Loss Analysis of P3 Laser Patterning of Perovskite Solar Cells via Hyperspectral Photoluminescence Imaging

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

- A 120 nm indium tin oxide (ITO, Rsheet ≈ 15 Ω) layer was deposited on glass substrates as the transparent front contact.

- This ITO layer was laser-patterned (P1, 1064 nm, ps laser) to define the cell stripe width and electrically isolate individual cells for series interconnection.

- Samples were then cleaned in an ultrasonic bath (900 s in soap solution, acetone, and isopropanol), dried in N2, and treated with UV-ozone for 900 s.

- A tin-oxide (SnO2) electron transport layer (ETL) was prepared by dissolving SnCl2·2H2O in C2H5OH, stirring for 12 h, and spin-coating at 1500 rpm for 30 s, then 2500 rpm for another 30 s, followed by curing at 180 °C.

- A 650 nm triple-cation perovskite absorber layer (Cs0.05FA0.79MA0.16PbBr0.51I2.49) was spin-coated.

- The hole transport layer (HTL) was spin-coated from a spiro-OMeTAD solution (36.2 mg/mL in chlorobenzene) doped with TBP, Li-TFSI, and cobalt(III) complex at 1800 rpm for 30 s.

- P2 laser patterning (532 nm, ps laser) created a pathway through the perovskite layer to connect to the back contact.

- A 100 nm gold back contact was evaporated under low pressure.

