Enhancing the Fracture Toughness Properties by Introducing Anchored Nano-Architectures at the Metal–FRP Composite Interface

Abstract

:1. Introduction

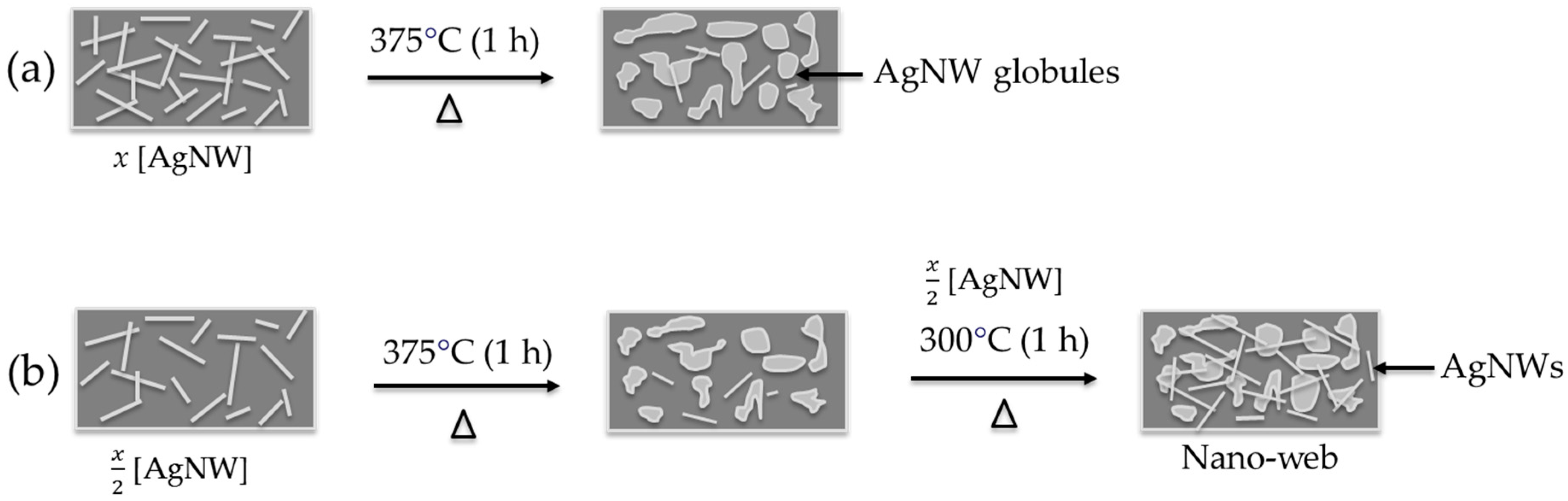

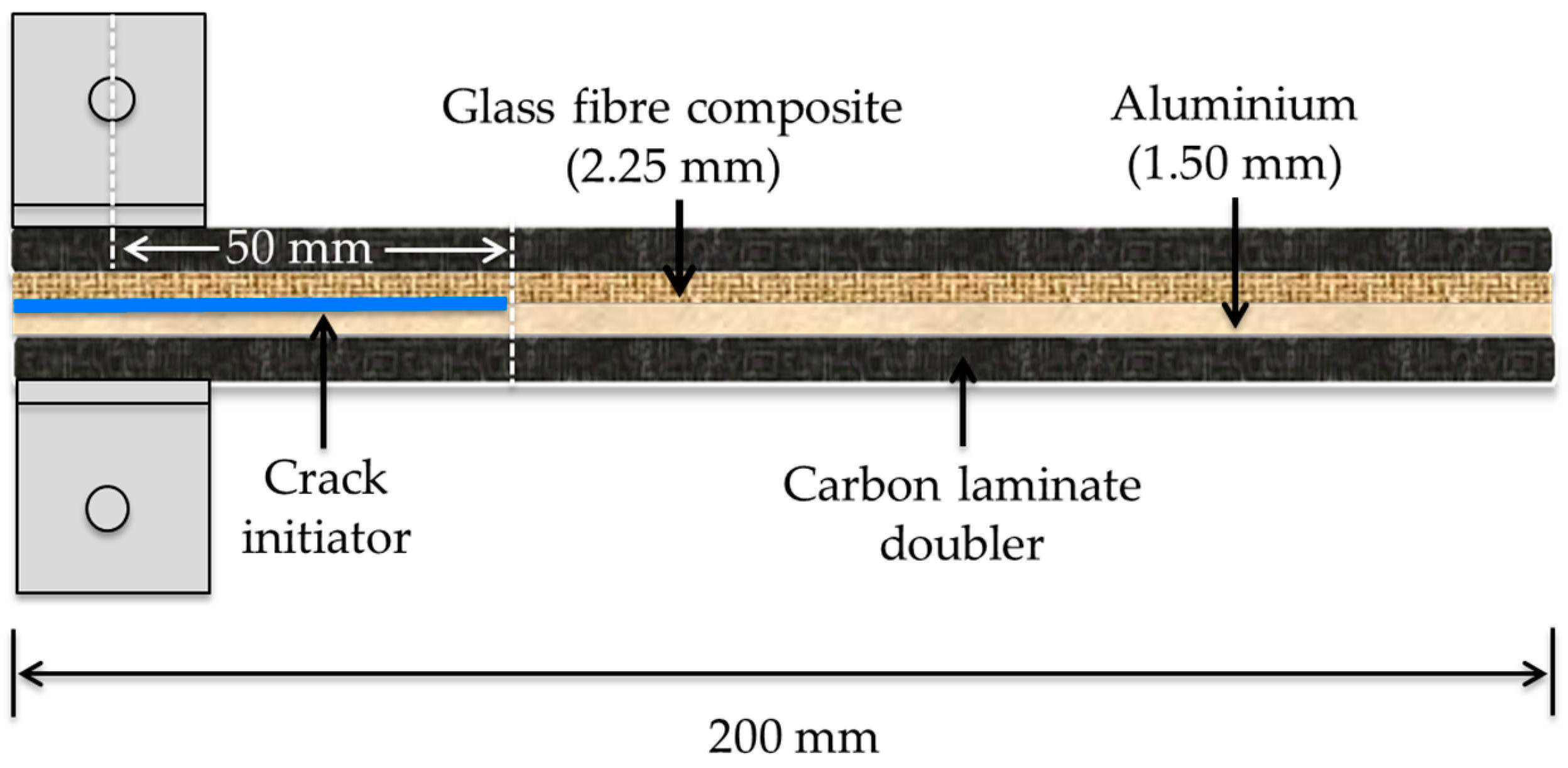

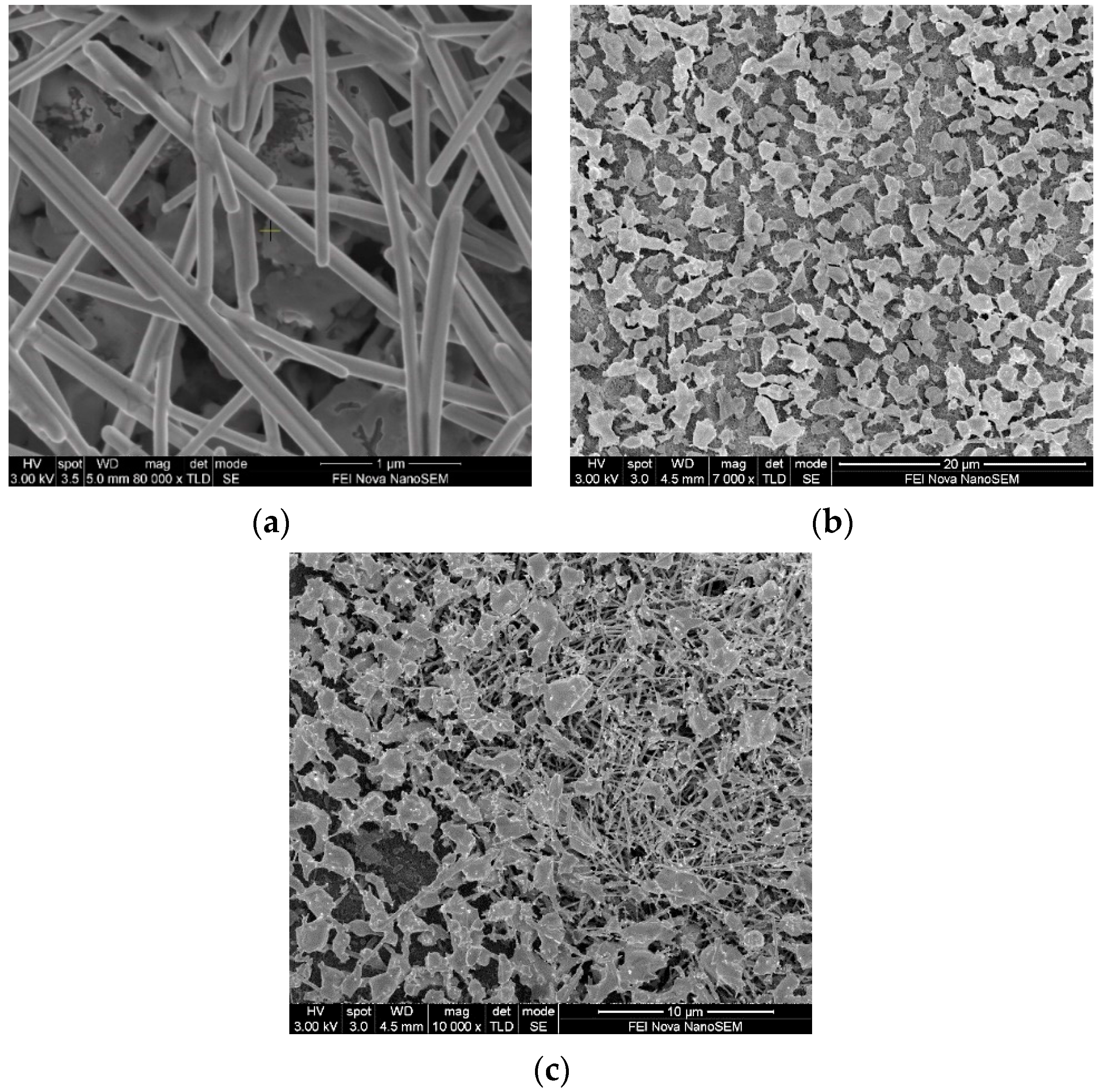

2. Materials and Methods

3. Results

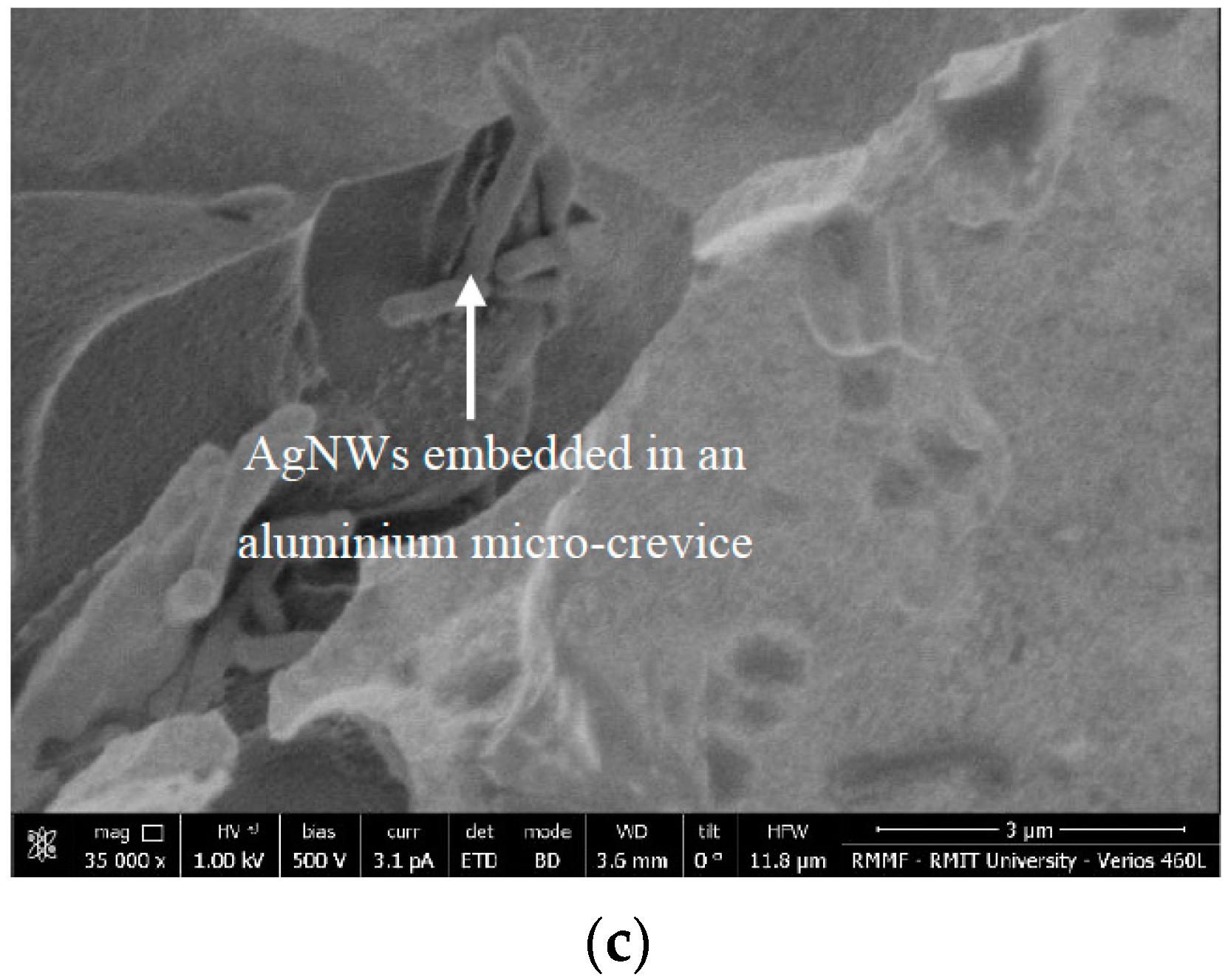

4. Discussion

