Determination of Various Drying Methods’ Impact on Odour Quality of True Lavender (Lavandula angustifolia Mill.) Flowers

Abstract

1. Introduction

2. Results and Discussion

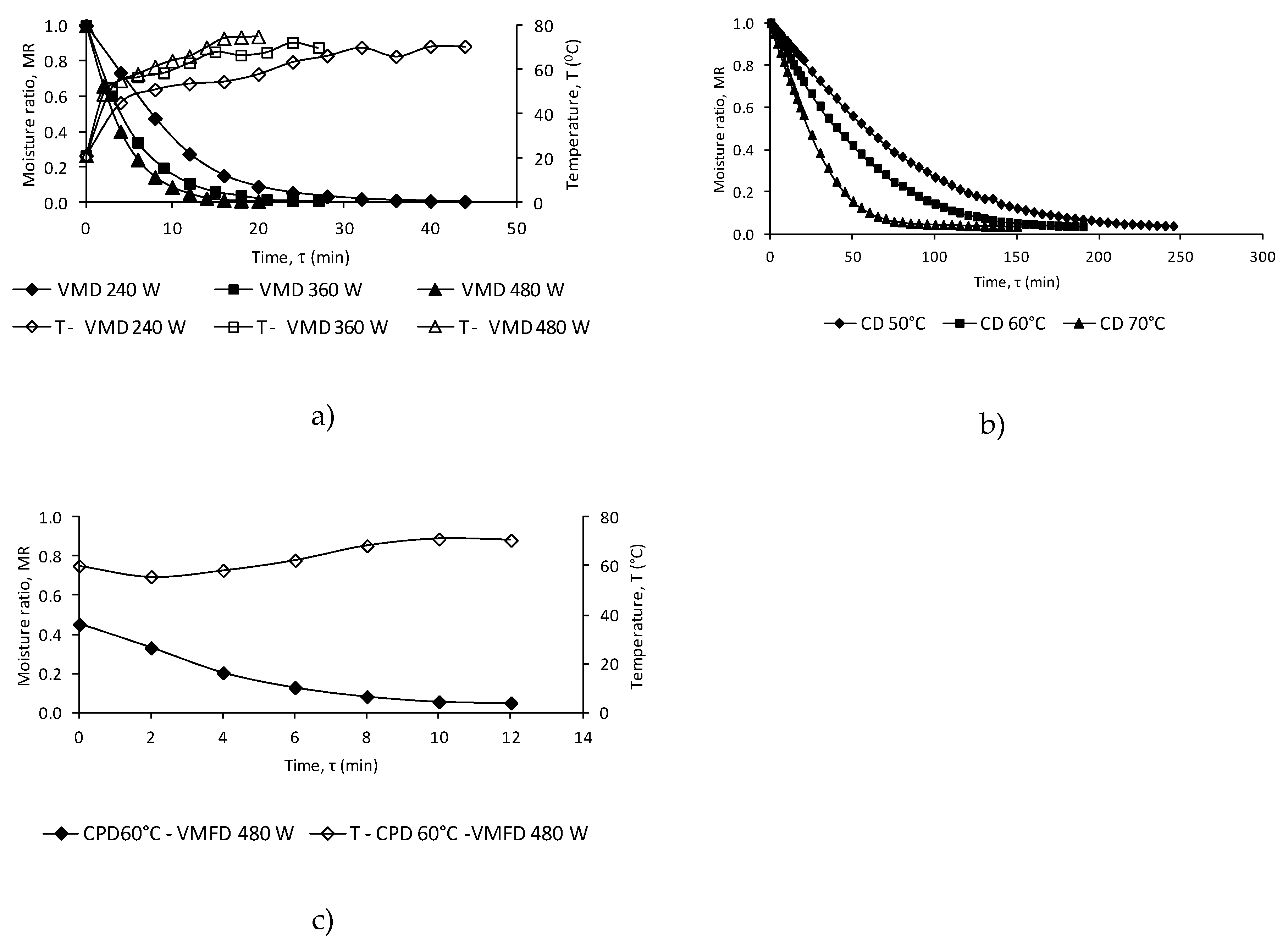

2.1. Drying Kinetics

2.2. Volatile Profile of True Lavender Flowers Cultivated in Poland

2.3. Influence of Various Drying Techniques on the Quality of True Lavender Flowers Cultivated in Poland

2.4. Odour-Active Compound Determination and Sensory Value of True Lavender Flowers Affected by Various Drying Methods

3. Materials and Methods

3.1. Plant Material

3.2. Drying Methods

3.3. Modelling of Drying Kinetics

3.4. Hydrodistillation of EO

3.5. EO GC-MS Analysis

3.6. Headspace Solid-Phase Microextraction (HS-SPME)

3.7. Identification and Quantification of Volatile Compounds and EO Constituents

3.8. Determination of Odour-Active Compounds of True Lavender Flowers

3.9. Sensory Evaluation

3.10. Statistical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Aprotosoaie, A.C.; Gille, E.; Trifan, A.; Luca, V.S.; Miron, A. Essential oils of Lavandula genus: a systematic review of their chemistry. Phytochem. Rev. 2017, 16, 761–799. [Google Scholar] [CrossRef]

