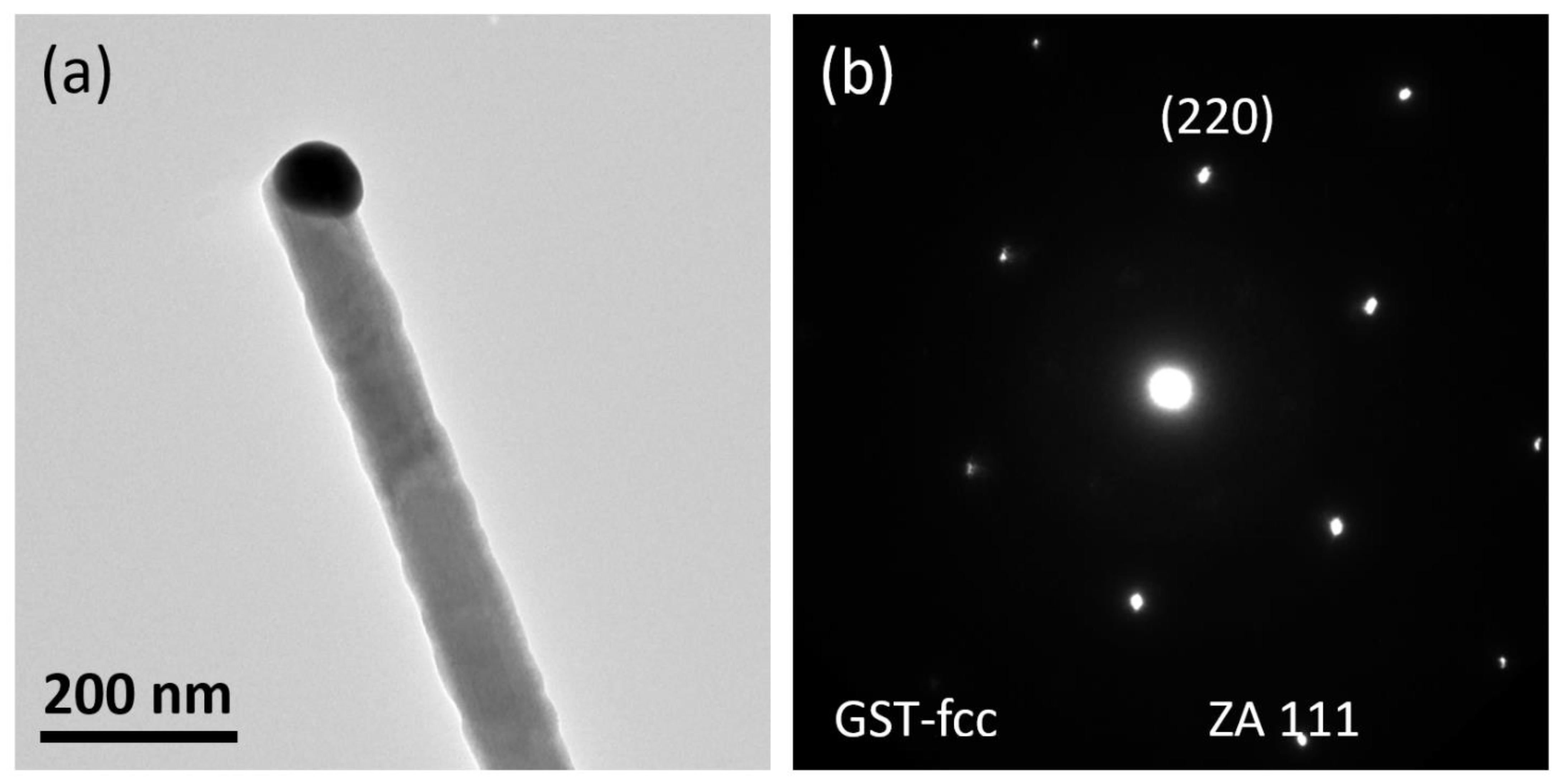

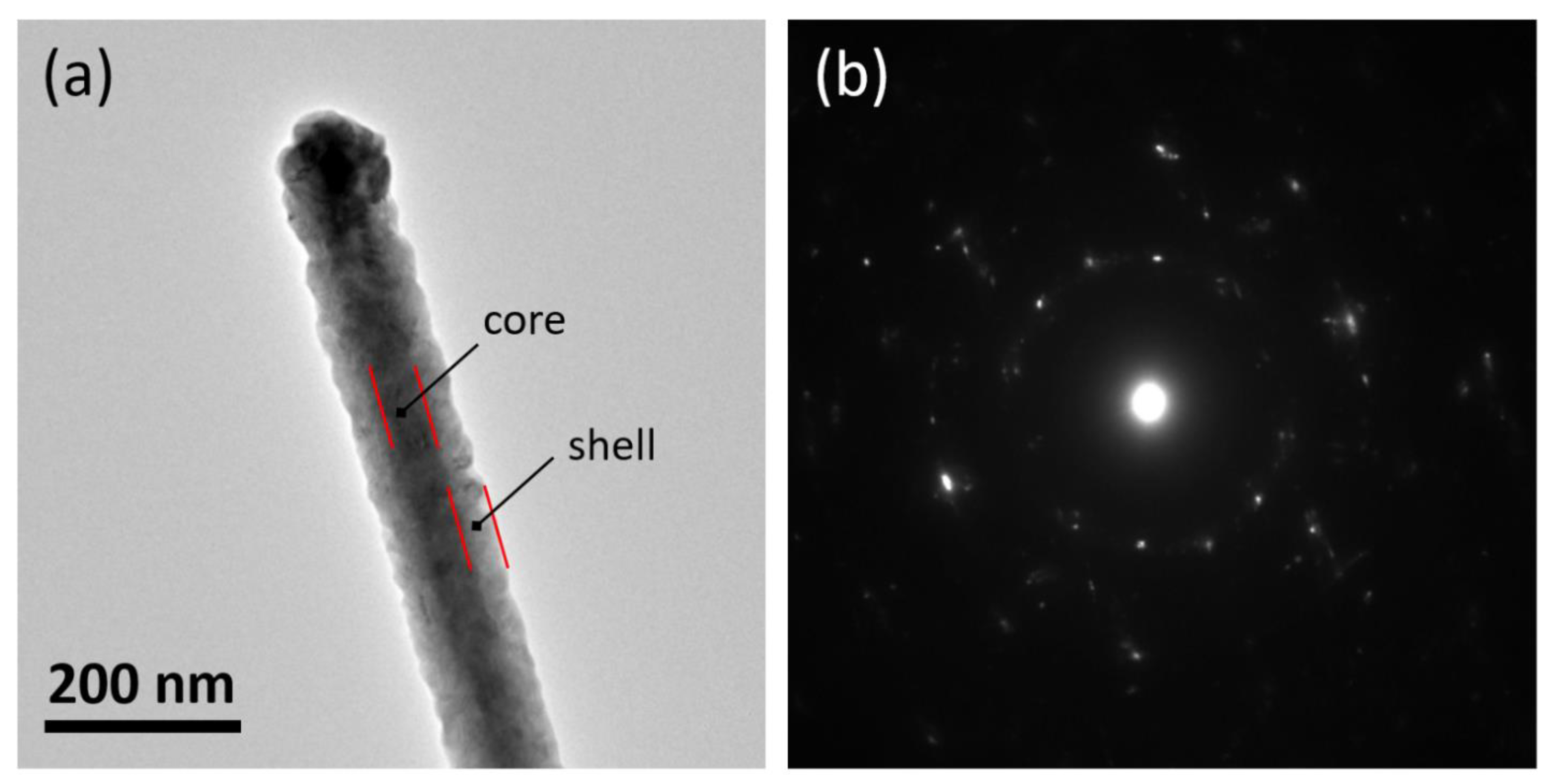

Phase Change Ge-Rich Ge–Sb–Te/Sb2Te3 Core-Shell Nanowires by Metal Organic Chemical Vapor Deposition

