Lactiplantibacillus plantarum, the Integral Member of Vegetable Fermentations

Abstract

1. Introduction

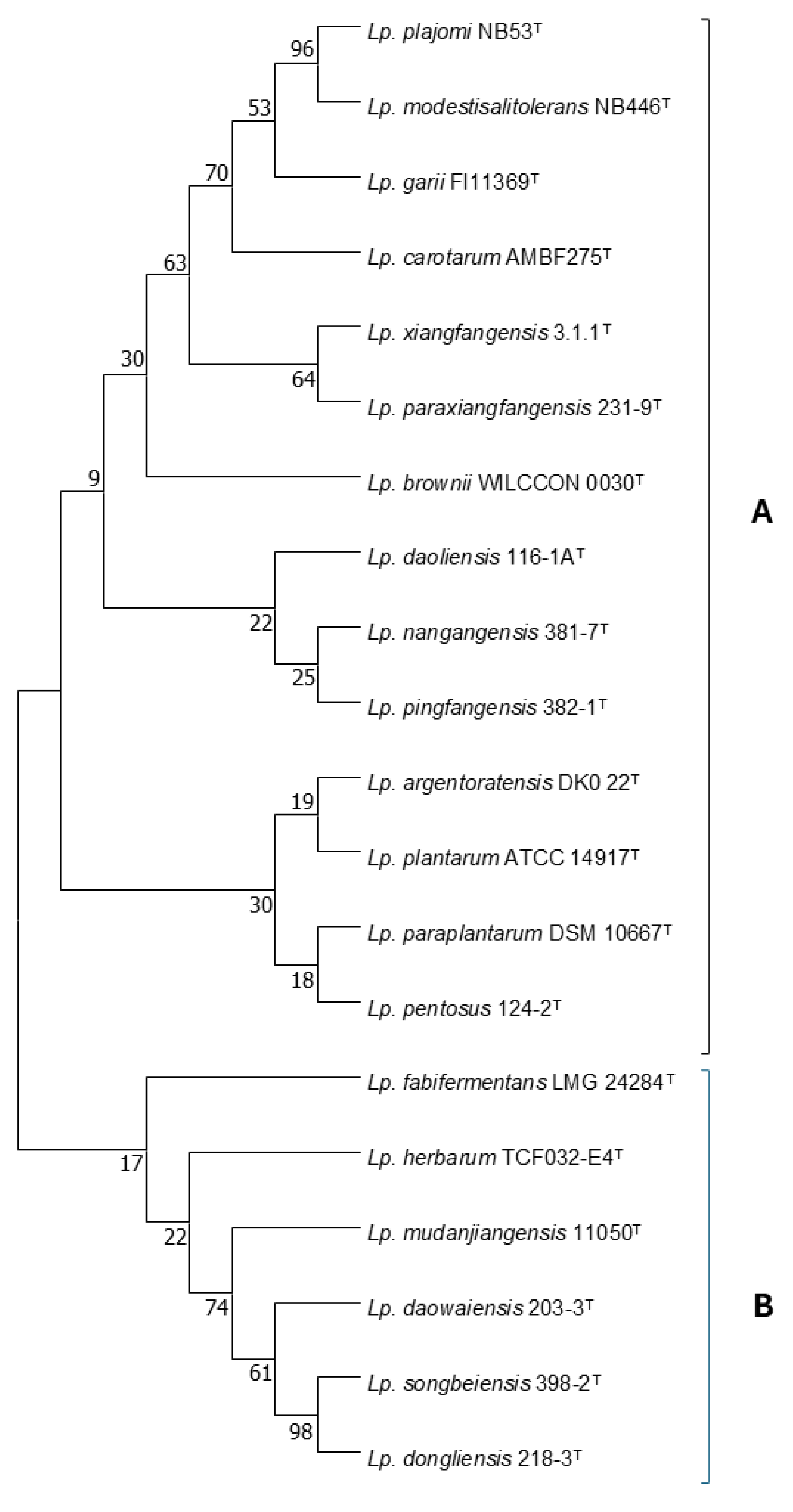

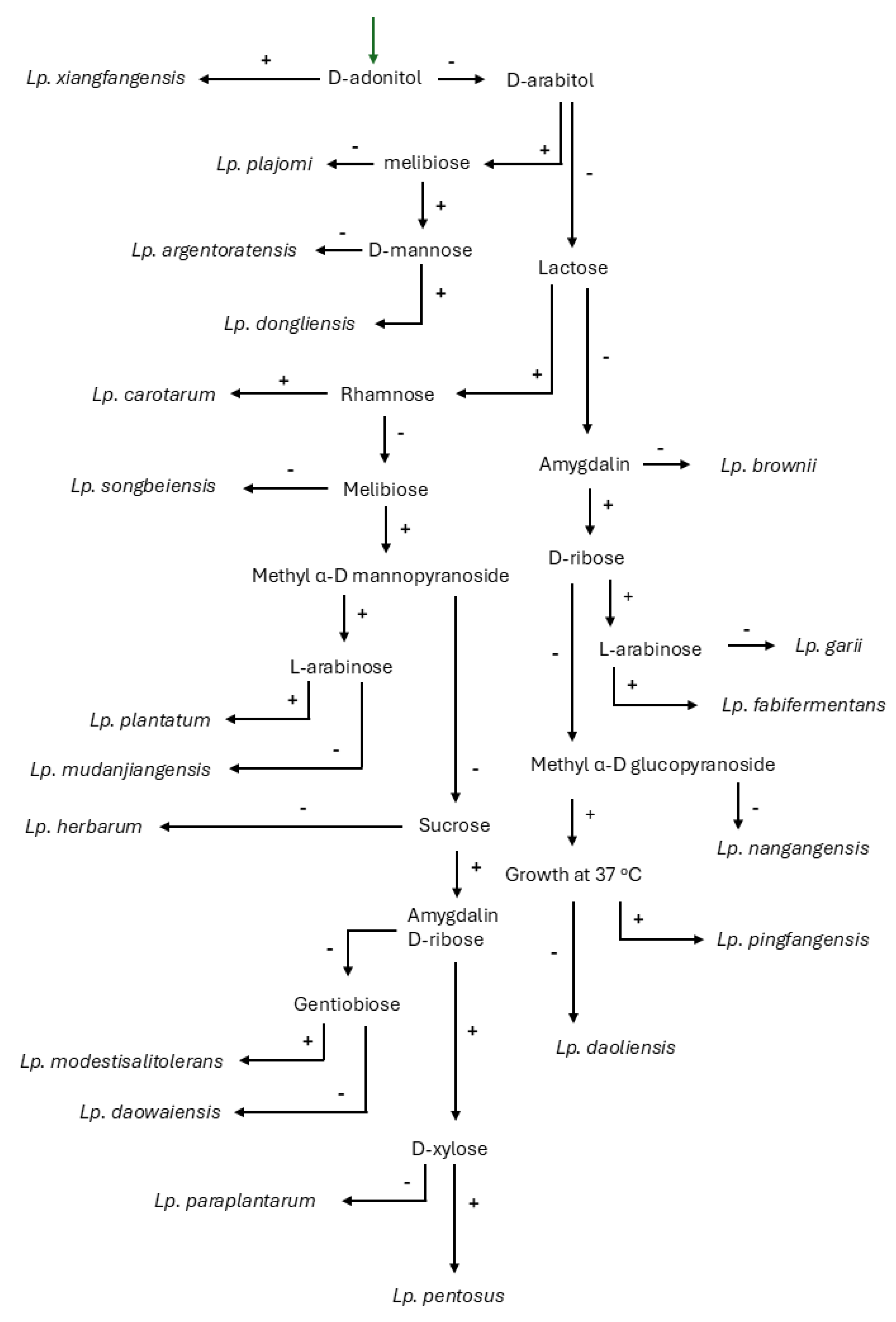

2. Lactiplantibacillus plantarum Taxonomic Position and Identification

3. Occurrence of Lp. plantarum in Vegetable Fermentation

4. Metabolic Activities Related to Vegetable Fermentation–Genomic Insights

5. Lactiplantibacillus plantarum as a Starter Culture in Vegetable Fermentation

| Product | Strain(s) | Remarks Regarding Fermentation | References |

|---|---|---|---|

| Fermented cauliflower and fermented vegetable mixture consisting of carrot, cauliflower, and green tomato | Lp. plantarum IMDO 788 | Fermentation took place in brine consisting of 3.5% NaCl and 2.0% sucrose at 25 °C for three days, and then at 16 °C for 5 weeks. The inoculum level was 6 log CFU/g. The final pH values were 3.35 and 3.23 for fermented cauliflower and mixed vegetables, respectively. The starter culture prevailed during the fermentation. The addition of the starter culture accelerated the fermentation. | [162] |

| Fermented caper berries | Lp. plantarum Lb9 | Fermentation took place in 10% brine (final concentration) at ambient temperature for six days. The inoculum level was 7 log CFU/g. The final pH value was 3.51. The starter culture dominated during fermentation. The addition of the starter culture accelerated the fermentation, resulted in a more homogeneous microecosystem composition, and a similar sensorial quality compared to spontaneous caper berries fermentation. | [171] |

| Fermented Raphanus sativus roots | Lp. plantarum LQC 740 | Fermentation took place in 5% brine at 20 and 30 °C. The inoculum level was 7.5 log CFU/mL. The fermentation was completed after 14 and 10 days, reaching final pH values of 3.40 and 3.37, and final TTA values of 0.62% and 0.41% lactic acid, at 20 and 30 °C, respectively. The starter culture prevailed during the fermentation. The plantaricin activity (in AU/mL) was reduced compared to the respective in MRS broth. However, this reduction was not accompanied by the downregulation of the 5 pln genes that were detected in the genome of this strain. | [161] |

| Chinese northeast sauerkraut | Ln. mesenteroides HBUAS 51041, Lp. plantarum ORC 2 | Fermentation took place in 0.5, 1.5, 2.5, and 3.5% brine at 18–20 °C for 30 days, with an inoculum level of 6 log CFU/g, with the LAB combined in a mixed culture at a 1:1 ratio. The final pH was approximately 3.2 in all cases except for the 0.5% brine, in which it was approximately 3.3. The acidity ranged between approximately 0.065 and 0.075% lactic acid in all cases, with the exception of the 0.5% brine, in which it was approximately 0.085%. Fermentation in 0.5% brine accelerated the maturation and improved the sensory quality of the product. A reduction in the nitrite content was reported. | [172] |

| Chinese northeast sauerkraut | Ln. mesenteroides, Lp. plantarum, La. paracasei, W. cibaria | Fermentation took place in 1% brine at 18–20 °C for 30 days, with an inoculum level of 6 log CFU/g, with the LAB used as monocultures. The final pH and TTA values ranged between 3.4–3.6 and 0.0930–0.1160% lactic acid, with the Lp. plantarum strain achieving the lowest pH and the highest TTA values. The sensorial quality of the final product depended upon the starter used, as the greatest abundance of esters was reported for the product made by Lp. plantarum, the greatest lactone content was reported for the product made by La. paracasei, while the Ln. mesenteroides and W. cibaria strains presented increased the acid and ketone contents. | [173] |

| Fermented cucumbers | Lp. plantarum NPL 1258, P. pentosaceus NPL 1264 | Fermentation took place in 4% brine at ambient temperature for 3 weeks, with an inoculum level of 7 log CFU/mL, with the LAB used as monocultures or combined as mixed cultures. The final pH value ranged between 3.0 and 3.5, with the mixed culture resulting in the lowest pH value. The highest TTA value of approximately 2.0 g lactic acid/100 mL was achieved by the P. pentosaceus monoculture. The application of the starter cultures accelerated the fermentation and reduced the population of pathogenic microorganisms. | [174] |

