A Review of the Application of Synthetic and Natural Polymers as Construction and Building Materials for Achieving Sustainable Construction

Abstract

:1. Introduction

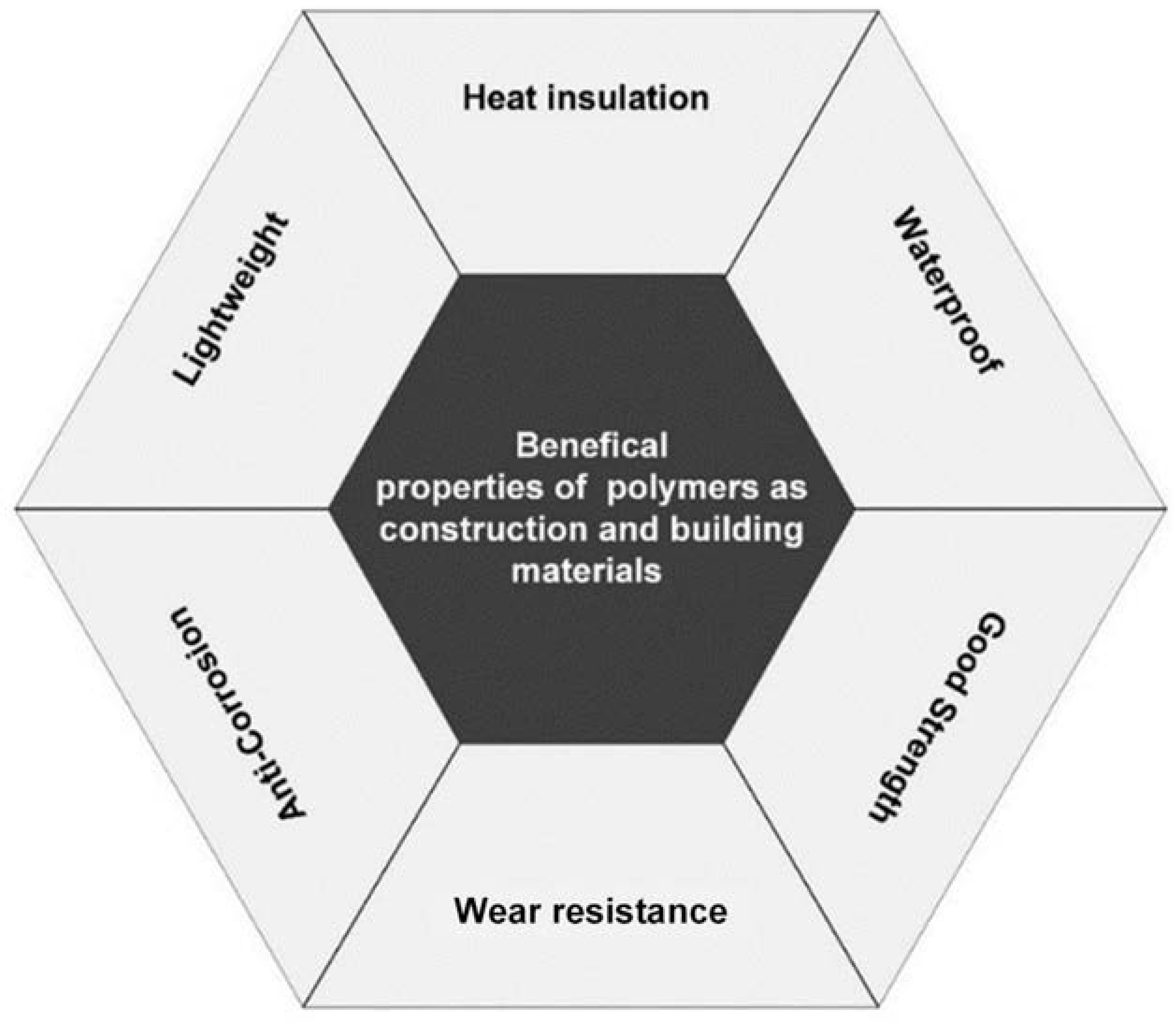

2. Synthetic and Natural Polymers as Construction and Building Materials

2.1. Poly(methylmethacrylate(PMMA))

2.2. Poly(vinylbutyrate(PVB))

2.3. Poly(vinylchloride(PVC))

2.4. Polyamides(nylons)

2.5. Polycarbonate (PC)

2.6. Polyethylene (PE)

2.7. Poly-Isobutylene (PIB)

2.8. Polypropylene (PP)

2.9. Polystyrene (PS)

2.10. Polyurethane (PU)

2.11. Cellulose

2.12. Alginate

2.13. Epoxy Resins

3. Conclusions and Perspectives

Author Contributions

Funding

Conflicts of Interest

References

- Hatefi, S.M.; Asadi, H.; Shams, G.; Tamošaitiene, J.; Turskis, Z. Model for the Sustainable Material Selection by Applying Integrated Dempster-Shafer Evidence Theory and Additive Ratio Assessment (ARAS) Method. Sustainability 2021, 13, 10438. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Turskis, Z.; Tamosaitiene, J. Selection of construction enterprises management strategy based on the SWOT and multi-criteria analysis. Arch. Civ. Mech. Eng. 2011, 11, 1063–1082. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Kaklauskas, A.; Turskis, Z.; Kalibatas, D. An approach to multi-attribute assessment of indoor environment before and after refurbishment of dwellings. J. Environ. Eng. Landsc. Manag. 2009, 17, 5–11. [Google Scholar] [CrossRef]

- Peldschus, F.; Zavadskas, E.K.; Turskis, Z.; Tamosaitiene, J. Sustainable assessment of construction site by applying Game Theory. Inz. Ekon. Eng. Econ. 2010, 21, 223–237. [Google Scholar]

- Sivilevičius, H.; Zavadskas, E.K.; Turskis, Z. Quality attributes and complex assessment methodology of the asphalt mixing plant. Balt. J. Road Bridge Eng. 2008, 3, 161–166. [Google Scholar] [CrossRef]

- Hashemi, H.; Mousavi, S.M.; Zavadskas, E.K.; Chalekaee, A.; Turskis, Z. A new group decision model based on grey-intuitionistic fuzzy-ELECTRE and VIKOR for contractor assessment problem. Sustainability 2018, 10, 1635. [Google Scholar] [CrossRef]

- Erdogan, S.A.; Šaparauskas, J.; Turskis, Z. A multi-criteria decision-making model to choose the best option for sustainable construction management. Sustainability 2019, 11, 2239. [Google Scholar] [CrossRef]

- Turskis, Z.; Zavadskas, E.K.; Kutut, V. A model based on ARAS-G and AHP methods for multiple criteria prioritizing of heritage value. Int. J. Inf. Technol. Decis. Mak. 2013, 12, 45–73. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Turskis, Z.; Vilutienė, T.; Lepkova, N. Integrated group fuzzy multi-criteria model: Case of facilities management strategy selection. Expert Syst. Appl. 2017, 82, 317–331. [Google Scholar] [CrossRef]

- Ghorabaee, M.K.; Amiri, M.; Zavadskas, E.K.; Turskis, Z. Multi-criteria group decision-making using an extended EDAS method with interval type-2 fuzzy sets. E M Ekon. A Manag. 2017, 20, 48–68. [Google Scholar] [CrossRef]

- Turskis, Z.; Goranin, N.; Nurusheva, A.; Boranbayev, S. A fuzzy WASPAS-based approach to determine critical information infrastructures of EU sustainable development. Sustainability 2019, 11, 424. [Google Scholar] [CrossRef]

- Shen, J.; Liang, J.; Lin, X.; Lin, H.; Yu, J.; Yang, Z. Recent progress in polymer-based building materials. Int. J. Polym. Sci. 2020, 2020, 8838160. [Google Scholar] [CrossRef]

- Hassan, A.A. The Potential application of Bio-polymeric materials in Building: A Framework of multi-performance criteria matrix for selecting optimal materials by the AHP and TOPSIS methods. In Proceedings of the Building Enclosure Science and Technology (BEST5) Conference, Philadelphia, PA, USA, 15–18 April 2018. [Google Scholar]

- European Commission. Horizon 2020-EU Bioeconomy Research and Innovation; European Commission: Brussels, Belgium, 2012.

