A Micromachined Silicon-on-Glass Accelerometer with an Optimized Comb Finger Gap Arrangement

Abstract

1. Introduction

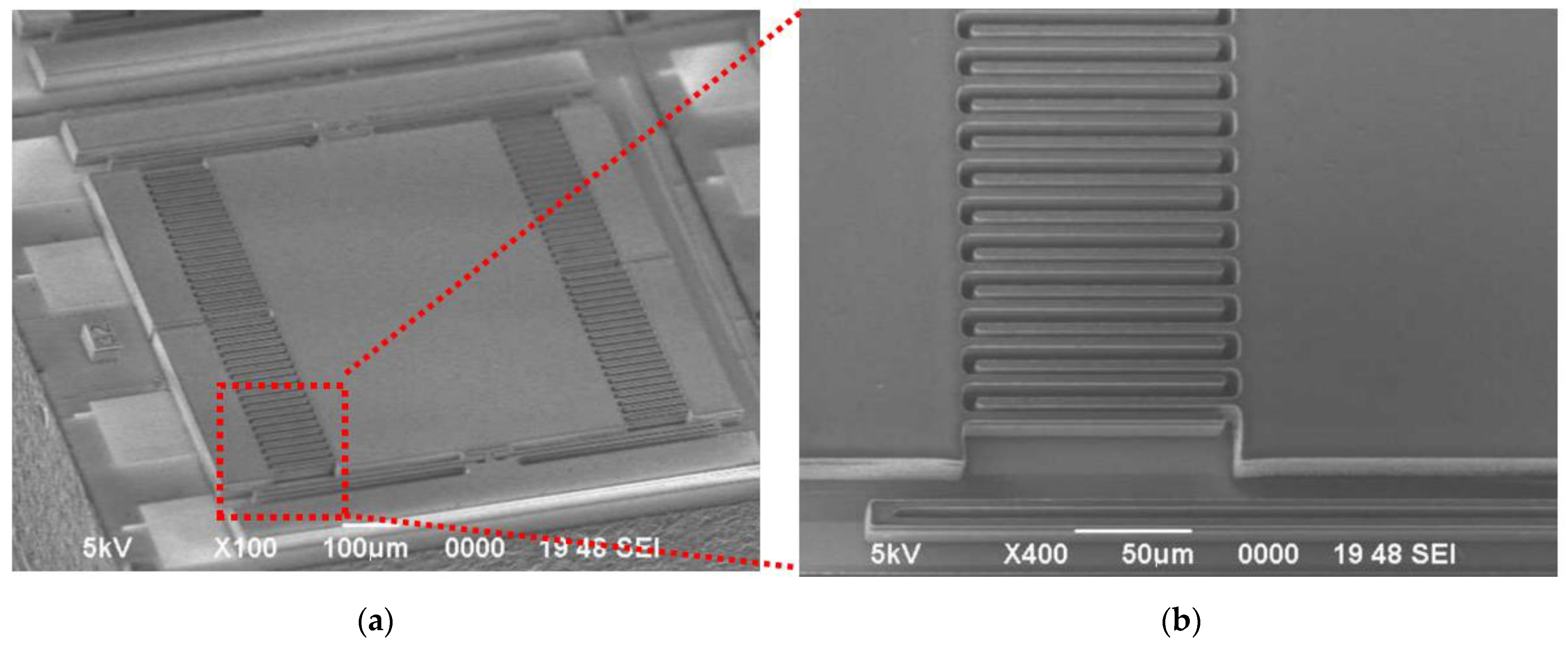

2. Design and Modeling

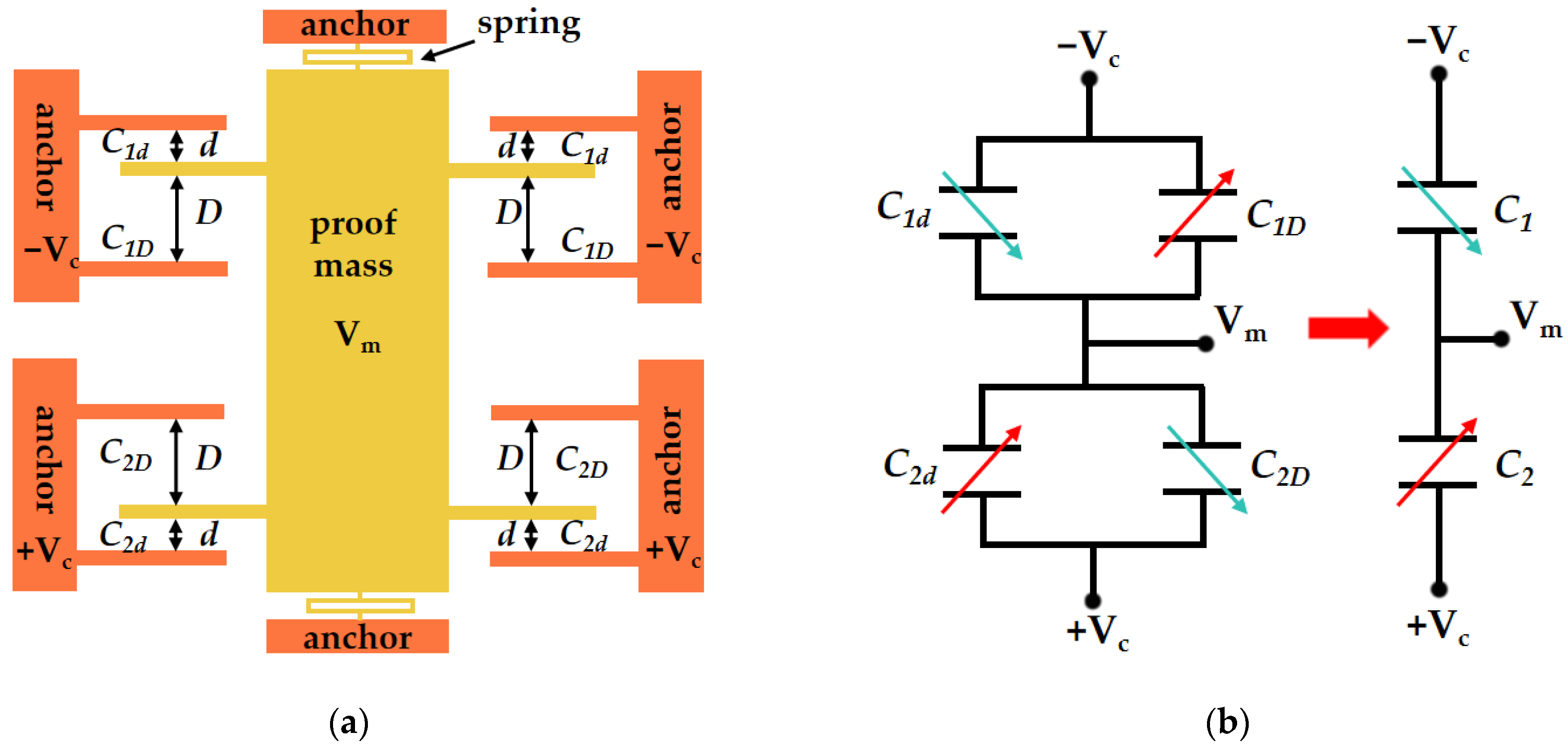

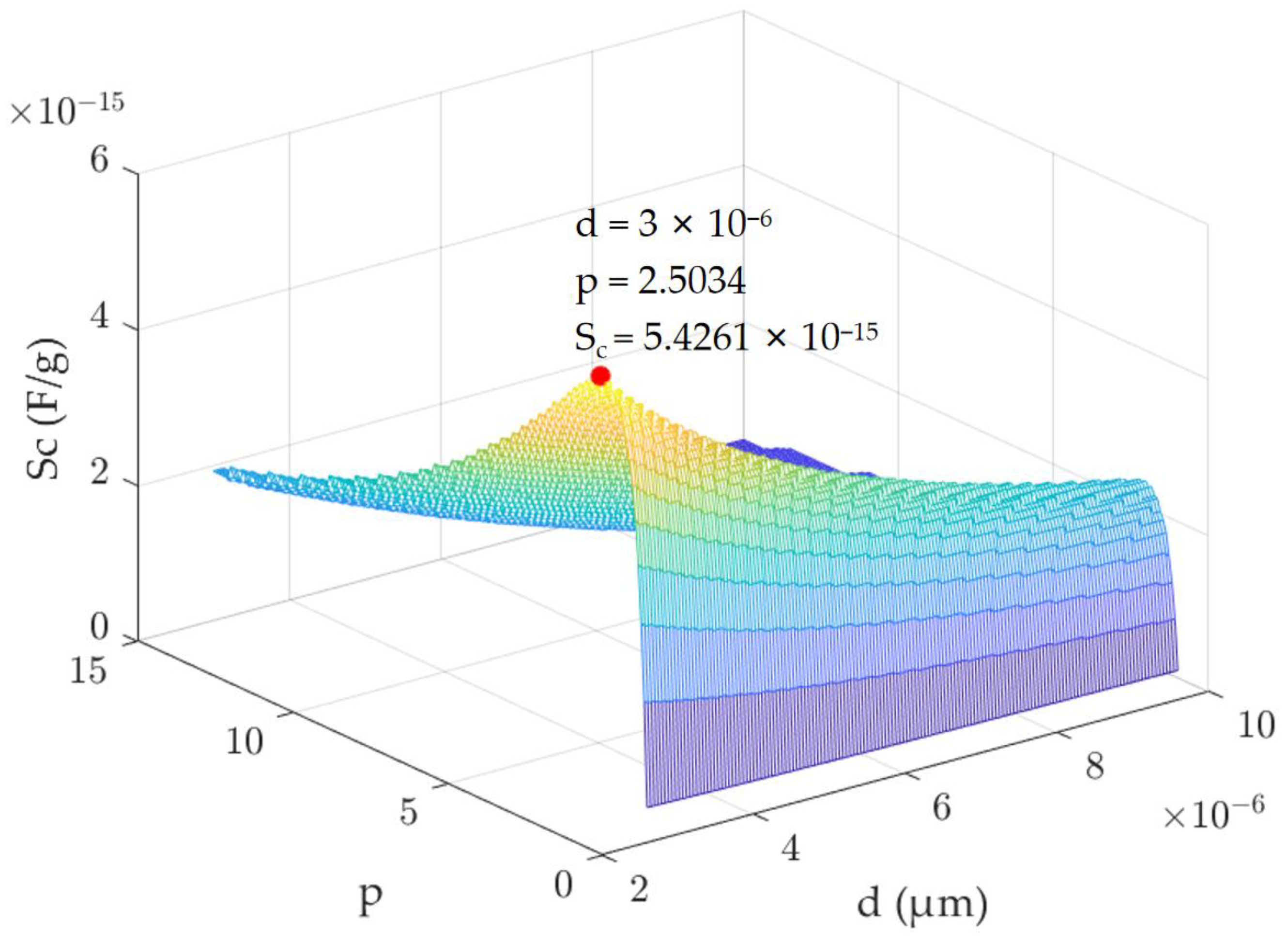

2.1. Structure Design

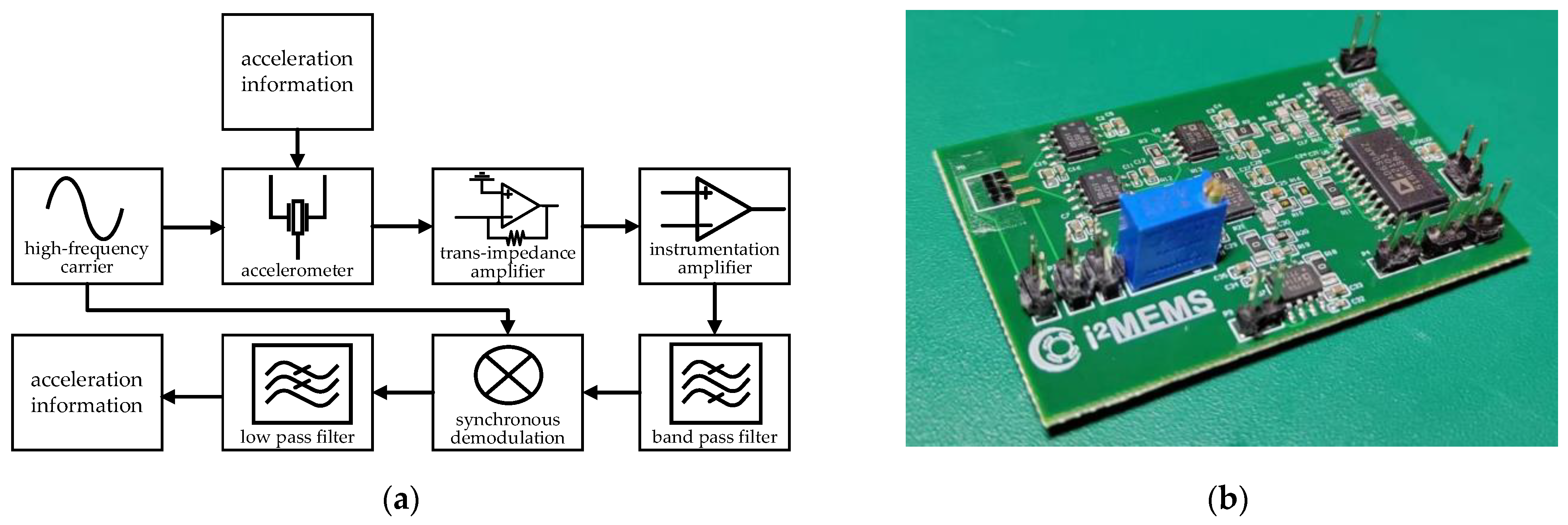

2.2. Signal Sensing Circuit Design

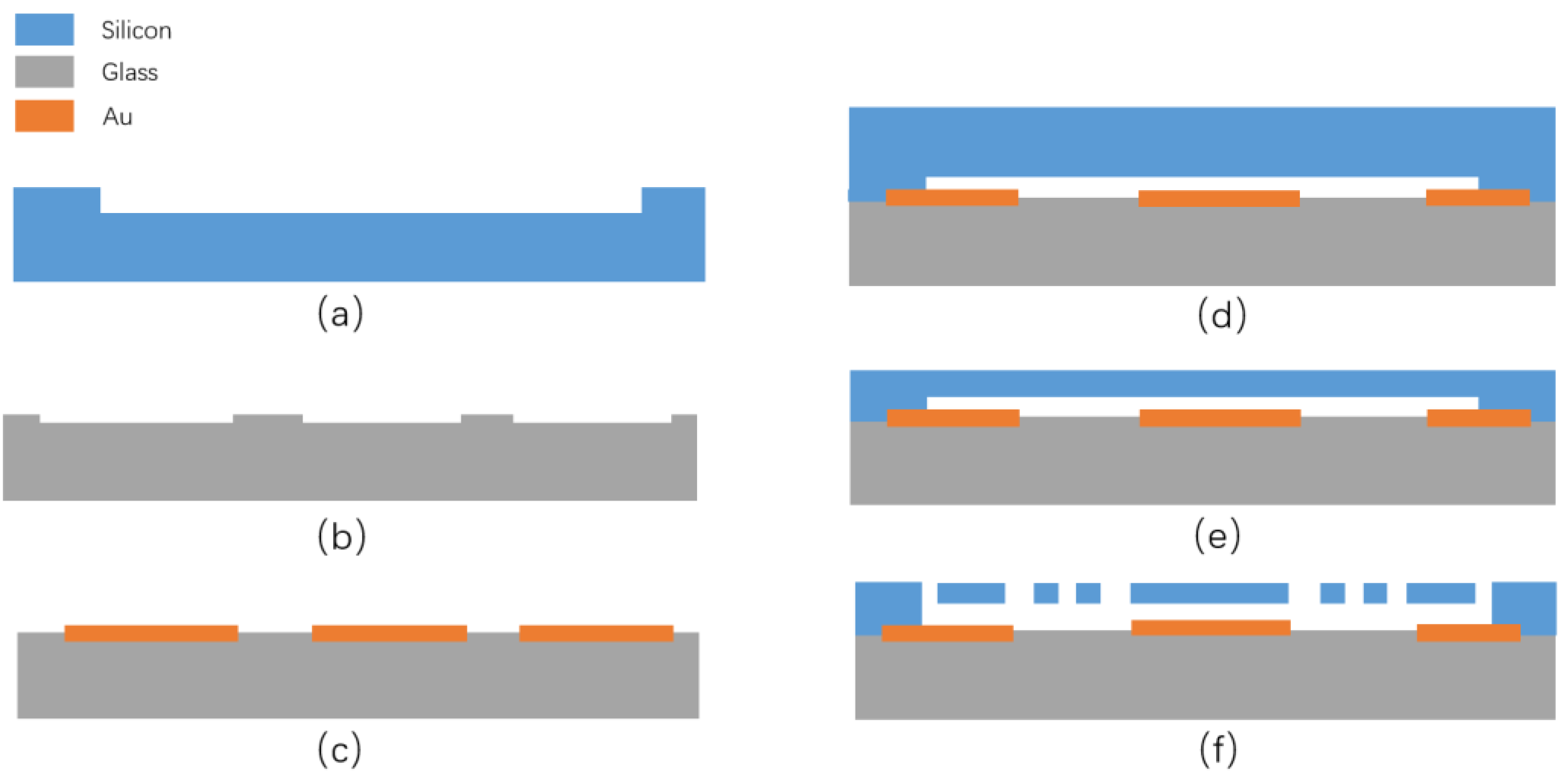

2.3. Fabrication Process

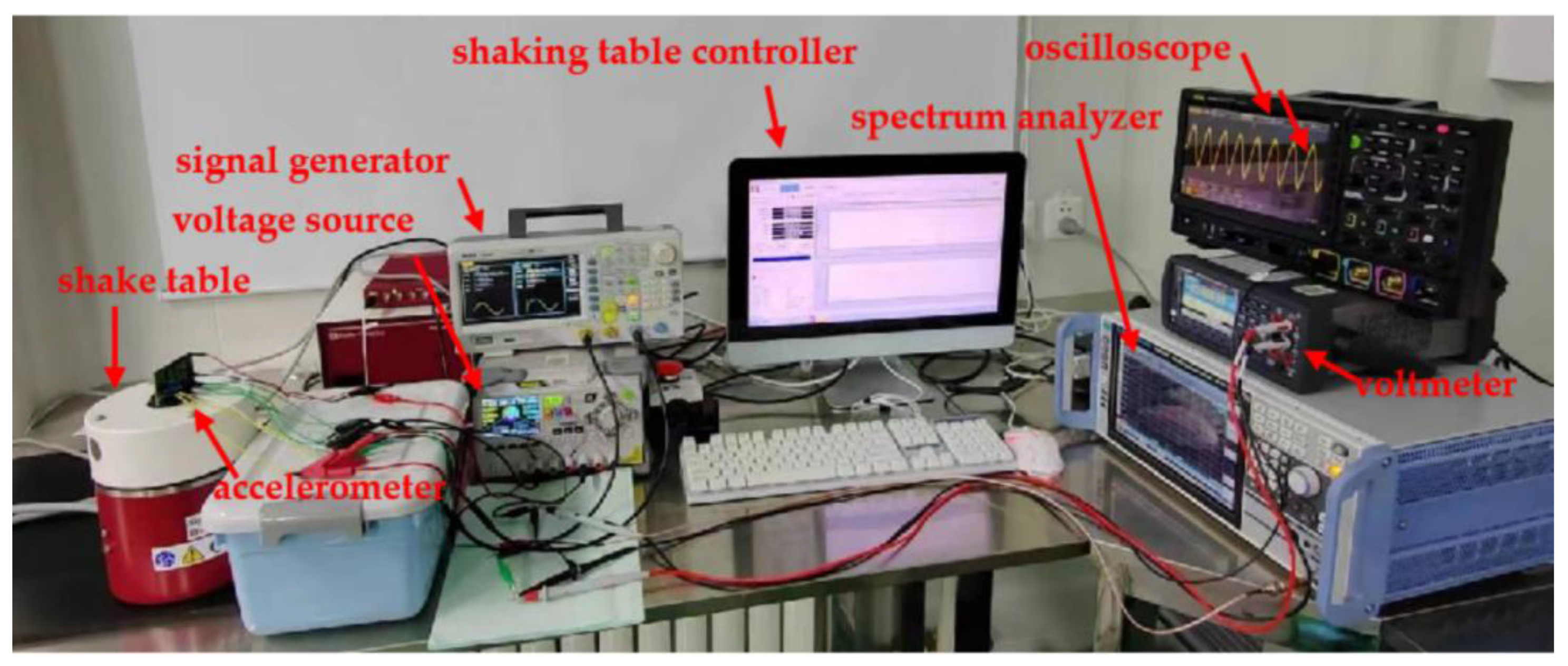

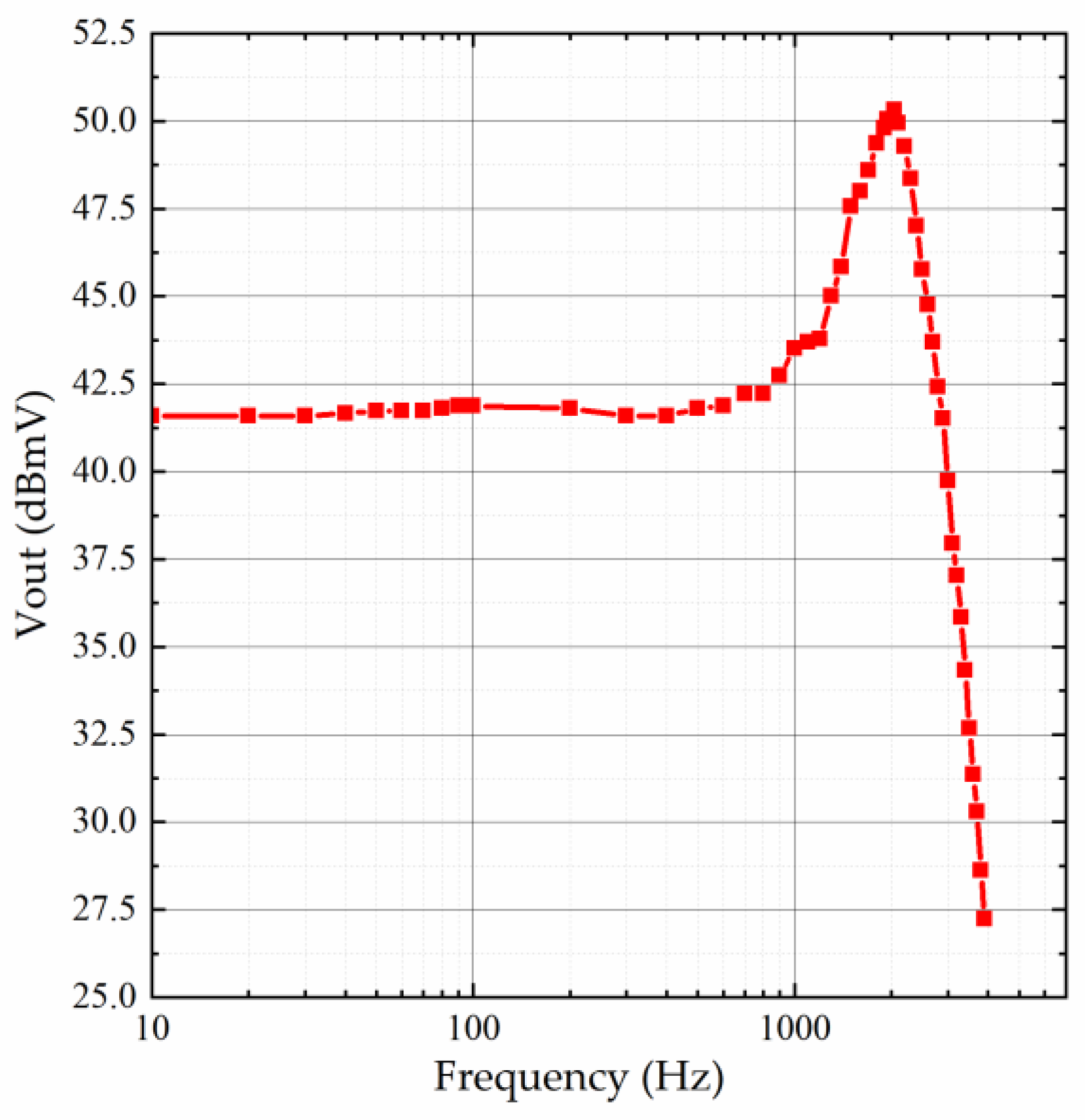

3. Experimental Results