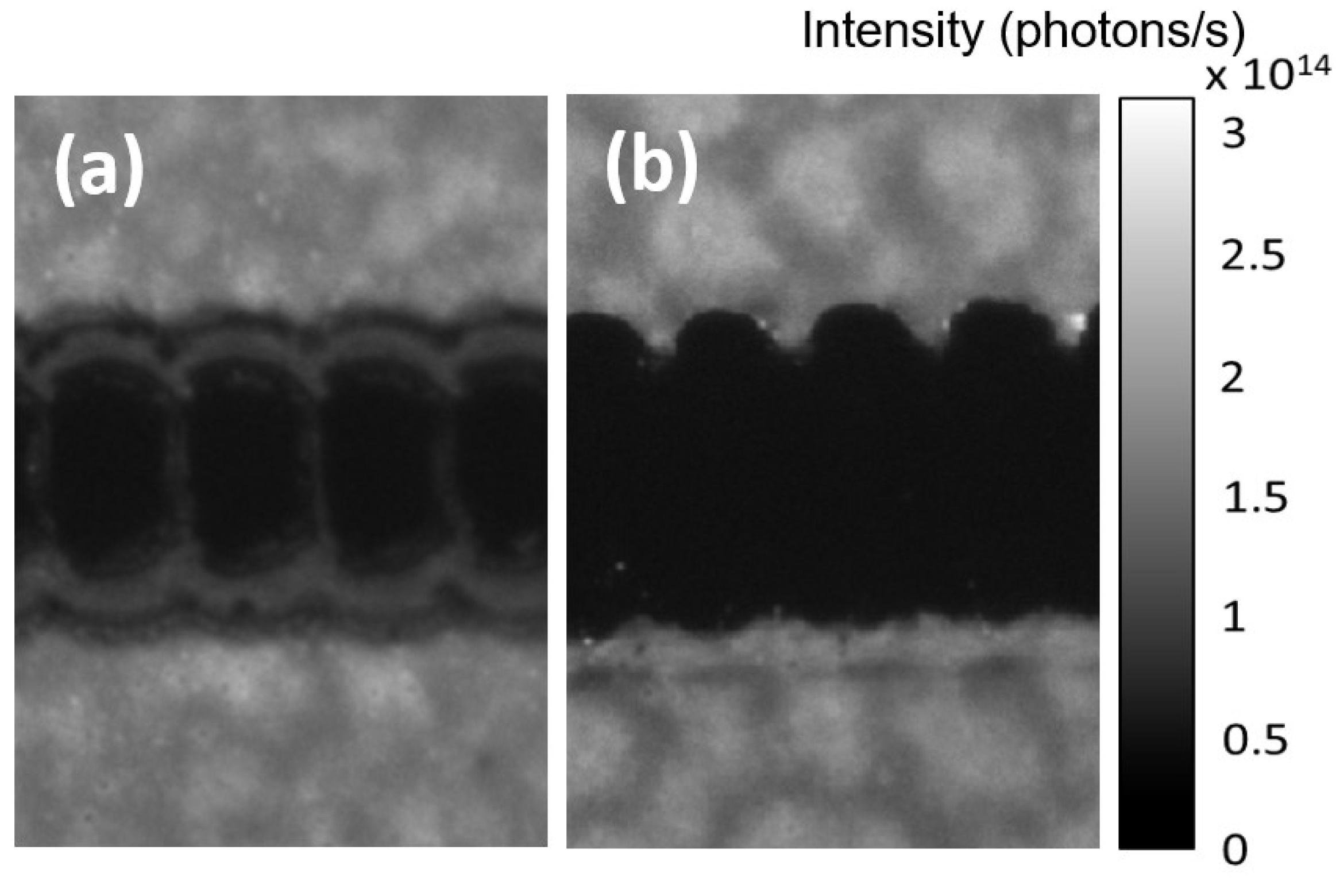

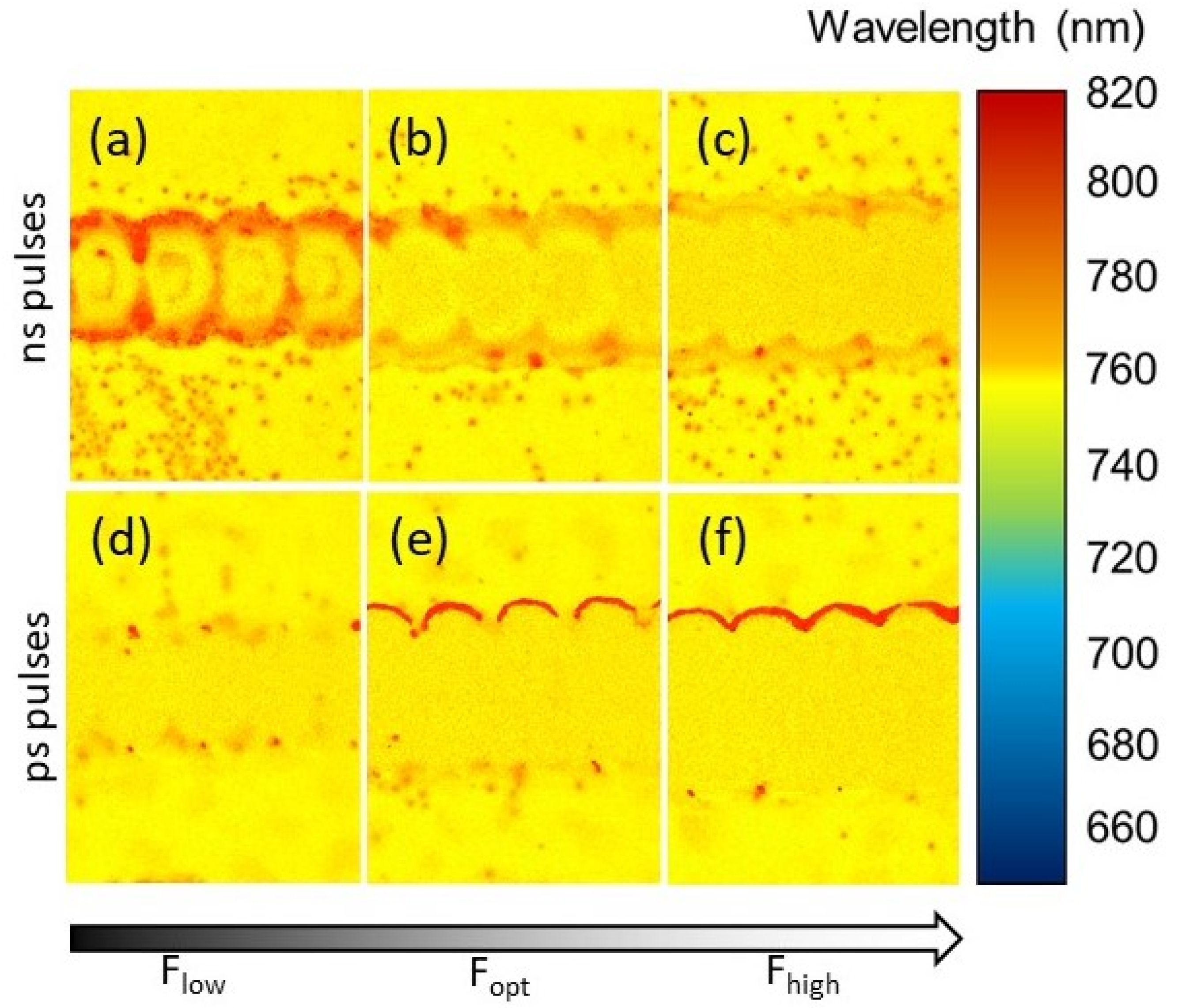

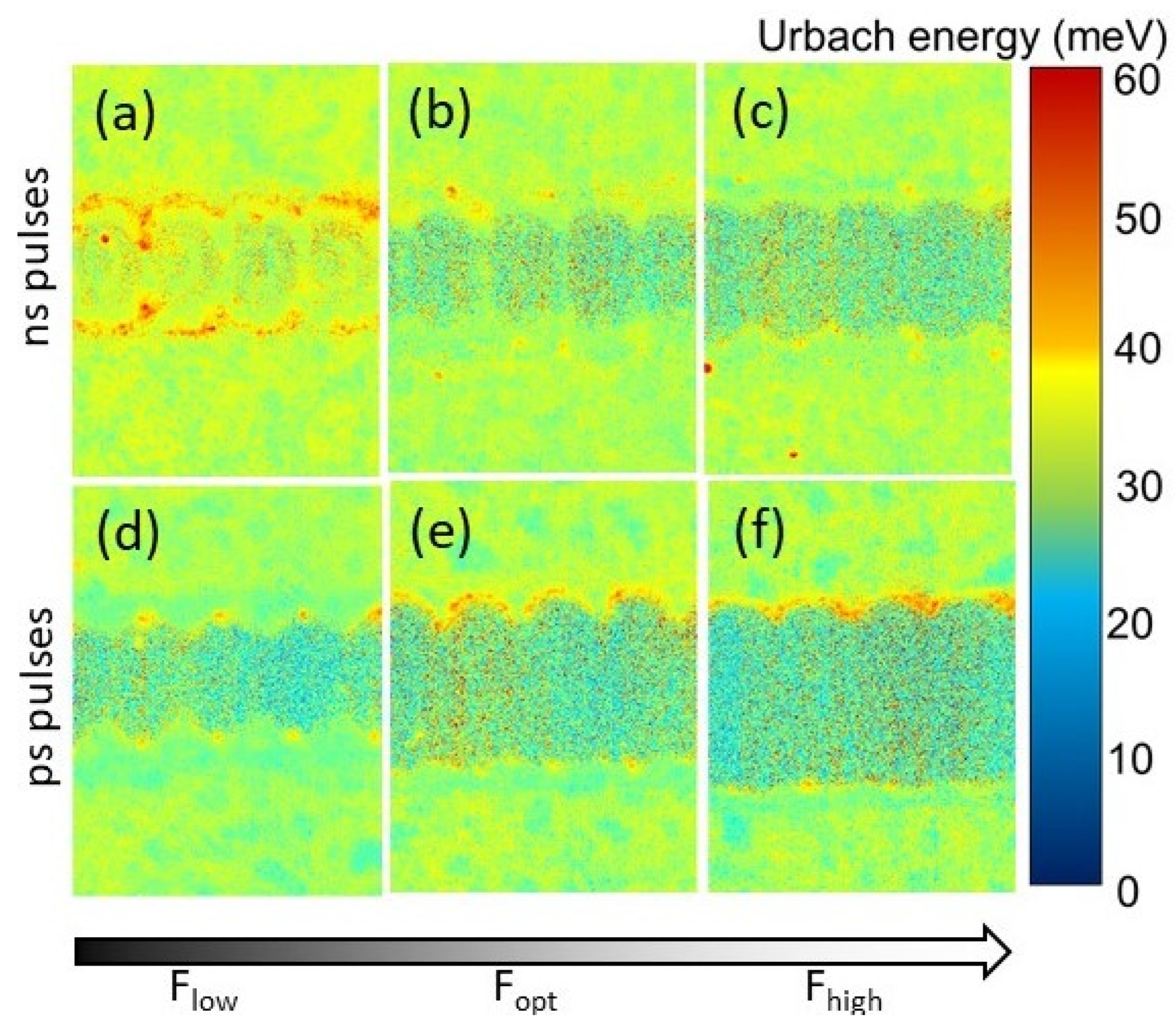

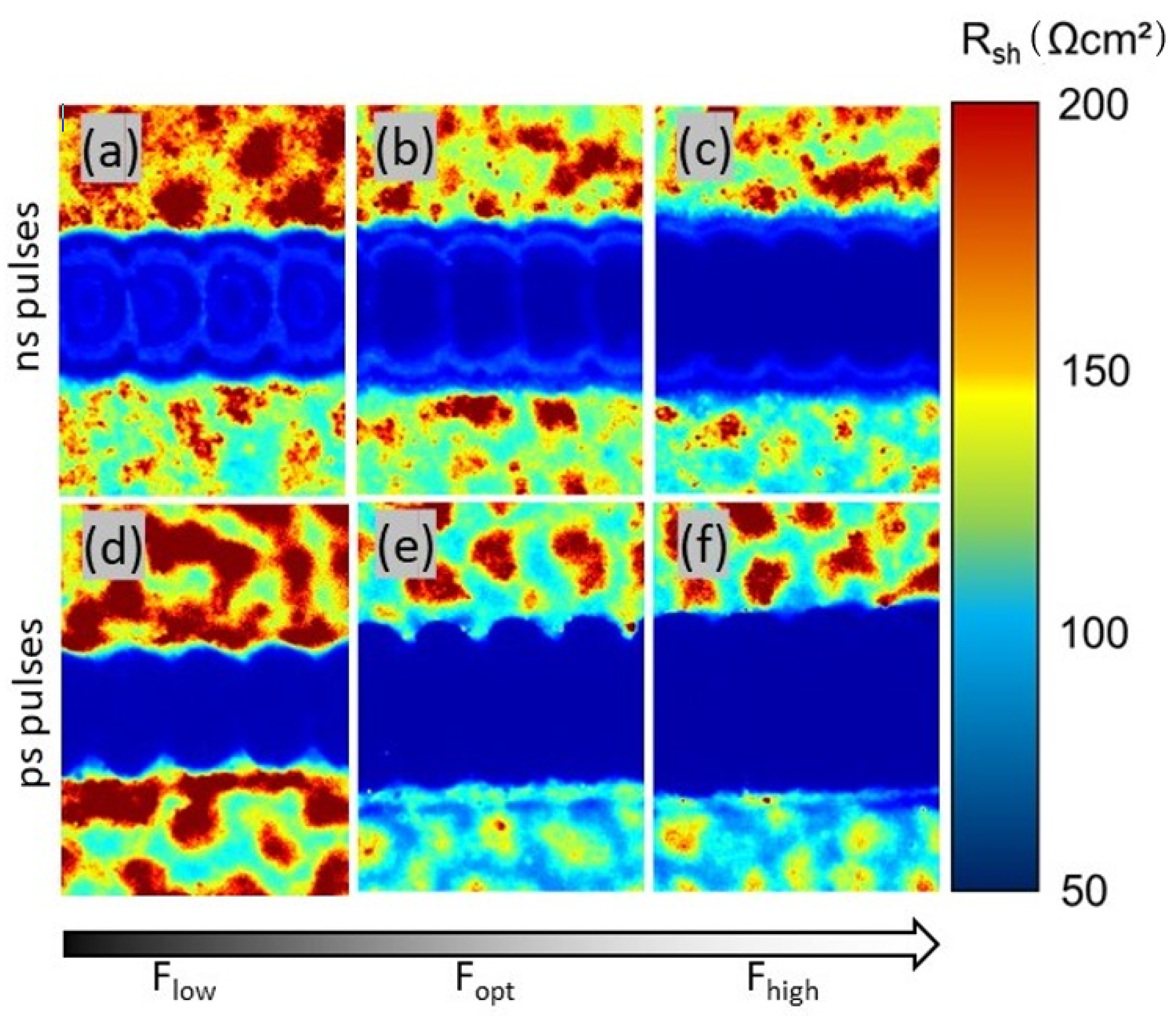

- P3 laser patterning (532 nm, ps/ns laser) electrically isolated the back-contact layer.

2.2. Laser Patterning

2.3. Characterization

3. Results and Discussion

4. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Manser, J.S.; Christians, J.A.; Kamat, P.V. Intriguing optoelectronic properties