- Kasapoğlu, E. Polymer-based building materials: Effects of quality on durability. In Proceedings of the 11DBMC International Conference on Durability of Building Materials and Components, Istanbul, Turkey, 11–14 May 2008. [Google Scholar]

- Correia Diogo, A. Polymers in building and construction. In Materials for Construction and Civil Engineering; Springer: Cham, Switzerland, 2015; pp. 447–499. [Google Scholar]

- Oprisan, G.; Taranu, N.; Munteanu, V.; Entuc, I. Application of modern polymeric composite materials in industrial construction. Bul. Institutului Politeh. Din Lasi. Sect. Constr. Arhit. 2010, 56, 121. [Google Scholar]

- Nurkulov, F.; Ziyamukhamedova, U.; Rakhmatov, E.; Nafasov, J. Slowing down the corrosion of metal structures using polymeric materials. E3S Web Conf. 2021, 264, 02055. [Google Scholar] [CrossRef]

- Yang, T.C.; Wu, J.H.; Noguchi, T.; Isshiki, M. Methodology of accelerated weathering test through physicochemical analysis for polymeric materials in building construction. Mater. Res. Innov. 2014, 18, S3–S91. [Google Scholar] [CrossRef]

- Wang, F.; Lu, X.; He, C. Some recent developments of polyhedral oligomeric silsesquioxane (POSS)-based polymeric materials. J. Mater. Chem. 2011, 21, 2775–2782. [Google Scholar] [CrossRef]

- Mosallam, A.S.; Bayraktar, A.; Elmikawi, M.; Pul, S.; Adanur, S. Polymer composites in construction: An overview. SOJ Mater. Sci. Eng. 2014, 2, 1–25. [Google Scholar] [CrossRef]

- Motavalli, M.; Czaderski, C.; Schumacher, A.; Gsell, D. Fibre reinforced polymer composite materials for building and construction. In Textiles, Polymers and Composites for Buildings; Woodhead Publishing: Sawston, UK, 2010; pp. 69–128. [Google Scholar]

- Yu, C.; Crump, D. A review of the emission of VOCs from polymeric materials used in buildings. Build. Environ. 1998, 33, 357–374. [Google Scholar] [CrossRef]

- Giannopoulou, I.; Dimas, D.; Maragkos, I.; Panias, D. Utilization of metallurgical solid by-products for the development of inorganic polymeric construction materials. Glob. NEST J. 2009, 11, 127–136. [Google Scholar]

- Sakkas, K.; Nomikos, P.; Sofianos, A.; Panias, D. Utilisation of FeNi-slag for the production of inorganic polymeric materials for construction or for passive fire protection. Waste Biomass Valoriz. 2014, 5, 403–410. [Google Scholar] [CrossRef]

- Hollaway, L.C. (Ed.) Polymers and Polymer Composites in Construction; Thomas Telford: London, UK, 1990. [Google Scholar]

- Hamilton, H.R.; Benmokrane, B.; Dolan, C.W.; Sprinkel, M.M. Polymer materials to enhance performance of concrete in civil infrastructure. Polym. Rev. 2009, 49, 1–24. [Google Scholar] [CrossRef]

- Benmokrane, B.; Wang, P.; Ton-That, T.; Rahman, H.; Robert, J. Durability of glass fiber reinforced polymer reinforcing bars in concrete environment. ASCE J. Compos. Constr. 2002, 6, 143–153. [Google Scholar] [CrossRef]

- Verghese, K. Durability of Polymer Matrix Composites for Infrastructure: The Role of the Interphase. Ph.D. Thesis, West Virginia Tech. University, Beckley, WV, USA, 1999. [Google Scholar]

- Brena, S.F.; Wood, S.L.; Kreger, M. Fatigue Tests of Reinforced Concrete Beams Strengthened Using Carbon Fiber Reinforced Polymer Composites. In Proceedings of the Second International Conference on Durability of Fiber Reinforced Polymer Composites for Construction, Montreal, QC, Canada, 29–31 May 2002; pp. 575–586. [Google Scholar]

- Karbhari, V.M.; Chin, J.W.; Hunston, D.; Benmokrane, B.; Juska, T.; Morgan, R.; Lesko, J.J.; Sorathia, U.; Reynaud, D. Durability gap analysis for fiber-reinforced polymer composites in civil infrastructure. J. Compos. Constr. 2003, 7, 238–247. [Google Scholar] [CrossRef]

- Bhatia, S. Natural polymers vs. synthetic polymer. In Natural Polymer Drug Delivery Systems; Springer: Cham, Switzerland, 2016; pp. 95–118. [Google Scholar]

- Feldman, D. Polymer nanocomposites in building, construction. J. Macromol. Sci. Part A 2014, 51, 203–209. [Google Scholar] [CrossRef]

- Tarannum, N.; Pooja, K.M.; Khan, R. Preparation and applications of hydrophobic multicomponent based redispersible polymer powder: A review. Constr. Build. Mater. 2020, 247, 118579. [Google Scholar] [CrossRef]

- Hutchinson, A.R.; Iglauer, S. Adhesion of construction sealants to polymer foam backer rod used in building construction. Int. J. Adhes. Adhes. 2006, 26, 555–566. [Google Scholar] [CrossRef]

- Niska, K.O.; Sain, M. (Eds.) Wood-Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Sri, M.D.; Devi, N.; Hendro, S.; Lilya, S. Addition of Bamboo pegs on the reinforcement. Int. J. Civ. Eng. Technol. 2019, 10, 724–734. [Google Scholar]

- Sandeep, P.; Shashikant, S.M.; Mohsin, K.; Anurag, S.; Amrit, K.R. Effects of glass Reinforcement and glass powder on the characteristics of concrete. Int. J. Civ. Eng. Technol. 2017, 8, 648–653. [Google Scholar]

- Balamurali, K.; Padmanaban, I. Trial Examination of Synthetic polymer as Shear Reinforcement. Int. J. Innov. Technol. Explor. Eng. 2019, 9, 2278–3075. [Google Scholar]

- Heecheul, K.; Min, S.K.; Myung, J.K.; Young, H.L. Shear Behavior of Concrete Beams Reinforced with GFRP Shear Reinforcement. Int. J. Polym. Sci. 2015, 2015, 213583. [Google Scholar]

- Woraphot, P.; Sitthichai, P.; Athawit, S.; Suchart, L. Behavior and Performance of GFRP Reinforced Concrete Columns with Various Types of Stirrups. Int. J. Polym. Sci. 2015, 2015, 237231. [Google Scholar]

- Aldousiri, B.; Alajmi, M.; Shalwan, A. Mechanical Properties of Palm Polymer Reinforced Recycled HDPE. Adv. Mater. Sci. Eng. 2013, 2013, 508179. [Google Scholar] [CrossRef]

- Katakalos, K.; Papakonstantinou, C.G. Fatigue of Reinforced beams Strengthened with steel-Reinforced inorganic polymer. J. Compos. Constr. 2009, 13, 103–112. [Google Scholar] [CrossRef]

- Ali, U.; Karim, K.J.; Buang, N.A. A review of the properties and applications of poly(methyl methacrylate)(PMMA). Polym. Rev. 2015, 55, 678–705. [Google Scholar] [CrossRef]

- Henri, L. Thermohygroelastic Properties of Polymethylmethacrylate; Koninklijke Philips Electronics: Amsterdam, The Netherlands, 2007; pp. 11–13. [Google Scholar]

- Demir, M.M.; Memesa, M.; Castignolles, P.; Wegner, G. PMMA/zinc oxide Nanocomposites prepared by insitu bulk polymerization. Macromol. Rapid Commun. 2006, 27, 763–770. [Google Scholar] [CrossRef]

