Solid State Transformers: Concepts, Classification, and Control

Abstract

:1. Introduction

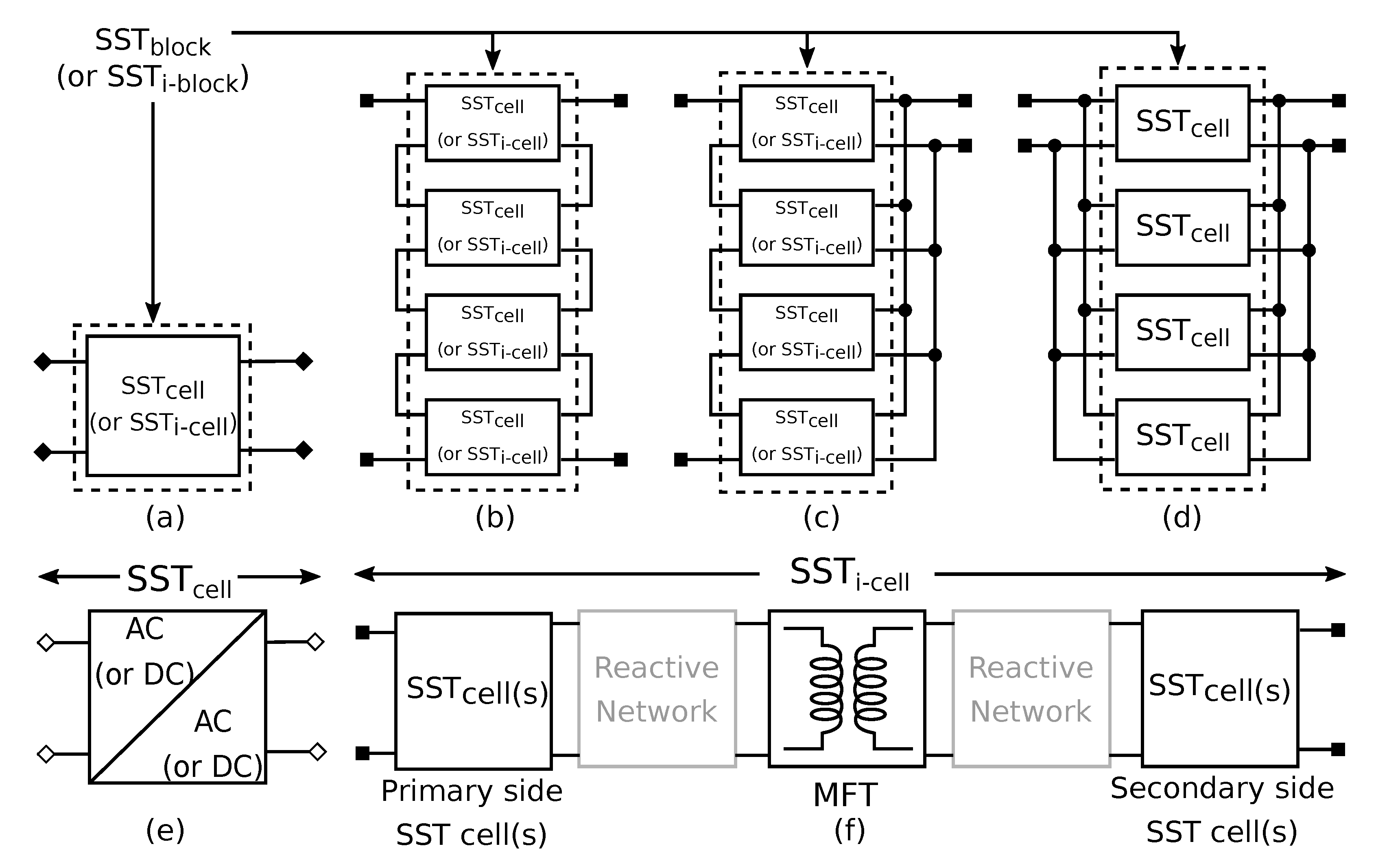

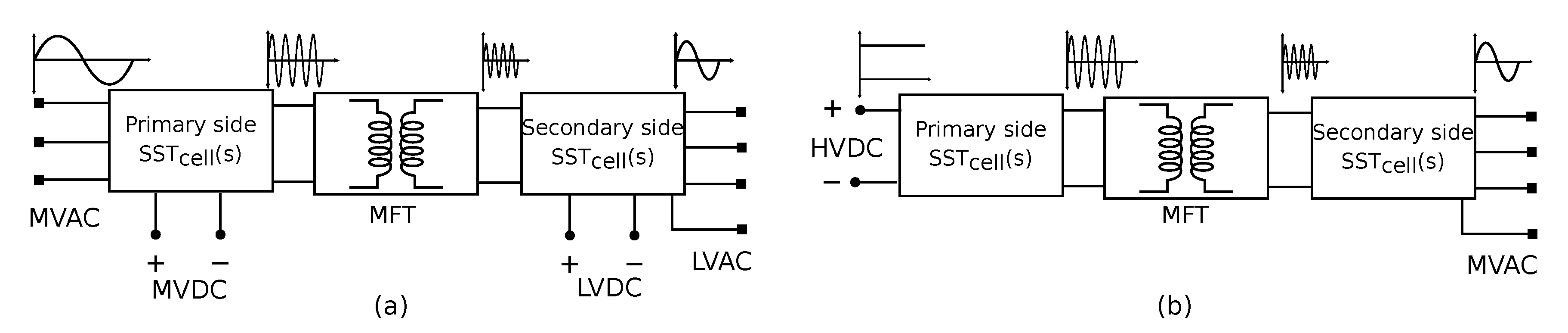

2. SST Architecture

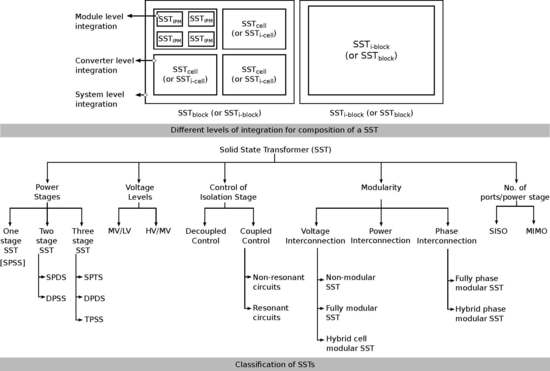

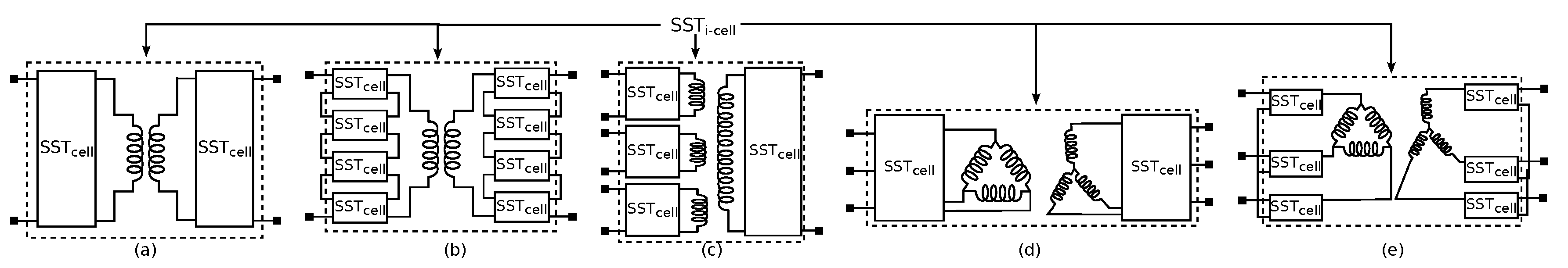

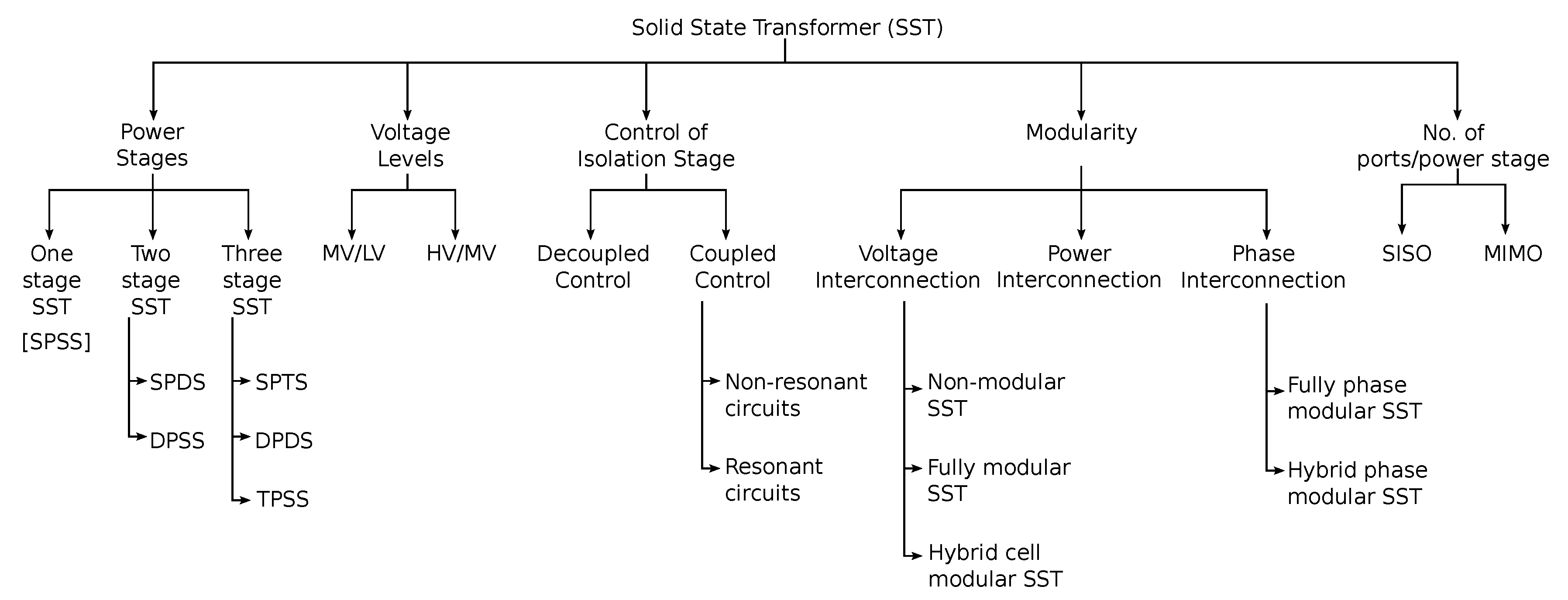

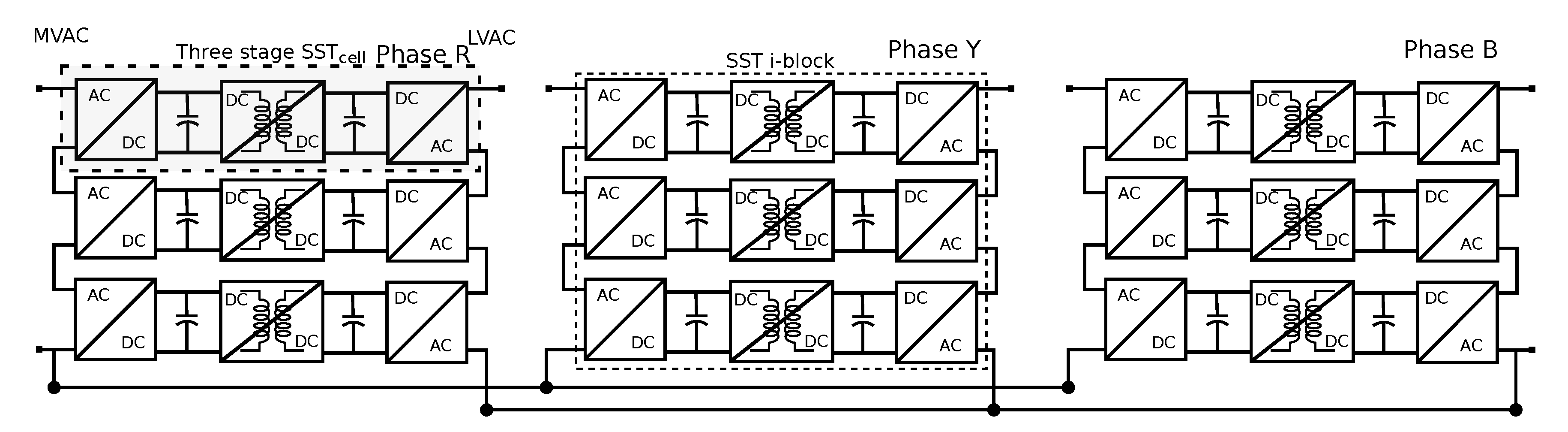

3. Composition of an SST

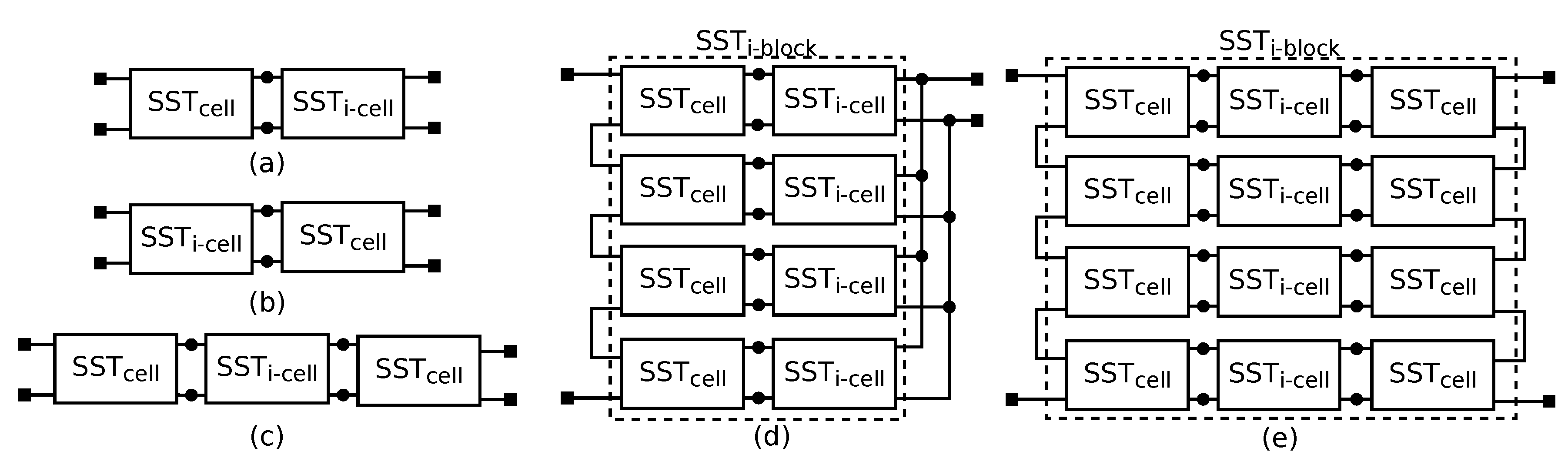

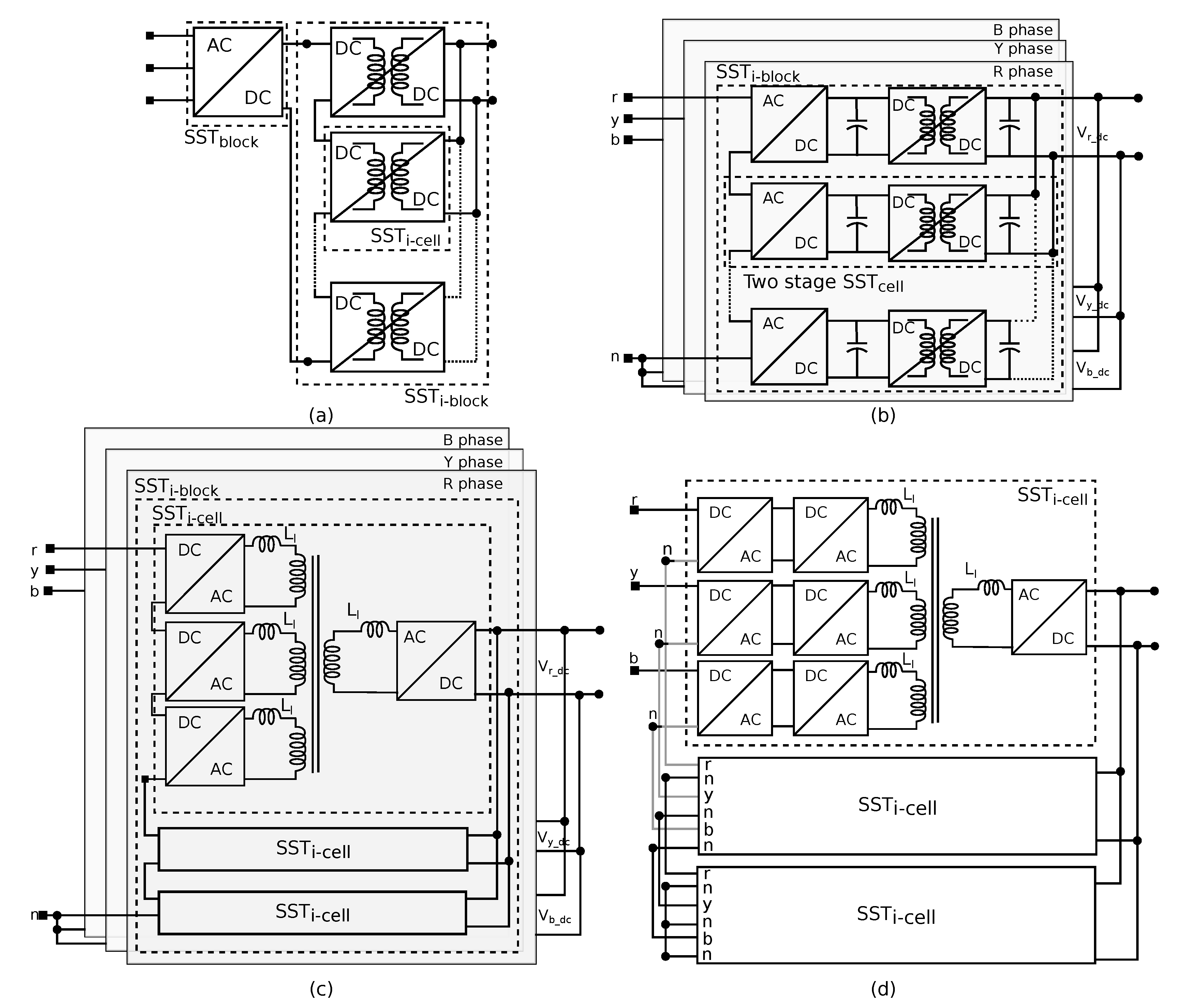

3.1. Module Integration Level

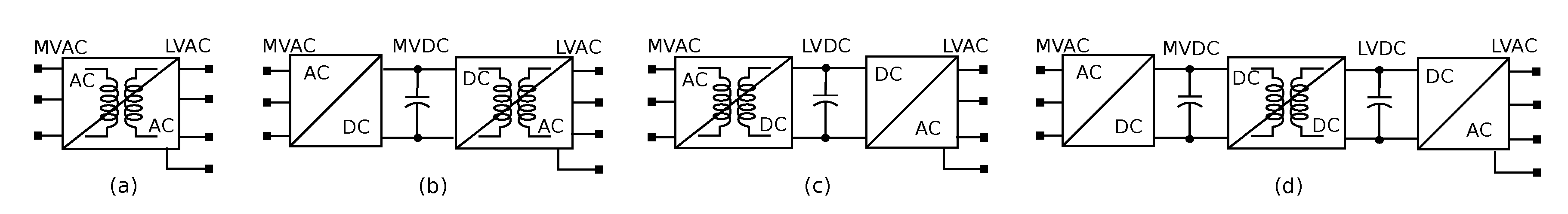

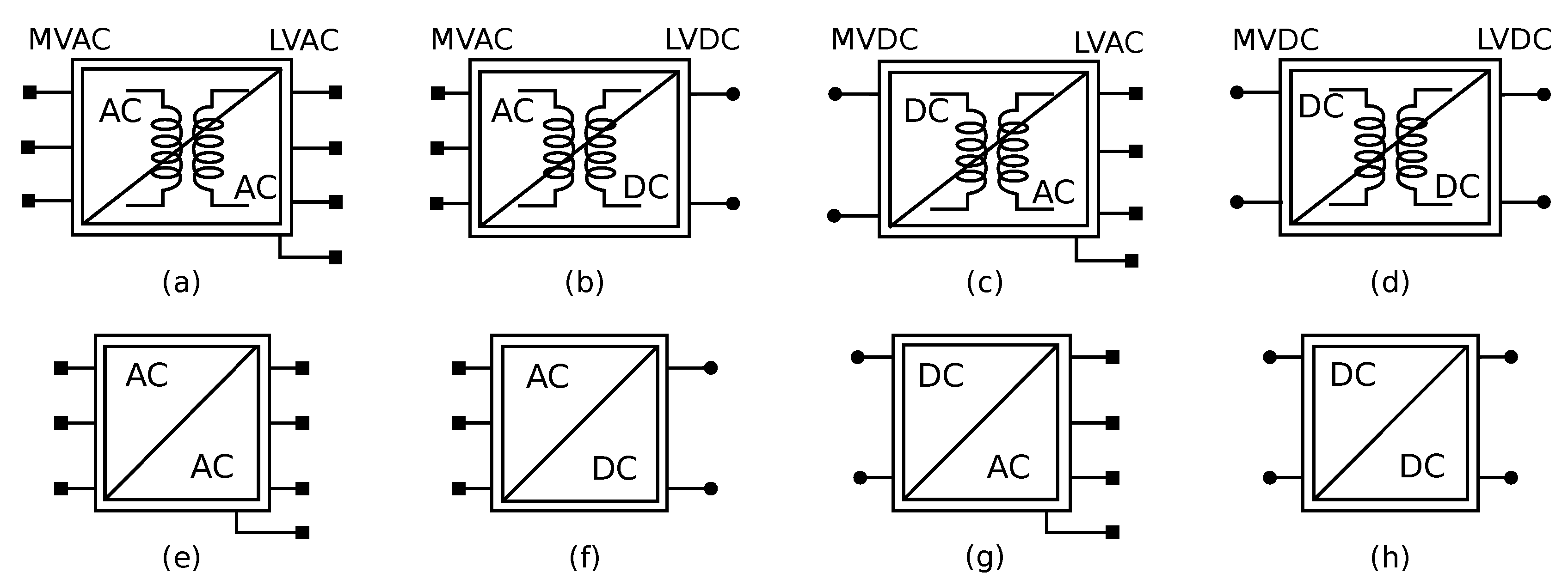

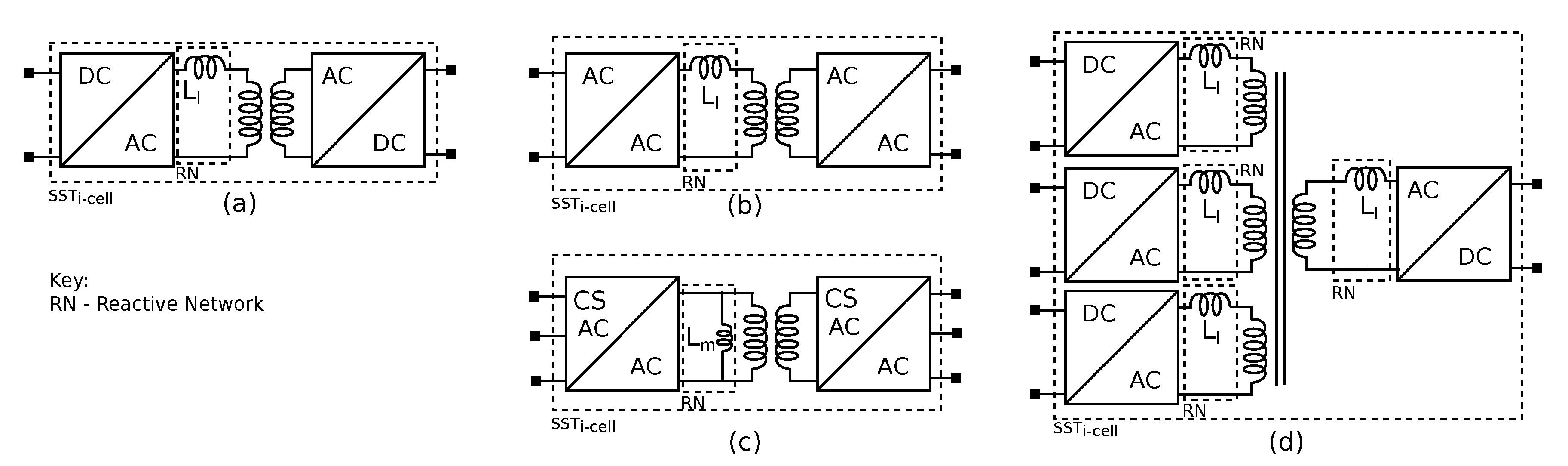

3.2. Converter Integration Level: SISO Configuration-I

3.3. Converter Integration Level: SISO Configuration-II

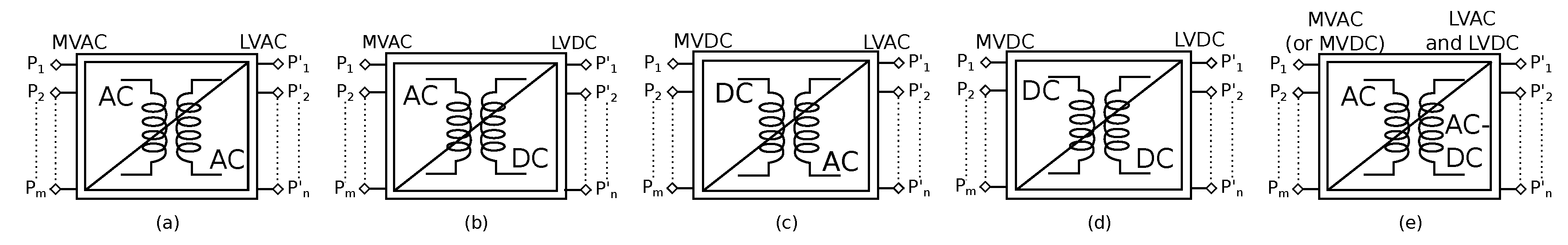

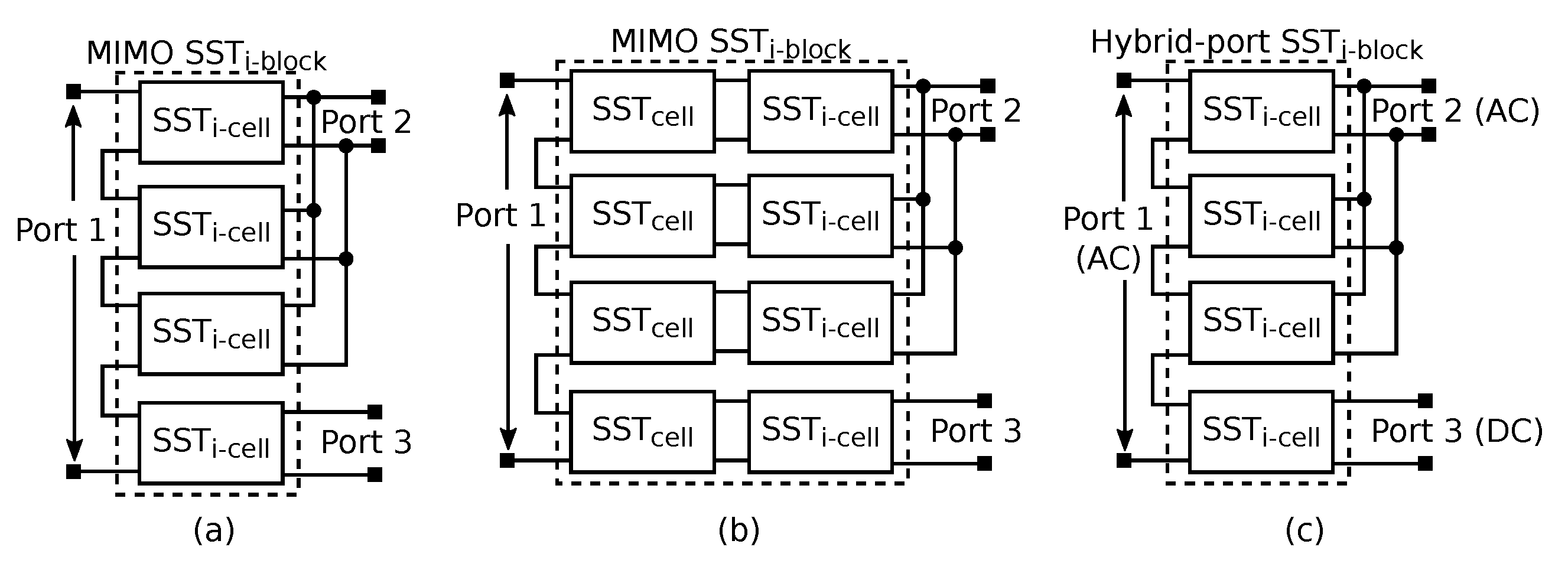

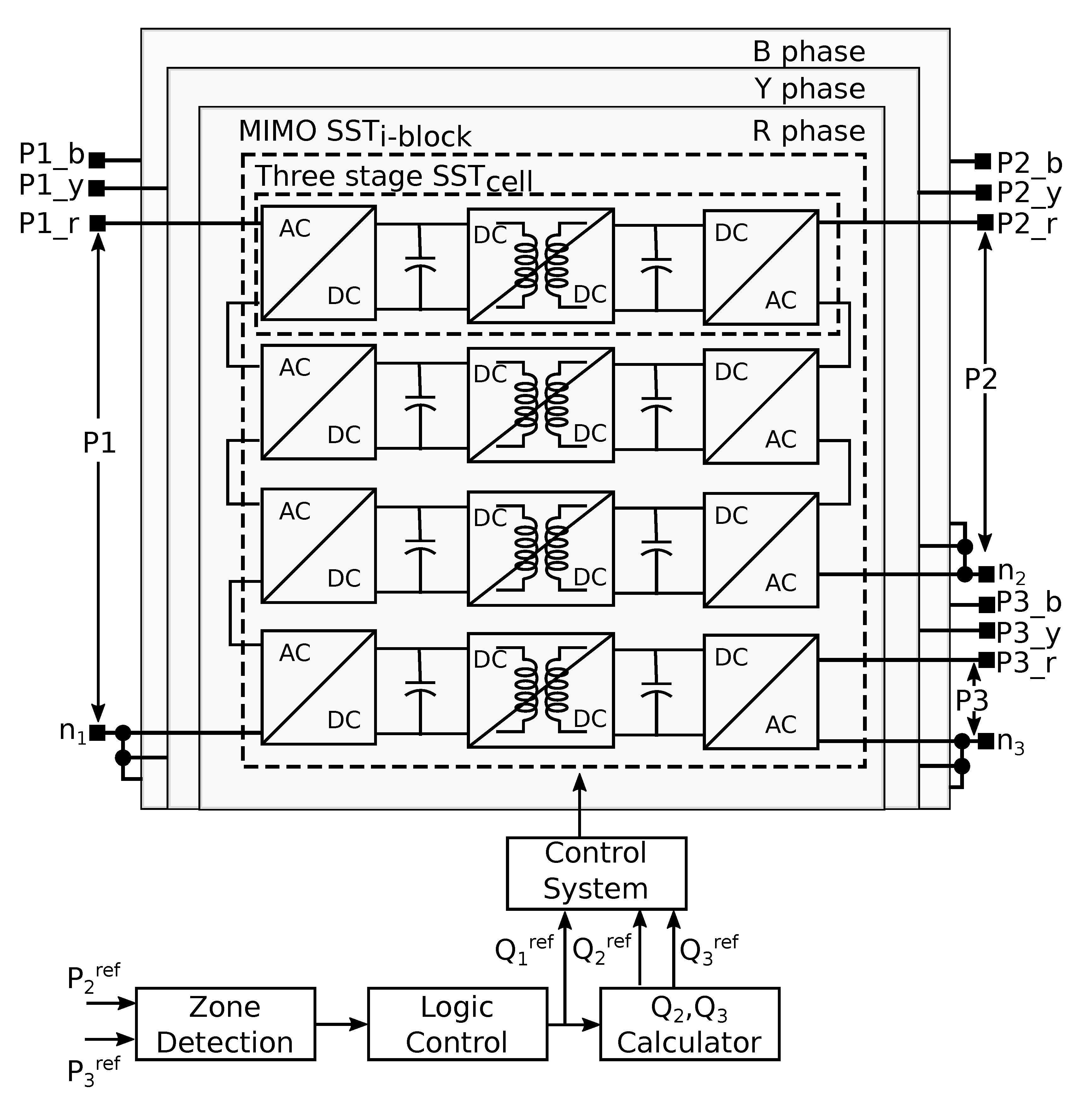

3.4. Converter Integration Level: MIMO Configuration

4. Classification of SSTs:

