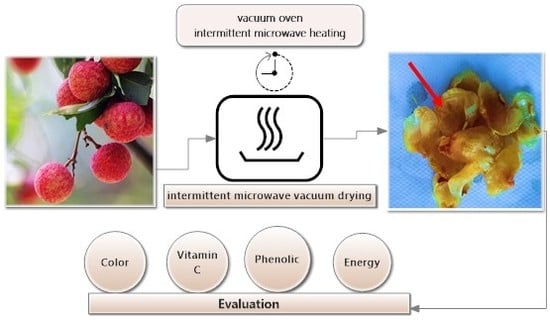

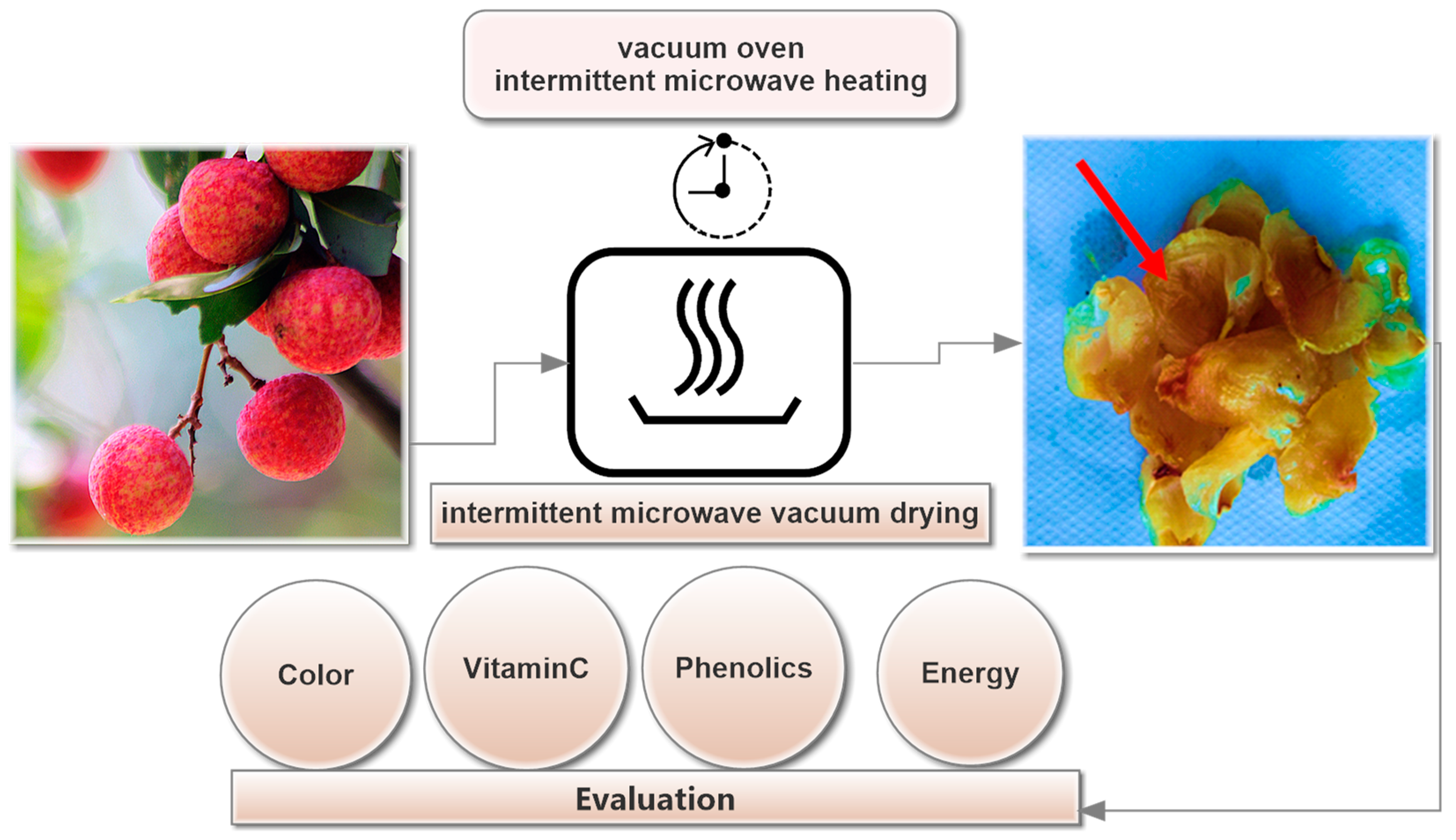

Effect of Intermittent Microwave Volumetric Heating on Dehydration, Energy Consumption, Antioxidant Substances, and Sensory Qualities of Litchi Fruit during Vacuum Drying