- Hashim, H.; Adam, N.I.; Zaki, N.H.M.; Mahmud, Z.S.; Said, C.M.S.; Yahya, M.Z.A.; Ali, A.M.M. Natural rubber-grafted with 30% Poly(methylmethacrylate) characterization for application in lithium polymer battery. In Proceedings of the Conference on Science and Social Research 2010 (CSSR 2010), Kuala Lumpur, Malaysia, 5–7 December 2010; pp. 485–488. [Google Scholar]

- Sarı, A.; Alkan, C.; Biçer, A.; Altuntaş, A.; Bilgin, C. Micro/nanoencapsulated n-nonadecane with poly(methyl methacrylate) shell for thermal energy storage. Energy Convers. Manag. 2014, 86, 614–621. [Google Scholar] [CrossRef]

- Wang, L.; Meng, D. Fatty acid eutectic/polymethyl methacrylate composite as form-stable phase change material for thermal energy storage. Appl. Energy 2010, 87, 2660–2665. [Google Scholar] [CrossRef]

- Kikuchi, Y.; Hirao, M.; Ookubo, T.; Sasaki, A. Design of recycling system for poly(methyl methacrylate)(PMMA). Part 1: Recycling scenario analysis. Int. J. Life Cycle Assess. 2014, 19, 120–129. [Google Scholar] [CrossRef]

- Wang, Y.; Xia, T.D.; Feng, H.X.; Zhang, H. Stearic acid/polymethylmethacrylate composite as form-stable phase change materials for latent heat thermal energy storage. Renew. Energy 2011, 36, 1814–1820. [Google Scholar] [CrossRef]

- Sánchez-Calderón, I.; Bernardo, V.; Martín-de-León, J.; Rodríguez-Pérez, M.Á. Thermal conductivity of low-density micro-and nanocellular poly(methyl-methacrylate) (PMMA): Experimental and modeling. Mater. Des. 2022, 221, 110938. [Google Scholar] [CrossRef]

- Sarı, A.; Alkan, C.; Özcan, A.N. Synthesis and characterization of micro/nano capsules of PMMA/capric–stearic acid eutectic mixture for low temperature-thermal energy storage in buildings. Energy Build. 2015, 90, 106–113. [Google Scholar] [CrossRef]

- Bowden, P.B.; Jukes, J.A. The plastic yield behaviour of polymethylmethacrylate. J. Mater. Sci. 1968, 3, 183–190. [Google Scholar] [CrossRef]

- Abokifa, M.; Moustafa, M.A. Experimental behavior of poly methyl methacrylate polymer concrete for bridge deck bulb tee girders longitudinal field joints. Constr. Build. Mater. 2021, 270, 121840. [Google Scholar] [CrossRef]

- Wang, J.; Chen, X.; Kang, Y.; Yang, G.; Yu, L.; Zhang, P. Preparation of superhydrophobic poly(methyl methacrylate)-silicon dioxide nanocomposite films. Appl. Surf. Sci. 2010, 257, 1473–1477. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Xia, T.; Zhao, W.; Yang, W. Effects of fabricated technology on particle size distribution and thermal properties of stearic–eicosanoic acid/polymethylmethacrylate nanocapsules. Sol. Energy Mater. Sol. Cells 2014, 1, 481–490. [Google Scholar] [CrossRef]

- Chen, D.; Wu, H.; Wei, J.S.; Xu, S.L.; Fang, Q. Nonlinear visco-hyperelastic tensile constitutive model of spray polyurea within wide strain-rate range. Int. J. Impact Eng. 2022, 163, 104184. [Google Scholar] [CrossRef]

- Zhang, X.; Hao, H.; Shi, Y.; Cui, J. The mechanical properties of Polyvinyl Butyral (PVB) at high strain rates. Constr. Build. Mater. 2015, 93, 404–415. [Google Scholar] [CrossRef]

- Zhang, X.; Hao, H.; Ma, G. Parametric study of laminated glass window response to blast loads. Eng. Struct. 2013, 56, 1707–1717. [Google Scholar] [CrossRef]

- Zhang, X.; Hao, H.; Ma, G. Laboratory test and numerical simulation of laminated glass window vulnerability to debris impact. Int. J. Impact Eng. 2013, 55, 49–62. [Google Scholar] [CrossRef]

- Zhang, X.; Hao, H.; Wang, Z. Experimental study of laminated glass window responses under impulsive and blast loading. Int. J. Impact Eng. 2015, 78, 1–9. [Google Scholar] [CrossRef]

- Wei, J.; Dharani, L.R. Response of laminated architectural glazing subjected to blast loading. Int. J. Impact Eng. 2006, 32, 2032–2047. [Google Scholar] [CrossRef]

- Hooper, P.A.; Sukhram, R.A.M.; Blackman, B.R.K.; Dear, J.P. On the blast resistance of laminated glass. Int. J. Solids Struct. 2012, 49, 899–918. [Google Scholar] [CrossRef]

- Larcher, M.; Solomos, G.; Casadei, F.; Gebbeken, N. Experimental and numerical investigations of laminated glass subjected to blast loading. Int. J. Impact Eng. 2012, 39, 42–50. [Google Scholar] [CrossRef]

- Chen, X.; Rosendahl, P.L.; Chen, S.; Schneider, J. On the delamination of polyvinyl butyral laminated glass: Identification of fracture properties from numerical modelling. Constr. Build. Mater. 2021, 306, 124827. [Google Scholar] [CrossRef]

- Regnault, V. Ueber die Zusammensetzung des Chlorkohlenwasserstoffs (Oel des ölbildenden Gases). Ann. Der Pharm. 1835, 14, 22–38. [Google Scholar] [CrossRef]

- Baumann, E. Umber engine Vinyl indulgent. Anna Lender Chemise Pharm. 1872, 163, 308–322. [Google Scholar] [CrossRef]

- Endo, K. Synthesis and structure of poly (vinyl chloride). Prog. Polym. Sci. 2002, 27, 2021–2054. [Google Scholar] [CrossRef]

- Semon, W.L.; Stahl, G.A. History of Polymer Science and Technology; Marcel Dekker: New York, NY, USA, 1982. [Google Scholar]

- Stephensen, R.C.; Smallwood, P.V. Encyclopedia of Polymer Science Engineering, 2nd ed.; John Wiley & Sons: New York, NY, USA, 1989; p. 843. [Google Scholar]

- Nikkan Kogyo Shinbun. Poly(vinyl chloride)—Basic and Application; Nikkan Kogyo Shinbun: Tokyo, Japan, 1988. [Google Scholar]

- Bell, V.B.; Rand, P. Materials for Architectural Design; Laurence King Publishing: London, UK, 2006. [Google Scholar]

- Xu, X.; Jiang, Q. Brief Analysis on Application of PVC Foam Materials in Building Material Industry. Mater. Sci. Forum 2019, 944, 729–735. [Google Scholar] [CrossRef]

- Patterson, J.; Szamborski, G. Expanding PVC as a building material. J. Vinyl Addit. Technol. 1995, 1, 148–154. [Google Scholar] [CrossRef]

- Fakharifar, M.; Chen, G. FRP-confined concrete filled PVC tubes: A new design concept for ductile column construction in seismic regions. Constr. Build. Mater. 2017, 130, 1–10. [Google Scholar] [CrossRef]

- Fakharifar, M.; Chen, G. Compressive behavior of FRP-confined concrete-filled PVC tubular columns. Compos. Struct. 2016, 141, 91–109. [Google Scholar] [CrossRef]

- Palmer, R.J. Polyamides, plastics. In Kirk-Othmer Encyclopedia of Chemical Technology, 2nd ed.; Wiley: Hoboken, NJ, USA, 2000; Volume 18, pp. 406–425. [Google Scholar]

- Fangueiro, R.; Pereira, C.G.; De Araújo, M. Applications of polyesters and polyamides in civil engineering. In Polyesters and Polyamides; Woodhead Publishing: Sawston, UK, 2008; pp. 542–592. [Google Scholar]