4.1. SST Classification Based on Voltage Levels

4.2. SST Classification Based on Control of Isolation Stage

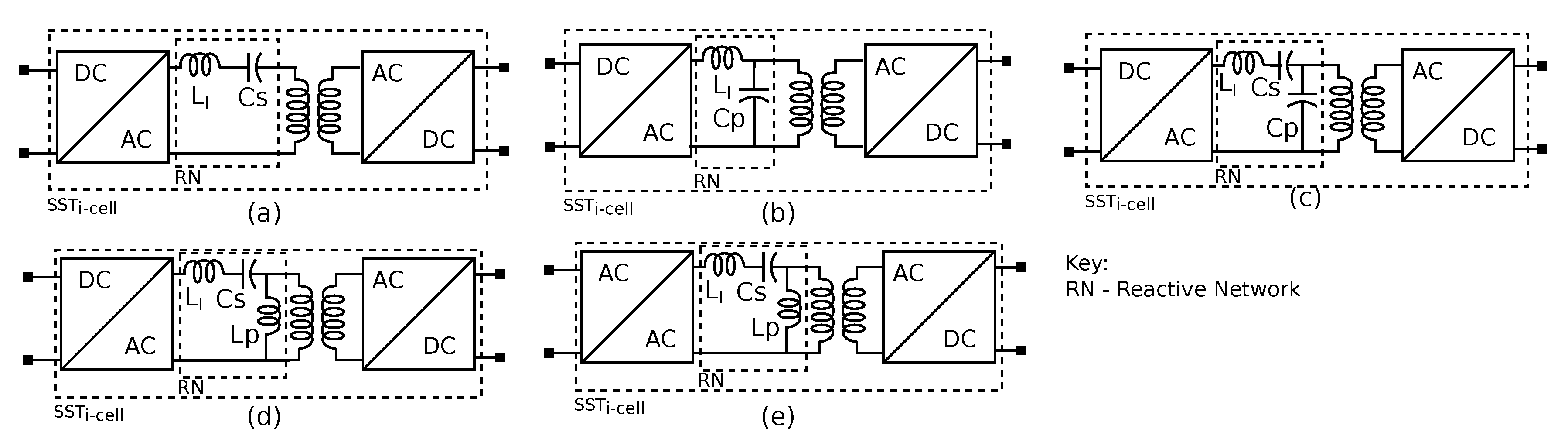

4.2.1. Decoupled Control of Isolation Stage

4.2.2. Coupled Control of Isolation Stage

Isolation Stage Based on Non-Resonant Circuits

Isolation Stage Based on Resonance Circuits

4.3. SST Classification Based on Modular Structure

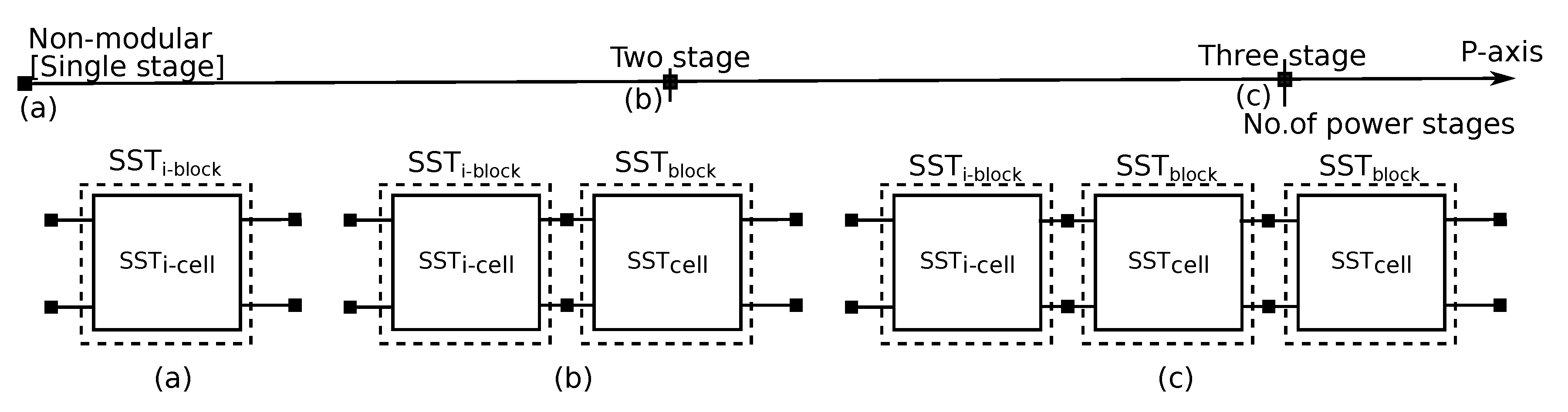

4.3.1. Modularity Based on Direction of Power Flow

4.3.2. Modularity Based on a Voltage/Current Level

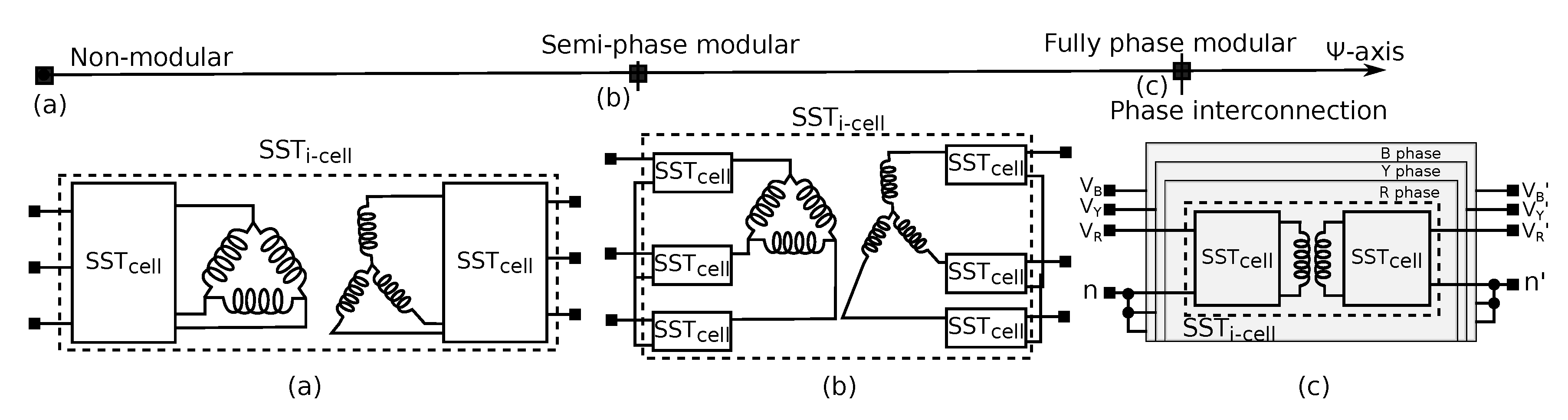

4.3.3. Modularity Based on Phase Interconnection

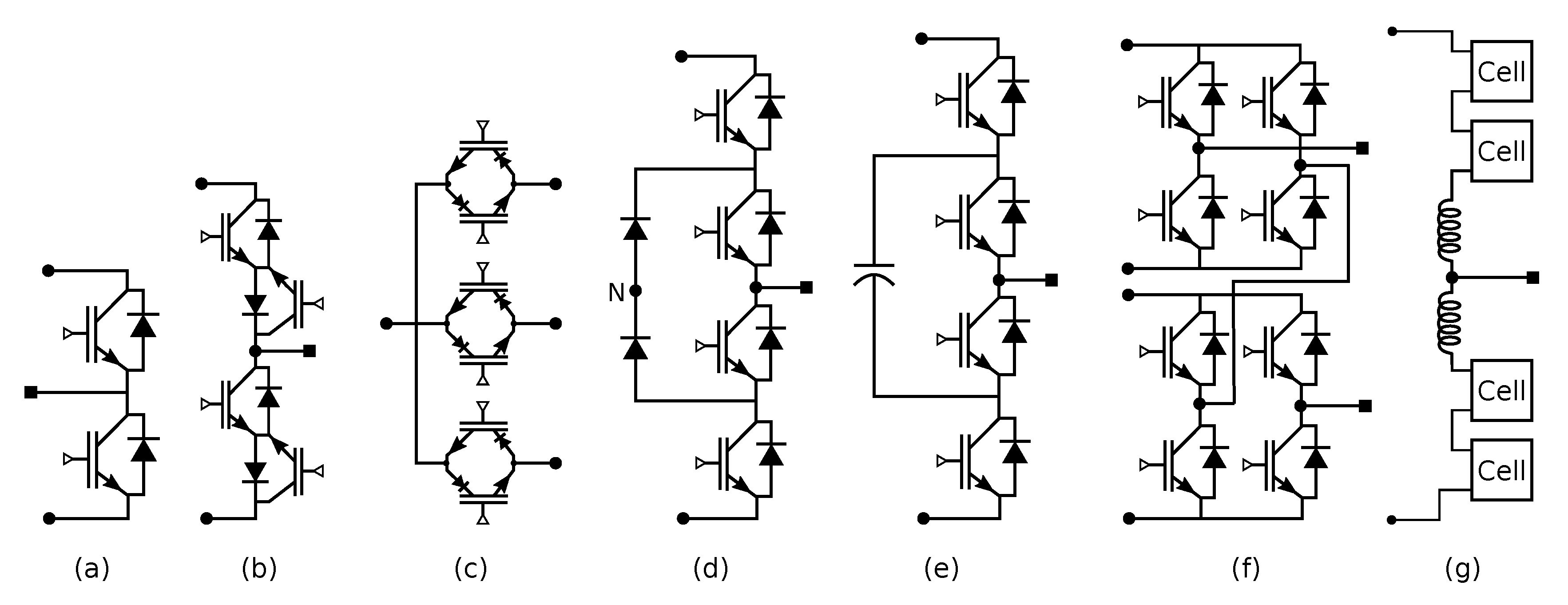

5. Power Converter Topologies and Modulation Schemes

5.1. MV (or HV) Side (s)

5.2. LV Side (s)

5.3. Modulation Schemes

6. Constructive Aspects of SST

6.1. Semiconductor Devices for

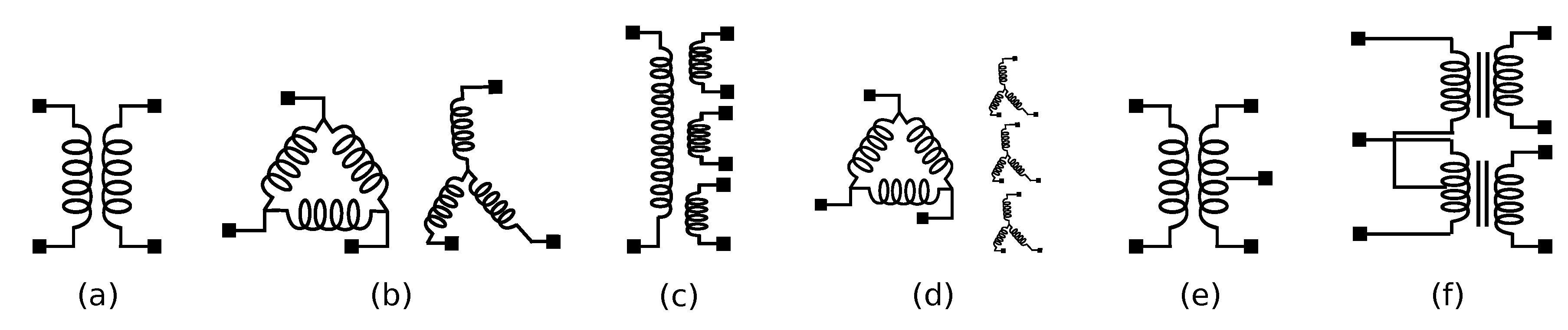

6.2. Medium Frequency Transformer

6.2.1. Core Material