- Lavender. The genus Lavandula; Lis-Balchin, M., Ed.; Taylor & Francis: London, UK, 2002; ISBN 0415284864. [Google Scholar]

- Angelini, L.G.; Najar, B.; Pistelli, L.; Tavarini, S.; Giovanelli, S.; Lorenzini, L. Agronomic and phytochemical evaluation of lavandin and lavender cultivars cultivated in the Tyrrhenian area of Tuscany (Italy). Ind. Crops Prod. 2017, 109, 37–44. [Google Scholar]

- KORKUNÇ, M. Research of Lavender Plant Propagation in the Province of Diyarbakir. Middle East J. Sci. 2018, 4, 58–65. [Google Scholar] [CrossRef]

- Preedy, V.R. (Ed.) Essential Oils in Food Preservation, Flavor and Safety; Academic Press: London, UK, 2016; ISBN 9780124166417. [Google Scholar]

- Stanev, S.; Zagorcheva, T.; Atanassov, I. Lavender Cultivation in Bulgaria - 21St Century Developments, Breeding. Bulg. J. Agric. Sci. 2016, 22, 584–590. [Google Scholar]

- Junaid, M.; Subhan, F.; Sadiq, A.; Ullah, F.; Ahmed, J.; Ayaz, M. Neuroprotective and Anti-Aging Potentials of Essential Oils from Aromatic and Medicinal Plants. Front. Aging Neurosci. 2017, 9, 1–16. [Google Scholar]

- López, V.; Nielsen, B.; Solas, M.; Ramírez, M.J.; Jäger, A.K. Exploring pharmacological mechanisms of lavender (Lavandula angustifolia) essential oil on central nervous system targets. Front. Pharmacol. 2017, 8, 1–8. [Google Scholar] [CrossRef]

- Kunicka-Styczyńska, A.; Śmigielski, K.; Prusinowska, R.; Rajkowska, K.; Kuśmider, B.; Sikora, M. Preservative activity of lavender hydrosols in moisturizing body gels. Lett. Appl. Microbiol. 2014, 60, 27–32. [Google Scholar] [CrossRef]

- Lesage-Meessen, L.; Bou, M.; Sigoillot, J.-C.; Faulds, C.B.; Lomascolo, A. Essential oils and distilled straws of lavender and lavandin: a review of current use and potential application in white biotechnology. Appl. Microbiol. Biotechnol. 2015, 99, 3375–3385. [Google Scholar] [CrossRef]

- Tomi, K.; Kitao, M.; Murakami, H.; Matsumura, Y.; Hayashi, T. Classification of lavender essential oils: sedative effects of Lavandula oils. J. Essent. Oil Res. 2018, 30, 56–68. [Google Scholar] [CrossRef]

- Ali, B.; Al-Wabel, N.A.; Shams, S.; Ahamad, A.; Khan, S.A.; Anwar, F. Essential oils used in aromatherapy: A systemic review. Asian Pac. J. Trop. Biomed. 2015, 5, 601–611. [Google Scholar] [CrossRef]

- Prusinowska, R.; Śmigielski, K.; Stobiecka, A.; Kunicka-Styczyńska, A. Hydrolates from lavender (Lavandula angustifolia) - Their chemical composition as well as aromatic, antimicrobial and antioxidant properties. Nat. Prod. Res. 2016, 30, 386–393. [Google Scholar] [CrossRef]

- Cesur Turgut, A.; Emen, F.M.; Seçilmiş Canbay, H.; Demirdöğen, R.E.; Çam, N.; Kılıç, D.; Yeşilkaynak, T. Chemical characterization of Lavandula angustifolia Mill. which is a phytocosmetic species and investigation of its antimicrobial effect in cosmetic products. J. Turkish Chem. Soc. Sect. A Chem. 2017, 4, 283. [Google Scholar] [CrossRef]

- Carvalho, I.T.; Estevinho, B.N.; Santos, L. Application of microencapsulated essential oils in cosmetic and personal healthcare products - A review. Int. J. Cosmet. Sci. 2016, 38, 109–119. [Google Scholar] [CrossRef]

- Aramachi, N.; Inaba, T.; Sasaki, J.; Yamanouch, K.; Arima, H.; Nagaki, M. Antibacterial Effect of Lavender (Lavandula) Flavor (Volatile). J. Food Sci. Eng. 2016, 5. [Google Scholar]

- Sangsuwan, J.; Pongsapakworawat, T.; Bangmo, P.; Sutthasupa, S. Effect of chitosan beads incorporated with lavender or red thyme essential oils in inhibiting Botrytis cinerea and their application in strawberry packaging system. LWT - Food Sci. Technol. 2016, 74, 14–20. [Google Scholar] [CrossRef]

- Özogul, F.; Tugce Aksun, E.; Öztekin, R.; Lorenzo, J.M. Effect of lavender and lemon balm extracts on fatty acid profile, chemical quality parameters and sensory quality of vacuum packaged anchovy (Engraulis encrasicolus) fillets under refrigerated condition. LWT - Food Sci. Technol. 2017, 84, 529–535. [Google Scholar] [CrossRef]

- Zhu, G.; Xiao, Z.; Zhou, R.; Feng, N. Production of a transparent lavender flavour nanocapsule aqueous solution and pyrolysis characteristics of flavour nanocapsule. J. Food Sci. Technol. 2014, 52, 4607–4612. [Google Scholar] [CrossRef]

- Farmakopea Polska VII; Urząd Rejestracji Produktów Leczniczych, Wyrobów Medycznych i Produktów Biobójczych: Warszawa, Poland, 2008.

