Co-Extraction and Co-Purification Coupled with HPLC-DAD for Simultaneous Detection of Acrylamide and 5-hydroxymethyl-2-furfural in Thermally Processed Foods

Abstract

1. Introduction

2. Results and Discussion

2.1. Optimization of HPLC Analytical Conditions

2.2. Co-Extraction of Acrylamide and 5-HMF

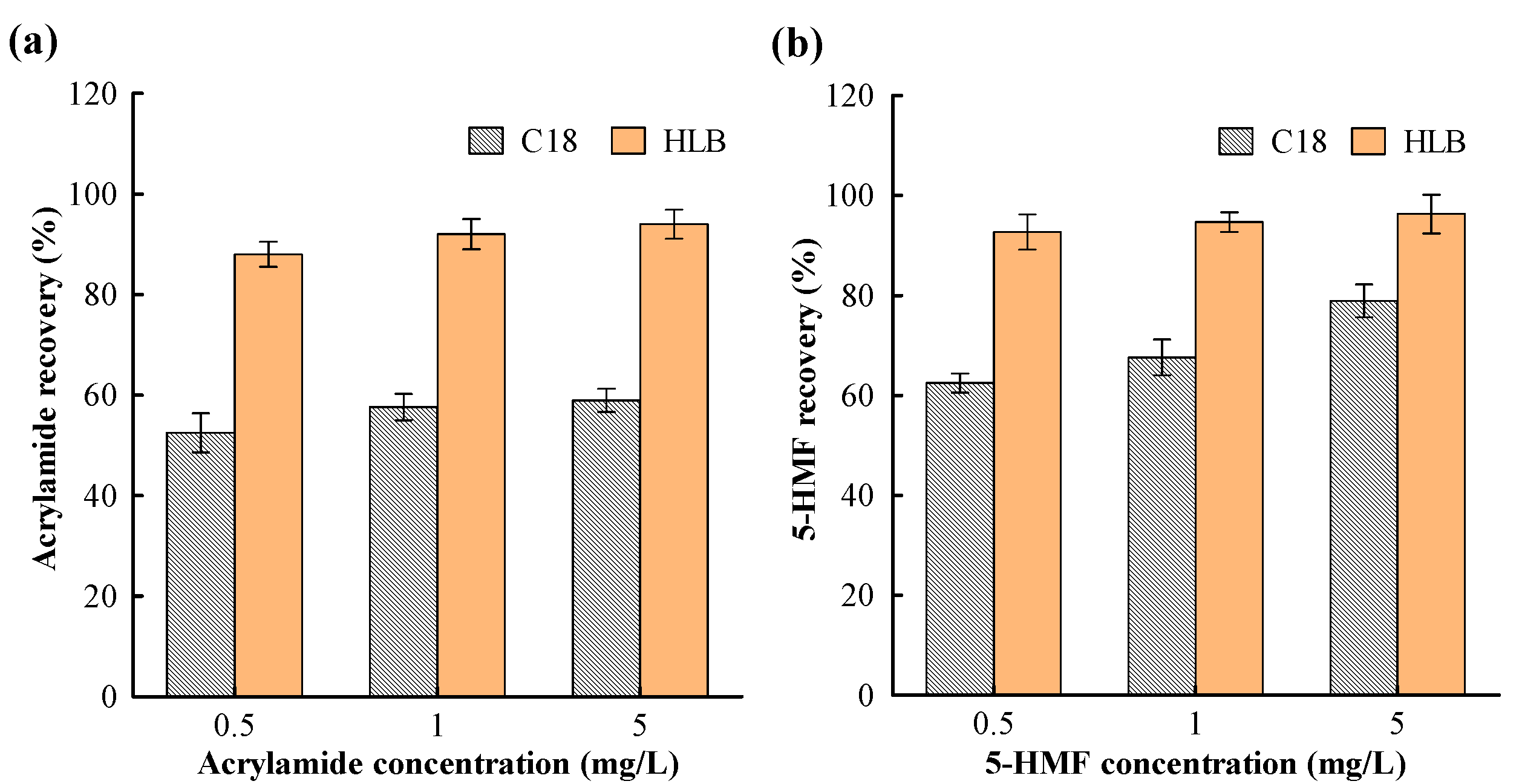

2.3. Co-Purification of Acrylamide and 5-HMF by SPE

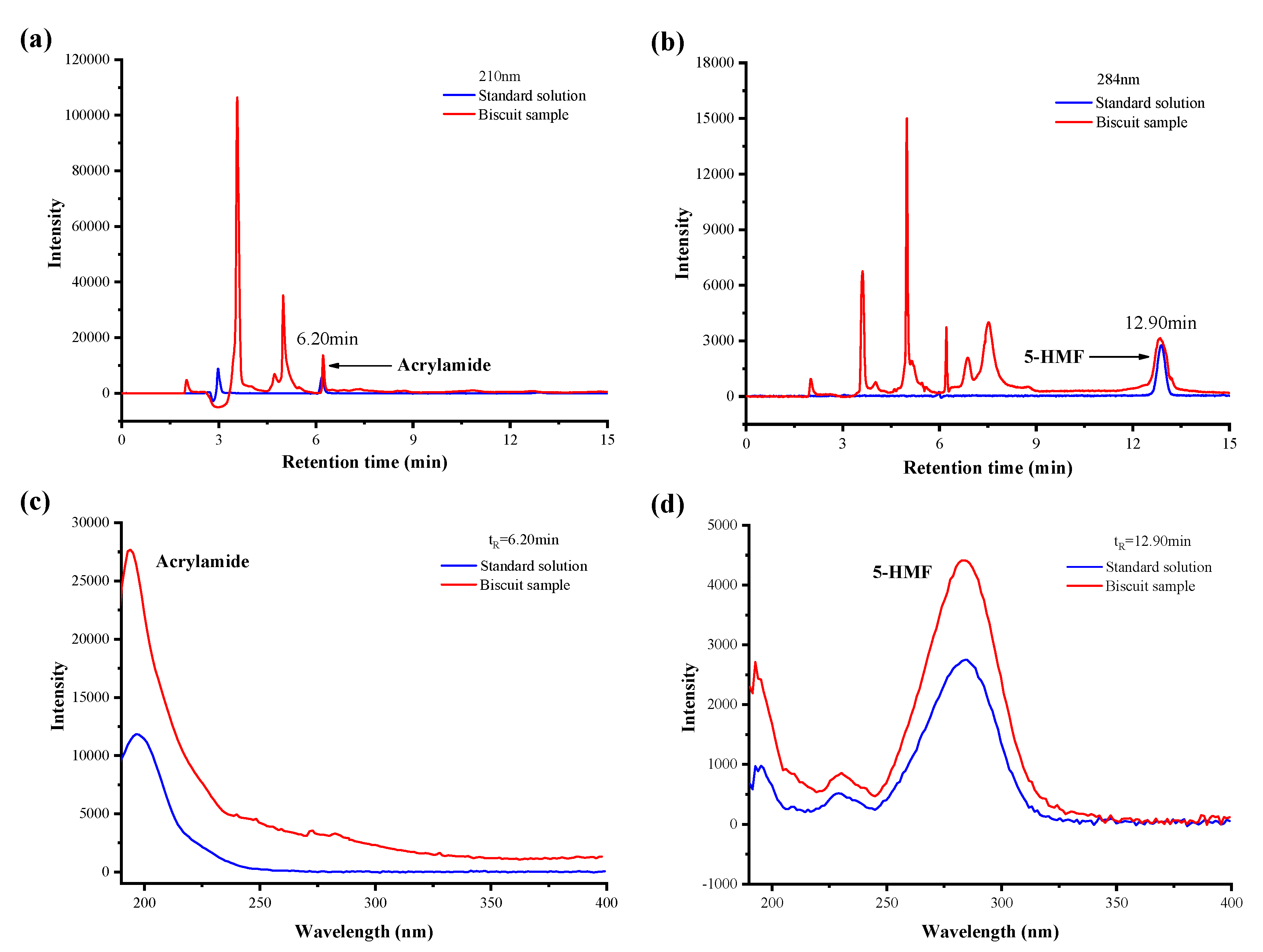

2.4. Application and Evaluation of the Established Method in Thermally Processed Foods

3. Materials and Methods

3.1. Reagents and Materials

3.2. Standards and Solutions Preparation

3.3. Instruments

3.4. Extraction of Acrylamide and 5-hydroxymethyl Furfural

3.5. Purification and Enrichment of Acrylamide and 5-HMF

3.6. Method Recovery in Food Sample

3.7. HPLC-DAD Analysis

3.8. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Vural, G.K.; Senyuva, H.Z. Improved method for the determination of hydroxymethylfurfural in baby foods using liquid chromatography-mass spectrometry. J. Agric. Food Chem. 2006, 54, 2845–2849. [Google Scholar] [CrossRef]

