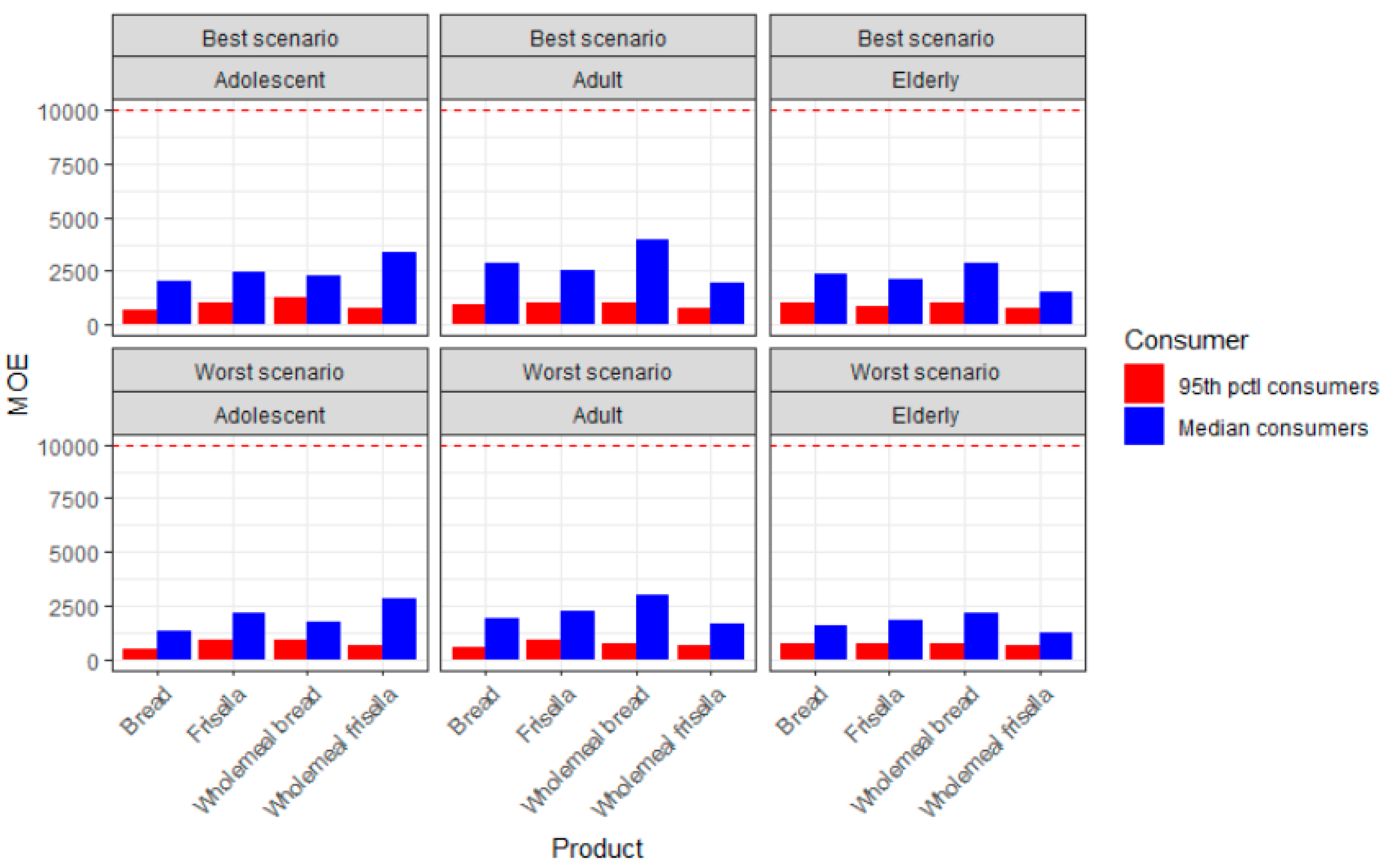

Exposure Assessment

3. Materials and Methods

3.1. Sampling

3.2. Reagents and Equipment

3.3. Preparation of the Analytical Standards

3.4. Extraction

3.5. Bromination

3.6. GC-MS Detection

3.7. Method Performance

3.8. Data Analysis

3.9. Exposure Assessment and MOE Evaluation

- DI = daily intake of acrylamide (ng/kg bw/day).

- C = median and 95th percentile concentration of acrylamide detected in the samples (ng/g).

- Q = individual food daily consumption of population within different age groups and for median and 95th pctl consumers (g/day).

- BW = individual body weight (kg bw).

- MOE = margin of exposure (dimensionless).