of metal halide perovskites. Chem. Rev. 2016, 116, 12956–13008. [Google Scholar] [CrossRef] [PubMed]

- Kim, G.-W.; Petrozza, A. Defect Tolerance and Intolerance in Metal-Halide Perovskites. Adv. Energy Mater. 2020, 10, 2001959. [Google Scholar] [CrossRef]

- Green, M.A.; Dunlop, E.D.; Yoshita, M.; Kopidakis, N.; Bothe, K.; Siefer, G.; Hao, X.; Jiang, J.Y. Solar Cell Efficiency Tables (Version 65). Prog. Photovolt. Res. Appl. 2025, 33, 3–15. [Google Scholar] [CrossRef]

- Sheng, Y.; Wen, X.; Jia, B.; Gan, Z. Direct laser writing on halide perovskites: From mechanisms to applications. Light Adv. Manuf. 2024, 4, 95–116. [Google Scholar] [CrossRef]

- Zhou, C.; Cao, G.; Gan, Z.; Ou, Q.; Chen, W.; Bao, Q.; Jia, B.; Wen, X. Spatially Modulating the Fluorescence Color of Mixed-Halide Perovskite Nanoplatelets through Direct Femtosecond Laser Writing. ACS Appl. Mater. Interfaces 2019, 11, 26017–26023. [Google Scholar] [CrossRef]