| Fermented African nightshade (Solanum scabrum) leaves | Lp. plantarum BFE 5092, Lm. fermentum BFE 6620 | Fermentation took place in 3% NaCl and 3.0% sugar brine at ambient temperature (approximately 25 °C) for 144 h, with an inoculum level of 6–7 log CFU/mL, with the LAB used as mixed cultures in a 1:1 ratio. The pH value decreased to 3.6 within 24 h. The TTA increased to 3–4 g lactic acid/L. The starter cultures used seemed to dominate throughout the fermentation. | [175] |

| Suan-Cai | Lb. plantarum, Lb. brevis, Ln. mesenteroides | Fermentation took place at 15 °C for 30 days, with an inoculum level of 7 log CFU/mL, using each LAB as monoculture. The final pH and TTA values ranged between 3.0–3.5 and 3.0–3.7 g lactic acid/L, with the Lp. plantarum strain achieving the lowest pH value but the lowest TTA. Lp. plantarum was reported as the dominant species after all of the fermentations. The concentration of volatile compound was higher in the products made by the starter cultures compared to the spontaneously fermented one. | [176] |

| Fermented Stachys sieboldii Miq. | Lp. plantarum ZJ316 | Fermentation took place in 0.96% NaCl and 0.46% sugar brine at 37 °C for 7 days, with an inoculum level of 2.4 108 CFU/mL. The final pH value was approximately 4.0. A reduction in the nitrite concentration was reported. | [162] |

| Paocai | Ln. mesenteroides CPTCC 1R3, W. cibaria CPTCC 1R15, Lv. brevis CPTCC 3R8, Lp. plantarum CPTCC 5R10 | Fermentation took place in 4.5% NaCl at 20 °C for 5 days, with an inoculum level of 6 log CFU/mL, either as monocultures or as a mixed culture at a ratio of 1:1:1:1. The final pH and TTA values ranged from approximately 3.0 to 3.7 and 0.25 to 0.5 g lactic acid/100 g, with the Lp. plantarum strain achieving the lowest pH and the highest TTA values. It was reported that paocai made by the mixed culture presented more advantages than the one made by the single cultures, and Ln. mesenteroides and Lp. plantarum were designated as the core microorganisms related to the flavor formation of paocai. | [177] |

| Fermented mustard leaves | Lp. plantarum ZJ316 | Fermentation took place in 8% brine at room temperature for 29 days with an inoculum level of 1.5 106 CFU/mL. The final pH value was below 4.0. A reduction in the nitrite concentration was reported. The supernatant of the fermented mustard leaves exhibited significant antibacterial activity against Staphylococcus aureus D48, Escherichia coli DH5α, and Listeria monocytogenes LM1 | [166] |

| Pickled Suan-Cai | Lp. plantarum strains 8, 11, 32, and 45 | Fermentation took place with a mustard/salt ratio of 8:1 (w/w) at ambient temperature (10 ± 2 °C–18 ± 2 °C) for 2 months, with a 0.5% (v/v) inoculum level, using each strain as a monoculture. The final TTA values ranged between 0.28 and 0.41 g lactic acid/100 g. The volatile compounds detected after fermentation differed by 11.42–32.35%. | [178] |

| Pickled radish roots | Lp. plantarum MC14, Ln. mesenteroides GDMCC 1.774 | Fermentation took place in 3% (m/v) brine at 28 °C for 60 h, with an inoculum level of 2.0 106 CFU/mL, using the strains as a mixed starter at a 1:1 ratio. The final pH and TTA values were 3.01 and above 0.3 g lactic acid/100 g, respectively. The starter culture enhanced both texture and flavor of the final product. | [167] |

| Dongbei Suan-Cai | Lp. plantarum DP189, and Ln. mesenteroides subsp. mesenteroides UA107 | Fermentation took place with the addition of 1% salt (on the fresh weight of cabbage) at 15 °C for 30 days, with an inoculum level of 5.0 106 CFU/g, using the strains as a mixed starter at a 1:1 ratio. The final pH value was 3.79 and the final TTA 31.78 g lactic acid/L. Compared to spontaneously fermented Dongbei Suan-Cai, the utilization of the starter culture resulted in more rapid acid production, the better utilization of soluble protein and reducing sugar, increased levels of umami amino acids, and an increased amount of volatile flavor substances by 12.43%. | [163] |

| Radish paocai | Lp. plantarum, La. rhamnosus, P. acidilactici, Lv. brevis, Le. buchneri, W. paramesenteroides | Fermentation took place in 4% (m/v) brine at 25 °C for 7 days, with an inoculum level of 107 CFU/mL, using each LAB as a monoculture. The lowest pH (3.56 and 3.54) and the highest TTA (8.00 and 8.92 mg lactic acid/mL) values were obtained by Lp. plantarum and La. rhamnosus, respectively. The OPLS-DA analysis, based on 31 quality indicators and fermentation performance ranking by the TOPSIS method, indicated that the highest scores were achieved by the Lp. plantarum and La. rhamnosus strains. | [178] |

| Sichuan radish paocai | Lp. plantarum LB6, Lp. pentosus LB3, W. cibaria W51 | Fermentation took place in 3% brine (after equilibration) at 25 °C for 7 days, with an inoculum level of 106 CFU/mL, either with each LAB as a monoculture or combined at a 1:1:1 ratio. In all cases, the final pH value was approximately 3.25 and the TTA increased to 3.59–3.89 g lactic acid/L. By using these starter cultures, acceleration of the fermentation was achieved, along with a reduction in the nitrite content and the abundance of opportunistic pathogens. | [168] |

6. Future Perspectives

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hurtado, A.; Reguant, C.; Bordons, A.; Rozès, N. Lactic acid bacteria from fermented table olives. Food Microbiol. 2012, 31, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Díaz, M.; Hayes, J.; Medina, E.; Anekella, K.; Daughtry, K.; Dieck, S.; Levi, M.; Price, R.; Butz, N.; Lu, Z.; et al. Reassessment of the succession of lactic acid bacteria in commercial cucumber fermentations and physiological and genomic features associated with their dominance. Food Microbiol. 2017, 63, 217–227. [Google Scholar] [CrossRef] [PubMed]

- Beganovic, J.; Kos, B.; Lebos Pavunc, A.; Uroic, K.; Jokic, M.; Suskovi, J. Traditionally produced sauerkraut as source of autochthonous functional starter cultures. Microbiol. Res. 2014, 169, 623–632. [Google Scholar] [CrossRef] [PubMed]

- Wouters, D.; Bernaert, N.; Conjaerts, W.; Van Droogenbroeck, B.; De Loose, M.; De Vuyst, L. Species diversity, community dynamics, and metabolite kinetics of spontaneous leek fermentations. Food Microbiol. 2013, 33, 185–196. [Google Scholar] [CrossRef]

- Pardali, E.; Paramithiotis, S.; Papadelli, M.; Mataragas, M.; Drosinos, E.H. Lactic acid bacteria population dynamics during spontaneous fermentation of radish (Raphanus sativus L.) roots in brine. World J. Microbiol. Biotechnol. 2017, 33, 110. [Google Scholar] [CrossRef] [PubMed]

- Aquilanti, L.; Santarelli, S.; Silvestri, G.; Osimani, A.; Petruzzelli, A.; Clementi, F. The microbial ecology of a typical Italian salami during its natural fermentation. Int. J. Food Microbiol. 2007, 120, 136–145. [Google Scholar] [CrossRef] [PubMed]

- Fontana, C.; Cocconcelli, P.S.; Vignolo, G. Monitoring the bacterial population dynamics during fermentation of artisanal Argentinean sausages. Int. J. Food Microbiol. 2005, 103, 131–142. [Google Scholar] [CrossRef]

- Drosinos, E.H.; Paramithiotis, S.; Kolovos, G.; Tsikouras, I.; Metaxopoulos, I. Phenotypic and technological diversity of lactic acid bacteria and staphylococci isolated from traditionally fermented sausages in southern Greece. Food Microbiol. 2007, 24, 260–270. [Google Scholar] [CrossRef]

- Rebecchi, A.; Crivori, S.; Sarra, P.G.; Cocconcelli, P.S. Physiological and molecular techniques for the study of bacterial community development in sausage fermentation. J. Appl. Microbiol. 1998, 84, 1043–1049. [Google Scholar] [CrossRef]

- Pisacane, V.; Callegari, M.L.; Puglisi, E.; Dallolio, G.; Rebecchi, A. Microbial analyses of traditional Italian salami reveal microorganisms transfer from the natural casing to the meat matrix. Int. J. Food Microbiol. 2015, 207, 57–65. [Google Scholar] [CrossRef]

- Garcia Fontan, M.C.; Lorenzo, J.M.; Martinez, S.; Franco, I.; Carballo, J. Microbiological characteristics of Botillo, a Spanish traditional pork sausage. LWT-Food Sci. Technol. 2007, 40, 610–622. [Google Scholar] [CrossRef]

- Garcia Fontan, M.C.; Lorenzo, J.M.; Parada, A.; Franco, I.; Carballo, J. Microbiological characteristics of ‘androlla’, a Spanish traditional pork sausage. Food Microbiol. 2007, 24, 52–58. [Google Scholar] [CrossRef]

- Prado, N.; Sampayo, M.; González, P.; Lombó, F.; Díaz, J. Physicochemical, sensory and microbiological characterisation of Asturian Chorizo, a traditional fermented sausage manufactured in northern Spain. Meat Sci. 2019, 156, 118–124. [Google Scholar] [CrossRef]

- Mbawala, A.; Mahbou, P.Y.; Mouafo, H.T.; Tatsadjieu, L.N. Antibacterial activity of some lactic acid bacteria isolated from a local fermented milk product (pendidam) in ngaoundere, Cameroon. J. Anim. Plant Sci. 2013, 23, 157–166. [Google Scholar]

- Ohenhen, R.E.; Imarenezor, E.P.K.; Kihuha, A.N. Microbiome of madila—A southern African fermented milk product. Int. J. Basic Appl. Sci. 2013, 2, 170–175. [Google Scholar] [CrossRef]

- Wullschleger, S.; Lacroix, C.; Bonfoh, B.; Sissoko-Thiam, A.; Hugenschmidt, S.; Romanens, E.; Baumgartner, S.; Traore, I.; Yaffee, M.; Jans, C.; et al. Analysis of lactic acid bacteria communities and their seasonal variations in a spontaneously fermented dairy product (Malian fene) by applying a cultivation/genotype based binary model. Int. Dairy J. 2013, 29, 28–35. [Google Scholar] [CrossRef]

- Mo, L.; Jin, H.; Pan, L.; Hou, Q.; Li, C.; Darima, I.; Zhang, H.; Yu, J. Biodiversity of lactic acid bacteria isolated from fermented milk products in Xinjiang, China. Food Biotechnol. 2019, 33, 174–192. [Google Scholar] [CrossRef]

- Li, J.; Huang, Q.; Zheng, X.; Ge, Z.; Lin, K.; Zhang, D.; Chen, Y.; Wang, B.; Shi, X. Investigation of the lactic acid bacteria in Kazak cheese and their contributions to cheese fermentation. Front. Microbiol. 2020, 11, 228. [Google Scholar] [CrossRef]

- Bozoudi, D.; Torriani, S.; Zdragas, A.; Litopoulou-Tzanetaki, E. Assessment of microbial diversity of the dominant microbiota in fresh and mature PDO Feta cheese made at three mountainous areas of Greece. LWT-Food Sci. Technol. 2016, 72, 525–533. [Google Scholar] [CrossRef]