3.1. Mechanical Test

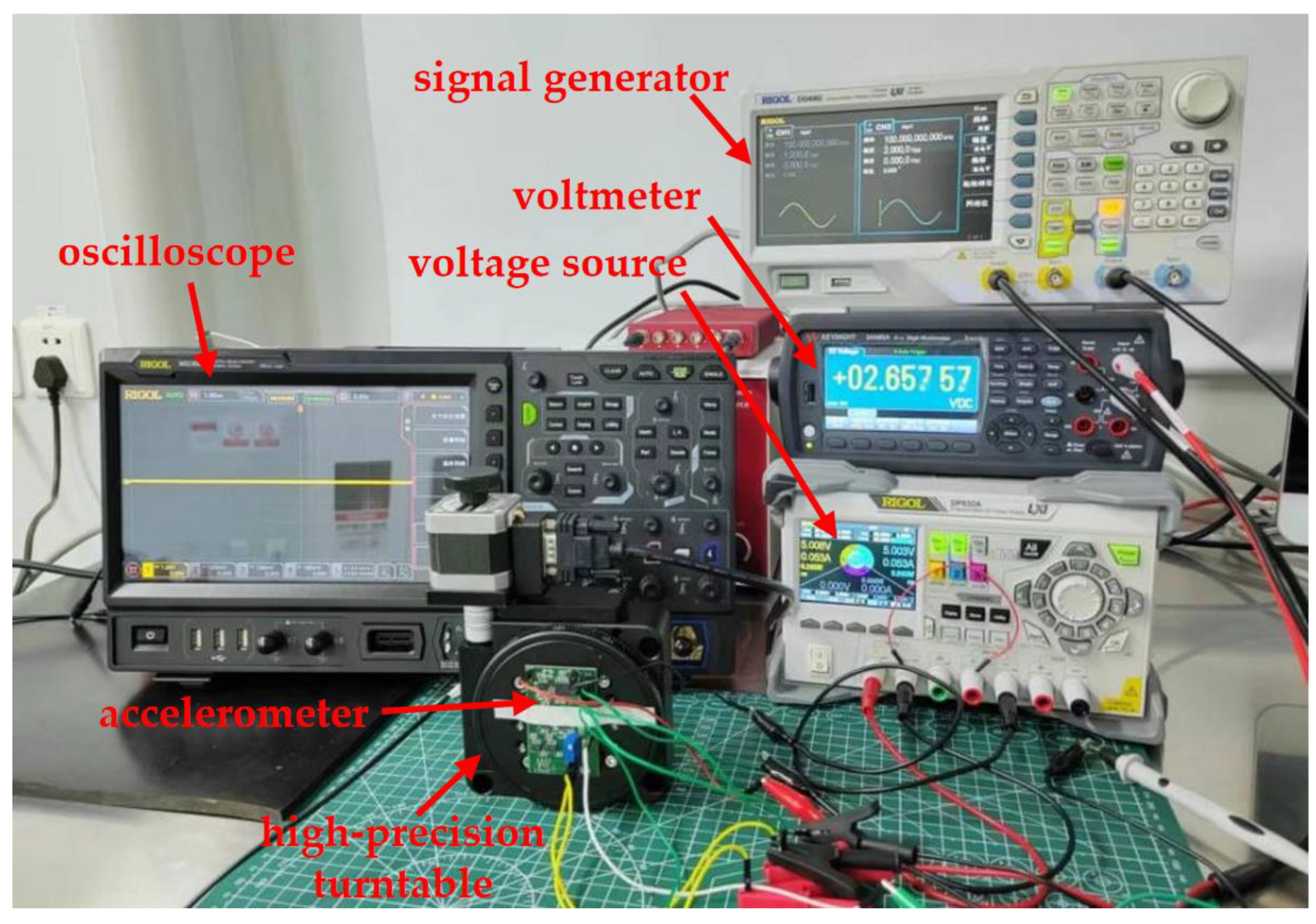

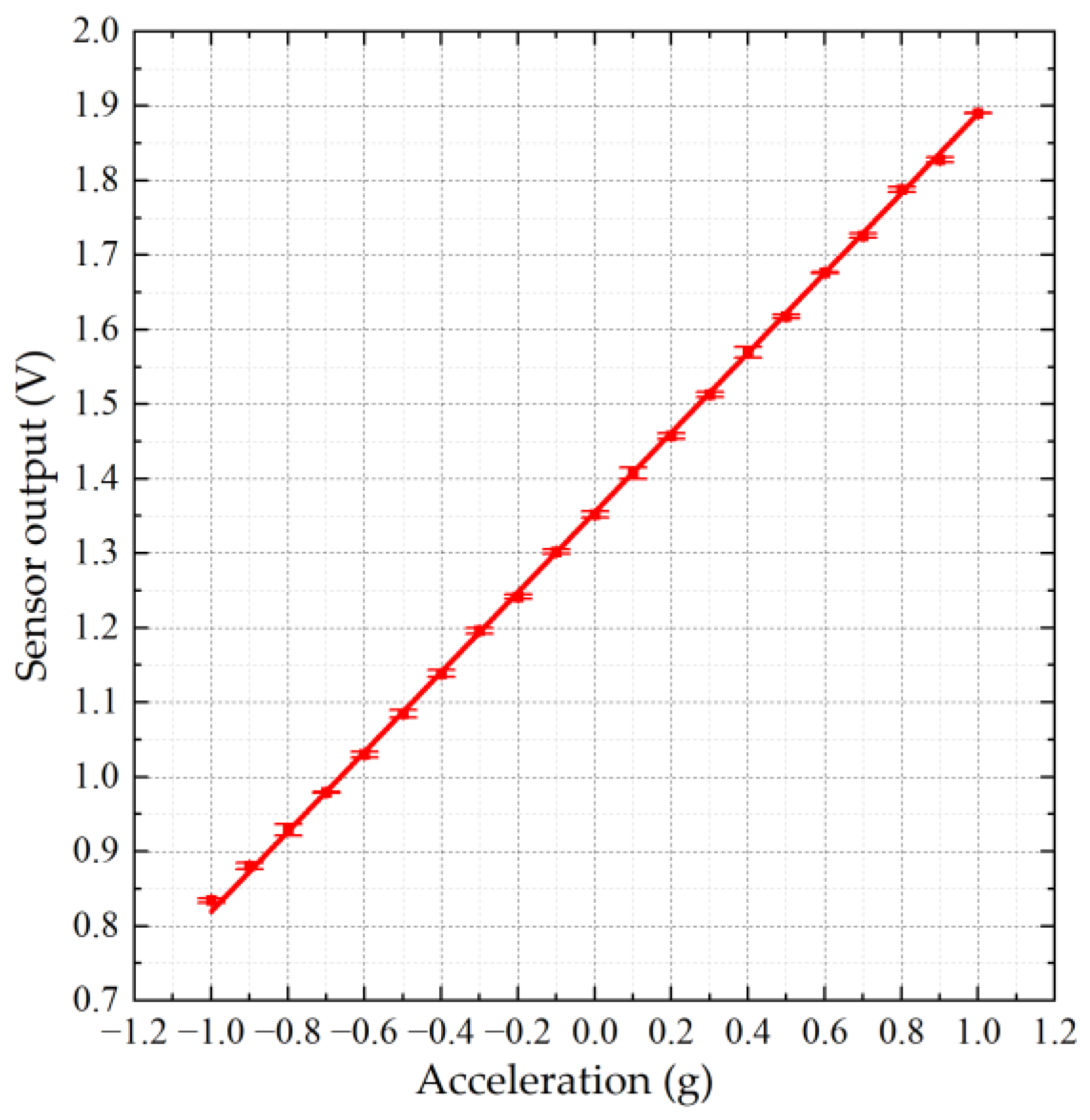

3.2. Quasi-Static Response Test

3.3. Noise Measurements

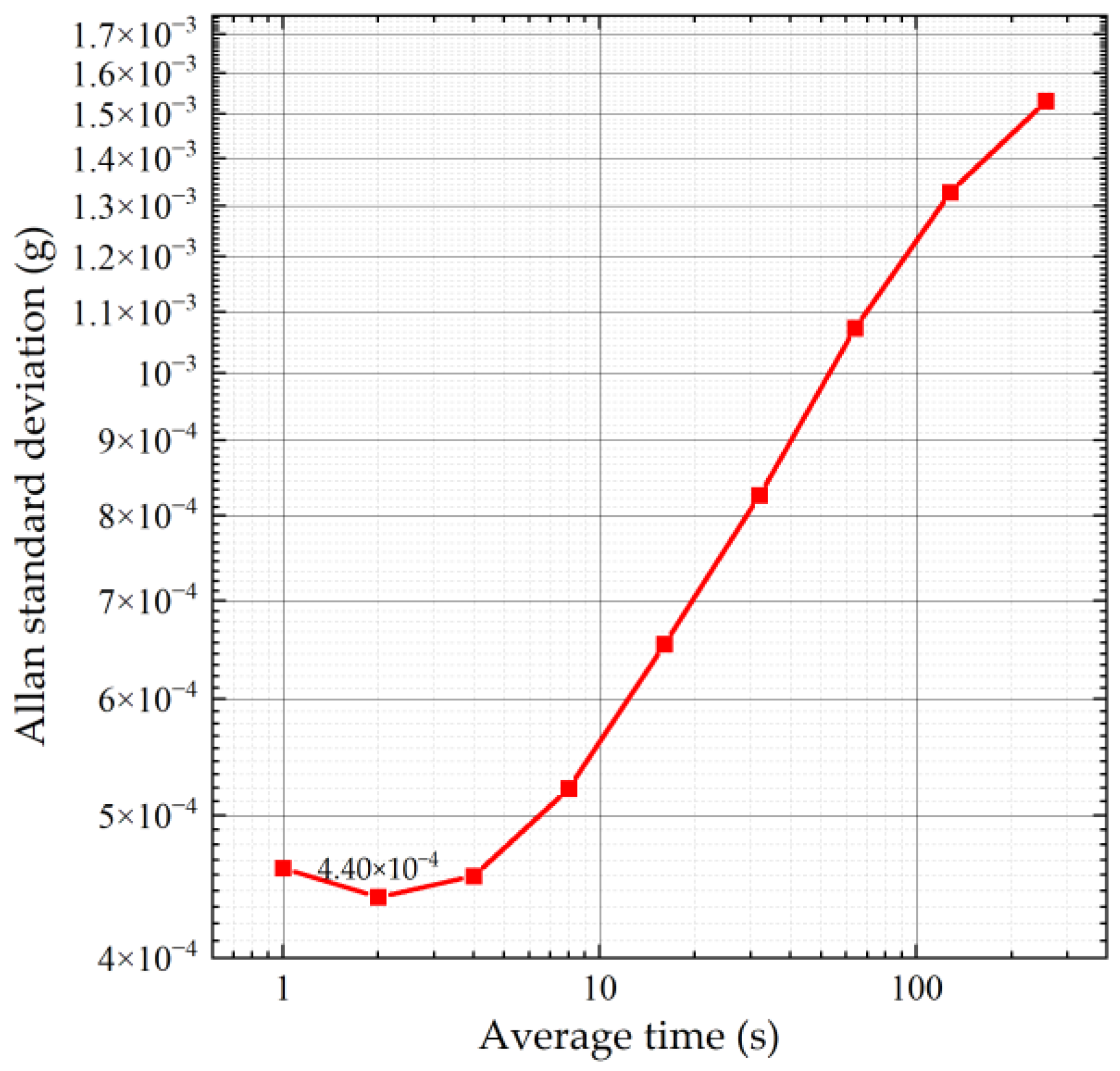

3.4. Zero-Bias Instability

4. Performance Comparison

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhu, J.; Liu, X. Development trends and perspectives of future sensors and MEMS/NEMS. Micromachines 2020, 11, 7. [Google Scholar] [CrossRef] [PubMed]

- El-Sheimy, N.; Youssef, A. Inertial sensors technologies for navigation applications: State of the art and future trends. Satell. Navig. 