Abstract

The beers’ lag time measured with the PBN (N-t-Butyl-α-phenylnitrone) spin trapping experiments coupled with EPR spectroscopy is related to their antioxidant capacity and shelf life. The effect on the lag time of the alcohol content of the beer (starting values, 9 and 13%) and PBN concentration (50 or 200 mM) was analyzed on three samples, a pilsner, a strong lager, and a blonde Ale heated at 60 °C to trigger the production of the 1-hydroxyethyl radical. The lag time was determined only for the strong lager beer, with the values depending on the experimental conditions, being higher when PBN had a lower concentration. The antioxidant activity of the three beers gave the following values: 0.9089 mL pilsner beer/mg DPPH, 0.8510 mL strong lager beer/mg DPPH, and 0.7184 mL blonde Ale beer/mg DPPH, indicating that the unsuccessful determination of the lag time was not due to stale beers. The EPR intensity of the PBN adduct after 150 min (I150) and the area under the curve (AUC) were also measured and related to the oxidative stability of beers. Further studies are needed to verify the influence of the heating temperature in samples that do not show a lag time at 60 °C.

1. Introduction

Electron paramagnetic resonance spectroscopy (EPR) has proved to be an effective technique to evaluate and predict the shelf life of beers. In the eighties, some authors started to use the nitrone spin trap PBN to stabilize the highly reactive and undetectable radicals produced during beer oxidation by converting them into relatively stable paramagnetic adducts, and observe their evolution over time through EPR [1,2]. The interest in the possibility to use the electron paramagnetic resonance method to improve beer flavor stability increased significantly [3,4,5,6,7] leading to the publication of a reference method by the American Society of Brewing Chemists [7,8]. This method involves the calculation of the “lag time” of radical generation during a forced oxidation test at a temperature of 60 °C. The lag time is correlated to stale flavors perceptions [3,4] and is delayed to different extents according to beer composition, and can thus be used to evaluate the endogenous antioxidant activity (EA) of beer.

Uchida and Ono [9] suggested that the lag time corresponds to the time needed to produce H2O2 through oxygen reduction by pro-oxidants as ferrous ions or Maillard products, time which can be increased by the presence of antioxidants (i.e., polyphenols) or sulfites, which may cause severe health effects in hyperallergic individuals [10]. Therefore, the lag time (or EA) reflects the overall composition of beer in terms of pro-oxidants and antioxidants. Beer flavor can be influenced by the presence and kind of precursors which can be oxidized by the generated OH radicals to produce stale flavor compounds [11].

Andersen and Skibsted [12] proved that the radical with the highest concentration is the 1-hydroxyethyl radical, suggesting that ethanol plays an important role in the oxidation of the beer.

An automated system for the lag time assay in beers was also proposed [6]. The measurement of the lag time has been later accompanied by other metrics, such as the intensity of the adduct signal after 120 (named “OH generation activity” by the authors) [13] or 150 min [14] of incubation at high temperatures (usually 60 °C), and the area under the curve (AUC), which allow us to apply the EPR method when the lag time is not easily detectable, i.e., in wort [11] or dark beers [15].

In all of these studies, the experimental conditions slightly differ in terms of ethanol and PBN concentration (usually 50 mM, see Table 1), and a common feature is the addition of it to the beer as a hydro-alcoholic solution. A consequence of this choice is a change in the sample alcohol content in different percentages according to the original alcohol content of the beer. Table 1 summarizes the experimental details of spin-trapping experiments with different beer samples in which the PBN and alcohol concentrations were varied.

Table 1.

Summary of the experimental conditions of spin trapping experiments with beer samples.

In the present work, three beer samples, differing in the alcohol content and style of production, were examined. Two PBN concentrations and three different final alcohol contents were employed in spin-trapping experiments with PBN to verify if there is an influence of these two variables in the determination of lag time. Since for two of the three beers, the determination of the lag time was impossible in all the experimental conditions, the antioxidant activity was also determined with the DPPH assay. The results reported here show that the impossibility of lag time determination in EPR spin-trapping experiments with PBN is not necessarily related to stale beer samples. Other parameters different from the lag time are necessary to characterize the resistance (or lack of resistance) of the beers to oxidation.

