Drying Induced Impact on Composition and Oil Quality of Rosemary Herb, Rosmarinus Officinalis Linn

Abstract

1. Introduction

2. Results and Discussion

2.1. Rosemary Oil Productivity in Different Drying Periods

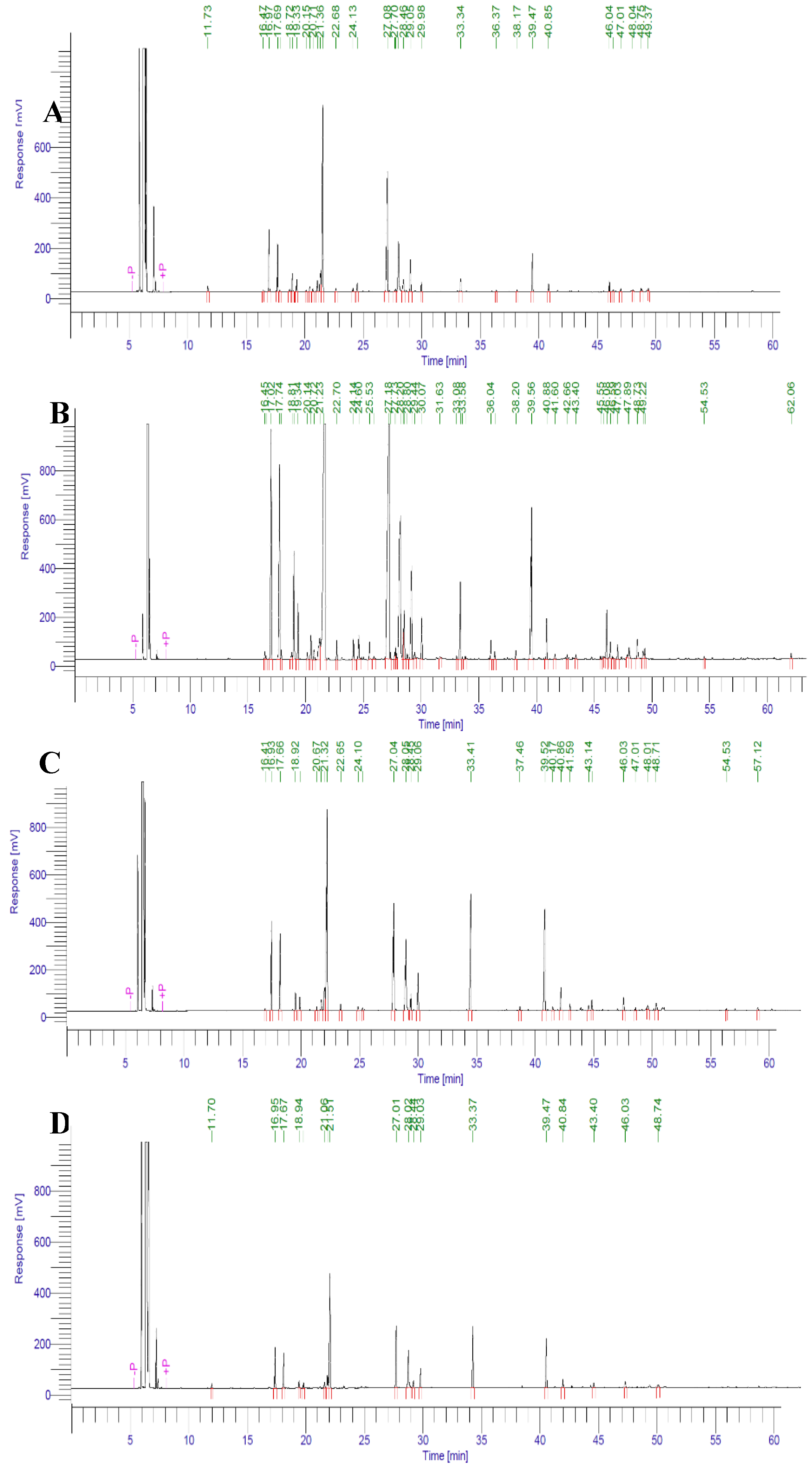

2.2. Rosemary Oil Constituents in Different Drying Periods

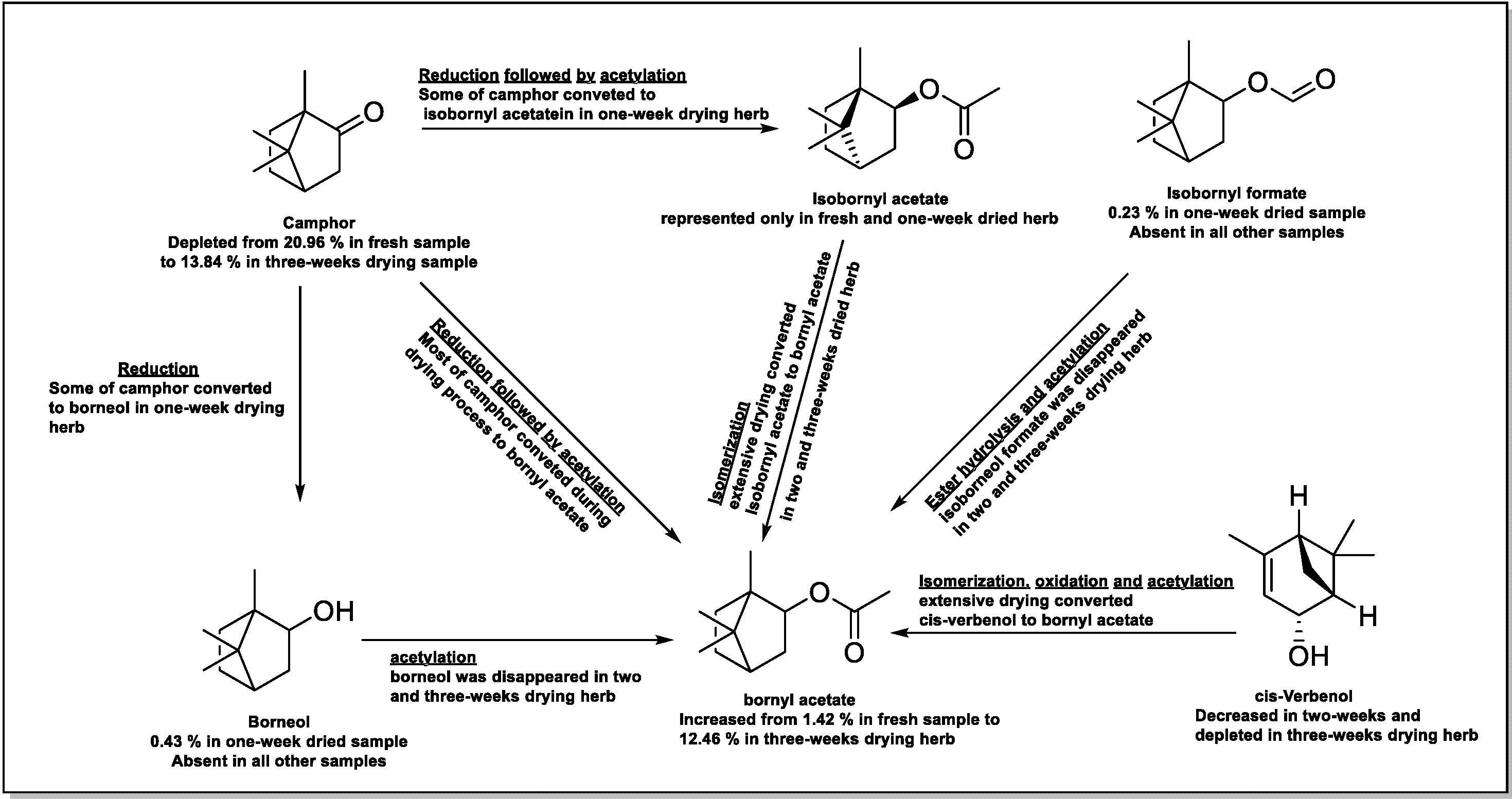

2.3. Possible Chemical-Biotransformations in Oil Constituents during Drying Periods

