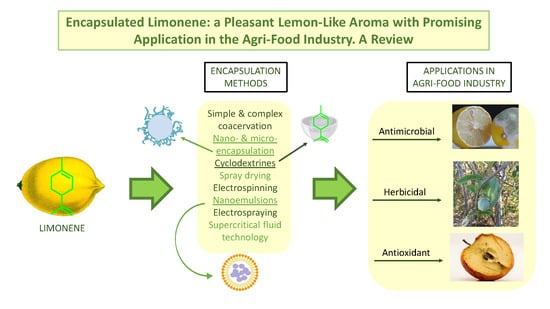

Encapsulated Limonene: A Pleasant Lemon-Like Aroma with Promising Application in the Agri-Food Industry. A Review

Abstract

1. Introduction

2. Results and Discussion

2.1. Applications of Limonene in the Agri-Food Industry

2.1.1. Prevention and Inhibition of Pest Attack in Crops and Food-Spoilage Microorganisms

2.1.2. Herbicidal Activity

2.1.3. Antioxidant Activity

2.2. Limonene Encapsulation Techniques

2.2.1. Coacervation

2.2.2. Nano(Micro)encapsulation Using Different Wall Materials

2.2.3. Cyclodextrins

2.2.4. Spray Drying

2.2.5. Electrospinning

2.2.6. Nanoemulsions

2.2.7. (Nano)-Emulsion Stabilizers

2.2.8. Alternative Encapsulating Methods

3. Conclusions

Funding

Conflicts of Interest

References

- Limonene. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/Limonene (accessed on 24 April 2020).

- Noma, Y.; Asakawa, Y. Biotransformation of monoterpenoids. In Comprehensive Natural Products II: Chemistry and Biology, 1st ed.; Townsend, C.A., Ebizuka, Y., Eds.; Elsevier: Kidlington, UK, 2010; Volume 1, pp. 669–801. [Google Scholar]

- González-Más, M.C.; Rambla, J.L.; Lopéz-Gresa, M.P.; Blázquez, M.A.; Granell, A. Volatile compounds in Citrus essential oils: A comprehensive review. Front. Plant Sci. 2019, 10, 12. [Google Scholar]

- Mahato, N.; Sharma, K.; Koteswararao, R.; Sinha, M.; Baral, E.; Cho, M.H. Citrus essential oils: Extraction, authentication and application in food preservation. Crit. Rev. Food Sci. Nutr. 2019, 59, 611–625. [Google Scholar] [CrossRef] [PubMed]

- Ravichandran, C.; Badgujar, P.C.; Gundev, P.; Upadhyay, A. Review of toxicological assessment of d-limonene, a food and cosmetic additive. Food Chem. Toxicol. 2018, 12, 668–680. [Google Scholar] [CrossRef] [PubMed]

- Vieira, A.J.; Beserra, F.P.; Souza, M.C.; Totti, B.M.; Rozza, A.L. Limonene: Aroma of innovation in health and disease. Chem. Biol. Interact. 2018, 283, 97–106. [Google Scholar] [CrossRef]

- Klimek-Szczykutowicz, M.; Szopa, A.; Ekiert, H. Citrus limon (Lemon) phenomenon-A review of the chemistry, pharmacological properties, applications in the modern pharmaceutical, food, and cosmetics industries, and biotechnological studies. Plants 2020, 9, 119. [Google Scholar] [CrossRef]

- d-Limonene. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/D-limonene (accessed on 24 April 2020).

- Duetz, W.A.; Bouwmeester, H.; van Beilen, J.B.; Witholt, B. Biotransformation of limonene by bacteria, fungi, yeasts, and plants. Appl. Microbiol. Biotechnol. 2003, 61, 269–277. [Google Scholar] [CrossRef]

- Kim, Y.W.; Kim, M.J.; Chung, B.Y.; Bang, D.Y.; Lim, S.K.; Choi, S.M.; Lim, D.S.; Cho, M.C.; Yoon, K.; Kim, H.S.; et al. Safety evaluation and risk assessment of d-limonene. J. Toxicol. Environ. Health B 2013, 16, 17–38. [Google Scholar] [CrossRef]

- Pires, T.C.M.; Ribeiro, M.G.T.C.; Machado, A.A.S.C. Extraction of R-(+)-limonene from orange peels: Assessment and optimization of the greenness of traditional extraction processes. Qum. Nova 2018, 41, 355–365. [Google Scholar]

- Lopresto, C.G.; Petrillo, F.; Csazza, A.A.; Aliakbarian, B.; Perego, P.; Calabrò, V. A non-conventional method to extract d-limonene from waste lemon peels and comparison with traditional Soxhlet extraction. Sep. Purif. Technol. 2014, 137, 13–20. [Google Scholar] [CrossRef]

- Lopresto, C.G.; Meluso, A.; Di Sanzo, G.; Chakraborty, S.; Calabrò, V. Process-intensified waste valorization and environmentally friendly d-limonene extraction. Euro-Mediterr. J. Environ. Integr. 2019, 4, 31. [Google Scholar] [CrossRef]

- Ozturk, B.; Winterburn, J.; Gonzalez-Miquel, M. Orange peel waste valorisation through limonene extraction using bio-based solvents. Biochem. Eng. J. 2019, 151, 107298. [Google Scholar] [CrossRef]

- Tan, Q.; Day, D.F. Bioconversion of limonene to α-terpineol by immobilized Penicillium digitatum. Appl. Microbiol. Biotechnol. 1998, 49, 96–101. [Google Scholar] [CrossRef]

- Erasto, P.; Viljoen, A.M. Limonene-A review: Biosynthetic, ecological and pharmacological relevance. Nat. Prod. Commun. 2008, 3, 1193–1202. [Google Scholar] [CrossRef]

- Malko, M.W.; Wróblewska, A. The importance of R-(+)-limonene as the raw material for organic syntheses and for organic industry. Chemik 2016, 70, 193–202. [Google Scholar]

- Aissou, M.; Chemat-Djenni, Z.; Yara-Varón, E.; Fabiano-Tixier, A.S.; Chemat, F. Limonene as an agro-chemical building block for the synthesis and extraction of bioactive compounds. CR Chim. 2017, 20, 346–358. [Google Scholar] [CrossRef]

- Global Limonene Market (2018–2023): Analysis by Source and Application. Available online: https://www.businesswire.com/news/home/20181012005144/en/Global-Limonene-Market-2018-2023-Analysis-Source-Application (accessed on 24 April 2020).

