Fatigue Performance of Wet and Dry Pulverized Wood Flour Reinforced PP Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Pulverization of Wood Flour

2.3. Processing of Composite

2.4. Characterization Techniques

3. Results and Discussion

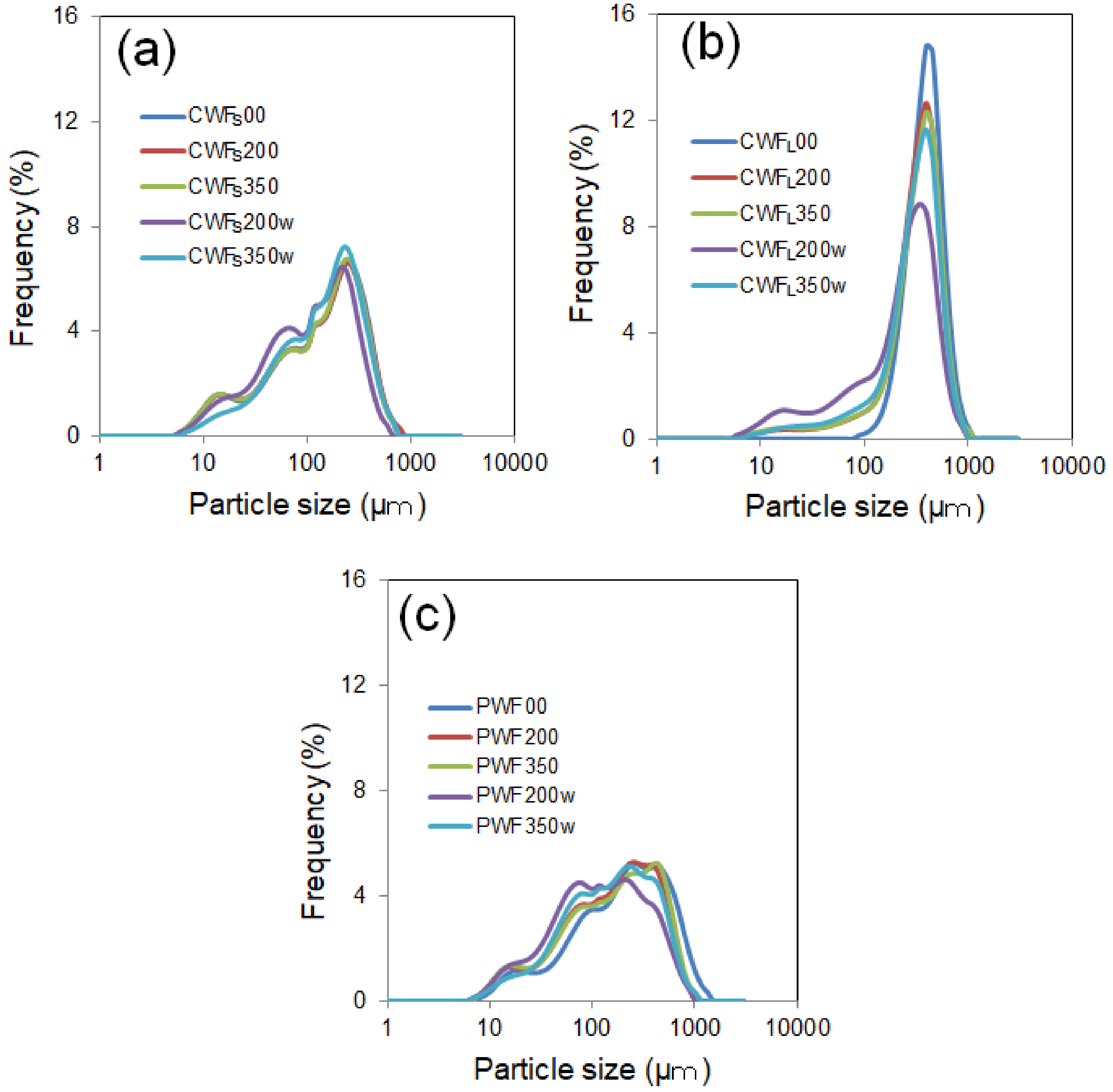

3.1. Wood Particle Size Distribution

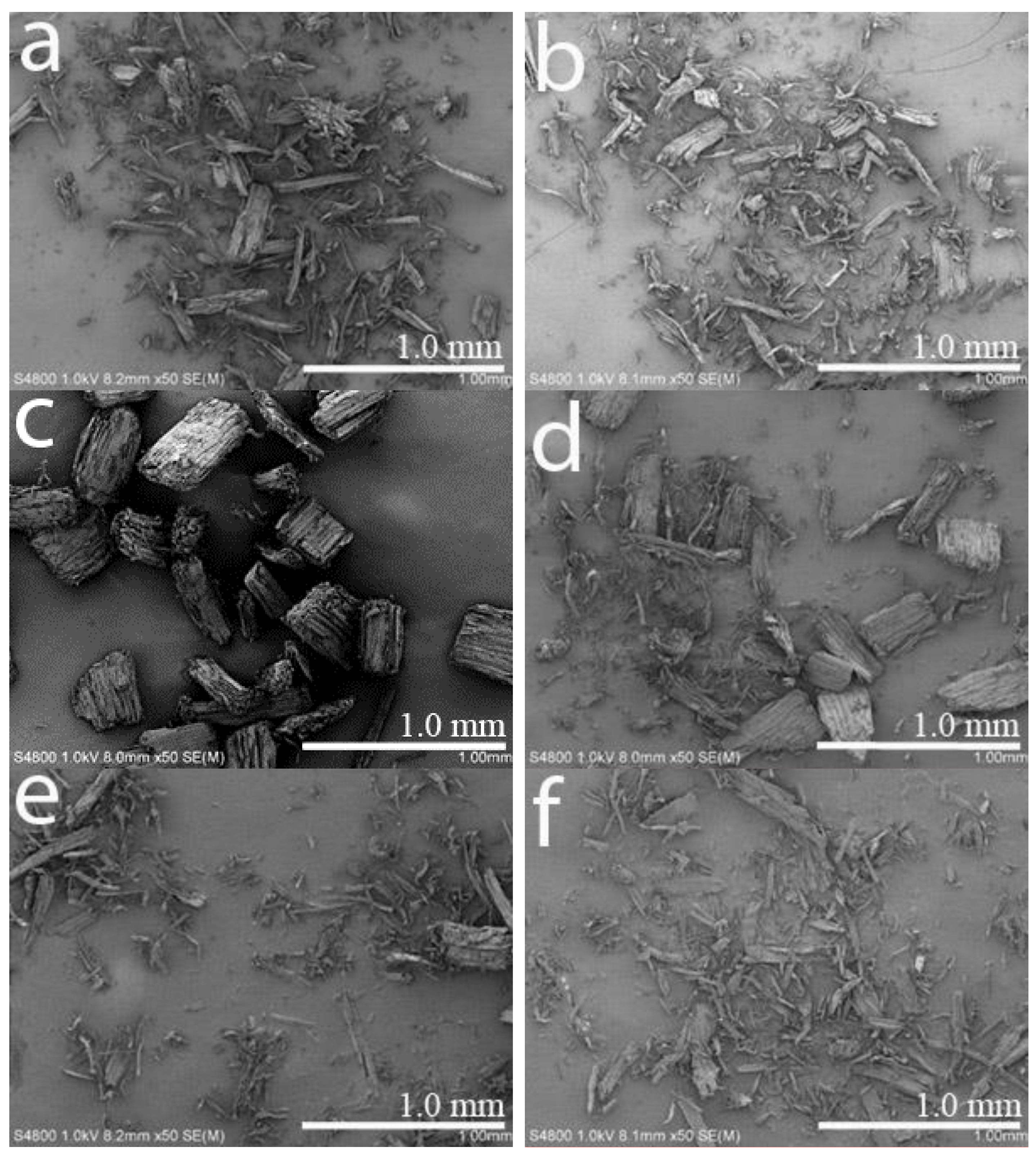

3.2. Wood Flour Morphology and Aspect Ratio

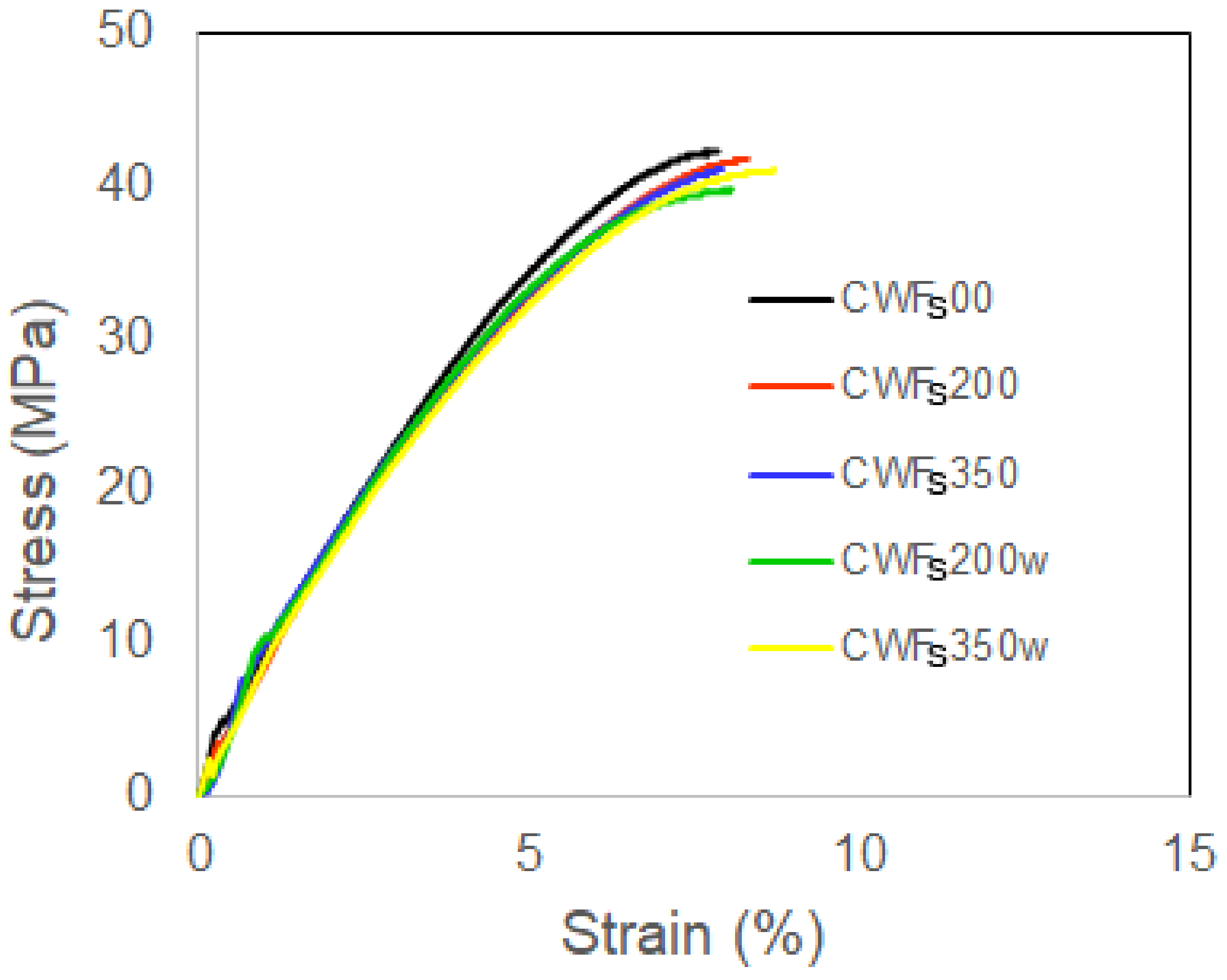