- Prusinowska, R.; Śmigielski, K.B. Composition, biological properties and therapeutic effects of lavender (Lavandula angustifolia L). A review. Herba Pol. 2014, 60, 56–66. [Google Scholar] [CrossRef]

- Başer, K.H.C.; Gerhard, B. (Eds.) Handbook of Essential Oils. Science, Technology, and Applications, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2016; ISBN 9781466590472. [Google Scholar]

- Figiel, A.; Michalska, A. Overall quality of fruits and vegetables products affected by the drying processes with the assistance of vacuum-microwaves. Int. J. Mol. Sci. 2017, 18. [Google Scholar] [CrossRef]

- Rocha, R.P. Influence of drying process on the quality of medicinal plants: A review. J. Med. Plants Res. 2012, 5, 7076–7084. [Google Scholar] [CrossRef]

- Łyczko, J.; Jałoszyński, K.; Surma, M.; Masztalerz, K.; Szumny, A. HS-SPME Analysis of True Lavender (Lavandula angustifolia Mill.) Leaves Treated by Various Drying Methods. Molecules 2019, 24, 764. [Google Scholar] [CrossRef]

- Motevali, A.; Younji, S.; Chayjan, R.A.; Aghilinategh, N.; Banakar, A. Drying kinetics of dill leaves in a convective dryer. Int. Agrophysics 2013, 27, 39–47. [Google Scholar] [CrossRef]

- Politowicz, J.; Lech, K.; Sánchez-Rodríguez, L.; Szumny, A.; Carbonell-Barrachina, Á.A. Volatile composition and sensory profile of Cantharellus cibarius Fr. as affected by drying method. J. Sci. Food Agric. 2017, 97, 5223–5232. [Google Scholar] [CrossRef]

- Politowicz, J.; Lech, K.; Sánchez-Rodríguez, L.; Figiel, A.; Szumny, A.; Grubor, M.; Carbonell-Barrachina, Á.A. Volatile composition and sensory profile of oyster mushroom as affected by drying method. Dry. Technol. 2018, 36, 685–696. [Google Scholar] [CrossRef]

- Lech, K.; Figiel, A.; Wojdyło, A.; Korzeniowska, M.; Serowik, M.; Szarycz, M. Drying Kinetics and Bioactivity of Beetroot Slices Pretreated in Concentrated Chokeberry Juice and Dried with Vacuum Microwaves. Dry. Technol. 2015, 33, 1644–1653. [Google Scholar] [CrossRef]

- Nöfer, J.; Lech, K.; Figiel, A.; Szumny, A.; Carbonell-Barrachina, Á.A. The Influence of Drying Method on Volatile Composition and Sensory Profile of Boletus edulis. J. Food Qual. 2018, 2018, 1–11. [Google Scholar] [CrossRef]

- Figiel, A. Drying kinetics and quality of beetroots dehydrated by combination of convective and vacuum-microwave methods. J. Food Eng. 2010, 98, 461–470. [Google Scholar] [CrossRef]

- Calín-Sánchez, Á.; Figiel, A.; Wojdyło, A.; Szarycz, M.; Carbonell-Barrachina, Á.A. Drying of Garlic Slices Using Convective Pre-drying and Vacuum-Microwave Finishing Drying: Kinetics, Energy Consumption, and Quality Studies. Food Bioprocess Technol. 2014, 7, 398–408. [Google Scholar] [CrossRef]

- Calín-Sanchez, Á.; Figiel, A.; Szarycz, M.; Lech, K.; Nuncio-Jáuregui, N.; Carbonell-Barrachina, Á.A. Drying Kinetics and Energy Consumption in the Dehydration of Pomegranate (Punica granatum L.) Arils and Rind. Food Bioprocess Technol. 2013, 7, 2071–2083. [Google Scholar] [CrossRef]

- Śmigielski, K.; Prusinowska, R.; Stobiecka, A.; Kunicka-Styczyñska, A.; Gruska, R. Biological Properties and Chemical Composition of Essential Oils from Flowers and Aerial Parts of Lavender (Lavandula angustifolia). J. Essent. Oil-Bearing Plants 2018, 21, 1303–1314. [Google Scholar] [CrossRef]

- Adams, R.P. Identification of essential oils by ion trap mass spectroscopy; Academic Press: San Diego, CA, USA, 2012. [Google Scholar]