- Zhang, Y.; Lin, Y.; Lin, Z.; Yan, Z.; Shuli, W.; Su, Y.; Lin, Y.; Kuo, H.C.; Chen, Z.; Lai, S.; et al. Application of Ultrafast Lasers: A Promising Route toward the Fabrication of Advanced Perovskite-Based Devices. Adv. Opt. Mater. 2025, 13, 2402924. [Google Scholar] [CrossRef]

- Yan, G.; Yuan, Y.; Kaba, M.; Kirchartz, T. Visualizing Performances Losses of Perovskite Solar Cells and Modules: From Laboratory to Industrial Scales. Adv. Energy Mater. 2024, 15, 2403706. [Google Scholar] [CrossRef]

- Stegemann, B.; Schultz, C. Laser patterning of thin films. In Digital Encyclopedia of Applied Physics; Wiley-VCH Verlag GmbH & Co. KGaA: Hoboken, NJ, USA, 2019; pp. 1–30. [Google Scholar] [CrossRef]

- Matteocci, F.; Vesce, L.; Kosasih, F.U.; Castriotta, L.A.; Cacovich, S.; Palma, A.L.; Divitini, G.; Ducati, C.; Di Carlo, A. Fabrication and Morphological Characterization of High-Efficiency Blade-Coated Perovskite Solar Modules. ACS Appl. Mater. Interfaces 2019, 11, 25195–25204. [Google Scholar] [CrossRef]

- Mincuzzi, G.; Palma, A.L.; Di Carlo, A.; Brown, T.M. Laser Processing in the Manufacture of Dye-Sensitized and Perovskite Solar Cell Technologies. ChemElectroChem 2016, 3, 9–30. [Google Scholar] [CrossRef]

- Schultz, C.; Fenske, M.; Dagar, J.; Zeiser, A.; Bartelt, A.; Schlatmann, R.; Unger, E.L.; Stegemann, B. Ablation mechanisms of nanosecond and picosecond laser scribing for metal halide perovskite module interconnection—An experimental and numerical analysis. Sol. Energy 2020, 198, 410–418. [Google Scholar] [CrossRef]

- Fenske, M.; Schultz, C.; Dagar, J.; Kosasih, F.U.; Zeiser, A.; Junghans, C.; Bartelt, A.; Ducati, C.; Schlatmann, R.; Unger, E.; et al. Improved Electrical Performance of Perovskite Photovoltaic Mini-Modules through Controlled PbI2 Formation Using Nanosecond Laser Pulses for P3 Patterning. Energy Technol. 2021, 9, 2000969. [Google Scholar] [CrossRef]

- Schultz, C.; Fenske, M.; Dion-Bertrand, L.-I.; Gélinas, G.; Marcet, S.; Dagar, J.; Bartelt, A.; Schlatmann, R.; Unger, E.; Stegemann, B. Hyperspectral Photoluminescence Imaging for Spatially Resolved Determination of Electrical Parameters of Laser-Patterned Perovskite Solar Cells. Sol. RRL 2023, 7, 2300538. [Google Scholar] [CrossRef]

- Trupke, T.; Bardos, R.A.; Abbott, M.D.; Cotter, J.E. Suns-photoluminescence: Contactless determination of current-voltage characteristics of silicon wafers. Appl. Phys. Lett. 2005, 87, 093503. [Google Scholar] [CrossRef]

- Abou-Ras, D.; Kirchartz, T.; Rau, U. Photoluminescence Analysis of Thin-Film Solar Cells; Abou-Ras, D., Kirchartz, T., Rau, U., Eds.; WILEY-VCH Verlag GmbH & Co. KGaA: Hoboken, NJ, USA, 2016; pp. 275–297. [Google Scholar] [CrossRef]

- Siebentritt, S.; Weiss, T.P.; Sood, M.; Wolter, M.H.; Lomuscio, A.; Ramirez, O. How photoluminescence can predict the efficiency of solar cells. J. Phys. Mater. 2021, 4, 042010. [Google Scholar] [CrossRef]

- Kirchartz, T.; Márquez, J.A.; Stolterfoht, M.; Unold, T. Photoluminescence-Based Characterization of Halide Perovskites for Photovoltaics. Adv. Energy Mater. 2020, 10, 1904134. [Google Scholar] [CrossRef]

- Schubert, M.C.; Mundt, L.E.; Walter, D.; Fell, A.; Glunz, S.W. Spatially Resolved Performance Analysis for Perovskite Solar Cells. Adv. Energy Mater. 2020, 10, 1904001. [Google Scholar] [CrossRef]

- Delamarre, A.; Paire, M.; Guillemoles, J.-F.; Lombez, L. Quantitative luminescence mapping of Cu(In,Ga)Se2 thin-film solar cells. Prog. Photovolt. Res. Appl. 2015, 23, 1305–1312. [Google Scholar] [CrossRef]