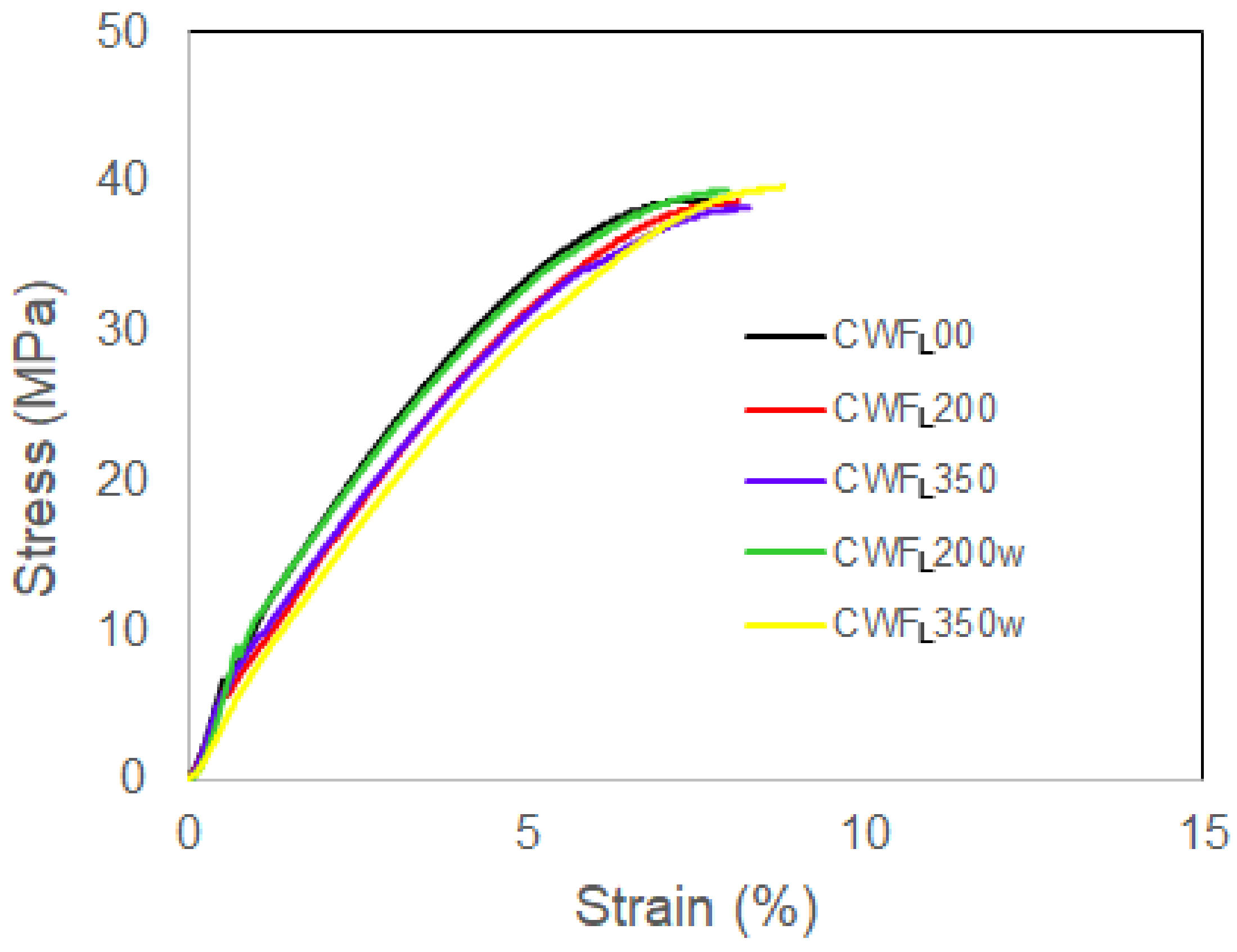

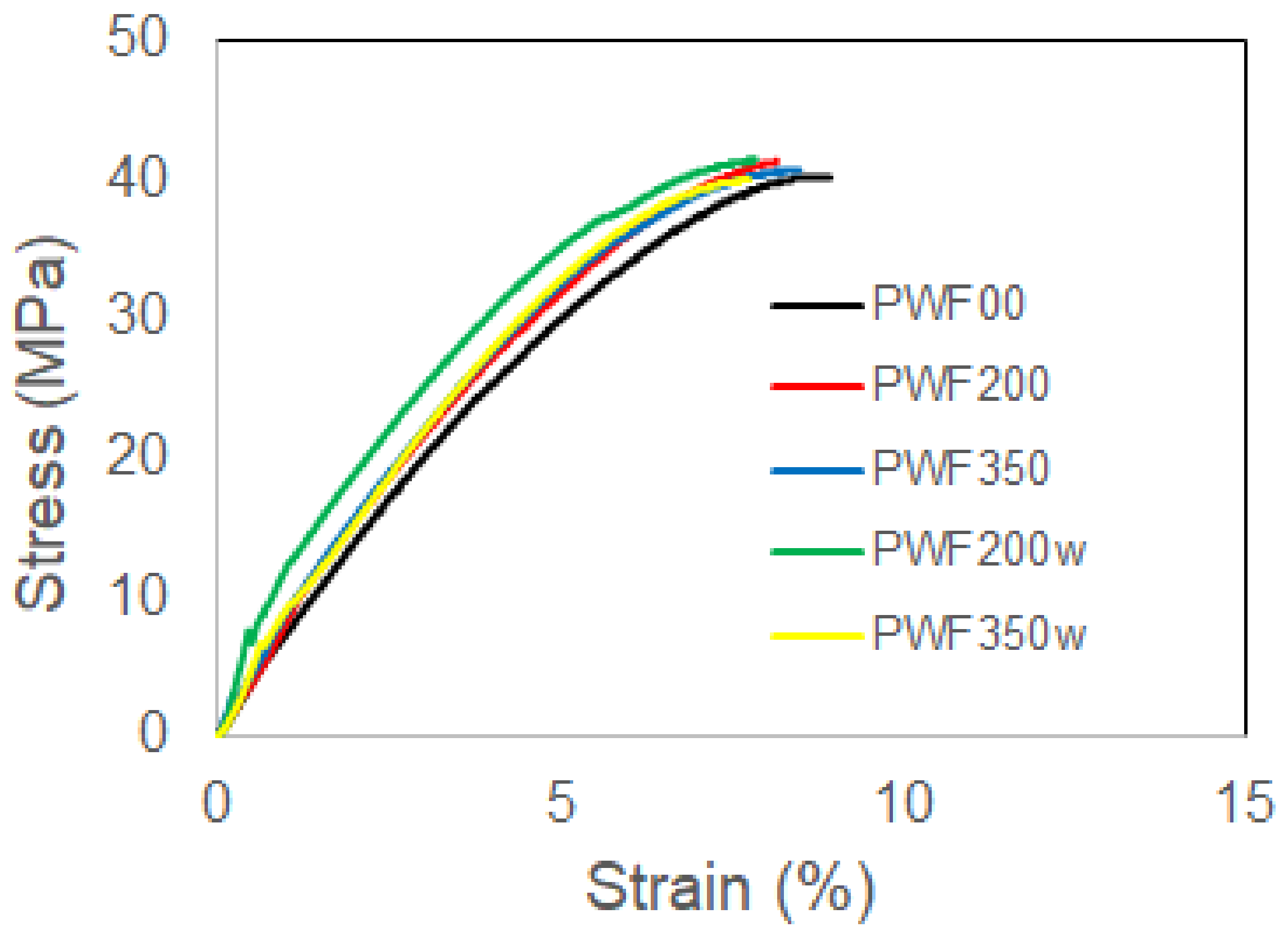

3.3. Tensile Properties of Composites

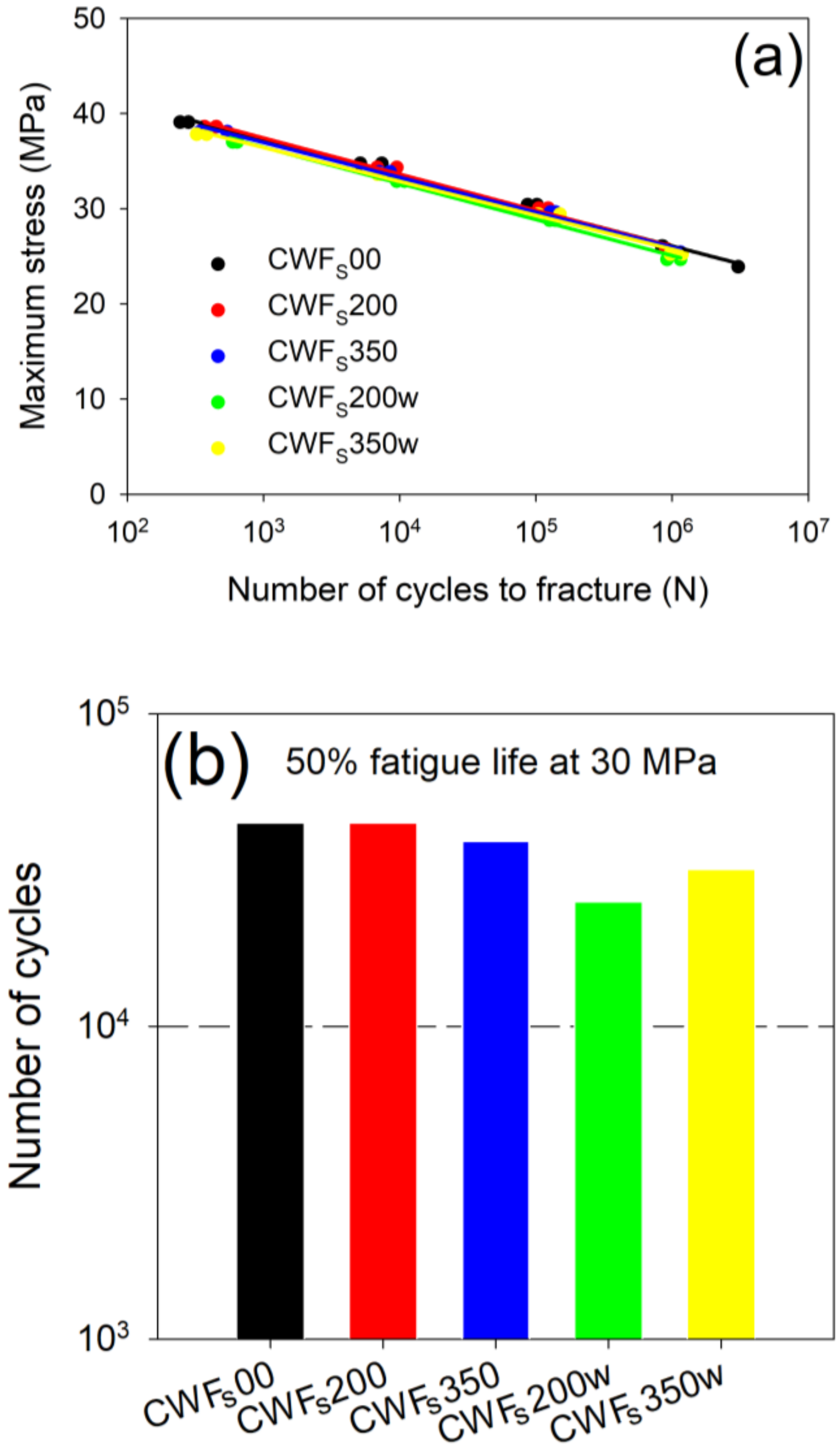

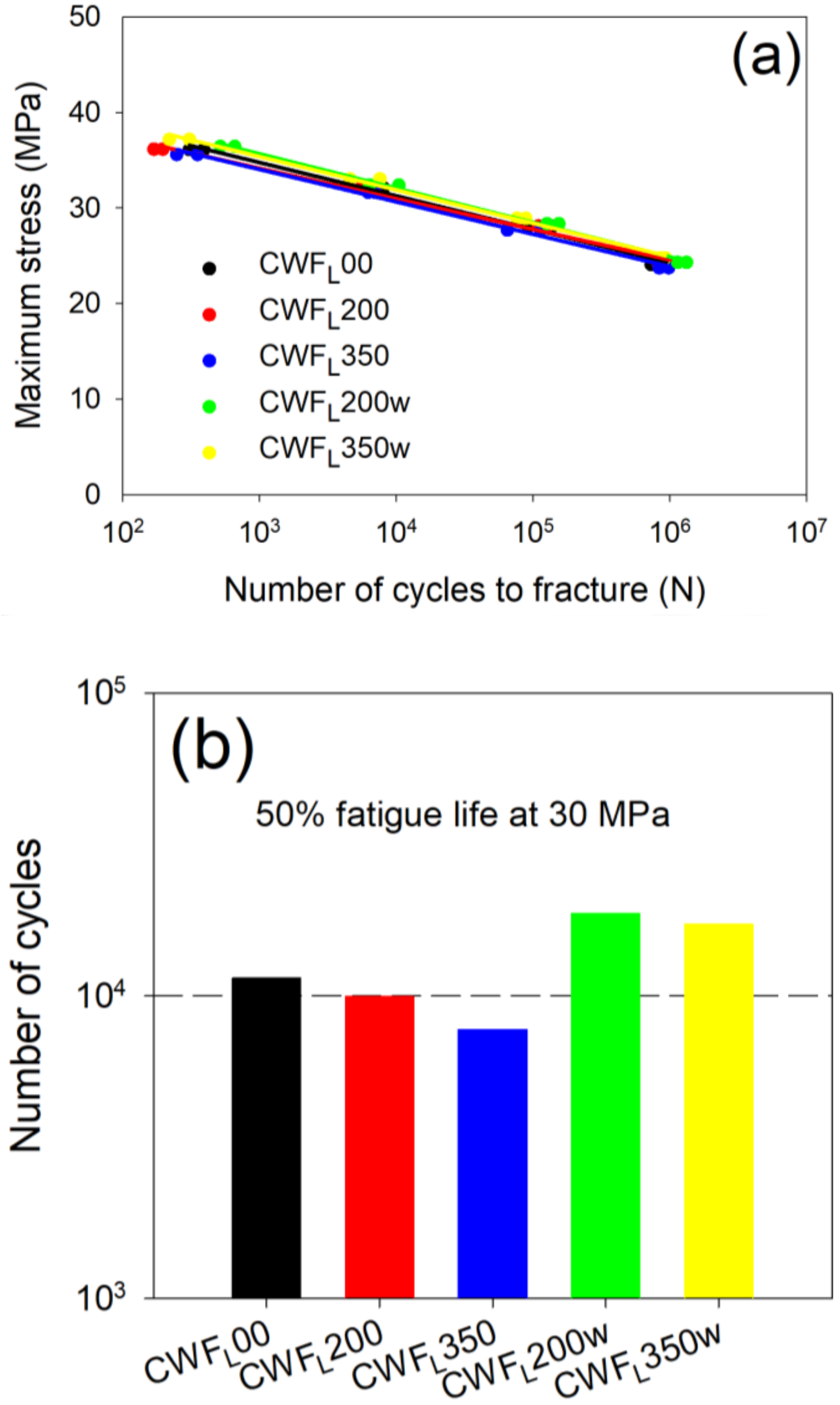

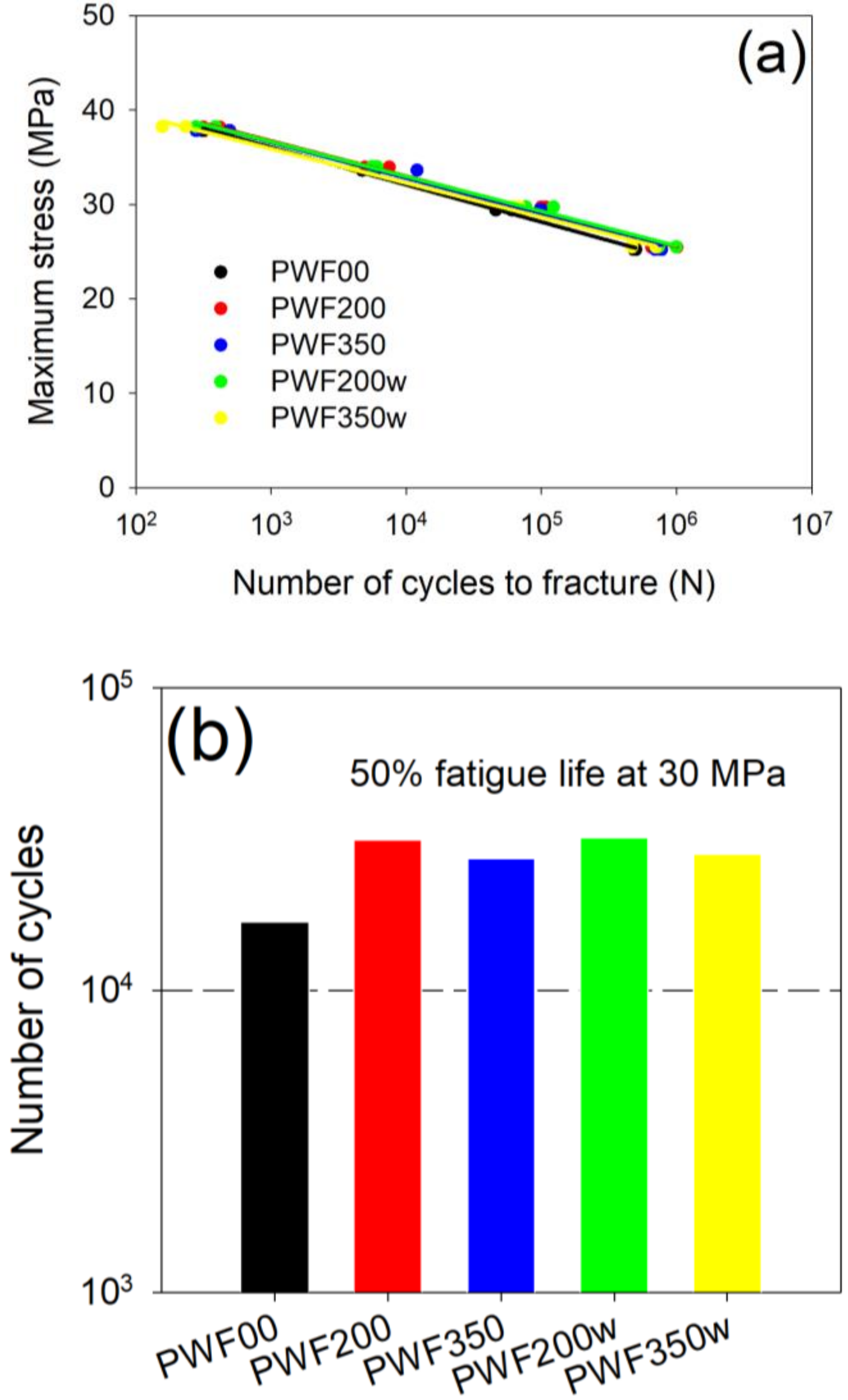

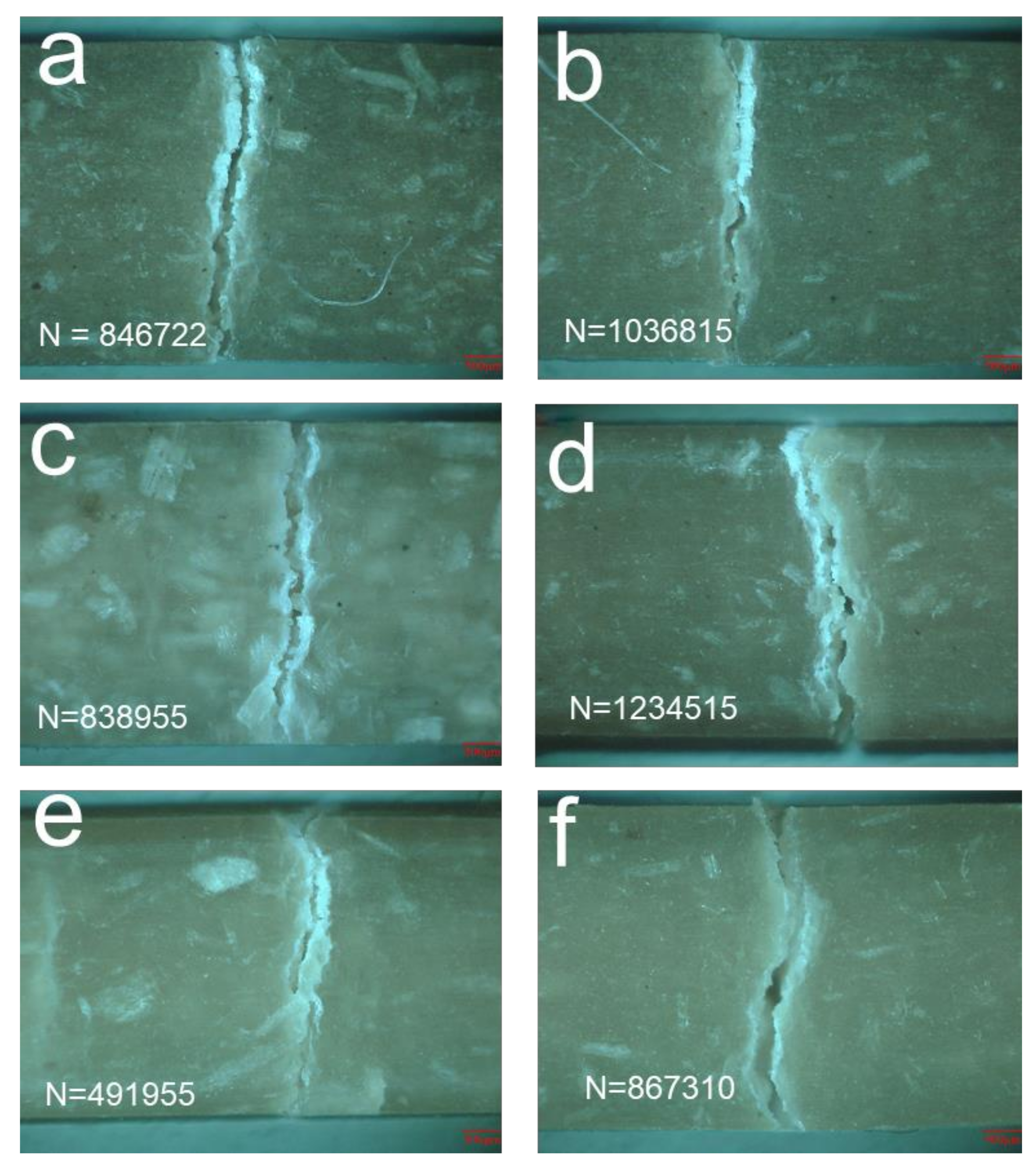

3.4. Fatigue Behavior of Composites

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Danyadi, L.; Janecska, T.; Szabo, Z.; Nagy, G.; Moczo, J.; Pukanszky, B. Wood