2. Materials and Methods

2.1. Chemicals

N-tert-Butyl-α-phenylnitrone (PBN), absolute ethanol and 2,2-Diphenyl-1-picrylhydrazyl (DPPH) were purchased from Sigma-Aldrich (Milan, Italy).

2.2. Beer Samples

Three commercially available beers differing by production style: a strong lager (Dortmunder Style Export) with 7.7% of alcohol, a lager (Bohemian Style Pilsner) with 4.4% of alcohol, and an Ale (Belgian Style Blonde) with 6.6% of alcohol, were analyzed. Beers were degassed by centrifugation (1210 g, at RT for 15 min, thrice), aliquoted and stored at −20 °C until analysis.

To evaluate the effect of PBN concentration on PBN adduct intensity, variable volumes of a PBN solution 2.5 mM in absolute ethanol were dried under a flux of nitrogen. The solid PBN was solubilized in 250 µL of decarbonated beer samples in order to have a final PBN concentration of 50 and 200 mM. PBN 200 mM was employed to be sure to trap a larger amount of eventually formed radical species.

The effect of ethanol was evaluated by adding absolute ethanol to obtain the final concentrations of 9 and 13%. The beer samples (100 µL) were transferred to capillary tubes and inserted in the EPR cavity heated at 60 ± 1 °C. EPR spectra were recorded for at least 150 min, acquiring spectra every 5 min. Three replicates were examined for each sample.

2.3. EPR Measurements

EPR measurements were carried out with a Bruker EMX spectrometer operating at the X-band (9.40 GHz) equipped with an HP 53150A frequency counter and with an ER 4111 VT variable temperature unit. The EPR instrument was set under the following conditions: modulation frequency 100 kHz; modulation amplitude 1.0 G; receiver gain 5 × 105, microwave power 20 mW, time constant and conversion time 163.84 ms. The lag time was determined by fitting the experimental points with a modified Boltzmann sigmoidal equation [20]: Y = Bottom + (Top − Bottom)/(1 + exp((V50 − x)/slope)) + rise ∗ x.

EPR spectra of the radicals were simulated with the software Bruker WINEPR SimFonia (version 1.26 (beta), Bruker Analytik GmbH: Berlin, Germany, 1997). According to Marques, Espinosa, Andrews and Foster [15], the intensity of the PBN adduct after 150 min of thermal treatment and the area under the curve intensity vs. time were also considered since it was not always possible to determine the lag time.

2.4. DPPH Assay

A solution of 1 mM of DPPH in absolute ethanol was prepared. A total of 100 μL of this solution were mixed with 150 μl of variably diluted beer samples and with 1.75 mL of absolute ethanol. The samples were kept in the dark at room temperature for 30 min and then the absorbance at 517 nm was measured with a Perkin Elmer Lambda 35 spectrophotometer. Since the samples became turbid, they were centrifuged at 1210 g for 5 min before the measurement. The % of inhibition was calculated as follows:

where ABSblank is the absorbance of a sample containing 150 μL of water instead of the diluted beer samples. A graph representing the % of inhibition as a function of the logarithm of the beer concentration in the samples was drawn and the experimental points were fitted with a straight-line model.

% of inhibition = (ABSblank − ABSsample)/ABSblank ∗ 100

2.5. Statistical Analysis

The curve fitting and the statistical analysis were carried out with GraphPad Prism 8 (GraphPad Software, San Diego, CA, USA). In the DPPH assay, the EC50 values and the corresponding 95% confidence intervals (CI 95%) were obtained with a straight-line modified model applied to a graph % inhibition as a function of the logarithm of the beer concentration. The lack of superimposition of the CI 95% of the EC50 values has been considered as a reliable criterion to distinguish statistically different values (p < 0.05) [21]. A one-way ANOVA was carried out to compare the lag time, the AUC and the I150 values obtained with varying experimental conditions for the same beer sample. The mean separation was calculated by the Holm-Sidak-test at p ≤ 0.05.

