Characterizing the Structural and Functional Properties of Soybean Protein Extracted from Full-Fat Soybean Flakes after Low-Temperature Dry Extrusion

Abstract

:1. Introduction

2. Results and Discussion

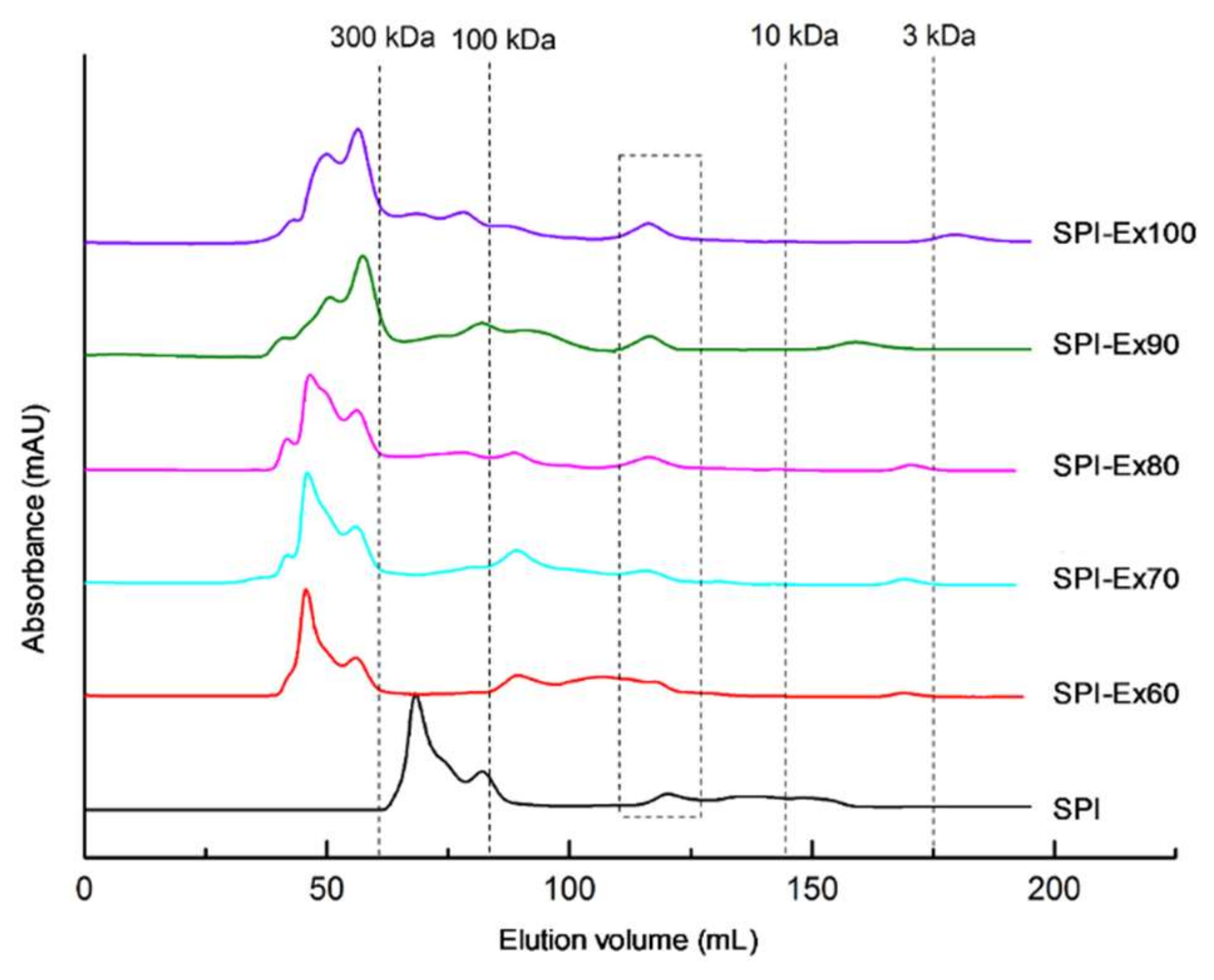

2.1. Molecular Weight Distribution Analysis

