Designing Lubricating Properties of Vegetable Base Oils

Abstract

1. Introduction

2. Results and Discussion

2.1. Abyssinian Oil Modification

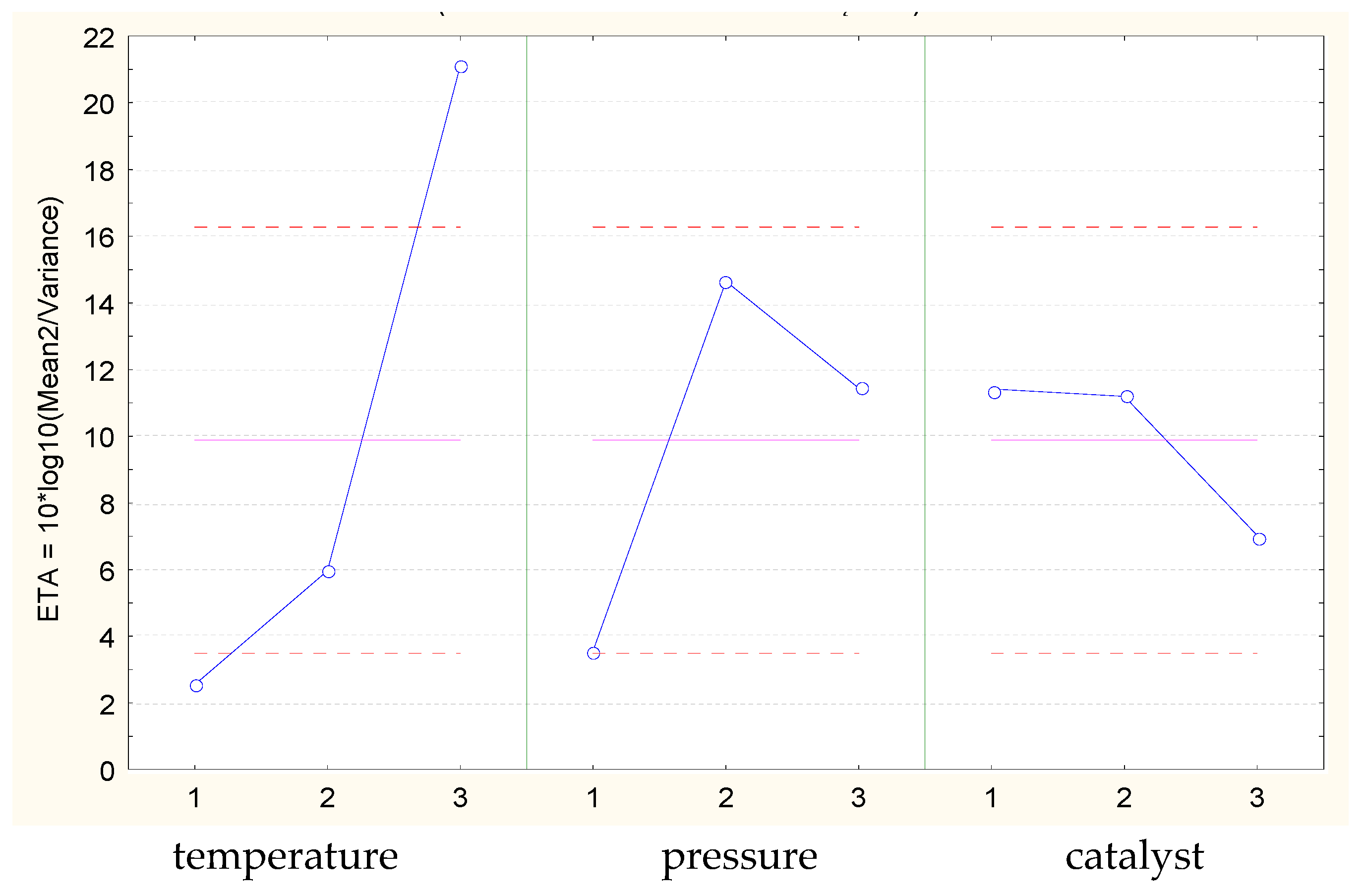

2.2. Statistical Analysis of Optimization Experiments

2.3. Model Verification

- A_CO2 oil (process with the use of solvent): the projected viscosity value was 150.7 ± 14.6 mm2/s. The value obtained in the experiment was 143.4 mm2/s.

- A_O2 oil (process without use of solvent): the projected viscosity value was 150.6 ± 13.1 mm2/s. The value obtained in the experiment was 156.9 mm2/s.

