Seaweed Cosmetics under the Spotlight of Sustainability

Abstract

1. Introduction

2. Materials and Methods

2.1. Goal and Scope

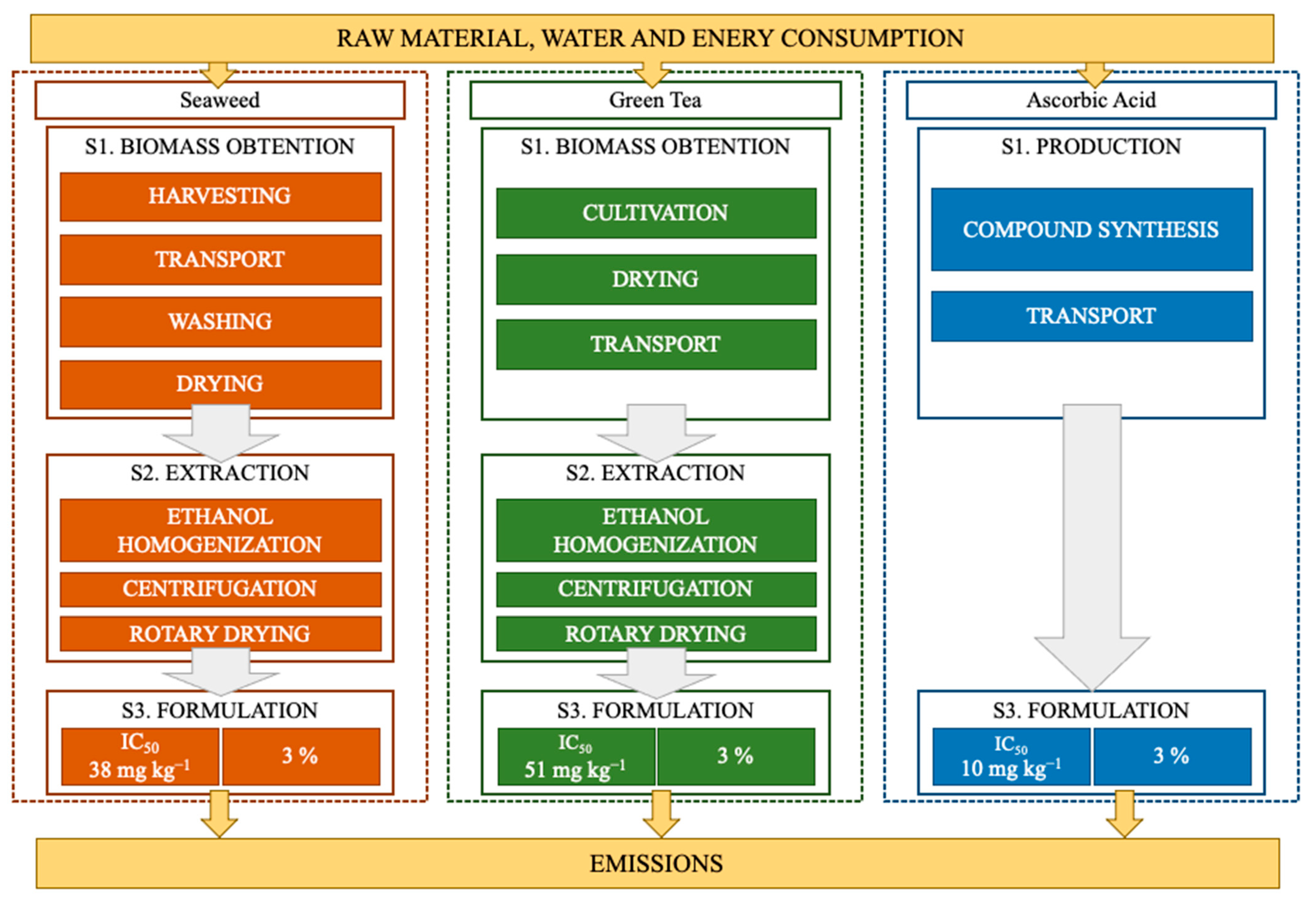

2.2. Process Description

2.3. Inventory Analysis

2.4. Sensitivity Analysis