5. Conclusions

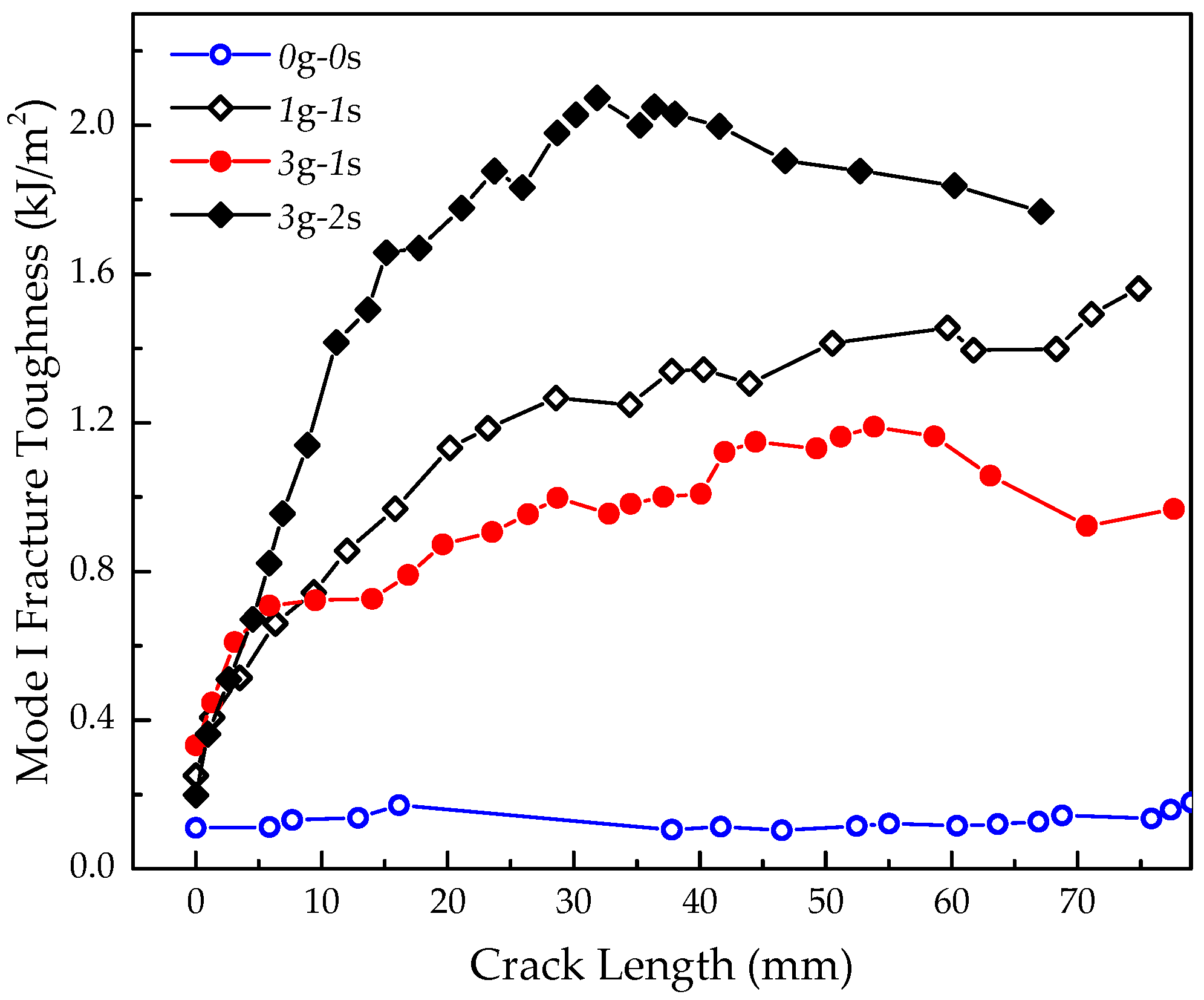

- For the single-stage deposition, the initiation fracture toughness increased with the incorporation of AgNWs regardless of the concentration, at least for the range considered in this study.

- The steady-state fracture toughness for the single-stage deposition FML was insensitive to changes in the AgNW concentration under invariable annealing conditions. Similar steady-state fracture toughness values were measured for 1g-1s and 3g-1s.

- The steady-state fracture toughness was found to be dependent on the morphology (e.g., form, size, shape and structure) of the AgNW architectures which was dictated by the deposition technique. The value measured for 3g-2s (2.09 ± 0.28 kJ/m2) is significantly higher than that of the 3g-1s composite (1.06 ± 0.19 kJ/m2) despite the invariable AgNW concentration.

- Fracture initiation toughness was found to be controlled by the presence of the nano-reinforcements within the polymer matrix while the steady-state fracture toughness was determined by the silver nano-architecture morphology.