6.2.2. Winding Material and Arrangement

6.2.3. Insulation and Thermal Considerations

7. Applications of SST and Control Techniques

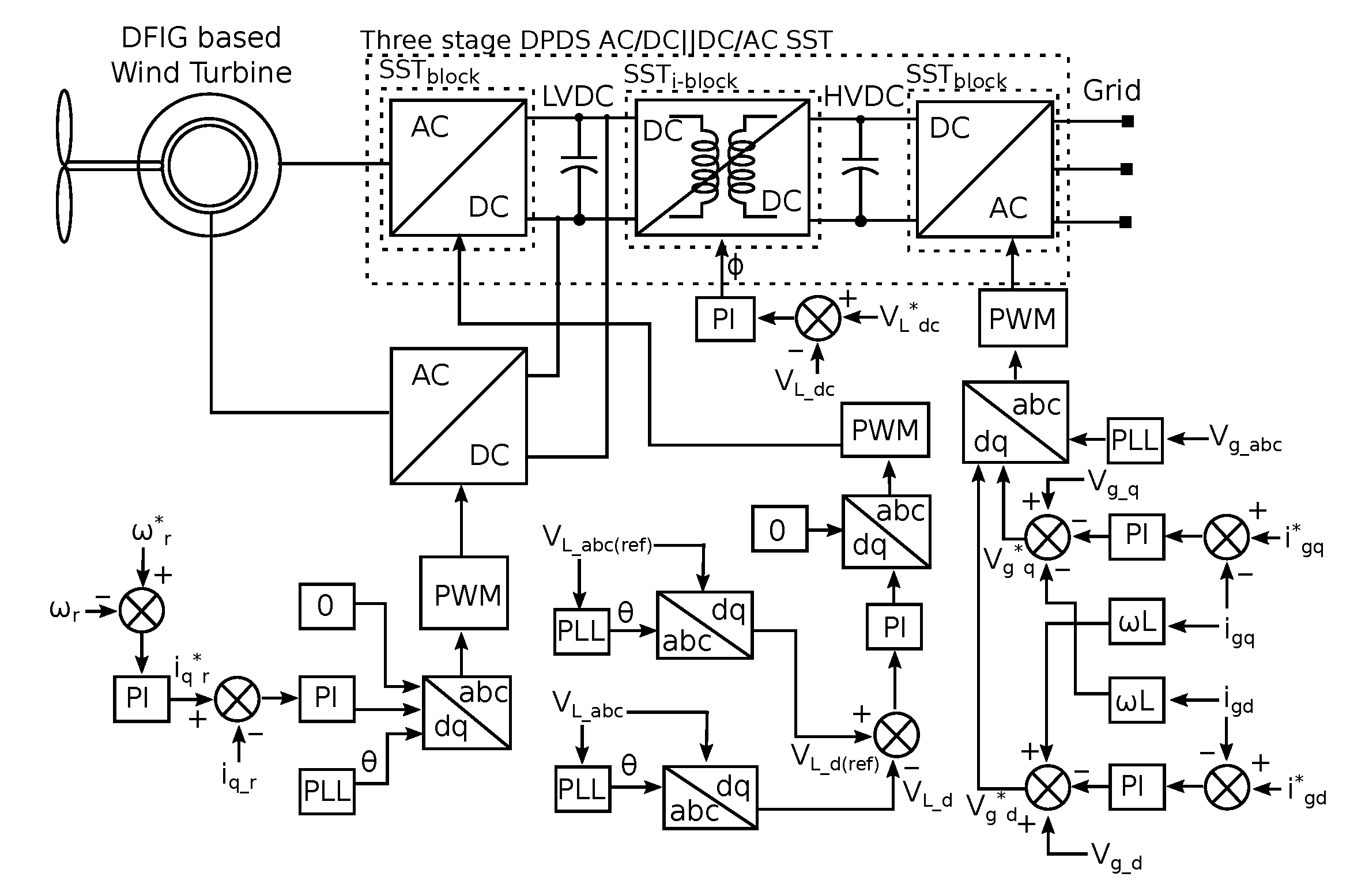

7.1. Wind Turbines

7.2. Traction

7.3. Energy Routing, Grid Interconnection, and Reactive Power

7.4. Asynchronous Connections

8. Safety and Protection of SST

9. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| CAGR | compound annual growth rate |

| DPS | dual phase shift |

| DPSS | dual pimary single secondary |

| DPDS | dual primary dual secondary |

| PEBB | power electronics building blocks |

| EPS | extended phase shift |

| HC-DCM | half-cycle discontinuous-conduction mode |

| HV | high voltage |

| IPOP | input parallel output parallel |

| ISOP | input series output parallel |

| ISOS | input series output series |

| LF | low frequency |

| LV | low voltage |

| MAB | multiple active bridge |

| MF | medium frequency |

| MFT | medium frequency transformer |

| MPC | model predictive control |

| MV | medium voltage |

| NLC | nearest level control |

| NVC | nearest vector control |

| PEBB | power electronics building blocks |

| PET | power electronic transformer |

| PRP | proportional resonant power |

| QAB | quad active bridge |

| SOP | soft open point |

| SPDS | single primary dual secondary |

| SPS | single phase shift |

| SPSS | single primary single secondary |

| SPTS | single primary triple secondary |

| SST | solid state transformer |

| solid state transformer block | |

| solid state transformer cell | |

| solid state transformer isolated block | |

| solid state transformer isolated cell | |

| solid state transformer integrated power module | |

| TPS | triple phase shift |

References

- Krause, C. Power transformer insulation—history, technology and design. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1941–1947. [Google Scholar] [CrossRef]