- Zheng, Z.; Feldman, D. Synthetic fibre-reinforced concrete. Prog. Polym. Sci. 1995, 20, 185–210. [Google Scholar] [CrossRef]

- Kurtz, S.; Balaguru, P. Postcrack Creep of Polymeric Fibre-Reinforced Concrete in Flexure. Cem. Concr. Res. 2000, 30, 183–190. [Google Scholar] [CrossRef]

- Song, P.S.; Hwang, S.; Sheu, B.C. Strength properties of nylon-and polypropylene-fiber-reinforced concretes. Cem. Concr. Res. 2005, 35, 1546–1550. [Google Scholar] [CrossRef]

- De Araújo, M. Natural and Man-Made Fibres: Physical and Mechanical Properties. In Fibrous and Composite Materials for Civil Engineering Applications; Series in Textiles; Woodhead Publishing: Sawston, UK, 2011; pp. 3–28. [Google Scholar]

- Rhoads, W.B. Continuity and Change along the National Road in Pennsylvania. In Western Pennsylvania History: 1918–2018; Penn State University: University Park, PA, USA, 1990; pp. 130–137. [Google Scholar]

- Agyekum, K.; Ayarkwa, J.; Koranteng, C. Controlling rising damp in new buildings: Field trials of proposed treatment methods. In Proceedings of the International Conference on Infrastructure Development in Africa (ICIDA), Johannesburg, South Africa, 19–22 November 2016; pp. 10–12. [Google Scholar]

- Matsumura, M.; Kitada, T. Experiment on Static Breaking of Rupture Controllable Side Block for Bridge Isolation Device. Mem. Fac. Eng. Osaka City Univ. 2004, 45, 47–52. [Google Scholar]

- Gohil, M.; Joshi, G. Perspective of polycarbonate composites and blends properties, applications, and future development: A review. Green Sustain. Process Chem. Environ. Eng. Sci. 2022, 1, 393–424. [Google Scholar]

- Ab Rahim, N.R.; Hakim, S.J. Performance of Polycarbonate Concrete Panels in Construction: A Critical Research Review. Recent Trends Civ. Eng. Built Environ. 2022, 3, 320–331. [Google Scholar]

- Agarwal, S.; Gupta, R.K. Plastics in buildings and construction. In Applied Plastics Engineering Handbook William Andrew Publishing; Elsevier: Amsterdam, The Netherlands, 2017; pp. 635–649. [Google Scholar]

- Blaga, A. Plastics in Glazing and Lighting Applications. Can Build Digest-213; National Research Council of Canada, IRC: London, ON, Canada, 1980. [Google Scholar]

- Köhler-Hammer, C.; Knippers, J.; Hammer, M.R. Bio-based plastics for building facades. In Start-Up Creation; Woodhead Publishing: Sawston, UK, 2016; pp. 329–346. [Google Scholar]

- Uetsuji, Y.; Yasuda, Y.; Yamauchi, S.; Matsushima, E.; Adachi, M.; Fuji, M.; Ito, H. Multiscale study on thermal insulating effect of a hollow silica-coated polycarbonate window for residential buildings. Renew. Sustain. Energy Rev. 2021, 152, 111718. [Google Scholar] [CrossRef]

- Bonenfant, N. Cellular polycarbonate glazing-the glass alternative. Constr. Specif. 2004, 57, 24–31. [Google Scholar]

- Tolinski, M. Building new opportunities for plastics-Plastics provide solutions for resilient, low-cost buildings and infrastructure. Plast. Eng. 2008, 64, 6. [Google Scholar]

- Laurenti, M.; Bianco, S.; Castellino, M.; Garino, N.; Virga, A.; Pirri, C.F.; Mandracci, P. Toward plastic smart windows: Optimization of indium tin oxide electrodes for the synthesis of electrochromic devices on polycarbonate substrates. ACS Appl. Mater. Interfaces 2016, 8, 8032–8042. [Google Scholar] [CrossRef]

- Ronca, S. Polyethylene. In Brydson’s Plastics Materials; Butterworth-Heinemann, Ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 247–278. [Google Scholar]

- Sulyman, M.; Haponiuk, J.; Formela, K. Utilization of recycled polyethylene terephthalate (PET) in engineering materials: A review. Int. J. Environ. Sci. Dev. 2016, 7, 100. [Google Scholar] [CrossRef]

- Dang, J.; Zhao, S.; Chen, G.; Cao, X.; Yang, J. Effect of polyethylene powder and heating treatment on the microstructure and hardened properties of foam concrete. J. Build. Eng. 2022, 50, 104143. [Google Scholar] [CrossRef]

- Basha, S.I.; Ali, M.R.; Al-Dulaijan, S.U.; Maslehuddin, M. Mechanical and thermal properties of lightweight recycled plastic aggregate concrete. J. Build. Eng. 2020, 32, 101710. [Google Scholar] [CrossRef]

- Ali, M.R.; Maslehuddin, M.; Shameem, M.; Barry, M.S. Thermal-resistant lightweight concrete with polyethylene beads as coarse aggregates. Constr. Build. Mater. 2018, 164, 739–749. [Google Scholar] [CrossRef]

- Nguyen, Q.T.; Tran, P.; Ngo, T.D.; Tran, P.A.; Mendis, P. Experimental and computational investigations on fire resistance of GFRP composite for building façade. Compos. Part B Eng. 2014, 62, 218–229. [Google Scholar] [CrossRef]

- Ruiz-Herrero, J.L.; Nieto, D.V.; López-Gil, A.; Arranz, A.; Fernández, A.; Lorenzana, A.; Merino, S.; De Saja, J.A.; Rodríguez-Pérez, M.Á. Mechanical and thermal performance of concrete and mortar cellular materials containing plastic waste. Constr. Build. Mater. 2016, 104, 298–310. [Google Scholar] [CrossRef]

- Perevozchikov, A.; Yakovlev, G.; Kodolov, V. Polyethylene foam waste utilization for light-weight concrete production. Int. J. Polym. Mater. 2000, 47, 7–17. [Google Scholar] [CrossRef]

- Bonilla-Blancas, A.E.; Romero-Ibarra, I.C.; Vazquez-Arenas, J.; Sanchez-Solis, A.; Manero, O.; Alvarez-Ramirez, J. Molecular interactions arising in polyethylene-bentonite nanocomposites. J. Appl. Polym. Sci. 2019, 136, 46920. [Google Scholar] [CrossRef]

- Lin, C.C. Recycling technology of poly (ethylene terephthalate) materials. In Macromolecular Symposia Weinheim; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 1998; Volume 135, pp. 129–135. [Google Scholar]

- Alves, J.B.; Vasconcelos, M.K.; Mangia, L.H.; Tatagiba, M.; Fidalgo, J.; Campos, D.; Invernici, P.L.; Rebouças, M.V.; Andrade, M.H.; Pinto, J.C. A Bibliometric Survey on Polyisobutylene Manufacture. Processes 2021, 9, 1315. [Google Scholar] [CrossRef]

- Cwyl, M.; Michalczyk, R.; Wierzbicki, S. Polyisobutylene and Silicone in Warm Edge Glazing Systems—Evaluation of Long-Term Performance. Materials 2021, 14, 3594. [Google Scholar] [CrossRef] [PubMed]

- Watson, T.; Kenney, M.; Kenney, R. IGU Seal and Flexible Spacer Displacement Failures, Field and Laboratory Study; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Frick, B.; Richter, D. Change of the vibrational dynamics near the glass transition in polyisobutylene: Inelastic neutron scattering on a nonfragile polymer. Phys. Rev. B. 1993, 47, 14795. [Google Scholar] [CrossRef]

- Podnebesnyi, A.P.; Savel’eva, N.V.; Lanina, T.F.; Zhukovskaia, N.V.; Grekul, A.I. New waterproof polymeric roof covering. Int. Polym. Sci. Technol. 2004, 31, T30. [Google Scholar] [CrossRef]