Abstract

1. Introduction

2. Results and Discussion

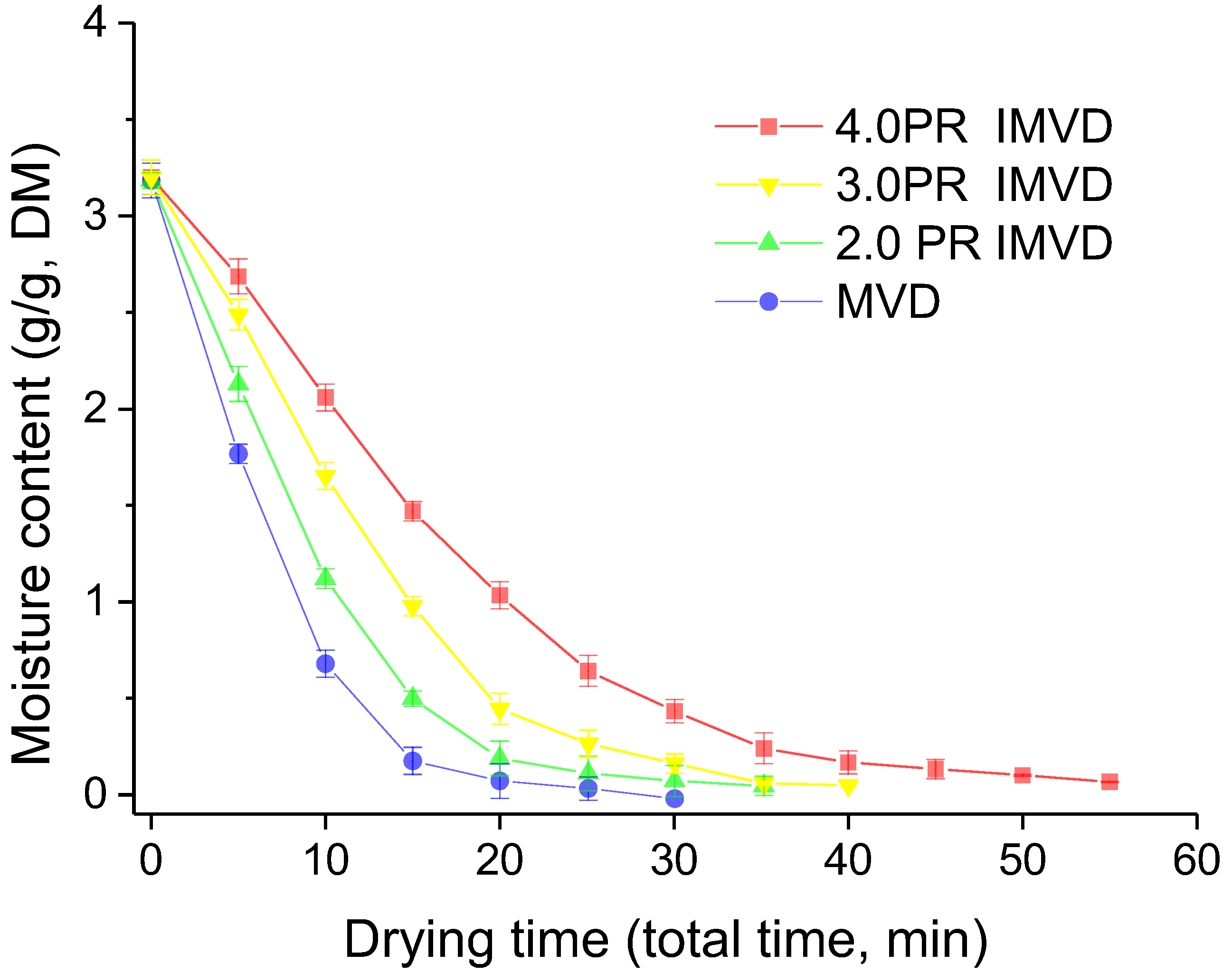

2.1. Water Dynamics

2.2. Drying Time and Energy Consumption

2.3. Color Evaluation

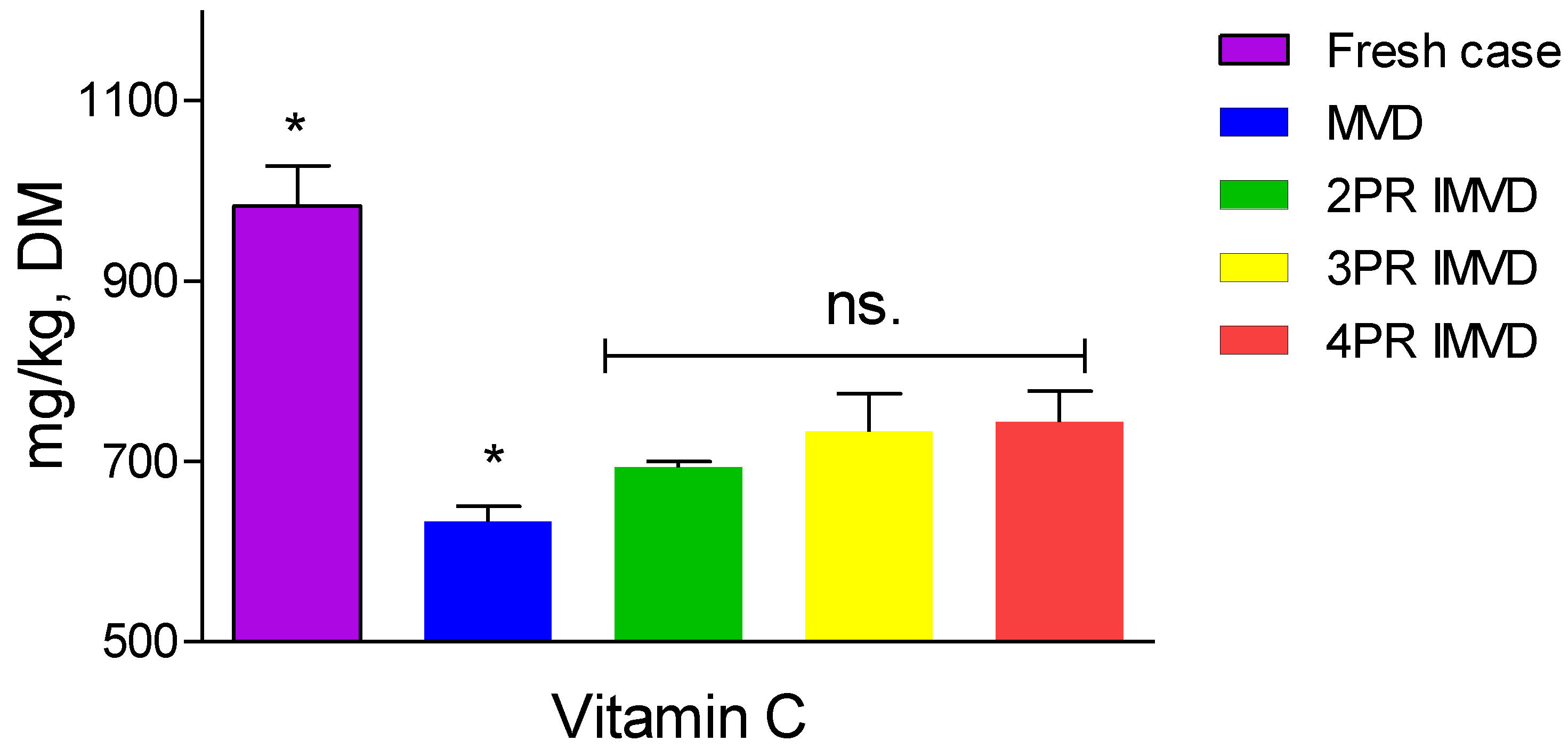

2.4. Vitamin C

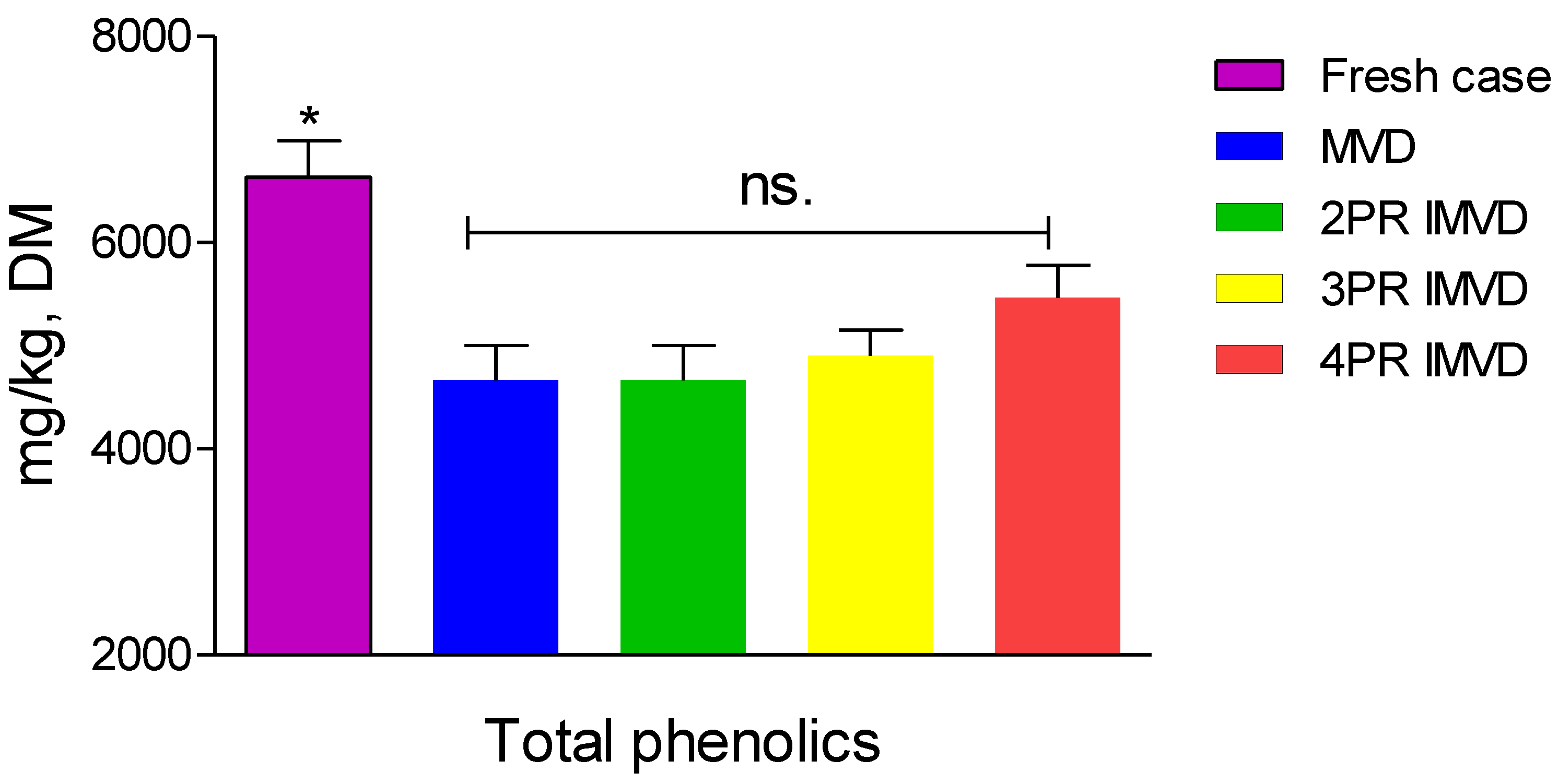

2.5. Total Phenolic Compounds

2.6. Approximate Nutrition

2.7. Sensory Evaluation

3. Materials and Methods

3.1. Materials

3.2. Procedure

3.3. Moisture Content

3.4. Determination of Vitamin C

3.5. Total Phenolic Compounds

3.6. Color Measurement

3.7. Approximate Nutrition

3.8. Energy Consumption

3.9. Sensory Evaluation

3.10. Data Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Duan, X.; Huang, L.L.; Wang, M.M.; Qiao, F.; Fang, C.F. Studies on the effects of microwave power and temperature control on the quality of whole lychee (Litchi chinensis Sonn.) fruit during microwave vacuum drying. J. Food Process. Preserv. 2015, 39, 423–431. [Google Scholar] [CrossRef]