- Da Porto, C.; Decorti, D. Analysis of the volatile compounds of flowers and essential oils from Lavandula angustifolia cultivated in northeastern Italy by headspace solid-phase microextraction coupled to gas chromatography-mass spectrometry. Planta Med. 2008, 74, 182–187. [Google Scholar] [CrossRef]

- Fu, J.; Zhao, J.; Zhu, Y.; Tang, J. Rapid Analysis of the Essential Oil Components in Dried Lavender by Magnetic Microsphere-Assisted Microwave Distillation Coupled with HS-SPME Followed by GC-MS. Food Anal. Methods 2017, 10, 2373–2382. [Google Scholar] [CrossRef]

- Marín, I.; Sayas-Barberá, E.; Viuda-Martos, M.; Navarro, C.; Sendra, E. Chemical Composition, Antioxidant and Antimicrobial Activity of Essential Oils from Organic Fennel, Parsley, and Lavender from Spain. Foods 2016, 5, 18. [Google Scholar] [CrossRef]

- Hajhashemi, V.; Ghannadi, A.; Sharif, B. Anti-inflammatory and analgesic properties of the leaf extracts and essential oil of Lavandula angustifolia Mill. J. Ethnopharmacol. 2003, 89, 67–71. [Google Scholar] [CrossRef]

- Dušková, E.; Dušek, K.; Indrák, P.; Smékalová, K. Postharvest changes in essential oil content and quality of lavender flowers. Ind. Crops Prod. 2016, 79, 225–231. [Google Scholar] [CrossRef]

- El-Zaeddi, H.; Martínez-Tomé, J.; Calín-Sánchez, Á.; Burló, F.; Carbonell-Barrachina, Á. Volatile Composition of Essential Oils from Different Aromatic Herbs Grown in Mediterranean Regions of Spain. Foods 2016, 5, 41. [Google Scholar] [CrossRef]

- Chua, L.Y.W.; Chua, B.L.; Figiel, A.; Chong, C.H.; Wojdyło, A.; Szumny, A.; Łyczko, J. Drying of Phyla nodiflora Leaves: Antioxidant Activity, Volatile and Phytosterol Content, Energy Consumption, and Quality Studies. Processes 2019, 7, 210. [Google Scholar] [CrossRef]

- Bettaieb, I.; Berrima, S.; Limam, F.; Marzouk, B.; Chahed, T.; Sellami, I.H.; Wannes, W.A. Qualitative and quantitative changes in the essential oil of Laurus nobilis L. leaves as affected by different drying methods. Food Chem. 2010, 126, 691–697. [Google Scholar]

- Carneiro, N.S.; Alves, C.C.F.; Alves, J.M.; Egea, M.B.; Martins, C.H.G.; Silva, T.S.; Bretanha, L.C.; Balleste, M.P.; Micke, G.A.; Silveira, E.V.; et al. Chemical composition, antioxidant and antibacterial activities of essential oils from leaves and flowers of Eugenia klotzschiana Berg (Myrtaceae). An. Acad. Bras. Cienc. 2017, 89, 1907–1915. [Google Scholar] [CrossRef]

- Orphanides, A.; Goulas, V.; Botsaris, G.; Gekas, V. Influence of Air-Drying on the Quality Characteristics of Spearmint: Effects of Air Temperature and Velocity. J. Food Process. Preserv. 2017, 41. [Google Scholar] [CrossRef]

- El-Kalamouni, C.; Venskutonis, P.; Zebib, B.; Merah, O.; Raynaud, C.; Talou, T. Antioxidant and Antimicrobial Activities of the Essential Oil of Achillea millefolium L. Grown in France. Medicines 2017, 4, 30. [Google Scholar] [CrossRef]

- Nekoei, M.; Mohammadhosseini, M. Chemical Compositions of the Essential Oils from the Aerial Parts of Achillea wilhelmsii Using Traditional Hydrodistillation, Microwave Assisted Hydro- distillation and Solvent-Free Microwave Extraction Methods: Comparison with the Volatile Compounds Obta. J. Essent. Oil-Bearing Plants 2016, 19, 59–75. [Google Scholar] [CrossRef]

- Prusinowska, R.; Śmigielski, K. Losses of essential oils and antioxidants during the drying of herbs and spices. A review. Eng. Sci. Technol. 2015, 2. [Google Scholar] [CrossRef][Green Version]

- Sadowska, U. The Influence of the Lavender and Lavendine Drying Method On the Plant Material Quality. J. Res. Appl. Agric. Eng. 2012, 57, 83–85. [Google Scholar]

- Figiel, A.; Szumny, A.; Gutiérrez-Ortíz, A.; Carbonell-Barrachina, Á.A. Composition of oregano essential oil (Origanum vulgare) as affected by drying method. J. Food Eng. 2010, 98, 240–247. [Google Scholar] [CrossRef]

- Wen Chua, L.Y.; Chua, B.L.; Figiel, A.; Chong, C.H.; Wojdyło, A.; Szumny, A.; Lech, K. Characterisation of the convective hot-air drying and vacuum microwave drying of Cassia alata: Antioxidant activity, essential oil volatile composition and quality studies. Molecules 2019, 1–20. [Google Scholar]

- Xiao, Z.; Li, Q.; Niu, Y.; Zhou, X.; Liu, J.; Xu, Y.; Xu, Z. Odor-active compounds of different lavender essential oils and their correlation with sensory attributes. Ind. Crops Prod. 2017, 108, 748–755. [Google Scholar] [CrossRef]

- Burdock, G.A. Fenaroli’s Handbook of Flavor Ingredients, 6th ed.; CRC Press: Boca Raton, FL, USA, 2010; ISBN 0849330343. [Google Scholar]

- The Good Scents Company. Available online: http://www.thegoodscentscompany.com (accessed on 8 June 2019).