- Nguyen, K.; Bui, A.D.; Mayon, A.O.; Nguyen, T.; White, T.; Truong, T.; Ho-Baillie, A.; Duong, T.; Shen, H.; Weber, K.; et al. Correlative imaging of optoelectronic properties for perovskite solar cells via hyperspectral luminescence imaging. Cell Rep. Phys. Sci. 2023, 4, 13. [Google Scholar] [CrossRef]

- Delamarre, A.; Lombez, L.; Guillemoles, J.-F. Characterization of solar cells using electroluminescence and photoluminescence hyperspectral images. J. Photonics Energy 2012, 2, 027004. [Google Scholar] [CrossRef]

- Levtchenko, A.; Lopez-Varo, P.; Provost, M.; Medjoubi, K.; Rousset, J.; Ory, D. Perovskite Mini-Module Voltage Loss Quantification and Analysis by Large-Scale Hyperspectral Photoluminescence Imaging. Sol. RRL 2025, 9, 2400796. [Google Scholar] [CrossRef]

- El-Hajje, G.; Momblona, C.; Gil-Escrig, L.; Ávila, J.; Guillemot, T.; Guillemoles, J.-F.; Sessolo, M.; Bolink, H.J.; Lombez, L. Quantification of spatial inhomogeneity in perovskite solar cells by hyperspectral luminescence imaging. Energy Environ. Sci. 2016, 9, 2286–2294. [Google Scholar] [CrossRef]

- Rey, G.; Paduthol, A.; Sun, K.; Nagle, T.; Poplavskyy, D.; Serrano Escalante, V.; Melchiorre, M.; Siebentritt, S.; Abbott, M.; Trupke, T. Photoluminescence-Based Method for Imaging Buffer Layer Thickness in CIGS Solar Cells. IEEE J. Photovolt. 2020, 10, 181–187. [Google Scholar] [CrossRef]

- Bui, A.D.; Nguyen, D.-T.; Fell, A.; Mozaffari, N.; Ahmad, V.; Duong, T.; Li, L.; Truong, T.N.; Wibowo, A.A.; Nguyen, K.; et al. Spatially resolved power conversion efficiency for perovskite solar cells via bias-dependent photoluminescence imaging. Cell Rep. Phys. Sci. 2023, 4, 101641. [Google Scholar] [CrossRef]

- Hameiri, Z.; Mahboubi Soufiani, A.; Juhl, M.; Liangcong, J.; Huang, F.; Bing, C.; Kampwerth, H.; Weber, J.; Green, M.; Trupke, T. Photoluminescence and electroluminescence imaging of perovskite solar cells. Prog. Photovolt. Res. Appl. 2015, 23, 1697–1705. [Google Scholar] [CrossRef]

- Hacene, B.; Laufer, F.; Ternes, S.; Farag, A.; Pappenberger, R.; Fassl, P.; Moghadamzadeh, S.; Nejand, B.A.; Feeney, T.; Howard, I.; et al. Intensity Dependent Photoluminescence Imaging for In-Line Quality Control of Perovskite Thin Film Processing. Adv. Mater. Technol. 2024, 9, 2301279. [Google Scholar] [CrossRef]

- Zikulnig, J.; Mühleisen, W.; Bolt, P.J.; Simor, M.; De Biasio, M. Photoluminescence Imaging for the In-Line Quality Control of Thin-Film Solar Cells. Solar 2022, 2, 1–11. [Google Scholar] [CrossRef]

- Schultz, C.; Fenske, M.; Dagar, J.; Farias Basulto, G.A.; Zeiser, A.; Bartelt, A.; Junghans, C.; Schlatmann, R.; Unger, E.; Stegemann, B. Laser-based series interconnection of chalcopyrite und perovskite solar cells: Analysis of material modifications and implications for achieving small dead area widths. Mater. Today Proc. 2022, 53, 299–306. [Google Scholar] [CrossRef]

- Cacovich, S.; Vidon, G.; Degani, M.; Legrand, M.; Gouda, L.; Puel, J.-B.; Vaynzof, Y.; Guillemoles, J.-F.; Ory, D.; Grancini, G. Imaging and quantifying non-radiative losses at 23% efficient inverted perovskite solar cells interfaces. Nat. Commun. 2022, 13, 2868. [Google Scholar] [CrossRef]

- Wolter, M.H.; Carron, R.; Avancini, E.; Bissig, B.; Weiss, T.P.; Nishiwaki, S.; Feurer, T.; Buecheler, S.; Jackson, P.; Witte, W.; et al. How band tail recombination influences the open-circuit voltage of solar cells. Prog. Photovolt. Res. Appl. 2022, 30, 702–712. [Google Scholar] [CrossRef]