- Orosz, T. Evolution and modern approaches of the power transformer cost optimization methods. Period. Polytech. Electr. Eng. Comput. Sci. 2019, 63, 37–50. [Google Scholar] [CrossRef] [Green Version]

- Tesla, N. System of Electrical Distribution. U.S. Patent 381,970, 1 May 1888. [Google Scholar]

- Rojas, F.; Díaz, M.; Espinoza, M.; Cárdenas, R. A solid state transformer based on a three-phase to single-phase Modular Multilevel Converter for power distribution networks. In Proceedings of the IEEE Southern Power Electronics Conference (SPEC), Puerto Varas, Chile, 4–7 December 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Del Vecchio, R.M.; Poulin, B.; Feghali, P.T.; Shah, D.M.; Ahuja, R. Transformer Design Principles: With Applications to Core-Form Power Transformers; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Harlow, J.H. Electric Power Transformer Engineering; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Mcmurray, W. Power Converter Circuits Having a High Frequency Link. U.S. Patent 3,517,300, 23 June 1970. [Google Scholar]

- Brooks, J.L. Solid State Transformer Concept Development; Technical Report; Civil Engineering Lab (Navy): Port Hueneme, CA, USA, 1980. [Google Scholar]

- Bowers, J.C.; Garrett, S.J.; Nienhaus, H.A.; Brooks, J.L. A solid state transformer. In Proceedings of the IEEE Power Electronics Specialists Conference, Atlanta, GA, USA, 16–20 June 1980; pp. 253–264. [Google Scholar] [CrossRef]

- Sudhoff, S.D. Solid State Transformer. U.S. Patent 5,943,229, 24 Ausgust 1999. [Google Scholar]

- Kang, M.; Enjeti, P.N.; Pitel, I.J. Analysis and design of electronic transformers for electric power distribution system. IEEE Trans. Power Electron. 1999, 14, 1133–1141. [Google Scholar] [CrossRef]

- Heinemann, L.; Mauthe, G. The universal power electronics based distribution transformer, an unified approach. In Proceedings of the IEEE 32nd Annual Power Electronics Specialists Conference (IEEE Cat. No. 01CH37230), Vancouver, BC, Canada, 17–21 June 2001; IEEE: Hoboken, NJ, USA, 2001; Volume 2, pp. 504–509. [Google Scholar]

- Huber, J.E.; Kolar, J.W. Solid-state transformers: On the origins and evolution of key concepts. IEEE Ind. Electron. Mag. 2016, 10, 19–28. [Google Scholar] [CrossRef]

- Huang, A.Q.; Crow, M.L.; Heydt, G.T.; Zheng, J.P.; Dale, S.J. The future renewable electric energy delivery and management (FREEDM) system: The energy internet. Proc. IEEE 2010, 99, 133–148. [Google Scholar] [CrossRef]

- Huang, A.Q. Solid state transformers, the Energy Router and the Energy Internet. In The Energy Internet; Elsevier: Amsterdam, The Netherlands, 2019; pp. 21–44. [Google Scholar]

- Huber, J.E.; Rothmund, D.; Kolar, J.W. Comparative evaluation of isolated front end and isolated back end multi-cell SSTs. In Proceedings of the IEEE 8th International Power Electronics and Motion Control Conference (IPEMC-ECCE Asia), Hefei, China, 22–26 May 2016; pp. 3536–3545. [Google Scholar] [CrossRef]

- Huber, J.E.; Kolar, J.W. Applicability of solid-state transformers in today’s and future distribution grids. IEEE Trans. Smart Grid 2017, 10, 317–326. [Google Scholar] [CrossRef]

- Bifaretti, S.; Zanchetta, P.; Watson, A.; Tarisciotti, L.; Clare, J.C. Advanced power electronic conversion and control system for universal and flexible power management. IEEE Trans. Smart Grid 2011, 2, 231–243. [Google Scholar] [CrossRef]

- Liserre, M.; Buticchi, G.; Andresen, M.; De Carne, G.; Costa, L.F.; Zou, Z.X. The smart transformer: Impact on the electric grid and technology challenges. IEEE Ind. Electron. Mag. 2016, 10, 46–58. [Google Scholar] [CrossRef] [Green Version]

- Maitra, A.; Sundaram, A.; Gandhi, M.; Bird, S.; Doss, S. Intelligent universal transformer design and applications. In Proceedings of the CIRED 2009-20th International Conference and Exhibition on Electricity Distribution-Part 1, Prague, Czech Republic, 8–11 June 2009; IET: London, UK, 2009; pp. 1–7. [Google Scholar]

- She, X.; Lukic, S.; Huang, A.Q.; Bhattacharya, S.; Baran, M. Performance evaluation of solid state transformer based microgrid in FREEDM systems. In Proceedings of the 2011 Twenty-Sixth Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Fort Worth, TX, USA, 6–11 March 2011; IEEE: Hoboken, NJ, USA, 2011; pp. 182–188. [Google Scholar]

- Rajashekara, K.; Krishnamoorthy, H.S.; Naik, B.S. Electrification of subsea systems: Requirements and challenges in power distribution and conversion. CPSS Trans. Power Electron. Appl. 2017, 2, 259–266. [Google Scholar] [CrossRef]

- Cao, W.; Wu, J.; Jenkins, N.; Wang, C.; Green, T. Operating principle of Soft Open Points for electrical distribution network operation. Appl. Energy 2016, 164, 245–257. [Google Scholar] [CrossRef] [Green Version]

- Srdic, S.; Lukic, S. Toward Extreme Fast Charging: Challenges and Opportunities in Directly Connecting to Medium-Voltage Line. IEEE Electrif. Mag. 2019, 7, 22–31. [Google Scholar] [CrossRef]

- Brando, G.; Dannier, A.; Del Pizzo, A.; Rizzo, R. A high performance control technique of power electronic transformers in medium voltage grid-connected PV plants. In Proceedings of the XIX International Conference on Electrical Machines-ICEM 2010, Rome, Italy, 6–8 September 2010; IEEE: Hoboken, NJ, USA, 2010; pp. 1–6. [Google Scholar]

- Gupta, R.K.; Castelino, G.F.; Mohapatra, K.K.; Mohan, N. A novel integrated three-phase, switched multi-winding power electronic transformer converter for wind power generation system. In Proceedings of the 2009 35th Annual Conference of IEEE Industrial Electronics, Porto, Portugal, 3–5 November 2009; IEEE: Hoboken, NJ, USA, 2009; pp. 4481–4486. [Google Scholar]

- Dujic, D.; Zhao, C.; Mester, A.; Steinke, J.K.; Weiss, M.; Lewdeni-Schmid, S.; Chaudhuri, T.; Stefanutti, P. Power electronic traction transformer-low voltage prototype. IEEE Trans. Power Electron. 2013, 28, 5522–5534. [Google Scholar] [CrossRef]

- Drabek, P.; Peroutka, Z.; Pittermann, M.; Cedl, M. New configuration of traction converter with medium-frequency transformer using matrix converters. IEEE Trans. Ind. Electron. 2011, 58, 5041–5048. [Google Scholar] [CrossRef]

- Javaid, U.; Dujić, D.; van der Merwe, W. MVDC marine electrical distribution: Are we ready? In Proceedings of the IECON 2015—41st Annual Conference of the IEEE Industrial Electronics Society, Yokohama, Japan, 9–12 November 2015; IEEE: Hoboken, NJ, USA, 2015; pp. 823–828. [Google Scholar]

- Doerry, N. Next, generation integrated power systems (NGIPS) for the future fleet. In Proceedings of the IEEE Electric Ship Technologies Symposium, Baltimore, MD, USA, 20–22 April 2009; IEEE: Hoboken, NJ, USA, 2009; Volume 150, pp. 200–250. [Google Scholar]

- Flynn, M.C.; Jones, C.; Rakhra, P.; Norman, P.; Galloway, S. Impact of key design constraints on fault management strategies for distributed electrical propulsion aircraft. In Proceedings of the 53rd AIAA/SAE/ASEE Joint Propulsion Conference, Atlanta, GA, USA, 10–12 July 2017; p. 5034. [Google Scholar]

- Ortiz, G. High-Power DC-DC Converter Technologies for Smart Grid and Traction Applications. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2014. [Google Scholar]

- Huber, J.E.; Kolar, J.W. Volume/weight/cost comparison of a 1MVA 10 kV/400 V solid-state against a conventional low-frequency distribution transformer. In Proceedings of the 2014 IEEE Energy Conversion Congress and Exposition (ECCE), Pittsburgh, PA, USA, 14–18 September 2014; IEEE: Hoboken, NJ, USA, 2014; pp. 4545–4552. [Google Scholar]

- Davis, S. Are Solid-State Transformers Ready for Prime Time? 2017. Available online: https://www.powerelectronics.com/alternative-energy/are-solid-state-transformers-ready-prime-time (accessed on 18 July 2019).

- Kanellos, M. Next, for the Grid: Solid State Transformers. 2011. Available online: https://www.greentechmedia.com/articles/read/next-for-the-grid-solid-state-transformers#gs.0mprf5 (accessed on 3 August 2019).

- Transparency Market Research. Solid State Transformer Market, Rep Id: TMRGL825. 2019. Available online: https://www.globenewswire.com/news-release/2019/05/02/1815398/0/en/Solid-State-Transformer-Market-to-be-Worth-US-1-141-0-Mn-by-2027-TMR.html (accessed on 18 July 2019).

- She, X.; Burgos, R.; Wang, G.; Wang, F.; Huang, A.Q. Review of solid state transformer in the distribution system: From components to field application. In Proceedings of the 2012 IEEE Energy Conversion Congress and Exposition (ECCE), Raleigh, NC, USA, 15–20 September 2012; IEEE: Hoboken, NJ, USA, 2012; pp. 4077–4084. [Google Scholar]

- Han, B.M.; Choi, N.S.; Lee, J.Y. New bidirectional intelligent semiconductor transformer for smart grid application. IEEE Trans. Power Electron. 2013, 29, 4058–4066. [Google Scholar] [CrossRef]

- Pipolo, S.; Bifaretti, S.; Bonaiuto, V.; Tarisciotti, L.; Zanchetta, P. Reactive power control strategies for UNIFLEX-PM Converter. In Proceedings of the IECON 2016-42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; IEEE: Hoboken, NJ, USA, 2016; pp. 3570–3575. [Google Scholar]

- Lee, F.C.; Peng, D. Power electronics building block and system integration. In Proceedings of the IPEMC 2000. Third International Power Electronics and Motion Control Conference (IEEE Cat. No. 00EX435), Beijing, China, 15–18 August 2000; IEEE: Hoboken, NJ, USA, 2000; Volume 1, pp. 1–8. [Google Scholar]

- Szczesniak, P. Three-Phase AC–AC Power Converters Based on Matrix Converter Topology; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Baker, R.H. Switching Circuit. U.S. Patent 4,210,826, 1 July 1980. [Google Scholar]

- Nabae, A.; Takahashi, I.; Akagi, H. A New Neutral-Point-Clamped PWM Inverter. IEEE Trans. Ind. Appl. 1981, IA-17, 518–523. [Google Scholar] [CrossRef]

- Meynard, T.; Foch, H. Multi-level conversion: High voltage choppers and voltage-source inverters. In Proceedings of the PESC’92 Record. 23rd Annual IEEE Power Electronics Specialists Conference, Toledo, Spain, 29 June–3 July 1992; IEEE: Hoboken, NJ, USA, 1992; pp. 397–403. [Google Scholar]

- Baker, R.H.; Bannister, L.H. Electric Power Converter. U.S. Patent 3867643A, 18 February 1975. [Google Scholar]

- Peng, F.Z.; Lai, J.S.; McKeever, J.W.; VanCoevering, J. A multilevel voltage-source inverter with separate DC sources for static VAr generation. In Proceedings of the Conference Record of the 1995 IEEE Industry Applications Conference Thirtieth IAS Annual Meeting, Orlando, FL, USA, 8–12 October 1995; IEEE: Hoboken, NJ, USA, 1995; Volume 3, pp. 2541–2548. [Google Scholar] [CrossRef] [Green Version]

- Lesnicar, A.; Marquardt, R. An innovative modular multilevel converter topology suitable for a wide power range. In Proceedings of the IEEE Bologna Power Tech Conference Proceedings, Bologna, Italy, 23–26 June 2003; IEEE: Hoboken, NJ, USA, 2003; Volume 3. [Google Scholar]

- She, X.; Huang, A.Q.; Burgos, R. Review of solid-state transformer technologies and their application in power distribution systems. IEEE J. Emerg. Sel. Top. Power Electron. 2013, 1, 186–198. [Google Scholar] [CrossRef]