- Miller, J.A.; Thompson, P.A.; Hakim, I.A.; Sherry Chow, H.H.; Thompson, C.A. d-limonene: A bioactive food component from citrus and evidence for a potential role in breast cancer prevention and treatment. Oncol. Rev. 2011, 5, 31–42. [Google Scholar] [CrossRef]

- Lima, N.G.P.B.; De Sousa, D.P.; Pimenta, F.C.F.; Alves, M.F.; De Souza, F.S.; Macedo, R.O.; Cardoso, R.B.; de Morais, L.C.S.L.; Diniz, M.d.F.F.M.; de Almeida, R.N. Anxiolytic-like activity and GC-MS analysis of (R)-(+)-limonene fragrance, a natural compound in foods and plants. Pharmacol. Biochem. Behav. 2013, 103, 450–454. [Google Scholar] [CrossRef]

- Soulimani, R.; Bouayed, J.; Joshi, R.K. Limonene: Natural monoterpene volatile compounds of potential therapeutic interest. Am. J. Essent. Oil 2019, 7, 1–10. [Google Scholar]

- Karr, L.L.; Coats, J.R. Insecticidal properties of d-limonene. J. Pesticide Sci. 1988, 13, 287–290. [Google Scholar] [CrossRef]

- Mei, H.J.; Ran, S.; Gao, S.Z.; Juan, H.Q.; Sheng, Y.F.; Ming, F. Research progress in antimicrobial activity of limonene. Food Fermen. Ind. 2007, 43, 274–278. [Google Scholar]

- Chaimovitsh, D.; Shachter, A.; Abu-Abied, M.; Rubin, B.; Sadot, E.; Dudai, N. Herbicidal activity of monoterpenes is associated with disruption of microtubule functionality and membrane integrity. Weed Sci. 2017, 65, 19–30. [Google Scholar] [CrossRef]

- Walia, S.; Saha, S.; Tripathi, V.; Sharma, K.K. Phytochemical biopesticides: Some recent developments. Phytochem. Rev. 2017, 16, 989–1007. [Google Scholar] [CrossRef]

- Kostyukovski, M.; Shaaya, E. Phytochemicals as natural fumigants and contact insecticides against stored-product insects. In Natural Products in Plant Pest Management, 1st ed.; Dubey, N.K., Ed.; CABI: Oxfordshire, UK, 2011; pp. 175–191. [Google Scholar]

- European Food Safety Authority. Conclusion on the peer review of the pesticide risk assessment of the active substance orange oil. EFSA J. 2013, 2, 3090. [Google Scholar]

- Castilhos, R.H.; Grützmacher, A.D.; Coats, J.R. Acute toxicity and sublethal effects of terpenoids and essential oils on the predator Chrysoperla externa (Neuroptera: Chrysopidae). Neotrop. Entomol. 2018, 47, 311–317. [Google Scholar] [CrossRef] [PubMed]

- Elbana, T.; Gaber, H.M.; Kishk, F.M. Soil chemical pollution and sustainable agriculture. In The Soils of Egypt; El-Ramady, H., Alshaal, T., Bakr, N., Elbana, T., Mohamed, E., Belal, A., Eds.; Springer: Cham, Switzerland, 2019; pp. 187–200. [Google Scholar]

- Mahmood, I.; Imadi, S.R.; Shazadi, K.; Gul, A.; Hakeem, K.R. Effects of pesticides on environment. In Plant, Soil and Microbes; Hakeem, K.R., Abdullah, S.N., Akhtar, M.S., Eds.; Springer: Kidlington, UK, 2016; Volume 1, pp. 253–270. [Google Scholar]

- Silva, V.; Mol, H.G.J.; Zomer, P.; Tienstra, M.; Ritsema, C.J.; Geissen, V. Pesticide residues in European agricultural soils—A hidden reality unfolded. Sci. Total Environ. 2019, 653, 1532–1545. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.; Kabir, E.; Jahan, S.A. Exposure to pesticides and the associated human health effects. Sci. Total Environ. 2017, 575, 525–535. [Google Scholar] [CrossRef]

- Pavela, R. Acute, synergistic and antagonistic effects of some aromatic compounds on the Spodoptera littoralis Boisd. (Lep., Noctuidae) larvae. Ind. Crop. Prod. 2014, 60, 247–258. [Google Scholar] [CrossRef]

- Turek, C.; Stintzing, F.C. Stability of essential oils: A review. Compr. Rev. Food Sci. Food Saf. 2013, 12, 40–53. [Google Scholar] [CrossRef]

- Malika, O.; Kamel, M.; Zahredine, D. Assessing the impact of storage temperature on the stability and biocidal activity of essential oils formulated. Case Tribolium castaneum (herbst). (insect, tenebrionidae). J. Environ. Eng. Sci. 2016, 5, 406–415. [Google Scholar]

- Pavela, R.; Sedlák, P. Post-application temperature as a factor influencing the insecticidal activity of essential oil from Thymus vulgaris. Ind. Crop. Prod. 2018, 113, 46–49. [Google Scholar] [CrossRef]

- Savary, S.; Willocquet, L.; Pethybridge, S.J.; Esker, P.; McRoberts, N.; Nelson, A. The global burden of pathogens and pests on major food crops. Nat. Ecol. 2019, 3, 430–439. [Google Scholar] [CrossRef] [PubMed]

- Pisoschi, A.M.; Pop, A.; Georgescu, C.; Turcuş, V.; Olah, N.K.; Mathe, E. An overview of natural antimicrobials role in food. Eur. J. Med. Chem. 2018, 143, 922–935. [Google Scholar] [CrossRef] [PubMed]

- Gyawali, R.; Ibrahim, S.A. Natural products as antimicrobial agents. Food Control 2014, 46, 412–429. [Google Scholar] [CrossRef]

- Ünal, M.U.; Uçan, F.; Şener, A.; Dinçer, S. Research on antifungal and inhibitory effects of dl-limonene on some yeasts. Turk. J. Agric. For. 2012, 36, 576–582. [Google Scholar]

- De Araújo, A.C.J.; Freitas, P.R.; Barbosa, C.R.d.S.; Muniz, D.F.; Rocha, J.E.; da Silva, A.C.A.; Oliveira-Tintino, C.D.d.M.; Ribeiro-Filho, J.; da Silva, L.E.; Confortin, C.; et al. GC-MS-FID characterization and antibacterial activity of the Mikania cordifolia essential oil and limonene against MDR strains. Food Chem. Toxicol. 2020, 136, 111023. [Google Scholar] [CrossRef]