Abstract

:1. Introduction

2. Experimental Methods

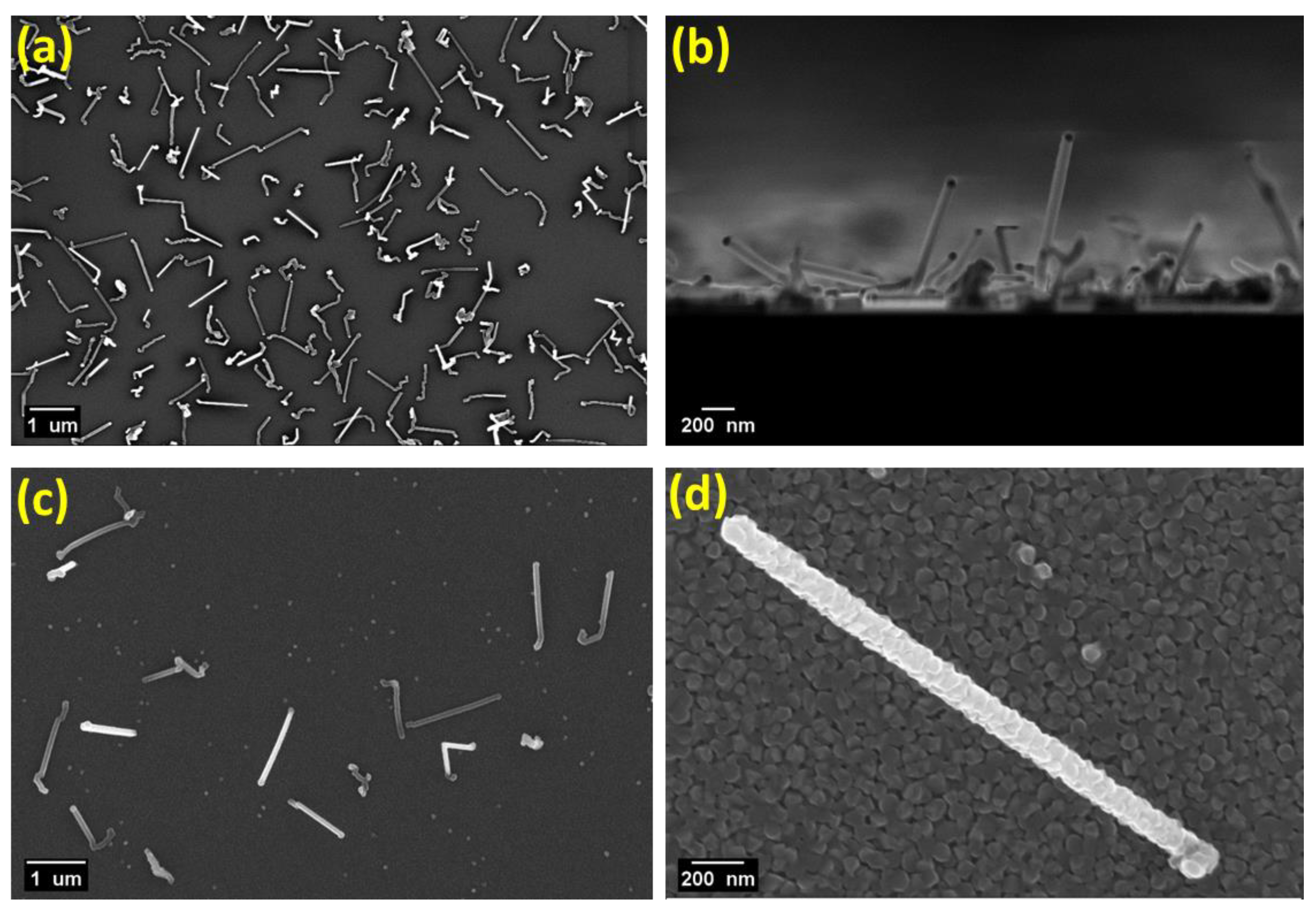

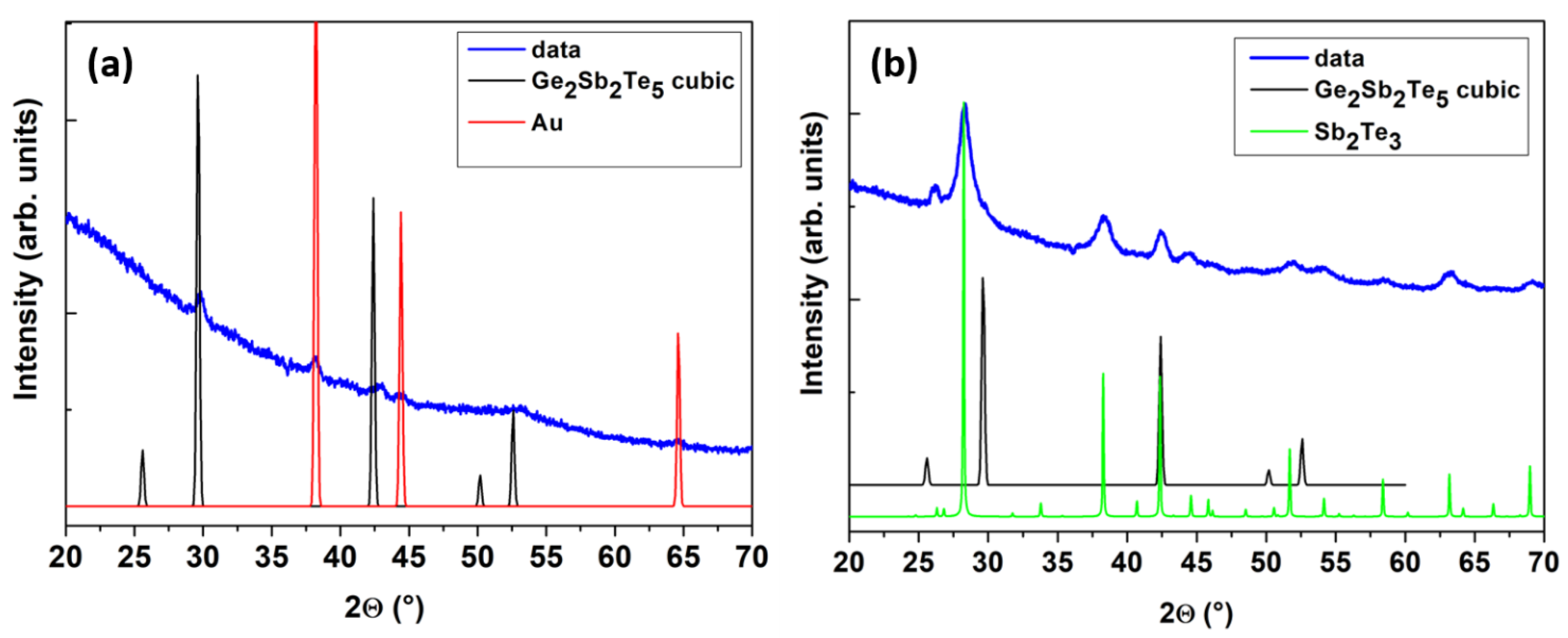

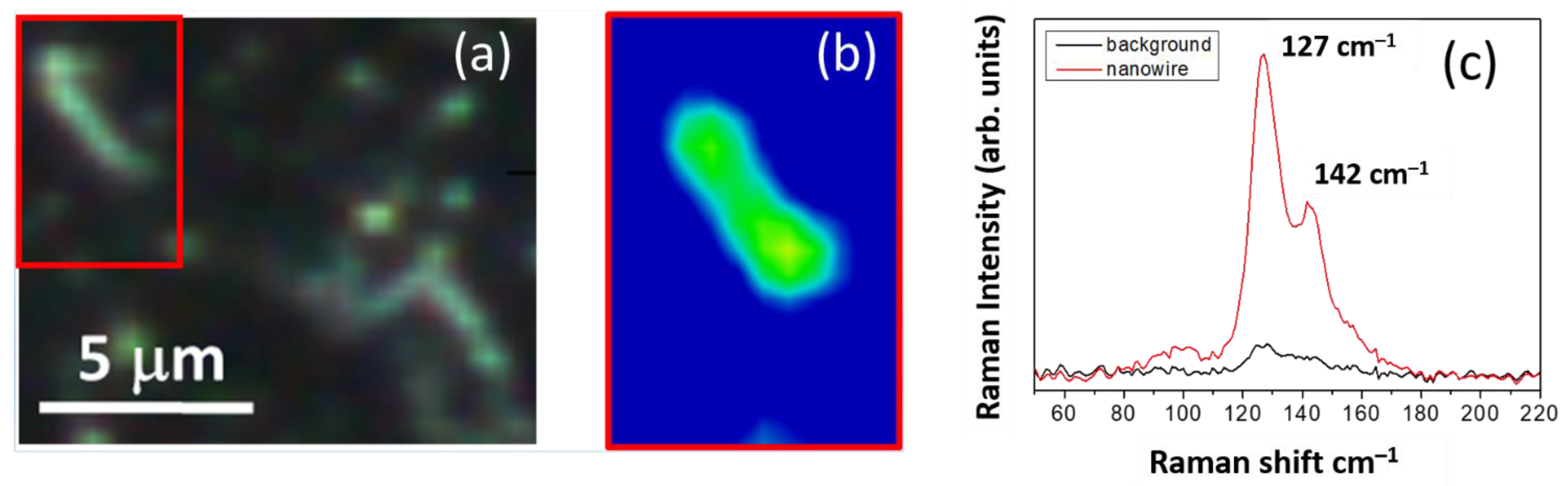

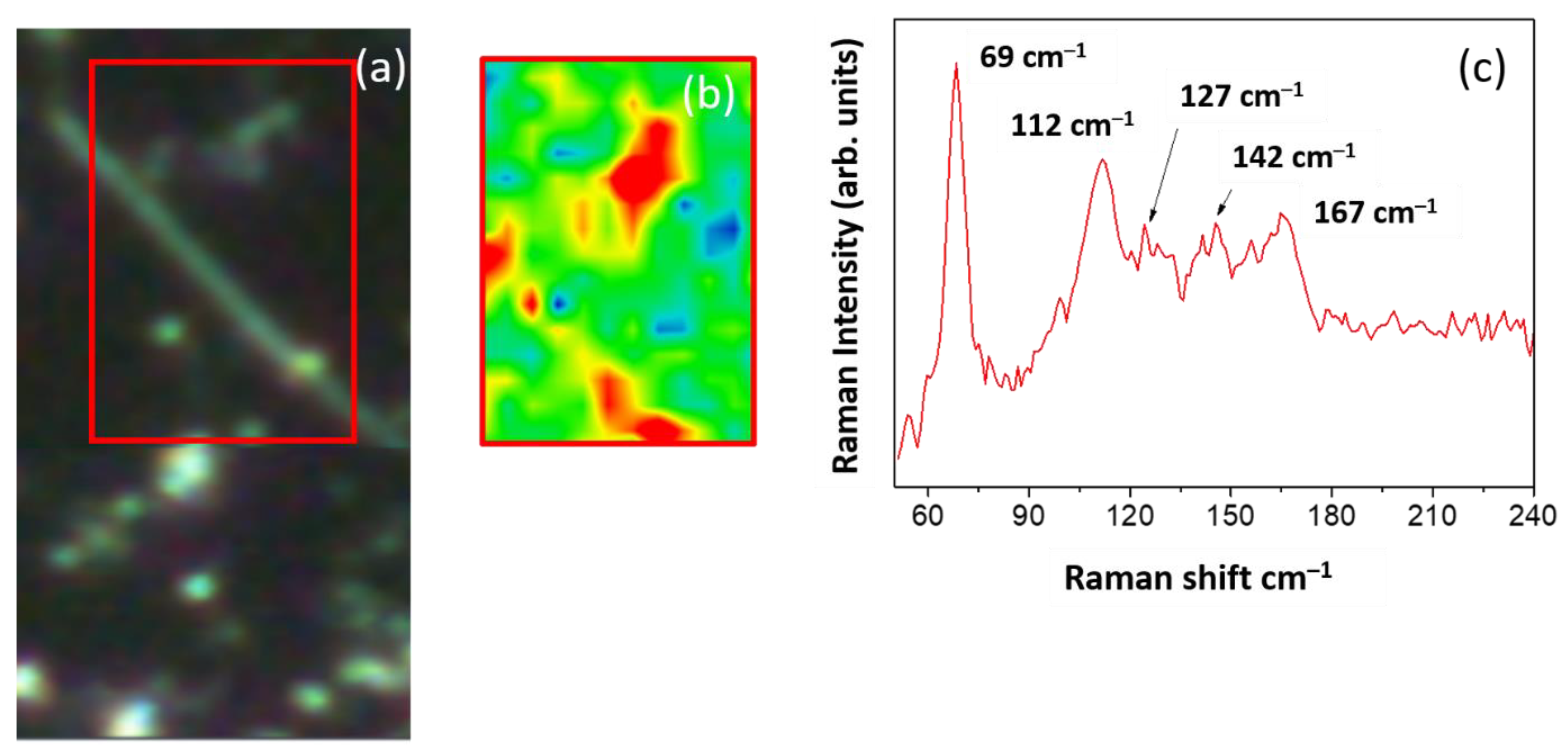

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Raoux, S.; Wełnic, W.; Ielmini, D. Phase Change Materials and Their Application to Nonvolatile Memories. Chem. Rev. 2009, 110, 240–267. [Google Scholar] [CrossRef]

- Zhang, W.; Mazzarello, R.; Wuttig, M.; Ma, E. Designing crystallization in phase-change materials for universal memory and neuro-inspired computing. Nat. Rev. Mater. 2019, 4, 150–168. [Google Scholar] [CrossRef]

