Definition

With the rise of individualism as a social trend and the wide use of the Internet and social media, today’s customers increasingly want to design and build unique products that fit their individual preferences and needs. Mass individualization is defined as a manufacturing paradigm that aims to produce individualized products cost-effectively. This paradigm differs from the previous paradigms in which the manufacturing company designed and manufactured the products, and the customer chose a product. In the mass individualization paradigm, the customers will be actively involved in product design, and the manufacturer will produce a unique product for each customer at a reasonable cost and of reliable quality. Due to the need for smooth communication and interactions between the buyer and the factory, new factories for individualized products will be located near potential buyers, which will have a significant impact on local economies. This entry explores the relationship between mass individualization and other emerging manufacturing paradigms and concepts in the Industry 4.0/5.0 era, and discusses how smart factories can improve manufacturing efficiency and facilitate the realization of the mass individualization paradigm.

1. Introduction

1.1. Evolution and Trends for Modern Manufacturing

The history of modern manufacturing has experienced several paradigms. These paradigms are driven by the needs of customers and society in different eras and are enabled by the scientific and technical developments in the corresponding era. The first manufacturing paradigm was the craft production paradigm, where products were made by skilled workers using general-purpose tools and relatively simple machines without employing a manufacturing system. These products were usually one of a kind. The invention of the moving assembly line by Henry Ford in Dearborn, Michigan, in 1913 is usually viewed as the start of the mass production paradigm, where identical products can be manufactured in the same factory at a high throughput and a low cost. The development of the Computer Numerical Control (CNC) machines in the mid-1970s and Flexible Manufacturing Systems (FMSs) in the 1980s enabled the mass customization paradigm, where multiple product variants could be manufactured using the same manufacturing system. However, the structure of FMSs could not be changed in response to the rapidly changing market demand that began in the last decade of the 20th century, and therefore the FMS is not appropriate for the auto powertrain industry (that produces engines and transmissions) or other large industries.

In response to production requirements such as a shorter product lifetime and frequently changing customer demands in a global market, the Reconfigurable Manufacturing System (RMS) was invented in 1998. Three pioneering US patents (reconfigurable manufacturing system, reconfigurable manufacturing machine, and reconfigurable inspection machine) legally define the RMS invention []. The RMS provides exactly the capacity and functionality needed, and exactly when needed. The RMS factory is a sustainable “live factory” that can be reconfigured rapidly and cost-effectively to quickly respond to changing market demands []. By combining the advantages of dedicated manufacturing lines and FMS, the RMS strikes a delicate balance between cost-effectiveness and the product variants that the manufacturing companies decide to offer. The customization of RMS is carried out around a family of products, or generations of products of the same product family.

In the recent decade, there has been an increasing trend for companies to shift focus from shareholders to customers []. According to an industry survey conducted in [], involving customers in product design will make end products more creative and innovative, and will improve the motivation and willingness of the customers to purchase the products. With the rise in individualism as a social trend, today’s customers have an increasing desire to design and build unique products that can reflect their individual preferences and special needs. With the wide use of the Internet and social media, it is easy for customers to come up with new design ideas []. With the increased popularity and affordability of additive manufacturing, many hobbyists today have a 3D printer at home and can print a product of their own design. However, this can only be carried out for simple products. The more professional and complex individualized products (e.g., the ones with high quality or functionality requirements, or those with more complicated structures) still need to be produced by professionals. To address such a need, a new type of factory is needed—mass individualization factories that can simultaneously produce a variety of individualized products at a reasonable cost. In mass individualization factories, the factory staff should be able to discuss and negotiate with customers on a personal level to propose better alternatives to the customers’ needs. Consequently, a new manufacturing paradigm—mass individualization—is emerging [].

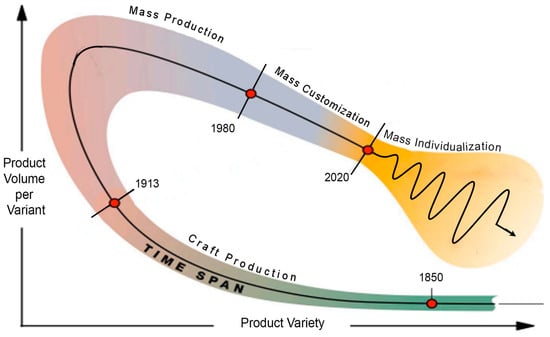

Mass individualization is defined as a manufacturing paradigm that aims to produce a large variety of “market-of-one” (or “one-of-a-kind”) products at a reasonable price that are affordable for the general public. From the “product variety vs. product volume per variant” relationship (as shown in Figure 1), one can see that the societal shift from craft production to mass production, mass customization, and now mass individualization is coming towards a full circle, but from market-of-one products for the wealthy to market-of-one products for an ordinary buyer. Also, compared to the products in the craft production paradigm that were made by skilled workers manually, mass-individualized products are usually much more complex and are made in factories with advanced manufacturing capabilities and automation technologies.