- BMDL10 = benchmark dose lower confidence limit for a benchmark response of 10% (mg/kg bw/day).

- DI = daily intake of acrylamide previously calculated (mg/kg bw/day).

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tareke, E.; Rydberg, P.; Karlsson, P.; Eriksson, S.; Törnqvist, M. Analysis of Acrylamide, a Carcinogen Formed in Heated Foodstuffs. J. Agric. Food Chem. 2002, 50, 4998–5006. [Google Scholar] [CrossRef] [PubMed]

- Kumar, J.; Das, S.; Teoh, S.L. Dietary Acrylamide and the Risks of Developing Cancer: Facts to Ponder. Front. Nutr. 2018, 5, 14. [Google Scholar] [CrossRef] [PubMed]

- Zyzak, D.V.; Sanders, R.A.; Stojanovic, M.; Tallmadge, D.H.; Eberhart, B.L.; Ewald, D.K.; Gruber, D.C.; Morsch, T.R.; Strothers, M.A.; Rizzi, G.P.; et al. Acrylamide formation mechanism in heated foods. J. Agric. Food Chem. 2003, 51, 4782–4787. [Google Scholar] [CrossRef] [PubMed]

- Mencin, M.; Abramovič, H.; Vidrih, R.; Schreiner, M. Acrylamide levels in food products on the Slovenian market. Food Control 2020, 114, 107267. [Google Scholar] [CrossRef]

- Yang, Y.; Achaerandio, I.; Pujolà, M. Influence of the frying process and potato cultivar on acrylamide formation in French fries. Food Control 2016, 62, 216–223. [Google Scholar] [CrossRef]

- EFSA. Scientific Opinion on acrylamide in food. EFSA J. 2015, 13, 1–321. [Google Scholar]

- Wenzl, T.; Lachenmeier, D.W.; Gökmen, V. Analysis of heat-induced contaminants (acrylamide, chloropropanols and furan) in carbohydrate-rich food. Anal. Bioanal. Chem. 2007, 389, 119–137. [Google Scholar] [CrossRef] [PubMed]

- Esposito, F.; Nardone, A.; Fasano, E.; Triassi, M.; Cirillo, T. Determination of acrylamide levels in potato crisps and other snacks and exposure risk assessment through a Margin of Exposure approach. Food Chem. Toxicol. 2017, 108, 249–256. [Google Scholar] [CrossRef] [PubMed]

- Mesìas, M.; Morales, F.J. Acrylamide in commercial potato crisps from Spanish market: Trends from 2004 to 2014 and assessment of the dietary exposure. Food Chem. Toxicol. 2015, 81, 104–110. [Google Scholar] [CrossRef] [PubMed]

- Başaran, B.; Aydın, F.; Kaban, G. The determination of acrylamide content in brewed coffee samples marketed in Turkey. Food Addit. Contam. Part A Chem. Anal. Control. Expo. Risk Assess. 2020, 37, 280–287. [Google Scholar] [CrossRef]

- Lyon, F. IARC Monographs on the evaluation of carcinogenic risks of chemicals to humans. Some Ind. Chem. 1994, 60, 389–433. [Google Scholar]

- Pelucchi, C.; Bosetti, C.; Galeone, C.; La Vecchia, C. Dietary acrylamide and cancer risk: An updated meta-analysis. Int. J. Cancer 2015, 136, 2912–2922. [Google Scholar] [CrossRef] [PubMed]

- Esposito, F.; Fasano, E.; De Vivo, A.; Velotto, S.; Sarghini, F.; Cirillo, T. Processing effects on acrylamide content in roasted coffee production. Food Chem. 2020, 126550. [Google Scholar] [CrossRef] [PubMed]

- Sanny, M.; Jinap, S.; Bakker, E.J.; Van Boekel, M.A.J.S.; Luning, P.A. Is lowering reducing sugars concentration in French fries an effective measure to reduce acrylamide concentration in food service establishments? Food Chem. 2012, 135, 2012–2020. [Google Scholar] [CrossRef]

- Baskar, G.; Aiswarya, R. Overview on mitigation of acrylamide in starchy fried and baked foods. J. Sci. Food Agric. 2018, 98, 4385–4394. [Google Scholar] [CrossRef]

- Schouten, M.A.; Tappi, S.; Romani, S. Acrylamide in coffee: Formation and possible mitigation strategies—A review. Crit. Rev. Food Sci. Nutr. 2020, 1–15. [Google Scholar] [CrossRef]

- Qi, Y.; Zhang, H.; Wu, G.; Zhang, H.; Gu, L.; Wang, L.; Qian, H.; Qi, X. Mitigation effects of proanthocyanidins with different structures on acrylamide formation in chemical and fried potato crisp models. Food Chem. 2018, 250, 98–104. [Google Scholar] [CrossRef]