3. Results and Discussion

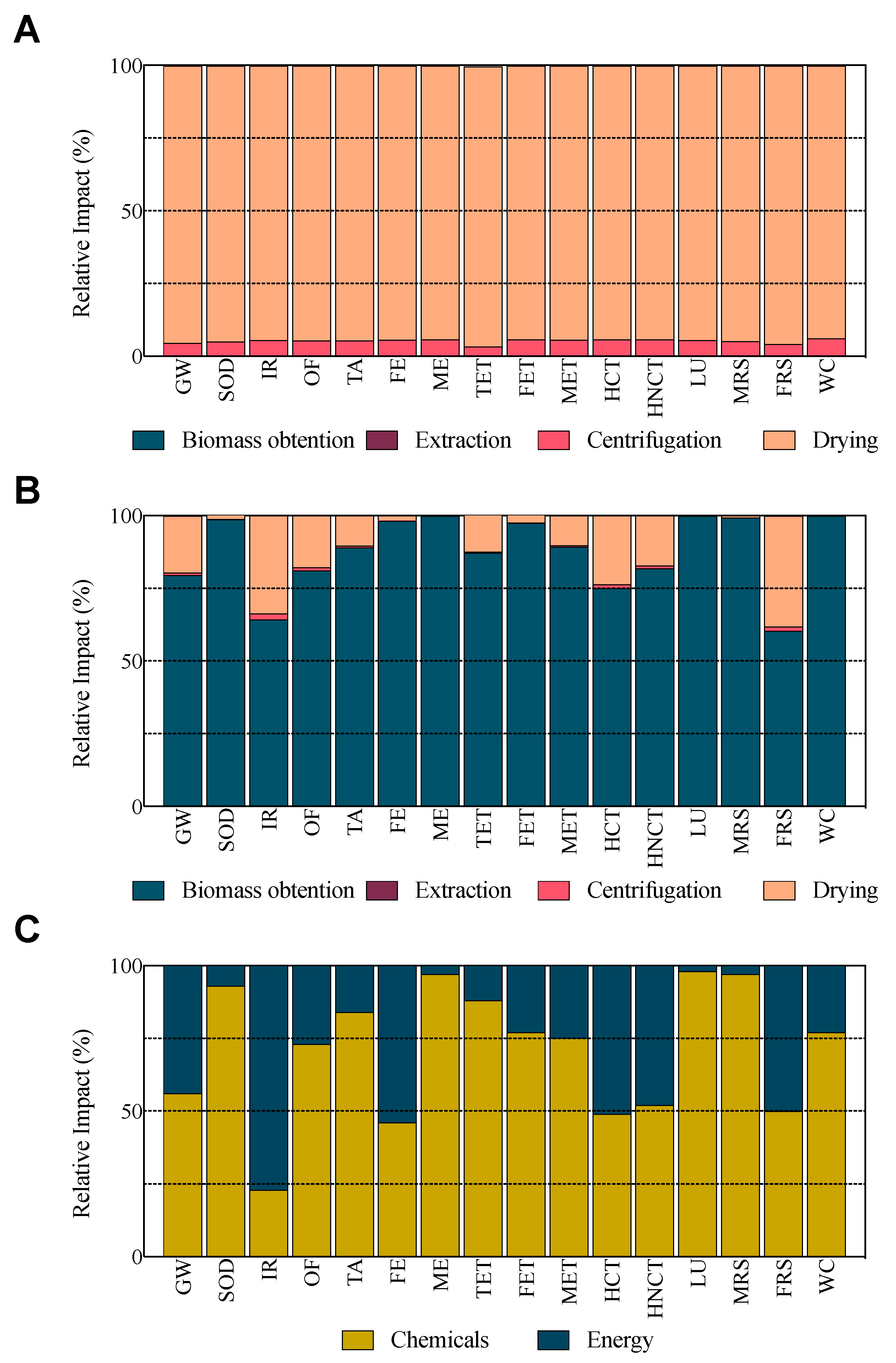

3.1. Evaluation of the Environmental Impact

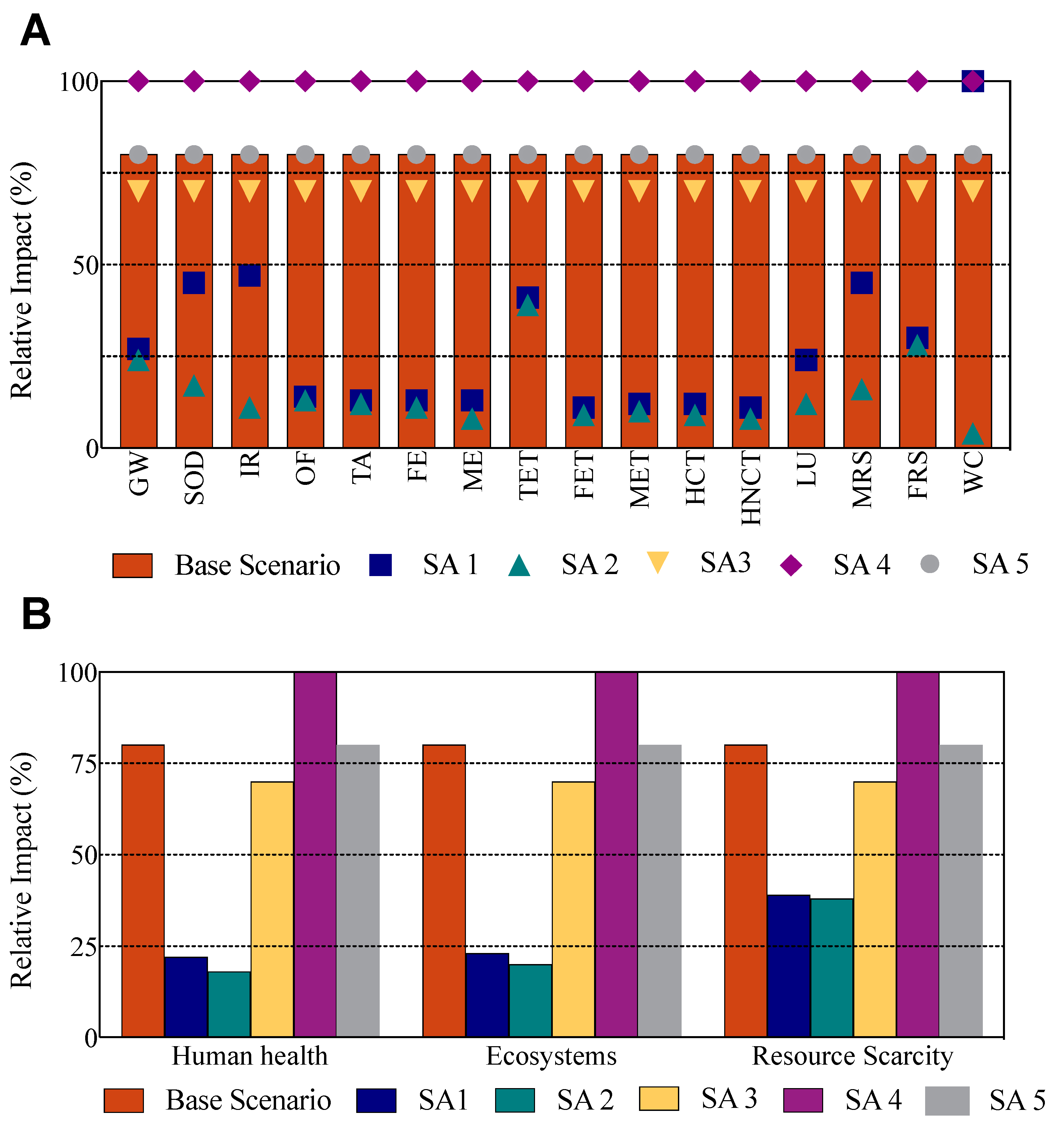

3.2. Sensitivity Analysis for Seaweed Extract Production

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chiu, S.P.; Chuang, L.W. Analysis on the Development Trend of Green Cosmetics. In Proceedings of the 2017 IEEE International Conference on Consumer Electronics-Taiwan, ICCE-TW, Taipei, Taiwan, 12–14 June 2017; pp. 291–292. [Google Scholar]