- Tsigkrimani, M.; Bakogianni, M.; Paramithiotis, S.; Bosnea, L.; Pappa, E.; Drosinos, E.H.; Skandamis, P.Ν.; Mataragas, M. Microbial ecology of artisanal Feta and Kefalograviera cheeses. Part I: Bacterial community and its functional characteristics with focus on lactic acid bacteria as determined by culture-dependent methods and phenotype microarrays. Microorganisms 2022, 10, 161. [Google Scholar] [CrossRef] [PubMed]

- Nionelli, L.; Curri, N.; Curiel, J.A.; Di Cagno, R.; Pontonio, E.; Cavoski, I.; Gobbetti, M.; Rizzello, C.G. Exploitation of Albanian wheat cultivars: Characterisation of the flours and lactic acid bacteria microbiota, and selection of starters for sourdough fermentation. Food Microbiol. 2014, 44, 96–107. [Google Scholar] [CrossRef] [PubMed]

- Paramithiotis, S.; Tsiasiotou, S.; Drosinos, E.H. Comparative study of spontaneously fermented sourdoughs originating from two regions of Greece: Peloponnesus and Thessaly. Eur. Food Res. Technol. 2010, 231, 883–890. [Google Scholar] [CrossRef]

- Boreczek, J.; Litwinek, D.; Żylińska-Urban, J.; Izak, D.; Buksa, K.; Gawor, J.; Gromadka, R.; Bardowski, J.K.; Kowalczyk, M. Bacterial community dynamics in spontaneous sourdoughs made from wheat, spelt, and rye wholemeal flour. MicrobiologyOpen 2020, 9, e1009. [Google Scholar] [CrossRef] [PubMed]

- Syrokou, M.K.; Themeli, C.; Paramithiotis, S.; Mataragas, M.; Bosnea, L.; Argyri, A.; Chorianopoulos, N.G.; Skandamis, P.N.; Drosinos, E.H. Microbial ecology of Greek wheat sourdoughs identified by culture-dependent and culture-independent approach. Foods 2020, 9, 1603. [Google Scholar] [CrossRef]

- Bartkiene, E.; Lele, V.; Ruzauskas, M.; Domig, K.; Starkute, V.; Zavistanaviciute, P.; Bartkevics, V.; Pugajeva, I.; Klupsaite, D.; Juodeikiene, G.; et al. Lactic acid bacteria isolation from spontaneous sourdough and their characterization including antimicrobial and antifungal properties evaluation. Microorganisms 2020, 8, 64. [Google Scholar] [CrossRef]

- Paramithiotis, S. Microorganisms associated with food fermentation. In Bioactive Compounds in Fermented Foods: Health Aspects; Rai, A.K., Anu Appaiah, K.A., Eds.; CRC Press: Cleveland, OH, USA, 2021; pp. 3–47. [Google Scholar]

- Du, G.; Zhang, G.; Shi, J.; Zhang, J.; Ma, Z.; Liu, X.; Yuan, C.; Li, X.; Zhang, B. Keystone taxa Lactiplantibacillus and Lacticaseibacillus directly improve the ensiling performance and microflora profile in co-ensiling cabbage byproduct and rice straw. Microorganisms 2021, 9, 1099. [Google Scholar] [CrossRef]

- Keshri, J.; Chen, Y.; Pinto, R.; Kroupitski, Y.; Weinberg, Z.G.; Sela Saldinger, S. Microbiome dynamics during ensiling of corn with and without Lactobacillus plantarum inoculant. Appl. Microbiol. Biotechnol. 2018, 102, 4025–4037. [Google Scholar] [CrossRef] [PubMed]

- Du, G.; Tišma, M.; He, B.; Zhai, X.; Yuan, C.; Su, Z.; Shi, J.; Zhang, B. Valorization of the Caragana waste via two-stage bioaugmentation: Optimizing nutrition composition, palatability, and microbial contaminant control. J. Bioresour. Bioprod. 2024, 9, 518–533. [Google Scholar]

- Iosca, G.; Turetta, M.; De Vero, L.; Bang-Berthelsen, C.H.; Gullo, M.; Pulvirenti, A. Valorization of wheat bread waste and cheese whey through cultivation of lactic acid bacteria for bio-preservation of bakery products. LWT-Food Sci. Technol. 2023, 176, 114524. [Google Scholar] [CrossRef]

- Dopazo, V.; Navarré, A.; Calpe, J.; Riolo, M.; Moreno, A.; Meca, G.; Luz, C. Revalorization of beer brewing waste as an antifungal ingredient for bread biopreservation. Food Biosci. 2024, 58, 103588. [Google Scholar] [CrossRef]

- Kachrimanidou, V.; Papadaki, A.; Lappa, I.; Papastergiou, S.; Kleisiari, D.; Kopsahelis, N. Biosurfactant production from Lactobacilli: An insight on the interpretation of prevailing assessment methods. Appl. Biochem. Biotechnol. 2022, 194, 882–900. [Google Scholar] [CrossRef]

- Deba-Rementeria, S.; Paz, A.; Estrada, O.; Vázquez-Araújo, L. Consumer perception and physicochemical characterization of a new product made from lactic acid fermented orange peels. Int. J. Gastron. Food Sci. 2023, 31, 100647. [Google Scholar] [CrossRef]

- Chiarini, E.; Alessandria, V.; Buzzanca, D.; Giordano, M.; Seif Zadeh, N.; Mancuso, F.; Zeppa, G. Valorization of fruit by-products through lactic acid fermentation for innovative beverage formulation: Microbiological and physiochemical effects. Foods 2024, 13, 3715. [Google Scholar] [CrossRef]

- Montemurro, M.; Casertano, M.; Vilas-Franquesa, A.; Rizzello, C.G.; Fogliano, V. Exploitation of spent coffee ground (SCG) as a source of functional compounds and growth substrate for probiotic lactic acid bacteria. LWT-Food Sci. Technol. 2024, 198, 115974. [Google Scholar] [CrossRef]

- Moore, J.F.; Johanningsmeier, S.D.; Pérez-Díaz, I.M. Enhancement of γ-aminobutyric acid in fermented cucumbers. J. Food Sci. 2024, 89, 9678–9691. [Google Scholar] [CrossRef] [PubMed]

- Kumar, V.; Amrutha, R.; Ahire, J.J.; Taneja, N.K. Techno-functional assessment of riboflavin-enriched yogurt-based fermented milk prepared by supplementing riboflavin-producing probiotic strains of Lactiplantibacillus plantarum. Probiotics Antimicrob. Proteins 2024, 16, 152–162. [Google Scholar] [CrossRef]

- Ashagrie, H.; Baye, K.; Guibert, B.; Rochette, I.; Tisseyre, P.; Humblot, C. The use of propionic and lactic acid bacteria to produce cobalamin and folate in injera, an Ethiopian cereal-based fermented food. Int. J. Food Microbiol. 2025, 426, 110909. [Google Scholar] [CrossRef]

- Wang, Z.; Shu, G.; Chen, L.; Dai, C.; Yao, C.; Zhang, M.; Dong, X. ACE inhibitory and antioxidant peptides from alcalase-assisted Lactiplantibacillus plantarum L60 and Lacticaseibacillus rhamnosus LR22 fermentation of goat milk: Optimization and identification. J. Food Process. Preserv. 2022, 46, e16514. [Google Scholar] [CrossRef]

- Sandez Penidez, S.H.; De Moreno De Le Blanc, A.; Gerez, C.L.; Rollán, G.C. Quinoa snack elaborated with Lactiplantibacillus plantarum CRL 1964 sourdough increases the mineral bioavailability in mice. J. Sci. Food Agric. 2025, 105, 171–178. [Google Scholar] [CrossRef] [PubMed]

- Capozzi, V.; Russo, P.; Ladero, V.; Fernández, M.; Fiocco, D.; Alvarez, M.A.; Grieco, F.; Spano, G. Biogenic amines degradation by Lactobacillus plantarum: Toward a potential application in wine. Front. Microbiol. 2012, 3, 122. [Google Scholar] [CrossRef]

- Karaseva, O.; Ozhegov, G.; Khusnutdinova, D.; Siniagina, M.; Anisimova, E.; Akhatova, F.; Fakhrullin, R.; Yarullina, D. Whole genome sequencing of the novel probiotic strain Lactiplantibacillus plantarum FCa3L. Microorganisms 2023, 11, 1234. [Google Scholar] [CrossRef] [PubMed]

- Isaac, S.L.; Malek, A.Z.A.; Hazif, N.S.; Roslan, F.S.; Hashim, A.M.; Song, A.A.-L.; Rahim, R.A.; Ismah, W.A.K.W.N. Genome mining of Lactiplantibacillus plantarum PA21: Insights into its antimicrobial potential. BMC Genom. 2024, 25, 571. [Google Scholar] [CrossRef] [PubMed]

- Colautti, A.; Orecchia, E.; Comi, G.; Iacumin, L. Lactobacilli, a weapon to counteract pathogens through the inhibition of their virulence factors. J. Bacteriol. 2022, 204, e00272-22. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Niu, H.; Qu, Q.; Guo, D.; Wan, X.; Yang, Q.; Mo, Z.; Tan, S.; Xiang, Q.; Tian, X.; et al. Advancements in Lactiplantibacillus plantarum: Probiotic characteristics, gene editing technologies and applications. Crit. Rev. Food Sci. Nutr. 2025, 1–22. [Google Scholar] [CrossRef] [PubMed]

- Pateiro, M.; Domínguez, R.; Munekata, P.E.S.; Nieto, G.; Bangar, S.P.; Dhama, K.; Lorenzo, J.M. Bioactive compounds from leaf vegetables as preservatives. Foods 2023, 12, 637. [Google Scholar] [CrossRef]

- Paramithiotis, S.; Das, G.; Shin, H.-S.; Patra, J.K. Fate of bioactive compounds during lactic acid fermentation of fruits and vegetables. Foods 2022, 11, 733. [Google Scholar] [CrossRef]

- Naseem, A.; Akhtar, S.; Ismail, T.; Qamar, M.; Sattar, D.-E.-S.; Saeed, W.; Esatbeyoglu, T.; Bartkiene, E.; Rocha, J.M. Effect of growth stages and lactic acid fermentation on anti-nutrients and nutritional attributes of spinach (Spinacia oleracea). Microorganisms 2023, 11, 2343. [Google Scholar] [CrossRef]

- Zheng, J.; Wittouck, S.; Salvetti, E.; Franz, C.M.A.P.; Harris, H.M.B.; Mattarelli, P.; O’Toole, P.W.; Pot, B.; Vandamme, P.; Walter, J.; et al. A taxonomic note on the genus Lactobacillus: Description of 23 novel genera, emended description of the genus Lactobacillus Beijerinck 1901, and union of Lactobacillaceae and Leuconostocaceae. Int. J. Syst. Evol. Microbiol. 2020, 70, 2782–2858. [Google Scholar] [CrossRef]

- Li, T.T.; Liu, D.D.; Fu, M.L.; Gu, C.T. Proposal of Lactobacillus kosoi Chiou et al. 2018 as a later heterotypic synonym of Lactobacillus micheneri McFrederick et al. 2018, elevation of Lactobacillus plantarum subsp. argentoratensis to the species level as Lactobacillus argentoratensis sp. nov., and Lactobacillus zhaodongensis sp. nov., isolated from traditional Chinese pickle and the intestinal tract of a honey bee (Apis mellifera). Int. J. Syst. Evol. Microbiol. 2020, 70, 3123–3133. [Google Scholar] [PubMed]

- Heng, Y.C.; Silvaraju, S.; Lee, J.K.Y.; Kittelmann, S. Lactiplantibacillus brownii sp. nov., a novel psychrotolerant species isolated from sauerkraut. Int. J. Syst. Evol. Microbiol. 2023, 73, 006194. [Google Scholar] [CrossRef]