3. Results and Discussion

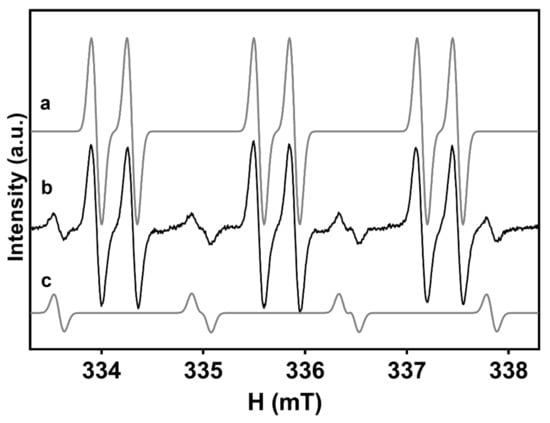

Figure 1 shows the EPR spectra of the radical species generated during the thermal treatment of beer samples at 60 °C. In the experimental spectrum (Figure 1b), two species can be detected; the predominant one in all the systems (Figure 1c) is the typical six lines PBN adduct of 1-hydroxyethyl radical with hyperfine coupling parameters aN = 16.0 G and aH = 3.5 G, g = 2.00625. Another species, present in minor amounts in all the examined samples, can be observed (Figure 1a) with aN = 14.5 G, aH = 13.5 G, g = 2.00635.

Figure 1.

Experimental ((b), black line) and simulated ((a,c), gray lines) spectra of the PBN–1-hydroxyethyl radical adduct (c) and tert-butyl aminoxyl radical (a) detected during the thermal treatment at 60 °C of beer samples. The experimental spectrum was obtained after 151 min of thermal treatment at 60 °C on a strong lager beer sample with PBN 200 mM and 13% of alcohol.

These two species have EPR parameters very similar to those previously reported during the thermal treatment at 90 °C of hydro-alcoholic myrtle extracts [22]. The slight differences depend on the concentration of ethanol in the samples: beers have 4.4–7.7% of alcohol, while for the myrtle hydro-alcoholic extracts it ranged from 60 to 90%. The four lines in Figure 1a can be interpreted as due to tert-butyl aminoxyl radical, which is thought to derive from the hydrolysis of PBN in acidic conditions. The hydrolysis of N-tert-butyl-α-phenylnitrone gives tert-butyl hydroxylamine, which is oxidized to the tert-butyl aminoxyl radical.

The experimental data representing the intensity of the PBN–1-hydroxyethyl radical adduct as a function of time were fitted not using the Boltzmann sigmoidal equation, previously proposed by Barr et al. [6] and employed during lag time determinations in beer samples, but with a modified Boltzmann sigmoidal equation. The original equation was modified to consider the slight but continuous growth of the PBN adduct intensity in the first stages of the reaction, before the inflection point, where a sudden increase in the PBN adduct intensity occurs. This modification has already been successfully proposed by Fadda, Molinu, Deiana and Sanna [20] when studying the oxidative stability of vegetable oils. With the original Boltzmann sigmoidal equation underestimated lag time values are obtained.