- Al-asmar, A.; Naviglio, D.; Giosafatto, C.V.L.; Mariniello, L. Hydrocolloid-Based Coatings are Effective at Reducing Acrylamide and Oil Content of French Fries. Coatings 2018, 8, 147. [Google Scholar] [CrossRef]

- Andačić, I.M.; Tot, A.; Ivešić, M.; Krivohlavek, A.; Thirumdas, R.; Barba, F.J.; Sabolović, M.B.; Kljusurić, J.G.; Brnčić, S.R. Exposure of the Croatian adult population to acrylamide through bread and bakery products. Food Chem. 2020, 322. [Google Scholar] [CrossRef]

- Mottram, D.S.; Low, M.Y.; Elmore, J.S. The Maillard reaction and its role in the formation of acrylamide and other potentially hazardous compounds in foods. Acrylamide Other Hazard. Compd. Heat Treat. Foods 2006, 3–22. [Google Scholar] [CrossRef]

- Komoike, Y.; Nomura-Komoike, K.; Matsuoka, M. Intake of acrylamide at the dietary relevant concentration causes splenic toxicity in adult zebrafish. Environ. Res. 2020, 189, 109977. [Google Scholar] [CrossRef]

- EC Commission Regulation (EU) 2017/2158: Establishing mitigation measures and benchmark levels for the reduction of the presence of acrylamide in food. Off. J. Eur. Union 2017, 2017, 24–44.

- Sansano, M.; Heredia, A.; Peinado, I.; Andrés, A. Dietary acrylamide: What happens during digestion? Food Chem. 2017, 237, 58–64. [Google Scholar] [CrossRef] [PubMed]

- Matthäus, B.; Haase, N.U.; Vosmann, K. Factors affecting the concentration of acrylamide during deep-fat frying of potatoes. Eur. J. Lipid Sci. Technol. 2004, 106, 793–801. [Google Scholar] [CrossRef]

- Bråthen, E.; Knutsen, S.H. Effect of temperature and time on the formation of acrylamide in starch-based and cereal model systems, flat breads and bread. Food Chem. 2005, 92, 693–700. [Google Scholar] [CrossRef]

- Mesías, M.; Morales, F.J.; Delgado-Andrade, C. Acrylamide in biscuits commercialised in Spain: A view of the Spanish market from 2007 to 2019. Food Funct. 2019, 10, 6624–6632. [Google Scholar] [CrossRef]

- Roszko, M.Ł.; Szczepańska, M.; Szymczyk, K.; Rzepkowska, M. Dietary risk evaluation of acrylamide intake with bread in Poland, determined by two comparable cleanup procedures. Food Addit. Contam. Part B Surveill. 2020, 13, 1–9. [Google Scholar] [CrossRef]

- Mojska, H.; Gielecińska, I.; Szponar, L.; Ołtarzewski, M. Estimation of the dietary acrylamide exposure of the Polish population. Food Chem. Toxicol. 2010, 48, 2090–2096. [Google Scholar] [CrossRef]

- Fernandes, J.O.; Soares, C. Application of matrix solid-phase dispersion in the determination of acrylamide in potato chips. J. Chromatogr. A 2007, 1175, 1–6. [Google Scholar] [CrossRef]

- Foodstuffs–Determination of Acrylamide in Food and Coffee by Gas Chromatography-Mass Spectrometry (GC-MS); CEN UNI CEN/TS 17083:2017; Swedish Institute for Standards: Stockholm, Sweden, June 2017.

- R: A Language and Environment for Statistical Computing; R Version 3.6.2; R Core Team: Murray Hill, NJ, USA, 2019.

- Rudis, B. Hrbrthemes: Additional Themes, Theme Components and Utilities for “ggplot2”. Hrbrthemes Documentation. Available online: https://rdrr.io/cran/hrbrthemes (accessed on 26 March 2020).

- Wickham, H.; Bryan, J. readxl: Read Excel Files. Available online: https://cran.r-project.org/web/packages/readxl/readxl.pdf (accessed on 13 March 2019).