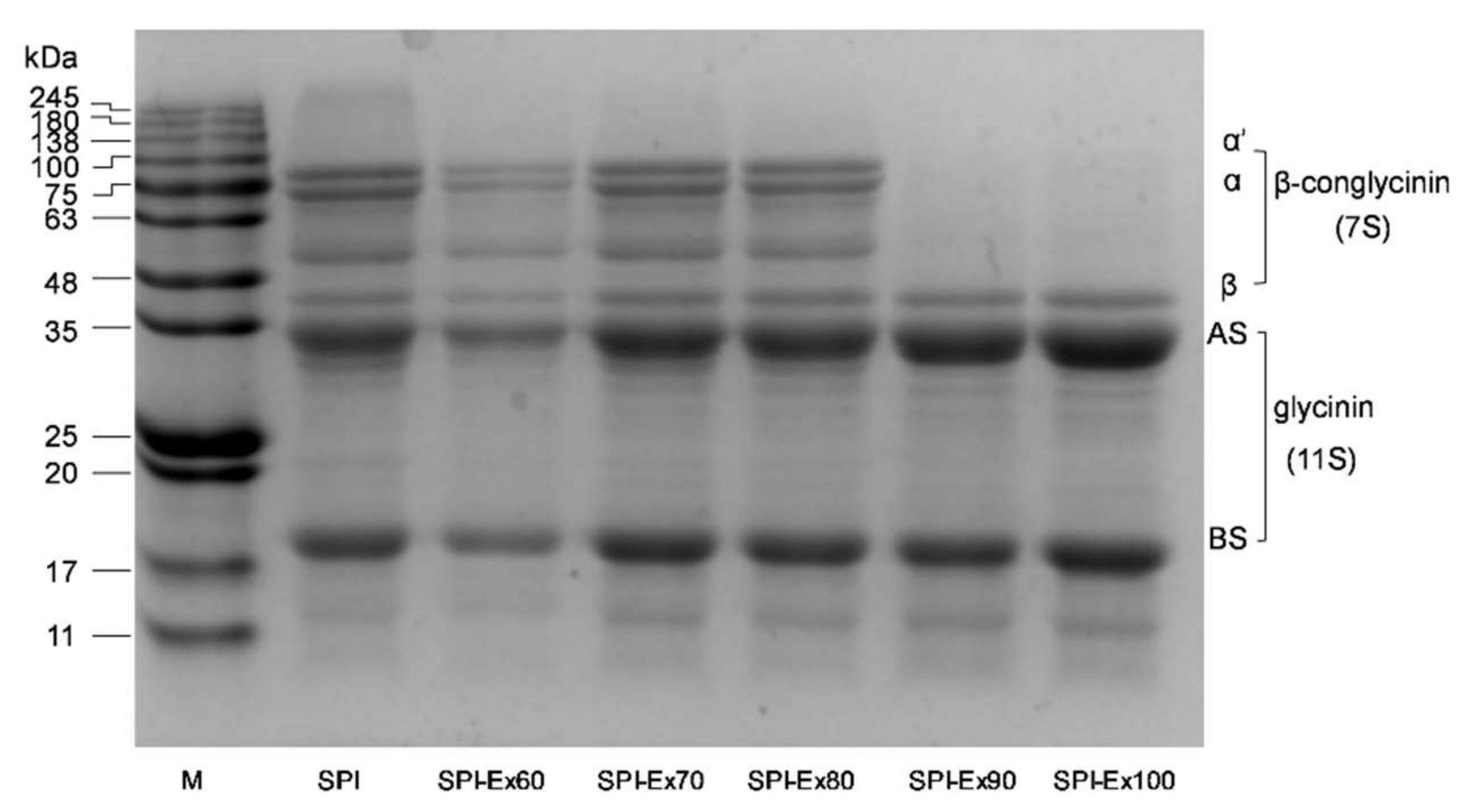

2.2. SDS-PAGE Analysis

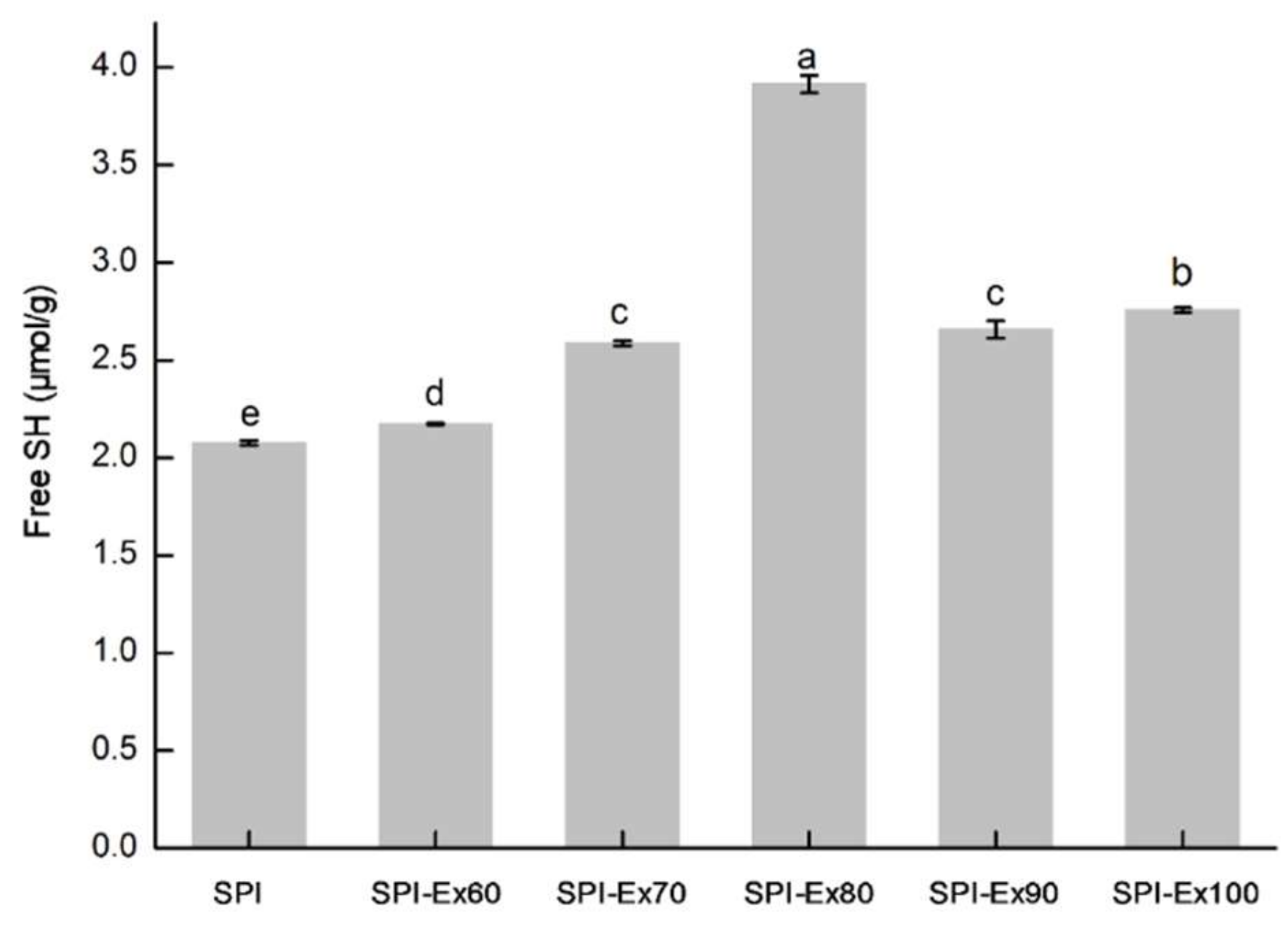

2.3. Free Sulfhydryl (SH) Content of Proteins

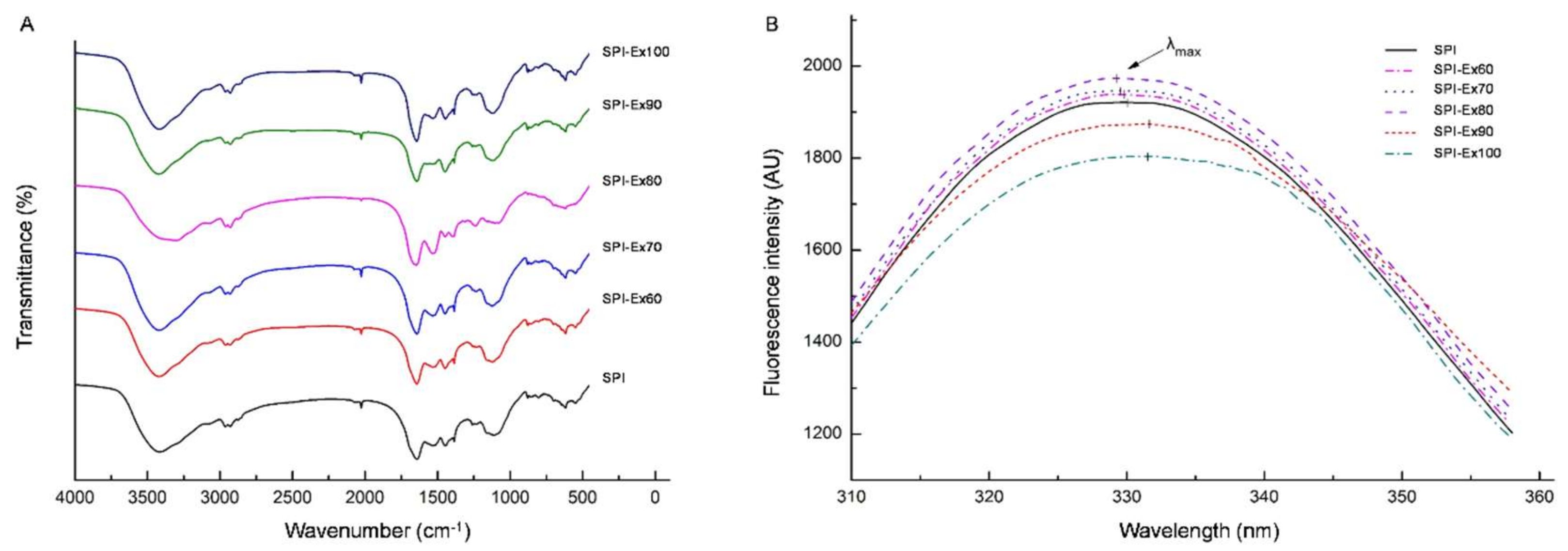

2.4. FTIR Spectra Analysis

2.5. Fluorescence Measurements

2.6. Measurement of Surface Hydrophobicity

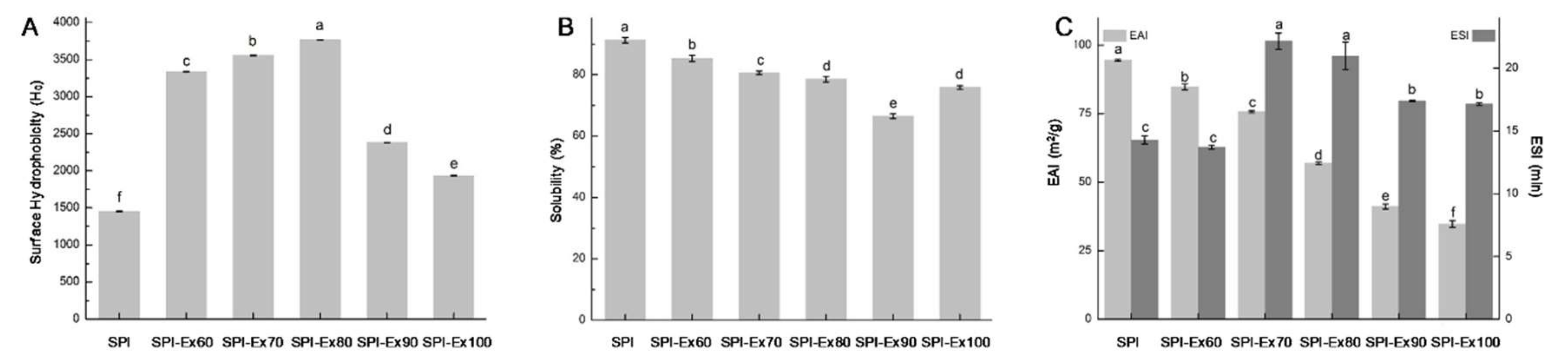