- Ihara, T.; Gustavsen, A.; Jelle, B.P. Fatigue resistance of double sealant composed of polyisobutylene sealant adjacent to silicone sealant. Constr. Build. Mater. 2014, 66, 467–475. [Google Scholar] [CrossRef]

- Maddah, H.A. Polypropylene as a promising plastic: A review. Am. J. Polym. Sci. 2016, 6, 1–10. [Google Scholar]

- Jhatial, A.A.; Mastoi, A.K.; Siyal, Z.A.; Rind, T.A.; Memon, I.A. Influence of long polypropylene fibre on the properties of concrete. Res. J. Eng. Sci. Technol. 2020, 18, 38–43. [Google Scholar]

- Memon, I.A.; Jhatial, A.A.; Sohu, S.; Lakhiar, M.T.; Hussain, Z. Influence of fibre length on the behaviour of polypropylene fibre reinforced cement concrete. Civ. Eng. J. 2018, 4, 2124–2131. [Google Scholar] [CrossRef]

- Madhavi, T.C.; Raju, L.S.; Mathur, D. Polypropylene fiber reinforced concrete-a review. Int. J. Emerg. Technol. Adv. Eng. 2014, 4, 114–118. [Google Scholar]

- Thirumurugan, S.; Siva Kumar, A. Compressive Strength Index of Crimped Polypropylene Fibers in High Strength Cementitious Matrix. World Appl. Sci. J. 2013, 24, 698–702. [Google Scholar]

- Gencel, O.; Ozel, C.; Brostow, W.; Martinez-Barrera, G. Mechanical Properties of Self-Compacting Concrete Reinforced with Polypropylene Fibres. Mater. Res. Innov. 2011, 15, 216–225. [Google Scholar] [CrossRef]

- Patel, P.A.; Desai, A.K.; Desai, J.A. Evaluation of Engineering Properties for Polypropylene Fibre Reinforced Concrete. Int. J. Adv. Eng. Technol. 2012, 3, 42–45. [Google Scholar]

- Murahari, K.; Rao, R. Effects of Polypropylene fibres on the strength properties of fly ash based concrete. Int. J. Eng. Sci. Invent. 2013, 2, 13–19. [Google Scholar]

- Jianzhuang, X.; Falkner, H. On residual strength of high performance concrete with and without polypropylene fibres at elevated temperatures. Fire Saf. J. 2006, 41, 115–121. [Google Scholar]

- Patel, M.J.S.; Kulkarni, S.M. Effect of Polypropylene Fibre on The High Strength Concrete. J. Inf. Knowl. Res. Civ. Eng. 2013, 2, 125–129. [Google Scholar]

- Abou Kheir, S.; Wakim, J.; Awwad, E. Flexural resistance of the polypropylene fibres reinforced cement mixes with waste material. MATEC Web Conf. 2019, 281, 01010. [Google Scholar] [CrossRef]

- Niaounakis, M. Polymers used in flexible packaging. In Recycling of Flexible Plastic Packaging, 1st ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2020; pp. 57–96. [Google Scholar]

- Maghfouri, M.; Alimohammadi, V.; Gupta, R.; Saberian, M.; Azarsa, P.; Hashemi, M.; Asadi, I.; Roychand, R. Drying shrinkage properties of expanded polystyrene (EPS) lightweight aggregate concrete: A review. Case Stud. Constr. Mater. 2022, 26, e00919. [Google Scholar] [CrossRef]

- Adeala, A.J.; Soyemi, O.B. Structural Use of Expanded Polystyrene Concrete. Int. J. Innov. Sci. Res. Technol. 2020, 5, 1131–1138. [Google Scholar]

- Sayadi, A.A.; Tapia, J.V.; Neitzert, T.R.; Clifton, G.C. Effects of expanded polystyrene (EPS) particles on fire resistance, thermal conductivity and compressive strength of foamed concrete. Constr. Build. Mater. 2016, 1, 716–724. [Google Scholar] [CrossRef]

- Lakatos, Á.; Kalmár, F. Analysis of water sorption and thermal conductivity of expanded polystyrene insulation materials. Build. Serv. Eng. Res. Technol. 2013, 34, 407–416. [Google Scholar] [CrossRef]

- Saleh, H.M.; Salman, A.A.; Faheim, A.A.; El-Sayed, A.M. Sustainable composite of improved lightweight concrete from cement kiln dust with grated poly (styrene). J. Clean. Prod. 2020, 277, 123491. [Google Scholar] [CrossRef]

- Tang, W.C.; Lo, T.Y.; Balendran, R.V. Bond performance of polystyrene aggregate concrete (PAC) reinforced with glass-fibre-reinforced polymer (GFRP) bars. Build. Environ. 2008, 43, 98–107. [Google Scholar] [CrossRef]

- Vakhshouri, B.; Nejadi, S. Review on the mixture design and mechanical properties of the lightweight concrete containing expanded polystyrene beads. Aust. J. Struct. Eng. 2018, 19, 1–23. [Google Scholar] [CrossRef]

- Somarathna, H.M.; Raman, S.N.; Mohotti, D.; Mutalib, A.A.; Badri, K.H. The use of polyurethane for structural and infrastructural engineering applications: A state-of-the-art review. Constr. Build. Mater. 2018, 190, 995–1014. [Google Scholar] [CrossRef]

- Chattopadhyay, D.K.; Raju, K.V. Structural engineering of polyurethane coatings for high performance applications. Prog. Polym. Sci. 2007, 32, 352–418. [Google Scholar] [CrossRef]

- Manalo, A. Structural behaviour of a prefabricated composite wall system made from rigid polyurethane foam and Magnesium Oxide board. Constr. Build. Mater. 2013, 41, 642–653. [Google Scholar] [CrossRef]

- Mohamed, M.; Anandan, S.; Huo, Z.; Birman, V.; Volz, J.; Chandrashekhara, K. Manufacturing and characterization of polyurethane based sandwich composite structures. Compos. Struct. 2015, 123, 169–179. [Google Scholar] [CrossRef]

- Hradil, P.; Toratti, T.; Vesikari, E.; Ferreira, M.; Häkkinen, T. Durability considerations of refurbished external walls. Constr. Build. Mater. 2014, 53, 162–172. [Google Scholar] [CrossRef]

- Abeysinghe, C.M.; Thambiratnam, D.P.; Perera, N.J. Flexural performance of an innovative hybrid composite floor plate system comprising glass–fibre reinforced cement, polyurethane and steel laminate. Compos. Struct. 2013, 95, 179–190. [Google Scholar] [CrossRef]

- Fam, A.; Sharaf, T. Flexural performance of sandwich panels comprising polyurethane core and GFRP skins and ribs of various configurations. Compos. Struct. 2010, 92, 2927–2935. [Google Scholar] [CrossRef]

- Lee, C.S.; Lee, J.M. Failure analysis of reinforced polyurethane foam-based LNG insulation structure using damage-coupled finite element analysis. Compos. Struct. 2014, 107, 231–245. [Google Scholar] [CrossRef]

- Gong, M.; Delahunty, S.; Chui, Y.H.; Li, L. Use of low grade hardwoods for fabricating laminated railway ties. Constr. Build. Mater. 2013, 41, 73–78. [Google Scholar] [CrossRef]

- Marchessault, R.H.; Sundararajan, P.R. Cellulose. In The Polysaccharides; Academic Press: Cambridge, MA, USA, 1983; pp. 11–95. [Google Scholar]

- Parham, S.; Kharazi, A.Z.; Nur, H. The limitations of natural resources in the use of medical and protective textiles. In Protective Textiles from Natural Resources; Woodhead Publishing: Sawston, UK, 2022; pp. 175–196. [Google Scholar]

- Yan, L.; Kasal, B.; Huang, L. A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos. Part B Eng. 2016, 92, 94–132. [Google Scholar] [CrossRef]

- Hakamy, A.; Shaikh, F.U.A.; Low, I.M. Thermal and mechanical properties of hemp fabric-reinforced nanoclay-cement nanocomposites. J. Mater. Sci. 2014, 49, 1684e94. [Google Scholar] [CrossRef]