- Costa, M.D.S.; Rocha, J.E.; Campina, F.F.; Silva, A.R.P.; Da Cruz, R.P.; Pereira, R.L.S.; Quintans-Júnior, L.J.; De Menezes, I.R.A.; Araújo, A.A.D.S.; de Freitas, T.S.; et al. Comparative analysis of the antibacterial and drug-modulatory effect of d-limonene alone and complexed with β-cyclodextrin. Eur. J. Pharm. Sci. 2019, 128, 158–161. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.; Sun, Z.; Chen, W. Antimicrobial susceptibility and antibacterial mechanism of limonene against Listeria monocytogenes. Molecules 2020, 25, 33. [Google Scholar] [CrossRef]

- Van Vuuren, S.F.; Viljoen, A.M. Antimicrobial activity of limonene enantiomers and 1,8-cineole alone and in combination. Flavour Frag. J. 2007, 22, 540–544. [Google Scholar] [CrossRef]

- Hąc-Wydro, K.; Flasiński, M.; Romańczuk, K. Essential oils as food eco-preservatives: Model system studies on the effect of temperature on limonene antibacterial activity. Food Chem. 2017, 235, 127–135. [Google Scholar] [CrossRef]

- Espina, L.; Gelaw, T.K.; de Lamo-Castellvi, S.; Pagán, R.; García-Gonzalo, D. Mechanism of bacterial inactivation by (+)-limonene and its potential use in food preservation combined processes. PLoS ONE 2013, 8, e56769. [Google Scholar] [CrossRef]

- Wang, C.; Chen, Y.; Hou, C. Antioxidant and antibacterial activity of seven predominant terpenoids. Int. J. Food Prop. 2019, 22, 230–238. [Google Scholar] [CrossRef]

- Cai, R.; Hu, M.; Zhang, Y.; Niu, C.; Yue, T.; Yuan, Y.; Wang, Z. Antifungal activity and mechanism of citral, limonene and eugenol against Zygosaccharomyces rouxii. LWT-Food Sci. Technol. 2019, 106, 50–56. [Google Scholar] [CrossRef]

- Badawy, M.E.I.; Marei, G.I.K.; Rabera, E.I.; Taktak, N.E.M. Antimicrobial and antioxidant activities of hydrocarbon and oxygenated monoterpenes against some foodborne pathogens through in vitro and in silico studies. Pestic. Biochem. Phys. 2019, 158, 185–200. [Google Scholar] [CrossRef]

- Jing, L.; Lei, Z.; Li, L.; Xie, R.; Xi, W.; Guan, Y.; Sumner, L.W.; Zhou, Z. Antifungal activity of Citrus essential oils. J. Agric. Food Chem. 2014, 62, 3011–3033. [Google Scholar] [CrossRef]

- Li, A.; Cai, M.; Liu, Y.; Sun, P.; Luo, S. Antibacterial activity and mechanisms of essential oil from Citrus medica L. var. sarcodactylis. Molecules 2019, 24, 1577. [Google Scholar] [CrossRef]

- Bevilacqua, A.; Corbo, M.R.; Sinigaglia, M. In vitro evaluation of the antimicrobial activity of eugenol, limonene, and Citrus extract against bacteria and yeasts, representative of the spoiling microflora of fruit juices. J. Food Protect. 2010, 73, 888–894. [Google Scholar] [CrossRef] [PubMed]

- Omran, S.M.; Moodi, M.A.; Amiri, S.M.B.N.; Mosavi, S.J.; Saeed, S.A.M.G.M.; Shiade, S.M.J.; Kheradi, E.; Salehi, M. The effects of limonene and orange peel extracts on some spoilage fungi. IJMCM 2011, 1, 82–86. [Google Scholar]

- Singh, P.; Shukla, R.; Prakash, B.; Kumar, A.; Singh, S.; Mishra, P.K.; Dubey, N.K. Chemical profile, antifungal, antiaflatoxigenic and antioxidant activity of Citrus maxima Burm. and Citrus sinensis (L.) Osbeck essential oils and their cyclic monoterpene, dl-limonene. Food Chem. Toxicol. 2010, 48, 1734–1740. [Google Scholar] [CrossRef] [PubMed]

- Oerke, E.C. Crop losses to pests. J. Agric. Sci. 2006, 144, 31–43. [Google Scholar] [CrossRef]

- Pacanoski, Z. Introductory chapter: Actual issues (moments). In Herbicide Resistance Weed and Crops, 1st ed.; Pacanoski, Z., Ed.; InTech: Rijeka, Croatia, 2017; pp. 1–6. [Google Scholar]

- Vats, S. Herbicides: History, classification and genetic manipulation of plants for herbicide resistance. In Sustainable Agriculture Reviews; Lichtfouse, E., Ed.; Springer: Cham, Switzerland, 2015; pp. 153–192. [Google Scholar]

- Herbicides-Global Market Outlook (2017–2023). Available online: https://www.prnewswire.com/news-releases/herbicides---global-market-outlook-2017-2023-300514763.html (accessed on 26 April 2020).

- Green, J.M. Current state of herbicides in herbicide-resistant crops. Pest. Manag. Sci. 2014, 70, 1351–1357. [Google Scholar] [CrossRef]

- Weeds Resistant to the Herbicide Glyphosate. Available online: http://www.weedscience.org/Home.aspx (accessed on 26 April 2020).

- Westwood, J.H.; Charudattan, R.; Duke, S.O.; Fennimore, S.A.; Marrone, P.; Slaugher, D.C.; Swanton, C.; Zollinger, R. Weed management in 2050: Perspectives on the future of weed science. Weed Sci. 2018, 66, 275–285. [Google Scholar] [CrossRef]

- Gressel, J. Global advances in weed management. J. Agric. Sci. 2011, 149, 47–53. [Google Scholar] [CrossRef]

- Singh, H.P.; Batish, D.R.; Kaur, S.; Ramezani, H.; Kohli, R.K. Comparative phytotoxicity of four monoterpenes against Cassia occidentalis. Ann. Appl. Biol. 2002, 141, 111–116. [Google Scholar] [CrossRef]

- Gouda, N.A.A.; Saad, M.M.G.; Abdelgaleil, S.A.M. Pre and post herbicidal activity of monoterpenes against barnyard grass (Echinochloa crus-galli). Weed Sci. 2016, 64, 191–200. [Google Scholar] [CrossRef]

- Macías, F.A.; Mejías, F.J.R.; Molinillo, J.M.G. Recent advances in allelopathy for weed control: From knowledge to applications. Pest. Manag. Sci. 2019, 75, 2413–2436. [Google Scholar] [CrossRef] [PubMed]