2.7. Solubility Measurement

2.8. Emulsion Properties Analysis

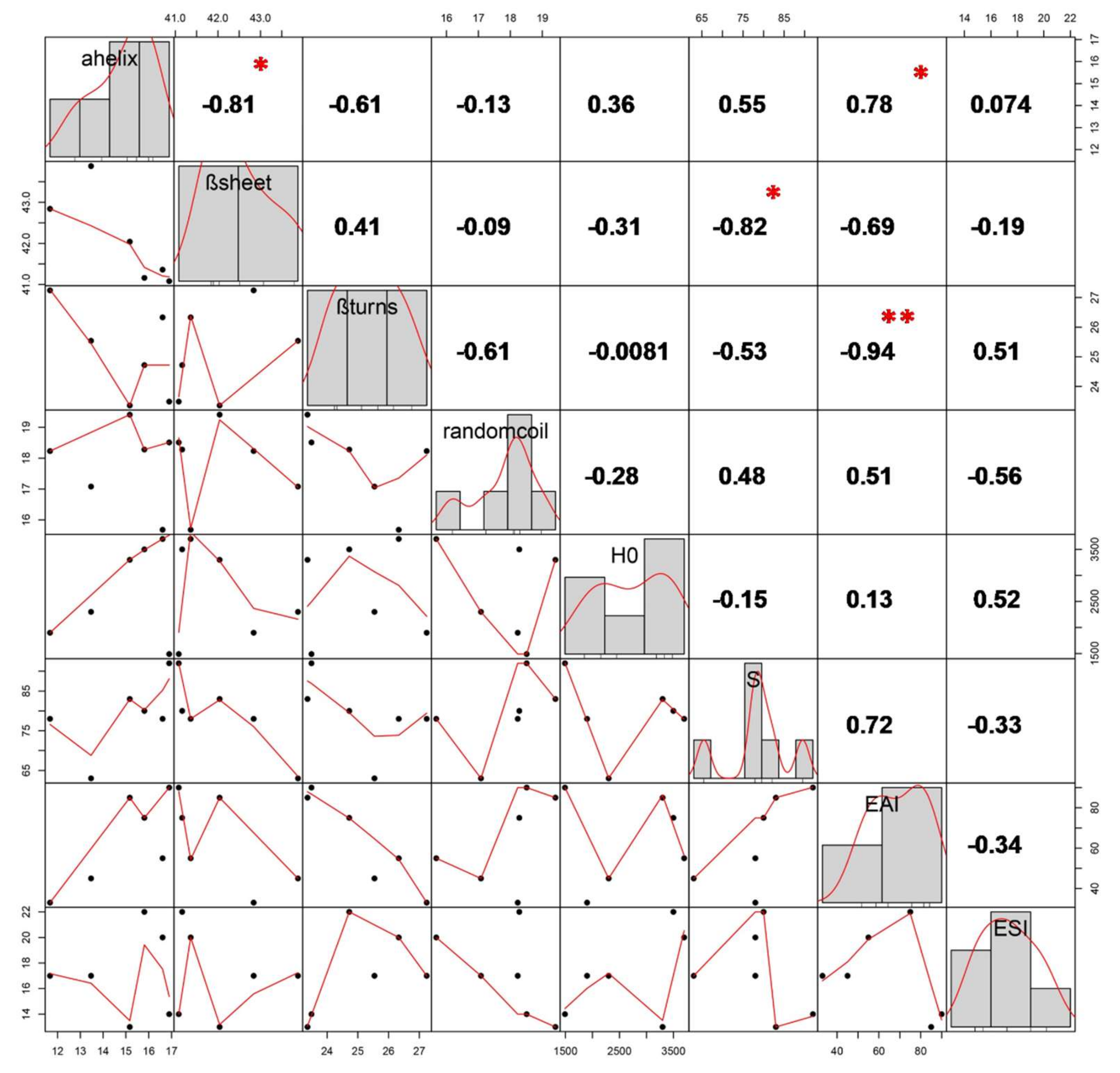

2.9. Statistical Correlation Analysis

3. Materials and Methods

3.1. Materials

3.2. Extrusion Pretreatment

3.3. Soy Protein Isolate Preparation

3.4. Molecular Weight (MW) Distribution Analysis

3.5. Sodium Dodecyl Sulfate-Polyacrylamide Gel Electrophoresis (SDS-PAGE) Analysis

3.6. Free Sulfhydryl (SH) Content Analysis

3.7. Measurement of Fourier Transform Infrared (FTIR) Spectra

3.8. Fluorescence Spectra Measurements

3.9. Surface Hydrophobicity Measurement

3.10. Solubility Measurement

3.11. Emulsion Properties

3.12. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jmln, D.M.B.; Maurer, D.; Yao, L.; Wang, T.; Jung, S.; Johnson, L.A. Characteristics of Oil and Skim in Enzyme-Assisted Aqueous Extraction of Soybeans. J. Am. Oil Chem. Soc. 2013, 90, 1079–1088. [Google Scholar]