- Yan, L. Plain concrete cylinders and beams externally strengthened with natural flax fabric reinforced epoxy composite. Mater. Struct. 2016, 49, 2083–2095. [Google Scholar] [CrossRef]

- Assarar, M.; Scida, D.; El Mahi, A.; Poilane, C.; Ayad, R. Influence of water ageing on mechanical properties and damage events of two reinforced composite materials: Flax-fibres and glass-fibres. Mater. Des. 2011, 32, 788e95. [Google Scholar] [CrossRef]

- Jawaid, M.; Abdul Khalil, H.P.S.; Hassan, A.; Dungani, R.; Hadiyane, A. Effect of jute fibre loading on tensile and dynamic mechanical properties of oil palm epoxy composites. Compos. Part B 2013, 45, 619e24. [Google Scholar] [CrossRef]

- Yan, L.; Su, S.; Chouw, N. Microstructure, flexural properties and durability of coir fibre reinforced concrete beams externally strengthened with flax FRP composites. Compos. Part B 2015, 80, 343e54. [Google Scholar] [CrossRef]

- Ibarra-Castanedo, C.; Sfarra, S.; Paoletti, D.; Bendada, A.; Maldague, X. Nondestructive testing of externally reinforced masonry structures for seismic retrofitting using flax fibre reinforced polymer (FFRP) composites. In Proceedings of the SPIE8705 Thermosense: Thermal Infrared Applications, Volume XXXV, Baltimore, MD, USA, 29 May 2013. 87050U. [Google Scholar] [CrossRef]

- Yang, J.S.; Xie, Y.J.; He, W. Research progress on chemical modification of alginate: A review. Carbohydr. Polym. 2011, 84, 33–39. [Google Scholar] [CrossRef]

- Draget, K.I.; Skjåk-Bræk, G.; Smidsrød, O. Alginate based new materials. Int. J. Biol. Macromol. 1997, 21, 47–55. [Google Scholar] [CrossRef]

- Inozemtcev, S.S.; Korolev, E.V. Sodium alginate emulsions for asphalt concrete modifiers encapsulating: Structural rheological properties. Mag. Civ. Eng. 2021, 1, 10104. [Google Scholar]

- Galán-Marín, C.; Rivera-Gómez, C.; Petric, J. Clay-based composite stabilized with natural polymer and fibre. Constr. Build. Mater. 2010, 24, 1462–1468. [Google Scholar] [CrossRef]

- Xu, S.; Liu, X.; Tabaković, A.; Schlangen, E. Investigation of the potential use of calcium alginate capsules for self-healing in porous asphalt concrete. Materials 2019, 12, 168. [Google Scholar] [CrossRef] [PubMed]

- Murugappan, V.; Muthadhi, A. Studies on the influence of alginate as a natural polymer in mechanical and long-lasting properties of concrete–A review. Mater. Today Proc. 2022, 65, 839–845. [Google Scholar] [CrossRef]

- Fatehi, H.; Bahmani, M.; Noorzad, A. Strengthening of dune sand with sodium alginate biopolymer. In Proceedings of the Geo-Congress 2019: Soil Improvement 2019: American Society of Civil Engineers, Reston, VA, USA, 21 May 2019; pp. 157–166. [Google Scholar]

- Wu, S.; Hoff, I.; Amirkhanian, S.; Xiao, Y. Special issue of environment-friendly construction materials. Materials 2019, 12, 1101. [Google Scholar] [CrossRef]

- Arab, M.G.; Mousa, R.A.; Gabr, A.R.; Azam, A.M.; El-Badawy, S.M.; Hassan, A.F. Resilient behavior of sodium alginate–treated cohesive soils for pavement applications. J. Mater. Civ. Eng. 2019, 31, 04018361. [Google Scholar] [CrossRef]

- Ellis, B. Introduction to the chemistry, synthesis, manufacture and characterization of epoxy resins. In Chemistry and Technology of Epoxy Resins; Springer: Dordrecht, The Netherlands, 1993; pp. 1–36. [Google Scholar]

- Rahman, M.M.; Akhtarul Islam, M. Application of epoxy resins in building materials: Progress and prospects. Polym. Bull. 2022, 79, 1949–1975. [Google Scholar] [CrossRef]

- Maherzi, W.; Ennahal, I.; Benzerzour, M.; Mammindy-Pajany, Y.; Abriak, N.E. Study of the polymer mortar based on dredged sediments and epoxy resin: Effect of the sediments on the behavior of the polymer mortar. Powder Technol. 2020, 361, 968–982. [Google Scholar] [CrossRef]

- Rahman, M.M.; Islam, M.A. Effect of epoxy resin on the intrinsic properties of masonry mortars. Iran. Polym. J. 2012, 21, 621–629. [Google Scholar] [CrossRef]

- Fernández-Ruiz, M.A.; Gil-Martín, L.M.; Carbonell-Márquez, J.F.; Hernández-Montes, E. Epoxy resin and ground tyre rubber replacement for cement in concrete: Compressive behaviour and durability properties. Constr. Build. Mater. 2018, 173, 49–57. [Google Scholar] [CrossRef]

- Jin, N.J.; Yeon, J.; Seung, I.; Yeon, K.S. Effects of curing temperature and hardener type on the mechanical properties of bisphenol F-type epoxy resin concrete. Constr. Build. Mater. 2017, 156, 933–943. [Google Scholar] [CrossRef]

- Sousa, J.M.; Correia, J.R.; Cabral-Fonseca, S. Durability of an epoxy adhesive used in civil structural applications. Constr. Build. Mater. 2018, 161, 618–633. [Google Scholar] [CrossRef]

- Agarwal, S.; Gupta, R.K. The use of thermosets in the building and construction industry. In Thermosets; Elsevier: Amsterdam, The Netherlands, 2018; pp. 279–302. [Google Scholar]

- Michels, J.; Widmann, R.; Czaderski, C.; Allahvirdizadeh, R.; Motavalli, M. Glass transition evaluation of commercially available epoxy resins used for civil engineering applications. Compos. Part B Eng. 2015, 77, 484–493. [Google Scholar] [CrossRef]

- Navabi, D.; Javidruzi, M.; Hafezi, M.R.; Mosavi, A. The high-performance light transmitting concrete and experimental analysis of using polymethylmethacrylate optical fibers in it. J. Build. Eng. 2021, 38, 102076. [Google Scholar] [CrossRef]

- Chen, S.; Chen, Z.; Chen, X.; Schneider, J. Evaluation of the delamination performance of polyvinyl-butyral laminated glass by through-cracked tensile tests. Constr. Build. Mater. 2022, 341, 127914. [Google Scholar] [CrossRef]

- Abdulla, N.A. Concrete filled PVC tube: A review. Constr. Build. Mater. 2017, 156, 321–329. [Google Scholar] [CrossRef]

- Hulsey, J.L.; Yang, L.; Raad, L. Wearing surfaces for orthotropic steel bridge decks. Transp. Res. Rec. 1999, 1654, 141–150. [Google Scholar] [CrossRef]

- Moretti, E.; Zinzi, M.; Belloni, E. Polycarbonate panels for buildings: Experimental investigation of thermal and optical performance. Energy Build. 2014, 70, 23–35. [Google Scholar] [CrossRef]

- Abeysinghe, S.; Gunasekara, C.; Bandara, C.; Nguyen, K.; Dissanayake, R.; Mendis, P. Engineering Performance of Concrete Incorporated with Recycled High-Density Polyethylene (HDPE)—A Systematic Review. Polymers 2021, 13, 1885. [Google Scholar] [CrossRef] [PubMed]

- Salazar, J. Life cycle assessment (LCA) of windows and window materials. In Eco-Efficient Construction and Building Materials; Woodhead Publishing: Sawston, UK, 2014; pp. 502–527. [Google Scholar]

- Phulpoto, K.B.; Jhatial, A.A.; Memon, M.J.; Sandhu, A.R.; Sohu, S. Effect of polypropylene fibre on the strength of concrete incorporating rice husk ash. J. Appl. Eng. Sci. 2020, 10, 69–71. [Google Scholar] [CrossRef]