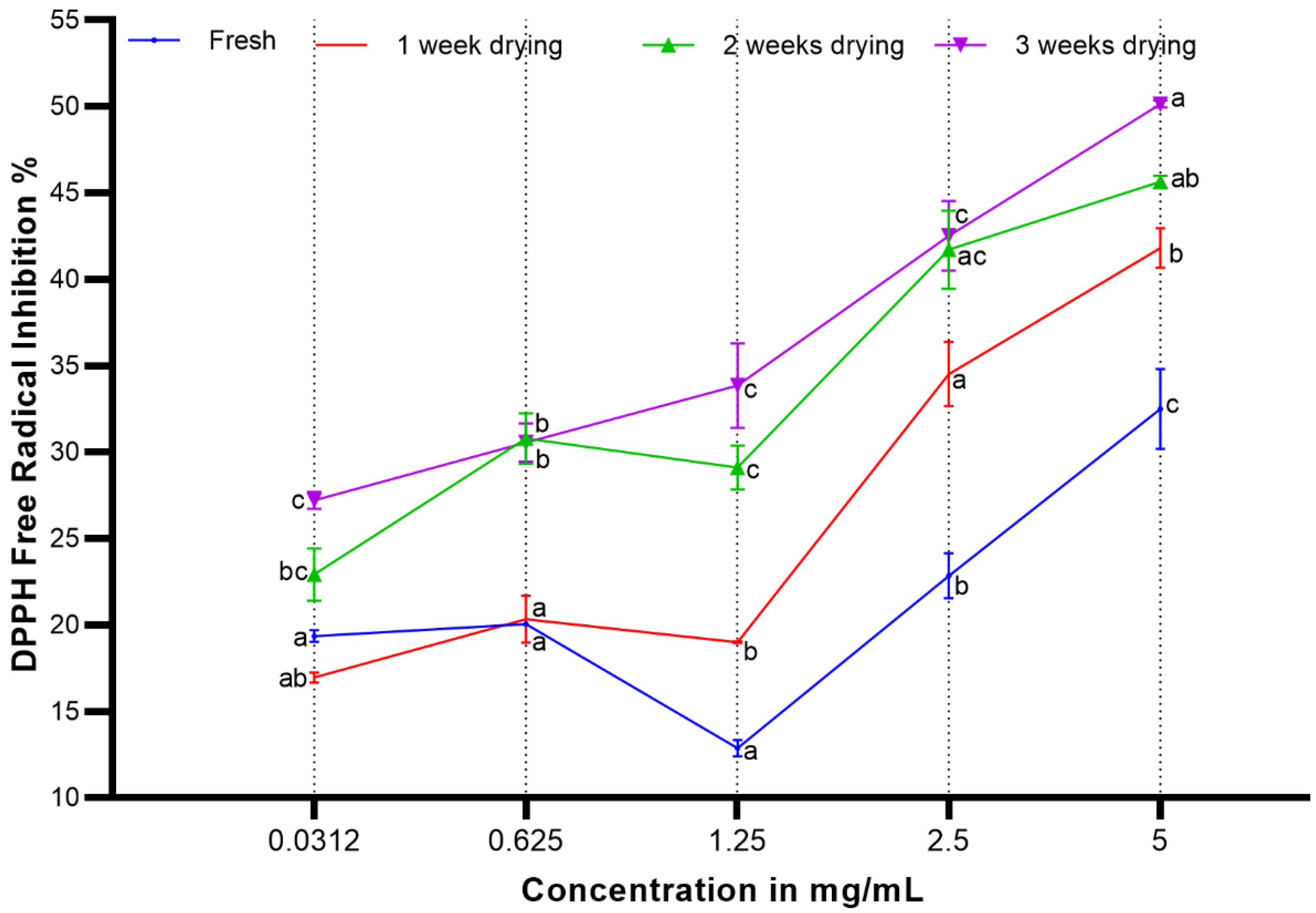

2.4. Antioxidant/Free Radical Scavenging-Based Quality of the Oil Samples

3. Materials and Methods

3.1. Plant Materials Collection

3.2. Plant Preparation and Distillation Method

3.3. Gas Chromatography–Mass Spectroscopy (GC–MS) Analyses

3.4. Gas Chromatography-Flame Ionization Detector (GC-FID) Analyses

3.5. Identifications of the Essential Oil Constituents

3.6. Determination of the Antioxidant Activity of Oil Samples by DPPH

3.7. Statistical Analyses

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bozin, B.; Mimica-Dukic, N.; Samojlik, I.; Jovin, E. Antimicrobial and antioxidant properties of rosemary and sage (Rosmarinus officinalis L. and Salvia officinalis L., Lamiaceae) essential oils. J. Agric. Food Chem. 2007, 55, 7879–7885. [Google Scholar] [CrossRef] [PubMed]