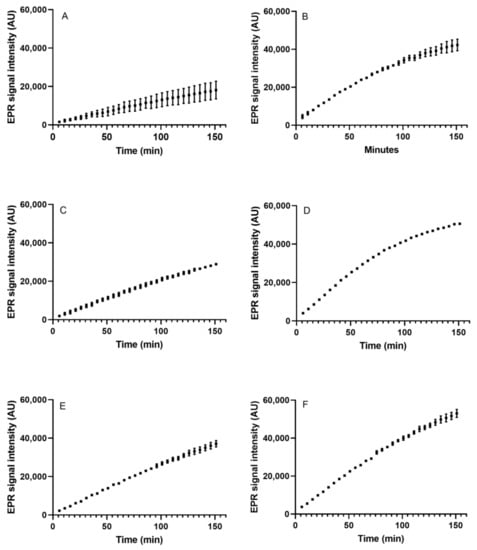

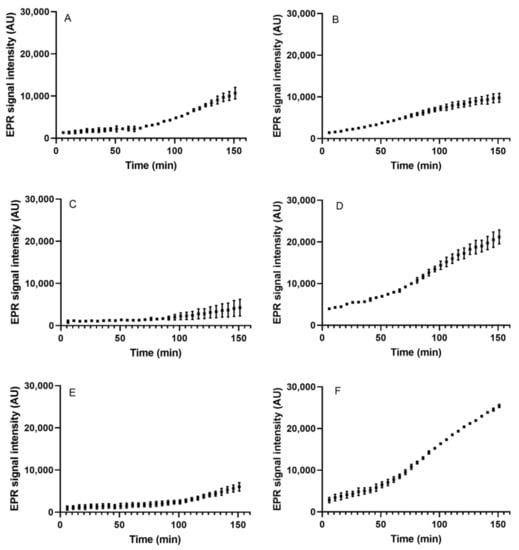

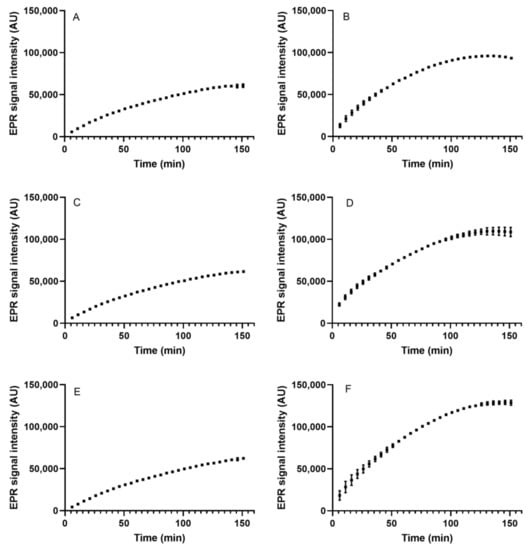

It is possible to observe in Table 2 and in Figure 2, Figure 3 and Figure 4 that a lag time value can be determined only for the strong lager beer samples; in all the experiments performed with pilsner beer and blonde Ale samples the curve representing the intensity of the PBN adduct versus time (Figure 2 and Figure 4) does not show any inflection point but a continuous increase in the intensity. A similar phenomenon has already been observed by Marques, Espinosa, Andrews and Foster [15] with stale lager, and with red and dark beer samples. However, these authors did not compare a stale lager beer with a fresh one, showing that the former sample did not have a measurable lag time, while the latter did. Therefore, the lack of a lag time in spin-trapping experiments with PBN is not proof of stale beer samples. Marques, Espinosa, Andrews and Foster [15] proposed other parameters to characterize the samples subjected to thermal treatment, such as the intensity at 150 min (I150) and the area under the curve (AUC) considering the same time interval. The AUC parameter takes into account the evolution of the intensity of the PBN adduct during the first 150 min of thermal treatment, while I150 represents the actual value of the intensity at the end of this time interval. Both are useful indicators of the capacity of beer samples to oppose the formation of radical species as a result of the heating at 60 °C, that is of their antioxidant capacity.

Table 2.

Lag time, Area Under the Curve (AUC) and Intensity at 150 min (I150) obtained for the beer samples examined in this work.

Figure 2.

Kinetic curves of the intensity of the PBN adduct as a function of time for pilsner beer samples subjected to thermal treatment at 60 °C: (A) PBN 50 mM, alcohol 4.4%; (B) PBN 200 mM, alcohol 4.4%; (C) PBN 50 mM, alcohol 9%; (D) PBN 200 mM, alcohol 9%; (E) PBN 50 mM, alcohol 13%; (F) PBN 200 mM, alcohol 13%. In the graphics, the means and the standard deviations of three replicates are reported.

Figure 3.