- Wang, T.-Y.; Gu, C.T. Lactiplantibacillus paraxiangfangensis sp. nov., isolated from traditional Chinese pickle. Int. J. Syst. Evol. Microbiol. 2024, 74, 006278. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Stecher, G.; Li, M.; Knyaz, C.; Tamura, K. MEGA X: Molecular Evolutionary Genetics Analysis across computing platforms. Mol. Biol. Evol. 2018, 35, 1547–1549. [Google Scholar] [CrossRef]

- Johnson, J.S.; Spakowicz, D.J.; Hong, B.-Y.; Petersen, L.M.; Demkowicz, P.; Chen, L.; Leopold, S.R.; Hanson, B.M.; Agresta, H.O.; Gerstein, M.; et al. Evaluation of 16S rRNA gene sequencing for species and strain-level microbiome analysis. Nat. Commun. 2019, 10, 5029. [Google Scholar] [CrossRef] [PubMed]

- Torriani, S.; Felis, G.E.; Dellaglio, F. Differentiation of Lactobacillus plantarum, L. pentosus, and L. paraplantarum by recA gene sequence analysis and multiplex PCR assay with recA gene-derived primers. Appl. Environ. Microbiol. 2001, 67, 3450–3454. [Google Scholar] [CrossRef]

- Kim, E.; Yang, S.-M.; Kim, H.-B.; Kim, H.-Y. Novel specific peaks for differentiating the Lactobacillus plantarum group using matrix-assisted laser desorption ionization time-of-flight mass spectrometry. J. Microbiol. Meth. 2020, 178, 106064. [Google Scholar] [CrossRef] [PubMed]

- Harrigan, W.F.; McCance, M.E. Laboratory Methods in Food and Dairy Microbiology; Academic Press: London, UK, 1976; pp. 47–49. [Google Scholar]

- Paramithiotis, S.; Doulgeraki, A.I.; Karahasani, A.; Drosinos, E.H. Microbial population dynamics during spontaneous fermentation of Asparagus officinalis L. young sprouts. Eur. Food Res. Technol. 2014, 239, 297–304. [Google Scholar] [CrossRef]

- Paramithiotis, S.; Kouretas, K.; Drosinos, E.H. Effect of ripening stage on the development of the microbial community during spontaneous fermentation of green tomatoes. J. Sci. Food Agric. 2014, 94, 1600–1606. [Google Scholar] [CrossRef]

- Garofalo, C.; Bancalari, E.; Milanovic, V.; Cardinali, F.; Osimani, A.; Sardaro, M.L.S.; Bottari, B.; Bernini, V.; Aquilanti, L.; Clementi, F. Study of the bacterial diversity of foods: PCR-DGGE versus LHPCR. Int. J. Food Microbiol. 2017, 242, 24–36. [Google Scholar] [CrossRef]

- Scheirlinck, I.; Van der Meulen, R.; Van Schoor, A.; Vancanneyt, M.; De Vuyst, L.; Vandamme, P.; Huys, G. Taxonomic structure and stability of the bacterial community in Belgian sourdough ecosystems as assessed by culture and population fingerprinting. Appl. Environ. Microbiol. 2008, 74, 2414–2423. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Yi, H.; Zhang, L.; Han, X.; Du, M.; Zhang, Y.; Li, J.; Sun, K.; Hou, Y. Isolation and applied potential of lactic acid bacteria from Chinese traditional fermented food in specific ecological localities. Food Sci. Biotechnol. 2011, 20, 1685–1690. [Google Scholar] [CrossRef]

- Cheng, L.; Luo, J.; Li, P.; Yu, H.; Huang, J.; Luo, L. Microbial diversity and flavor formation in onion fermentation. Food Funct. 2014, 5, 2338. [Google Scholar] [CrossRef] [PubMed]

- Phan, Y.T.N.; Tang, M.T.; Tran, T.T.M.; Nguyen, V.H.; Nguyen, T.H.; Tsuruta, T.; Nishino, N. Diversity of lactic acid bacteria in vegetable-based and meat-based fermented foods produced in the central region of Vietnam. AIMS Microbiol. 2017, 3, 61–70. [Google Scholar] [CrossRef]

- Dolci, P.; Zenato, S.; Pramotton, R.; Barmaz, A.; Alessandria, V.; Rantsiou, K.; Cocolin, L. Cheese surface microbiota complexity: RT-PCR-DGGE, a tool for a detailed picture? Int. J. Food Microbiol. 2013, 162, 8–12. [Google Scholar] [CrossRef]

- Iacumin, L.; Cecchini, F.; Manzano, M.; Osualdini, M.; Boscolo, D.; Orlic, S.; Comi, G. Description of the microflora of sourdoughs by culture dependent and culture-independent methods. Food Microbiol. 2009, 26, 128–135. [Google Scholar] [CrossRef]

- Lai, H.; Yan, L.; Wang, Y.; Mei, Y.; Huang, Y.; Zeng, X.; Ge, L.; Zhao, J.; Zhu, Y.; Huang, Q.; et al. Effects of substrates and suppliers of ingredients on microbial community and metabolites of traditional non-salt Suancai. Microbiome Res. Rep. 2024, 3, 21. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Fan, Y.; Li, T.; Yang, Y.; Zeng, F.; Wang, H.; Suo, H.; Song, J.; Zhang, Y. Microbial composition and correlation between microbiota and quality-related physiochemical characteristics in chongqing radish paocai. Food Chem. 2022, 369, 130897. [Google Scholar] [CrossRef] [PubMed]

- Nishioka, H.; Ohno, T.; Iwahashi, H.; Horie, M. Diversity of lactic acid bacteria involved in the fermentation of awa-bancha. Microbes Environ. 2021, 36, ME21029. [Google Scholar] [CrossRef] [PubMed]

- Jun, Z.; Shuaishuai, W.; Lihua, Z.; Qilong, M.; Xi, L.; Mengyang, N.; Tong, Z.; Hongli, Z. Culture-dependent and -independent analysis of bacterial community structure in Jiangshui, a traditional Chinese fermented vegetable food. LWT-Food Sci. Technol. 2018, 96, 244–250. [Google Scholar] [CrossRef]

- Tamang, B.; Tamang, J.P.; Schillinger, U.; Franz, C.M.A.P.; Gores, M.; Holzapfel, W.H. Phenotypic and genotypic identification of lactic acid bacteria isolated from ethnic fermented bamboo tender shoots of North East India. Int. J. Food Microbiol. 2008, 121, 35–40. [Google Scholar] [CrossRef]

- Yu, J.; Gao, W.; Qing, M.; Sun, Z.; Wang, W.; Liu, W.; Pan, L.; Sun, T.; Wang, H.; Bai, N.; et al. Identification and characterization of lactic acid bacteria isolated from traditional pickles in Sichuan, China. J. Gen. Appl. Microbiol. 2012, 58, 163–172. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, D.T.L.; Van Hoorde, K.; Cnockaert, M.; De Brandt, E.; Aerts, M.; Thanh, L.B.; Vandamme, P. A description of the lactic acid bacteria microbiota associated with the production of traditional fermented vegetables in Vietnam. Int. J. Food Microbiol. 2013, 163, 19–27. [Google Scholar] [CrossRef] [PubMed]

- Chaikaew, S.; Baipong, S.; Sone, T.; Kanpiengjai, A.; Chui-chai, N.; Asano, K.; Khanongnuch, C. Diversity of lactic acid bacteria from Miang, a traditional fermented tea leaf in northern Thailand and their tannin-tolerant ability in tea extract. J. Microbiol. 2017, 55, 720–729. [Google Scholar] [CrossRef] [PubMed]

- Tamang, J.P.; Tamang, B.; Schillinger, U.; Franz, C.M.A.P.; Gores, M.; Holzapfel, W.H. Identification of predominant lactic acid bacteria isolated from traditionally fermented vegetable products of the Eastern Himalayas. Int. J. Food Microbiol. 2005, 105, 347–356. [Google Scholar] [CrossRef]

- Tamang, J.P.; Sarkar, P.K. Sinki: A traditional radish tap root lactic acid fermented root product. J. Gen. Appl. Microbiol. 1993, 39, 395–408. [Google Scholar] [CrossRef]

- Hong, Y.; Yang, H.-S.; Li, J.; Han, S.-K.; Chang, H.-C.; Kim, H.-Y. Identification of lactic acid bacteria in salted Chinese cabbage by SDS-PAGE and PCR-DGGE. J. Sci. Food Agric. 2014, 94, 296–300. [Google Scholar] [CrossRef]

- Bo, B.; Kim, S.-A.; Han, N.S. Bacterial and fungal diversity in Laphet, traditional fermented tea leaves in Myanmar, analyzed by culturing, DNA amplicon-based sequencing, and PCR-DGGE methods. Int. J. Food Microbiol. 2020, 320, 108508. [Google Scholar] [CrossRef]

- Liang, T.; Xie, X.; Wu, L.; Li, L.; Li, H.; Xi, Y.; Feng, Y.; Xue, L.; Chen, M.; Chen, X.; et al. Microbial communities and physiochemical properties of four distinctive traditionally fermented vegetables from north China and their influence on quality and safety. Foods 2022, 11, 21. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zhang, C.; Wu, W.; Lv, X.; Xin, X.; Liu, D.; Hu, H.; Guo, S. Correlation of the bacterial communities with umami components, and chemical characteristics in Zhejiang xuecai and fermented brine. Food Res. Int. 2021, 140, 109986. [Google Scholar] [CrossRef] [PubMed]

- Maifreni, M.; Marino, M.; Conte, L. Lactic acid fermentation of Brassica rapa: Chemical and microbial evaluation of a typical Italian product (brovada). Eur. Food Res. Technol. 2004, 218, 469–473. [Google Scholar] [CrossRef]

- Plengvidhya, V.; Breidt, F., Jr.; Lu, Z.; Fleming, H.P. DNA fingerprinting of lactic acid bacteria in sauerkraut fermentations. Appl. Environ. Microbiol. 2007, 73, 7697–7702. [Google Scholar] [CrossRef]

- Gaudioso, G.; Weil, T.; Marzorati, G.; Solovyev, P.; Bontempo, L.; Franciosi, E.; Bertoldi, L.; Pedrolli, C.; Tuohy, K.M.; Fava, F. Microbial and metabolic characterization of organic artisanal sauerkraut fermentation and study of gut health-promoting properties of sauerkraut brine. Front. Microbiol. 2022, 13, 929738. [Google Scholar] [CrossRef]

- Endo, A.; Mizuno, H.; Okada, S. Monitoring the bacterial community during fermentation of sunki, an unsalted, fermented vegetable traditional to the Kiso area of Japan. Lett. Appl. Microbiol. 2008, 47, 221–226. [Google Scholar] [CrossRef] [PubMed]

- Ogihara, H.; Kawarai, T.; Furukawa, S.; Miyao, S.; Yamasaki, M. Microfloral and chemical changes of salted pickles (suguki) during its manufacturing process. Jpn. J. Food Microbiol. 2009, 26, 98–106. [Google Scholar] [CrossRef]

- Paramithiotis, S.; Hondrodimou, O.L.; Drosinos, E.H. Development of the microbial community during spontaneous cauliflower fermentation. Food Res. Int. 2010, 43, 1098–1103. [Google Scholar] [CrossRef]

- Wouters, D.; Grosu-Tudor, S.; Zamfir, M.; De Vuyst, L. Bacterial community dynamics, lactic acid bacteria species diversity and metabolite kinetics of traditional Romanian vegetable fermentations. J. Sci. Food Agric. 2013, 93, 749–760. [Google Scholar] [CrossRef]

- Yeun, H.; Yang, H.-S.; Chang, H.-C.; Kim, H.-Y. Comparison of bacterial community changes in fermenting kimchi at two different temperatures using a denaturing gradient gel electrophoresis analysis. J. Microbiol. Biotechnol. 2013, 23, 76–84. [Google Scholar]