flour filled PP composites: Compatibilization and adhesion. Compos. Sci. Technol. 2007, 67, 2838–2846. [Google Scholar] [CrossRef]

- Jacob, A. WPC industry focuses on performance and cost. Reinf. Plast. 2006, 50, 32–33. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Faruk, O.; Sperber, V.E. Cars from bio-fibres. Macromol. Mater. Eng. 2006, 291, 449–457. [Google Scholar] [CrossRef]

- Clemons, C. Wood–plastic composites in the United States: The interfacing of two industries. For. Prod. J. 2002, 52, 10–20. [Google Scholar]

- Arao, Y.; Nakamura, S.; Tomita, Y.; Takakuwa, K.; Umemura, T.; Tanaka, T. Improvement on fire retardancy of wood flour/polypropylene composites using various fire retardants. Polym. Degrad. Stab. 2014, 100, 79–85. [Google Scholar] [CrossRef]

- Sun, L.; Wu, Q.; Xie, Y.; Song, K.; Lee, S.; Wang, Q. Thermal decomposition of fire-retarded wood flour/polypropylene composites. J. Therm. Anal. Calorim. 2016, 123, 309–318. [Google Scholar] [CrossRef]

- Bakar, M.A.; Ishak, Z.M.; Taib, R.M.; Rozman, H.D.; Jani, S.M. Flammability and mechanical properties of wood flour-filled polypropylene composites. J. Appl. Polym. Sci. 2010, 116, 2714–2722. [Google Scholar] [CrossRef]

- Mashkour, M.; Ranjbar, Y. Superparamagnetic Fe3O4@ wood flour/polypropylene nanocomposites: Physical and mechanical properties. Ind. Crops Prod. 2018, 111, 47–54. [Google Scholar] [CrossRef]

- Luo, S.; Cao, J.; Sun, W. Evaluation of K raft lignin as natural compatibilizer in wood flour/polypropylene composites. Polym. Compos. 2017, 38, 2387–2394. [Google Scholar] [CrossRef]

- Kiguchi, M.; Kataoka, Y.; Matsunaga, H.; Yamamoto, K.; Evans, P.D. Surface deterioration of wood-flour polypropylene composites by weathering trials. J. Wood Sci. 2007, 53, 234–238. [Google Scholar] [CrossRef]