Kinetic curves of the intensity of the PBN adduct as a function of time for strong lager beer samples subjected to thermal treatment at 60 °C: (A) PBN 50 mM, alcohol 7.7%; (B) PBN 200 mM, alcohol 7.7%; (C) PBN 50 mM, alcohol 9%; (D) PBN 200 mM, alcohol 9%; (E) PBN 50 mM, alcohol 13%; (F) PBN 200 mM, alcohol 13%. In the graphics, the means and the standard deviations of three replicates are reported.

Figure 4.

Kinetic curves of the intensity of the PBN adduct as a function of time for blonde Ale beer samples subjected to thermal treatment at 60 °C: (A) PBN 50 mM, alcohol 6.6%; (B) PBN 200 mM, alcohol 6.6%; (C) PBN 50 mM, alcohol 9%; (D) PBN 200 mM, alcohol 9%; (E) PBN 50 mM, alcohol 13%; (F) PBN 200 mM, alcohol 13%. In the graphics, the means and the standard deviations of three replicates are reported.

When comparing the lag time values obtained for strong lager beer samples at PBN 50 and 200 mM, it is possible to observe that the values obtained when PBN is 50 mM are always higher, but significantly different values are obtained only when alcohol is 7.7 and 13%, not when it is 9%. The lag time can be related to the antioxidant capacity of beer, that is, the greater the lag time value, the larger the antioxidant capacity of beer. The increase in PBN concentration should not affect the lag time value because this variable should only concern the amount of trapped radicals. If larger amounts of radicals are trapped, these could not react with antioxidants which should be depleted more slowly. Therefore, longer lag time values should be expected after increasing the PBN concentration.

The AUC value represents a measure of the amount of 1-hydroxyethyl radicals present and trapped during the thermal treatment at 60 °C in the time interval of 150 min.

The AUC and the I150 are larger for strong lager beer samples when PBN is 200 mM and when alcohol content is 9 and 13%, indicating that a higher PBN concentration can trap a larger amount of 1-hydroxyethyl radicals.

In strong lager beer samples, when PBN is 200 mM, the AUC value increased with increasing the alcohol content from 7.7 to 13%. This confirmed that the higher the alcohol content, the larger the amount of 1-hydroxyethyl radicals produced and trapped by PBN. With PBN 50 mM the same trend was not followed, probably because the PBN concentration was too low and beer antioxidants significantly affect the result.

The same trend described for AUC can be observed for I150. In strong lager beer samples, when PBN is 200 mM, the intensity increases with increasing the alcohol content from 7.7 to 13%. On the contrary, the same trend was not observed when PBN was 50 mM.

For strong lager beer samples, when PBN was 50 mM, increasing the alcohol content from 7.7 to 9% there was a statistically significant decrease in the AUC value and then it remained almost constant; the same trend was shown by I150 values. This indicates that the 1-hydroxyethyl radicals are trapped by PBN or are quenched by antioxidants or by ethanol. The contribution of ethanol to the quenching is larger as its concentration increases. In these conditions, the antioxidants contribute for a longer time to the quenching and the samples show a larger lag time value. Since the 1-hydroxyethyl radical is an extremely reactive species, all these reactions have no activation energy and are controlled only by diffusion. Therefore, the experimental outcome is determined by the relative concentration of PBN, antioxidants and ethanol.

When the three beer samples are compared, the AUC and I150 values are in the order: strong lager < pilsner < blonde Ale, suggesting that the amount of trapped radicals increases in the opposite order. An important aspect that should be highlighted is that there is no relationship between the amount of trapped radicals and the original alcohol content of the beer samples, which increases in the order: pilsner (4.4%) < blonde Ale (6.6%) < strong lager (7.7%).

In pilsner beer samples, the AUC values increased with increasing the alcohol content when PBN was 50 mM, but when PBN is 200 mM, the increase was observed only when changing from alcohol 4.4 to 9%.

The I150 values, in the same beer samples, increased with increasing the alcohol content, both for PBN 50 and 200 mM, even if these differences are not always statistically significant

If these two concentrations are compared, while keeping constant the ethanol concentration, the intensity of samples with PBN 200 mM was always higher than those with 50 mM, confirming that higher PBN concentrations were able to trap larger amounts of 1-hydroxyethyl radicals. For the blonde Ale beer samples, when PBN is 50 mM, the AUC and the I150 values remained almost constant while increasing the alcohol content. On the contrary, when PBN was 200 mM, both the AUC and I150 increased with increasing the alcohol content from 6.6 to 13%.