Figure 1.

Four manufacturing paradigms have been driven by changes in technology and customer needs (schematic diagram by Koren, adapted with permission from Ref. [], Copyright 2010 John Wiley & Sons, Inc., Hoboken, NJ, USA).

1.2. An Example: Interior Design of Automobiles

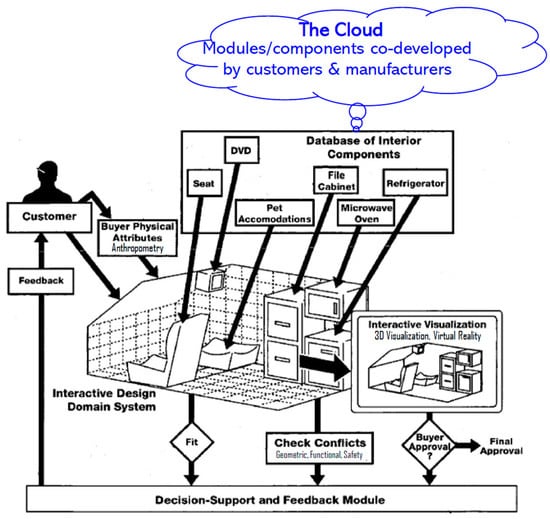

The idea of mass individualization originated from the consideration of the interior design of cars. The Ford Model T automobile that was introduced by Henry Ford in 1908 had seats for the driver and a passenger in the front, and a seat for passengers in the rear. In the last 115 years, the car engine, transmission, etc., have dramatically changed, but we still have the driver’s seat and a passenger’s seat in the front, and a bench for passengers in the back. Why not let car buyers design the interior of their new cars? A driver who takes his/her two children to school needs a different car interior than a person who drives 100 km every day to work. Therefore, on 5 January 2006, we applied for the patent “Method and Apparatus for Reconfigurable Vehicle Interior” []. Figure 2 is adapted from this patent application, and it shows how the buyer could use a database for designing a unique car interior prior to purchasing an automobile. (The patent has 11 drawings to convey this new interior design.)

Figure 2.

Example of car interior design (adapted from Ref. []).

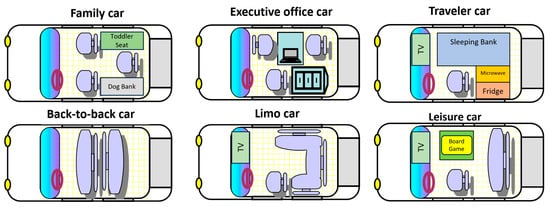

The user views an empty space version of the car interior and populates it with interior components at will through drag and drop operations. A variety of possible interior components can be selected, with several options for each such component. With such an interface, the user can design various interior configurations, as demonstrated in Figure 3.

Figure 3.

Several options for car interior design (adapted with permission from Ref. [], copyright 2022 Taylor & Francis, Oxfordshire, UK).

Apparently, the car interior assembly factory will need to create the new role of Design Advisor for brainstorming ideas and opportunities with the car buyers. To compromise between the buyer’s wishes and production limitations, the factory Design Advisor should have both production engineering knowledge and social negotiations skills []. Furthermore, if the buyer’s needs change in the future, or when the buyer sells the car, there is the option to change the interior of the car. Today, some of these features are becoming a reality in the auto industry. For example, the XPeng P5 model has an optional full-width projection screen, rear center console mini-fridge, and 220 V third-party appliances [].

1.3. Types of Mass-Individualized Products

There are two types of individualized products that differ in their product architecture and their main manufacturing processes.

For the first type of product, the individualization comes from their manufacturing operations (e.g., additive manufacturing, CNC machining, die-based manufacturing []) within the manufacturing system. These can be standalone products that are manufactured by a single machine (such as a bone implant or a 3D accessory toy produced by a 3D printer), or more complex products that need additional operations using other machines in the manufacturing system (e.g., adding metal fittings to hold the product together, quality inspection []).