- Kolar, J.W.; Ortiz, G. Solid-state-transformers: Key components of future traction and smart grid systems. In Proceedings of the International Power Electronics Conference (IPEC), Hiroshima, Japan, 18–21 May 2014. [Google Scholar]

- Krismer, F. Modeling and Optimization of Bidirectional Dual Active Bridge DC-DC Converter Topologies. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2010. [Google Scholar]

- Cougo, B.; Kolar, J.W. Integration of leakage inductance in tape wound core transformers for dual active bridge converters. In Proceedings of the 7th International Conference on Integrated Power Electronics Systems (CIPS), Nuremberg, Germany, 6–8 March 2012; IEEE: Hoboken, NJ, USA, 2012; pp. 1–6. [Google Scholar]

- Abedini, A.; Lipo, T. A novel topology of solid state transformer. In Proceedings of the 2010 1st Power Electronic & Drive Systems & Technologies Conference (PEDSTC), Tehran, Iran, 17–18 February 2010; IEEE: Hoboken, NJ, USA, 2010; pp. 101–105. [Google Scholar]

- Huber, J.E.; Kolar, J.W. Analysis and design of fixed voltage transfer ratio DC/DC converter cells for phase-modular solid-state transformers. In Proceedings of the 2015 IEEE Energy Conversion Congress and Exposition (ECCE), Montreal, QC, Canada, 20–24 September 2015; IEEE: Hoboken, NJ, USA, 2015; pp. 5021–5029. [Google Scholar]

- Tarisciotti, L.; Zanchetta, P.; Watson, A.; Wheeler, P.; Clare, J.C.; Bifaretti, S. Multiobjective modulated model predictive control for a multilevel solid-state transformer. IEEE Trans. Ind. Appl. 2015, 51, 4051–4060. [Google Scholar] [CrossRef]

- Costa, L.F.; Buticchi, G.; Liserre, M. Modular Smart Transformer architectures: An overview and proposal of a interphase architecture. In Proceedings of the 2017 IEEE 8th International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Florianopolis, Brazil, 17–20 April 2017; IEEE: Hoboken, NJ, USA, 2017; pp. 1–7. [Google Scholar]

- Mainali, K.; Tripathi, A.; Madhusoodhanan, S.; Kadavelugu, A.; Patel, D.; Hazra, S.; Hatua, K.; Bhattacharya, S. A Transformerless Intelligent Power Substation: A three-phase SST enabled by a 15-kV SiC IGBT. IEEE Power Electron. Mag. 2015, 2, 31–43. [Google Scholar] [CrossRef]

- Falcones, S.; Mao, X.; Ayyanar, R. Topology comparison for solid state transformer implementation. In Proceedings of the Power and Energy Society General Meeting, Providence, RI, USA, 25–29 July 2010; IEEE: Hoboken, NJ, USA, 2010; pp. 1–8. [Google Scholar]

- Besselmann, T.; Mester, A.; Dujic, D. Power electronic traction transformer: Efficiency improvements under light-load conditions. IEEE Trans. Power Electron. 2013, 29, 3971–3981. [Google Scholar] [CrossRef]

- Sahoo, A.K.; Mohan, N. Modulation and control of a single-stage hvdc/ac solid state transformer using modular multilevel converter. In Proceedings of the 2017 IEEE Applied Power Electronics Conference and Exposition (APEC), Tampa, FL, USA, 26–30 March 2017; IEEE: Hoboken, NJ, USA, 2017; pp. 1857–1864. [Google Scholar]

- Wrede, H.; Staudt, V.; Steimel, A. Design of an electronic power transformer. In Proceedings of the IEEE 28th Annual Conference of the Industrial Electronics Society, Sevilla, Spain, 5–8 November 2002; IEEE: Hoboken, NJ, USA, 2002; Volume 2, pp. 1380–1385. [Google Scholar]

- Kimura, N.; Morizane, T.; Iyoda, I.; Nakao, K.; Yokoyama, T. Middle frequency solid state transformer for HVDC transmission from offshore windfarm. In Proceedings of the 2018 International Power Electronics Conference (IPEC-Niigata 2018-ECCE Asia), Niigata, Japan, 20–24 May 2018; IEEE: Hoboken, NJ, USA, 2018; pp. 2914–2920. [Google Scholar]

- Li, Y.; Li, Y.; Han, J.; Tan, Y.; Cai, Y.; Jiang, Y. A MMC-SST based power quality improvement method for the medium and high voltage distribution network. In Proceedings of the 2016 IEEE 16th International Conference on Environment and Electrical Engineering (EEEIC), Florence, Italy, 7–10 June 2016; IEEE: Hoboken, NJ, USA, 2016; pp. 1–5. [Google Scholar]

- Legrand. Power Guide Book, Book 3, Electrical Energy Supply; Technical report; Legrand: Limoges, France, 2009. [Google Scholar]

- Voltages, I.S. IEC 60038. Edition 2002, 7, 2009-06. [Google Scholar]

- BDEW. Technical Guideline Generating PlantsConnected to the Medium-Voltage Network; BDEW: Berlin, Germany, 2008. [Google Scholar]

- Decree, F. Decree No. 88-1056 of 14 November 1988, Book II of the Labor Code (Title III: Health, Safety and Working Conditions). 1988. Available online: https://www.legifrance.gouv.fr/affichTexte.do?cidTexte=JORFTEXT000000866441&categorieLien=cid (accessed on 10 November 2019).

- Villar, I. Multiphysical Characterization of Medium-Frequency Power Electronic Transformers; Ecole Polytechnique Fédérale de Lausanne: Lausanne, Switzerland, 2010. [Google Scholar]

- Chen, H.; Divan, D. Soft-switching solid-state transformer (S4T). IEEE Trans. Power Electron. 2017, 33, 2933–2947. [Google Scholar] [CrossRef]

- DeDoncker, R.W.; Kheraluwala, M.H.; Divan, D.M. Power conversion apparatus for dc/dc conversion using dual active bridges. U.S. Patent 5,027,264, 25 July 1991. [Google Scholar]

- Schoneman, G.K. 500-W zero-voltage-switched full-bridge two-quadrant power modulator. In Proceedings of the Eighth Annual Applied Power Electronics Conference and Exposition, San Diego, CA, USA, 7–11 March 1993; pp. 700–706. [Google Scholar] [CrossRef]

- Flores, L.; Garcia, O.; Oliver, J.; Cobos, J. High-frequency bi-directional DC/DC converter using two inductor rectifier. In Proceedings of the 2006 IEEE International Power Electronics Congress, Puebla, Mexico, 16–18 October 2006; IEEE: Hoboken, NJ, USA, 2006; pp. 1–6. [Google Scholar]

- Qin, H.; Kimball, J.W. Solid-state transformer architecture using AC–AC dual-active-bridge converter. IEEE Trans. Ind. Electron. 2012, 60, 3720–3730. [Google Scholar] [CrossRef]

- Zhu, Q. 7.2 kV Solid State Transformer Based on 15 kV SiC MOSFETs and A Novel Single Stage AC-AC Converter. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 8 December 2018. [Google Scholar]

- Chen, H.; Prasai, A.; Divan, D. Dyna-C: A minimal topology for bidirectional solid-state transformers. IEEE Trans. Power Electron. 2016, 32, 995–1005. [Google Scholar] [CrossRef]

- Pena-Alzola, R.; Gohil, G.; Mathe, L.; Liserre, M.; Blaabjerg, F. Review of modular power converters solutions for smart transformer in distribution system. In Proceedings of the 2013 IEEE Energy Conversion Congress and Exposition, Denver, CO, USA, 15–19 September 2013; IEEE: Hoboken, NJ, USA, 2013; pp. 380–387. [Google Scholar]

- Falcones, S.; Ayyanar, R.; Mao, X. A DC–DC multiport-converter-based solid-state transformer integrating distributed generation and storage. IEEE Trans. Power Electron. 2012, 28, 2192–2203. [Google Scholar] [CrossRef]

- Costa, L.F.; Buticchi, G.; Liserre, M. Quad-active-bridge dc–dc converter as cross-link for medium-voltage modular inverters. IEEE Trans. Ind. Appl. 2016, 53, 1243–1253. [Google Scholar] [CrossRef]

- Tao, H.; Kotsopoulos, A.; Duarte, J.L.; Hendrix, M.A. Family of multiport bidirectional DC–DC converters. IEE Proc. Electr. Power Appl. 2006, 153, 451–458. [Google Scholar] [CrossRef] [Green Version]

- Schwarz, F.C. A Method of Resonant Current Pulse Modulation for Power Converters. IEEE Trans. Ind. Electron. Control Instrum. 1970, IECI-17, 209–221. [Google Scholar] [CrossRef]

- Corradini, L.; Seltzer, D.; Bloomquist, D.; Zane, R.; Maksimović, D.; Jacobson, B. Minimum current operation of bidirectional dual-bridge series resonant DC/DC converters. IEEE Trans. Power Electron. 2011, 27, 3266–3276. [Google Scholar] [CrossRef]

- Rothmund, D.; Huber, J.E.; Kolar, J.W. Operating behavior and design of the half-cycle discontinuous- conduction-mode series-resonant-converter with small dc link capacitors. In Proceedings of the 2013 IEEE 14th Workshop on Control and Modeling for Power Electronics (COMPEL), Salt Lake City, UT, USA, 23–26 June 2013; IEEE: Hoboken, NJ, USA, 2013; pp. 1–9. [Google Scholar]

- Hannan, M.A.; Ker, P.J.; Lipu, M.S.H.; Choi, Z.H.; Rahman, M.S.A.; Muttaqi, K.M.; Blaabjerg, F. State of the Art of Solid-State Transformers: Advanced Topologies, Implementation Issues, Recent Progress and Improvements. IEEE Access 2020, 8, 19113–19132. [Google Scholar] [CrossRef]

- Harada, K.; Anan, F.; Yamasaki, K.; Jinno, M.; Kawata, Y.; Nakashima, T. Intelligent transformer. In Proceedings of the PESC Record. 27th Annual IEEE Power Electronics Specialists Conference, Baveno, Italy, 23–27 June 1996; IEEE: Hoboken, NJ, USA, 1996; Volume 2, pp. 1337–1341. [Google Scholar]

- Krishnaswami, H.; Ramanarayanan, V. Control of high-frequency AC link electronic transformer. IEEE Proc. Electr. Power Appl. 2005, 152, 509–516. [Google Scholar] [CrossRef] [Green Version]

- Harada, K.; Sakamoto, H.; Shoyaraa, M. Phase controlled DC-AC converter with high frequency switching. In Proceedings of the 1987 IEEE Power Electronics Specialists Conference, Blacksburg, VA, USA, 21–26 June 1987; IEEE: Hoboken, NJ, USA, 1987; pp. 13–19. [Google Scholar]

- Banaei, M.; Salary, E. Power quality improvement based on novel power electronic transformer. In Proceedings of the 2011 2nd Power Electronics, Drive Systems and Technologies Conference, Tehran, Iran, 16–17 February 2011; IEEE: Hoboken, NJ, USA, 2011; pp. 286–291. [Google Scholar]

- Stieneker, M.; Mortimer, B.J.; Hinz, A.; Müller-Hellmann, A.; De Doncker, R.W. MVDC Distribution Grids for Electric Vehicle Fast-Charging Infrastructure. In Proceedings of the 2018 International Power Electronics Conference (IPEC-Niigata 2018-ECCE Asia), Niigata, Japan, 20–24 May 2018; IEEE: Hoboken, NJ, USA, 2018; pp. 598–606. [Google Scholar]

- Khan, M.M.S.; Faruque, M.O.; Newaz, A. Fuzzy logic based energy storage management system for MVDC power system of all electric ship. IEEE Trans. Energy Convers. 2017, 32, 798–809. [Google Scholar] [CrossRef] [Green Version]

- Steub, V. Study of Modulation Schemes for the Dual-Active-Bridge Converter in a Grid-Connected Photovoltaic Park. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2018. [Google Scholar]

- Firouzjaee, A.; Ebrahim, E. Advanced modeling of solid state transformer. Ph.D. Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, January 2018. [Google Scholar]

- Qin, H.; Kimball, J.W. AC-AC dual active bridge converter for solid state transformer. In Proceedings of the 2009 IEEE Energy Conversion Congress and Exposition, San Jose, CA, USA, 20–24 September 2009; IEEE: Hoboken, NJ, USA, 2009; pp. 3039–3044. [Google Scholar]

- Liserre, M.; Andresen, M.; Costa, L.; Buticchi, G. Power routing in modular smart transformers: Active thermal control through uneven loading of cells. IEEE Ind. Electron. Mag. 2016, 10, 43–53. [Google Scholar] [CrossRef] [Green Version]