- De Martino, L.; Mancini, E.; de Almeida, L.F.R.; De Feo, V. The antigerminative activity of twenty-seven monoterpenes. Molecules 2010, 15, 6630–6637. [Google Scholar] [CrossRef]

- Fagodia, S.K.; Singh, H.P.; Batish, D.R.; Kohli, R.K. Phytotoxicity and cytotoxicity of Citrus aurantiifolia essential oil and its major constituents: Limonene and citral. Ind. Crop. Prod. 2017, 108, 708–715. [Google Scholar] [CrossRef]

- Azirak, S.; Karaman, S. Allelopathic effect of some essential oils and components on germination of weed species. Acta Agric. Scand. B Sect. Soil Plant Sci. 2008, 58, 88–92. [Google Scholar] [CrossRef]

- Scrivanti, L.R.; Zunino, M.P.; Zygadlo, J.A. Tagetes minuta and Schinus areira essential oils as allelopathic agents. Biochem. Syst. Ecol. 2003, 31, 563–572. [Google Scholar] [CrossRef]

- Vokou, D.; Douvli, P.; Blionis, G.J.; Halley, J.M. Effects of monoterpenoids, acting alone or in pairs, on seed germination and subsequent seedling growth. J. Chem. Ecol. 2003, 29, 2281–2301. [Google Scholar] [CrossRef]

- Ibáñez, M.D.; Blázquez, M.A. Phytotoxic effects of commercial Eucalyptus citriodora, Lavandula angustifolia, and Pinus sylvestris essential oils on weeds, crops, and invasive species. Molecules 2019, 24, 2847. [Google Scholar] [CrossRef] [PubMed]

- Sekine, T.; Appiah, K.S.; Azizi, M.; Fujii, Y. Plant growth inhibitory activities and volatile active compounds of 53 spices and herbs. Plants 2020, 9, 264. [Google Scholar] [CrossRef] [PubMed]

- Vaid, S.; Batish, D.R.; Singh, H.P.; Kohli, R.K. Phytotoxicity of limonene against Amaranthus viridis L. Bioscan 2011, 6, 163–165. [Google Scholar]

- Choi, J.; Ko, Y.; Cho, N.; Hwang, K.; Koo, S. Herbicidal activity of d-limonene to Burcucumber (Sciyos angulatus L.) with potential as natural herbicide. Korean J. Weed Sci. 2012, 32, 263–272. [Google Scholar] [CrossRef][Green Version]

- Abrahim, D.; Braguini, W.L.; Kelmer-Bracht, A.M.; Ishii-Iwamoto, E. Effects of four monoterpenes on germination, primary root growth, and mitochondrial respiration of maize. J. Chem. Ecol. 2000, 26, 611–624. [Google Scholar] [CrossRef]

- Ibrahim, M.A.; Oksanen, E.J.; Holopainen, J.K. Effects of limonene on the growth and physiology of cabbage (Brassica oleracea L.) and carrot (Daucus carota L.) plants. J. Sci. Food Agric. 2004, 84, 1319–1326. [Google Scholar] [CrossRef]

- Zhao, J.; Yang, L.; Zhou, L.; Bai, Y.; Wang, B.; Hou, P.; Xu, Q.; Yang, W.; Zuo, Z. Inhibitory effects of eucalyptol and limonene on the photosynthetic abilities in Chlorella vulgaris (Chlorophyaceae). Phycologia 2016, 55, 696–702. [Google Scholar] [CrossRef]

- Ibrahim, M.; Kainulainen, P.; Aflatuni, A.; Tiilikkala, K.; Holopainen, J.K. Insecticidal, repellent, antimicrobial activity and phytotoxicity of essential oils: With special reference to limonene and its suitability for control of insect pests. Agric. Food Sci. Finl. 2001, 10, 243–259. [Google Scholar] [CrossRef]

- Marichali, A.; Hosni, K.; Dallali, S.; Ouerghemmi, S.; Bel Hadj Ltaief, H.; Benzarti, S.; Kerkeni, A.; Sebei, H. Allelopathic effects of Carum carvi L. essential oil on germination and seedling growth of wheat, maize, flax and canary glass. Allelopath. J. 2014, 34, 81–94. [Google Scholar]

- Limonene-Containing Herbicide Compositions, Herbicide Concentrate Formulations and Methods for Making and Using Same. Available online: https://patentimages.storage.googleapis.com/02/3e/41/3e349865fdb53c/US8273687.pdf (accessed on 26 April 2020).

- Limonene Pesticides. Available online: https://patentimages.storage.googleapis.com/33/ba/2d/d20492d37d6c20/US5951992.pdf (accessed on 26 April 2020).

- Brewer, M.S. Natural antioxidants: Sources, compounds, mechanisms of action, and potential applications. Compr. Rev. Food Sci. Food Saf. 2011, 10, 221–247. [Google Scholar] [CrossRef]

- Wang, D.; Dong, Y.; Wang, Q.; Wang, X.; Fan, W. Limonene, the compound in essential oil of nutmeg displayed antioxidant effect in sunflower oil during the deep-frying of Chinese Maye. Food Sci. Nutr. 2019, 8, 511–520. [Google Scholar] [CrossRef] [PubMed]

- Bacanli, M.; Başaran, A.A.; Başaran, N. The antioxidant and antigenotoxic properties of citrus phenolics limonene and narangin. Food Chem. Toxicol. 2015, 81, 160–170. [Google Scholar] [CrossRef] [PubMed]

- Pérez-López, A.J.; Saura, D.; Lorente, J.; Carbonell-Barrachina, A.A. Limonene, linalool, α-terpineol, and terpinen-4-ol as quality control parameters in mandarin juice processing. Eur. Food Res. Technol. 2006, 222, 281–285. [Google Scholar] [CrossRef]

- Tao, N.; Chen, Y.; Wu, Y.; Wang, X.; Li, L.; Zhu, A. The terpene limonene induced the green mold of citrus fruit through regulation of reactive oxygen species (ROS) homeostasis in Penicillium digitalum spores. Food Chem. 2019, 277, 414–422. [Google Scholar] [CrossRef]

- Sarjorno, P.R.; Ismiyarto; Ngadiwiyana; Adiwibawa Prasetya, N.B.; RosydhUlfa; Ariestiani, B.; Kusuma, A.B.; Darmastuti, N.E.; Rohman, J.H.F. Antioxidant activity from limonene encapsulated by chitosan. IOP Conf. Ser. Mater. Sci. Eng. 2019, 509, 012113. [Google Scholar] [CrossRef]