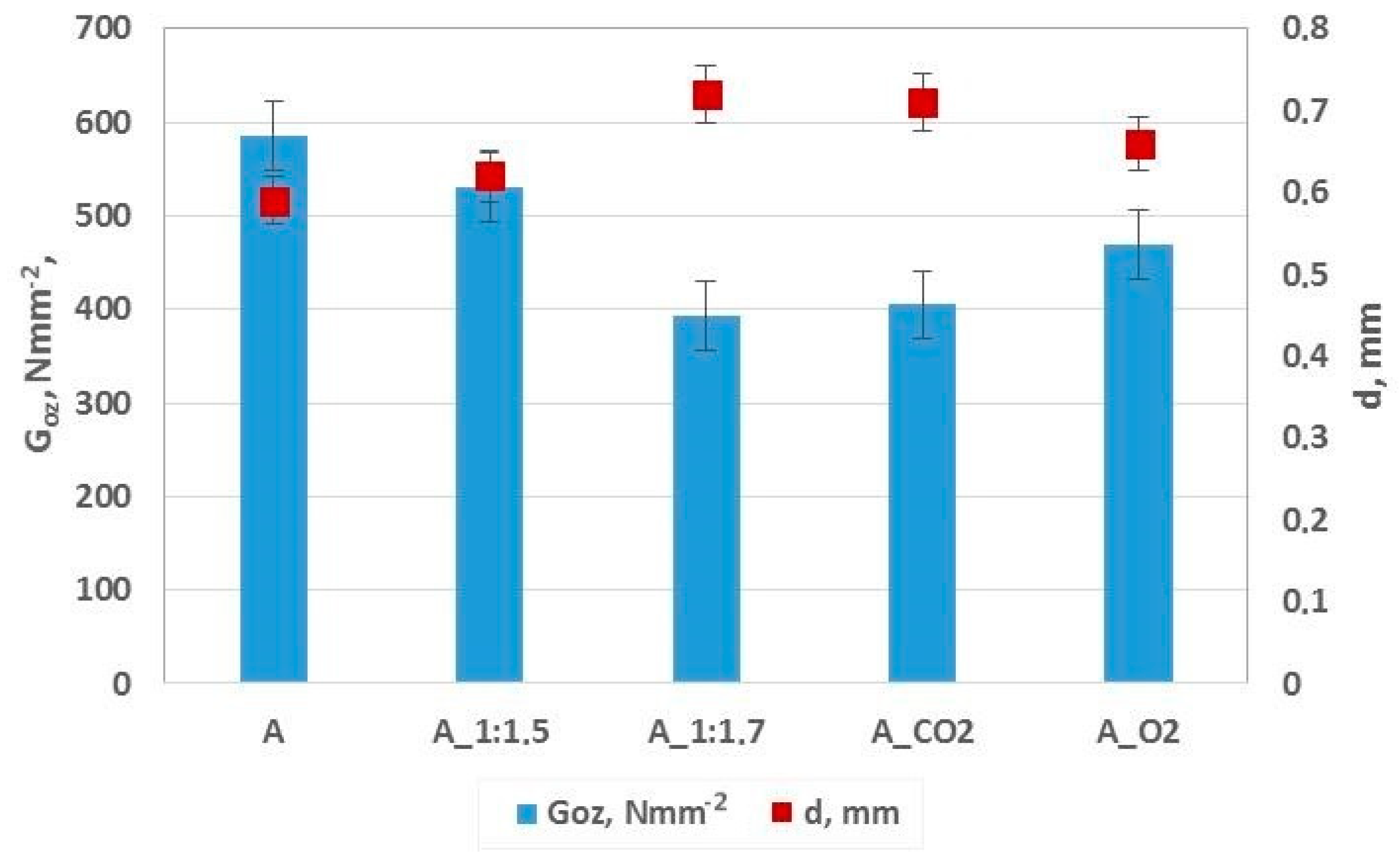

2.4. Properties Evaluation

2.4.1. Characteristics of Lubricating and Rheological Properties

2.4.2. Raman Spectroscopy

3. Materials and Methods

3.1. Design of Experiments

3.2. Method of Oxidation

3.3. Determination of Modified Oils Properties

3.4. Evaluation of Lubricating and Rheological Properties

3.5. Raman Spectroscopy

4. Conclusions

5. Patents

Author Contributions

Funding

Conflicts of Interest

References

- Karmakar, G.; Ghosh, P.; Sharma, B.K. Chemically modifying vegetable oils to prepare green lubricants. Lubricants 2017, 5, 44. [Google Scholar] [CrossRef]