- IARC Working Group on the Evaluation of Carcinogenic Risks to Humans. Diesel and gasoline engine exhausts and some nitroarenes. Iarc monographs on the evaluation of carcinogenic risks to humans. IARC Monogr. Eval. Carcinog. Risks Hum. 2014, 105, 9–699. [Google Scholar] [CrossRef]

- EFSA Panel on Contaminants in the Food Chain (CONTAM). Scientific opinion on acrylamide in food. EFSA J. 2016, 13, 4104. [Google Scholar] [CrossRef]

- Capuano, E.; Fogliano, V. Acrylamide and 5-hydroxymethylfurfural (HMF): A review on metabolism, toxicity, occurrence in food and mitigation strategies. LWT-Food Sci. Technol. 2011, 44, 793–810. [Google Scholar] [CrossRef]

- Stadler, R.H.; Studer, A. Acrylamide Formation Mechanisms. In Acrylamide in Food Analysis, Content and Potential Health Effects; Gökmen, V., Ed.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 1–17. ISBN 0128028327. [Google Scholar]

- Alizadeh, M.; Khodaei, H.; Abbasi, M.M.; Saleh-Ghadimi, S. Assessing the effect of 5-hydroxymethylfurfuralon on selected components of immune responses in mice immunized with ovalbumin: Effect of 5-HMF on immune response. J. Sci. Food Agric. 2017, 97, 3979–3984. [Google Scholar] [CrossRef]

- Rizelio, V.M.; Gonzaga, L.V.; Borges, G.D.C.; Micke, G.A.; Fett, R.; Costa, A.C.O. Development of a fast MECK method for determination of 5-HMF in honey samples. Food Chem. 2012, 133, 1640–1645. [Google Scholar] [CrossRef]

- Locas, C.P.; Yaylayan, V.A. Isotope labeling studies on the formation of 5-(hydroxymethyl)-2-furaldehyde (HMF) from sucrose by pyrolysis-GC/MS. J. Agric. Food Chem. 2008, 56, 6717–6723. [Google Scholar] [CrossRef]

- Ebrary, I.; Organization, W.H. Some industrial chemicals. IARC Monogr. Eval. Carcinog. Risks Hum. 1994, 77. [Google Scholar]

- Kromhout, H. IARC Monographs on the evaluation of carcinogenic risks to humans; dry cleaning, some chlorinated solvents and other industrial chemicals. Cancer Causes Control. 1995, 7, 289–291. [Google Scholar] [CrossRef]

- Ya, B.L.; Li, H.F.; Wang, H.Y.; Wu, F.; Xin, Q.; Cheng, H.J.; Li, W.J.; Lin, N.; Ba, Z.H.; Zhang, R.J.; et al. 5-HMF attenuates striatum oxidative damage via Nrf2/ARE signaling pathway following transient global cerebral ischemia. Cell Stress Chaperones 2017, 22, 55–65. [Google Scholar] [CrossRef]

- Ono, H.; Chuda, Y.; Ohnishi-Kameyama, M.; Yada, H.; Ishizaka, M.; Kobayashi, H.; Yoshida, M. Analysis of acrylamide by LC-MS/MS and GC-MS in processed Japanese foods. Food Addit. Contam. 2003, 20, 215–220. [Google Scholar] [CrossRef] [PubMed]

- Katerina, M.; Lehotay, S.J. Rapid sample preparation method for LC-MS/MS or GC-MS analysis of acrylamide in various food matrices. J. Agric. Food Chem. 2006, 54, 7001–7008. [Google Scholar] [CrossRef]