- Beale, D.J.; Morrison, P.D.; Karpe, A.V.; Dunn, M.S. Chemometric analysis of lavender essential oils using targeted and untargeted GC-MS acquired data for the rapid identification and characterization of oil quality. Molecules 2017, 22. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Kianmehr, M.H.; Samimi-Akhijahani, H. Influence of drying conditions on the effective moisture diffusivity, energy of activation and energy consumption during the thin-layer drying of berberis fruit (Berberidaceae). Energy Convers. Manag. 2008, 49, 2865–2871. [Google Scholar] [CrossRef]

- Alibas, I. Characteristics of chard leaves during microwave, convective, and combined microwave-convective drying. Dry. Technol. 2006, 24, 1425–1435. [Google Scholar] [CrossRef]

- Dadali, G.; Apar, D.K.; Özbek, B. Microwave drying kinetics of okra. Dry. Technol. 2007, 25, 917–924. [Google Scholar] [CrossRef]

- Szumny, A.; Figiel, A.; Gutiérrez-Ortíz, A.; Carbonell-Barrachina, Á.A. Composition of rosemary essential oil (Rosmarinus officinalis) as affected by drying method. J. Food Eng. 2010, 97, 253–260. [Google Scholar] [CrossRef]

- Meilgaard, M.C.; Civille, G.V.; Carr, B.T. Sensory Evaluation Techniques, 5th ed.; CRC Press: Boca Raton, FL, USA, 2016; ISBN 0962-1067. [Google Scholar]

- International Standard Organization. Sensory analysis—General guidance for the selection, training and monitoring of assessors—Part 1: Selected assessors; ISO 8586-1:1993.

| Drying Conditions | A | Constants k | n | R2 | RMSE | τ | τ1 | T(°C) | Mfwb (%) |

|---|---|---|---|---|---|---|---|---|---|

| CD 50 °C | 1 | 0.0063 | 1.154 | 0.9998 | 0.0049 | 245 | - | 50 | 7.72 |

| CD 60 °C | 1 | 0.0118 | 1.103 | 0.9997 | 0.0062 | 190 | - | 60 | 7.26 |

| CD 70 °C | 1 | 0.0181 | 1.150 | 0.9976 | 0.0193 | 150 | - | 70 | 7.79 |

| VMD 240 W | 1 | 0.0544 | 1.263 | 0.9995 | 0.0071 | - | 44 | 64 | 6.81 |

| VMD 360 W | 1 | 0.1619 | 1.049 | 0.9999 | 0.0033 | - | 27 | 73 | 7.01 |

| VMD 480 W | 1 | 0.1972 | 1.097 | 0.9999 | 0.0025 | - | 20 | 75 | 6.94 |

| CPD 60 °C - VMFD 480 W | 0.45 | 0.2244 | 1.111 | 0.9998 | 0.0072 | 60 | 12 | 71 | 6.91 |

| Compound | RT [min] | Retention Indices (RI) | Content4 [%] | The Match Fitting Score of Obtained Mass Spectra to Mass Spectra Available in Data Base [%] | ||