2020, 1, 2. [Google Scholar] [CrossRef]

- D’Alessandro, A.; Scudero, S. A review of the capacitive MEMS for seismology. Sensors 2019, 19, 3093. [Google Scholar] [CrossRef] [PubMed]

- Algamili, A.S.; Khir, M.H.M. A review of actuation and sensing mechanisms in MEMS-based sensor devices. Nanoscale Res. Lett 2021, 16, 16. [Google Scholar] [CrossRef] [PubMed]

- Tang, B.; Sato, K. Process development of an all-silicon capacitive accelerometer with a highly symmetrical spring-mass structure etched in TMAH + Triton-X-100. Sens. Actuators A 2014, 217, 105–110. [Google Scholar] [CrossRef]

- Qiu, S.; Zhao, H. Multi-sensor information fusion based on machine learning for real applications in human activity recognition: State-of-the-art and research challenges. Inform. Fusion 2022, 80, 241–265. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, J. Design and experiment of pushpull MEMS resonant accelerometers. IEEE Sens. J. 2023, 23, 22233–22239. [Google Scholar] [CrossRef]

- Masihi, S.; Panahi, M. A highly sensitive capacitive based dual-axis accelerometer for wearable applications. In Proceedings of the 2020 IEEE International Conference on Electro-Information Technology, Chicago, IL, USA, 31 July–1 August 2020; pp. 557–561. [Google Scholar]

- Ma, Y.; Wang, S. Design and test of MEMS resonant accelerometer with a novel die-attach structure. In Proceedings of the 2023 IEEE Sensors, Vienna, Austria, 29 October–1 November 2023; pp. 1–4. [Google Scholar]

- Wang, Y.-Y.; Wu, G.-Y. Study of silicon-based MEMS technology and its standard process. Acta Electron. Sin. 2002, 30, 1577. [Google Scholar]