- Lee, H.Y.; Haque, M.A.; Cho, K.M. Changes in physicochemical property and lactic acid bacterial community during kimchi fermentation at different temperatures. J. Appl. Biol. Chem. 2020, 63, 429–437. [Google Scholar] [CrossRef]

- Sakai, M.; Ohta, H.; Niidome, T.; Morimura, S. Changes in microbial community composition during production of takanazuke. Food Sci. Technol. Res. 2014, 20, 693–698. [Google Scholar] [CrossRef][Green Version]

- Yang, H.; Zou, H.; Qu, C.; Zhang, L.; Liu, T.; Wu, H.; Li, Y. Dominant microorganisms during the spontaneous fermentation of suan cai, a Chinese fermented vegetable. Food Sci. Technol. Res. 2014, 20, 915–926. [Google Scholar] [CrossRef]

- Wu, R.; Yu, M.; Liu, X.; Meng, L.; Wang, Q.; Xue, Y.; Wu, J.; Yue, X. Changes in flavour and microbial diversity during natural fermentation of suan-cai, a traditional food made in Northeast China. Int. J. Food Microbiol. 2015, 211, 23–31. [Google Scholar] [CrossRef]

- Saeedi, M.; Shahidi, F.; Mortazavi, S.A.; Milani, E.; Yazdi, F.T. Isolation and identification of lactic acid bacteria in winter salad (local pickle) during fermentation using 16S rRNA gene sequence analysis. J. Food Saf. 2015, 35, 287–294. [Google Scholar] [CrossRef]

- Liang, H.; Zhang, A.; Wu, Z.; Liu, C.; Zhang, W. Characterization of microbial community during the fermentation of Chinese homemade paocai, a traditional fermented vegetable food. Food Sci. Technol. Res. 2016, 22, 467–475. [Google Scholar] [CrossRef]

- Wang, D.; Chena, G.; Tang, Y.; Li, H.; Shen, W.; Wang, M.; Liu, S.; Qin, W.; Zhang, Q. Effects of temperature on paocai bacterial succession revealed by culture dependent and culture-independent methods. Int. J. Food Microbiol. 2020, 317, 1084. [Google Scholar] [CrossRef]

- Chen, A.-J.; Luo, W.; Peng, Y.-T.; Niu, K.-L.; Liu, X.-Y.; Shen, G.-H.; Zhang, Z.-Q.; Wan, H.; Luo, Q.-Y.; Li, S.-S. Quality and microbial flora changes of radish paocai during multiple fermentation rounds. Food Control 2019, 106, 106733. [Google Scholar] [CrossRef]

- Chiou, T.-Y.; Suda, W.; Oshima, K.; Hattori, M.; Takahashi, T. Changes in the bacterial community in the fermentation process of kôso, a Japanese sugar-vegetable fermented beverage. Biosci. Biotechnol. Biochem. 2017, 81, 403–410. [Google Scholar] [CrossRef] [PubMed]

- Paramithiotis, S.; Syrokou, M.K.; Papadia-Nikolaidou, A.; Papoutsis, G.; Drosinos, E.H. Towards recreation of food commodities based on ancient texts; the case of avyrtake. Appl. Sci. 2022, 12, 1697. [Google Scholar] [CrossRef]

- Xiong, S.; Xu, X.; Zhang, L.; Du, T.; Huang, T.; Huang, J.; Ren, H.; Xiong, T.; Xie, M. Integrated metatranscriptomics and metabolomics reveal microbial succession and flavor formation mechanisms during the spontaneous fermentation of Laotan Suancai. Food Res. Int. 2024, 177, 113865. [Google Scholar] [CrossRef] [PubMed]

- Rosa, E.; David, M.; Gomes, M.H. Glucose, fructose and sucrose content in broccoli, white cabbage and Portuguese cabbage grown in early and late seasons. J. Sci. Food Agric. 2001, 81, 1145–1149. [Google Scholar] [CrossRef]

- Vincente, A.R.; Manganaris, G.A.; Ortiz, C.M.; Sozzi, G.O.; Crisosto, C.H. Nutritional quality of fruits and vegetables. In Postharvest Handling, 3rd ed.; Florkowski, W.J., Shewfelt, R.L., Brueckner, B., Prussia, S.E., Eds.; Academic Press: Cambridge, MA, USA, 2014; pp. 69–122. [Google Scholar]

- Wruss, J.; Waldenberger, G.; Huemer, S.; Uygun, P.; Lanzerstorfer, P.; Muller, U.; Hoglinger, O.; Weghuber, J. Compositional characteristics of commercial beetroot products and beetroot juice prepared from seven beetroot varieties grown in Upper Austria. J. Food Compos. Anal. 2015, 42, 46–55. [Google Scholar] [CrossRef]

- Lisciani, S.; Gambelli, L.; Durazzo, A.; Marconi, S.; Camilli, E.; Rossetti, C.; Gabrielli, P.; Aguzzi, A.; Temperini, O.; Marletta, L. Carbohydrates components of some Italian local landraces: Garlic (Allium sativum L.). Sustainability 2017, 9, 1922. [Google Scholar] [CrossRef]

- Bhandari, S.R.; Choi, C.S.; Rhee, J.; Jo, J.S.; Shin, Y.K.; Song, J.W.; Lee, J.G. Seasonal variation in agronomic characteristics and sugar content of cabbage genotypes. Chil. J. Agric. Res. 2021, 81, 80–91. [Google Scholar] [CrossRef]

- Yusuf, E.; Tkacz, K.; Turkiewicz, I.P.; Wojdyło, A.; Nowicka, P. Analysis of chemical compounds’ content in different varieties of carrots, including qualification and quantification of sugars, organic acids, minerals, and bioactive compounds by UPLC. Eur. Food Res. Technol. 2021, 247, 3053–3062. [Google Scholar] [CrossRef]

- Hammes, W.P.; Hertel, C.; Genus, I. Lactobacillus Beijerinck 1901, 212AL. In Bergey’s Manual of Systematic Bacteriology, 2nd ed.; De Vos, P., Garrity, G.M., Jones, D., Krieg, N.R., Ludwig, W., Rainey, F.A., Schleifer, K.-H., Whitman, W.B., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; Volume 3, The Firmicutes; pp. 465–510. [Google Scholar]

- Paventi, G.; Di Martino, C.; Crawford, T.W., Jr.; Iorizzo, M. Enzymatic activities of Lactiplantibacillus plantarum: Technological and functional role in food processing and human nutrition. Food Biosci. 2024, 61, 104944. [Google Scholar] [CrossRef]

- Syrokou, M.K.; Tziompra, S.; Psychogiou, E.-E.; Mpisti, S.-D.; Paramithiotis, S.; Bosnea, L.; Mataragas, M.; Skandamis, P.N.; Drosinos, E.H. Technological and safety attributes of lactic acid bacteria and yeasts isolated from spontaneously fermented Greek wheat sourdoughs. Microorganisms 2021, 9, 671. [Google Scholar] [CrossRef] [PubMed]

- Tsigkrimani, M.; Panagiotarea, K.; Paramithiotis, S.; Bosnea, L.; Pappa, E.; Drosinos, E.H.; Skandamis, P.Ν.; Mataragas, M. Microbial ecology of sheep milk, artisanal Feta and Kefalograviera cheeses. Part II: Technological, safety and probiotic attributes of lactic acid bacteria isolates. Foods 2022, 11, 459. [Google Scholar] [CrossRef]

- Yilmaz, B.; Bangar, S.P.; Echegaray, N.; Suri, S.; Tomasevic, I.; Manuel Lorenzo, J.; Melekoglu, E.; Rocha, J.M.; Ozogul, F. The impacts of Lactiplantibacillus plantarum on the functional properties of fermented foods: A review of current knowledge. Microorganisms 2022, 10, 826. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.; Nadeem, M.; Al-Asmari, F.; Imran, M.; Ambreen, S.; Rahim, M.A.; Oranab, S.; Esatbeyoglu, T.; Bartkiene, E.; Rocha, J.M. Effect of Lactiplantibacillus plantarum on the conversion of linoleic acid of vegetable oil to conjugated linoleic acid, lipolysis, and sensory properties of cheddar cheese. Microorganisms 2023, 11, 2613. [Google Scholar] [CrossRef]

- Mao, B.; Yin, R.; Li, X.; Cui, S.; Zhang, H.; Zhao, J.; Chen, W. Comparative genomic analysis of Lactiplantibacillus plantarum isolated from different niches. Genes 2021, 12, 241. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Wang, S.; Liu, W.; Kwok, L.-Y.; Bilige, M.; Zhang, W. Comparative genomic analysis of 455 Lactiplantibacillus plantarum isolates: Habitat-specific genomes shaped by frequent recombination. Food Microbiol. 2022, 104, 103989. [Google Scholar] [CrossRef]

- Carpi, F.M.; Coman, M.M.; Silvi, S.; Picciolini, M.; Verdenelli, M.C.; Napolioni, V. Comprehensive pan-genome analysis of Lactiplantibacillus plantarum complete genomes. J. Appl. Microbiol. 2022, 132, 592–604. [Google Scholar] [CrossRef]

- McLeod, A.; Fagerlund, A.; Rud, I.; Axelsson, L. Large plasmid complement resolved: Complete genome sequencing of Lactobacillus plantarum MF1298, a candidate probiotic strain associated with unfavorable effect. Microorganisms 2019, 7, 262. [Google Scholar] [CrossRef]

- Davray, D.; Bawane, H.; Kulkarni, R. Non-redundant nature of Lactiplantibacillus plantarum plasmidome revealed by comparative genomic analysis of 105 strains. Food Microbiol. 2023, 109, 104153. [Google Scholar] [CrossRef] [PubMed]

- Zhai, Z.; Yang, Y.; Wang, J.; Wang, G.; Ren, F.; Hao, Y. Complete genome sequencing of Lactobacillus plantarum CAUH2 reveals a novel plasmid pCAUH203 associated with oxidative stress tolerance. 3 Biotech 2019, 9, 116. [Google Scholar] [CrossRef]

- Flórez, A.B.; Vázquez, L.; Rodríguez, J.; Mayo, B. Phenotypic and safety assessment of the cheese strain Lactiplantibacillus plantarum LL441, and sequence analysis of its complete genome and plasmidome. Int. J. Mol. Sci. 2023, 24, 605. [Google Scholar] [CrossRef]

- Garcia-Gonzalez, N.; Bottacini, F.; van Sinderen, D.; Gahan, C.G.M.; Corsetti, A. comparative genomics of Lactiplantibacillus plantarum: Insights into probiotic markers in strains isolated from the human gastrointestinal tract and fermented foods. Front. Microbiol. 2022, 13, 854266. [Google Scholar] [CrossRef]

- Crawley, A.B.; Henriksen, E.D.; Stout, E.; Brandt, K.; Barrangou, R. Characterizing the activity of abundant, diverse and active CRISPR-Cas systems in lactobacilli. Sci. Rep. 2018, 8, 11544. [Google Scholar] [CrossRef] [PubMed]

- Surve, S.; Shinde, D.B.; Kulkarni, R. Isolation, characterization and comparative genomics of potentially probiotic Lactiplantibacillus plantarum strains from Indian foods. Sci. Rep. 2022, 12, 1940. [Google Scholar] [CrossRef]

- Syrokou, M.K.; Paramithiotis, S.; Drosinos, E.H.; Bosnea, L.; Mataragas, M. Comparative genomics and safety assessment of six Lactiplantibacillus plantarum subsp. argentoratensis strains isolated from spontaneously fermented Greek wheat sourdoughs for potential biotechnological application. Int. J. Mol. Sci. 2022, 23, 2487. [Google Scholar] [CrossRef]