- Lai, J.S.; Maitra, A.; Mansoor, A.; Goodman, F. Multilevel intelligent universal transformer for medium voltage applications. In Proceedings of the Fourtieth IAS Annual Meeting. Conference Record of the 2005 Industry Applications Conference, Kowloon, Hong Kong, China, 2–6 October 2005; IEEE: Hoboken, NJ, USA, 2005; Volume 3, pp. 1893–1899. [Google Scholar]

- Costa, L.F.; De Carne, G.; Buticchi, G.; Liserre, M. The smart transformer: A solid-state transformer tailored to provide ancillary services to the distribution grid. IEEE Power Electron. Mag. 2017, 4, 56–67. [Google Scholar] [CrossRef]

- Vechalapu, K.; Kadavelugu, A.K.; Bhattacharya, S. High voltage dual active bridge with series connected high voltage silicon carbide (SiC) devices. In Proceedings of the 2014 IEEE Energy Conversion Congress and Exposition (ECCE), Pittsburgh, PA, USA, 14–18 September 2014; pp. 2057–2064. [Google Scholar] [CrossRef]

- Mcmurray, W. Fast Response Stepped-Wave Switching Power Converter Circuit. U.S. Patent 3,581,212, 25 May 1971. [Google Scholar]

- Hammond, P.W. Medium Voltage PWM Drive and Method. U.S. Patent 5,625,545, 25 April 1997. [Google Scholar]

- Rodriguez, J.; Franquelo, L.G.; Kouro, S.; Leon, J.I.; Portillo, R.C.; Prats, M.A.M.; Perez, M.A. Multilevel converters: An enabling technology for high-power applications. Proc. IEEE 2009, 97, 1786–1817. [Google Scholar] [CrossRef] [Green Version]

- Briz, F.; Lopez, M.; Rodriguez, A.; Arias, M. Modular power electronic transformers: Modular multilevel converter versus cascaded H-bridge solutions. IEEE Ind. Electron. Mag. 2016, 10, 6–19. [Google Scholar] [CrossRef]

- Saeed, M.; Cuartas, J.M.; Rodríguez, A.; Arias, M.; Briz, F. Energization and Start-Up of CHB-Based Modular Three-Stage Solid-State Transformers. IEEE Trans. Ind. Appl. 2018, 54, 5483–5492. [Google Scholar] [CrossRef]

- Shojaei, A.; Joós, G. A topology for three-stage Solid State Transformer. In Proceedings of the 2013 IEEE Power & Energy Society General Meeting, Vancouver, BC, Canada, 21–25 July 2013; IEEE: Hoboken, NJ, USA, 2013; pp. 1–5. [Google Scholar]

- Jianqiao, Z.; Jianwen, Z.; Xu, C.; Jiacheng, W.; Jiajie, Z. Family of modular multilevel converter (MMC) based solid state transformer (SST) topologies for hybrid AC/DC distribution grid applications. In Proceedings of the 2018 IEEE International Power Electronics and Application Conference and Exposition (PEAC), Shenzhen, China, 4–7 November 2018; IEEE: Hoboken, NJ, USA, 2018; pp. 1–5. [Google Scholar]

- López, M.; Rodríguez, A.; Blanco, E.; Saeed, M.; Martínez, Á.; Briz, F. Design and implementation of the control of an MMC-based solid state transformer. In Proceedings of the 2015 IEEE 13th International Conference on Industrial Informatics (INDIN), Cambridge, UK, 22–24 July 2015; IEEE: Hoboken, NJ, USA, 2015; pp. 1583–1590. [Google Scholar]

- Li, Y.; Han, J.; Cao, Y.; Li, Y.; Xiong, J.; Sidorov, D.; Panasetsky, D. A modular multilevel converter type solid state transformer with internal model control method. Int. J. Electr. Power Energy Syst. 2017, 85, 153–163. [Google Scholar] [CrossRef]

- Rojas Lobos, F.E. A High Performance Power Supply Based on a Four-Leg Three-Level NPC Converter for Non-Linear and Unbalanced Systems. Ph.D. Thesis, Technische Universität München, Munich, Germany, July 2016. [Google Scholar]

- Miveh, M.R.; Rahmat, M.F.; Ghadimi, A.A.; Mustafa, M.W. Control techniques for three-phase four-leg voltage source inverters in autonomous microgrids: A review. Renew. Sustain. Energy Rev. 2016, 54, 1592–1610. [Google Scholar] [CrossRef]

- Wheeler, P.W.; Rodriguez, J.; Clare, J.C.; Empringham, L.; Weinstein, A. Matrix converters: A technology review. IEEE Trans. Ind. Electron. 2002, 49, 276–288. [Google Scholar] [CrossRef]

- Friedli, T.; Kolar, J.W. Milestones in matrix converter research. IEEJ J. Ind. Appl. 2012, 1, 2–14. [Google Scholar] [CrossRef] [Green Version]

- Kolar, J.W.; Friedli, T.; Rodriguez, J.; Wheeler, P.W. Review of three-phase PWM AC–AC converter topologies. IEEE Trans. Ind. Electron. 2011, 58, 4988–5006. [Google Scholar] [CrossRef]

- Rodriguez, J.; Rivera, M.; Kolar, J.W.; Wheeler, P.W. A review of control and modulation methods for matrix converters. IEEE Trans. Ind. Electron. 2011, 59, 58–70. [Google Scholar] [CrossRef]

- García Franquelo, L.; Rodriguez, J.; Leon, J.I.; Kouro, S.; Martín Prats, M.d.l.Á.; Portillo Guisado, R.C. The age of multilevel converters arrives. IEEE Ind. Electron. Mag. 2008, 2, 28–39. [Google Scholar] [CrossRef] [Green Version]

- Schibli, N. Symmetrical Multilevel Converters with Two Quadrant DC-DC Feeding; Technical Report; EPFL: Lausanne, Switzerland, 2000. [Google Scholar]

- Jauch, F.; Biela, J. Generalized modeling and optimization of a bidirectional dual active bridge DC-DC converter including frequency variation. IEEJ J. Ind. Appl. 2015, 4, 593–601. [Google Scholar] [CrossRef] [Green Version]

- Cui, Y.; Hou, R.; Malysz, P.; Emadi, A. Improved combined modulation strategy for dual active bridge converter in electrified vehicles. In Proceedings of the 2017 IEEE Transportation Electrification Conference and Expo (ITEC), Chicago, IL, USA, 22–24 June 2017; IEEE: Hoboken, NJ, USA, 2017; pp. 101–107. [Google Scholar]

- Krismer, F.; Biela, J.; Kolar, J.W. A comparative evaluation of isolated bi-directional DC/DC converters with wide input and output voltage range. In Proceedings of the Fourtieth IAS Annual Meeting, Conference Record of the 2005 Industry Applications Conference, Hong Kong, China, 2–6 October 2005; Volume 1, pp. 599–606. [Google Scholar]

- Zhao, B.; Yu, Q.; Sun, W. Extended-phase-shift control of isolated bidirectional DC–DC converter for power distribution in microgrid. IEEE Trans. Power Electron. 2011, 27, 4667–4680. [Google Scholar] [CrossRef]

- Bai, H.; Mi, C. Eliminate reactive power and increase system efficiency of isolated bidirectional dual-active-bridge DC-DC converters using novel dual-phase-shift control. IEEE Trans. Power Electron. 2008, 23, 2905. [Google Scholar] [CrossRef]

- Kim, M.; Rosekeit, M.; Sul, S.K.; De Doncker, R.W. A dual-phase-shift control strategy for dual-active-bridge DC-DC converter in wide voltage range. In Proceedings of the 8th International Conference on Power Electronics-ECCE Asia, Jeju, Korea, 30 May–3 June 2011; IEEE: Hoboken, NJ, USA, 2011; pp. 364–371. [Google Scholar]

- Guo, Z.; Sha, D. New Topologies and Modulation Schemes for Soft-Switching Isolated DC–DC Converters; Springer: Singapore, 2020. [Google Scholar]

- Wu, K.; de Silva, C.W.; Dunford, W.G. Stability analysis of isolated bidirectional dual active full-bridge DC–DC converter with triple phase-shift control. IEEE Trans. Power Electron. 2011, 27, 2007–2017. [Google Scholar] [CrossRef]

- Jain, A.K.; Ayyanar, R. PWM control of dual active bridge: Comprehensive analysis and experimental verification. IEEE Trans. Power Electron. 2010, 26, 1215–1227. [Google Scholar] [CrossRef]

- Zhao, B.; Song, Q.; Liu, W.; Sun, Y. Overview of dual-active-bridge isolated bidirectional DC–DC converter for high-frequency-link power-conversion system. IEEE Trans. Power Electron. 2013, 29, 4091–4106. [Google Scholar] [CrossRef]

- Zhao, B.; Song, Q.; Liu, W.; Liu, G.; Zhao, Y. Universal high-frequency-link characterization and practical fundamental-optimal strategy for dual-active-bridge DC-DC converter under PWM plus phase-shift control. IEEE Trans. Power Electron. 2015, 30, 6488–6494. [Google Scholar] [CrossRef]

- Choi, W.; Rho, K.M.; Cho, B.H. Fundamental duty modulation of dual-active-bridge converter for wide-range operation. IEEE Trans. Power Electron. 2015, 31, 4048–4064. [Google Scholar] [CrossRef]

- Huang, A.Q. Power semiconductor devices for smart grid and renewable energy systems. In Power Electronics in Renewable Energy Systems and Smart Grid: Technology and Applications; IEEE: Hoboken, NJ, USA, 2019; pp. 85–152. [Google Scholar]

- Millán, J.; Godignon, P.; Perpiñà, X.; Pérez-Tomás, A.; Rebollo, J. A survey of wide bandgap power semiconductor devices. IEEE Trans. Power Electron. 2013, 29, 2155–2163. [Google Scholar] [CrossRef]

- Inoue, S.; Akagi, H. A bidirectional isolated DC–DC converter as a core circuit of the next-generation medium-voltage power conversion system. IEEE Trans. Power Electron. 2007, 22, 535–542. [Google Scholar] [CrossRef]

- Bolotnikov, A.; Losee, P.; Permuy, A.; Dunne, G.; Kennerly, S.; Rowden, B.; Nasadoski, J.; Harfman-Todorovic, M.; Raju, R.; Tao, F.; et al. Overview of 1.2 kV–2.2 kV SiC MOSFETs targeted for industrial power conversion applications. In Proceedings of the 2015 IEEE Applied Power Electronics Conference and Exposition (APEC), Charlotte, NC, USA, 15–19 March 2015; IEEE: Hoboken, NJ, USA, 2015; pp. 2445–2452. [Google Scholar]

- Ferrari, M. Stato dell’arte e prospettive di sviluppo dei sistemi solid state transformer nelle reti elettriche. Master’s Thesis, Politecnico di Milano, Milan, Italy, 2015. [Google Scholar]

- Bahmani, A. Design and Optimization Considerations of Medium-Frequency Power Transformers in High-Power DC-DC Applications. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2016. [Google Scholar]

- Zhao, S.; Li, Q.; Lee, F.C.; Li, B. High-frequency transformer design for modular power conversion from medium-voltage ac to 400 Vdc. IEEE Trans. Power Electron. 2017, 33, 7545–7557. [Google Scholar] [CrossRef]

- Versele, C.; Deblecker, O.; Lobry, J. Multiobjective optimal design of high frequency transformers using genetic algorithm. In Proceedings of the 2009 13th European Conference on Power Electronics and Applications, Barcelona, Spain, 8–10 September 2009; pp. 1–10. [Google Scholar]

- Ortiz, G.; Leibl, M.; Kolar, J.; Apeldoorn, O. Medium frequency transformers for solid-state-transformer applications—Design and experimental verification. In Proceedings of the 2013 IEEE 10th International Conference on Power Electronics and Drive Systems (PEDS), Barcelona, Spain, 8–10 September 2009; IEEE: Hoboken, NJ, USA, 2013; pp. 1285–1290. [Google Scholar]

- Ferch, D.M. Nanocrystalline Core Materials For Modern Power Electronic Designs. 2013. Available online: https://www.magnetec.de/fileadmin/pdf/np_powerelectronic_e.pdf (accessed on 26 September 2019).