- Crews, C. Liquid Chromatographic Tandem Mass Spectrometry to Determine Acrylamide in Foods. In Acrylamide in Food Analysis, Content and Potential Health Effects; Gökmen, V., Ed.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 463–479. ISBN 0128028327. [Google Scholar]

- Gökmen, V. Analysis of Acrylamide in Foods with Special Emphasis on Sample Preparation and Gas Chromatography–Mass Spectrometry Detection. In Acrylamide in Food Analysis, Content and Potential Health Effects; Gökmen, V., Ed.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 445–461. ISBN 0128028327. [Google Scholar]

- Troise, A.D.; Fiore, A.; Fogliano, V. Quantitationof Acrylamide in Foods by High-ResolutionMass Spectrometry. J. Agric. Food Chem. 2014, 62, 74–79. [Google Scholar] [CrossRef] [PubMed]

- Molina-Garcia, L.; Santos, C.S.P.; Melo, A.; Fernandes, J.O.; Cunha, S.C.; Casal, S. Acrylamide in Chips and French Fries: A Novel and Simple Method Using Xanthydrol for Its GC-MS Determination. Food Anal. Methods 2015, 8, 1436–1445. [Google Scholar] [CrossRef]

- Batra, B.; Pundir, C.S. Detection of Acrylamide by Biosensors. In Acrylamide in Food Analysis, Content and Potential Health Effects; Gökmen, V., Ed.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 497–505. ISBN 0128028327. [Google Scholar]

- Wu, M.; Chen, W.; Wang, G.; He, P.; Wang, Q. Analysis of acrylamide in food products by microchip electrophoresis with on-line multiple-preconcentration techniques. Food Chem. 2016, 209, 154–161. [Google Scholar] [CrossRef]

- Rufián-Henares, J.A.; García-Villanova, B.; Guerra-Hernández, E. Occurrence of furosine and hydroxymethylfurfural as markers of thermal damage in dehydrated vegetables. Eur. Food Res. Technol. 2008, 228, 249–256. [Google Scholar] [CrossRef]

- Veríssimo, M.I.S.; Gamelas, J.A.F.; Evtuguin, D.V.; Gomes, M.T.S.R. Determination of 5-hydroxymethylfurfural in honey, using headspace-solid-phase microextraction coupled with a polyoxometalate-coated piezoelectric quartz crystal. Food Chem. 2017, 220, 420–426. [Google Scholar] [CrossRef]

- Serra-Cayuela, A.; Castellari, M.; Bosch-Fusté, J.; Riu-Aumatell, M.; Buxaderas, S.; López-Tamames, E. Identification of 5-hydroxymethyl-2-furfural (5-HMF) in Cava sparkling wines by LC-DAD-MS/MS and NMR spectrometry. Food Chem. 2013, 141, 3373–3380. [Google Scholar] [CrossRef]

- Bignardi, C.; Cavazza, A.; Corradini, C. Selected product ion monitoring for quantification of 5-hydroxymethylfurfural in food products by capillary zone electrophoresis-tandem ion trap mass spectrometry. Food Control. 2014, 46, 41–48. [Google Scholar] [CrossRef]

- Huang, Y.; Li, C.; Hu, H.; Wang, Y.; Shen, M.; Nie, S.; Chen, J.; Zeng, M.; Xie, M. Simultaneous Determination of Acrylamide and 5-Hydroxymethylfurfural in Heat-Processed Foods Employing Enhanced Matrix Removal-Lipid as a New Dispersive Solid-Phase Extraction Sorbent Followed by Liquid Chromatography-Tandem Mass Spectrometry. J. Agric. Food Chem. 2019, 67, 5017–5025. [Google Scholar] [CrossRef]

- Jozinovic, A.; Sarkanj, B.; Ackar, D.; Balentic, J.P.; Subaric, D.; Cvetkovic, T.; Ranilovic, J.; Guberac, S.; Babic, J. Simultaneous Determination of Acrylamide and Hydroxymethylfurfural in Extruded Products by LC-MS/MS Method. Molecules 2019, 24, 1971. [Google Scholar] [CrossRef] [PubMed]

- Qin, L.; Zhang, Y.-Y.; Xu, X.-B.; Wang, X.-S.; Liu, H.-W.; Zhou, D.-Y.; Zhu, B.-W.; Thornton, M. Isotope dilution HPLC-MS/MS for simultaneous quantification of acrylamide and 5-hydroxymethylfurfural (HMF) in thermally processed seafood. Food Chem. 2017, 232, 633–638. [Google Scholar] [CrossRef] [PubMed]