- Chen, B.; Liu, J. Properties of lightweight expanded polystyrene concrete reinforced with steel fiber. Cem. Concr. Res. 2004, 34, 1259–1263. [Google Scholar] [CrossRef]

- Haber, Z.B.; Mackie, K.R.; Zhao, L. Mechanical and environmental loading of concrete beams strengthened with epoxy and polyurethane matrix carbon fiber laminates. Constr. Build. Mater. 2012, 26, 604–612. [Google Scholar] [CrossRef]

- Xu, Y.; Chung, D.D.L. Carbon fiber reinforced cement improved by using silane treated carbon fibres. Cem. Concr. Res. 1999, 29, 773–776. [Google Scholar] [CrossRef]

- Shu, B.; Wu, S.; Dong, L.; Wang, Q.; Liu, Q. Microfluidic synthesis of ca-alginate microcapsules for self-healing of bituminous binder. Materials 2018, 11, 630. [Google Scholar] [CrossRef]

- Gad, M.M.; Abualsaud, R.; Rahoma, A.; Al-Thobity, A.M.; Al-Abidi, K.S.; Akhtar, S. Effect of zirconium oxide nanoparticles addition on the optical and tensile properties of polymethyl methacrylate denture base material. Int. J. Nanomed. 2018, 13, 283. [Google Scholar] [CrossRef]

- Chen, S.; Chen, X.; Wu, X. The mechanical behaviour of polyvinyl butyral at intermediate strain rates and different temperatures. Constr. Build. Mater. 2018, 182, 66–79. [Google Scholar] [CrossRef]

- Rostam, S.; Ali, A.K.; AbdalMuhammad, F.H. Experimental investigation of mechanical properties of PVC polymer under different heating and cooling conditions. J. Eng. 2016, 2016, 3791417. [Google Scholar] [CrossRef]

- Peters, E.N. Engineering thermoplastics—Materials, Properties, Trends. In Applied Plastics Engineering Handbook; William Andrew Publishing: Norwich, NY, USA, 2017; pp. 3–26. [Google Scholar] [CrossRef]

- Masood, S.H.; Mau, K.; Song, W.Q. Tensile properties of processed FDM polycarbonate material. Mater. Sci. Forum 2010, 654, 2556–2559. [Google Scholar] [CrossRef]

- Ahmed, S.F.; Maalej, M. Tensile strain hardening behaviour of hybrid steel-polyethylene fibre reinforced cementitious composites. Constr. Build. Mater. 2009, 23, 96–106. [Google Scholar] [CrossRef]

- Wypych, G. Handbook of Polymers, 2nd ed.; ChemTech Publishing: Scarborough, ON, Canada, 2016; p. 706. [Google Scholar]

- Greene, J.P. Automotive Plastics and Composites: Materials and Processing; Elsevier Science: Amsterdam, The Netherlands, 2021; p. 392. [Google Scholar]

- Kakita, H.; Kamishima, H. Some properties of alginate gels derived from algal sodium alginate. In Nineteenth International Seaweed Symposium; Springer: Dordrecht, The Netherlands, 2008; pp. 93–99. [Google Scholar]

- Mishra, B.P.; Mishra, D.; Panda, P. An experimental investigation of the effects of reinforcement of graphene fillers on mechanical properties of bi-directional glass/epoxy composite. Mater. Today: Proc. 2020, 33, 5429–5441. [Google Scholar] [CrossRef]

- Wang, N.; Adeli, H. Sustainable building design. J. Civ. Eng. Manag. 2014, 20, 1–10. [Google Scholar] [CrossRef]

- Sarvari, H.; Mehrabi, A.; Chan, D.W.M.; Cristofaro, M. Evaluating urban housing development patterns in developing countries: Case study of worn-out urban fabrics in Iran. Sustain. Cities Soc. 2021, 170, 102941. [Google Scholar] [CrossRef]

- Akadiri, P.O.; Chinyio, E.A.; Olomolaiye, P.O. Design of a sustainable building: A conceptual framework for implementing sustainability in the building sector. Buildings 2012, 2, 126–152. [Google Scholar] [CrossRef]

- John, G.; Clements-Croome, D.; Jeronimidis, G. Sustainable building solutions: A review of lessons from the natural world. Build. Environ. 2005, 40, 319–328. [Google Scholar] [CrossRef]

- Sarvari, H.; Rakhshanifar, M.; Tamošaitienė, J.; Chan, D.W.M.; Beer, M. A risk based approach to evaluating the impacts of Zayanderood drought on sustainable development indicators of riverside urban in Isfahan-Iran. Sustainability 2019, 11, 6797. [Google Scholar] [CrossRef]

- Melchert, L. The Dutch sustainable building policy: A model for developing countries? Build. Environ. 2007, 42, 893–901. [Google Scholar] [CrossRef]

- Reddy, B.V. Sustainable building technologies. Curr. Sci. 2004, 10, 899–907. [Google Scholar]

- Sarvari, H.; Chan, D.W.M.; Rakhshanifar, M.; Banaitiene, N.; Banaitis, A. Evaluating the impact of Building Information Modeling (BIM) on mass house building projects. Buildings 2020, 10, 35. [Google Scholar] [CrossRef]

- Fowler, K.M.; Rauch, E.M. Sustainable Building Rating Systems Summary; Pacific Northwest National Lab (PNNL): Richland, WA USA, 2006. [Google Scholar]

- Chan, D.W.M.; Cristofaro, M.; Nassereddine, H.; Yiu, N.S.N.; Sarvari, H. Perceptions of safety climate in construction projects between workers and managers/supervisors in the developing country of Iran. Sustainability 2021, 13, 10398. [Google Scholar] [CrossRef]

- Häkkinen, T.; Belloni, K. Barriers and drivers for sustainable building. Build. Res. Inf. 2011, 39, 239–255. [Google Scholar] [CrossRef]

- Sathiparan, N.; Anburuvel, A.; Selvam, V.V. Utilization of agro-waste groundnut shell and its derivatives in sustainable construction and building materials–A review. J. Build. Eng. 2023, 66, 105866. [Google Scholar] [CrossRef]

- Singh, A.K.; Kumar, V.P.; Dehdasht, G.; Mohandes, S.R.; Manu, P.; Rahimian, F.P. Investigating the barriers to the adoption of blockchain technology in sustainable construction projects. J. Clean. Prod. 2023, 403, 136840. [Google Scholar] [CrossRef]

- Yan, Q.; Wu, X.; Jiang, H.; Wang, H.; Xu, F.; Li, H.; Zhang, H.; Yang, S. Transition metals-catalyzed amination of biomass feedstocks for sustainable construction of N-heterocycles. Coord. Chem. Rev. 2024, 502, 215622. [Google Scholar] [CrossRef]

- Oladele, I.O.; Onuh, L.N.; Siengchin, S.; Sanjay, M.R.; Adelani, S.O. Modern applications of polymer composites in structural industries: A review of philosophies, product development, and graphical applications. Appl. Sci. Eng. Prog. 2023, 17, 6884. [Google Scholar] [CrossRef]

- Yusof, M.Y.M.; Shahidan, S. A Comprehensive Review on Physical and Mechanical Properties of Polymer as Concrete Material. Recent Trends Civ. Eng. Built Environ. 2023, 4, 70–83. [Google Scholar]

- Li, M.; Zhong, J.; Li, G.; Zhang, Q.; Cen, F.; Gao, P. Study on the Performance of Polymer-Modified Conductive Cement-Based Materials. Buildings 2023, 13, 2961. [Google Scholar] [CrossRef]

- Salami, B.A.; Bahraq, A.A.; ul Haq, M.M.; Ojelade, O.A.; Taiwo, R.; Wahab, S.; Adewumi, A.A.; Ibrahim, M. Polymer-enhanced concrete: A comprehensive review of innovations and pathways for resilient and sustainable materials. Next Mater. 2024, 4, 100225. [Google Scholar] [CrossRef]