- McLyman, C.W.T. Transformer and inductor design handbook; Dekker: New York, NY, USA, 1988. [Google Scholar]

- Rylko, M.S.; Hartnett, K.J.; Hayes, J.G.; Egan, M.G. Magnetic material selection for high power high frequency inductors in dc-dc converters. In Proceedings of the 2009 Twenty-Fourth Annual IEEE Applied Power Electronics Conference and Exposition, Singapore, 25–27 October 2016; IEEE: Hoboken, NJ, USA, 2009; pp. 2043–2049. [Google Scholar]

- Vaisambhayana, S.; Dincan, C.; Shuyu, C.; Tripathi, A.; Haonan, T.; Karthikeya, B. State of art survey for design of medium frequency high power transformer. In Proceedings of the 2016 Asian Conference on Energy, Power and Transportation Electrification (ACEPT), Singapore, 25–27 October 2016; IEEE: Hoboken, NJ, USA, 2016; pp. 1–9. [Google Scholar]

- Mumuluh, R.N. Design Considerations for a High Power, Medium Frequency Transformer for a DC-DC Converter Stage of a Solid State Transformer. Master’s Thesis, School of Electrical and Electronic Engineering, University College Dublin, Dublin, Ireland, May 2016. [Google Scholar]

- Steinmetz, C.P. On the law of hysteresis. Trans. Am. Inst. Electr. Eng. 1892, 9, 1–64. [Google Scholar] [CrossRef]

- Agheb, E.; Høidalen, H.K. Medium frequency high power transformers, state of art and challenges. In Proceedings of the 2012 International conference on renewable energy research and applications (ICRERA), Nagasaki, Japan, 11–14 November 2012; IEEE: Hoboken, NJ, USA, 2012; pp. 1–6. [Google Scholar]

- Ortiz, G.; Biela, J.; Bortis, D.; Kolar, J.W. 1 Megawatt, 20 kHz, isolated, bidirectional 12kV to 1. In 2 kV DC-DC converter for renewable energy applications. In Proceedings of the The 2010 International Power Electronics Conference, Sapporo, Japan, 21–24 June 2010; IEEE: Hoboken, NJ, USA, 2010; pp. 3212–3219. [Google Scholar]

- Olivares-Galvan, J.; De Leon, F.; Georgilakis, P.; Escarela-Perez, R. Selection of copper against aluminium windings for distribution transformers. IET Electr. Power Appl. 2010, 4, 474–485. [Google Scholar] [CrossRef] [Green Version]

- Kheraluwala, M.H.; Novotny, D.W.; Divan, D.M. Design considerations for high power high frequency transformers. In Proceedings of the 21st Annual IEEE Conference on Power Electronics Specialists, San Antonio, TX, USA, 11–14 June 1990; pp. 734–742. [Google Scholar] [CrossRef]

- Lotfi, A.W.; Lee, F.C. A high frequency model for Litz wire for switch-mode magnetics. In Proceedings of the Conference Record of the 1993 IEEE Industry Applications Conference Twenty-Eighth IAS Annual Meeting, Toronto, ON, Canada, 2–8 October 1993; IEEE: Hoboken, NJ, USA, 1993; pp. 1169–1175. [Google Scholar]

- Elektrisola. High Frequency Litz Wire; Product program and technical data. Available online: https://www.mintex.si/wp-content/uploads/2018/06/EE_Litz-wire_brochure_eng.pdf. (accessed on 21 November 2019).

- Iyer, K.V.; Robbins, W.P.; Mohan, N. Winding design of a high power medium frequency transformer. In Proceedings of the 2014 International Symposium on Power Electronics, Electrical Drives, Automation and Motion, Ischia, Italy, 18–20 June 2014; IEEE: Hoboken, NJ, USA, 2014; pp. 665–669. [Google Scholar]

- Iyer, K.V.; Robbins, W.P.; Mohan, N. Design and comparison of high frequency transformers using foil and round windings. In Proceedings of the 2014 International Power Electronics Conference (IPEC-Hiroshima 2014-ECCE ASIA), Hiroshima, Japan, 18–21 May 2014; IEEE: Hoboken, NJ, USA, 2014; pp. 3037–3043. [Google Scholar]

- Dincan, C.; Kaer, P. Control and modulation for loss minimization for DC/DC converter in wind farm. In Proceedings of the PCIM Europe 2016; International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 10–12 May 2016; VDE: Frankfurt, Germany, 2016; pp. 1–8. [Google Scholar]

- Leibl, M.; Ortiz, G.; Kolar, J.W. Design and experimental analysis of a medium-frequency transformer for solid-state transformer applications. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 5, 110–123. [Google Scholar] [CrossRef]

- Fofana, I. 50 years in the development of insulating liquids. IEEE Electr. Insul. Mag. 2013, 29, 13–25. [Google Scholar] [CrossRef]

- Grzesik, B.; Stepien, M. Coaxial HF Power Transformer with Tubular Linear Windings-FEM Results vs. Laboratory Test. In Proceedings of the 2006 12th International Power Electronics and Motion Control Conference, Portoroz, Slovenia, 30 August–1 September 2006; IEEE: Hoboken, NJ, USA; pp. 1313–1317. [Google Scholar]

- Grzesik, B.; Stępień, M.; Nowak, A.J.; Smołka, J. Influence of Cooling System on the Performance Coaxial Transformer. 2005. Available online: https://www.bg.polsl.pl/expertus/view/exprec.php?term=0000055191 (accessed on 21 November 2019).

- Ronanki, D.; Williamson, S.S. Topological overview on solid-state transformer traction technology in high-speed trains. In Proceedings of the 2018 IEEE Transportation Electrification Conference and Expo (ITEC), Long Beach, CA, USA, 13–15 June 2018; IEEE: Hoboken, NJ, USA, 2018; pp. 32–37. [Google Scholar]

- Grider, D.; Agarwal, A.; Ryu, S.-H.; Cheng, L.; Capell, C.; Jonas, C.; Burk, A.; O’Loughlin, M.; Das, M.; Palmour, J. Advanced SiC Power Technology for High Megawatt Power Conditioning; Technical Report; Cree, Inc.: Durham, NC, USA, 2012. [Google Scholar]

- Huber, J.E.; Böhler, J.; Rothmund, D.; Kolar, J.W. Analysis and cell-level experimental verification of a 25 kW all-SiC isolated front end 6.6 kV/400 V AC-DC solid-state transformer. CPSS Trans. Power Electron. Appl. 2017, 2, 140–148. [Google Scholar] [CrossRef]

- Orosz, T.; Poór, P.; Karban, P.; Pánek, D. Power transformer design optimization for carbon footprint. In Proceedings of the 2019 Electric Power Quality and Supply Reliability Conference (PQ) & 2019 Symposium on Electrical Engineering and Mechatronics (SEEM), Kärdla, Estonia, 12–15 June 2019; IEEE: Hoboken, NJ, USA, 2019; pp. 1–4. [Google Scholar]

- Georgilakis, P.S. Spotlight on Modern Transformer Design; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Abu-Siada, A.; Budiri, J.; Abdou, A.F. Solid state transformers topologies, controllers, and applications: State-of-the-art literature review. Electronics 2018, 7, 298. [Google Scholar] [CrossRef] [Green Version]

- She, X.; Wang, F.; Burgos, R.; Huang, A.Q. Solid state transformer interfaced wind energy system with integrated active power transfer, reactive power compensation and voltage conversion functions. In Proceedings of the 2012 IEEE Energy Conversion Congress and Exposition (ECCE), Raleigh, NC, USA, 15–20 September 2012; IEEE: Hoboken, NJ, USA, 2012; pp. 3140–3147. [Google Scholar]

- Syed, I.; Khadkikar, V. Replacing the grid interface transformer in wind energy conversion system with solid-state transformer. IEEE Trans. Power Syst. 2016, 32, 2152–2160. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Y.; Abu-Rub, H.; Ge, B. Model predictive control of matrix converter based solid state transformer. In Proceedings of the 2016 IEEE International Conference on Industrial Technology (ICIT), Taipei, Taiwan, 14–17 March 2016; pp. 1248–1253. [Google Scholar] [CrossRef]

- Guillod, T.; Krismer, F.; Färber, R.; Franck, C.M.; Kolar, J.W. Protection of MV/LV solid-state transformers in the distribution grid. In Proceedings of the IECON 2015-41st Annual Conference of the IEEE Industrial Electronics Society, Yokohama, Japan, 9–12 November 2015; IEEE: Hoboken, NJ, USA, 2015; pp. 3531–3538. [Google Scholar]

- Guillod, T.; Krismer, F.; Kolar, J.W. Protection of MV converters in the grid: The case of MV/LV solid-state transformers. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 5, 393–408. [Google Scholar] [CrossRef]

- Madhusoodhanan, S.; Patel, D.; Bhattacharya, S.; Carr, J.A.; Wang, Z. Protection of a transformerless intelligent power substation. In Proceedings of the 2013 4th IEEE International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Rogers, AR, USA, 8–11 July 2013; IEEE: Hoboken, NJ, USA, 2013; pp. 1–8. [Google Scholar]

- Shah, D.G.; Crow, M. Stability design criteria for distribution systems with solid-state transformers. IEEE Trans. Power Deliv. 2014, 29. [Google Scholar] [CrossRef]

| Low | Medium | High | Standard | |

|---|---|---|---|---|

| AC power systems | 100 V–1 kV | 1 kV–35 kV | 35 kV–230 kV | |

| DC traction systems | 500 V–900 V | 1 kV–3.6 kV | - | IEC 60038 |

| DC power systems | - | 12 kV–27.5 kV | - | |

| Distribution systems | - | 1 kV–66 kV | - | German: BDEW 2008 |

| AC voltage levels | EVA LVA LVB | - | HVA: (1 kV–50 kV) HVB: (>50 kV) | French Decree 2008 No. 88–1056 |

| Material | Alloy Composition in % | Losses in [W/kg] at (20 kHz, 200 mT) | Bsat in Tesla | at (50 Hz) | Max Working Temp [CC] | |

|---|---|---|---|---|---|---|

| Grain Oriented Silicon Steel | Fe97Si3 | >1000 | 2 | 9 | 2000–35,000 | ∼120 |

| Standard crystalline permalloy I | Ni45Fe55 | >150 | 1.55 | 25 | 12,000–80,000 | 130 |

| Standard crystalline permalloy II | Ni45Fe55 | >100 | 1.5 | 25 | 60,000–125,000 | 130 |

| Advanced Silicon steel | Fe93.5 Si6.5 | 40 | 1.3 | 0.1 | 16,000 | 130 |

| Fe- amorphous alloy | Fe76(Si,B)24 | 18 | 1.56 | 27 | 6500–8000 | 150 |

| High performance ferrite | MnZn | 17 | 0.5 | 21 | 1500–15,000 | 100/120 |

| Advanced crystalline permalloy | Ni80Fe20 | >15 | 0.8 | 1 | 150,000–300,000 | 130 |

| Co-amorphous alloys a | Co73(Si,B)27 | 5 | 0.55 | <0.2 | 100,000–150,000 | 90/120 |

| Co-amorphous alloys b | Co77(Si,B)23 | 5.5 | 0.82 | <0.2 | 2000–4500 | 120 |

| Co-amorphous alloys c | Co80(Si,B)20 | 6.5 | 1 | <0.2 | 1000–2500 | 120 |

| Nanocrystalline alloys I | FeCuNbSiB | 4 | 1.23 | 0.1 | 20,000–200,000 | 120/180 |

| Nanocrystalline alloys II | FeCuNbSiB | 4.5 | 1.35 | 2.3 | 20,000–200,000 | 120/180 |

| Nanocrystalline alloys III | FeCuNbSiB | 8 | 1.45 | 5.5 | ∼100,000 | 120/180 |

| Material | Continuous | Dielectric | Dielectric | Thermal |

|---|---|---|---|---|

| Temperature (°C) | Strength | Constant | Conductivity (W/mK) | |

| Mylar | 105 | 10.0 kVAC (3 mil) | 3.30 | 0.37 @ 50 °C |

| Tedlar | 107 | 4.2 kVAC (2 mil) | 11.0 | 0.35 @ 50 °C |

| Nomex | 220 | 1.6 kVAC (3 mil) | 1.6 | 0.11 @ 50 °C |

| Kapton | 400 | 13.8 kVAC (3 mil) | 3.70 | 0.18 @ 50 °C |

| Epoxy Powder Coating | 130 | 10.0 kVAC (10 mil) | 4.00 | 0.60 @ 50 °C |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shamshuddin, M.A.; Rojas, F.; Cardenas, R.; Pereda, J.; Diaz, M.; Kennel, R. Solid State Transformers: Concepts, Classification, and Control. Energies 2020, 13, 2319. https://doi.org/10.3390/en13092319

Shamshuddin MA, Rojas F, Cardenas R, Pereda J, Diaz M, Kennel R. Solid State Transformers: Concepts, Classification, and Control. Energies. 2020; 13(9):2319. https://doi.org/10.3390/en13092319

Chicago/Turabian StyleShamshuddin, Mohammed Azharuddin, Felix Rojas, Roberto Cardenas, Javier Pereda, Matias Diaz, and Ralph Kennel. 2020. "Solid State Transformers: Concepts, Classification, and Control" Energies 13, no. 9: 2319. https://doi.org/10.3390/en13092319