- Barber, D.S.; Hunt, J.; LoPachin, R.M.; Ehrich, M. Determination of acrylamide and glycidamide in rat plasma by reversed-phase high performance liquid chromatography. J. Chromatogr. B 2001, 758, 289–293. [Google Scholar] [CrossRef]

- Geng, Z.; Jiang, R.; Chen, M. Determination of acrylamide in starch-based foods by ion-exclusion liquid chromatography. J. Food Compos. Anal. 2008, 21, 178–182. [Google Scholar] [CrossRef]

- Gökmen, V.; Şenyuva, H.Z.; Acar, J.; Sarıoğlu, K. Determination of acrylamide in potato chips and crisps by high-performance liquid chromatography. J. Chromatogr. A 2005, 1088, 193–199. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Templeton, A.C.; Reed, R.A. Quantification of 5-HMF and dextrose in commercial aqueous dextrose solutions. J. Pharm. Biomed. Anal. 2003, 32, 451–459. [Google Scholar] [CrossRef]

- Birlouez-Aragon, I.; Leclere, J.; Quedraogo, C.L.; Birlouez, E.; Grongnet, J.F. The FAST method, a rapid approach of the nutritional quality of heat-treated foods. Nahrung-Food 2001, 45, 201–205. [Google Scholar] [CrossRef]

- Ramirez-Jimenez, A.; Garcia-Villanova, B.; Guerra-Hernandez, E. Hydroxymethylfurfural and methylfurfural content of selected bakery products. Food Res. Int. 2000, 33, 833–838. [Google Scholar] [CrossRef]

- Ramírez-Jiménez, A.; Guerra-Hernández, E.; García-Villanova, B. Browning indicators in bread. J. Agric. Food Chem. 2000, 48, 4176–4181. [Google Scholar] [CrossRef]

- Zhang, H.J.; Wei, L.; Liu, J.B.; Lin, S.Y.; Yuan, Y. Detection of 5-hydroxymethyl-2-furfural Levels in Selected Chinese Foods by Ultra-High-Performance Liquid Chromatograph Analytical Method. Food Anal. Methods 2014, 7, 181–188. [Google Scholar] [CrossRef]

- Adam, B.; Lau, B.-P.Y.; David, L.; Seaman, S.W.; Stephen, H.; Michael, S.; Manoharan, R.; Yves, L. Acrylamide in French fries: Influence of free amino acids and sugars. J. Agric. Food Chem. 2004, 52, 3801–3806. [Google Scholar] [CrossRef]

- Teixido, E.; Santos, F.J.; Puignou, L.; Galceran, M.T. Analysis of 5-hydroxymethylfurfural in foods by gas chromatography-mass spectrometry. J. Chromatogr. A. 2006, 1135, 85–90. [Google Scholar] [CrossRef] [PubMed]

- Han, Z.H.; Gao, J.X.; Wang, X.M.; Wang, W.X.; Dong, J.; Zhang, Y.; Wang, S. Formation and Alterations of the Potentially Harmful Maillard Reaction Products during the Production and Storage of Brown Fermented Milk. Molecules 2019, 24, 272. [Google Scholar] [CrossRef] [PubMed]

| Standard | Linear Equation | R2 | Linear Range (μg/L) | LOD (μg/L) | LOQ (μg/L) |

|---|---|---|---|---|---|

| Acrylamide | Y = 100661.2X + 2159.18 | 0.9999 | 25–5000 | 6.90 | 20.90 |

| 5-HMF | Y = 95429.02X − 817.05 | 0.9999 | 25–5000 | 4.66 | 14.12 |

| Sample. | Acrylamide | 5-HMF | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Original Concn. (μg/kg) | Spiked Concn. (μg/kg) | Detected Concn. (μg/kg) | Recovery (%) | RSD (%) | Original Concn. (μg/kg) | Spiked Concn. (μg/kg) | Detected Concn.(μg/kg) | Recovery (%) | RSD (%) | |