- Wickham, H. ggplot2: Elegant Graphics for Data Analysis; Springer: New York, NY, USA, 2016; ISBN 978-3-319-24277-4. [Google Scholar]

- Leclercq, C.; Arcella, D.; Piccinelli, R.; Sette, S.; Le Donne, C.; Turrini, A. The Italian National Food Consumption Survey INRAN-SCAI 2005-06: Main results in terms of food consumption. Public Health Nutr. 2009, 12, 2504–2532. [Google Scholar] [CrossRef]

Sample Availability: Samples of the standards of acrylamide are available from the authors. |

| Category | Product | Acrylamide (µg/kg) | Benchmark Levels According to EU 2017/2158 (µg/kg) | |||

|---|---|---|---|---|---|---|

| Mean ± SD | Median | 95th Percentile | Min–Max | |||

| Bread (n = 102) | Bread | 57 ± 18 a | 55 | 82 | 31–90 | 50 |

| Bread rolls | 52 ± 8 a | 55 | 64 | 42–67 | 50 | |

| Wholemeal bread | 61 ± 10 a | 60 | 80 | 44–88 | 50 | |

| Friselle | 358 ± 36 b,c | 353 | 403 | 306–454 | 350 | |

| Wholemeal Friselle | 384 ± 37 b | 375 | 450 | 328–450 | 350 | |

| Sweets (n = 98) | Butter cookies | 310 ± 36 d,e | 330 | 346 | 249–350 | 350 |

| “Babà” cake | 292 ± 62 e | 278 | 391 | 207–400 | 300 | |

| Ice cream wafers | 337 ± 5 c,d | 336 | 344 | 330–346 | 350 | |

| “Frolla” cake | 362 ± 11 b,c | 356 | 380 | 350–380 | 300 | |

| Croissants | 313 ± 55 d,e | 330 | 382 | 204–396 | 300 | |

| Product | Moisture (%) | Sugars (%) | Salt (%) |

|---|---|---|---|

| Bread (n = 22) | 41–43 | 1.0–1.2 | 1.6–1.8 |

| Bread rolls (n = 22) | 42–48 | 1.0–1.2 | 1.5–1.7 |

| Wholemeal bread (n = 22) | 41–45 | 1.0–1.2 | 1.6–1.8 |

| Friselle (n = 18) | 39–42 | 1.1–1.3 | 1.7–1.9 |

| Wholemeal Friselle (n = 18) | 35–40 | 1.2–1.4 | 1.5–1.8 |

| Product | Moisture (%) | Sugars (%) | Salt (%) |

|---|---|---|---|

| Butter cookies (n = 20) | 14–18 | 36–39 | 0.5–0.8 |

| “Babà” cake (n = 20) | 43–46 | 5–6 | 0.0–0.1 |

| Ice cream wafers (n = 20) | 34–35 | 22–24 | 0.0–0.1 |

| “Frolla” cake (n = 18) | 30–32 | 3–5 | 0.0–0.1 |

| Croissants (n = 20) | 36–38 | 10–12 | 1.0–1.1 |

| Product | Daily Exposure (ng/kg bw/day) (BS–WS) | ||

|---|---|---|---|

| Adolescents | Adults | Elderly | |

| Bread | 84–125 | 59–88 | 71–105 |

| Wholemeal bread | 75–100 | 43–57 | 60–80 |

| Friselle | 68–78 | 67–77 | 81–92 |

| Wholemeal Friselle | 50–70 | 86–103 | 114–137 |

| Product | Daily Exposure (ng/kg bw/day) (BS–WS) | ||

|---|---|---|---|

| Adolescents | Adults | Elderly | |

| Bread | 236–351 | 189–281 | 165–246 |

| Wholemeal bread | 137–182 | 171–229 | 174–232 |

| Friselle | 173–197 | 161–184 | 197–225 |

| Wholemeal Friselle | 230–276 | 214–257 | 213–255 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Esposito, F.; Velotto, S.; Rea, T.; Stasi, T.; Cirillo, T. Occurrence of Acrylamide in Italian Baked Products and Dietary Exposure Assessment. Molecules 2020, 25, 4156. https://doi.org/10.3390/molecules25184156

Esposito F, Velotto S, Rea T, Stasi T, Cirillo T. Occurrence of Acrylamide in Italian Baked Products and Dietary Exposure Assessment. Molecules. 2020; 25(18):4156. https://doi.org/10.3390/molecules25184156

Chicago/Turabian StyleEsposito, Francesco, Salvatore Velotto, Teresa Rea, Tommaso Stasi, and Teresa Cirillo. 2020. "Occurrence of Acrylamide in Italian Baked Products and Dietary Exposure Assessment" Molecules 25, no. 18: 4156. https://doi.org/10.3390/molecules25184156

APA StyleEsposito, F., Velotto, S., Rea, T., Stasi, T., & Cirillo, T. (2020). Occurrence of Acrylamide in Italian Baked Products and Dietary Exposure Assessment. Molecules, 25(18), 4156. https://doi.org/10.3390/molecules25184156