- Gschwender, L.J.; Kramer, D.C.; Lok, B.K.; Sharma, S.K.; Snyder, C.E.; Sztenderowicz, M.L. Liquid lubricants and lubrication. In Modern Tribology Handbook; Bhushan, B., Ed.; CRC Press LLC: Florida, FL, USA, 2001; ISBN 0-8493-8403-6. [Google Scholar]

- Fox, N.J.; Stachowiak, G.W. Vegetable oil-based lubricants—A review for oxidation. Tribol. Int. 2007, 40, 1035–1046. [Google Scholar] [CrossRef]

- Beran, E. Wpływ Budowy Chemicznej Bazowych Olejów Smarowych Na Ich Biodegradowalność I Wybrane Właściwości Eksploatacyjne; Oficyna Wydawnicza Politechniki Wrocławskiej: Wrocław, Polska, 2008. [Google Scholar]

- Salimo, J.; Abdullah, B.M.; Yusop, R.M.; Salih, N. Synthesis, reactivity and application studies for different biolubricants. Chem. Cent. J. 2014, 8, 16. [Google Scholar] [CrossRef] [PubMed]

- Wagner, H.; Luther, R.; Mang, T. Lubricant base fluids based on renewable raw materials their catalytic manufacture and modification. Appl. Catal. A 2001, 221, 429–442. [Google Scholar] [CrossRef]

- Smart Growth Operational Programme 2014–2020 Project, Subaction 4.1.2 Regional Scientific-Research Agendas. Technology Development of New Generation of High Quality Lubricants, for Food Industry, that Guarantee the Food Safety. No. 04.01.02-00-0004/16; Poland, 2017–2019. Available online: http://www.icso.com.pl/projekty/fundusze-strukturalne/projekt-rozwoj-technologii-nowej-generacji-wysokojakosciowych-srodkow-smarowych-dla-sektoa-rolno-spozywczego-gwarantujacych-bezpieczenstwo-produkcji-zywnosci.html (accessed on 13 August 2018).

- Iłowska, J.; Grabowski, R.; Szmatoła, M.; Gniady, J.; Woch, J.; Chrobak, J.; Korasiak, K.; Dejnega, B.; Szwach, I.; Fiszer, R. Sposób Modyfikacji Olejów Roślinnych. Patent Application No. P.425863, 11 June 2018. [Google Scholar]

- Iłowska, J.; Grabowski, R.; Szmatoła, M.; Gniady, J.; Woch, J.; Chrobak, J.; Korasiak, K.; Dejnega, B.; Szwach, I.; Fiszer, R. Sposób Modyfikacji Olejów Roślinnych. Patent Application No. P.425873, 11 June 2018. [Google Scholar]

- Grabowski, R.; Orlińska, B.; Zawadiak, J.; Iłowska, J. N-Hydroxphthalimide as a potential industrial catalyst for oxidation of hydrocarbons. Przem. Chem. 2014, 93, 495. [Google Scholar] [CrossRef]

- Hermans, I.; Vereecken, L.; Jacobs, P.A.; Peeters, J. Mechanism of the catalytic oxidation of hydrocarbons by N-hydroxyphthalimide: a theoretical study. Chem. Commun. 2004, 9, 1140–1141. [Google Scholar] [CrossRef] [PubMed]

- Seki, T.; Baiker, A. Catalytic oxidations in dense carbon dioxide. Chem. Rev. 2009, 109, 2409. [Google Scholar] [CrossRef] [PubMed]

- Lalas, S.; Gortzi, O.; Anthanasiadis, V.; Dourtoglou, E.; Dourtoglou, V. Full characterization of crambe abyssinica hochst. seed oil. J. Am. Oil Chem. Soc. 2012, 89, 2253–2258. [Google Scholar] [CrossRef]

- Ruta, R. Application of taguchi experiments in a planning method for tribological research. Tribologia 2011, 2, 125–141. [Google Scholar]

- Karna, S.K.; Sahai, R. An overview on taguchi method. Int. J. Math. Sci. Eng. 2012, 1, 11–18. [Google Scholar]

- Drabik, J. Tribological characteristics of greases prepared on modified vegetable oils. Tribologia 2015, 2, 31. [Google Scholar]