- Song, C.F.; Cui, Z.W.; Jin, G.Y.; Mujumdar, A.S.; Yu, J.F. Effects of four different drying methods on the quality characteristics of peeled litchis (Litchi chinensis Sonn.). Dry. Technol. 2015, 33, 583–590. [Google Scholar] [CrossRef]

- Li, W.; Liang, H.; Zhang, M.W.; Zhang, R.F.; Deng, Y.Y.; Wei, Z.C. Phenolic profiles and antioxidant activity of litchi (Litchi chinensis Sonn.) fruit pericarp from different commercially available cultivars. Molecules 2012, 17, 14954–14967. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Lu, H.; Mo, C.; Yang, Z.; Hohimer, C.J.; Qiu, G. Experiments on the mechanical harvesting of litchi and its effects on litchi storage. Trans. ASABE 2017, 60, 1529–1535. [Google Scholar] [CrossRef]

- Cao, X.H.; Zhang, M.; Fang, Z.X.; Mujumdar, A.S.; Jiang, H.; Qian, H.; Ai, H.Y. Drying kinetics and product quality of green soybean under different microwave drying methods. Dry. Technol. 2017, 35, 240–248. [Google Scholar] [CrossRef]

- Huang, L.L.; Qiao, F.; Peng, G.; Yang, X.T.; Duan, X. Effect of two drying methods on antioxidant activity and hypoglycemic action of polysaccharides in three cultivars of lychee pulp. Dry. Technol. 2017, 35, 1994–2001. [Google Scholar] [CrossRef]

- Huang, F.; Zhang, R.F.; Yi, Y.; Tang, X.J.; Zhang, M.W.; Su, D.X.; Wei, Z.C. Comparison of physicochemical properties and immunomodulatory activity of polysaccharides from fresh and dried litchi pulp. Molecules 2014, 19, 3909–3925. [Google Scholar] [CrossRef]

- Maurya, V.K.; Gothandam, K.M.; Ranjan, V.; Shakya, A.; Pareek, S. Effect of drying methods (microwave vacuum, freeze, hot air and sun drying) on physical, chemical and nutritional attributes of five pepper (Capsicum annuum var. annuum) cultivars. J. Sci. Food Agric. 2017, 98, 3492–3500. [Google Scholar] [CrossRef]

- Martin-Gomez, J.; Varo, M.A.; Merida, J.; Serratosa, M.P. The influence of berry perforation on grape drying kinetic and total phenolic compounds. J. Sci. Food Agric. 2019. [Google Scholar] [CrossRef]

- Melvin, J.F.; Simpson, B. Chemical changes and respiratory drift during the air drying of ryegrass. J. Sci. Food Agric. 2010, 14, 228–234. [Google Scholar] [CrossRef]

- Cao, X.H.; Zhang, M.; Mujumdar, A.S.; Zhong, Q.F.; Wang, Z.S. Effect of microwave freeze drying on quality and energy supply in drying of barley grass. J. Sci. Food Agric. 2018, 98, 1599–1605. [Google Scholar] [CrossRef] [PubMed]