|---|---|---|---|---|---|---|

| RI_exp1 | RI_lit2 | RI_lit3 | ||||

| cis-3-Hexenal | 3.75 | 801 | 800 | 797 | tr5 | 91 |

| cis-3-Hexen-1-ol | 4.83 | 853 | 857 | 850 | tr | 94 |

| 1-Hexanol | 5.09 | 865 | 868 | 863 | tr | 89 |

| α-Thujene | 6.59 | 927 | 929 | 924 | tr | 96 |

| α-Pinene | 6.79 | 934 | 937 | 932 | 0.06 ± 0.02 | 97 |

| Camphene | 7.22 | 949 | 952 | 946 | 0.05 ± 0.01 | 95 |

| Sabinene | 7.90 | 973 | 974 | 969 | tr | 94 |

| 1-Octen-3-ol | 8.03 | 977 | 979 | 974 | 0.13 ± 0.06 | 97 |

| Octan-3-one | 8.24 | 984 | 986 | 979 | 0.50 ± 0.10 | 97 |

| β-Myrcene | 8.42 | 991 | 991 | 988 | 0.23 ± 0.03 | 97 |

| 3-Octanol | 8.53 | 995 | 994 | 988 | 0.05 ± 0.01 | 93 |

| α-Phellandrene | 8.86 | 1005 | 1005 | 1002 | tr | 88 |

| Hexyl acetate | 9.09 | 1012 | 1011 | 1007 | 0.17 ± 0.05 | 97 |

| o-Cymene | 9.39 | 1021 | 1022 | 1022 | tr | 93 |

| p-Cymene | 9.48 | 1024 | 1025 | 1020 | 0.08 ± 0.01 | 95 |

| Limonene | 9.61 | 1028 | 1030 | 1024 | 0.14 ± 0.02 | 91 |

| Eucalyptol | 9.70 | 1030 | 1032 | 1026 | 0.24 ± 0.10 | 96 |

| cis-β-Ocimene | 9.90 | 1037 | 1037 | 1032 | 4.97 ± 0.74 | 94 |

| trans-β-Ocimene | 10.20 | 1046 | 1048 | 1044 | 3.99 ± 0.11 | 97 |

| γ-Terpinene | 10.58 | 1058 | 1060 | 1054 | 0.21 ± 0.08 | 96 |

| cis-Sabinene hydrate | 10.88 | 1067 | 1070 | 1065 | 0.21 ± 0.04 | 91 |

| cis-Linalool oxide | 11.06 | 1072 | 1074 | 1067 | tr | 94 |

| Terpinolene | 11.62 | 1089 | 1088 | 1086 | tr | 90 |

| Linalool | 11.93 | 1099 | 1099 | 1095 | 8.95 ± 0.48 | 95 |

| 1-Octen-3-ol acetate | 12.40 | 1113 | 1111 | 1110 | 1.57 ± 0.20 | 96 |

| 3-Octanol acetate | 12.78 | 1123 | 1124 | 1120 | 0.31 ± 0.05 | 85 |

| Cosmene | 13.05 | 1032 | 1031 | - | tr | 91 |

| Camphor | 13.50 | 1145 | 1145 | 1141 | 0.07 ± 0.02 | 96 |

| Hexyl isobutyrate | 13.61 | 1148 | 1150 | 1149 | 0.07 ± 0.02 | 95 |

| Borneol+Lavandulol | 14.34 | 1170 | 1170 | 1165 | 0.57 ± 0.29 | 94–95 |

| 1,trans-3,cis-5-Undecatriene | 14.52 | 1174 | 1174 | - | 0.10 ± 0.01 | 95 |

| Terpinen-4-ol | 14.69 | 1180 | 1177 | 1174 | 3.36 ± 0.29 | 91 |

| p-Cymen-8-ol | 14.80 | 1183 | 1183 | 1179 | tr | 88 |

| Cryptone | 14.95 | 1187 | 1184 | 1183 | 0.08 ± 0.02 | 93 |

| α-Terpineol | 15.12 | 1192 | 1189 | 1186 | 0.32 ± 0.04 | 94 |

| Myrtenal | 15.28 | 1197 | 1193 | 1195 | tr | 91 |

| Octyl acetate | 15.77 | 1212 | 1210 | 1211 | tr | 94 |

| Nerol | 16.39 | 1230 | 1232 | 1235 | tr | 92 |

| Hexyl 2-methylbutyrate | 16.64 | 1238 | 1236 | 1233 | tr | 97 |

| Cumin aldehyde | 16.81 | 1243 | 1239 | 1238 | tr | 93 |

| Carvone | 16.94 | 1247 | 1242 | 1239 | tr | 94 |

| Linalyl acetate | 17.22 | 1255 | 1257 | 1254 | 56.94 ± 0.54 | 96 |

| Isopulegol acetate | 18.08 | 1281 | 1285 | 1283 | 0.05 ± 0.01 | 91 |

| Bornyl acetate | 18.32 | 1288 | 1285 | 1284 | 0.30 ± 0.07 | 92 |

| Lavandulyl acetate | 18.49 | 1293 | 1290 | 1292 | 5.17 ± 0.48 | 96 |

| Hexyl tiglate | 19.76 | 1335 | 1330 | 1330 | tr | 96 |

| α-Longipinene | 20.40 | 1357 | 1353 | 1350 | tr | 89 |

| cis-Geranyl acetate | 20.77 | 1369 | 1364 | 1359 | 0.11 ± 0.02 | 97 |

| α-Copaene | 21.13 | 1382 | 1376 | 1374 | 0.06 ± 0.01 | 94 |

| trans-Geranyl acetate | 21.27 | 1386 | 1382 | 1379 | 0.12 ± 0.02 | 96 |

| β-Bourbonene | 21.40 | 1391 | 1384 | 1387 | tr | 91 |

| 7-epi-Sesquithujene | 21.48 | 1394 | 1391 | 1390 | 0.18 ± 0.03 | 97 |

| β-Longipinene | 21.62 | 1399 | 1400 | 1400 | tr | 89 |