- Augarten, Y.; Trupke, T.; Lenio, M.; Bauer, J.; Weber, J.W.; Juhl, M.; Kasemann, M.; Breitenstein, O. Calculation of quantitative shunt values using photoluminescence imaging. Prog. Photovolt. Res. Appl. 2013, 21, 933–941. [Google Scholar] [CrossRef]

- El-Hajje, G.; Ory, D.; Paire, M.; Guillemoles, J.F.; Lombez, L. Contactless characterization of metastable defects in Cu(In,Ga)Se2 solar cells using time-resolved photoluminescence. Sol. Energy Mater. Sol. Cells 2016, 145, 462–467. [Google Scholar] [CrossRef]

- Ramírez Quiroz, C.O.; Dion-Bertrand, L.-I.; Brabec, C.J.; Müller, J.; Orgassa, K. Deciphering the Origins of P1-Induced Power Losses in Cu(Inx,Ga1–x)Se2 (CIGS) Modules Through Hyperspectral Luminescence. Engineering 2020, 6, 1395–1402. [Google Scholar] [CrossRef]

- Delamarre, A.; Lombez, L.; Guillemoles, J.-F. Contactless mapping of saturation currents of solar cells by photoluminescence. Appl. Phys. Lett. 2012, 100, 131108. [Google Scholar] [CrossRef]

- Kaiser, C.; Sandberg, O.J.; Zarrabi, N.; Li, W.; Meredith, P.; Armin, A. A universal Urbach rule for disordered organic semiconductors. Nat. Commun. 2021, 12, 3988. [Google Scholar] [CrossRef]

- Holovský, J.; Ridzoňová, K.; Peter Amalathas, A.; Conrad, B.; Sharma, R.K.; Chin, X.Y.; Bastola, E.; Bhandari, K.; Ellingson, R.J.; De Wolf, S. Below the Urbach Edge: Solar Cell Loss Analysis Based on Full External Quantum Efficiency Spectra. ACS Energy Lett. 2023, 8, 3221–3227. [Google Scholar] [CrossRef]

- Chantana, J.; Kawano, Y.; Nishimura, T.; Mavlonov, A.; Minemoto, T. Impact of Urbach energy on open-circuit voltage deficit of thin-film solar cells. Sol. Energy Mater. Sol. Cells 2020, 210, 110502. [Google Scholar] [CrossRef]

- Ugur, E.; Ledinský, M.; Allen, T.G.; Holovský, J.; Vlk, A.; De Wolf, S. Life on the Urbach Edge. J. Phys. Chem. Lett. 2022, 13, 7702–7711. [Google Scholar] [CrossRef]

- Ledinsky, M.; Schönfeldová, T.; Holovský, J.; Aydin, E.; Hájková, Z.; Landová, L.; Neyková, N.; Fejfar, A.; De Wolf, S. Temperature Dependence of the Urbach Energy in Lead Iodide Perovskites. J. Phys. Chem. Lett. 2019, 10, 1368–1373. [Google Scholar] [CrossRef]