- Cao, X.; Zhang, M.; Chitrakar, B.; Mujumdar, A.S.; Zhong, Q.; Wang, Z.; Wang, L. Radio frequency heating for powder pasteurization of barley grass: Antioxidant substances, sensory quality, microbial load and energy consumption. J. Sci. Food Agric. 2019, 99, 4460–4467. [Google Scholar] [CrossRef] [PubMed]

- Monteiro, R.L.; Link, J.V.; Tribuzi, G.; Carciofi, B.A.; Laurindo, J.B. Effect of multi-flash drying and microwave vacuum drying on the microstructure and texture of pumpkin slices. Lwt Food Sci. Technol. 2018, 96, 612–619. [Google Scholar] [CrossRef]

- Clary, C.D.; Mejia-Meza, E.; Wang, S.; Petrucci, V.E. Improving grape quality using microwave vacuum drying associated with temperature control. J. Food Sci. 2007, 72, e23–e28. [Google Scholar] [CrossRef] [PubMed]

- Chong, C.H.; Figiel, A.; Law, C.L.; Wojdyo, A. Combined drying of apple cubes by using of heat pump, vacuum-microwave, and intermittent techniques. Food Bioprocess. Technol. 2004, 7, 975–989. [Google Scholar] [CrossRef]

- Zhu, Z.S.; Yang, Z.; Wang, F. Experimental research on intermittent heat pump drying with constant and time-variant intermittency ratio. Dry. Technol. 2016, 34, 1630–1640. [Google Scholar] [CrossRef]

- Zhang, Z.J.; Qin, W.C.; Shi, B.; Gao, J.X.; Zhang, S.W. Modelling of intermittent microwave convective drying: Parameter sensitivity. Open Phys. 2017, 15, 405–419. [Google Scholar] [CrossRef]

- Soysal, Y.; Arslan, M.; Keskin, M. Intermittent microwave-convective air drying of oregano. Food Sci. Technol. Int. 2009, 15, 397–406. [Google Scholar] [CrossRef]

- Kumar, C.; Karim, M.A.; Joardder, M.U.H. Intermittent drying of food products: A critical review. J. Food Eng. 2014, 121, 48–57. [Google Scholar] [CrossRef]

- Janjai, S.; Mahayothee, B.; Lamlert, N.; Bala, B.K.; Precoppe, M.; Nagle, M.; Muller, J. Diffusivity, shrinkage and simulated drying of litchi fruit (Litchi chinensis Sonn.). J. Food Eng. 2010, 96, 214–221. [Google Scholar] [CrossRef]

- Lafarga, T.; Bobo, G.; Vinas, I.; Zudaire, L.; Simo, J.; Aguilo-Aguayo, I. Steaming and sous-vide: Effects on antioxidant activity, vitamin C, and total phenolic content of Brassica vegetables. Int. J. Gastron. Food Sci. 2018, 13, 134–139. [Google Scholar] [CrossRef]

- Muzolf-Panek, M.; Kleiber, T.; Kaczmarek, A. Effect of increasing manganese concentration in nutrient solution on the antioxidant activity, vitamin C, lycopene and polyphenol contents of tomato fruit. Food Addit. Contam. Part A Chem. Anal. Control Expo. Risk Assess. 2017, 34, 379–389. [Google Scholar] [CrossRef] [PubMed]

- Pu, H.J.; Li, Z.F.; Hui, J.; Raghavan, G.S.V. Effect of relative humidity on microwave drying of carrot. J. Food Eng. 2016, 190, 167–175. [Google Scholar] [CrossRef]

- Song, F.H.; Li, Z.F.; Raghavan, G.S.V. Combined microwave-hot-air drying of burdock slices with feedback temperature control at surface and core. Dry. Technol. 2017, 35, 1781–1790. [Google Scholar] [CrossRef]

- Xu, W.X.; Song, C.F.; Li, Z.F.; Song, F.H.; Hu, S.G.; Li, J.; Raghauan, G.S.V. Temperature gradient control during microwave combined with hot air drying. Biosyst. Eng. 2018, 169, 175–187. [Google Scholar] [CrossRef]