- Gianeti, M.D.; Maia Campos, P.M.B.G. Efficacy Evaluation of a Multifunctional Cosmetic Formulation: The Benefits of a Combination of Active Antioxidant Substances. Molecules 2014, 19, 18268–18282. [Google Scholar] [CrossRef] [PubMed]

- Ravetti, S.; Clemente, C.; Brignone, S.; Hergert, L.; Allemandi, D.; Palma, S. Ascorbic Acid in Skin Health. Cosmetics 2019, 6, 58. [Google Scholar] [CrossRef]

- Pappenberger, G.; Hohmann, H.P. Industrial Production of l-Ascorbic Acid (Vitamin C) and D-Isoascorbic Acid. Adv. Biochem. Eng. Biotechnol. 2013, 143, 143–188. [Google Scholar] [CrossRef]

- Kusumawati, I.; Indrayanto, G. Natural Antioxidants in Cosmetics. In Studies in Natural Products Chemistry; Elsevier: Amsterdam, The Netherlands, 2013; Volume 40. [Google Scholar]

- Koch, W.; Zagórska, J.; Marzec, Z.; Kukula-Koch, W. Applications of Tea (Camellia sinensis) and Its Active Constituents in Cosmetics. Molecules 2019, 24, 4277. [Google Scholar] [CrossRef] [PubMed]

- Gianeti, M.D.; Mercurio, D.G.; Maia Campos, P.M. The Use of Green Tea Extract in Cosmetic Formulations: Not Only an Antioxidant Active Ingredient. Dermatol. Ther. 2013, 26, 267–271. [Google Scholar] [CrossRef] [PubMed]

- Pagels, F.; Lopes, G.; Vasconcelos, V.; Guedes, A.C. Cosmetic Applications of Microalgal and Cyanobacterial Pigments. In Algal Genetic Resources Cosmeceuticals, Nutraceuticals, and Pharmaceuticals from Algae; Sangeetha, J., Thangadurai, D., Eds.; Apple Academic Press: Waretown, NJ, USA, 2022; Volume 1. [Google Scholar]

- Morais, T.; Cotas, J.; Pacheco, D.; Pereira, L. Seaweeds Compounds: An Ecosustainable Source of Cosmetic Ingredients? Cosmetics 2021, 8, 8. [Google Scholar] [CrossRef]

- Pereira, L. Seaweeds as Source of Bioactive Substances and Skin Care Therapy-Cosmeceuticals, Algotheraphy, and Thalassotherapy. Cosmetics 2018, 5, 68. [Google Scholar] [CrossRef]

- Zhang, Y.I.; Singh, S.; Bakshi, B.R. Accounting for Ecosystem Sewices in Life Cycle Assessment Part I: A Critical Review. Environ. Sci. Technol. 2010, 44, 2232–2242. [Google Scholar] [CrossRef] [PubMed]

- Murray, P.M.; Moane, S.; Collins, C.; Beletskaya, T.; Thomas, O.P.; Duarte, A.W.F.; Nobre, F.S.; Owoyemi, I.O.; Pagnocca, F.C.; Sette, L.D.; et al. Sustainable Production of Biologically Active Molecules of Marine Based Origin. New Biotechnol. 2013, 30, 839–850. [Google Scholar] [CrossRef] [PubMed]

- Guedes, A.C.; Amaro, H.M.; Gião, M.S.; Malcata, F.X. Optimization of ABTS Radical Cation Assay Specifically for Determination of Antioxidant Capacity of Intracellular Extracts of Microalgae and Cyanobacteria. Food Chem. 2013, 138, 638–643. [Google Scholar] [CrossRef] [PubMed]

- Gaspar, R.; Pereira, L.; Sousa-Pinto, I. The Seaweed Resources of Portugal. Bot. Mar. 2019, 62, 499–525. [Google Scholar] [CrossRef]

- Doepfert, M.; Castro, R. Techno-Economic Optimization of a 100% Renewable Energy System in 2050 for Countries with High Shares of Hydropower: The Case of Portugal. Renew. Energy 2021, 165, 491–503. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The Ecoinvent Database Version 3 (Part I): Overview and Methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Huijbregts, M.; Steinmann, Z.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.D.M.; Hollander, A.; Zijp, M.; van Zelm, R. ReCiPe 2016 v1. 1 a Harmonized Life Cycle Impact Assessment Method at Midpoint and Endpoint Level Report I: Characterization. RIVM Report 2016-0104a. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Mila, G.; Primasari, B.; Aziz, R. Application of Life Cycle Assessment (LCA) On Green Tea Product (Case Study in the X Company). IOP Conf. Ser. Mater. Sci. Eng. 2021, 1041, 012025. [Google Scholar] [CrossRef]