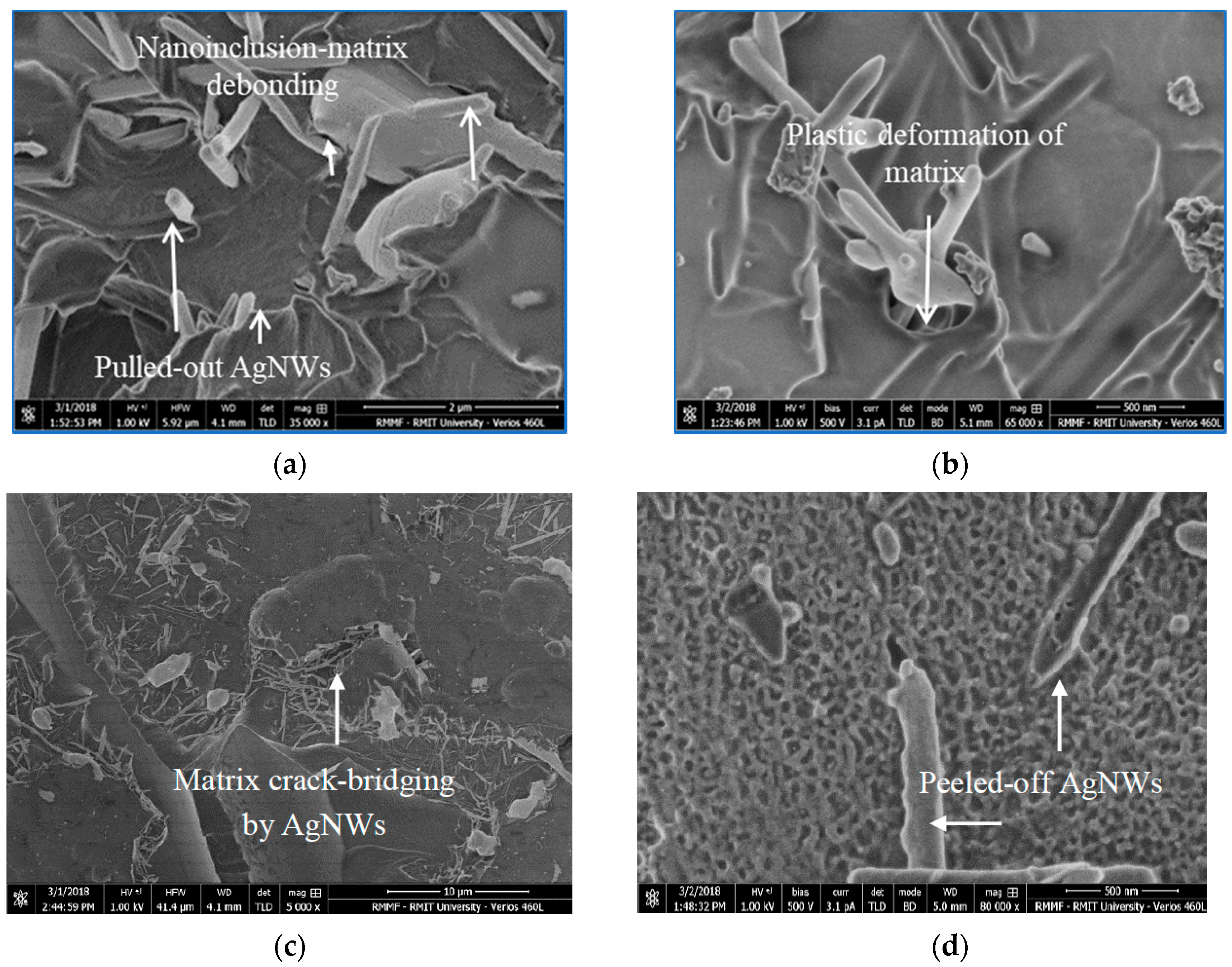

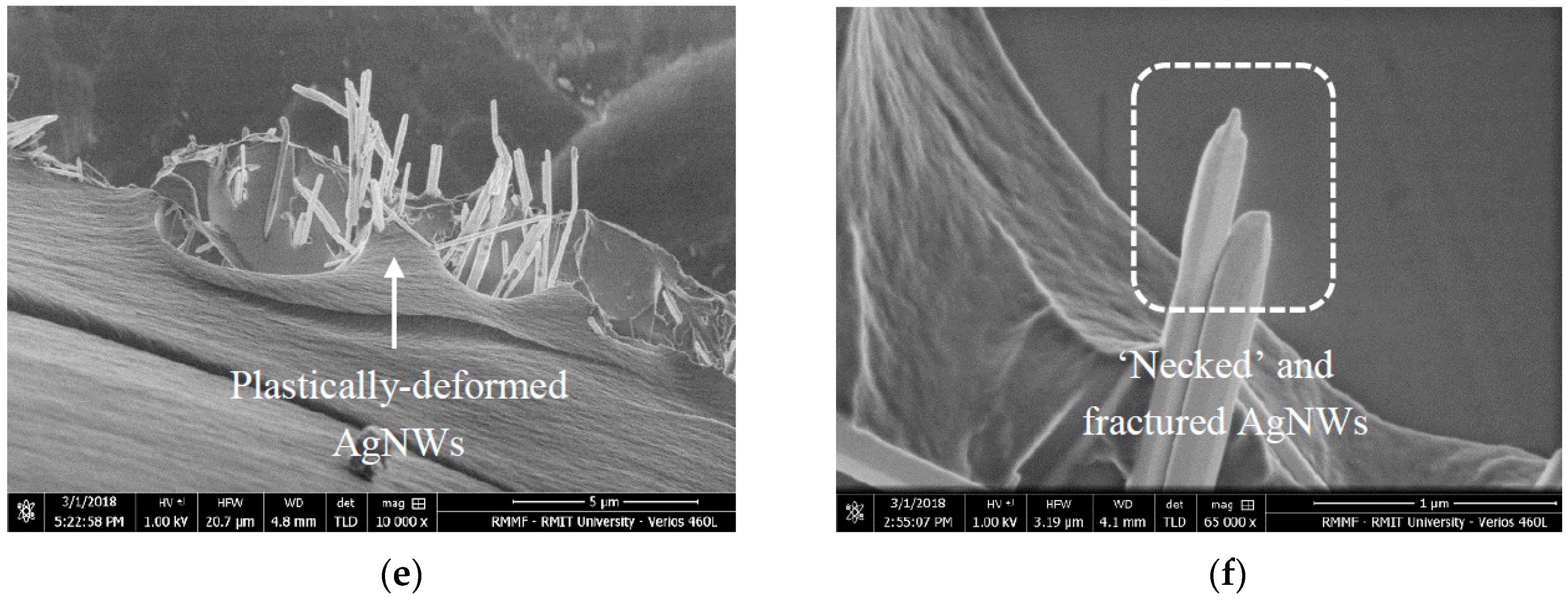

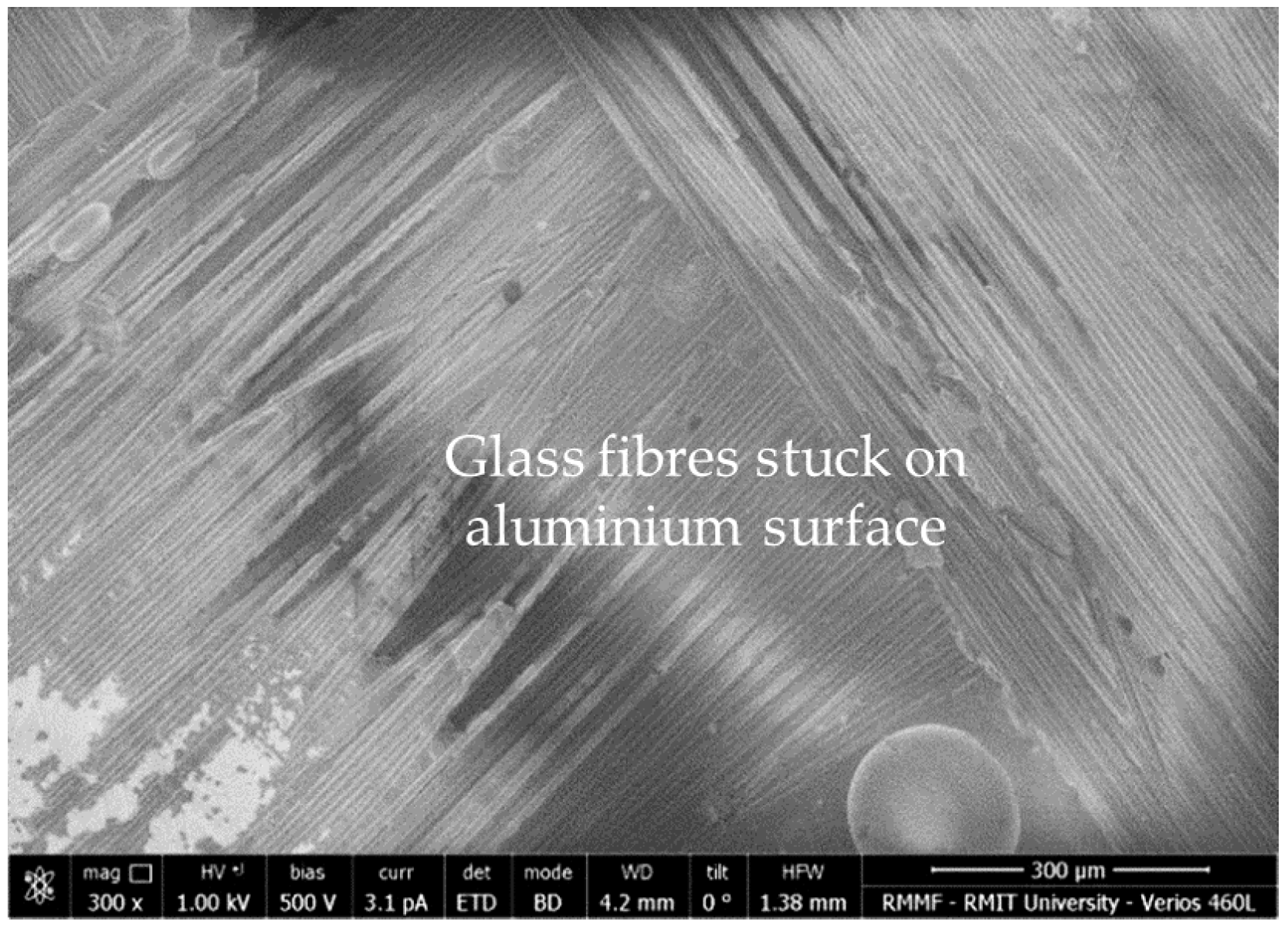

- The enhanced fracture toughness properties of the nano-modified FMLs resulted from both intrinsic and extrinsic toughening mechanisms triggered by the presence of AgNW architectures within the metal–FRP laminate interfacial region. Some of the toughening mechanisms identified through SEM analysis of the delamination surfaces included nanowire-epoxy matrix debonding, nanowire pull-out and peel-off from the aluminium surface, plastic deformation and subsequent fracture of the AgNWs, plastic deformation of the matrix due to the subbing caused by bundled nanowires, as well as the matrix crack-bridging by AgNWs.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Starke, E.A., Jr.; Staley, J. Application of modern aluminum alloys to aircraft. Prog. Aerosp. Sci. 1996, 32, 131–172. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Y.; Hu, J. Recent advances in the development of aerospace materials. Prog. Aerosp. Sci. 2018, 97, 22–34. [Google Scholar] [CrossRef]

- Vogelesang, L.B.; Vlot, A. Development of fibre metal laminates for advanced aerospace structures. J. Mater. Process. Technol. 2000, 103, 1–5. [Google Scholar] [CrossRef]