- Al-Aamri, M.S.; Al-Abousi, N.M.; Al-Jabri, S.S.; Alam, T.; Khan, S.A. Chemical composition and in-vitro antioxidant and antimicrobial activity of the essential oil of Citrus aurantifolia L. leaves grown in Eastern Oman. J. Taibah Univ. Sci. 2018, 13, 108–112. [Google Scholar] [CrossRef]

- Bora, H.; Kamle, M.; Mahato, D.K.; Tiwari, P.; Kumar, P. Citrus essential oils (CEOs) and their applications in food: An overview. Plants 2020, 9, 357. [Google Scholar] [CrossRef]

- Fancello, F.; Petretto, G.L.; Zara, S.; Sanna, M.L.; Addis, R.; Maldini, M.; Foddai, M.; Rourke, J.P.; Chessa, M.; Pintore, G. Chemical characterization, antioxidant capacity and antimicrobial activity against food related microorganisms of Citrus limon var. pompia leaf essential oil. LWT-Food Sci. Technol. 2016, 69, 579–585. [Google Scholar] [CrossRef]

- Mahmoud, E.A. Essential oils of Citrus fruit peels antioxidant, antibacterial and additive value as food preservative. J. Food Dairy Sci. 2017, 8, 111–116. [Google Scholar] [CrossRef]

- Baschieri, A.; Ajvazi, M.D.; Tonfack, J.L.F.; Valgimigli, L.; Amorati, R. Explaining the antioxidant activity of some common non-phenolic components of essential oils. Food Chem. 2017, 232, 656–663. [Google Scholar] [CrossRef]

- Yuliani, S.; Torley, P.J.; Bhandari, B. Physical and processing characteristics of extrudates made from starch and d-limonene. Int. J. Food Prop. 2009, 12, 482–495. [Google Scholar] [CrossRef]

- Ibáñez, M.D. Commercial Essential Oils: Sustainable Alternatives in the Agri-Food Industry. Ph.D. Thesis, Universitat de València, Valencia, Spain, December 2019. [Google Scholar]

- Souza, J.M.; Caldas, A.L.; Tohidi, S.D.; Molina, J.; Souto, A.P.; Fangueiro, R.; Zille, A. Properties and controlled release of chitosan microencapsulated limonene oil. Rev. Bras. Farmacogn. 2014, 24, 691–698. [Google Scholar] [CrossRef]

- Prata, A.S.; Grosso, C.R.F. Production of microparticles with gelatin and chitosan. Carbohydr. Polym. 2015, 116, 292–299. [Google Scholar] [CrossRef] [PubMed]

- Lopes, S.; Afonso, C.; Fernandes, I.; Barreiro, M.-F.; Costa, P.; Rodrigues, A.E. Chitosan-cellulose particles as delivery vehicles for limonene fragrance. Ind. Crop. Prod. 2019, 139, 111407–111415. [Google Scholar] [CrossRef]

- Ghasemi, S.; Jafari, S.M.; Assadpour, E.; Khomeiri, M. Nanoencapsulation of d-limonene within nanocarriers produced by pectin-whey protein complexes. Food Hydrocoll. 2018, 77, 152–162. [Google Scholar] [CrossRef]

- Leclercq, S.; Harlander, K.R.; Reineccius, G.A. Formation and characterization of microcapsules by complex coacervation with liquid and solide aroma cores. Flavour. Fragr. J. 2009, 24, 17–24. [Google Scholar] [CrossRef]

- Martinez-Camacho, A.P.; Cortez-Rocha, M.; Ezquerra-Brauer, J.; Graciano-Verdugo, A.; Rodriguez-Félix, F.; Castillo-Ortega, M.; Yépiz-Gómez, M.S.; Plascencia-Jatomea, M. Chitosan composite films: Thermal, structural, mechanical and antifungal properties. Carbohydr. Polym. 2010, 82, 305–315. [Google Scholar] [CrossRef]

- Rabisková, M.; Valásková, J. The influence of HBL on the encapsulation of oils by complex coacervation. J. Microencapsul. 1998, 15, 747–751. [Google Scholar] [CrossRef]

- Chen, Q.; Zhong, F.; Wen, J.; McGillivray, D.; Quek, S.Y. Properties and stability of spray-dried and freeze-dried microcapsules co-encapsulated with fish oil, phytosterol esters and limonene. Dry. Technol. 2013, 31, 707–716. [Google Scholar] [CrossRef]

- Jafari, S.M.; He, Y.; Bhandari, B. Encapsulation of nanoparticles of d-limonene by spray drying: Role of emulsifiers and emulsifying techniques. Dry. Technol. 2007, 25, 1079–1089. [Google Scholar] [CrossRef]

- Scarfato, P.; Avallone, E.; Iannelli, P.; De Feo, V.; Acierno, D. Synthesis and characterization of polyurea microcapsules containing essential oils with antigerminative activity. J. Appl. Polym. Sci. 2007, 105, 3568–3577. [Google Scholar] [CrossRef]

- Thorne, M.F.; Simkovic, F.; Slater, A.G. Production of monodisperse polyurea microcapsules using microfluidics. Sci. Rep. 2019, 9, 17983–17989. [Google Scholar] [CrossRef] [PubMed]

- Rac, V.; Manojlović, V.; Rakić, V.; Bugarski, B.; Flock, T.; Krzyczmonik, K.E.; Nedović, V. Limonene encapsulation in alginate/poly (vinyl alcohol). Procedia Food Sci. 2011, 1, 1816–1820. [Google Scholar]

- Arrieta, M.P.; López, J.; Hernández, A.; Rayón, E. Ternary PLA-PHB-limonene blends intended for biodegradable food packaging applications. Eur. Polym. J. 2014, 50, 255–270. [Google Scholar] [CrossRef]

- Sansukcharearnpon, A.; Wanichwecharungruang, S.; Leepipatpaiboon, N.; Kerdcharoen, T.; Arayachukeat, S. High loading fragrance encapsulation based on polymer-blend: Preparation and release behaviour. Int. J. Pharm. 2010, 391, 267–273. [Google Scholar] [CrossRef] [PubMed]

- Tojo, K.; Hatae, N.; Nakagawa, K.; Yoshida, A. Adhesive systems for pesticide delivery through plant stems. Pestic. Sci. 1997, 49, 35–39. [Google Scholar] [CrossRef]