- Saeedi, A.; Motavalli, M.; Shahverdi, M. Recent advancements in the applications of fiber-reinforced polymer structures in railway industry—A review. Polym. Compos. 2024, 45, 77–97. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, Z.; Li, Q.; Wang, K.; Jiang, D.; Hou, P.; Huang, Y.; Zhao, P. Insights on the role of particulate filler on the polymer-modified cement-based coating and its application. J. Build. Eng. 2023, 76, 107395. [Google Scholar] [CrossRef]

- Kermani, S.; Khalatbari, S. Enhancing Concrete Strength with Polymer-Based Additives in the Cement Matrix: A Comprehensive Review. J. Civ. Eng. Res. 2024, 6, 48–64. [Google Scholar] [CrossRef]

- Schroeder, H. Sustainable Building with Earth; Springer: New York, NY, USA, 2016. [Google Scholar]

| No. | Polymer | Result | [Ref.] |

|---|---|---|---|

| 1 | Poly(methyl methacrylate (PMMA) | To produce high-performance light-transmitting concrete, specific quantities of Portland cement, polymethylmethacrylate (PMMA) optical fibers, silica fume, fine aggregate, polycarboxylate superplasticizer, silica powder, and water were mixed. The concrete was then put through a series of tests to determine its optical and physical properties. | [167] |

| 2 | Polyvinylbutyrate (PVB) | Both the safety of PVB-laminated glass and its behavior after it has been broken are highly dependent on the interfacial adhesion that exists between the interlayer and the glass. By increasing the thickness of the PVB layer, it is possible to improve the maximum force and energy absorption capacity of the laminated glass. | [168] |

| 3 | Polyvinylchloride (PVC) | The mechanical, confinement, and deformability qualities of thin-walled polyvinyl chloride (PVC) tubular specimens filled with concrete are discussed along with their other applications in civil and building construction. | [169] |

| 4 | Polyamides(nylons) | The orthotropic steel that makes up the bridge’s wearing surfaces also serves as the bridge’s abutments. | [170] |

| 5 | Polycarbonate (PC) | This study provides a greater understanding of the thermal and optical behavior of the polycarbonate panels and a collection of important data for precise studies in building integration, proposing that these systems may be a viable alternative to traditional windows in commercial buildings. | [171] |

| 6 | Polyethylene (PE) | The purpose of this research is to provide a comprehensive literature review on the engineering performance of recycled high-density polyethylene (HDPE) aggregates, fibers, and cementitious materials that are utilized in concrete. In conclusion, this research is the first of its kind to describe and evaluate the status of the mechanical and durability performance of recycled HDPE as a sustainable CBM. | [172] |

| 7 | Polyisobutylene | The insulated glass unit is installed into the window frame (or sash, in the case of operable windows) and secured with a glazing stop. | [173] |

| 8 | Polypropylene (PP) | The compressive and flexural strengths of concrete that was produced with rice husk ash (RHA) as an additional cementitious ingredient were evaluated. As a result, polypropylene (PP) fibers were applied to reinforce RHA-based environmentally friendly concrete. | [174] |

| 9 | Polystyrene (PS) | Expanded polystyrene (EPS) concrete was mixed using a premix process analogous to the sand-wrapping approach to create a lightweight, low-strength material with high energy-absorbing qualities. EPS concrete has poor workability and reduced strength because the hydrophobic surface and light weight of the EPS beads cause them to segregate during casting. | [175] |

| 10 | Polyurethane (PU) | The behavior of the three different methods that can be used to reinforce concrete bridge girders is compared here. One technique involves using carbon fiber-reinforced polymer (CFRP) sheets that have already been pre-impregnated with a water-activated polyurethane (PU) matrix. | [176] |

| 11 | Cellulose | Denser and more robust composites were produced by including silane, which functioned as a bridge between the cellulosic fiber surface, the fumed silica, and the cement matrix. | [177] |

| 12 | Alginate | This research aims to construct multinuclear Ca–alginate microcapsules with a rejuvenator for the self-healing of bituminous binder by integrating the alginate micro-emulsion technique with the droplet’s microfluidic technology. | [178] |

| 13 | Epoxy resins | The glass transition of commercially available epoxy resins used for structural strengthening of concrete members for instance by means of carbon-fiber reinforced polymer (CFRP) strips | [166] |

| No. | Polymer | Result | [Ref.] |

|---|---|---|---|

| 1 | Poly(methylmethacrylate (PMMA) | The tensile strength is about 58.07 ± 3.14 MPa. | [179] |

| 2 | Poly(vinylbutyrate (PVB) | When considering dynamic loadings, such as impact or blast loading, the strain rate effect of PVB is of relevance. This research explored the strain rate impact in various strain rate ranges, including 0.07 s−1–89 s−1, 0.0067 s−1–118 s−1, 0.2 s−1–400 s−1, and 0.008 s−1–1360 s−1. | [180] |

| 3 | Poly(vinylchloride (PVC) | The tensile strength is equal to 63.67 N/mm2. | [181] |

| 4 | Polyamides(nylons) | The tensile strength of nylon-6, nylon-66, nylon-11, nylon-12, and nylon-46, respectively, is 83 MPa, 80 MPa, 48 MPa, 66 MPa, and 100 MPa. | [182] |

| 5 | Polycarbonate (PC) | The reported tensile strength of low-viscosity, molding, and extrusion-grade PC ranges between 62.7 and 72.4 MPa. Nonetheless, the maximum tensile strength measured in this experiment was 58.8 MPa. | [183] |

| 6 | Polyethylene (PE) | The tensile strength of polyethylene is 2610 MPa. | [184] |

| 7 | Polyisobutylene | Tensile strength is about 1.7–2.5 MPa. | [185] |

| 8 | Polypropylene (PP) | Tensile strength at break is about 4500–6000 psi. | [113] |

| 9 | Polystyrene (PS) | Tensile strength is about 5000 MPa and tensile modulus is 80,000 GPa. | [186] |

| 10 | Polyurethane (PU) | The tensile strength of commercially available polyurethane (PU) ranges from 20.7 to 65.5 MPa, and this polymer has a greater strain capacity and cut-and-tear resistance. | [131] |

| 11 | Cellulose | Cotton has a relative density of around 1.5–1.6 g/cm3, a tensile strength of 287–800 MPa, and an elastic modulus of 5.5–12.6 GPa. | [142] |

| 12 | Alginate | The wet tensile strength ranged from 0.166 g d−1 at 16 mPa·s to 0.494 g d−1 at 994 mPa·s. | [187] |

| 13 | Epoxy resins | The tensile strength of epoxy resin is about 8 MPa. | [188] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tamošaitienė, J.; Parham, S.; Sarvari, H.; Chan, D.W.M.; Edwards, D.J. A Review of the Application of Synthetic and Natural Polymers as Construction and Building Materials for Achieving Sustainable Construction. Buildings 2024, 14, 2569. https://doi.org/10.3390/buildings14082569

Tamošaitienė J, Parham S, Sarvari H, Chan DWM, Edwards DJ. A Review of the Application of Synthetic and Natural Polymers as Construction and Building Materials for Achieving Sustainable Construction. Buildings. 2024; 14(8):2569. https://doi.org/10.3390/buildings14082569

Chicago/Turabian StyleTamošaitienė, Jolanta, Shokoh Parham, Hadi Sarvari, Daniel W. M. Chan, and David J. Edwards. 2024. "A Review of the Application of Synthetic and Natural Polymers as Construction and Building Materials for Achieving Sustainable Construction" Buildings 14, no. 8: 2569. https://doi.org/10.3390/buildings14082569

APA StyleTamošaitienė, J., Parham, S., Sarvari, H., Chan, D. W. M., & Edwards, D. J. (2024). A Review of the Application of Synthetic and Natural Polymers as Construction and Building Materials for Achieving Sustainable Construction. Buildings, 14(8), 2569. https://doi.org/10.3390/buildings14082569