- Small, E. Culinary Herbs, 2nd ed.; NRC Research Press: Ottawa, ON, Canada, 2006; pp. 517–524. ISBN 9780660190730. [Google Scholar]

- Ribeiro-Santos, R.; Carvalho-Costa, D.; Cavaleiro, C.; Costa, H.S.; Albuquerque, T.G.; Castilho, M.C.; Ramos, F.; Melo, N.R.; Sanches-Silva, A. A novel insight on an ancient aromatic plant: The rosemary (Rosmarinus officinalis L.). Trends Food Sci. Technol. 2015, 45, 355–368. [Google Scholar] [CrossRef]

- Nieto, G.; Díaz, P.; Bañón, S.; Garrido, M.D. Dietary administration of ewe diets with a distillate from rosemary leaves (Rosmarinus officinalis L.): Influence on lamb meat quality. Meat Sci. 2010, 84, 23–29. [Google Scholar] [CrossRef] [PubMed]

- Elmhalli, F.; Garboui, S.S.; Borg-Karlson, A.-K.; Mozūraitis, R.; Baldauf, S.L.; Grandi, G. The repellency and toxicity effects of essential oils from the Libyan plants Salvadora persica and Rosmarinus officinalis against nymphs of Ixodes ricinus. Exp. Appl. Acarol. 2019, 77, 585–599. [Google Scholar] [CrossRef] [PubMed]

- Trotter, R.T., II. Folk remedies as indicators of common illnesses: Examples from the United States-Mexico border. J. Ethnopharmacol. 1981, 4, 207–221. [Google Scholar] [CrossRef]

- Hassani, F.V.; Shirani, K.; Hosseinzadeh, H. Rosemary (Rosmarinus officinalis) as a potential therapeutic plant in metabolic syndrome: A review. Naunyn. Schmiedebergs. Arch. Pharmacol. 2016, 389, 931–949. [Google Scholar] [CrossRef]

- Moreno, S.; Ojeda Sana, A.M.; Gaya, M.; Barni, M.V.; Castro, O.A.; van Baren, C. Rosemary compounds as nutraceutical health products. In Food Additives; El-Samragy, Y., Ed.; InTech: Rijeka, Croatia, 2012; pp. 157–174. [Google Scholar]

- Fahim, F.; Esmat, A.; Fadel, H.; Hassan, K. Allied studies on the effect of Rosmarinus officinalis L. on experimental hepatotoxicity and mutagenesis. Int. J. Food Sci. Nutr. 1999, 50, 413–427. [Google Scholar] [CrossRef]

- Ho, C.-T.; Ferraro, T.; Chen, Q.; Rosen, R.T.; Huang, M.-T. Phytochemicals in teas and rosemary and their cancer-preventive properties. In Food Phytochemicals for Cancer Prevention II; Ho, C.-T., Osawa, T., Huang, M.-T., Rosen, R.T., Eds.; American Chemical Society: Washington, DC, USA, 1994; Volume 547, pp. 2–19. [Google Scholar]

- Baratta, M.T.; Dorman, H.J.D.; Deans, S.G.; Biondi, D.M.; Ruberto, G. Chemical composition, antimicrobial and antioxidative activity of laurel, sage, rosemary, oregano and coriander essential oils. J. Essent. Oil Res. 1998, 10, 618–627. [Google Scholar] [CrossRef]

- Jamshidi, R.; Afzali, Z.; Afzali, D. Chemical composition of hydrodistillation essential oil of rosemary in different origins in Iran and comparison with other countries. Am. J. Agric. Environ. Sci. 2009, 5, 78–81. [Google Scholar]

- Özcan, M.M.; Chalchat, J.-C. Chemical composition and antifungal activity of rosemary (Rosmarinus officinalis L.) oil from Turkey. Int. J. Food Sci. Nutr. 2008, 59, 691–698. [Google Scholar] [CrossRef]

- Sienkiewicz, M.; Łysakowska, M.; Pastuszka, M.; Bienias, W.; Kowalczyk, E. The potential of use basil and rosemary essential oils as effective antibacterial agents. Molecules 2013, 18, 9334. [Google Scholar] [CrossRef] [PubMed]

- Zheljazkov, V.D.; Astatkie, T.; Zhalnov, I.; Georgieva, T.D. Method for attaining rosemary essential oil with differential composition from dried or fresh material. J. Oleo Sci. 2015, ess14258. [Google Scholar] [CrossRef] [PubMed]