- Heo, S.; Jung, E.J.; Park, M.-K.; Sung, M.-H.; Jeong, D.-W. Evolution and competitive struggles of Lactiplantibacillus plantarum under different oxygen contents. Int. J. Mol. Sci. 2024, 25, 8861. [Google Scholar] [CrossRef] [PubMed]

- Molenaar, D.; Bringel, F.; Schuren, F.H.; de Vos, W.M.; Siezen, R.J.; Kleerebezem, M. Exploring Lactobacillus plantarum genome diversity by using microarrays. J. Bacteriol. 2005, 187, 6119–6127. [Google Scholar] [CrossRef] [PubMed]

- Martino, M.E.; Bayjanov, J.R.; Caffrey, B.E.; Wels, M.; Joncour, P.; Hughes, S.; Gillet, B.; Kleerebezem, M.; van Hijum, S.A.F.T.; Leulier, F. Nomadic lifestyle of Lactobacillus plantarum revealed by comparative genomics of 54 strains isolated from different habitats. Environ. Microbiol. 2016, 18, 4974–4989. [Google Scholar] [CrossRef]

- Choi, S.; Jin, G.-D.; Park, J.; You, I.; Kim, E.B. Pan-Genomics of Lactobacillus plantarum revealed group-specific genomic profiles without habitat association. J. Microbiol. Biotechnol. 2018, 28, 1352–1359. [Google Scholar] [CrossRef] [PubMed]

- Cen, S.; Yin, R.; Mao, B.; Zhao, J.; Zhang, H.; Zhai, Q.; Chen, W. Comparative genomics shows niche-specific variations of Lactobacillus plantarum strains isolated from human, Drosophila melanogaster, vegetable and dairy sources. Food Biosci. 2020, 35, 100581. [Google Scholar] [CrossRef]

- Pan, Q.; Cen, S.; Yu, L.; Tian, F.; Zhao, J.; Zhang, H.; Chen, W.; Zhai, Q. Niche-specific adaptive evolution of Lactobacillus plantarum strains isolated from human feces and paocai. Front. Cell. Infect. Microbiol. 2021, 10, 615876. [Google Scholar] [CrossRef]

- Sato, K.; Ikagawa, Y.; Niwa, R.; Nishioka, H.; Horie, M.; Iwahashi, H. Genome sequencing unveils nomadic traits of Lactiplantibacillus plantarum in Japanese post-fermented tea. Curr. Microbiol. 2024, 81, 52. [Google Scholar] [CrossRef] [PubMed]

- Mazzeo, M.F.; Sorrentino, A.; Morandi, S.; Abouloifa, H.; Asehraou, A.; Brasca, M.; Siciliano, R.A. Catalogue of surface proteins of Lactiplantibacillus plantarum strains of dairy and vegetable niches. Int. J. Food Microbiol. 2025, 426, 110922. [Google Scholar] [CrossRef]

- Cui, Y.; Wang, M.; Zheng, Y.; Miao, K.; Qu, X. The carbohydrate metabolism of Lactiplantibacillus plantarum. Int. J. Mol. Sci. 2021, 22, 13452. [Google Scholar] [CrossRef]

- Padan, E.; Bibi, E.; Ito, M.; Krulwich, T.A. Alkaline pH homeostasis in bacteria: New insights. Biochim. Biophys. Acta. 2005, 1717, 67–88. [Google Scholar] [CrossRef]

- Kleerebezem, M.; Boekhorst, J.; van Kranenburg, R.; Molenaar, D.; Kuipers, O.P.; Leer, R.; Tarchini, R.; Peters, S.A.; Sandbrink, H.M.; Fiers, M.W.E.J.; et al. Complete genome sequence of Lactobacillus plantarum WCFS1. Proc. Natl Acad. Sci. USA 2003, 100, 1990–1995. [Google Scholar] [CrossRef]

- Jung, S.; Lee, J.-H. Characterization of transcriptional response of Lactobacillus plantarum under acidic conditions provides insight into bacterial adaptation in fermentative environments. Sci. Rep. 2020, 10, 19203. [Google Scholar] [CrossRef] [PubMed]

- Colautti, A.; Arnoldi, M.; Comi, G.; Iacumin, L. Antibiotic resistance and virulence factors in lactobacilli: Something to carefully consider. Food Microbiol. 2022, 103, 103934. [Google Scholar] [CrossRef]

- Barbieri, F.; Montanari, C.; Gardini, F.; Tabanelli, G. Biogenic amine production by lactic acid bacteria: A review. Foods 2019, 8, 17. [Google Scholar] [CrossRef]

- Li, S.; Du, X.; Feng, L.; Mu, G.; Tuo, Y. The microbial community, biogenic amines content of soybean paste, and the degradation of biogenic amines by Lactobacillus plantarum HM24. Food Sci. Nutr. 2021, 9, 6458–6470. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Zhang, T.; Zhai, Y.; Sun, L.; Zhai, M.; Kang, L.; Zhao, X.; Wang, B.; Duan, Y.; Jin, Y. Effect of Lactiplantibacillus plantarum X22-2 on biogenic amine formation and quality of fermented lamb sausage during storage. Fermentation 2023, 9, 883. [Google Scholar] [CrossRef]

- Zhang, S.; Oh, J.-H.; Alexander, L.M.; eOzcam, M.; van Pijkeren, J.-P. d-alanyl-d-alanine ligase as a broad-host-range counterselection marker in vancomycin-resistant lactic acid bacteria. J. Bacteriol. 2018, 200, e00607-17. [Google Scholar] [CrossRef] [PubMed]

- Qiao, N.; Gaur, G.; Modesto, M.; Chinnici, F.; Scarafile, D.; Borruso, L.; Marin, A.C.; Spiezio, C.; Valente, D.; Sandri, C.; et al. Physiological and genomic characterization of Lactiplantibacillus plantarum isolated from Indri indri in Madagascar. J. Appl. Microbiol. 2023, 134, lxad255. [Google Scholar] [CrossRef] [PubMed]

- Sunardi, J.; Purnama, E.T.; Sugata, M.; Victor, H.; Jan, T.T.; Jo, J. A comparative assessment of Lactiplantibacillus plantarum isolated from chicken and humans as candidates for probiotics. Biodiversitas 2023, 24, 5198–5206. [Google Scholar] [CrossRef]

- Pulido-Mateos, E.C.; Lessard-Lord, J.; Guyonnet, D.; Desjardins, Y.; Roy, D. Comprehensive analysis of the metabolic and genomic features of tannin-transforming Lactiplantibacillus plantarum Strains. Sci. Rep. 2022, 12, 22406. [Google Scholar] [CrossRef]

- Fuhren, J.; Schwalbe, M.; Peralta-Marzal, L.; Rösch, C.; Schols, H.A.; Kleerebezem, M. Phenotypic and genetic characterization of differential galacto-oligosaccharide utilization in Lactobacillus plantarum. Sci. Rep. 2020, 10, 21657. [Google Scholar] [CrossRef] [PubMed]

- Paramithiotis, S.; Pateraki, C. Lactic acid bacterial cell factories for the production of gamma aminobutyric acid. In Lactic Acid Bacteria as Cell Factories; Montet, D., Ray, R.C., Azevedo, V.A.D.C., Paramithiotis, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 121–152. [Google Scholar]

- Syrokou, M.K.; Paramithiotis, S.; Drosinos, E.H. Health promoting functional genomic features of lactic acid bacteria. In Lactic Acid Bacteria in Food Biotechnology Innovations and Functional Aspects; Paramithiotis, S., Azevedo, V.A.D.C., Montet, D., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 221–244. [Google Scholar]

- Paramithiotis, S.; Pateraki, C. Lactic acid bacteria for riboflavin production. In Lactic Acid Bacteria as Cell Factories; Montet, D., Ray, R.C., Azevedo, V.A.D.C., Paramithiotis, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 109–120. [Google Scholar]

- Sirithanakorn, C.; Cronan, J.E. Biotin, a universal and essential cofactor: Synthesis, ligation and regulation. FEMS Microbiol. Rev. 2021, 45, fuab003. [Google Scholar] [CrossRef]

- Tenea, G.N.; Ortega, C. Genome Characterization of Lactiplantibacillus plantarum strain UTNGt2 originated from Theobroma grandiflorum (White Cacao) of Ecuadorian Amazon: Antimicrobial peptides from safety to potential applications. Antibiotics 2021, 10, 383. [Google Scholar] [CrossRef] [PubMed]

- Turpin, W.; Weiman, M.; Guyot, J.-P.; Lajus, A.; Cruveiller, S.; Humblot, C. The genomic and transcriptomic basis of the potential of Lactobacillus plantarum A6 to improve the nutritional quality of a cereal based fermented food. Int. J. Food Microbiol. 2018, 266, 346–354. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.; Baek, M.G.; Chung, M.J.; Lim, S.; Yi, H. Distribution of bacteriocin genes in the lineages of Lactiplantibacillus plantarum. Sci. Rep. 2021, 11, 20063. [Google Scholar] [CrossRef] [PubMed]

- Goel, A.; Halami, P.M.; Tamang, J.P. Genome analysis of Lactobacillus plantarum isolated from some Indian fermented foods for bacteriocin production and probiotic marker genes. Front. Microbiol. 2020, 11, 40. [Google Scholar] [CrossRef] [PubMed]

- Jabbar, Z.; Ikram-ul-Haq; Mukhtar, H.; Tayyeb, A.; Manzoor, A. Next-generation sequencing to elucidate adaptive stress response and plantaricin genes among Lactobacillus plantarum strains. Future Microbiol. 2020, 15, 333–348. [Google Scholar] [CrossRef]

- Kim, E.; Chang, H.C.; Kim, H.-Y. Complete genome sequence of Lactobacillus plantarum EM, a putative probiotic strain with the cholesterol-lowering effect and antimicrobial activity. Curr. Microbiol. 2020, 77, 1871–1882. [Google Scholar] [CrossRef]

- Lee, I.C.; Caggianiello, G.; van Swam, I.I.; Taverne, N.; Meijerink, M.; Bron, P.A. Strain-specific features of extracellular polysaccharides and their impact on Lactobacillus plantarum-host interactions. Appl. Environ. Microbiol. 2016, 82, 3959–3970. [Google Scholar] [CrossRef]

- Wang, Y.; Ahmed, Z.; Feng, W.; Li, C.; Song, S. Physicochemical properties of exopolysaccharide produced by Lactobacillus kefiranofaciens ZW3 isolated from Tibet kefir. Int. J. Biol. Macromol. 2008, 43, 283–288. [Google Scholar] [CrossRef]

- Bachtarzi, N.; Gomri, M.A.; Meradji, M.; Gil-Cardoso, K.; Ortega, N.; Chomiciute, G.; Del Bas, J.M.; López, Q.; Martínez, V.; Kharroub, K. In vitro assessment of biofunctional properties of Lactiplantibacillus plantarum strain Jb21-11 and the characterization of its exopolysaccharide. Int. Microbiol. 2024, 27, 239–256. [Google Scholar] [CrossRef] [PubMed]

- Remus, D.M.; van Kranenburg, R.; van Swam, I.I.; Taverne, N.; Bongers, R.S.; Wels, M.; Wells, J.M.; Bron, P.A.; Kleerebezem, M. Impact of 4 Lactobacillus plantarum capsular polysaccharide clusters on surface glycan composition and host cell signaling. Microb. Cell Fact. 2012, 11, 149. [Google Scholar] [CrossRef]

- Zhao, X.F.; Liang, Q.; Song, X.M.; Zhang, Y. Whole genome sequence of Lactiplantibacillus plantarum MC5 and comparative analysis of eps gene clusters. Front. Microbiol. 2023, 14, 1146566. [Google Scholar] [CrossRef] [PubMed]