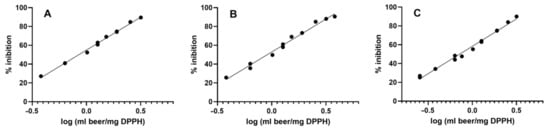

The unsuccessful determination of lag time in pilsner and blonde Ale beers could be connected with stale samples, even if the examined ones were used long before their expiration date. In order to clarify this aspect, the antioxidant activity of the two three beer samples was determined with the DPPH assay. In the DPPH assay, after determining the % of inhibition as described in the experimental section, a graphic was drawn reporting the % of inhibition as a function of the logarithm of the concentration of the beer samples. These graphics exhibit a linear trend (see Figure 5) and a linear fitting gives the EC50 value with the respective confidence interval (CI 95%). The values obtained for the three samples were: 0.9089 mL beer/mg DPPH for the pilsner, 0.8510 mL beer/mg DPPH for the strong lager, and 0.7184 mL beer/mg DPPH for the blond ale; the respective CI 95% values were 0.8424–0.9744 mL beer/mg DPPH for the pilsner, 0.8183–0.8830 mL beer/mg DPPH for the strong lager, and 0.6754–0.7621 mL beer/mg DPPH for the blonde Ale. These first two intervals were superimposed and therefore the difference in the two EC50 values cannot be considered as statistically significant [21]. On the contrary, the confidence interval for the blonde Ale was not superimposed with the other two and this beer can be considered more antioxidant. The need to convert the concentrations into their logarithm values was due to the flattening of the values of the % of inhibition at the higher beer concentrations. Similar phenomena have already been observed in the DPPH assay [23,24].

Figure 5.

Percentage of inhibition as a function of the logarithm of the concentration of: (A) strong lager and; (B) pilsner beer; and (C) blonde Ale samples in the DPPH assay.

The DPPH assay demonstrated that the two beer samples (pilsner and strong lager) had similar antioxidant activity since the two EC50 values were very similar and not statistically different. Therefore, the unsuccessful determination of the lag time for the pilsner and the blond Ale was not due to stale beers. It is also important to highlight that the blonde Ale beer despite having the highest antioxidant capacity, among the three beers, showed the highest intensity of the PBN-adducts with the larger values of AUC and I150.

The three beers were produced with different styles, so their composition was likely different both in terms of antioxidants and other substances, besides the alcohol content. It is not clear if there could be experimental conditions (lower PBN concentrations or lower temperature at which the experiments could be carried out) that make possible the lag time determination: further studies are needed in this regard.

Despite the comparable antioxidant activity of the three beers, measured with the DPPH assay, the Pilsner showed, in all the experimental conditions, a PBN adduct intensity higher than the strong lager. This could be explained by hypothesizing that the antioxidants of the three beers had different scavenging effectiveness against the radical species formed during the continuous heating at 60 °C. In fact, the other components of the two beers could have also a role in strengthening or weakening their antioxidant activity.

4. Conclusions

The results obtained in this work show that different lag time values are obtained when variable PBN or alcohol concentrations are employed in a strong lager beer with an alcohol content of 7.7%.

The pilsner and the blonde Ale beer samples examined in this work were not stale since they had an antioxidant capacity similar to or slightly larger than that of the strong lager beer; however, the lag time determination failed.

Changing the PBN and alcohol final concentrations affects also the other experimental parameters which have been used to estimate the resistance of beer samples to oxidation, AUC and I150. The intensity values of the EPR signals of the PBN adduct are in the order: blonde Ale > pilsner > strong lager, which give AUC and I150 values which decrease in the same order.