- Le Gallo, M.; Sebastian, A. An overview of phase-change memory device physics. J. Phys. D. Appl. Phys. 2020, 53, 213002. [Google Scholar] [CrossRef]

- Raoux, S.; Xiong, F.; Wuttig, M.; Pop, E. Phase change materials and phase change memory. MRS Bull. 2014, 39, 703–710. [Google Scholar] [CrossRef] [Green Version]

- Singh, K.; Kumari, S.; Singh, H.; Bala, N.; Singh, P.; Kumar, A.; Thakur, A. A review on GeTe thin film-based phase-change materials. Appl. Nanosci. 2021, 2021, 1–16. [Google Scholar] [CrossRef]

- Jacobs-Gedrim, R.B.; Murphy, M.T.; Yang, F.; Jain, N.; Shanmugam, M.; Song, E.S.; Kandel, Y.; Hesamaddin, P.; Yu, H.Y.; Anantram, M.P.; et al. Reversible phase-change behavior in two-dimensional antimony telluride (Sb2Te3) nanosheets. Appl. Phys. Lett. 2018, 112, 133101. [Google Scholar] [CrossRef]

- Liu, G.Y.; Wu, L.C.; Song, Z.T.; Rao, F.; Song, S.N.; Cheng, Y. Stability of Sb2Te Crystalline Films for Phase Change Memory. Mater. Sci. Forum 2017, 898, 1829–1833. [Google Scholar] [CrossRef]

- Guo, P.; Sarangan, A.M.; Agha, I. A Review of Germanium-Antimony-Telluride Phase Change Materials for Non-Volatile Memories and Optical Modulators. Appl. Sci. 2019, 9, 530. [Google Scholar] [CrossRef] [Green Version]

- Loke, D.; Lee, T.H.; Wang, W.J.; Shi, L.P.; Zhao, R.; Yeo, Y.C.; Chong, T.C.; Elliott, S.R. Breaking the Speed Limits of Phase-Change Memory. Science 2012, 336, 1566–1569. [Google Scholar] [CrossRef] [Green Version]

- Fallica, R.; Stoycheva, T.; Wiemer, C.; Longo, M. Structural and electrical analysis of In–Sb–Te-based PCM cells. Phys. Status Solidi—Rapid Res. Lett. 2013, 7, 1009–1013. [Google Scholar] [CrossRef]

- Lee, S.H.; Yeonwoong, J.; Agarwal, R. Size-Dependent Surface-Induced heterogeneous nucleation driven Phase-Change in Ge 2Sb 2Te 5 nanowires. Nano Lett. 2008, 8, 3303–3309. [Google Scholar] [CrossRef]

- Jung, C.S.; Kim, H.S.; Im, H.S.; Seo, Y.S.; Park, K.; Back, S.H.; Cho, Y.J.; Kim, C.H.; Park, J.; Ahn, J.P. Polymorphism of GeSbTe superlattice nanowires. Nano Lett. 2013, 13, 543–549. [Google Scholar] [CrossRef] [PubMed]

- Pellizzer, F.; Benvenuti, A.; Gleixner, B.; Kim, Y.; Johnson, B.; Magistretti, M.; Marangon, T.; Pirovano, A.; Bez, R.; Atwood, G. A 90nm phase change memory technology for stand-alone non-volatile memory applications. In Proceedings of the 2006 Symposium on VLSI Technology, Honolulu, HI, USA, 13–15 June 2006; pp. 122–123. [Google Scholar] [CrossRef]

- Zuliani, P.; Varesi, E.; Palumbo, E.; Borghi, M.; Tortorelli, I.; Erbetta, D.; Libera, G.D.; Pessina, N.; Gandolfo, A.; Prelini, C.; et al. Overcoming temperature limitations in phase change memories with optimized Gex Sby Tez. IEEE Trans. Electron. Devices 2013, 60, 4020–4026. [Google Scholar] [CrossRef]

- Cheng, H.Y.; Hsu, T.H.; Raoux, S.; Wu, J.Y.; Du, P.Y.; Breitwisch, M.; Zhu, Y.; Lai, E.K.; Joseph, E.; Mittal, S.; et al. A high performance phase change memory with fast switching speed and high temperature retention by engineering the Ge xSb yTe z phase change material. In Proceedings of the Technical Digest—International Electron Devices Meeting, IEDM, Washington, DC, USA, 5–7 December 2011. [Google Scholar]