- Jung, S.; Mahfuz, A. Low temperature dry extrusion and high-pressure processing prior to enzyme-assisted aqueous extraction of full fat soybean flakes. Food Chem. 2009, 114, 947–954. [Google Scholar] [CrossRef]

- De Almeida, N.M.; de Moura Bell, J.M.L.N.; Johnson, L.A. Properties of Soy Protein Produced by Countercurrent, Two-Stage, Enzyme-Assisted Aqueous Extraction. J. Am. Oil Chem. Soc. 2014, 91, 1077–1085. [Google Scholar] [CrossRef]

- Tabtabaei, S.; Diosady, L. Aqueous and enzymatic extraction processes for the production of food-grade proteins and industrial oil from dehulled yellow mustard flour. Food Res. Int. 2013, 52, 547–556. [Google Scholar] [CrossRef]

- De Moura, J.M.L.N.; De Almeida, N.M.; Jung, S.; Johnson, L.A. Flaking as a Pretreatment for Enzyme-assisted Aqueous Extraction Processing of Soybeans. J. Am. Oil Chem. Soc. 2010, 87, 1507–1515. [Google Scholar] [CrossRef]

- Campbell, K.A.; Glatz, C.E.; Johnson, L.A.; Jung, S.; Jmn, D.M.; Kapchie, V.; Murphy, P. Advances in Aqueous Extraction Processing of Soybeans. J. Am. Oil Chem. Soc. 2011, 88, 449–465. [Google Scholar] [CrossRef]

- Jung, S.; Mahfuz, A.; Maurer, D. Structure, protein interactions and in vitro protease accessibility of extruded and pressurized full-fat soybean flakes. J. Am. Oil Chem. Soc. 2009, 86, 475–483. [Google Scholar] [CrossRef]

- Yusoff, M.M.; Gordon, M.H.; Niranjan, K. Aqueous enzyme assisted oil extraction from oilseeds andemulsion de-emulsifying methods: A review. Trends Food Sci. Technol. 2015, 41, 60–82. [Google Scholar] [CrossRef]

- Nelson, A.I.; Wijeratne, W.B.; Yeh, S.W.; Wei, T.M.; Wei, L.S. Dry extrusion as an aid to mechanical expelling of oil from soybeans. J. Am. Oil Chem. Soc. 1987, 64, 1341–1347. [Google Scholar] [CrossRef]

- Campbell, K.A.; Glatz, C.E. Mechanisms of aqueous extraction of soybean oil. J. Agric. Food Chem. 2009, 57, 10904–10912. [Google Scholar] [CrossRef]

- Wu, J.; Johnson, L.; Jung, S. Demulsification of oil-rich emulsion from enzyme-assisted aqueous extraction of extruded soybean flakes. Bioresour. Technol. 2009, 100, 527–533. [Google Scholar] [CrossRef] [PubMed]

- Lamsal, B.P.; Murphy, P.A.; Johnson, L.A. Flaking and extrusion as mechanical treatments for enzyme-assisted aqueous extraction of oil from soybeans. J. Am. Oil Chem. Soc. 2006, 83, 973–979. [Google Scholar] [CrossRef]

- Guo, J.; Yang, X.Q.; He, X.T.; Wu, N.N.; Wang, J.M.; Gu, W.; Zhang, Y.Y. Limited Aggregation Behavior of β-Conglycinin and Its Terminating Effect on Glycinin Aggregation during Heating at pH 7.0. J. Agric. Food Chem. 2012, 60, 3782–3791. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Johnson, L.A.; Wang, T. Preparation of soy protein concentrate and isolate from extruded-expelled soybean meals. J. Am. Oil Chem. Soc. 2004, 81, 713–717. [Google Scholar] [CrossRef]

- Chen, F.L.; Wei, Y.M.; Bo, Z.; Ojokoh, A.O. System parameters and product properties response of soybean protein extruded at wide moisture range. J. Food Eng. 2010, 96, 208–213. [Google Scholar] [CrossRef]

- Mujoo, R.; Trinh, D.; Ng, P.K.W. Characterization of storage proteins in different soybean varieties and their relationship to tofu yield and texture. Food Chem. 2003, 82, 265–273. [Google Scholar]

- Li, M.; Lee, T.C. Effect of extrusion temperature on solubility and molecular weight distribution of wheat flour proteins. J. Agric. Food. Chem. 1996, 44, 763–768. [Google Scholar]