The second type of product is built on an open-architecture platform with modular components that can be added, such as the car interior example mentioned above, where the individualization comes from its modular design and assembly. Another example is the production of a modular hospital bed, in which modules that fit the patient’s situation and illness may be integrated into the hospital bed. The hardware modules may be manufactured by various companies. Big manufacturing companies can design and build the open-architecture platform with defined mechanical, electronic, and information interfaces, while the modules may be designed and produced by small companies (and even by the customers themselves). The final assembly can either be carried out by the customers themselves (if there is no safety concern) or by an assembly factory (for more complex products or products that need more professional operations). These types of products are called open-architecture products (OAPs) []. The software equivalent to open-architecture products is the smartphone, where big companies develop the mobile operation system (e.g., iOS, Android) that enables the integration of various apps (i.e., software modules) developed by different companies.

1.4. Study Scope

Mass individualization is centered around buyers and can improve their experience. It can create new jobs for the design and manufacture of individualized products and for providing services (e.g., maintenance, product upgrades) during the entire life cycle of new individualized products []. New factories (e.g., a car interior assembly factory) will be built near potential customers to facilitate smooth and timely communication and interaction between the customers and manufacturers, which will benefit local economies as well as innovation ecosystems [].

Mass individualization factories have already started to appear in industries such as apparel [], furniture [], and electronics (e.g., printed circuit boards) []. To facilitate the realization of mass individualization and make it applicable for more products, there is a need for further technological developments in their design and manufacture. Due to recent technological advancements, especially developments in automation and information and communication technology (ICT), many new manufacturing paradigms and concepts are emerging. Terms such as Industry 4.0 and Industry 5.0 are introduced to demonstrate how such new technologies can revolutionize the manufacturing industries to meet the needs of modern society.

This paper explores the relationship between mass individualization and other emerging manufacturing paradigms and concepts in the Industry 4.0/5.0 era with regard to their goals and focus. By discussing the architecture of manufacturing systems for mass individualization and how characteristics and techniques in smart factories can improve the cost-effectiveness of individualized production, this paper contributes to the identification of key enabling technologies that facilitate the realization of mass individualization.

2. Relationship between Mass Individualization and Other Manufacturing Paradigms in Industry 4.0/5.0 Era

Next, we discuss the relationship between mass individualization and several emerging manufacturing paradigms/concepts in the Industry 4.0/5.0 era.

2.1. Mass Individualization and Industry 4.0

Industry 4.0 is mainly characterized by cyber–physical production systems, which are enabled by the development of information and communication technologies and manufacturing technologies []. Some of the key enabling technologies for Industry 4.0 include the Internet of Things (IoT), cloud computing, data analytics, artificial intelligence (AI), and machine learning. Esmaeilian, Behdad, and Wang [] reviewed the emerging manufacturing paradigms that are triggered by data analytics techniques. Smart manufacturing is defined by the National Institute of Standards and Technology (NIST) as a “fully integrated, collaborative manufacturing system that responds in real time to meet changing demands and conditions in the factory, in the supply network and in customer needs” []. Smart manufacturing integrates the manufacturing assets of today and tomorrow with sensors, computing platforms, communication technology, data-intensive modeling, control, simulation, and predictive engineering by using techniques in cyber-physical systems (CPSs), IoT (and Everything), cloud computing, service-oriented computing, AI, and data science []. Note that a similar term related to smart manufacturing is intelligent manufacturing. Jardim-Goncalves, Romero, and Grilo [] reviewed intelligent manufacturing by addressing areas such as manufacturing system frameworks and modeling, CPSs, semantic technologies and interoperability, virtual organizations, and the sterilization of manufacturing systems. Wang et al. [] conducted a comparative literature review between smart manufacturing and intelligent manufacturing in terms of their focus, components, core concepts, and related concepts, etc. One of the key features that distinguish smart manufacturing from intelligent manufacturing is that smart manufacturing is usually data-driven []. Cloud manufacturing is a service-oriented manufacturing paradigm based on cloud computing and aims to provide a platform that aggregates distributed resources from different manufacturers, and the customers pay for the manufacturing as a service []. Zhong et al. [] compared the characteristics, technologies, research directions, and applications of intelligent manufacturing, IoT-enabled manufacturing, and cloud manufacturing from different perspectives. Liu and Xu [] conducted a comparative analysis between Industry 4.0 and cloud manufacturing and illustrated that both Industry 4.0 and cloud manufacturing converge to satisfy customers’ increasingly individualized requirements.