Further studies will be performed to evaluate the effect of heating temperature on the kinetic pattern and on the determination of the lag time in beer samples. Temperature is usually set at 60 °C but in some cases this value could be unsuitable. On vegetable oil samples subjected to thermal treatment the temperature strongly affects the shape of the kinetic curve representing the intensity of the PBN adduct versus time [20,25]. A similar dependence could be expected for beer samples, and spin trapping experiments performed at lower temperatures for beer samples which apparently do not show a measurable lag time at 60 °C are surely advisable in future studies. If the temperature at which spin trapping experiments are performed turn out to be a parameter affecting the lag time determination, a new experimental protocol might be proposed.

Author Contributions

Conceptualization, D.S., M.C.P. and A.F.; methodology, A.F. and D.S.; validation, D.S., M.C.P. and A.F.; formal analysis, D.S. and M.C.P.; investigation, M.C.P.; data curation, M.C.P.; writing—original draft preparation, D.S.; writing—review and editing, A.F. and M.C.P.; supervision, D.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kaneda, H.; Kano, Y.; Osawa, T.; Ramarathnam, N.; Kawakishi, S.; Kamada, K. Detection of Free Radicals in Beer Oxidation. J. Food Sci. 1988, 53, 885–888. [Google Scholar] [CrossRef]

- Kaneda, H.; Kano, Y.; Osawa, T.; Kawakishi, S.; Kamada, K. The Role of Free Radicals in Beer Oxidation. J. Am. Soc. Brew. Chem. 1989, 47, 49–53. [Google Scholar] [CrossRef]

- Uchida, M.; Ono, M. Improvement for Oxidative Flavor Stability of Beer—Role of OH-Radical in Beer Oxidation. J. Am. Soc. Brew. Chem. 1996, 54, 198–204. [Google Scholar] [CrossRef]

- Uchida, M.; Suga, S.; Ono, M. Improvement for Oxidative Flavor Stability of Beer—Rapid Prediction Method for Beer Flavor Stability by Electron Spin Resonance Spectroscopy. J. Am. Soc. Brew. Chem. 1996, 54, 205–211. [Google Scholar] [CrossRef]

- Takaoka, S.; Kondo, H.; Uchida, M.; Kawasaki, Y. Improvement of beer flavor stability by applying ESR method to industrial plant. Tech. Q. Master Brew. Assoc. Am. 1998, 35, 157–161. [Google Scholar]

- Barr, D.; Heiss, A.; Kamlowski, A.; Maier, D.; Erstling, J.; Bruker, H.; Gmbh, B. Shelf Life Analysis of Beer Using an Automated Lag-Time EPR System. Spectroscopy 2001, 16, 16–19. [Google Scholar]

- Barr, D.; Bradshaw, T.; Browers, M.; Hight, H.; Kibor, T.; Kunz, T.; Loyet, D.; Robertson, V.; Robinette, K.; Romanov, K.; et al. Method for Measure of Resistance of Oxidation in Beer by Electron Paramagnetic Resonance. J. Am. Soc. Brew. Chem. 2006, 64, 250–251. [Google Scholar] [CrossRef]

- Barr, D.; Baker, B.; Bosben, S.; Bradshaw, T.; Converse, E.; Daar, A.; Garner, R.; Giarratano, C.; Gonzalez, S.; Hight, H.; et al. Standard Method for Measurement of Oxidative Resistance of Beer by Electron Paramagnetic Resonance. J. Am. Soc. Brew. Chem. 2008, 66, 259–260. [Google Scholar] [CrossRef]

- Uchida, M.; Ono, M. Determination of Hydrogen Peroxide in Beer and its Role in Beer Oxidation. J. Am. Soc. Brew. Chem. 1999, 57, 145–150. [Google Scholar] [CrossRef]

- Randhawa, S.; Bahna, S.L. Hypersensitivity reactions to food additives. Curr. Opin. Allergy Clin. Immunol. 2009, 9, 278–283. [Google Scholar] [CrossRef]

- Uchida, M.; Ono, M. Technological Approach to Improve Beer Flavor Stability: Adjustments of Wort Aeration in Modern Fermentation Systems Using the Electron Spin Resonance Method. J. Am. Soc. Brew. Chem. 2000, 58, 30–37. [Google Scholar] [CrossRef]