- Drabik, J.; Kozdrach, R.; Wrona, M.; Iłowska, J. Zastosowanie techniki DWS I spektroskopii Ramana do oceny emulsji parafinowych formowanych metodą homogenizacji. Przem. Chem. 2017, 1, 2544–2549. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds are not available from the authors. |

| System No. | Temperature, °C | O2 Pressure, MPa | Catalyst, % |

|---|---|---|---|

| 1 | 80 | 0.1 | 0 |

| 2 | 80 | 0.4 | 0.05 |

| 3 | 80 | 0.6 | 0.5 |

| 4 | 100 | 0.4 | 0.5 |

| 5 | 100 | 0.6 | 0 |

| 6 | 100 | 0.1 | 0.05 |

| 7 | 120 | 0.6 | 0.05 |

| 8 | 120 | 0.1 | 0.5 |

| 9 | 120 | 0.4 | 0 |

| System No. | Temperature, °C | Σ Pressure, MPa | Catalyst, % |

|---|---|---|---|

| 1 | 80 | 10 | 0 |

| 2 | 80 | 15 | 0.05 |

| 3 | 80 | 20 | 0.5 |

| 4 | 100 | 10 | 0.5 |

| 5 | 100 | 15 | 0 |

| 6 | 100 | 20 | 0.05 |

| 7 | 120 | 10 | 0.05 |

| 8 | 120 | 15 | 0.5 |

| 9 | 120 | 20 | 0 |

| Processes without CO2 | Processes with CO2 | |||||||

|---|---|---|---|---|---|---|---|---|

| SS | df | p | % Share | SS | df | p | % Share | |

| Temperature | 1760.55 | 2 | 0.000 | 58.3% | 2190.32 | 2 | 0.000 | 85.7% |

| Pressure | 585.21 | 2 | 0.001 | 19.4% | 54.96 | 2 | 0.059 | 2.1% |

| Catalyst | 109.90 | 2 | 0.169 | 3.6% | 143.07 | 2 | 0.002 | 5.6% |

| Rest | 565.24 | 20 | 18.7% | 168.36 | 20 | 6.6% | ||

| SUM | 3020.90 | 100.0% | 2556.71 | 100.0% | ||||

| Oil | A_O2 | A_CO2 |

|---|---|---|

| Temperature, °C | 120 | 120 |

| Pressure O2/Σ, MPa | 0.4 | 10 |

| Catalyst, % | 0.05 | 0.05 |

| Projected viscosity in 40 °C, cSt | 150.6 | 150.7 |

| Oil | A_O2 | A_CO2 |

|---|---|---|

| Viscosity 40 °C, cSt | 156.9 | 143.4 |

| LN, meq O2/kg | 15.16 | 13.10 |

| LJ, g I2/100 g | 54.10 | 63.70 |

| LZ, mg KOH/g | 214.23 | 248.70 |

| LK, mg KOH/g | 25.70 | 28.05 |

| Parameters | Determination Method (Standard Number) | Tested Oils | ||||

|---|---|---|---|---|---|---|

| Oil | Blending | Modification | ||||

| A | A_1:1.5 S/A 1:1.5 | A_1:1.7 S/A 1:1.7 | A_CO2 | A_O2 | ||

| Kinematic viscosity in temp. of 40 °C, mm2/s | PN EN ISO 3104:2004 | 46.9 | 140.2 | 171.4 | 143.4 | 156.9 |

| Kinematic viscosity in temp. of 100 °C, mm2/s | PN EN ISO 3104:2004 | 10.1 | 22.8 | 24.4 | 16.1 | 17.2 |

| Viscosity indicator, WL | PN ISO 2909:2009 | 208 | 192 | 184 | 138 | 138 |

| VG viscosity class according to ISO | ISO 3448 | 46 | 150 | 150/220 | 150 | 150 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iłowska, J.; Chrobak, J.; Grabowski, R.; Szmatoła, M.; Woch, J.; Szwach, I.; Drabik, J.; Trzos, M.; Kozdrach, R.; Wrona, M. Designing Lubricating Properties of Vegetable Base Oils. Molecules 2018, 23, 2025. https://doi.org/10.3390/molecules23082025

Iłowska J, Chrobak J, Grabowski R, Szmatoła M, Woch J, Szwach I, Drabik J, Trzos M, Kozdrach R, Wrona M. Designing Lubricating Properties of Vegetable Base Oils. Molecules. 2018; 23(8):2025. https://doi.org/10.3390/molecules23082025

Chicago/Turabian StyleIłowska, Jolanta, Justyna Chrobak, Rafał Grabowski, Michał Szmatoła, Julia Woch, Iwona Szwach, Jolanta Drabik, Magdalena Trzos, Rafał Kozdrach, and Małgorzata Wrona. 2018. "Designing Lubricating Properties of Vegetable Base Oils" Molecules 23, no. 8: 2025. https://doi.org/10.3390/molecules23082025

APA StyleIłowska, J., Chrobak, J., Grabowski, R., Szmatoła, M., Woch, J., Szwach, I., Drabik, J., Trzos, M., Kozdrach, R., & Wrona, M. (2018). Designing Lubricating Properties of Vegetable Base Oils. Molecules, 23(8), 2025. https://doi.org/10.3390/molecules23082025