2.2. Mass Individualization and Industry 5.0

Recently, the concept of Industry 5.0 has emerged in the literature. Industry 5.0 refers to the future of industry that moves towards human-centric, sustainable, and resilient manufacturing []. While Industry 4.0 is technology-driven with a focus on using digitalization and AI-driven technologies to improve production efficiency and flexibility, Industry 5.0 is value-driven and emphasizes societal needs and personalized value creation [].

One of the key characteristics of Industry 5.0 is its human-centricity. Humans can either be human users (i.e., customers) or human operators (i.e., manufacturers). It is apparent that an individualized product that fits the unique needs of a customer provides personalized value to that customer. From a product design perspective, the concept of the Metaverse within Industry 5.0 enables individuals and organizations to collaborate using a human-centric approach to create personalized value []. In terms of manufacturing, Industry 5.0 sets the worker pillar in the center of the production system by utilizing human creativity. Humans are an integral part of a manufacturing system where they collaborate with other resources (e.g., machines and robots). The presence of humans in the systems brings the system more fault-tolerant capabilities []. This is very important in a complex manufacturing environment such as mass-individualized production.

In addition, Industry 5.0 addresses the environmental and societal needs and challenges related to emerging manufacturing paradigms/concepts such as sustainable manufacturing and social manufacturing.

The goal of sustainable manufacturing is to simultaneously consider the impacts of industrial activities on the economy, environment, and society []. The 6R (reduce, reuse, recycle, recover, redesign, and remanufacturing)-based sustainable manufacturing practices can achieve sustainability in systems, processes, and products []. Among the 6R-based principles, “reduce” is typically considered a key principle of lean manufacturing, which is focused on improving the manufacturing productivity and reducing waste []. Although the main focuses of sustainable manufacturing and mass individualization seem different (i.e., environment friendly for the former and unique products for the latter), these two paradigms share some common characteristics and requirements. Both require accounting for the manufacturing systems and products during their entire life cycles. Designing a manufacturing system that is scalable and reconfigurable increases the lifecycle of the system, thus making it more sustainable. Koren et al. [] studied the relationship between reconfigurability and sustainability. Boër et al. [] pointed out that mass individualization is a suitable approach to achieve sustainability.

Social manufacturing is a paradigm that allows customers to co-create fully customized and personalized products and individualized services by sharing and manufacturing resources and information with others []. It uses social IoT and cyber–physical–social system approaches by integrating social aspects into IoT and CPS []. Zhou et al. [] identified the conditions and situations where social manufacturing implementation is suitable, and reviewed how the techniques in social manufacturing can realize mass individualization. Social manufacturing and mass individualization are closely related, with the former considered a suitable approach to realize the latter [].

2.3. Summary

In the discussion above, several manufacturing paradigms and concepts are defined by their goals/objectives (e.g., sustainable manufacturing, smart manufacturing) or by their enabling technologies or characteristics (e.g., cloud manufacturing, digital manufacturing). The technology-driven Industry 4.0 and value-driven Industry 5.0 coexist with each other, and they emphasize different aspects of the “Techno-Social System”, with technology as the enabling tool and social needs as the goal []. Mass individualization emphasizes the goal of simultaneously achieving cost-effectiveness (reflected in “mass”) and personal value creation (reflected in “individualization”). Smart manufacturing emphasizes the use of Industry 4.0 technologies (especially data-driven methods) to improve the smartness and intelligence of manufacturing systems so that smart decisions can be made in the system. These Industry 4.0 techniques have the potential to transfer the manufacturing paradigm from mass customization to mass individualization [].

3. Product Design for Mass Individualization

The involvement of customers in their product design is the primary factor that differentiates mass individualization from its immediate previous paradigm, mass customization. In the mass customization era, the manufacturer defines and designs all products and all variants. Customers choose one option from the given options, but do not participate in the product design process. One common strategy for building mass-customized products is through assembly (e.g., Dell’s assemble-to-order model for personal computers and laptops). However, in the mass individualization paradigm, unique products are co-designed by both the customer and the manufacturer.

