Investigation into the Effects of Prior Plasticity on Creep Accumulation in 316H Stainless Steel †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Specimen Design

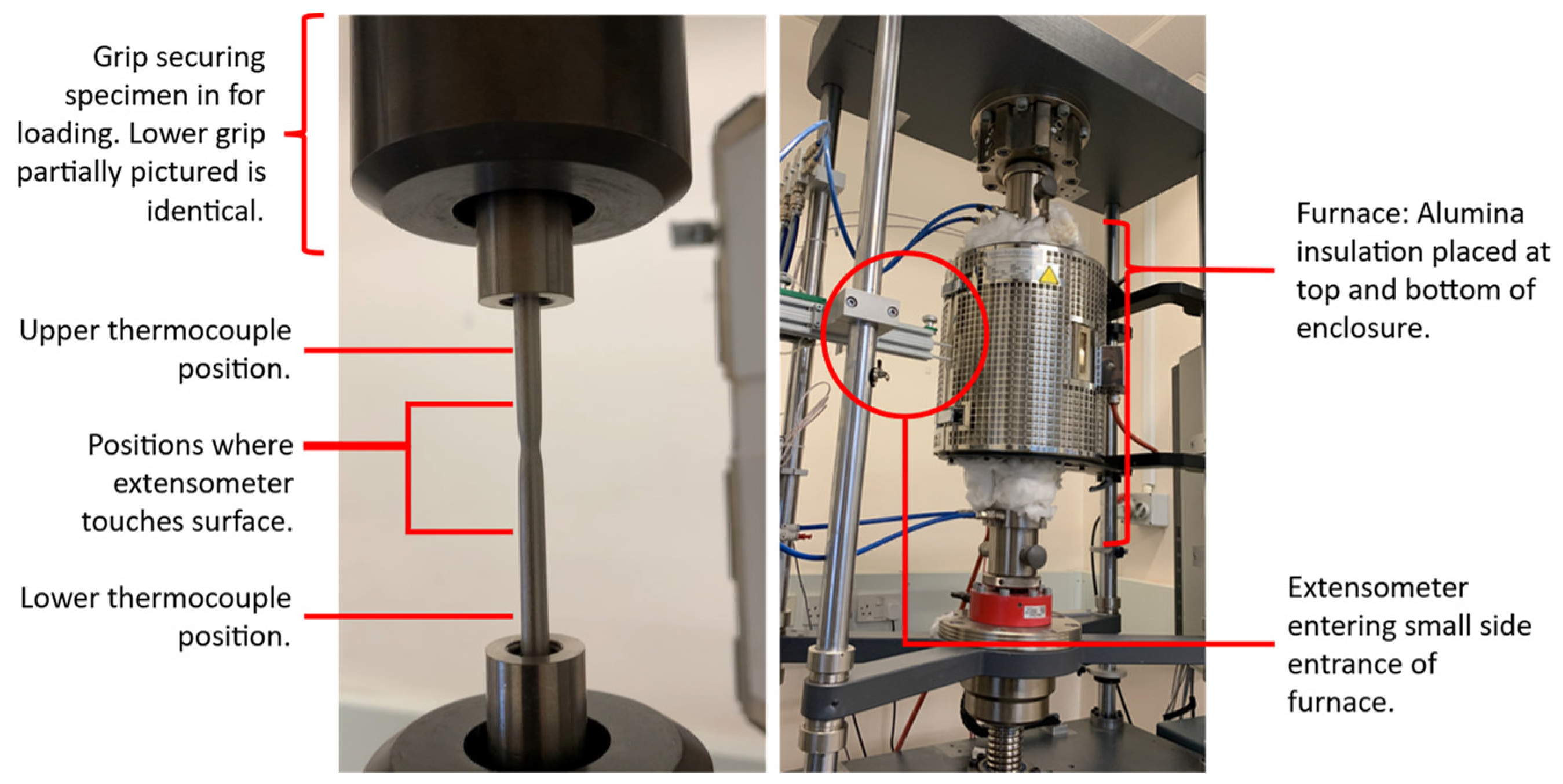

2.3. Test Setup

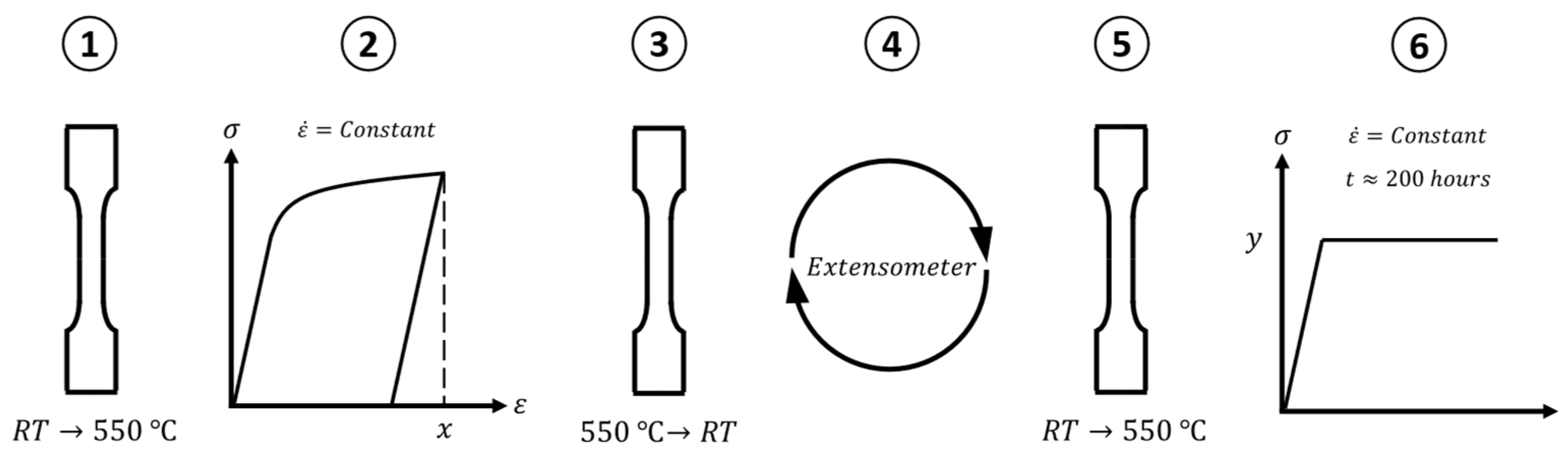

2.4. Testing Regime and Procedure

3. Results and Discussion

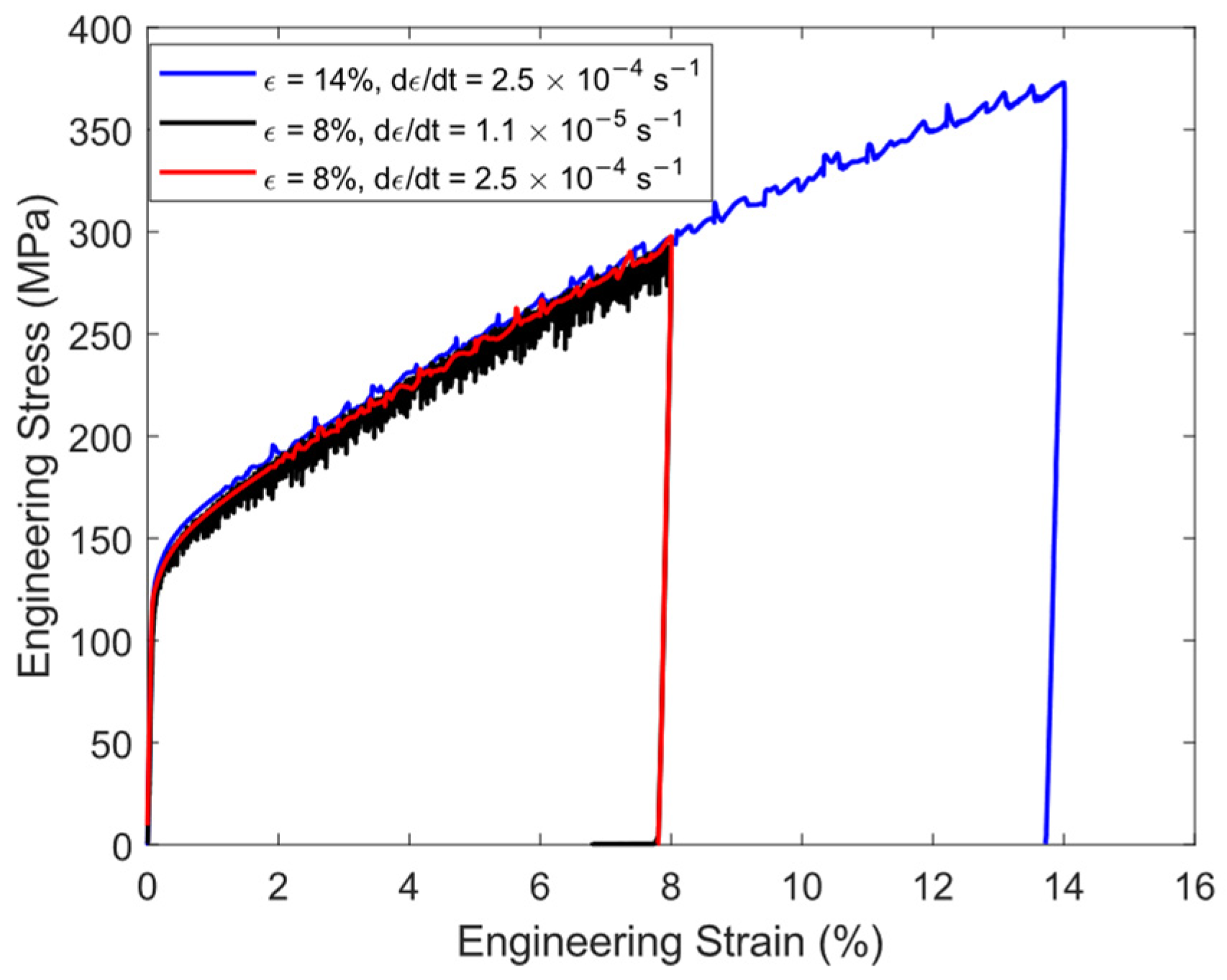

3.1. Specimen Loading

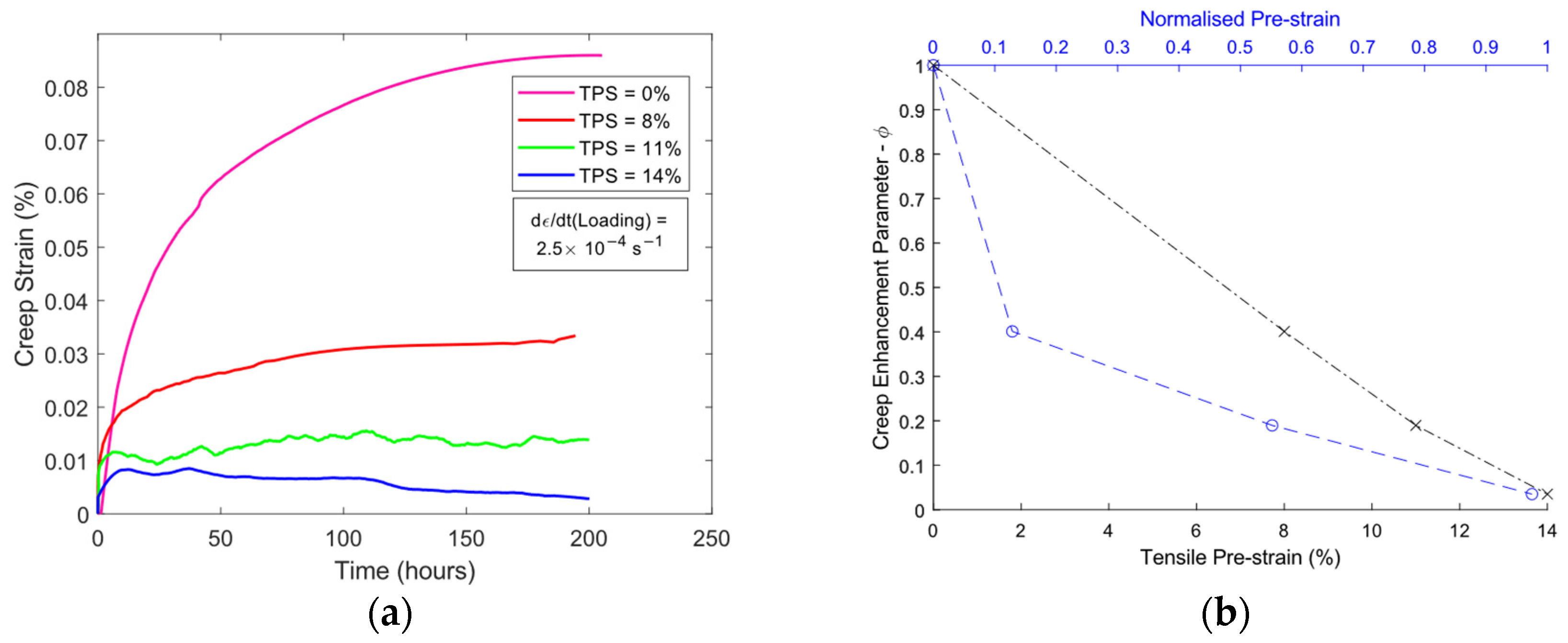

3.2. Creep Tests

3.3. Macroscale Simulations

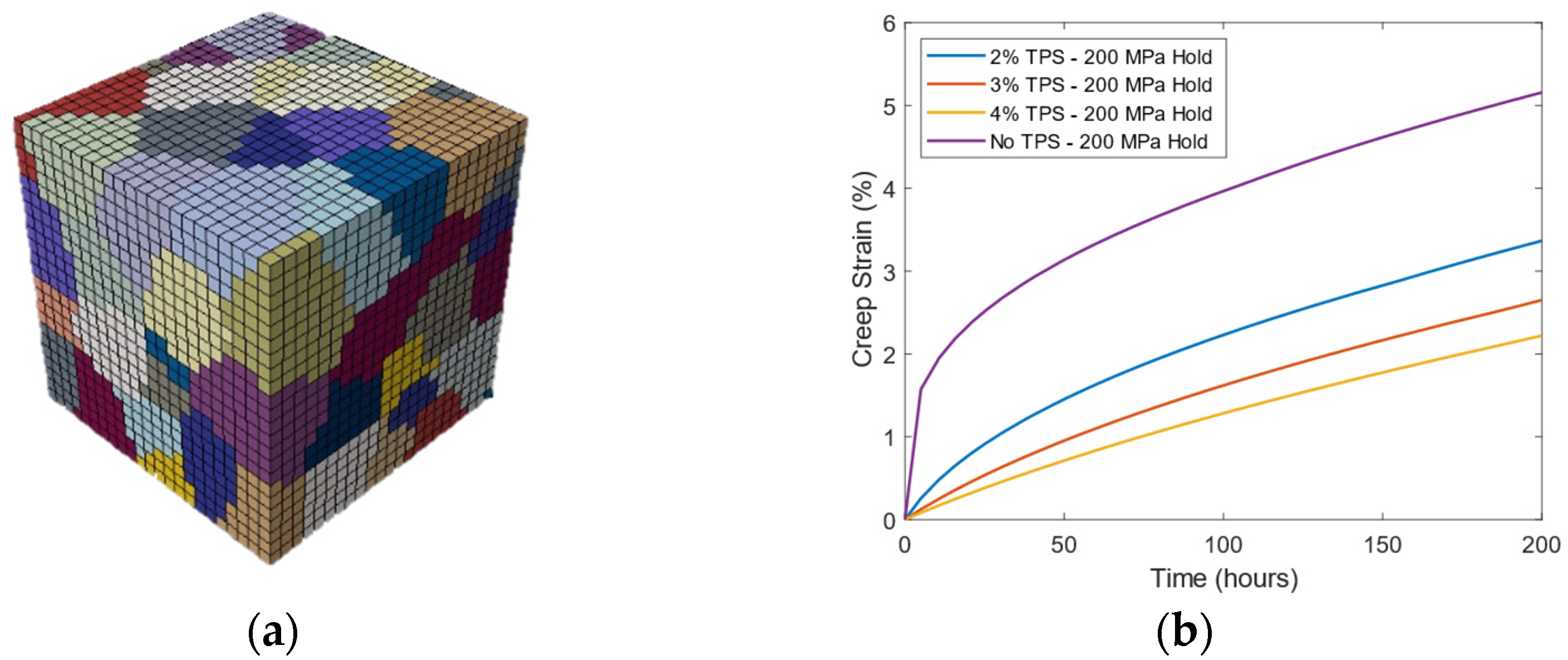

3.4. Microscale Simulations

4. Further Work

- More tests performed in this experimental strain range, particularly the 7.1% to 8% range, to further quantify the observed trend.