- Wu, G.; Yang, J.-M. The mechanical behavior of GLARE laminates for aircraft structures. JOM 2005, 57, 72–79. [Google Scholar] [CrossRef]

- Sinmazcelik, T.; Avcu, E.; Bora, M.Ö.; Çoban, O. A review: Fibre metal laminates, background, bonding types and applied test methods. Mater. Des. 2011, 32, 3671–3685. [Google Scholar] [CrossRef]

- Asundi, A.; Choi, A.Y. Fiber metal laminates: An advanced material for future aircraft. J. Mater. Process. Technol. 1997, 63, 384–394. [Google Scholar] [CrossRef]

- Ostapiuk, M.; Surowska, B.; Bieniaś, J. Interface analysis of fiber metal laminates. Compos. Interfaces 2014, 21, 309–318. [Google Scholar] [CrossRef]

- Remmers, J.; De Borst, R. Delamination buckling of fibre–metal laminates. Compos. Sci. Technol. 2001, 61, 2207–2213. [Google Scholar] [CrossRef]

- Carrino, L.; Napolitano, G.; Sorrentino, L. Wettability improving of 2024 aluminium alloy by oxygen cold plasma treatment. Int. J. Adv. Manuf. Technol. 2006, 31, 465–473. [Google Scholar] [CrossRef]

- Davis, G.D.; Groff, G.B.; Zatorski, R.A. Plasma Spray Coatings as Treatments for Aluminum, Titanium and Steel Adherends. Surf. Interface Anal. 1997, 25, 366–373. [Google Scholar] [CrossRef]