- Li, T.; Shen, J.; Wu, L.; Song, Z.; Lv, S.; Cai, D.; Zhang, S.; Guo, T.; Song, S.; Zhu, M. Atomic-Scale Observation of Carbon Distribution in High-Performance Carbon-Doped Ge2Sb2Te5 and Its Influence on Crystallization Behavior. J. Phys. Chem. C 2019, 123, 13377–13384. [Google Scholar] [CrossRef]

- Luong, M.A.; Cherkashin, N.; Pecassou, B.; Sabbione, C.; Mazen, F.; Claverie, A. Effect of Nitrogen Doping on the Crystallization Kinetics of Ge2Sb2Te5. Nanomaterials 2021, 11, 1729. [Google Scholar] [CrossRef] [PubMed]

- Wei, S.J.; Zhu, H.F.; Chen, K.; Xu, D.; Li, J.; Gan, F.X.; Zhang, X.; Xia, Y.J.; Li, G.H. Phase change behavior in titanium-doped Ge2Sb2Te5 films. Appl. Phys. Lett. 2011, 98, 231910. [Google Scholar] [CrossRef]

- Madhavan, V.E.; Carignano, M.; Kachmar, A.; Sangunni, K.S. Crystallization properties of arsenic doped GST alloys. Sci. Rep. 2019, 9, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Rao, F.; Song, Z.; Zhong, M.; Wu, L.; Feng, G.; Liu, B.; Feng, S.; Chen, B. Multilevel data storage characteristics of phase change memory cell with doublelayer chalcogenide films (Ge2Sb2Te5 and Sb2Te3). Jpn. J. Appl. Phys. Part 2 Lett. 2007, 46, L25. [Google Scholar] [CrossRef]

- Chong, T.C.; Shi, L.P.; Wei, X.Q.; Zhao, R.; Lee, H.K.; Yang, P.; Du, A.Y. Crystalline amorphous semiconductor superlattice. Phys. Rev. Lett. 2008, 100, 136101. [Google Scholar] [CrossRef] [PubMed]

- Yu, D.; Wu, J.; Gu, Q.; Park, H. Germanium telluride nanowires and nanohelices with memory-switching behavior. J. Am. Chem. Soc. 2006, 128, 8148–8149. [Google Scholar] [CrossRef]

- Longo, M.; Wiemer, C.; Salicio, O.; Fanciulli, M.; Lazzarini, L.; Rotunno, E. Au-catalyzed self assembly of GeTe nanowires by MOCVD. J. Cryst. Growth 2011, 315, 152–156. [Google Scholar] [CrossRef]

- Nukala, P.; Lin, C.C.; Composto, R.; Agarwal, R. Ultralow-power switching via defect engineering in germanium telluride phase-change memory devices. Nat. Commun. 2016, 7, 10482. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Meister, S.; Peng, H.; McIlwrath, K.; Jarausch, K.; Zhang, X.F.; Cui, Y. Synthesis and characterization of phase-change nanowires. Nano Lett. 2006, 6, 1514–1517. [Google Scholar] [CrossRef] [PubMed]

- Longo, M.; Stoycheva, T.; Fallica, R.; Wiemer, C.; Lazzarini, L.; Rotunno, E. Au-catalyzed synthesis and characterisation of phase change Ge-doped Sb-Te nanowires by MOCVD. J. Cryst. Growth 2013, 370, 323–327. [Google Scholar] [CrossRef]

- Jung, Y.; Lee, S.H.; Ko, D.K.; Agarwal, R. Synthesis and characterization of Ge2Sb2Te5 nanowires with memory switching effect. J. Am. Chem. Soc. 2006, 128, 14026–14027. [Google Scholar] [CrossRef]

- Cecchini, R.; Selmo, S.; Wiemer, C.; Fanciulli, M.; Rotunno, E.; Lazzarini, L.; Rigato, M.; Pogany, D.; Lugstein, A.; Longo, M. In-doped Sb nanowires grown by MOCVD for high speed phase change memories. Micro Nano Eng. 2019, 2, 117–121. [Google Scholar] [CrossRef]

- Sun, X.; Yu, B.; Ng, G.; Nguyen, T.D.; Meyyappan, M. III-VI compound semiconductor indium selenide (In2Se3) nanowires: Synthesis and characterization. Appl. Phys. Lett. 2006, 89, 233121. [Google Scholar] [CrossRef]