- Conde-Hernández, L.A.; Espinosa-Victoria, J.R.; Trejo, A.; Guerrero-Beltrán, J.Á. CO2-supercritical extraction, hydrodistillation and steam distillation of essential oil of rosemary (Rosmarinus officinalis). J. Food Eng. 2017, 200, 81–86. [Google Scholar] [CrossRef]

- Boutekedjiret, C.; Bentahar, F.; Belabbes, R.; Bessiere, J.M. Extraction of rosemary essential oil by steam distillation and hydrodistillation. Flavour Fragr. J. 2003, 18, 481–484. [Google Scholar] [CrossRef]

- Lo Presti, M.; Ragusa, S.; Trozzi, A.; Dugo, P.; Visinoni, F.; Fazio, A.; Dugo, G.; Mondello, L. A comparison between different techniques for the isolation of rosemary essential oil. J. Sep. Sci. 2005, 28, 273–280. [Google Scholar] [CrossRef] [PubMed]

- Reverchon, E.; Senatore, F. Isolation of rosemary oil: Comparison between hydrodistillation and supercritical CO2 extraction. Flavour Fragr. J. 1992, 7, 227–230. [Google Scholar] [CrossRef]

- Müller, J.; Heindl, A. Drying of medicinal plants. Frontis 2006, 17, 237–252. [Google Scholar]

- Rocha, R.P.; Melo, E.C. Influence of drying process on the quality of medicinal plants: A review. J. Med. Plants Res. 2011, 5, 7076–7084. [Google Scholar] [CrossRef]

- Venskutonis, P.R. Effect of drying on the volatile constituents of thyme (Thymus vulgaris L.) and sage (Salvia officinalis L.). Food Chem. 1997, 59, 219–227. [Google Scholar] [CrossRef]

- Piga, A.; Usai, M.; Marchetti, M.; Foddai, M.; Del Caro, A.; Meier, P.; Onorati, V.; Vinci, F. Influence of different drying parameters on the composition of volatile compounds of thyme and rosemary cultivated in Sardinia. In Proceedings of the 3rd International Symposium on Food and Agricultural Products: Processing and Innovations, Naples, Italy, 24–26 September 2007. [Google Scholar]

- Hossain, M.B.; Barry-Ryan, C.; Martin-Diana, A.B.; Brunton, N.P. Effect of drying method on the antioxidant capacity of six Lamiaceae herbs. Food Chem. 2010, 123, 85–91. [Google Scholar] [CrossRef]

- RAO, L.J.; Singh, M.; Raghavan, B.; Abraham, K.O. Rosemary (Rosmarinus officinalis L.): Impact of drying on its flavor quality. J. Food Qual. 1998, 21, 107–115. [Google Scholar] [CrossRef]

- Usai, M.; Marchetti, M.; Foddai, M.; Del Caro, A.; Desogus, R.; Sanna, I.; Piga, A. Influence of different stabilizing operations and storage time on the composition of essential oil of thyme (Thymus officinalis L.) and rosemary (Rosmarinus officinalis L.). LWT-Food Sci. Technol. 2011, 44, 244–249. [Google Scholar] [CrossRef]

- Jerković, I.; Mastelić, J.; Miloš, M. The impact of both the season of collection and drying on the volatile constituents of Origanum vulgare L. ssp. hirtum grown wild in Croatia. Int. J. Food Sci. Technol. 2001, 36, 649–654. [Google Scholar] [CrossRef]

- Sefidkon, F.; Abbasi, K.; Khaniki, G.B. Influence of drying and extraction methods on yield and chemical composition of the essential oil of Satureja hortensis. Food Chem. 2006, 99, 19–23. [Google Scholar] [CrossRef]

- Sellami, I.H.; Wannes, W.A.; Bettaieb, I.; Berrima, S.; Chahed, T.; Marzouk, B.; Limam, F. Qualitative and quantitative changes in the essential oil of Laurus nobilis L. leaves as affected by different drying methods. Food Chem. 2011, 126, 691–697. [Google Scholar] [CrossRef]

- Croteau, R.; Felton, M.; Karp, F.; Kjonaas, R. Relationship of camphor biosynthesis to leaf development in sage (Salvia officinalis). Plant Physiol. 1981, 67, 820–824. [Google Scholar] [CrossRef]