- Fernandes, J.C.S.; Ferreira, M.G.S.; Haddow, D.B.; Goruppa, A.; Short, R.; Dixon, D.G. Plasma-polymerised coatings used as pre-treatment for aluminium alloys. Surf. Coat. Technol. 2002, 154, 8–13. [Google Scholar] [CrossRef]

- De Iorio, I.; Leone, C.; Nele, L.; Tagliaferri, V. Plasma treatments of polymeric materials and Al alloy for adhesive bonding. J. Mater. Process. Technol. 1997, 68, 179–183. [Google Scholar] [CrossRef]

- Park, S.Y.; Choi, W.J.; Choi, H.S.; Kwon, H.; Kim, S.H. Recent Trends in Surface Treatment Technologies for Airframe Adhesive Bonding Processing: A Review (1995–2008). J. Adhes. 2010, 86, 192–221. [Google Scholar] [CrossRef]

- Critchlow, G.W.; Brewis, D.M.; Emmony, D.C.; Cottam, C.A. Initial investigation into the effectiveness of CO2-laser treatment of aluminium for adhesive bonding. Int. J. Adhes. Adhes. 1995, 15, 233–236. [Google Scholar] [CrossRef]

- Wong, R.C.P.; Hoult, A.P.; Kim, J.K.; Yu, T.X. Improvement of adhesive bonding in aluminium alloys using a laser surface texturing process. J. Mater. Process. Technol. 1997, 63, 579–584. [Google Scholar] [CrossRef]

- Harris, A.; Beevers, A. The effects of grit-blasting on surface properties for adhesion. Int. J. Adhes. Adhes. 1999, 19, 445–452. [Google Scholar] [CrossRef]

- Lefebvre, D.; Ahn, B.; Dillard, D.; Dillard, J. The effect of surface treatments on interfacial fatigue crack initiation in aluminum/epoxy bonds. Int. J. Fract. 2002, 114, 191–202. [Google Scholar] [CrossRef]

- Park, S.Y.; Choi, W.J.; Choi, H.S.; Kwon, H. Effects of surface pre-treatment and void content on GLARE laminate process characteristics. J. Mater. Process. Technol. 2010, 210, 1008–1016. [Google Scholar] [CrossRef]

- Ning, H.; Li, Y.; Hu, N.; Cao, Y.; Yan, C.; Azuma, T.; Peng, X.; Wu, L.; Li, J.; Li, L. Improvement of the mode II interface fracture toughness of glass fiber reinforced plastics/aluminum laminates through vapor grown carbon fiber interleaves. Sci. Technol. Adv. Mater. 2014, 15, 035004. [Google Scholar] [CrossRef]

- Khan, S.U.; Kim, J.-K. Improved interlaminar shear properties of multiscale carbon fiber composites with bucky paper interleaves made from carbon nanofibers. Carbon 2012, 50, 5265–5277. [Google Scholar] [CrossRef]

- Kinloch, A.; Little, M.; Watts, J. The role of the interphase in the environmental failure of adhesive joints. Acta Mater. 2000, 48, 4543–4553. [Google Scholar] [CrossRef]

- Ning, H.; Iijima, T.; Hu, N.; Liu, Y.; Wu, L.; Liu, F.; Arai, M. Investigation on mode-II interface fracture toughness of CFRP/Al laminates toughened by VGCF interleaves. J. Mater. Sci. 2015, 50, 1915–1923. [Google Scholar] [CrossRef]

- Ning, H.; Li, Y. Improvement of interlaminar mechanical properties of CARALL based on nanofiller interface reinforcement and other fabrication techniques. In Proceedings of the ICF13, Beijing, China, 16–21 June 2013. [Google Scholar]

- Sun, Z.; Jeyaraman, J.; Sun, S.; Hu, X.; Chen, H. Carbon-fiber aluminum-foam sandwich with short aramid-fiber interfacial toughening. Compos. Part A Appl. Sci. Manuf. 2012, 43, 2059–2064. [Google Scholar] [CrossRef]

- Shi, S.-S.; Sun, Z.; Hu, X.-Z.; Chen, H.-R. Carbon-fiber and aluminum-honeycomb sandwich composites with and without Kevlar-fiber interfacial toughening. Compos. Part A Appl. Sci. Manuf. 2014, 67, 102–110. [Google Scholar] [CrossRef]

- Sun, Z.; Hu, X.; Chen, H. Effects of aramid-fibre toughening on interfacial fracture toughness of epoxy adhesive joint between carbon-fibre face sheet and aluminium substrate. Int. J. Adhes. Adhes. 2014, 48, 288–294. [Google Scholar] [CrossRef]

- Sun, Z.; Shi, S.; Hu, X.; Guo, X.; Chen, J.; Chen, H. Short-aramid-fiber toughening of epoxy adhesive joint between carbon fiber composites and metal substrates with different surface morphology. Compos. Part B Eng. 2015, 77, 38–45. [Google Scholar] [CrossRef]

- Ning, H.; Li, Y.; Hu, N.; Arai, M.; Takizawa, N.; Liu, Y.; Wu, L.; Li, J.; Mo, F. Experimental and numerical study on the improvement of interlaminar mechanical properties of Al/CFRP laminates. J. Mater. Process. Technol. 2015, 216, 79–88. [Google Scholar] [CrossRef]

- Nguyen, A.T.; Brandt, M.; Orifici, A.C.; Feih, S. Hierarchical surface features for improved bonding and fracture toughness of metal–metal and metal–composite bonded joints. Int. J. Adhes. Adhes. 2016, 66, 81–92. [Google Scholar] [CrossRef]