- Melis, R.; Braca, A.; Mulas, G.; Sanna, R.; Spada, S.; Serra, G.; Anedda, R. Effect of freezing and drying processes on the molecular traits of edible yellow mealworm. Innov. Food Sci. Emerg. Technol. 2018, 48, 138–149. [Google Scholar] [CrossRef]

- Rizzo, V.; Clifford, A.N.; Brown, J.E.; Siracusa, L.; Muratore, G. Effects of processing on the polyphenol and phenolic acid content and antioxidant capacity of semi-dried cherry tomatoes (Lycopersicon esculentum M.). J. Sci. Food Agric. 2016, 96, 2040–2046. [Google Scholar] [CrossRef]

- Chua, L.Y.W.; Chua, B.L.; Figiel, A.; Chong, C.H.; Wojdylo, A.; Szumny, A.; Choong, T.S.Y. Antioxidant activity, and volatile and phytosterol contents of Strobilanthes crispus dehydrated using conventional and vacuum microwave drying methods. Molecules 2019, 24, 1397. [Google Scholar] [CrossRef]

- Chua, L.Y.W.; Chua, B.L.; Figiel, A.; Chong, C.H.; Figiel, A.; Szumny, A.; Chong, C.H.; Wojdylo, A.; Szumny, A.; Lech, K. Characterisation of the convective hot-air drying and vacuum microwave drying of Cassia alata: Antioxidant activity, essential oil volatile composition and quality studies. Molecules 2019, 24, 1625. [Google Scholar] [CrossRef]

- Rodriguez-Jimenez, J.R.; Amaya-Guerra, C.A.; Baez-Gonzalez, J.G.; Aguilera-Gonzalez, C.; Urias-Orona, V.; Nino-Medina, G. Physicochemical, functional, and nutraceutical properties of eggplant flours obtained by different drying methods. Molecules 2018, 23, 3210. [Google Scholar] [CrossRef]

- Ambros, S.; Foerst, P.; Kulozik, U. Temperature-controlled microwave-vacuum drying of lactic acid bacteria: Impact of drying conditions on process and product characteristics. J. Food Eng. 2018, 224, 80–87. [Google Scholar] [CrossRef]

- Azam, S.M.R.; Zhang, M.; Mujumdar, A.S.; Yang, C.H. Study on 3D printing of orange concentrate and material characteristics. J. Food Eng. 2018, 41, e12689. [Google Scholar] [CrossRef]

- Wojdylo, A.; Lech, K.; Nowicka, P.; Hernandez, F.; Figiel, A.; Carbonell-Barrachina, A.A. Influence of different drying techniques on phenolic compounds, antioxidant capacity and colour of Ziziphus jujube Mill. Fruits. Molecules 2019, 24, 2361. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.X.; Duan, Z.H.; Fan, L.P.; Li, J.W. Supercritical CO2 fluid extraction of Elaeagnus mollis diels seed oil and its antioxidant ability. Molecules 2019, 2, 911. [Google Scholar] [CrossRef]

| Drying | Total Time (min) | On-Drying Time Accumulation (min) | Off-Drying Time Accumulation (min) | Energy Consumption (KJ/g) |

|---|---|---|---|---|

| 4.0 PR IMVD | 55 | 15 | 40 | 33.5 ± 1.15 b |

| 3.0 PR IMVD | 40 | 15 | 25 | 32.3 ± 1.11 c |

| 2.0 PR IMVD | 35 | 20 | 15 | 45.5 ± 1.25 b |

| MVD | 30 | 30 | 0 | 65.7 ± 1.21 a |

| Drying/70 °C | PR | L | a | b | ΔE |

|---|---|---|---|---|---|

| Fresh | 52.72 ± 1.44 a | −4.45 ± 0.11 a | 5.55 ± 0.32 a | ||

| On 5 min/off 15 min | 4 | 29.44 ± 1.35 b | 3.31 ± 0.15 b | 8.25 ± 0.44 b | 6.11 ± 0.31 a |

| On 5 min/off 10 min | 3 | 27.72 ± 1.13 b,c | 3.12 ± 0.21 b | 9.55 ± 0.51 c | 7.53 ± 0.42 b |