- Anderson, A.K.; Ng, P.K.W. Changes in Disulfide and Sulfhydryl Contents and Electrophoretic Patterns of Extruded Wheat Flour Proteins. Cereal Chem. 2007, 77, 354–359. [Google Scholar] [CrossRef]

- Hu, H.; Wu, J.; Li-Chan, E.C.Y.; Zhu, L.; Zhang, F.; Xu, X.; Fan, G.; Wang, L.; Huang, X.; Pan, S. Effects of ultrasound on structural and physical properties of soy protein isolate (SPI) dispersions. Food Hydrocolloid. 2013, 30, 647–655. [Google Scholar] [CrossRef]

- Huang, Y.; Hua, Y.; Qiu, A. Soybean protein aggregation induced by lipoxygenase catalyzed linoleic acid oxidation. Food Res. Int. 2006, 39, 240–249. [Google Scholar] [CrossRef]

- Podtelezhnikov, A.A.; Wild, D.L. Reconstruction and Stability of Secondary Structure Elements in the Context of Protein Structure Prediction. Biophys. J. 2009, 96, 4399–4408. [Google Scholar] [CrossRef]

- Bonwell, E.S.; Wetzel, D.L. Innovative FT-IR imaging of protein film secondary structure before and after heat treatment. J. Agric. Food Chem. 2009, 57, 10067–10072. [Google Scholar] [CrossRef] [PubMed]

- Keerati-U-Rai, M.; Miriani, M.; Iametti, S.; Bonomi, F.; Corredig, M. Structural changes of soy proteins at the oil-water interface studied by fluorescence spectroscopy. Colloids Surf. B 2012, 93, 41–48. [Google Scholar] [CrossRef] [PubMed]

- Tapal, A.; Tiku, P.K. Complexation of curcumin with soy protein isolate and its implications on solubility and stability of curcumin. Food Chem. 2012, 130, 960–965. [Google Scholar]

- Wang, X.S.; Tang, C.H.; Li, B.S.; Yang, X.Q.; Ling, L.; Ma, C.Y. Effects of high-pressure treatment on some physicochemical and functional properties of soy protein isolates. Food Hydrocolloid. 2008, 22, 560–567. [Google Scholar] [CrossRef]

- Chen, L.; Chen, J.; Ren, J.; Zhao, M. Modifications of soy protein isolates using combined extrusion pre-treatment and controlled enzymatic hydrolysis for improved emulsifying properties. Food Hydrocolloid. 2011, 25, 887–897. [Google Scholar] [CrossRef]

- Damodaran, S.; Parkin, K.L.; Fennema, O.R. Fennema’s Food Chemistry, 4th ed.; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Maruyama, N.; Prak, K.; Motoyama, S.; Choi, S.K.; Yagasaki, K.; Ishimoto, M.; Utsumi, S. Structure-physicochemical function relationships of soybean glycinin at subunit levels assessed by using mutant lines. J. Agric. Food Chem. 2004, 52, 8197–8201. [Google Scholar] [CrossRef] [PubMed]

- Sui, X.; Li, Q.; Wang, Z.; Qi, B.; Zou, X.; Li, Y.; Jiang, L. Does the hydrophobic group on sn-2 position of phosphatidylcholine decide its emulsifying ability? LWT-Food Sci. Technol. 2016, 74, 255–262. [Google Scholar] [CrossRef]

- Morel, M.; Dehlon, P.; Autran, J.C.; Leygue, J.P.; Bar-L’Helgouac’h, C. Effects of temperature, sonication time, and power settings on size distribution and extractability of total wheat flour proteins as determined by size-exclusion high-performance liquid chromatography. Cereal Chem. 2000, 77, 685–691. [Google Scholar]

- Jiang, L.; Wang, J.; Li, Y.; Wang, Z.; Liang, J.; Wang, R.; Chen, Y.; Ma, W.; Qi, B.; Zhang, M. Effects of ultrasound on the structure and physical properties of black bean protein isolates. Food Res. Int. 2014, 62, 595–601. [Google Scholar] [CrossRef]

- Lowry, O.; Rosebrough, N.; Farr, A.; Randall, R. Protein measurement with the phenol reagent. J. Biol. Chem. 1951, 193, 265–275. [Google Scholar]