- Tez, S.; Akin, T. Fabrication of a sandwich type three axis capacitive MEMS accelerometer. In Proceedings of the 2013 IEEE Sensors, Baltimore, MD, USA, 3–6 November 2013; pp. 1863–1866. [Google Scholar]

- Chae, J.; Kulah, H. A CMOS-compatible high aspect ratio silicon-on-glass in-plane micro-accelerometer. J. Micromech. Microeng. 2005, 15, 336–345. [Google Scholar] [CrossRef]

- Li, R.; Mohammed, Z. Design, modelling and characterization of comb drive MEMS gap-changeable differential capacitive accelerometer. Measurement 2021, 169, 108377. [Google Scholar] [CrossRef]

- Bansal, A.; Paul, B.C. An analytical fringe capacitance model for interconnects using conformal mapping. IEEE Trans. Comput. -Aided Des. Integr. Circuits Syst. 2006, 25, 2765–2774. [Google Scholar] [CrossRef]

- Jansen, H.V.; de Boer, M.J. Black silicon method X: A review on high speed and selective plasma etching of silicon with profile control: An in-depth comparison between Bosch and cryostat DRIE processes as a roadmap to next generation equipment. J. Micromech. Microeng. 2009, 19, 033001. [Google Scholar] [CrossRef]