- Soccalingame, L.; Perrin, D.; Benezet, J.C.; Bergeret, A. Reprocessing of UV-weathered wood flour reinforced polypropylene composites: Study of a natural outdoor exposure. Polym. Degrad. Stab. 2016, 133, 389–398. [Google Scholar] [CrossRef]

- Peng, Y.; Liu, R.; Cao, J. Characterization of surface chemistry and crystallization behavior of polypropylene composites reinforced with wood flour, cellulose, and lignin during accelerated weathering. Appl. Surf. Sci. 2015, 332, 253–259. [Google Scholar] [CrossRef]

- Peng, Y.; Liu, R.; Cao, J.; Guo, X. Effects of vitamin E combined with antioxidants on wood flour/polypropylene composites during accelerated weathering. Holzforschung 2015, 69, 113–120. [Google Scholar] [CrossRef]

- Ye, X.; Wang, H.; Wu, Z.; Zhou, H.; Tian, X. The functional features and interface design of wood/polypropylene composites based on microencapsulated wood particles via adopting in situ emulsion polymerization. Polym. Compos. 2018, 39, 427–436. [Google Scholar] [CrossRef]

- Malakani, M.; Bazyar, B.; Talaiepour, M.; Hemmasi, A.H.; Ghasemi, I. Effect of acetylation of wood flour and MAPP content during compounding on physical properties, decay resistance, contact angle, and morphology of polypropylene/wood flour composites. BioResources 2015, 10, 2113–2129. [Google Scholar] [CrossRef]

- Askanian, H.; Verney, V.; Commereuc, S.; Guyonnet, R.; Massardier, V. Wood polypropylene composites prepared by thermally modified fibers at two extrusion speeds: Mechanical and viscoelastic properties. Holzforschung 2015, 69, 313–319. [Google Scholar] [CrossRef]

- Luo, S.; Cao, J.; Peng, Y. Properties of glycerin-thermally modified wood flour/polypropylene composites. Polym. Compos. 2014, 35, 201–207. [Google Scholar] [CrossRef]

- Zhu, L.; Cao, J.; Wang, Y.; Liu, R.; Zhao, G. Effect of MAPP on interfacial compatibility of wood flour/polypropylene composite evaluated with dielectric approach. Polym. Compos. 2014, 35, 489–494. [Google Scholar] [CrossRef]

- Danyadi, L.; Moczo, J.; Pukanszky, B. Effect of various surface modifications of wood flour on the properties of PP/wood composites. Compos. Part A 2010, 41, 199–206. [Google Scholar] [CrossRef]

- Kim, H.S.; Lee, B.H.; Choi, S.W.; Kim, S.; Kim, H.J. The effect of types of maleic anhydride-grafted polypropylene (MAPP) on the interfacial adhesion properties of bio-flour-filled polypropylene composites. Compos. Part A 2007, 38, 1473–1482. [Google Scholar] [CrossRef]

- Carlborn, K.; Matuana, L.M. Influence of processing conditions and material compositions on the performance of formaldehyde-free wood-based composites. Polym. Compos. 2006, 27, 599–607. [Google Scholar] [CrossRef]

- Hristov, V.N.; Vasileva, S.T.; Krumova, M.; Lach, R.; Michler, G.H. Deformation mechanisms and mechanical properties of modified polypropylene/wood fiber composites. Polym. Compos. 2004, 25, 521–526. [Google Scholar] [CrossRef]

- Lee, S.Y.; Yang, H.S.; Kim, H.J.; Jeong, C.S.; Lim, B.S.; Lee, J.N. Creep behavior and manufacturing parameters of wood flour filled polypropylene composites. Compos. Struct. 2004, 65, 459–469. [Google Scholar] [CrossRef]

- Ichazo, M.N.; Albano, C.; Gonzalez, J.; Perera, R.; Candal, A.M. Polypropylene/wood flour composites: Treatments and properties. Compos. Struct. 2001, 54, 207–214. [Google Scholar] [CrossRef]

- Oksman, K.; Clemons, C. Mechanical properties and morphology of impact modified polypropylene–wood flour composites. J. Appl. Polym. Sci. 1998, 67, 1503–1513. [Google Scholar] [CrossRef]

- Myers, G.E.; Chahyadi, I.S.; Coberly, C.A.; Ermer, D.S. Wood flour/polypropylene composites: Influence of maleated polypropylene and process and composition variables on mechanical properties. Int. J. Polym. Mater. 1991, 15, 21–44. [Google Scholar] [CrossRef]

- Kokta, B.V.; Raj, R.G.; Daneault, C. Use of wood flour as filler in polypropylene: Studies on mechanical properties. Polym.-Plast. Technol. Eng. 1989, 28, 247–259. [Google Scholar] [CrossRef]

- Stark, N.M.; Rowlands, R.E. Effects of wood fiber characteristics on mechanical properties of wood/polypropylene composites. Wood Fiber Sci. 2003, 35, 167–174. [Google Scholar]

- Zaini, M.J.; Fuad, M.A.; Ismail, Z.; Mansor, M.S.; Mustafah, J. The effect of filler content and size on the mechanical properties of polypropylene/oil palm wood flour composites. Polym. Int. 1996, 40, 51–55. [Google Scholar] [CrossRef]

- Maiti, S.N.; Hassan, M.R. Melt rheological properties of polypropylene–wood flour composites. J. Appl. Polym. Sci. 1989, 37, 2019–2032. [Google Scholar] [CrossRef]

- Inoue, T.; Suzuki, T. Selective crosslinking reaction in polymer blends. III. The effects of the crosslinking of dispersed EPDM particles on the impact behavior of PP/EPDM blends. J. Appl. Polym. Sci. 1995, 56, 1113–1125. [Google Scholar] [CrossRef]

- Niu, Z.; Chen, Y.; Feng, J. Preparation, structure, and property of wood flour incorporated polypropylene composites prepared by a solid-state mechanochemical method. J. Appl. Polym. Sci. 2016, 133, 43108. [Google Scholar] [CrossRef]

- Makise, R.; Okamoto, M.; Hasegawa, T.; Ito, H.; Minamino, J.; Isa, A.; Kojima, Y. Effect of the shape of pulverized wood flour on the mechanical properties of wood-plastic composites. In Proceedings of the 11th Pacific Rim Bio-Based Composites Symposium (BIOCOMP 2012), Shizuoka, Japan, 27–30 November 2012; pp. 461–466. [Google Scholar]