- Repeat tests at controlled true creep stresses to provide a clearer comparison between data sets.

- Development of the crystal plasticity simulations, specifically calibration, will determine how effectively the model can be a predictive tool.

5. Conclusions

- The high-temperature uniaxial stress–strain relationship of this cast of 316H is rate invariant over a loading time of 5 min to 2 h.

- Increasing tensile pre-strain reduces the average creep rate of this cast of 316H. The results of these experiments show that at the highest normalized pre-strain recorded (~100%), the creep rate was reduced by a factor of 10.

- The RCC-MR deformation law in combination with a non-linear isotropic/kinematic hardening law is ineffective at modelling the creep–plasticity interaction experimentally observed.

- Crystal plasticity simulations have shown that they can predict the creep–plasticity trends observed experimentally. Further calibration and simulations would prove whether this can align well with experimental data.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Petkov, M.P.; Hu, J.; Cocks, A.C.F. Self-Consistent Modelling of Cyclic Loading and Relaxation in Austenitic 316H Stainless Steel. Philos. Mag. 2019, 99, 789–834. [Google Scholar] [CrossRef]

- Li, D.F.; O’Dowd, N.P.; Davies, C.M.; Nikbin, K.M. A Review of the Effect of Prior Inelastic Deformation on High Temperature Mechanical Response of Engineering Alloys. Int. J. Press. Vessel. Pip. 2010, 87, 531–542. [Google Scholar] [CrossRef]

- Ohashi, Y.; Kawai, M.; Momose, T. Effects of Prior Plasticity on Subsequent Creep of Type 316 Stainless Steel at Elevated Temperature. J. Eng. Mater. Technol. 1986, 108, 68–74. [Google Scholar] [CrossRef]

- Taylor, M.; Mamun, A.; Knowles, D. The Influence of Prior Plastic Loading on the Accumulation of Creep Strain in 316H Stainless Steel. In Proceedings of the ASME 2019 Pressure Vessels & Piping Conference, San Antonio, TX, USA, 14–19 July 2019; AMSE: New York, NY, USA, 2019. Volume 6B: Materials and Fabrication. [Google Scholar]

- Tai, K.; Endo, T. Effect of Pre-Creep on the Succeeding Creep Behavior of a 2.25Cr-1Mo Steel. Scr. Metall. Mater. 1993, 29, 643–646. [Google Scholar] [CrossRef]

- Mamun, A.A.; Simpson, C.; Agius, D.; Lee, T.L.; Kabra, S.; Truman, C.; Mostafavi, M.; Knowles, D. A Novel Insight into the Primary Creep Regeneration Behaviour of a Polycrystalline Material at High-Temperature Using In-Situ Neutron Diffraction. Mater. Sci. Eng. A 2020, 786, 139374. [Google Scholar] [CrossRef]

- ASTM E139-11(2018); Standard Test Methods for Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2018.