- Ganje, M.; Jafari, S.M.; Tamadon, A.M.; Niakosari, M.; Maghsoudlou, Y. Mathematical and fuzzy modelling of limonene release from amylose nanostructures and evaluation of its release kinetics. Food Hydrocoll. 2019, 95, 186–194. [Google Scholar] [CrossRef]

- Sánchez-González, L.; Cháfer, M.; González-Martínez, C.; Chiralt, A.; Desobry, S. Study of the release of limonene present in chitosan films enriched with bergamot oil in food simulants. J. Food Eng. 2011, 105, 138–143. [Google Scholar] [CrossRef]

- Vu, K.D.; Hollingsworth, R.G.; Leroux, E.; Salmieri, S.; Lacroix, M. Development of edible bioactive coating based on modified chitosan for increasing the shelf life of strawberries. Food Res. Int. 2011, 44, 198–203. [Google Scholar] [CrossRef]

- Bolton, T.A.; Reineccius, G.A. The oxidative stability and retention of a limonene based model flavor plated on amorphous silica and other selected carriers. Perfum Flavor J. 1992, 17, 1–19. [Google Scholar]

- Himed, L.; Merniz, S.; Monteagudo-Olivan, R.; Barkat, M.; Coronas, J. Antioxidant activity of the essential oil of citrus limon before and after its encapsulation in amorphous SiO2. Sci. Afr. 2019, 6, e00181–e00190. [Google Scholar] [CrossRef]

- Elabbadi, A.; Jerri, H.A.; Ouali, L.; Erni, P. Sustainable deliver systems: Retention of model volatile oils trapped on hybrid calcium carbonate microparticles. ACS Sustain. Chem. Eng. 2015, 3, 2178–2186. [Google Scholar] [CrossRef]

- Chen, Y.; Shu, M.; Yao, X.; Wu, K.; Zhang, K.; He, Y.; Nishinari, K.; Phillips, G.O.; Yao, X.; Jiang, F. Effect of zein-based microcapsules on the release and oxidation of loaded limonene. Food Hydrocoll. 2018, 84, 330–336. [Google Scholar] [CrossRef]

- Marcuzzo, E.; Debeaufort, F.; Sensidoni, A.; Tat, L.; Beney, L.; Hambleton, A.; Peressini, D.; Voilley, A. Release behaviour and stability of encapsulated d-limonene from emulsion-based edible films. J. Agric. Food Chem. 2012, 60, 12177–12185. [Google Scholar] [CrossRef] [PubMed]

- Hambleton, A.; Voilley, A.; Debeaufort, F. Transport parameters for aroma compounds through i-carrageenan and sodium alginate-based edible films. Food Hydrocoll. 2011, 25, 1128–1133. [Google Scholar] [CrossRef]

- Liu, S.; Li, X.; Chen, L.; Li, L.; Li, B.; Zhu, J. Tunable d-limonene permeability in starch-based nanocomposite films reinforced by cellulose nanocrystals. J. Agric. Food Chem. 2018, 66, 979–987. [Google Scholar] [CrossRef]

- Cabral Marques, H.M. A review on cyclodextrin encapsulation of essential oils and volatiles. Flavour Fragr. J. 2010, 25, 313–326. [Google Scholar] [CrossRef]

- Mortensen, A.; Aguilar, F.; Crebelli, R.; Di Domenico, A.; Dusemund, B.; Frutos, M.J.; Galtier, P.; Gott, D.; Gundert-Remy, U.; Leblanc, J.C.; et al. Re-evaluation of β-cyclodextrin (E459) as food additive. EFSA J. 2016, 14, 4628. [Google Scholar]

- Furuta, T.; Yoshii, H.; Kobayashi, T.; Nishitarumi, T.; Yasunishi, A. Powdery encapsulation of d-limonene by kneading with mixed powders of β-cyclodextrin and maltodextrin at low water content. Biosci. Biotechnol. Biochem. 2014, 847–850. [Google Scholar] [CrossRef]

- Dos Passos Menezes, P.; Pereira dos Santos, P.B.; Azevedo Dória, G.A.; Hipólito de Sousa, B.M.; Russo Serafini, M.; Nunes, P.S.; Quintans-Júnior, L.J.; de Matos, I.L.; Alves, P.B.; Bezerra, D.P.; et al. Molecular modelling and physicochemical properties of supramolecular complexes of limonene with α- and β-cyclodextrines. AAPS PharmSciTech 2017, 18, 49–57. [Google Scholar] [CrossRef]

- Astray, G.; Mejuto, J.C.; Morales, J.; Rial-Otero, R.; Simal-Gándara, J. Factors controlling flavors binding constants to cyclodextrines and their applications in foods. Food Res. Int. 2010, 43, 1212–1218. [Google Scholar] [CrossRef]

- Mallardo, S.; De Vito, V.; Malinconico, M.; Grazia Volpe, M.; Santagata, G.; Di Lorenzo, M.L. Poly (butylene succinate)-based composites containing β-cyclodextrin/d-limonene inclusion complex. Eur. Polym. J. 2016, 79, 82–96. [Google Scholar] [CrossRef]

- Szejtli, J. Utilization of cyclodextrins in industrial products and processes. J. Mater. Chem. 1997, 7, 575–587. [Google Scholar] [CrossRef]

- Yuliani, S.; Terley, P.; D’Arcy, B.R.; Nicholson, T.; Bhandari, B. Extrusion of mixtures of starch and d-limonene encapsulated with β-cyclodextrin: Flavour retention and physical properties. Food Res. Int. 2006, 39, 318–331. [Google Scholar] [CrossRef]

- Yamanoto, C.; Neoh, T.L.; Honbou, H.; Furuta, T.; Kimura, S.; Yoshii, H. Formation of a polymer-coated inclusion complex of d-limonene and β-cyclodextrin by spray drying. Dry. Technol. 2012, 30, 1714–1719. [Google Scholar] [CrossRef]

- Fuenmayor, C.A.; Mascheroni, E.; Cosio, M.S.; Piergiovanni, L.; Benedetti, S.; Ortenzi, M.; Schiraldi, A.; Mannino, S. Encapsulation of R-(+)-limonene in edible electrospun nanofibers. Chem. Eng. Trans. 2013, 32, 1771–1776. [Google Scholar]

- Soottitantawat, A.; Yoshii, H.; Furuta, T.; Ohgawara, M.; Forssell, P.; Partanen, R.; Poutanen, K.; Linko, P. Effect of water activity on the release characteristics and oxidative stability of d-limonene encapsulated by spray drying. J. Agric. Food Chem. 2004, 52, 1269–1276. [Google Scholar] [CrossRef] [PubMed]