| Sesquithujene | 21.84 | 1408 | 1405 | 1405 | tr | 88 |

| α-Cedrene | 22.05 | 1419 | 1411 | 1410 | 0.07 ± 0.01 | 96 |

| Caryophyllene | 22.19 | 1426 | 1419 | 1417 | 7.57 ± 1.45 | 95 |

| cis-β-Copaene | 22.38 | 1436 | 1436 | 1430 | tr | 97 |

| trans-α-Bergamotene | 22.48 | 1440 | 1435 | 1432 | 0.20 ± 0.06 | 93 |

| Unknown | 22.64 | 1449 | tr | - | ||

| Isogermacrene D | 22.72 | 1453 | 1448 | - | tr | 90 |

| Cadina-3,5-diene | 22.75 | 1454 | 1458 | - | tr | 90 |

| Allo-aromadendrene | 22.90 | 1462 | 1461 | 1458 | 3.80 ± 0.76 | 94 |

| γ-Muurolene | 23.10 | 1472 | 1477 | 1478 | 0.05 ± 0.01 | 92 |

| Germacrene D | 23.42 | 1488 | 1481 | 1484 | 0.73 ± 0.20 | 90 |

| β-Himachalene | 23.64 | 1499 | 1500 | 1500 | tr | 91 |

| Unknown | 23.72 | 1503 | tr | - | ||

| α-Farnesene | 23.83 | 1510 | 1508 | 1505 | tr | 92 |

| β-Bisabolene | 23.87 | 1513 | 1509 | 1505 | tr | 88 |

| γ-Cadinene | 24.01 | 1522 | 1513 | 1513 | 0.29 ± 0.11 | 96 |

| δ-Cadinene | 24.15 | 1530 | 1524 | 1522 | tr | 92 |

| α-Cadinene | 24.39 | 1546 | 1538 | 1537 | tr | 91 |

| Caryophyllene oxide | 25.15 | 1592 | 1581 | 1582 | tr | 94 |

| Epicubenol | 25.57 | 1624 | 1627 | 1627 | tr | 95 |

| τ-Cadinol | 25.85 | 1645 | 1640 | 1635 | tr | 97 |

| Compound | Drying Method | |||||||

|---|---|---|---|---|---|---|---|---|

| Fresh | CD 50 °C | CD 60 °C | CD 70 °C | CPD-VMFD | VMD 240 W | VMD 360 W | VMD 480 W | |

| Content [mg 100 g−1 dw]1,2 | ||||||||

| Octan-3-one | 101.26a | 20.21b | 7.90e | 11.41de | 15.14cd | 14.95cd | 17.85bc | 17.23bc |

| Myrcene | 145.56a | 26.52b | 12.80d | 17.07c | 19.19c | 11.09d | 12.16d | 9.66d |

| cis-β-Ocimene | 448.38a | 99.01b | 57.81e | 76.89cd | 80.49cd | 66.11de | 88.36bc | 77.09cd |

| trans-β-Ocimene | 309.18a | 69.90b | 37.09d | 50.20c | 50.25c | 41.45cd | 43.43cd | 37.62d |

| Linalool | 951.51a | 228.67bc | 128.01d | 192.97c | 249.87b | 187.99c | 194.95c | 193.83c |

| 1-Octen-3-ol acetate | 102.97a | 21.76b | 13.87d | 18.49c | 15.15d | 6.62e | 7.88e | 6.23e |

| Borneol+Lavandulol | 133.24a | 29.69c | 20.77d | 21.55d | 33.77b | 17.26e | 9.93f | 14.99e |

| Terpinen-4-ol | 367.96a | 96.42b | 62.12de | 83.30c | 65.32d | 53.47e | 73.28cd | 63.71de |

| α-Terpineol | 260.85a | 58.85b | 34.91de | 39.44cd | 44.67c | 28.24e | 32.97de | 25.73f |

| Linalyl acetate | 983.24a | 342.22c | 272.40d | 377.50b | 299.99d | 164.82f | 203.26e | 211.33e |

| Lavandulyl acetate | 358.48a | 79.85b | 52.84d | 79.23b | 77.80b | 56.04cd | 77.91b | 70.38bc |

| cis-Geranyl acetate | 144.51a | 28.29b | 14.13d | 18.36c | 19.41c | 10.39de | 11.61de | 8.53e |

| trans-Geranyl acetate | 270.15a | 60.15b | 32.30d | 41.68c | 43.36c | 24.09ef | 26.40e | 19.51f |

| trans-β-Farnesene | 133.12a | 31.13b | 17.47e | 26.42c | 21.45d | 4.44h | 7.35g | 9.18f |

| Total EO [g 100 g−1 dw] | 5.18a | 1.35b | 0.86c | 1.16b | 1.16b | 0.65d | 0.90c | 0.87c |

| Compound | Drying Method | |||||||

|---|---|---|---|---|---|---|---|---|

| Fresh | CD 50 °C | CD 60 °C | CD 70 °C | CPD-VMFD | VMD 240 W | VMD 360 W | VMD 480 W | |

| Content [%]1,2 | ||||||||

| cis-β-Ocimene | 4.97a | 1.35bc | 1.60b | 1.31bc | 1.62b | 1.16bc | 0.85c | 1.17bc |

| trans-β-Ocimene | 3.98a | 1.10b | 1.15b | 0.96bc | 1.19b | 0.59cd | 0.21d | 0.62cd |

| Linalool | 8.94a | 22.17c | 8.94a | 14.91b | 22.03c | 30.90e | 24.05cd | 26.03d |