- Andersen, M.L.; Skibsted, L.H. Electron Spin Resonance Spin Trapping Identification of Radicals Formed during Aerobic Forced Aging of Beer. J. Agric. Food Chem. 1998, 46, 1272–1275. [Google Scholar] [CrossRef]

- Uchida, M.; Ono, M. Technological Approach to Improve Beer Flavor Stability: Analysis of the Effect of Brewing Processes on Beer Flavor Stability by the Electron Spin Resonance Method. J. Am. Soc. Brew. Chem. 2000, 58, 8–13. [Google Scholar] [CrossRef]

- ASBC Methods of Analysis. Beer Method 46: Measurement of Oxidative Resistance in Beer by Electron Paramagnetic Resonance; American Society of Brewing Chemists: St. Paul, MN, USA, 2008. [Google Scholar]

- Marques, L.; Espinosa, M.H.; Andrews, W.; Foster, R.T. Advancing Flavor Stability Improvements in Different Beer Types Using Novel Electron Paramagnetic Resonance Area and Forced Beer Aging Methods. J. Am. Soc. Brew. Chem. 2017, 75, 35–40. [Google Scholar] [CrossRef]

- Andersen, M.L.; Outtrup, H.; Skibsted, L.H. Potential Antioxidants in Beer Assessed by ESR Spin Trapping. J. Agric. Food Chem. 2000, 48, 3106–3111. [Google Scholar] [CrossRef]

- Andersen, M.L.; Skibsted, L.H. Modification of the Levels of Polyphenols in Wort and Beer by Addition of Hexamethylenetetramine or Sulfite during Mashing. J. Agric. Food Chem. 2001, 49, 5232–5237. [Google Scholar] [CrossRef]

- Nøddekær, T.V.; Andersen, M.L. Effects of Maillard and Caramelization Products on Oxidative Reactions in Lager Beer. J. Am. Soc. Brew. Chem. 2007, 65, 15–20. [Google Scholar] [CrossRef]

- Schmallegger, M.; Gescheidt, G. Antioxidant Activity of Beer: An EPR Experiment for an Undergraduate Physical-Chemistry Laboratory. J. Chem. Educ. 2018, 95, 2013–2016. [Google Scholar] [CrossRef]

- Fadda, A.; Molinu, M.G.; Deiana, P.; Sanna, D. Electron Paramagnetic Resonance Spin Trapping of Sunflower and Olive Oils Subjected to Thermal Treatment: Optimization of Experimental and Fitting Parameters. ACS Food Sci. Technol. 2021, 1, 1294–1303. [Google Scholar] [CrossRef]

- Schenker, N.; Gentleman, J.F. On Judging the Significance of Differences by Examining the Overlap Between Confidence Intervals. Am. Stat. 2001, 55, 182–186. [Google Scholar] [CrossRef]

- Sanna, D.; Mulas, M.; Molinu, M.G.; Fadda, A. Oxidative stability of plant hydroalcoholic extracts assessed by EPR spin trapping under forced ageing conditions: A myrtle case study. Food Chem. 2019, 271, 753–761. [Google Scholar] [CrossRef] [PubMed]

- Locatelli, M.; Gindro, R.; Travaglia, F.; Coïsson, J.-D.; Rinaldi, M.; Arlorio, M. Study of the DPPH-scavenging activity: Development of a free software for the correct interpretation of data. Food Chem. 2009, 114, 889–897. [Google Scholar] [CrossRef]

- Chen, Z.; Bertin, R.; Froldi, G. EC50 estimation of antioxidant activity in DPPH assay using several statistical programs. Food Chem. 2013, 138, 414–420. [Google Scholar] [CrossRef] [PubMed]

- Vicente, L.; Deighton, N.; Glidewell, S.M.; Empis, J.A.; Goodman, B.A. In situ measurement of free radical formation during the thermal decomposition of grape seed oil using “spin trapping” and electron paramagnetic resonance spectroscopy. Z. Lebensm. Unters. Forsch. 1995, 200, 44–46. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).