- Torres, M.D.; Kraan, S.; Domínguez, H. Seaweed Biorefinery. Rev. Environ. Sci. Biotechnol. 2019, 18, 335–388. [Google Scholar] [CrossRef]

- Vijay Anand, K.G.; Eswaran, K.; Ghosh, A. Life Cycle Impact Assessment of a Seaweed Product Obtained from Gracilaria edulis—A Potent Plant Biostimulant. J. Clean. Prod. 2018, 170, 1621–1627. [Google Scholar] [CrossRef]

- Kroposki, B.; Johnson, B.; Zhang, Y.; Gevorgian, V.; Denholm, P.; Hodge, B.M.; Hannegan, B. Achieving a 100% Renewable Grid: Operating Electric Power Systems with Extremely High Levels of Variable Renewable Energy. IEEE Power Energy Mag. 2017, 15, 61–73. [Google Scholar] [CrossRef]

- Ertem, F.C.; Neubauer, P.; Junne, S. Environmental Life Cycle Assessment of Biogas Production from Marine Macroalgal Feedstock for the Substitution of Energy Crops. J. Clean. Prod. 2017, 140, 977–985. [Google Scholar] [CrossRef]

- Álvarez-Viñas, M.; Flórez-Fernández, N.; Torres, M.D.; Domínguez, H. Successful Approaches for a Red Seaweed Biorefinery. Mar. Drugs 2019, 17, 620. [Google Scholar] [CrossRef] [PubMed]

| Inputs from Nature | |||||

| Seaweed | Green Tea | Ascorbic Acid | |||

| Seawater (cleaning): 340 g | - | - | |||

| Inputs from technosphere | |||||

| Seaweed | Green Tea | Ascorbic Acid | |||

| Biomass Obtention | Biomass Obtention | Production | |||

| Transport | 8.50 g km | Tea leaves a | 143 g | Ascorbic acid a | 30 g |

| Drying | 1.36 kJ | ||||

| Extraction b | Extraction b | ||||

| Ethanol c | 8.16 L | Ethanol c | 8.58 L | ||

| Homogenization | 0.36 kJ d | Homogenization | 0.38 kJ d | ||

| Homogenization | 7.40 Wh | Homogenization | 7.80 Wh | ||

| Centrifugation | 108.80 Wh | Centrifugation | 114.40 Wh | ||

| Drying | 201.96 kJ | Drying | 212.35 kJ | ||

| Output to technosphere | |||||

| Cosmetic product: 1 kg | |||||

| Impact 1 | Unit | 3% incorporation | IC50 | ||||

|---|---|---|---|---|---|---|---|

| Seaweed | Green Tea | Ascorbic Acid | Seaweed | Green Tea | Ascorbic Acid | ||

| Midpoint impacts | |||||||

| GW | kg CO2 eq | 6.81 × 10−2 | 3.48 × 10−1 | 9.60 × 10−2 | 8.63 × 10−5 | 5.92 × 10−4 | 3.20 × 10−5 |

| SOD | kg CFC11 eq | 2.34 × 10−8 | 1.82 × 10−6 | 1.97 × 10−7 | 2.96 × 10−11 | 3.09 × 10−9 | 6.56 × 10−11 |

| IR | kBq Co-60 eq | 3.38 × 10−3 | 9.92 × 10−3 | 6.88 × 10−3 | 4.29 × 10−6 | 1.69 × 10−5 | 2.29 × 10−6 |

| OF | kg NOx eq | 1.46 × 10−4 | 8.21 × 10−4 | 2.27 × 10−4 | 1.83 × 10−7 | 1.36 × 10−6 | 7.46 × 10−8 |

| TA | kg SO2 eq | 2.95 × 10−4 | 2.80 × 10−3 | 5.83 × 10−4 | 3.74 × 10−7 | 4.75 × 10−6 | 1.94 × 10−7 |

