Topic Editors

Numerical Modelling on Metallic Materials, 2nd Edition

Topic Information

Dear Colleagues,

Following the success of the first volume of the Topic on Numerical Modelling on Metallic Materials, we are pleased to announce the launch of the second volume. Numerical modelling has been applied across a wide range of areas, from microstructural evolution to macroscopic mechanical behaviour, and to understanding the response of metallic materials under diverse processing and service conditions.

In this new volume, we will continue to welcome contributions using physics-based modelling, while placing particular emphasis on encouraging data-driven modelling studies. This Topic aims to provide a collective platform to showcase the current state of the art in numerical modelling on metallic materials, fostering interdisciplinary interaction and cross-fertilisation that will drive the future development and application of modelling techniques in materials science and engineering.

We cordially invite scientists, researchers, and engineers to contribute to this follow-up Topic, with subjects including, but not limited to:

- Ab initio calculations of alloy design and property prediction;

- Multiscale and multiphysics modelling;

- AI and machine learning;

- Data mining and its application in metallic materials design and manufacturing;

- Surrogate and reduced-order modelling;

- Materials constitutive modelling;

- Modelling and simulation of materials’ manufacturing processes;

- Solidification, deformation, and phase transformation;

- Prediction of microstructure and properties;

- Plasticity and strain damage;

- Fatigue and fracture of metallic materials;

- Prediction and mitigation of residual stress and distortion;

- Numerical methods, software technology, verification/validation, and standardisation.

Dr. Shuwen Wen

Dr. Yongle Sun

Dr. Xin Chen

Topic Editors

Keywords

- numerical modelling

- metallic materials

- microstructure and properties

- ab initio calculation

- molecular dynamics (MD)

- finite element method (FEM)

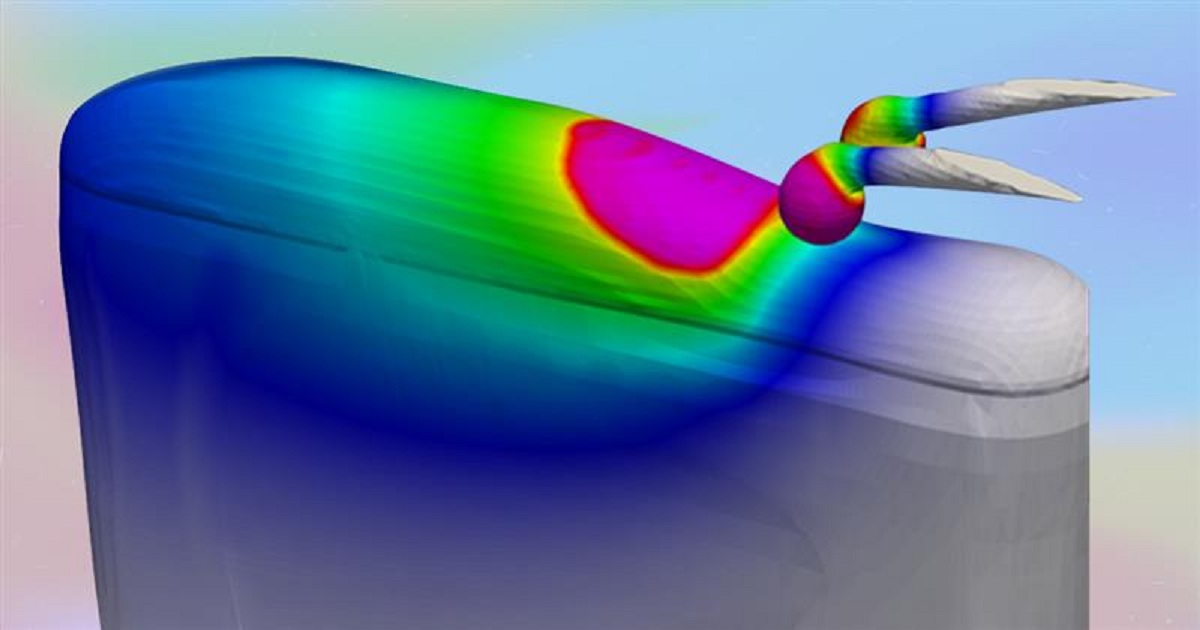

- computational fluid dynamics (CFD)

- data analysis

- modelling and simulation

- verification and validation

- engineering

- manufacturing processes

- fatigue and fracture

- service performance

Participating Journals

| Journal Name | Impact Factor | CiteScore | Launched Year | First Decision (median) | APC | |

|---|---|---|---|---|---|---|

Materials

|

3.2 | 6.4 | 2008 | 15.5 Days | CHF 2600 | Submit |

Metals

|

2.5 | 5.3 | 2011 | 18.7 Days | CHF 2600 | Submit |

Applied Sciences

|

2.5 | 5.5 | 2011 | 16 Days | CHF 2400 | Submit |

Journal of Manufacturing and Materials Processing

|

3.3 | 5.2 | 2017 | 15.9 Days | CHF 1800 | Submit |

Alloys

|

- | 3.2 | 2022 | 19.1 Days | CHF 1000 | Submit |

Preprints.org is a multidisciplinary platform offering a preprint service designed to facilitate the early sharing of your research. It supports and empowers your research journey from the very beginning.

MDPI Topics is collaborating with Preprints.org and has established a direct connection between MDPI journals and the platform. Authors are encouraged to take advantage of this opportunity by posting their preprints at Preprints.org prior to publication:

- Share your research immediately: disseminate your ideas prior to publication and establish priority for your work.

- Safeguard your intellectual contribution: Protect your ideas with a time-stamped preprint that serves as proof of your research timeline.

- Boost visibility and impact: Increase the reach and influence of your research by making it accessible to a global audience.

- Gain early feedback: Receive valuable input and insights from peers before submitting to a journal.

- Ensure broad indexing: Web of Science (Preprint Citation Index), Google Scholar, Crossref, SHARE, PrePubMed, Scilit and Europe PMC.

Related Topic

- Numerical Modelling on Metallic Materials (21 articles)