- Guo, Z.; Li, Y. Research progress of lock-in amplifiers. Acta Phys. Sin. 2023, 72, 224206. [Google Scholar] [CrossRef]

- Dai, G.; Li, M. Thermal drift analysis using a multiphysics model of bulk silicon MEMS capacitive accelerometer. Sens. Actuators A 2011, 172, 369–378. [Google Scholar] [CrossRef]

- Vollenbroek, J.C.; Nieuwelink, A.-E. Droplet microreactor for high-throughput fluorescence-based measurements of single catalyst particle acidity. Microsyst. Nanoeng. 2023, 9, 39. [Google Scholar] [CrossRef]

- Nieuwelink, A.-E.; Vollenbroek, J.C. High-throughput activity screening and sorting of single catalyst particles with a droplet microreactor using dielectrophoresis. Nat. Catal. 2021, 4, 1070–1079. [Google Scholar] [CrossRef]

- Qu, H.Z. Development of DRIE CMOS-MEMS Process and Integrated Accelerometers. Ph.D. Thesis, University of Florida, Gainesville, FL, USA, 2006. [Google Scholar]

- Kuehnel, W. Modelling of the mechanical behaviour of a differential capacitor acceleration sensor. Sens. Actuators A 1995, 48, 101–108. [Google Scholar] [CrossRef]

- Fang, D.Z. Low-Noise and Low-Power Interface Circuits Design for Integrated CMOS-MEMS Inertial Sensors. Ph.D. Thesis, University of Florida, Gainesville, FL, USA, 2006. [Google Scholar]

- Gabrielson, T.B. Mechanical-thermal noise in micromachined acoustic and vibration sensors. IEEE Trans. Electron Devices 1993, 40, 903–909. [Google Scholar] [CrossRef]

- Li, J.; Fang, J. Not fully overlapping allan variance and total variance for inertial sensor stochastic error analysis. IEEE Trans. Instrum. Meas. 2013, 62, 2659–2672. [Google Scholar] [CrossRef]

- He, J.; Xie, J. Analytical study and compensation for temperature drifts of a bulk silicon MEMS capacitive accelerometer. Sens. Actuators A 2016, 239, 174–184. [Google Scholar] [CrossRef]

- Wang, C.; Hao, Y. Design of a capacitive MEMS accelerometer with softened beams. Micromachines 2022, 13, 459. [Google Scholar] [CrossRef] [PubMed]

| Gap ratio D/d | 2 | 2.5 | 5 | 10 | 12 | 15 |

| Sc (F/g) | 5.78 × 10−15 | 5.97 × 10−15 | 5.24 × 10−15 | 5.18 × 10−15 | 5.16 × 10−15 | 5.13 × 10−15 |

| Parameter | Symbol | Values |

|---|---|---|

| Overall sensor size | As | 1000 μm × 950 μm |

| Thickness of the structure | T | 45 μm |

| Comb finger gap/anti-finger gap | d/D | 3 μm/7.5 μm |

| Sensing fingers | Lfinger × Wfinger | 120 μm × 4 μm |

| Number of comb finger | N | 42 |

| Proof mass size | Lmass × Wmass | 750 μm × 560 μm |

| Spring dimension | Lspring × Wspring | 410 μm × 4 μm |

| Procedure | Cavity Pressure | ICP Power | LF Power | C4F8 | SF6 | Time |

|---|---|---|---|---|---|---|

| mtorr | W | W | sccm | sccm | s | |

| Passivation | 30 | 1800 | 0 | 150 | 0 | 2 |

| Etching-1 | 60 | 2200 | 300 | 0 | 200 | 1 |

| Etching-2 | 60 | 2200 | 60 | 0 | 200 | 3 |

| References | Sensor Area (mm2) | Comb Finger Gap (μm) | Capacitive Sensitivity (fF/g) | Resonant Frequency (Hz) | Electrical Sensitivity (mV/g) | Noise Floor (μg/√Hz) | Zero-Bias Instability (g) | CSPA |

|---|---|---|---|---|---|---|---|---|

| This work | 0.95 | 3 | 5.4 | 2050 | 532 | 28 | 4.4 × 10−4 | 51.15 |

| Li et al. [13] | 2.48 | 1 | 80 | 4270 | 35.93 | NA | NA | 32.25 |

| Wang et al. [26] | 77.44 | 4 | 178 | 400 | 3..47 | 40 | 8.24 × 10−6 | 36.77 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Feng, R.; Wang, X.; Cao, H.; Gong, K.; Xie, H. A Micromachined Silicon-on-Glass Accelerometer with an Optimized Comb Finger Gap Arrangement. Micromachines 2024, 15, 1173. https://doi.org/10.3390/mi15091173

Li J, Feng R, Wang X, Cao H, Gong K, Xie H. A Micromachined Silicon-on-Glass Accelerometer with an Optimized Comb Finger Gap Arrangement. Micromachines. 2024; 15(9):1173. https://doi.org/10.3390/mi15091173

Chicago/Turabian StyleLi, Jiacheng, Rui Feng, Xiaoyi Wang, Huiliang Cao, Keru Gong, and Huikai Xie. 2024. "A Micromachined Silicon-on-Glass Accelerometer with an Optimized Comb Finger Gap Arrangement" Micromachines 15, no. 9: 1173. https://doi.org/10.3390/mi15091173

APA StyleLi, J., Feng, R., Wang, X., Cao, H., Gong, K., & Xie, H. (2024). A Micromachined Silicon-on-Glass Accelerometer with an Optimized Comb Finger Gap Arrangement. Micromachines, 15(9), 1173. https://doi.org/10.3390/mi15091173