- Selmo, S.; Cecchini, R.; Cecchi, S.; Wiemer, C.; Fanciulli, M.; Rotunno, E.; Lazzarini, L.; Rigato, M.; Pogany, D.; Lugstein, A.; et al. Low power phase change memory switching of ultra-thin In3Sb1Te2 nanowires. Appl. Phys. Lett. 2016, 109, 213103. [Google Scholar] [CrossRef]

- Kumar, A.; Cecchini, R.; Wiemer, C.; Mussi, V.; De Simone, S.; Calarco, R.; Scuderi, M.; Nicotra, G.; Longo, M. MOCVD Growth of GeTe/Sb2Te3 Core–Shell Nanowires. Coatings 2021, 11, 718. [Google Scholar] [CrossRef]

- Canvel, Y.; Lagrasta, S.; Boixaderas, C.; Barnola, S.; Mazel, Y.; Martinez, E. Study of Ge-rich GeSbTe etching process with different halogen plasmas. J. Vac. Sci. Technol. A 2019, 37, 031302. [Google Scholar] [CrossRef]

- Canvel, Y.; Lagrasta, S.; Boixaderas, C.; Barnola, S.; Mazel, Y.; Dabertrand, K.; Martinez, E. Modification of Ge-rich GeSbTe surface during the patterning process of phase-change memories. Microelectron. Eng. 2020, 221, 111183. [Google Scholar] [CrossRef]

- Rotunno, E.; Lazzarini, L.; Longo, M.; Grillo, V. Crystal structure assessment of Ge-Sb-Te phase change nanowires. Nanoscale 2013, 5, 1557–1563. [Google Scholar] [CrossRef] [PubMed]

- Pitchappa, P.; Kumar, A.; Prakash, S.; Jani, H.; Venkatesan, T.; Singh, R. Chalcogenide Phase Change Material for Active Terahertz Photonics. Adv. Mater. 2019, 31, 1808157. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sosso, G.C.; Caravati, S.; Bernasconi, M. Vibrational properties of crystalline Sb2Te3 from first principles. J. Phys. Condens. Matter 2009, 21, 095410. [Google Scholar] [CrossRef] [PubMed]

- Shahil, K.M.F.; Hossain, M.Z.; Goyal, V.; Balandin, A.A. Micro-Raman spectroscopy of mechanically exfoliated few-quintuple layers of Bi2Te3, Bi2Se3, and Sb2Te3 materials. J. Appl. Phys. 2012, 111, 054305. [Google Scholar] [CrossRef] [Green Version]

- Cecchi, S.; Dragoni, D.; Kriegner, D.; Tisbi, E.; Zallo, E.; Arciprete, F.; Holý, V.; Bernasconi, M.; Calarco, R. Interplay between Structural and Thermoelectric Properties in Epitaxial Sb2+xTe3 Alloys. Adv. Funct. Mater. 2019, 29, 1805184. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, A.; Cecchini, R.; Wiemer, C.; Mussi, V.; De Simone, S.; Calarco, R.; Scuderi, M.; Nicotra, G.; Longo, M. Phase Change Ge-Rich Ge–Sb–Te/Sb2Te3 Core-Shell Nanowires by Metal Organic Chemical Vapor Deposition. Nanomaterials 2021, 11, 3358. https://doi.org/10.3390/nano11123358

Kumar A, Cecchini R, Wiemer C, Mussi V, De Simone S, Calarco R, Scuderi M, Nicotra G, Longo M. Phase Change Ge-Rich Ge–Sb–Te/Sb2Te3 Core-Shell Nanowires by Metal Organic Chemical Vapor Deposition. Nanomaterials. 2021; 11(12):3358. https://doi.org/10.3390/nano11123358

Chicago/Turabian StyleKumar, Arun, Raimondo Cecchini, Claudia Wiemer, Valentina Mussi, Sara De Simone, Raffaella Calarco, Mario Scuderi, Giuseppe Nicotra, and Massimo Longo. 2021. "Phase Change Ge-Rich Ge–Sb–Te/Sb2Te3 Core-Shell Nanowires by Metal Organic Chemical Vapor Deposition" Nanomaterials 11, no. 12: 3358. https://doi.org/10.3390/nano11123358

APA StyleKumar, A., Cecchini, R., Wiemer, C., Mussi, V., De Simone, S., Calarco, R., Scuderi, M., Nicotra, G., & Longo, M. (2021). Phase Change Ge-Rich Ge–Sb–Te/Sb2Te3 Core-Shell Nanowires by Metal Organic Chemical Vapor Deposition. Nanomaterials, 11(12), 3358. https://doi.org/10.3390/nano11123358