Although it is easier for today’s customers to come up with unique product ideas, the feasibility of such ideas should be verified by the design and manufacturing engineers using their domain knowledge, considering multiple factors such as materials, cost, manufacturability, sustainability, and safety. The factory engineers should precisely understand individual customer’s needs and effectively transform them to the functional requirements, product features, and design parameters, and then establish the manufacturing plan.

Multiple design iterations might be needed for a design that accurately represents the customer’s needs, which might be time-consuming and complicated (especially from the customer’s perspective). The engineers who communicate with the buyers should have both production engineering knowledge and social negotiations skills. The interactive design process should be adaptive according to the individual customer’s willingness and the expertise of the design. Modern visualization techniques such as virtual reality and augmented reality can be embedded into the design platforms to demonstrate the design results to customers to ensure that the design meets their expectations.

To reduce the time and complexity involved in the product development and to efficiently engage customers, new design frameworks, methods, platforms, and toolkits should be developed. For example, Tseng, Jiao, and Wang [] formulated a product ecosystem based on a design platform and active customer participation, encompassing customer, functional, physical, process, and logistics domains. Tao et al. [] proposed a digital-twin-driven design framework to better engage customers by presenting them with both physical and virtual products. Zheng et al. [] developed a user-experience-based product development framework to improve user experience and satisfaction. Zhou, Ji, and Jiao [] reviewed affective and cognitive design methods that address individual customer’s latent needs.

Regarding open-architecture products, methods have been developed to optimize their design. For example, Barry, Wang, and Hu [] developed a product architecting method that integrates personalized/individualized modules, customized modules, and standardized modules. Tan et al. [] developed a design framework based on assembly architecture and cyber physical systems and used it for the design of an individualized bike. Cheng, Peng, and Gu [] proposed an optimization method for the adaptable design of open-architecture products. Zheng et al. [] developed a conceptual framework for a personalized product configuration system based on an adaptable open-architecture platform. Tan et al. [] proposed an optimization method for determining an open product architecture design that incorporates individual customer preferences.

4. Smart Factories for Mass-Individualized Production

4.1. Manufacturing Systems for Individualized Products

From a manufacturing perspective, factories with the machines and equipment that can perform the necessary operations to produce individualized products should be built. The core of a factory is its manufacturing system. To improve the cost-effectiveness means to improve the utilization of machines in the system and reduce their idle time. Therefore, new system architectures that can simultaneously manufacture multiple different products should be developed. For example, Gu and Koren [] proposed a system architecture for mass individualization that is enabled by flexible routing. Zhang, Ming, and Bao [] developed a flexible manufacturing system model based on a multi-module platform, multi-virtual unit, and multi-production line. Lanz and Tukko [] discussed other examples/concepts of factories for individualized production, such as micro- and desktop factories as well as a competitive sustainable manufacturing hotel (i.e., a platform targeted toward small and midsize enterprises collaborating under the same factory roof or in the same area).

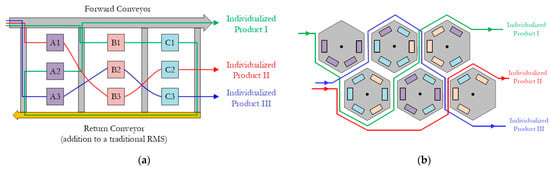

Since products are unique, these manufacturing machines and systems need to be frequently programmed to meet the customer’s requirements. Reconfigurability is a desired characteristic that can not only provide the required flexibility, but also enhance sustainability, and thus should be embedded into manufacturing systems for mass individualization. Reconfigurable manufacturing systems can be adapted into manufacturing systems for mass individualization by adding various routings for the manufactured products to travel flexibly between machines, so a large number of product variants can be manufactured simultaneously. Note that RMSs are typically easily reconfigurable and scalable (i.e., additional production resources can be added quickly and cost-effectively) []. Two system architectures are described below to illustrate the idea of using RMSs for the manufacturing and assembly of individualized products:

- RMS architecture with a return conveyor

Traditional RMSs consist of multiple stages, with each stage composed of multiple identical machines and an in-stage gantry that transports parts to the parallel machines in the same stage. In the US auto powertrain industry, a forward conveyor or a gantry is built to transport parts between stages (from upstream to downstream). In this case, the transport of products is unidirectional. We can make such transport bi-directional by adding a return conveyor (or gantry) to the existing system, as illustrated in Figure 4a, which shows that three different individualized products are simultaneously produced in the system by going through different sequences of machines/operations (blocks with different colors represent different types of machines, e.g., CNC milling or drilling, 3D printer, assembly station). Such a revised RMS architecture with a return conveyor was proposed in []. With both the forward and return conveyors, a product can be transported from one machine to any other machine in the system, thereby significantly improving the system flexibility.