- Qi, L.M.; Zhang, J.; Zhao, Y.L.; Zuo, Z.T.; Jin, H.; Wang, Y.Z. Quantitative and Qualitative Characterization ofGentiana rigescensFranch (Gentianaceae) on Different Parts and Cultivations Years by HPLC and FTIR Spectroscopy. J. Anal. Methods Chem. 2017, 2017, 1–10. [Google Scholar] [CrossRef]

- Guerrero, P.; Kerry, J.P.; Caba, K.D.L. FTIR characterization of protein–polysaccharide interactions in extruded blends. Carbohydr. Polym. 2014, 111, 598–605. [Google Scholar] [CrossRef] [PubMed]

- Tang, C.H.; Ma, C.Y. Effect of high pressure treatment on aggregation and structural properties of soy protein isolate. LWT-Food Sci. Technol. 2009, 42, 606–611. [Google Scholar] [CrossRef]

- Jiang, J.; Xiong, Y.L.; Chen, J. pH Shifting alters solubility characteristics and thermal stability of soy protein isolate and its globulin fractions in different pH, salt concentration, and temperature conditions. J. Agric. Food Chem. 2010, 58, 8035–8042. [Google Scholar] [CrossRef] [PubMed]

- Kato, A.; Nakai, S. Hydrophobicity determined by a fluorescence probe method and its correlation with surface properties of proteins. Biochem. Biophys. Acta 1980, 624, 13–20. [Google Scholar] [CrossRef]

- Pearce, K.N.; Kinsella, J.E. Emulsifying properties of proteins: Evaluation of a turbidimetric technique. J. Agric. Food Chem. 1978, 26, 716–723. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds are available from the Wenjun Ma. |

| Secondary Structure Composition (%) | ||||

|---|---|---|---|---|

| α-Helix | β-Sheet | β-Turns | Random Coil | |

| untreated | 16.90 ± 0.04 a | 41.08 ± 0.07 a | 23.49 ± 0.04 e | 18.51 ± 0.05 a,b |

| SPI-Ex60 | 15.17 ± 0.04 b | 42.04 ± 0.06 a | 23.36 ± 0.05 e | 19.41 ± 0.07 a |

| SPI-Ex70 | 15.81 ± 0.02 b | 41.16 ± 0.03 a | 24.72 ± 0.03 d | 18.28 ± 0.07 a |

| SPI-Ex80 | 16.61 ± 0.08 a | 41.36 ± 0.09 a | 26.33 ± 0.03 b | 15.68 ± 0.08 c |

| SPI-Ex90 | 13.47 ± 0.01 c | 43.88 ± 0.08 b | 25.54 ± 0.09 c | 17.08 ± 0.09 b |

| SPI-Ex100 | 11.67 ± 0.02 d | 42.84 ± 0.00 c | 27.24 ± 0.07 a | 18.23 ± 0.10 a,b |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, W.; Xie, F.; Zhang, S.; Wang, H.; Hu, M.; Sun, Y.; Zhong, M.; Zhu, J.; Qi, B.; Li, Y. Characterizing the Structural and Functional Properties of Soybean Protein Extracted from Full-Fat Soybean Flakes after Low-Temperature Dry Extrusion. Molecules 2018, 23, 3265. https://doi.org/10.3390/molecules23123265

Ma W, Xie F, Zhang S, Wang H, Hu M, Sun Y, Zhong M, Zhu J, Qi B, Li Y. Characterizing the Structural and Functional Properties of Soybean Protein Extracted from Full-Fat Soybean Flakes after Low-Temperature Dry Extrusion. Molecules. 2018; 23(12):3265. https://doi.org/10.3390/molecules23123265

Chicago/Turabian StyleMa, Wenjun, Fengying Xie, Shuang Zhang, Huan Wang, Miao Hu, Yufan Sun, Mingming Zhong, Jianyu Zhu, Baokun Qi, and Yang Li. 2018. "Characterizing the Structural and Functional Properties of Soybean Protein Extracted from Full-Fat Soybean Flakes after Low-Temperature Dry Extrusion" Molecules 23, no. 12: 3265. https://doi.org/10.3390/molecules23123265

APA StyleMa, W., Xie, F., Zhang, S., Wang, H., Hu, M., Sun, Y., Zhong, M., Zhu, J., Qi, B., & Li, Y. (2018). Characterizing the Structural and Functional Properties of Soybean Protein Extracted from Full-Fat Soybean Flakes after Low-Temperature Dry Extrusion. Molecules, 23(12), 3265. https://doi.org/10.3390/molecules23123265