- Ishihara, K.; Hamada, H.; Hirata, T.; Nakajima, N. Biotransformation using plant cultured cells. J. Mol. Catal. B Enzym. 2003, 23, 145–170. [Google Scholar] [CrossRef]

- El-Ghorab, A.H. Supercritical fluid extraction of the Egyptian rosemary (Rosmarinus officinalis) leaves and Nigella sativa L. seeds volatile oils and their antioxidant activities. J. Essent. Oil Bear. Plants 2003, 6, 67–77. [Google Scholar] [CrossRef]

- Carvalho, R.N., Jr.; Moura, L.S.; Rosa, P.T.V.; Meireles, M.A.A. Supercritical fluid extraction from rosemary (Rosmarinus officinalis): Kinetic data, extract’s global yield, composition, and antioxidant activity. J. Supercrit. Fluids 2005, 35, 197–204. [Google Scholar] [CrossRef]

- Carrillo, J.D.; Tena, M.T. Determination of volatile compounds in antioxidant rosemary extracts by multiple headspace solid-phase microextraction and gas chromatography. Flavour Fragr. J. 2006, 21, 626–633. [Google Scholar] [CrossRef]

- Amorati, R.; Foti, M.C.; Valgimigli, L. Antioxidant activity of essential oils. J. Agric. Food Chem. 2013, 61, 10835–10847. [Google Scholar] [CrossRef] [PubMed]

- Roginsky, V.; Lissi, E.A. Review of methods to determine chain-breaking antioxidant activity in food. Food Chem. 2005, 92, 235–254. [Google Scholar] [CrossRef]

- Mohammed, H.A.; Abdel-Aziz, M.M.; Hegazy, M.M. Anti-Oral Pathogens of Tecoma stans (L.) and Cassia javanica (L.) Flower Volatile Oils in Comparison with Chlorhexidine in Accordance with Their Folk Medicinal Uses. Medicina 2019, 55, 301. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, H.A.; Al-Omar, M.S.; Aly, M.S.A.; Hegazy, M.M. Essential Oil Constituents and Biological Activities of the Halophytic Plants, Suaeda Vermiculata Forssk and Salsola Cyclophylla Bakera Growing in Saudi Arabia. J. Essent. Oil Bear. Plants 2019, 22, 1–12. [Google Scholar] [CrossRef]

- Parejo, I.; Codina, C.; Petrakis, C.; Kefalas, P. Evaluation of scavenging activity assessed by Co (II)/EDTA-induced luminol chemiluminescence and DPPH·(2, 2-diphenyl-1-picrylhydrazyl) free radical assay. J. Pharmacol. Toxicol. Methods 2000, 44, 507–512. [Google Scholar] [CrossRef]

- Nile, S.H.; Khobragade, C.N. Antioxidant activity and flavonoid derivatives of Plumbago zeylanica. J. Nat. Prod. 2010, 3, 130–133. [Google Scholar]

Sample Availability: Samples of the volatile oil batches could be available from the authors. |

| Period of Natural Drying | Weight of the Fresh Herbs (Grams) | Weight of Herbs at Distillation(Grams) | % Weight Loss of Herb | Volatile Oil Yields (Milligrams) 1 | % Weight Loss of Oil 2 |

|---|---|---|---|---|---|

| Fresh | 200 | 200 | 0% | 198 ± 3.45 | 39.44% |

| One week | 200 | 70 | 65% | 327 ± 5.91 | 100% 2 |

| Two weeks | 200 | 68 | 66% | 168.7 ± 5.11 | 48.40% |

| Three weeks | 200 | 68 | 66% | 97.8 ± 1.27 | 70.09% |

| Serial No. | Components | Retention Index (RI) | The Percentage of the Total Area in GC–MS Analyses | ||||

|---|---|---|---|---|---|---|---|

| One-Way ANOVA (p-Value) | Fresh Herbs | One Week Drying | Two Weeks Dryings | Three Weeks Dryings | |||

| 1. | α-Pinene | 932 | 0.0066 *** | 0.14a | 0.18b | 0.15a | - |

| 2. | Camphene | 943 | 0.4512 | 6.42 | 7.19 | 6.82 | 6.99 |

| 3. | β-Pinene | 973 | 0.4884 | 5.10 | 5.90 | 5.90 | 5.98 |

| 4. | Myrcene | 990 | - | 0.19 | 0.20 | - | - |

| 5. | α-Phellandrene | 1004 | - | 0.34 | 0.28 | - | - |

| 6. | α-Terpinene | 1016 | <0.0001 *** | 2.07 a | 2.99b | 1.34c | 1.83a |

| 7. | p-Cymene | 1025 | 0.4616 | 1.24 | 1.33 | 0.99 | 0.99 |

| 8. | 1,8-Cineole (Eucalyptol) | 1030 | 0.0006 *** | 28.59a | 24.12b | 22.56cb | 24.04db |