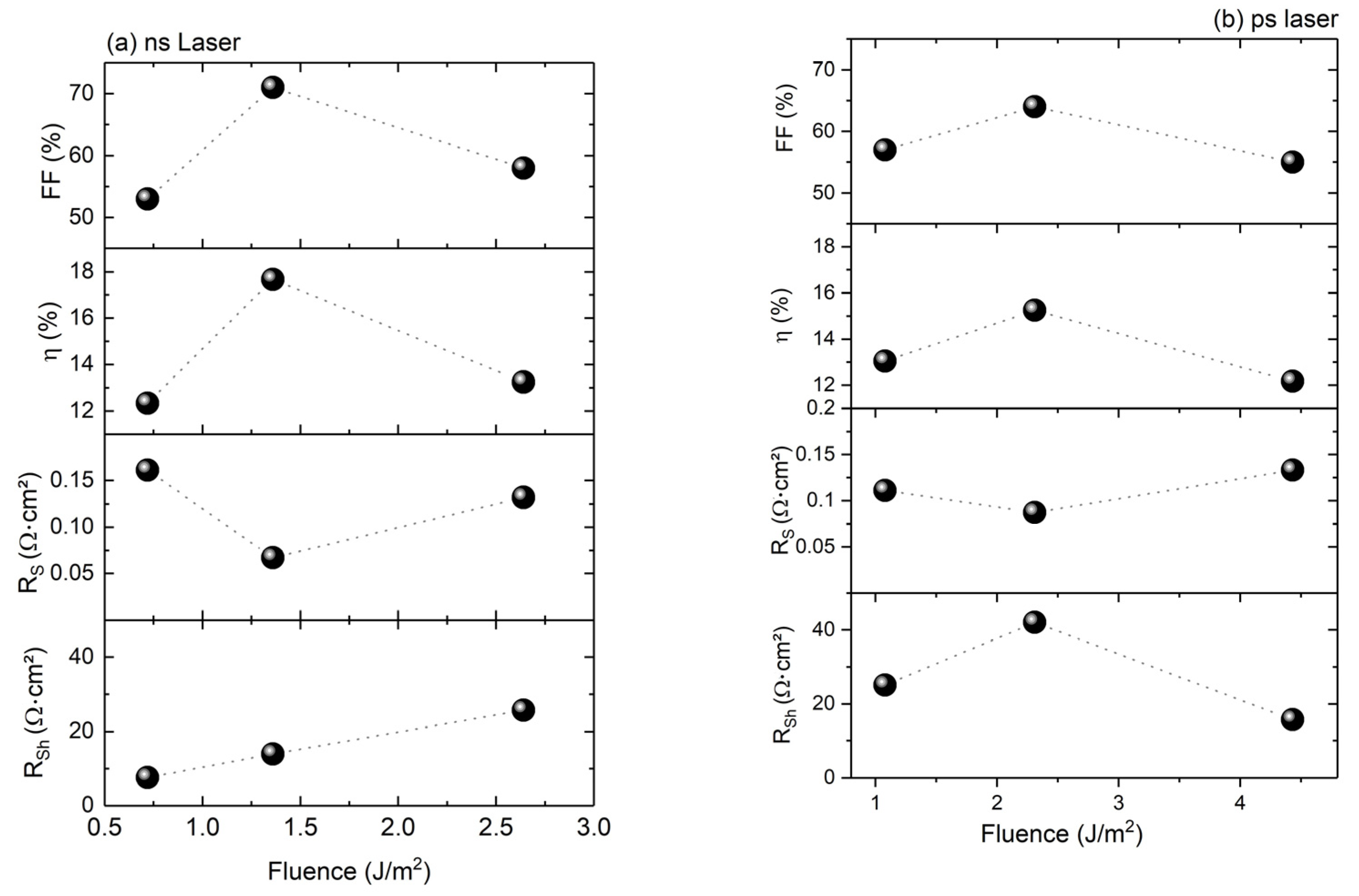

| ps Laser Patterning | ns Laser Patterning | ||

|---|---|---|---|

| Wavelength | 532 nm | ||

| Scribing velocity | 500 mm/s | ||

| Pulse repetition rate | 20 kHz | ||

| Pulse duration | 10 ps | 20 ns | |

| Beam diameter | 26.7 (±10%) µm | 28.1 (±10%) µm | |

| Fluences | |||

| - Optimal | Fopt | 2.31 J/m2 | 1.36 J/m2 |

| - Low (ca. half of the optimal value) | Flow | 1.08 J/m2 | 0.72 J/m2 |

| - High (ca. twice the optimal value) | Fhigh | 4.31 J/m2 | 2.64 J/m2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schultz, C.; Fenske, M.; Otto, N.; Dion-Bertrand, L.-I.; Gélinas, G.; Marcet, S.; Dagar, J.; Schlatmann, R.; Unger, E.; Stegemann, B. Loss Analysis of P3 Laser Patterning of Perovskite Solar Cells via Hyperspectral Photoluminescence Imaging. Solar 2025, 5, 13. https://doi.org/10.3390/solar5020013

Schultz C, Fenske M, Otto N, Dion-Bertrand L-I, Gélinas G, Marcet S, Dagar J, Schlatmann R, Unger E, Stegemann B. Loss Analysis of P3 Laser Patterning of Perovskite Solar Cells via Hyperspectral Photoluminescence Imaging. Solar. 2025; 5(2):13. https://doi.org/10.3390/solar5020013

Chicago/Turabian StyleSchultz, Christof, Markus Fenske, Nicolas Otto, Laura-Isabelle Dion-Bertrand, Guillaume Gélinas, Stéphane Marcet, Janardan Dagar, Rutger Schlatmann, Eva Unger, and Bert Stegemann. 2025. "Loss Analysis of P3 Laser Patterning of Perovskite Solar Cells via Hyperspectral Photoluminescence Imaging" Solar 5, no. 2: 13. https://doi.org/10.3390/solar5020013

APA StyleSchultz, C., Fenske, M., Otto, N., Dion-Bertrand, L.-I., Gélinas, G., Marcet, S., Dagar, J., Schlatmann, R., Unger, E., & Stegemann, B. (2025). Loss Analysis of P3 Laser Patterning of Perovskite Solar Cells via Hyperspectral Photoluminescence Imaging. Solar, 5(2), 13. https://doi.org/10.3390/solar5020013