| FE | kg P eq | 1.93 × 10−5 | 1.14 × 10−3 | 3.43 × 10−5 | 2.45 × 10−8 | 1.93 × 10−6 | 1.14 × 10−8 |

| ME | kg N eq | 1.20 × 10−6 | 8.82 × 10−4 | 4.10 × 10−5 | 1.52 × 10−9 | 1.50 × 10−6 | 1.37 × 10−8 |

| TET | kg 1.4-DCB | 5.99 × 10−2 | 4.87 × 10−1 | 1.65 × 10−1 | 7.58 × 10−5 | 8.28 × 10−4 | 5.51 × 10−5 |

| FET | kg 1.4-DCB | 5.64 × 10−4 | 2.25 × 10−2 | 2.25 × 10−3 | 7.15 × 10−7 | 3.83 × 10−5 | 7.49 × 10−7 |

| MET | kg 1.4-DCB | 8.12 × 10−4 | 7.86 × 10−3 | 2.82 × 10−3 | 1.03 × 10−6 | 1.34 × 10−5 | 9.39 × 10−7 |

| HCT | kg 1.4-DCB | 1.21 × 10−3 | 5.06 × 10−3 | 2.20 × 10−3 | 1.53 × 10−6 | 8.61 × 10−6 | 7.34 × 10−7 |

| HNCT | kg 1.4-DCB | 3.15 × 10−2 | 1.82 × 10−1 | 5.11 × 10−2 | 3.99 × 10−5 | 3.09 × 10−4 | 1.70 × 10−5 |

| LU | m2a crop eq | 1.04 × 10−3 | 7.71 × 10−1 | 2.19 × 10−2 | 1.32 × 10−6 | 1.31 × 10−3 | 7.28 × 10−6 |

| MRS | kg Cu eq | 3.70 × 10−6 | 5.61 × 10−4 | 3.33 × 10−4 | 4.69 × 10−9 | 9.54 × 10−7 | 1.11 × 10−7 |

| FRS | kg oil eq | 2.03 × 10−2 | 5.35 × 10−2 | 2.60 × 10−2 | 2.57 × 10−5 | 9.09 × 10−5 | 8.68 × 10−6 |

| WC | m3 | 4.37 × 10−4 | 3.77 × 10−1 | 1.42 × 10−3 | 5.54 × 10−7 | 6.40 × 10−4 | 4.73 × 10−7 |

| Endpoint impacts | |||||||

| HH | DALY | 1.35 × 10−7 | 9.28 × 10−7 | 2.36 × 10−7 | 1.71 × 10−10 | 1.58 × 10−9 | 7.88 × 10−11 |

| ECO | Species yr−1 | 2.97 × 10−10 | 9.92 × 10−9 | 6.58 × 10−10 | 3.77 × 10−13 | 1.69 × 10−11 | 2.19 × 10−13 |

| RS | USD2013 | 5.35 × 10−3 | 1.51 × 10−2 | 7.08 × 10−3 | 6.78 × 10−6 | 2.57 × 10−5 | 2.36 × 10−6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pagels, F.; Arias, A.; Guerreiro, A.; Guedes, A.C.; Moreira, M.T. Seaweed Cosmetics under the Spotlight of Sustainability. Phycology 2022, 2, 374-383. https://doi.org/10.3390/phycology2040021

Pagels F, Arias A, Guerreiro A, Guedes AC, Moreira MT. Seaweed Cosmetics under the Spotlight of Sustainability. Phycology. 2022; 2(4):374-383. https://doi.org/10.3390/phycology2040021

Chicago/Turabian StylePagels, Fernando, Ana Arias, Adriana Guerreiro, A. Catarina Guedes, and Maria Teresa Moreira. 2022. "Seaweed Cosmetics under the Spotlight of Sustainability" Phycology 2, no. 4: 374-383. https://doi.org/10.3390/phycology2040021

APA StylePagels, F., Arias, A., Guerreiro, A., Guedes, A. C., & Moreira, M. T. (2022). Seaweed Cosmetics under the Spotlight of Sustainability. Phycology, 2(4), 374-383. https://doi.org/10.3390/phycology2040021