| On 5 min/off 5 min | 2 | 25.71 ± 1.24 c | 4.44 ± 0.22 c | 10.75 ± 0.55 d | 9.25 ± 0.45 c |

| MVD | 22.62 ± 1.18 d | 5.56 ± 0.25 d | 12.81 ± 0.58 e | 12.11 ± 2.43 d |

| IMVD | Approximate Nutrition of Dried Litchi Fruits Using IMVD (g/100g) | |||||

|---|---|---|---|---|---|---|

| PR | Protein | Glucose | Fructose | Sucrose | Fat | Acid |

| 2.0 | 2.40 ± 0.05 a | 27.65 ± 0.55 a | 21.25 ± 0.23 b | 15.77 ± 0.52 a | 2.57 ± 0.03 a | 2.22 ± 0.05 a |

| 3.0 | 2.55 ± 0.07 a | 28.77 ± 0.21 a | 21.27 ± 0.55 b | 12.52 ± 0.71 b | 2.60 ± 0.03 a | 2.24 ± 0.01 a |

| 4.0 | 2.52 ± 0.03 a | 28.62 ± 0.53 a | 23.17 ± 0.32 c | 13.72 ± 0.73 b | 2.70 ± 0.05 a | 2.21 ± 0.03 a |

| MVD | 1.57 ± 0.03 b | 25.11 ± 0.45 b | 18.68 ± 0.55 a | 11.55 ± 0.41 c | 2.75 ± 0.02 a | 3.12 ± 0.01 b |

| Parameters | IMVD | |||

|---|---|---|---|---|

| MVD | 2 PR | 3 PR | 4 PR | |

| Color | 3.62 ± 0.12 a | 4.12 ± 0.15 a | 4.44 ± 0.12 b | 4.54 ± 0.13 b |

| Hardness | 4.21 ± 0.12 b | 4.24 ± 0.12 a | 4.32 ± 0.12 a | 4.41 ± 0.11 a |

| Bitterness | 2.12 ± 0.15 a | 3.45 ± 0.15 b | 3.25 ± 0.12 b | 3.57 ± 0.13 b |

| Sweet | 4.21 ± 0.13 a | 4.15 ± 0.17 a | 4.25 ± 0.10 a | 4.67 ± 0.12 a |

| Acid | 4.11 ± 0.20 a | 4.34 ± 0.15 a | 4.42 ± 0.17 a | 4.51 ± 0.16 a |

| Average score | 3.64 ± 0.12 a | 4.06 ± 0.13 a | 4.13 ± 0.15 b | 4.34 ± 0.13 b |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, X.; Chen, J.; Islam, M.N.; Xu, W.; Zhong, S. Effect of Intermittent Microwave Volumetric Heating on Dehydration, Energy Consumption, Antioxidant Substances, and Sensory Qualities of Litchi Fruit during Vacuum Drying. Molecules 2019, 24, 4291. https://doi.org/10.3390/molecules24234291

Cao X, Chen J, Islam MN, Xu W, Zhong S. Effect of Intermittent Microwave Volumetric Heating on Dehydration, Energy Consumption, Antioxidant Substances, and Sensory Qualities of Litchi Fruit during Vacuum Drying. Molecules. 2019; 24(23):4291. https://doi.org/10.3390/molecules24234291

Chicago/Turabian StyleCao, Xiaohuang, Jianping Chen, Md. Nahidul Islam, Wanxiu Xu, and Saiyi Zhong. 2019. "Effect of Intermittent Microwave Volumetric Heating on Dehydration, Energy Consumption, Antioxidant Substances, and Sensory Qualities of Litchi Fruit during Vacuum Drying" Molecules 24, no. 23: 4291. https://doi.org/10.3390/molecules24234291

APA StyleCao, X., Chen, J., Islam, M. N., Xu, W., & Zhong, S. (2019). Effect of Intermittent Microwave Volumetric Heating on Dehydration, Energy Consumption, Antioxidant Substances, and Sensory Qualities of Litchi Fruit during Vacuum Drying. Molecules, 24(23), 4291. https://doi.org/10.3390/molecules24234291