- Soottitantawat, A.; Bigeard, F.; Yoshii, H.; Furuta, T.; Ohkawara, M.; Linko, P. Influence of emulsion and powder size on the stability of encapsulated d-limonene by spray drying. Innov. Food Sci. Emerg. 2005, 6, 107–114. [Google Scholar] [CrossRef]

- Paramita, V.; Furuta, T.; Yoshii, H. High-oil-load encapsulation of medium-chain triglycerides and d-limonene mixture in modified starch by spray drying. J. Food Sci. 2012, 77, E38–E44. [Google Scholar] [CrossRef]

- Verdalet-Guzmán, I.; Martínez-Ortiz, L.; Martínez-Bustos, F. Characterization of new sources of derivative starches as wall materials of essential oil by spray drying. Food Sci. Technol. 2013, 33, 757–764. [Google Scholar] [CrossRef][Green Version]

- Ordoñez, M.; Herrera, A. Morphologic and stability cassava starch matrices for encapsulating limonene by spray drying. Powder Technol. 2014, 253, 89–97. [Google Scholar] [CrossRef]

- Charve, J.; Reineccius, G.A. Encapsulation performance of proteins and traditional materials for spray dried flavors. J. Agric. Food Chem. 2009, 57, 2486–2492. [Google Scholar] [CrossRef] [PubMed]

- Fisk, I.D.; Linforth, R.; Trophardy, G.; Gray, D. Entrapment of a volatile lipophilic aroma compound (d-limonene) in spray dried water-washed bodies naturally derived from sunflower seeds (Helianthus annus). Food Res. Int. 2013, 54, 861–866. [Google Scholar] [CrossRef] [PubMed]

- Burgos-Díaz, C.; Hernández, X.; Wandersleben, T.; Barahona, T.; Medina, C.; Quiroz, A.; Rubilar, M. Influence of multilayer O/W emulsions stabilized by proteins from a novel lupin variety AluProt-CGNA and ionic polysaccharides on d-limonene retention during spray-drying. Colloid Surf. A 2018, 536, 234–241. [Google Scholar] [CrossRef]

- Gharsallaoui, A.; Roudaut, G.; Chambin, O.; Voilley, A.; Saurel, R. Applications of spray-drying in microencapsulation of food ingredients: An overview. Food Res. Int. 2007, 40, 1107–1121. [Google Scholar] [CrossRef]

- Yamamoto, C.; Neoh, T.L.; Honbou, H.; Yoshii, H.; Furuta, T. Kinetic analysis and evaluation of controlled release of d-limonene encapsulated in spray-dried cyclodextrin powder under linearly ramped humidity. Dry. Technol. 2012, 30, 1283–1291. [Google Scholar] [CrossRef]

- Do Carmo, C.S.; Pair, R.; Simplício, A.L.; Mateus, M.; Duarte, C.M.M. Improvement of aroma and shelf-lide of non-alcoholic beverages through cyclodextrins-limonene inclusion complexes. Food Bioprocess. Technol. 2017, 10, 1297–1309. [Google Scholar] [CrossRef]

- Khoshakhlagh, K.; Koocheki, A.; Mohebbi, M.; Allafchian, A. Development and characterization of electrosprayed Alyssum homolocarpum seed gum nanoparticles for encapsulation of d-limonene. J. Colloid Interf. Sci. 2017, 490, 562–575. [Google Scholar] [CrossRef]

- Camerlo, A.; Bühlmann-Popa, A.M.; Vebert-Nardin, C.; Rossi, R.M.; Fortunato, G. Environmentally controlled emulsion electrospinning for the encapsulation of temperature-sensitive compounds. J. Mater. Sci. 2014, 49, 8154–8162. [Google Scholar] [CrossRef]

- Camerlo, A.; Vebert-Nardin, C.; Rossi, R.M.; Popa, A.M. Fragrance encapsulation in polymeric matrices by emulsion electrospinning. Eur. Polym. J. 2013, 49, 3806–3813. [Google Scholar] [CrossRef]

- Wang, X.; Yuan, Y.; Huang, X.; Yue, T. Controlled release of protein from core-shell nanofibers prepared by emulsion electrospinning based on green chemical. J. Appl. Polym. Sci. 2015, 132, 41811–41819. [Google Scholar] [CrossRef]

- Zahi, M.R.; Liang, H.; Yuan, Q. Improving the antimicrobial activity of d-limonene using a novel organogel-based nanoemulsion. Food Control 2015, 50, 554–559. [Google Scholar] [CrossRef]

- Jiménez, A.; Sánchez-González, L.; Desobry, S.; Chiralt, A.; Tehrany, E.A. Influence of nanoliposomes incorporation on properties of film forming dispersions and films based on corn starch and sodium caseinate. Food Hydrocoll. 2014, 35, 159–169. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Z.; Yuan, Q.; Liang, H.; Vriesekoop, F. Process optimization and stability of d-limonene nanoemulsions prepared by catastrophic phase inversion method. J. Food Eng. 2013, 119, 419–424. [Google Scholar] [CrossRef]

- Zhang, Z.; Vriesekoop, F.; Yuan, Q.; Liang, H. Effects of nisin on the antimicrobial activity of d-limonene and its nanoemulsion. Food Chem. 2014, 150, 307–312. [Google Scholar] [CrossRef]

- Soukoulis, C.; Gaiani, C.; Hoffmann, L. Plant seed mucilage as emerging biopolymer in food industry applications. Curr. Opin. Food Sci. 2018, 22, 28–42. [Google Scholar] [CrossRef]

- Jafari, S.M.; Beheshti, P.; Assadpour, E. Emulsification properties of novel hydrocolloid (Angum gum) for d-limonene droplets compared with Arabic gum. Int. J. Biol. Macromol. 2013, 61, 182–188. [Google Scholar] [CrossRef]

- Lević, S.; Pajić Lijaković, I.; Đorđević, V.; Rac, V.; Rakić, V.; Šolević Knudsen, T.; Pavlović, V.; Bugarski, B.; Nedović, V. Characterization of sodium alginate/d-limonene emulsions and respective calcium alginate/d-limonene beads produced by electrostatic extrusion. Food Hydrocoll. 2015, 45, 111–123. [Google Scholar] [CrossRef]

- Wen, C.X.; Yuan, Q.P.; Liang, H.; Vriesekoop, F. Preparation and stabilization of d-limonene pickering emulsions by cellulose nanocrystals. Carbohydr. Polym. 2014, 112, 695–700. [Google Scholar] [CrossRef]