- Davies, C.; Mueller, F.; Nikbin, K.; O’Dowd, N.; Webster, G. Analysis of Creep Crack Initiation and Growth in Different Geometries for 316H and Carbon Manganese Steels. J. ASTM Int. 2006, 3, JAI13220. [Google Scholar] [CrossRef]

- Poirier, J.-P. Creep of Crystals: High-Temperature Deformation Processes in Metals, Ceramics and Minerals; Cambridge Earth Science Series; Cambridge University Press: Cambridge, UK, 1985; ISBN 978-0-521-27851-5. [Google Scholar]

- Wasilkowska, A.; Bartsch, M.; Messerschmidt, U.; Herzog, R.; Czyrska-Filemonowicz, A. Creep Mechanisms of Ferritic Oxide Dispersion Strengthened Alloys. J. Mater. Processing Technol. 2003, 133, 218–224. [Google Scholar] [CrossRef]

- Wilshire, B.; Willis, M. Mechanisms of Strain Accumulation and Damage Development during Creep of Prestrained 316 Stainless Steels. Metall Mater Trans. A 2004, 35, 563–571. [Google Scholar] [CrossRef]

- Cairney, J.M.; Rong, T.S.; Jones, I.P.; Smallman, R.E. Intermediate Temperature Creep Mechanisms in Ni3Al. Philos. Mag. 2003, 83, 1827–1843. [Google Scholar] [CrossRef]

- Coules, H.E.; Nneji, S.O.; James, J.A.; Kabra, S.; Hu, J.N.; Wang, Y. Full-Tensor Measurement of Multiaxial Creep Stress Relaxation in Type 316H Stainless Steel. Exp. Mech. 2022, 62, 19–33. [Google Scholar] [CrossRef]

- Association Francaise pour les Regles de Conception et de Construction des Materiels des Chaudieres Electro-Nucleaires (AFCEN). Design and Construction Rules for Mechanical Components of FBR Nuclear Islands: RCC-MR Tome 5: Fabrication; AFCEN: Paris, France, 1985. [Google Scholar]

- Association Francaise pour les Regles de Conception et de Construction des Materiels des Chaudieres Electro-Nucleaires (AFCEN). Regles de Conception et de Construction des Materiels Mecaniques des Ilots Nucleaires RNR: RCC-MR Tome 5: Fabrication; AFCEN: Paris, France, 1985. [Google Scholar]

- Agius, D.; Mamun, A.A.; Simpson, C.A.; Truman, C.; Wang, Y.; Mostafavi, M.; Knowles, D. Microstructure-Informed, Predictive Crystal Plasticity Finite Element Model of Fatigue-Dwells. Comput. Mater. Sci. 2020, 183, 109823. [Google Scholar] [CrossRef]

| Material | C | S | Co | Cr | Mn | Mo | Ni | P | Si |

|---|---|---|---|---|---|---|---|---|---|

| ELG | 0.06525 | 0.00575 | 0.2075 | 17.29 | 1.37 | 2.04 | 10.115 | 0.0405 | 0.445 |

| Ex-service | 0.06 | 0.014 | 0.1 | 17.17 | 0.98 | 2.19 | 11.83 | 0.021 | 0.4 |

| Pre-Strain (%) | Loading Strain Rate (s−1) | Creep Stress (MPa) | Creep Hold Time (Hours) |

|---|---|---|---|

| 0 | 280 | 2323 (fracture) | |

| 8 | 280 | 200 | |

| 8 | NA | NA | |

| 11 | 280 | 200 | |

| 14 | 280 | 200 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Allen, C.; Coules, H.; Truman, C. Investigation into the Effects of Prior Plasticity on Creep Accumulation in 316H Stainless Steel. Phys. Sci. Forum 2022, 4, 16. https://doi.org/10.3390/psf2022004016

Allen C, Coules H, Truman C. Investigation into the Effects of Prior Plasticity on Creep Accumulation in 316H Stainless Steel. Physical Sciences Forum. 2022; 4(1):16. https://doi.org/10.3390/psf2022004016

Chicago/Turabian StyleAllen, Christopher, Harry Coules, and Christopher Truman. 2022. "Investigation into the Effects of Prior Plasticity on Creep Accumulation in 316H Stainless Steel" Physical Sciences Forum 4, no. 1: 16. https://doi.org/10.3390/psf2022004016

APA StyleAllen, C., Coules, H., & Truman, C. (2022). Investigation into the Effects of Prior Plasticity on Creep Accumulation in 316H Stainless Steel. Physical Sciences Forum, 4(1), 16. https://doi.org/10.3390/psf2022004016