| 9. | β-Phellandrene | 1031 | - | 0.18 | 0.20 | - | - |

| 10. | Terpinolene | 1090 | 0.2009 | 1.52 | 1.12 | 1.17 | |

| 11. | p-Cymenene | 1091 | 0.8203 | 0.34 | 0.46 | 0.47 | - |

| 12. | Linalool | 1102 | 0.0019 ** | 3.29a | 1.52b | 3.01a | 3.08a |

| 13. | α-Campholenal | 1127 | 0.0002 *** | 0.94a | 0.81a | 0.22b | - |

| 14. | cis-Verbenol | 1142 | 0.3993 | 0.46 | 0.53 | 0.34 | - |

| 15. | Camphor | 1145 | <0.0001 *** | 20.96a | 19.64a | 12.09b | 13.84c |

| 16. | Borneol | 1165 | - | - | 0.43 | - | - |

| 17. | α-Terpineol | 1193 | 0.8816 | 8.92 | 9.01 | 8.99 | 9.61 |

| 18. | Verbenone | 1215 | 0.0763 | 2.04 | 1.30 | 1.34 | 1.47 |

| 19. | Citronellol | 1227 | 0.9956 | 3.98 | 3.89 | 3.58 | 3.86 |

| 20. | Isobornyl formate | 1237 | - | - | 0.23 | - | - |

| 21. | Isobornyl acetate | 1285 | - | 1.13 | 1.28 | - | - |

| 22. | Bornyl acetate | 1292 | <0.0001 *** | 1.42a | 2.34a | 12.25b | 12.46b |

| 23. | Piperitenone | 1342 | - | - | 0.47 | - | - |

| 24. | β-Caryophyllene | 1427 | 0.0001 *** | 4.62a | 6.21a | 11.09b | 9.91b |

| 25. | Germacrene-D | 1490 | 0.0263 | 0.90a | 1.12 | 1.88b | 1.71 |

| 26. | epi-α-bisabolol | 1686 | 0.5035 | 0.26 | 0.38 | 0.49 | - |

| 27. | Total percentage of constituents accounted from GC–MS | 95.05 | 92.01 | 94.63 | 96.94 | ||

| 28. | Total identified number of constituents | 23 | 25 | 19 | 14 | ||

| 29. | The projected weight percentage of constituents 1 | 88.46 | 96.15 | 73.07 | 53.85 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammed, H.A.; Al-Omar, M.S.; Mohammed, S.A.A.; Aly, M.S.A.; Alsuqub, A.N.A.; Khan, R.A. Drying Induced Impact on Composition and Oil Quality of Rosemary Herb, Rosmarinus Officinalis Linn. Molecules 2020, 25, 2830. https://doi.org/10.3390/molecules25122830

Mohammed HA, Al-Omar MS, Mohammed SAA, Aly MSA, Alsuqub ANA, Khan RA. Drying Induced Impact on Composition and Oil Quality of Rosemary Herb, Rosmarinus Officinalis Linn. Molecules. 2020; 25(12):2830. https://doi.org/10.3390/molecules25122830

Chicago/Turabian StyleMohammed, Hamdoon A., Mohsen S. Al-Omar, Salman A. A. Mohammed, Mohamed S. A. Aly, Abdulmalik N. A. Alsuqub, and Riaz A. Khan. 2020. "Drying Induced Impact on Composition and Oil Quality of Rosemary Herb, Rosmarinus Officinalis Linn" Molecules 25, no. 12: 2830. https://doi.org/10.3390/molecules25122830

APA StyleMohammed, H. A., Al-Omar, M. S., Mohammed, S. A. A., Aly, M. S. A., Alsuqub, A. N. A., & Khan, R. A. (2020). Drying Induced Impact on Composition and Oil Quality of Rosemary Herb, Rosmarinus Officinalis Linn. Molecules, 25(12), 2830. https://doi.org/10.3390/molecules25122830