| 1-Octen-3-ol acetate | 1.57a | 0.71c | 1.00b | 0.85bc | 0.81bc | 0.38d | 0.29d | 0.29d |

| Terpinen-4-ol | 3.36a | 6.44b | 4.28a | 3.62a | 6.10b | 1.37c | 3.45a | 3.45a |

| Linalyl acetate | 56.94a | 43.32d | 58.43a | 57.48a | 46.77b | 44.46cd | 47.02b | 46.01bc |

| Lavandulyl acetate | 5.17a | 2.92c | 5.10a | 4.32b | 3.34c | 0.79e | 1.43de | 1.64d |

| Caryophyllene | 7.57a | 3.88c | 5.14bc | 4.46c | 3.78c | 6.35ab | 7.39a | 6.88ab |

| Allo-aromadendrene | 3.80a | 4.91ab | 5.46b | 4.18a | 3.96a | 1.91c | 2.27c | 2.15c |

| Compound | Drying Method | Aroma Description | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Fresh | CD 50 °C | CD 60 °C | CD 70 °C | CPD-VMFD | VMD 240 W | VMD 360 W | VMD 480 W | ||

| Content [%] 1,2 | |||||||||

| 1-Octen-3-ol | 0.12ab | 0.26bc | 0.09a | 0.13ab | 0.12a | 0.27bc | 0.32c | 0.15ab | Sweet, earthy odor with a strong, herbaceous note reminiscent of lavender–lavandin, rose and hay [53] |

| Eucalyptol | 0.24a | 0.08ab | 0.08a | 0.12a | 0.15a | 0.58a | 0.96b | 0.19a | Sweet, sharp vanilla, creamy with spicy clove-like nuances [53] |

| Linalool | 8.94a | 22.17c | 8.94a | 14.91b | 22.03c | 30.90e | 24.05cd | 26.03d | Typical pleasant floral odor, free from camphoraceous and terpenic notes [53] |

| Borneol+Lavandulol | 0.57a | 3.10b | 1.16b | 1.54ab | 2.85b | 1.84ab | 2.97b | 2.03ab | Floral, waxy, mimosa, herbal [54] |

| Terpinen-4-ol | 3.36a | 6.44b | 4.28a | 3.62ab | 6.10b | 1.37c | 3.45a | 3.45a | Cooling, woody, earthy, clove spicy with a citrus undernote [54] |

| Nerol | 0.03a | 0.09b | 0.05ab | 0.05ab | 0.06ab | 0.08b | 0.09b | 0.10b | Rosy, slightly citrus, terpy and floral, reminiscent of linalool oxide with aldehydic waxy and fruity nuances [53] |

| Linalyl acetate | 56.94a | 43.32d | 58.43a | 57.48a | 46.77b | 44.46cd | 47.02b | 46.01bc | Characteristic bergamot–lavender odor and persistent sweet [53] |

| cis-geranyl acetate | 0.11a | 0.32d | 0.27c | 0.23c | 0.25c | 0.16b | 0.16b | 0.14ab | Floral, rosy, sweet, soapy, citrus, grapefruit and fruity with a tropical nuance [54] |

| trans-geranyl acetate | 0.12a | 0.49f | 0.39e | 0.30cd | 0.37de | 0.25bc | 0.23bc | 0.22b | Pleasant, flowery odor reminiscent of rose lavender [53] |

| 7-epi-Sesquithujene | 0.18a | 0.11b | 0.16a | 0.12b | 0.10bc | 0.07c | 0.07c | 0.08c | Not available |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Łyczko, J.; Jałoszyński, K.; Surma, M.; García-Garví, J.M.; Carbonell-Barrachina, Á.A.; Szumny, A. Determination of Various Drying Methods’ Impact on Odour Quality of True Lavender (Lavandula angustifolia Mill.) Flowers. Molecules 2019, 24, 2900. https://doi.org/10.3390/molecules24162900

Łyczko J, Jałoszyński K, Surma M, García-Garví JM, Carbonell-Barrachina ÁA, Szumny A. Determination of Various Drying Methods’ Impact on Odour Quality of True Lavender (Lavandula angustifolia Mill.) Flowers. Molecules. 2019; 24(16):2900. https://doi.org/10.3390/molecules24162900

Chicago/Turabian StyleŁyczko, Jacek, Klaudiusz Jałoszyński, Mariusz Surma, José Miguel García-Garví, Ángel A. Carbonell-Barrachina, and Antoni Szumny. 2019. "Determination of Various Drying Methods’ Impact on Odour Quality of True Lavender (Lavandula angustifolia Mill.) Flowers" Molecules 24, no. 16: 2900. https://doi.org/10.3390/molecules24162900

APA StyleŁyczko, J., Jałoszyński, K., Surma, M., García-Garví, J. M., Carbonell-Barrachina, Á. A., & Szumny, A. (2019). Determination of Various Drying Methods’ Impact on Odour Quality of True Lavender (Lavandula angustifolia Mill.) Flowers. Molecules, 24(16), 2900. https://doi.org/10.3390/molecules24162900