- Mikulcová, V.; Bordes, R.; Kašpárková, V. On the preparation and antibacterial activity of emulsions stabilized with nanocellulose particles. Food Hydrocoll. 2016, 61, 780–792. [Google Scholar]

- Radulova, G.M.; Slavova, T.G.; Kralchevsky, P.A.; Basheva, E.S.; Marinova, K.G.; Danov, K.D. Encapsulation of oils and fragances by core-in-shell structures from silica particles, polymers and surfactants: The brick-and-mortar concept. Colloid Surf. A 2018, 559, 351–364. [Google Scholar] [CrossRef]

- Khoshakhlagh, K.; Koocheki, A.; Mohebbi, M.; Allafchian, A. Encapsulation of d-limonene in Alyssum homolocarpum seed gum nanocapsules by emulsion electrospraying: Morphology characterization and stability assessment. Bioact. Carbohydr. Diet. Fibre 2018, 16, 43–52. [Google Scholar] [CrossRef]

- Evageliou, V.; Saliari, D. Limonene encapsulation in freeze dried gellan systems. Food Chem. 2017, 223, 72–75. [Google Scholar] [CrossRef]

- Vaughn, J.; Wu, H.; Efremovska, B.; Olson, D.H.; Mattai, J.; Ortiz, C.; Puchalski, A.; Li, J.; Pan, L. Encapsulated recyclable porous materials: An effective moisture-triggered fragrance release system. Chem. Commun. 2013, 49, 5724–5726. [Google Scholar] [CrossRef] [PubMed]

- Machado, L.C.; Pelegati, V.B.; Oliveira, A.L. Study of simple microparticles formation of limonene in modified starch using PGSS—Particle from gas-saturated suspensions. J. Supercrit. Fluids 2016, 107, 260–269. [Google Scholar] [CrossRef]

| Wall Material | Highlighted Results | Ref. |

|---|---|---|

| Polymer | ||

| Polymer-blend in a HPMC:PV(OH):EC 1 | HPMC:PV(OH):EC w/w/w ratio of 1:1:6. Low Limonene’s EE% due to unsaturated hydrocarbon functionality. | [109] |

| Acrylic adhesive polymer or natural rubber | Application as pesticide (Solanum melongena). Penetration rate of the active agent, imidacloprid, was enhanced 2.4 times in the presence of d-limonene. Bursting release avoided. | [110] |

| Polysaccharide | ||

| Amylose | Amylose-limonene showed less than 5% limonene released at pH acid. At pH 6–7 burst release followed by a controlled and retarded release (6 h with 34–79% release depending on the % of amylose used in the formulation). | [111] |

| Chitosan | Release tested in five different food simulating liquids (aqueous solutions with 0%, 10%, 50% and 95% of ethanol and isooctane). Kinetic constants augmented with the addition of ethanol, due to the increase of Limonene’s solubility. | [112] |

| Functionalized chitosan | Increasing the shelf-life of strawberries during storage. Chitosan functionalized with palmitoyl chloride provided better preservation after 14 days at 4 °C. Chitosan modification increased its hydrophobicity, ensuring limonene controlled release and improved its stability and adhesion to the fruit. | [113] |

| Inorganic carriers | ||

| Silica | Limonene oxidation and retention depended on the type of silica (chemical purity, small pore volume/diameter and hydroxylated surface area). | [114,115] |

| Hybrid CaCO3 with lecithin, sodium stearate (NaSt) and acacia gum (AG) | Particles with lecithin and NaSt presenting more hydrophobic surface retained more limonene. CaCO3-lecithin presented minimal loss after 3 months’ storage at r.t 2 Hydrophobicity was more efficient than specific surface area in increasing Limonene’s retention and absorption capacity. | [116] |

| Protein | ||

| Corn’s Zein | Optimal limonene/zein ratio was 2.0 yielding particles with D4.3 of 10 µm and shell thickness of 25 nm. Maximum burst release at 30 min, followed by sustained release of environ 80%. | [117] |

| Emulsification Method | Highlighted Results | Ref. |

|---|---|---|

| High-Energy | ||

| High pressure homogenizer | d-limonene/monosterin organogel (4% w/w) presented better antimicrobial activity than free d-limonene due to the higher solubility of encapsulated limonene. Small size nanoemulsion (36 nm) droplets can easily fuse with bacterial cells. | [146] |

| Sonication | Nanoliposomes of d-limonene/soy or rapeseed lecithins (150 nm) were added to starch-sodium caseinate (50:50) film forming dispersions. Encapsulation prevented limonene evaporation. Antimicrobial activity against L. monocytogens was inhibited. | [147] |

| Microfluidization vs. Ultrasound | Microfluidization produced droplets of 700–800 nm with the highest retention (86.2%) of d-limonene and minimum amounts of non-encapsulated oil at the surface of particles. | [104] |

| Low-Energy | ||

| CPI | Water/Tween 80/d-limonene system. Nanoemulsions stored at 28 °C were more stable than those stored at 4 °C. | [148] |

| CPI | d-limonene/nisin system showing synergistic effects against food-related microorganisms: S. aureus, B. subtilis, E. coli and Saccharomyces cerevisiae. | [149] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibáñez, M.D.; Sanchez-Ballester, N.M.; Blázquez, M.A. Encapsulated Limonene: A Pleasant Lemon-Like Aroma with Promising Application in the Agri-Food Industry. A Review. Molecules 2020, 25, 2598. https://doi.org/10.3390/molecules25112598

Ibáñez MD, Sanchez-Ballester NM, Blázquez MA. Encapsulated Limonene: A Pleasant Lemon-Like Aroma with Promising Application in the Agri-Food Industry. A Review. Molecules. 2020; 25(11):2598. https://doi.org/10.3390/molecules25112598

Chicago/Turabian StyleIbáñez, María Dolores, Noelia M. Sanchez-Ballester, and María Amparo Blázquez. 2020. "Encapsulated Limonene: A Pleasant Lemon-Like Aroma with Promising Application in the Agri-Food Industry. A Review" Molecules 25, no. 11: 2598. https://doi.org/10.3390/molecules25112598

APA StyleIbáñez, M. D., Sanchez-Ballester, N. M., & Blázquez, M. A. (2020). Encapsulated Limonene: A Pleasant Lemon-Like Aroma with Promising Application in the Agri-Food Industry. A Review. Molecules, 25(11), 2598. https://doi.org/10.3390/molecules25112598