- Wouters, D.; Grosu-Tudor, S.; Zamfir, M.; De Vuyst, L. Applicability of Lactobacillus plantarum IMDO 788 as a starter culture to control vegetable fermentations. J. Sci. Food Agric. 2013, 93, 3352–3361. [Google Scholar] [CrossRef]

- Paramithiotis, S.; Papadelli, M.; Pardali, E.; Mataragas, M.; Drosinos, E.H. Evaluation of plantaricin genes expression during fermentation of Raphanus sativus roots with a plantaricin producing Lactobacillus plantarum starter. Curr. Microbiol. 2019, 76, 909–916. [Google Scholar] [CrossRef]

- Hang, S.; Zeng, L.; Han, J.; Zhang, Z.; Zhou, Q.; Meng, X.; Gu, Q.; Li, P. Lactobacillus plantarum ZJ316 improves the quality of Stachys sieboldii Miq. pickle by inhibiting harmful bacteria growth, degrading nitrite and promoting the gut microbiota health in vitro. Food Funct. 2022, 13, 1551. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, Z.; Gao, Y.; Yang, G.; Liu, X.; Huang, R.; Liang, W.; Li, S. Assessment of autochthonous lactic acid bacteria as starter culture for improving traditional Chinese Dongbei Suancai fermentation. LWT-Food Sci. Technol. 2023, 178, 114615. [Google Scholar] [CrossRef]

- Luetic, S.; Knezovic, Z.; Jurcic, K.; Majic, Z.; Tripkovic, K.; Sutlovic, D. Leafy vegetable nitrite and nitrate content: Potential health effects. Foods 2023, 12, 1655. [Google Scholar] [CrossRef] [PubMed]

- Moreno-Vivián, C.; Cabello, P.; Martínez-Luque, M.; Blasco, R.; Castillo, F. Prokaryotic nitrate reduction: Molecular properties and functional distinction among bacterial nitrate reductases. J. Bacteriol. 1999, 181, 6573–6584. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Han, J.; Zheng, X.; Yan, J.; Chen, X.; Zhou, Q.; Zhao, X.; Gu, Q.; Li, P. Use of Lactiplantibacillus plantarum ZJ316 as a starter culture for nitrite degradation, foodborne pathogens inhibition and microbial community modulation in pickled mustard fermentation. Food Chem. X 2022, 14, 100344. [Google Scholar] [CrossRef] [PubMed]

- Xiong, J.; Wang, Y.-Y.; Yousaf, M.; Liu, D.-M. Improvement of physicochemical properties and flavour of pickled radish through the use of a direct-vat set starter consisting of Lactiplantibacillus plantarum and Leuconostoc mesenteroides. Int. J. Food Sci. Technol. 2023, 58, 6272–6284. [Google Scholar] [CrossRef]

- Xu, B.; Mi, T.; Ma, S.; Yi, X.; Huang, P.; Huang, P.; Wu, C. Insight into the autochthonous lactic acid bacteria as starter culture for improving the quality of Sichuan radish paocai: Changes in microbial diversity and metabolic profiles. Int. J. Food Microbiol. 2024, 425, 110877. [Google Scholar] [CrossRef]

- Yuan, J.; Zeng, X.; Zhang, P.; Leng, L.; Du, Q.; Pan, D. Nitrite reductases of lactic acid bacteria: Regulation of enzyme synthesis and activity, and different applications. Food Biosci. 2024, 59, 103833. [Google Scholar] [CrossRef]

- Shakil, M.H.; Trisha, A.T.; Rahman, M.; Talukdar, S.; Kobun, R.; Huda, N.; Zzaman, W. Nitrites in cured meats, health risk issues, alternatives to nitrites: A review. Foods 2022, 11, 3355. [Google Scholar] [CrossRef] [PubMed]

- Palomino, J.M.; del Arbol, J.T.; Benomar, N.; Abriouel, H.; Martínez Canamero, M.; Galvez, A.; Perez Pulido, R. Application of Lactobacillus plantarum Lb9, as starter culture in caper berry fermentation. LWT-Food Sci. Technol. 2015, 60, 788–794. [Google Scholar] [CrossRef]

- Yang, X.; Hu, W.; Jiang, A.; Xiu, Z.; Ji, Y.; Guan, Y.; Sarengaowa; Yang, X. Effect of salt concentration on quality of Chinese northeast sauerkraut fermented by Leuconostoc mesenteroides and Lactobacillus plantarum. Food Biosci. 2019, 30, 100421. [Google Scholar] [CrossRef]

- Yang, X.; Hu, W.; Xiu, Z.; Jiang, A.; Yang, X.; Sarengaowa; Ji, Y.; Guan, Y.; Feng, K. Comparison of northeast sauerkraut fermentation between single lactic acid bacteria strains and traditional fermentation. Food Res. Int. 2020, 137, 109553. [Google Scholar] [CrossRef]

- Ahmed, S.; Ashraf, F.; Tariq, M.; Zaidi, A. Aggrandizement of fermented cucumber through the action of autochthonous probiotic cum starter strains of Lactiplantibacillus plantarum and Pediococcus pentosaceus. Ann. Microbiol. 2021, 71, 33. [Google Scholar] [CrossRef]

- Stoll, D.A.; Wafula, E.N.; Mathara, J.M.; Trierweiler, B.; Kulling, S.E.; Huch, M. Fermentation of African nightshade leaves with lactic acid bacterial starter cultures. Int. J. Food Microbiol. 2021, 342, 109056. [Google Scholar] [CrossRef]

- Cao, X.; Zhao, M.; Zou, S.; Li, Z.; Wu, Y.; Ji, C.; Chen, Y.; Dong, L.; Zhang, S.; Liang, H. Effect of autochthonous lactic acid bacteria-enhanced fermentation on the quality of suancai. Foods 2022, 11, 3310. [Google Scholar] [CrossRef]

- Wang, D.; Chen, G.; Tang, Y.; Ming, J.; Huang, R.; Li, J.; Ye, M.; Fan, Z.; Chi, Y.; Zhang, Q.; et al. Study of bacterial community succession and reconstruction of the core lactic acid bacteria to enhance the flavor of paocai. Int. J. Food Microbiol. 2022, 375, 109702. [Google Scholar] [CrossRef]

- Yang, M.; Lai, H.; Wang, Y.; Mei, Y.; Huang, Y.; Zeng, X.; Ge, L.; Zhao, J.; Zhu, Y.; Huang, Q.; et al. Characterizing the impact of species/strain-specific Lactiplantibacillus plantarum with community assembly and metabolic regulation in pickled Suancai. Food Res. Int. 2023, 174, 113650. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.; Yang, X.; Hu, C.; Wei, B.; Xu, F.; Guo, Q. Fermentation performance evaluation of lactic acid bacteria strains for Sichuan radish paocai production. Foods 2024, 13, 1813. [Google Scholar] [CrossRef] [PubMed]

| Product | Identification Methodology | Lactic Acid Bacteria | Reference |

|---|---|---|---|

| Sinki (non-salted fermented radish tap root) | Phenotypic | Lm. fermentum, Lp. plantarum, Lv. brevis | [76] |

| Provada (fermented turnips (Brassica rapa)) | Phenotypic | C. maltaromaticum, Le. higardii, Lo. coryniformis, Lp. plantarum, P. parvulus, W. viridescens | [81] |

| Gundruk (non-salted fermented mixture of leaves of ‘rayo-sag’ (Brassica rapa L. ssp. campestris (L.) Clapham), mustard leaves (Brassica juncea (L.) Czern), cauliflower leaves (Brassica oleracea L.), and cabbages (Brassica sp.)) | Phenotypic, species-specific PCR | Lp. plantarum, P. pentosaceus | [75] |

| Khalpi (fermented cucumber (Cucumis sativus L.)) | Phenotypic, species-specific PCR | Ln. fallax, Lp. plantarum, Lv. brevis | [75] |

| Inziangsang (fermented mustard leaves (Brassica juncea (L.) Czern)) | Phenotypic, species-specific PCR | Lp. plantarum, Lv. brevis, P. acidilactici | [75] |

| Sauerkraut (fermented Brassica oleracea L. var. capitata) | 16S rRNA gene sequencing | La. paracasei, Ln. argentinum, Ln. citreum, Ln. fallax, Ln. lactis, Ln. mesenteroides, Lo. coryniformis, Lp. paraplantarum, Lp. plantarum, Lq. mali, Lt. curvatus, Lv. brevis, P. pentosaceus, Weissella spp. | [82] |

| Sauerkraut (fermented Brassica oleracea L. var. capitata) | 16S rRNA gene sequencing, 16S rRNA gene metataxonomic analysis | Lc. taiwanensis, Ln. citreum, Ln. mesenteroides, Lp. dongliensis, Lp. plantarum/paraplantarum, Lp. plantarum/pentosus, Lv. brevis, Lv. koreensis, P. parvulus | [83] |

| Mesu (fermented bamboo shoots) | Phenotypic, 16S rRNA gene sequencing, species-specific PCR | Ln. citreum, Lp. plantarum, Lt. curvatus, Lv. brevis, P. pentosaceus | [71] |

| Soibum (fermented bamboo shoots) | Phenotypic, 16S rRNA gene sequencing, species-specific PCR | E. durans, Ln. fallax, Ln. lactis, Ln. mesenteroides, Lp. plantarum, Lv. brevis | [71] |

| Sunki (non-salted fermented red beet leaves) | 16S rRNA gene sequencing | Lb. delbrueckii, Le. parabuchneri, Lm. fermentum, Lp. plantarum | [84] |

| Suguki (salted vegetable pickles) | 16S rRNA gene sequencing | Ln. citreum, Ln. mesenteroides, Lp. plantarum, Lt. curvatus, Lt. sakei, Lv. brevis | [85] |

| Fermented cauliflower | 16S rRNA gene sequencing | E. faecalis-group, E. faecium-group, Ln. mesenteroides-group, Lp. plantarum-group | [86] |

| Fermented cauliflower | PCR-DGGE | Enterococcus spp., Ln. mesenteroides, Lp. plantarum, Lt. sakei/curvatus, P. pentosaceus, W. kimchi, W. viridescens | [87] |

| Gansu (fermented cabbage) | Phenotypic | La. paracasei ssp. paracasei, La. rhamnosus, Lp. plantarum | [62] |

| Chengdu fermented vegetables (summer radish) | Phenotypic, 16S rRNA gene sequencing, species-specific PCR | Co. alimentarius, Lp. pentosus, Lp. plantarum, Lt. sakei | [72] |

| Chongzhou fermented vegetables (celery, cowpea, cabbage, and bamboo shoots) | Phenotypic, 16S rRNA gene sequencing, species-specific PCR | La. paracasei, Lp. pentosus, Lp. plantarum, Lt. sakei, Lv. brevis | [72] |

| Dayi fermented vegetables (summer radish, celery, cowpea, cabbage, and Chinese cabbage) | Phenotypic, 16S rRNA gene sequencing, species-specific PCR | E. thailandicus, Co. alimentarius, La. paracasei, Lp. pentosus, Lp. plantarum, Lv. brevis, Lv. spicheri, P. ethanolidurans | [72] |

| Pujiang fermented vegetables (summer radish, celery, cowpea, cabbage, and bamboo) | Phenotypic, 16S rRNA gene sequencing, species-specific PCR | Co. alimentarius, Lp. plantarum, Lv. brevis | [72] |

| Qionglai fermented vegetables (summer radish, celery, cowpea, Chinese cabbage, and carrot) | Phenotypic, 16S rRNA gene sequencing, species-specific PCR | Co. alimentarius, La. paracasei, Ln. lactis, Lp. pentosus, Lp. plantarum, Lv. brevis, P. ethanolidurans | [72] |