| Biscuits | 378.6 ± 4.38 | 100 | 467.4 ± 6.75 | 88.84 | 1.44 | 739.75 ± 14.89 | 100 | 829.4 ± 8.36 | 89.67 | 1.01 |

| 200 | 562.8 ± 9.61 | 92.14 | 1.71 | 500 | 1220.6 ± 15.1 | 96.17 | 1.24 | |||

| 500 | 862.1 ± 6.73 | 96.70 | 0.78 | 1000 | 1686.9 ± 18.2 | 94.72 | 1.08 | |||

| Bread | 186.2 ± 5.40 | 100 | 275.8 ± 3.84 | 89.69 | 1.39 | 1885.67 ± 16.52 | 100 | 1971.4 ± 15.8 | 85.68 | 0.80 |

| 200 | 375.9 ± 5.81 | 94.87 | 1.55 | 500 | 2351.8 ± 12.9 | 93.22 | 0.55 | |||

| 500 | 666.3 ± 9.91 | 96.03 | 1.49 | 1000 | 2813.3 ± 18.6 | 92.76 | 0.66 | |||

| Chinese Doughnut | 173.3 ± 7.11 | 100 | 264.1 ± 8.86 | 90.78 | 3.35 | 419.42 ± 14.25 | 100 | 507.6 ± 6.88 | 88.22 | 1.36 |

| 200 | 348.8 ± 7.22 | 87.72 | 2.07 | 500 | 894.6 ± 7.04 | 95.03 | 0.79 | |||

| 500 | 633.2 ± 6.88 | 91.97 | 1.09 | 1000 | 1359.8 ± 9.92 | 94.04 | 0.73 | |||

| Breakfast Cereals | 284.8 ± 4.11 | 100 | 376.1 ± 5.09 | 91.29 | 1.35 | 1166.50 ± 14.51 | 100 | 1253.3 ± 10.3 | 86.75 | 0.82 |

| 200 | 473.8 ± 3.73 | 94.48 | 0.79 | 500 | 1626.8 ± 11.6 | 92.07 | 0.71 | |||

| 500 | 762.5 ± 6.92 | 95.54 | 0.91 | 1000 | 2109.8 ± 12.7 | 94.33 | 0.60 | |||

| Milk-Based Baby Food | 100.2 ± 0.69 | 100 | 192.5 ± 5.07 | 92.31 | 2.63 | 194.58 ± 5.28 | 100 | 287.9 ± 8.10 | 93.35 | 2.81 |

| 200 | 290.1 ± 3.16 | 94.92 | 1.09 | 500 | 648.6 ± 8.61 | 90.80 | 1.33 | |||

| 500 | 579.1 ± 8.17 | 95.77 | 1.41 | 1000 | 1114.4 ± 13.2 | 91.98 | 1.18 | |||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, J.; Shao, Z.; Li, H.; Zhang, Y.; Wang, S. Co-Extraction and Co-Purification Coupled with HPLC-DAD for Simultaneous Detection of Acrylamide and 5-hydroxymethyl-2-furfural in Thermally Processed Foods. Molecules 2019, 24, 3734. https://doi.org/10.3390/molecules24203734

Shi J, Shao Z, Li H, Zhang Y, Wang S. Co-Extraction and Co-Purification Coupled with HPLC-DAD for Simultaneous Detection of Acrylamide and 5-hydroxymethyl-2-furfural in Thermally Processed Foods. Molecules. 2019; 24(20):3734. https://doi.org/10.3390/molecules24203734

Chicago/Turabian StyleShi, Jiaqi, Zeping Shao, Honglei Li, Yan Zhang, and Shuo Wang. 2019. "Co-Extraction and Co-Purification Coupled with HPLC-DAD for Simultaneous Detection of Acrylamide and 5-hydroxymethyl-2-furfural in Thermally Processed Foods" Molecules 24, no. 20: 3734. https://doi.org/10.3390/molecules24203734

APA StyleShi, J., Shao, Z., Li, H., Zhang, Y., & Wang, S. (2019). Co-Extraction and Co-Purification Coupled with HPLC-DAD for Simultaneous Detection of Acrylamide and 5-hydroxymethyl-2-furfural in Thermally Processed Foods. Molecules, 24(20), 3734. https://doi.org/10.3390/molecules24203734