- Nguyen, A.T.; Brandt, M.; Feih, S.; Orifici, A.C. Pin pull-out behaviour for hybrid metal-composite joints with integrated reinforcements. Compos. Struct. 2016, 155, 160–172. [Google Scholar] [CrossRef]

- Cui, Q.; Gao, F.; Mukherjee, S.; Gu, Z. Joining and interconnect formation of nanowires and carbon nanotubes for nanoelectronics and nanosystems. Small 2009, 5, 1246–1257. [Google Scholar] [CrossRef] [PubMed]

- Peng, P.; Hu, A.; Gerlich, A.P.; Zou, G.; Liu, L.; Zhou, Y.N. Joining of silver nanomaterials at low temperatures: Processes, properties, and applications. ACS Appl. Mater. Interfaces 2015, 7, 12597–12618. [Google Scholar] [CrossRef] [PubMed]

- Hu, A.; Guo, J.; Alarifi, H.; Patane, G.; Zhou, Y.; Compagnini, G.; Xu, C. Low temperature sintering of Ag nanoparticles for flexible electronics packaging. Appl. Phys. Lett. 2010, 97, 153117. [Google Scholar] [CrossRef]

- Bai, J.G.; Zhang, Z.Z.; Calata, J.N.; Lu, G.-Q. Low-temperature sintered nanoscale silver as a novel semiconductor device-metallized substrate interconnect material. IEEE Trans. Compon. Packag. Technol. 2006, 29, 589–593. [Google Scholar] [CrossRef]

- Ide, E.; Angata, S.; Hirose, A.; Kobayashi, K.F. Metal–metal bonding process using Ag metallo-organic nanoparticles. Acta Mater. 2005, 53, 2385–2393. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Abe, Y.; Maeda, T.; Yasuda, Y.; Morita, T. A metal–metal bonding process using metallic copper nanoparticles produced by reduction of copper oxide nanoparticles. J. Mater. Res. Technol. 2014, 3, 114–121. [Google Scholar] [CrossRef]

- Wakuda, D.; Hatamura, M.; Suganuma, K. Novel method for room temperature sintering of Ag nanoparticle paste in air. Chem. Phys. Lett. 2007, 441, 305–308. [Google Scholar] [CrossRef]

- Yan, J.; Zou, G.; Wu, A.-p.; Ren, J.; Yan, J.; Hu, A.; Zhou, Y. Pressureless bonding process using Ag nanoparticle paste for flexible electronics packaging. Scr. Mater. 2012, 66, 582–585. [Google Scholar] [CrossRef]

- Peng, P.; Hu, A.; Zhao, B.; Gerlich, A.P.; Zhou, Y.N. Reinforcement of Ag nanoparticle paste with nanowires for low temperature pressureless bonding. J. Mater. Sci. 2012, 47, 6801–6811. [Google Scholar] [CrossRef]

- NormanáZhou, Y. Room-temperature pressureless bonding with silver nanowire paste: Towards organic electronic and heat-sensitive functional devices packaging. J. Mater. Chem. 2012, 22, 12997–13001. [Google Scholar]

- Garnett, E.C.; Cai, W.; Cha, J.J.; Mahmood, F.; Connor, S.T.; Christoforo, M.G.; Cui, Y.; McGehee, M.D.; Brongersma, M.L. Self-limited plasmonic welding of silver nanowire junctions. Nat. Mater. 2012, 11, 241. [Google Scholar] [CrossRef] [PubMed]

| FML Configuration | AgNW Concentration (g/m2) | No. of Deposition Stages |

|---|---|---|

| 0g-0s * | 0.0 | 0 |

| 1g-1s | 1.0 | 1 |

| 3g-1s | 3.0 | 1 |

| 3g-2s | 3.0 | 2 |

| FML Configuration | Initiation Fracture Toughness (kJ/m2) | Steady-State Fracture Toughness (kJ/m2) |

|---|---|---|

| 0g-0s * | 0.14 ± 0.06 | 0.14 ± 0.05 |

| 1g-1s | 0.26 ± 0.06 | 1.31 ± 0.25 |

| 3g-1s | 0.36 ± 0.14 | 1.06 ± 0.19 |

| 3g-2s | 0.28 ± 0.12 | 2.09 ± 0.28 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahendrarajah, G.; Kandare, E.; Khatibi, A.A. Enhancing the Fracture Toughness Properties by Introducing Anchored Nano-Architectures at the Metal–FRP Composite Interface. J. Compos. Sci. 2019, 3, 17. https://doi.org/10.3390/jcs3010017

Mahendrarajah G, Kandare E, Khatibi AA. Enhancing the Fracture Toughness Properties by Introducing Anchored Nano-Architectures at the Metal–FRP Composite Interface. Journal of Composites Science. 2019; 3(1):17. https://doi.org/10.3390/jcs3010017

Chicago/Turabian StyleMahendrarajah, Ghowsalya, Everson Kandare, and Akbar A. Khatibi. 2019. "Enhancing the Fracture Toughness Properties by Introducing Anchored Nano-Architectures at the Metal–FRP Composite Interface" Journal of Composites Science 3, no. 1: 17. https://doi.org/10.3390/jcs3010017

APA StyleMahendrarajah, G., Kandare, E., & Khatibi, A. A. (2019). Enhancing the Fracture Toughness Properties by Introducing Anchored Nano-Architectures at the Metal–FRP Composite Interface. Journal of Composites Science, 3(1), 17. https://doi.org/10.3390/jcs3010017