| Xinjin fermented vegetables (summer radish, cowpea, celery, cabbage, and Capsicum frutescens) | Phenotypic, 16S rRNA gene sequencing, species-specific PCR | Lp. plantarum, Lv. brevis | [72] |

| Mixed vegetable fermentation (green tomatoes, carrots, and cauliflower) | PCR-DGGE | Enterococcus sp., Ln. mesenteroides, Ln. pseudomesenteroides, Lp. plantarum, Lv. brevis, P. pentosaceus, W. kimchii, W. paramesenteroides, W. viridescens | [87] |

| Fermented leek | 16S rRNA gene sequencing | C. maltaromaticum, Co. crustorum, Co. nodensis, Lc. lactis, Lc. raffinolactis, Ln. gasicomitatum, Ln. gelidum, Ln. kimchi, Ln. lactis/citreum, Ln. lactis/garlicum, Ln. mesenteroides, Lp. plantarum, Lt. sakei, Lt. sakei/curvatus, Lv. brevis, Lv. hammessii/parabrevis, Lv. parabrevis, W. soli | [4] |

| Dua-Cai Be Muoi (fermented mustard) | MALDI-TOF MS, pheS sequencing, 16S rRNA gene sequencing | Lm. fermentum, Lp. pentosus, Lp. plantarum, P. pentosaceus | [73] |

| Dua Cu Cai Muoi (fermented beet) | MALDI-TOF MS, pheS sequencing, 16S rRNA gene sequencing | La. pantheris, Lm. fermentum, Lp. pentosus, Lp. plantarum, P. acidilactici, P. pentosaceus | [73] |

| Kimchi (cabbage, dycon, red pepper powder, red pepper, garlic, green onion, ginger, onion, salted shrimp, fish sauce, and sugar) | 16S rRNA gene sequencing, species-specific PCR | Lc. citreum, Ln. carnosum, Ln. gelidum, Ln. mesenteroides, Lt. curvatus, Lt. sakei, Lp. plantarum, Lv. parabrevis, Lv. spicheri, W. confusa | [88] |

| Kimchi (composition not reported) | 16S rRNA gene sequencing, species-specific PCR | Lc. lactis, Ln. carnosum, Ln. citreum, Ln. gasicomitatum, Ln. gelidum, Ln. mesenteroides, Lp. pentosus, Lp. plantarum, Lt. curvatus, Lt. sakei, Lv. brevis, P. pentosaceus, W. confusa, W. koreensis | [89] |

| Fermented onion | 16S rRNA gene sequencing | A. ursingii, Ac. orientalis, Ac. pasteurianus, Ci. freundii, Cr. sakazakii, Lp. plantarum, Lv. zymae, M. odoratus, Se. malefermentans | [63] |

| Takanazuke | 16S rRNA gene sequencing | Co. alimentarius, Lp. plantarum/paraplantarum, Lt. curvatus, Lt. sakei, Weissella spp. | [90] |

| Fermented Chinese cabbage | 16S rRNA gene sequencing | Lc. lactis, Ln. carnosum, Ln. citreum, Ln. gelidum, Ln. mesenteroides, Lp. pentosus, Lp. plantarum, Lt. curvatus, Lt. sakei, Lv. brevis, Lv. parabrevis, Lv. spicheri, W. confusa, W. koreensis | [77] |

| Suan-Cai (fermented Chinese cabbage) | 16S rRNA gene sequencing | Acinetobacter sp., Ln. mesenteroides, Lt. curvatus, Lp. plantarum, Pa. oligofermentans, Ps. fragi | [91] |

| Suan-Cai (fermented Chinese cabbage) | 16S rRNA gene sequencing | Lb. acidophilus, Lb. gasseri, Lb. jensenii, Lb. taiwanensis, Lm. fermentum, Lo. coryniformis, Lp. plantarum, Lt. curvatus, W. minor | [92] |

| Winter salad (fermented mixture consisting of cabbage, carrot, pepper, garlic, cauliflower, Jerusalem artichoke, celery, chili peppers, garlic, seeds of Heracleum persicum and Nigella sativa, tomato juice, and vinegar) | 16S rRNA gene sequencing | E. faecalis, E. faecium, Lm. fermentum, Ln. citreum, Ln. mesenteroides subsp. mesenteroides, Lp. plantarum, P. pentosaceus, W. cibaria | [93] |

| Paocai (fermented mixture consisting of cabbage, cowpea, carrot, ginger, pepper, and green pepper) | 16S rRNA gene sequencing | Bacillus sp., Citrobacter sp., Lc. lactis, Lp. plantarum, Lv. brevis, Ps. plecoglossicida, W. confusa, W. koreensis | [94] |

| Paocai (fermented cabbage) | 16S rRNA gene sequencing, 16S rRNA gene metataxonomic analysis | A. baumannii, A. calcoaceticus, A. junii, Eb. aerogenes, Eb. cloacae, Eb. kobei, H. alvei, K. cryocrescens, K. georgiana, Kl. oxytoca, L. amnigena, Lc. lactis, Ln. mesenteroides, Lp. plantarum, Lv. brevis, R. ornithinolytica, R. terrigena, St. arlettae | [95] |

| Fermented Chinese cabbage | 16S rRNA gene sequencing | Le. parabuchneri, Lp. plantarum, Lv. brevis | [70] |

| Fermented Pakchoi | 16S rRNA gene sequencing | Lp. plantarum, Lv. brevis | [70] |

| Fermented potherbs | 16S rRNA gene sequencing | Le. parabuchneri, Lp. plantarum, Lv. brevis | [70] |

| Fermented radish roots | 16S rRNA gene sequencing | Lp. plantarum, Lv. brevis, P. pentosaceus | [5] |

| Radish paocai | 16S rRNA gene sequencing | Ln. lactis, Lp. plantarum, Lv. brevis, W. cibaria | [96] |

| Chongqing radish paocai | 16S rRNA gene metataxonomic analysis | Co. ginsenosidimutans, Lb. acetotolerans, Le. buchneri, Ln. pseudomesenteroides, Lp. plantarum, P. ethanolidurans, Pa. vaccinostercus, W. cibaria | [49] |

| Dua-Cai (fermented cabbage) | 16S rRNA gene sequencing | Lb. delbrueckii, Lb. helveticus, Lm. fermentum, Lm. pontis, Lp. plantarum | [64] |

| Mang-chua (fermented bamboo shoots) | 16S rRNA gene sequencing | Lb. helveticus, Lm. fermentum, Lm. pontis, Lp. plantarum | [64] |

| Koso (fermented beverage made of vegetables, mushrooms, and sugars) | 16S rRNA gene metataxonomic analysis | A. calcoaceticus, A. oleivorans, Ar. davidanieli, Bf. pseudolongum, B. coagulans, Brochothrix sp., Bu. aphidicola, Ch. indoltheticum, Curtobacterium sp., Eb. cloacae, Er. billingiae, Ex. sibiricum, Ha. gallinarum, Janthinobacterium sp., La. casei, Lc. lactis, Ln. citreum, Ln. gasicomitatum, Ln. pseudomesenteroides, Lp. plantarum, Lt. sakei, W. hellenica, Pn. vagans, Pr. acnes, Ps. fluorescens, Ps. fuscovaginae, Ps. psychrotolerans, Rahnella sp., Rhodanobacter sp., St. capitis, W. minor, W. viridescens, X. oryzae | [97] |

| Miang (fermented tea leaf) | 16S rRNA gene sequencing, species-specific PCR | E. faecalis, La. camelliae, La. casei, La. pantheris, Lc. lactis, Lm. fermentum, Lm. panis, Ln. mesenteroides, Lo. coryniformis, Lp. pentosus, Lp. plantarum, Lv. brevis, P. pentosaceus, W. confusa | [55] |

| Laphet (fermented tea leaves) | 16S rRNA gene sequencing, 16S rRNA gene metataxonomic analysis | Ac. orientalis, At. scotiae, Enterobacter sp., La. pantheris, Lp. pentosus, Lp. plantarum, P. cellicola, P. ethanolidurans, Pa. suebicus, Pe. favisporus, Pl. gergoviae, Se. collinoides, Se. paracollinoides, Sx. acetivorans | [74] |

| Awa-bancha (fermented tea leaves) | 16S rRNA gene sequencing, species-specific PCR | Ln. mesenteroides, Lo. coryniformis, Lp. mudanjiangensis, Lp. paraplantarum, Lp. plantarum, Lv. brevis, Se. collinoides | [69] |

| Zhejiang xuecai (fermented leaves of potherb mustard (Brassica juncea var. multiceps)) | 16S rRNA gene metataxonomic analysis | Ab. marinus, Co. alimentarius, Co. ginsenosidimutans, Cb. japonicus, Hl. praevalens, Hl. salsuginis, Hm. alimentaria, Hm. jeotgali, Lb. acetotolerans, Lp. plantarum, Me. adhaesivum, P. pentosaceus, Ps. brenneri, Ps. parafulva, Sp. phyllosphaerae | [80] |

| Fermented Brassica napobrassica | 16S rRNA gene metataxonomic analysis | Ab. marinus, Co. ginsenosidimutans, Fr. fructivorans, Lb. acetotolerans, Li. acidipiscis, Lp. plantarum, Lv. brevis, P. parvulus, St. saprophyticus, O. oncorhynchi subsp. incaldanensis, W. cibaria | [79] |

| Avyrtake (cabbage (Brassica oleracea), leek (Allium ampeloprasum), garlic (Allium sativum), pomegranate (Punica granatum) seeds, raisins, green cardamon (Elettaria cardamomum) seeds, and mustard (Brassica alba) seeds) | 16S rRNA gene sequencing, species-specific PCR | Lp. plantarum, Lv. brevis | [98] |

| Laotan Suan-Cai (fermented mixture consisting of potherb mustard, sugar, red pepper, ginger, garlic, and spice) | 16S rRNA gene metataxonomic analysis | Co. alimentarius, Co. farciminis, Co. futsaii, Lc. lactis, Lo. coryniformis, Lp. pentosus, Lp. plantarum, V. zhugei, W. cibaria, W. paramesenteroides | [99] |

| Suan-Cai (non-salted fermented cabbage) | 16S rRNA gene metataxonomic analysis | Bf. longum, E. faecalis, Eb. hormaechei, Es. coli, L. amnigena, La. paracasei, Lb. delbrueckii, Lb. helveticus, Lc. cremoris, Lc. lactis, Le. parakefiri, Li. acidipiscis, Ll. adecarboxylata, Lm. fermentum, Ln. carnosum, Ln. citreum, Ln. garlicum, Ln. gelidum, Ln. lactis, Ln. mesenteroides, Ln. pseudomesenteroides, Ln. suionicum, Lo. coryniformis, Lp. paraplantarum, Lp. pentosus, Lp. plantarum, Lt. curvatus, Lv. brevis, P. ethanolidurans, W. cibaria, W. hellenica, W. paramesenteroides, W. viridescens | [67] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paramithiotis, S. Lactiplantibacillus plantarum, the Integral Member of Vegetable Fermentations. Appl. Biosci. 2025, 4, 7. https://doi.org/10.3390/applbiosci4010007

Paramithiotis S. Lactiplantibacillus plantarum, the Integral Member of Vegetable Fermentations. Applied Biosciences. 2025; 4(1):7. https://doi.org/10.3390/applbiosci4010007

Chicago/Turabian StyleParamithiotis, Spiros. 2025. "Lactiplantibacillus plantarum, the Integral Member of Vegetable Fermentations" Applied Biosciences 4, no. 1: 7. https://doi.org/10.3390/applbiosci4010007

APA StyleParamithiotis, S. (2025). Lactiplantibacillus plantarum, the Integral Member of Vegetable Fermentations. Applied Biosciences, 4(1), 7. https://doi.org/10.3390/applbiosci4010007