- Haque, M.M.; Goda, K.; Ito, H.; Ogoe, S.; Okamoto, M.; Ema, T.; Kagawa, K.; Nogami, H. Melt-viscosity and mechanical behaviour of polypropylene (PP)/wood flour composites: Effect of pulverization of wood flour with and without water. Adv. Ind. Eng. Polym. 2018. [Google Scholar] [CrossRef]

- Isa, A.; Toyoda, T.; Suzuki, S.; Kojima, Y.; Ito, H.; Makise, R.; Okamoto, M. The effects of wet-milled wood flour on the mechanical properties of wood flour/polypropylene composites. J. Wood Chem. Technol. 2014, 34, 20–30. [Google Scholar] [CrossRef]

- Kanters, M.J.W. Prediction of Long-Term Performance of Load-Bearing Thermoplastics. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 3 September 2015. [Google Scholar]

- Yang, H.S.; Qiao, P.; Wolcott, M.P. Fatigue characterization and reliability analysis of wood flour filled polypropylene composites. Polym. Compos. 2010, 31, 553–560. [Google Scholar] [CrossRef]

- Gaurav, A.; Singh, K.K. Fatigue behavior of FRP composites and CNT-Embedded FRP composites: A review. Polym. Compos. 2018, 39, 1785–1808. [Google Scholar] [CrossRef]

- Reifsnider, K. Fatigue behavior of composite materials. Int. J. Fract. 1980, 16, 563–583. [Google Scholar] [CrossRef]

- Nordin, M.N.A.; Makino, Y.; Goda, K.; Ito, H. Fatigue properties of wood plastic composites. Sen’i Gakkaishi 2015, 71, 339–344. (In Japanese) [Google Scholar]

- Lavengood, R.E.; Gulbransen, L.B. The effect of aspect ratio on the fatigue life of short boron fiber reinforced composites. Polym. Eng. Sci. 1969, 9, 365–369. [Google Scholar] [CrossRef]

| Sample Abbreviation for Wood Flour | Sources (tree) | Pulverization Conditions | Average Wood Particle Size (µm) | Average Wood Particle Aspect Ratio | |

|---|---|---|---|---|---|

| Mill-plate Gap (µm) | Water | ||||

| CWFS00 | Cypress | – | – | 165.0 | 5.9 |

| CWFS200 | 200 | No | 165.4 | – | |

| CWFS350 | 350 | 161.7 | – | ||

| CWFS200w | 200 | Yes | 135.0 | 3.9 | |

| CWFS350w | 350 | 167.0 | – | ||

| CWFL00 | Cypress | – | – | 379.2 | 2.3 |

| CWFL200 | 200 | No | 313.9 | – | |

| CWFL350 | 350 | 323.1 | – | ||

| CWFL200w | 200 | Yes | 245.9 | 3.3 | |

| CWFL350w | 350 | 304.7 | – | ||

| PWF00 | Scots pine | – | – | 265.7 | 4.2 |

| PWF200 | 200 | No | 201.2 | – | |

| PWF350 | 350 | 213.9 | – | ||

| PWF200w | 200 | Yes | 168.4 | 4.3 | |

| PWF350w | 350 | 198.7 | – | ||

| Wood Flour | Tensile Strength (MPa) | * Fatigue Strength (MPa) at Different Number of Cycle (N) | |

|---|---|---|---|

| 103 (N) | 106 (N) | ||

| CWFS00 | 43.42 ± 0.50 | 37.3 | 26.1 |

| CWFS200 | 42.89 ± 0.43 | 37.4 | 26.0 |

| CWFS350 | 42.32 ± 0.11 | 37.0 | 26.0 |

| CWFS200w | 41.10 ± 0.43 | 36.5 | 25.1 |

| CWFS350w | 42.01 ± 0.38 | 36.4 | 25.7 |

| CWFL00 | 40.09 ± 0.21 | 34.8 | 24.3 |

| CWFL200 | 40.14 ± 0.36 | 34.1 | 24.6 |

| CWFL350 | 39.52 ± 0.11 | 34.0 | 23.9 |

| CWFL200w | 40.46 ± 0.16 | 35.7 | 24.8 |

| CWFL350w | 41.28 ± 0.33 | 35.4 | 24.9 |

| PWF00 | 42.01 ± 0.17 | 36.0 | 24.2 |

| PWF200 | 42.41 ± 0.16 | 36.7 | 25.5 |

| PWF350 | 42.01 ± 0.40 | 36.6 | 25.2 |

| PWF200w | 42.47 ± 0.29 | 36.6 | 25.6 |

| PWF350w | 43.73 ± 0.36 | 35.9 | 25.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haque, M.M.-U.; Goda, K.; Ito, H.; Ogoe, S.; Okamoto, M.; Ema, T.; Kagawa, K.; Nogami, H. Fatigue Performance of Wet and Dry Pulverized Wood Flour Reinforced PP Composites. J. Compos. Sci. 2019, 3, 20. https://doi.org/10.3390/jcs3010020

Haque MM-U, Goda K, Ito H, Ogoe S, Okamoto M, Ema T, Kagawa K, Nogami H. Fatigue Performance of Wet and Dry Pulverized Wood Flour Reinforced PP Composites. Journal of Composites Science. 2019; 3(1):20. https://doi.org/10.3390/jcs3010020

Chicago/Turabian StyleHaque, Md Minhaz-Ul, Koichi Goda, Hirokazu Ito, Shinji Ogoe, Masaki Okamoto, Tomoyuki Ema, Keiko Kagawa, and Hidetaka Nogami. 2019. "Fatigue Performance of Wet and Dry Pulverized Wood Flour Reinforced PP Composites" Journal of Composites Science 3, no. 1: 20. https://doi.org/10.3390/jcs3010020

APA StyleHaque, M. M.-U., Goda, K., Ito, H., Ogoe, S., Okamoto, M., Ema, T., Kagawa, K., & Nogami, H. (2019). Fatigue Performance of Wet and Dry Pulverized Wood Flour Reinforced PP Composites. Journal of Composites Science, 3(1), 20. https://doi.org/10.3390/jcs3010020