Figure 4.

Modified RMS architectures for mass individualization systems: (a) RMS with a return conveyor (adapted with permission from Ref. [], copyright 2022 Taylor & Francis); (b) integrated RMS with honeycomb structure (adapted from Ref. []).

- Integrated RMS with honeycomb architecture

Another system that enables flexible routing and the simultaneous production of multiple product variants is shown in Figure 4b, where there are multiple manufacturing cells that have a hexagonal shape and, thus, the manufacturing system has a honeycomb structure []. Each cell has up to six machines. Different cells are connected by conveyors/gantries, such that the product can move from any cell to any other cell. Such systems are easily scalable by adding additional cells, or additional machines to a cell.

One of the main challenges for manufacturing individualized products lies in the operations of the manufacturing systems. Advanced operational algorithms need to be developed by jointly considering a lot of information (e.g., system reconfiguration, manufacturing process information of all individualized products in the system, and the status of all machines in the system). The scheduling of customized products in flexible job shops/reconfigurable manufacturing systems is already a significantly challenging problem []. Several additional challenges are raised in the operations of mass individualization systems:

- Although embedding flexible routings improves system flexibility, it will make the traffic in the system significantly complicated, thereby increasing the difficulty in terms of control and coordination. In addition, there are multiple types of operational decisions to make, such as scheduling, reconfiguration, and maintenance, and these decisions should be made simultaneously, which makes operational decision-making extremely challenging.

- Since mass-individualized products are unique, the operations that are performed on a new product may not be the same for any of the old products, so uncertainties may exist in parameter estimations. The incorporation of such parameter uncertainties into the decision-making process is essential for cost-effectively manufacturing mass-individualized products.

- Due to the dynamic conditions (i.e., different configurations, different scenarios of the up/down states of the machines) of the manufacturing systems as well as unpredictable events (e.g., rush orders, programming errors, random failures of machines/material handling systems), real-time data collection, analysis, and decision-making are usually needed. Therefore, the optimization algorithms should have high efficiency, which is challenging, especially when coupled with the complexity of the system.

- Because of the complexity of the tasks, humans will play a significant role in such systems and are required to responsively change system capabilities by reprogramming machines and adjusting tools. Modeling human behavior and efficiency is difficult, as they may change over time due to learning (e.g., a worker will be more and more familiar with the process over time) and are affected by environmental and emotional factors.

Next, we will review the concept of smart factories and discuss how smart factories can address the challenges of manufacturing individualized products.

4.2. Concept of Smart Factories

The smart factory represents a factory-of-things and is one of the key initiatives associated with Industry 4.0 []. While a generally accepted definition of the term “smart factory” is still lacking, the name itself indicates that it is closely related to smart manufacturing. Strozzi et al. [] analyzed the key words of 462 papers on the concept of the “smart factory” using a Systematic Literature Network Analysis (SLNA) approach, and found that these key words can be classified into the following five clusters: (1) real-time, wireless manufacturing, and agent, (2) Radio-Frequency Identification (RFID), intelligent manufacturing system, and real-time manufacturing, (3) intelligent manufacturing, ontology, and multi-agent, (4) smart manufacturing, cloud computing, cloud manufacturing, and sustainability, and (5) optimization, flexible manufacturing, scheduling, and simulation. Osterrieder, Budde, and Friedli [] conducted a systematic literature review and analysis of 106 papers on “smart factories” and found that these publications can be categorized into eight perspectives: (1) decision making, (2) cyber–physical systems, (3) data handling, (4) IT infrastructure, (5) digital transformation, (6) human–machine interaction, (7) IoT, and (8) cloud manufacturing and services. There are also reviews focused on the roles of intelligent sensors and IoT in smart factories [,]. These key words and themes demonstrate that the characteristics of smart factories are essentially the enabling technologies for smart manufacturing. The integration of these technologies and principles forms the foundation for smart factories.

A smart factory contains the necessary hardware, software, and interface that realize the “connectedness” among various levels of elements (e.g., sensors, barcodes, RFIDs, machine tools, robots, material handling systems) so that they can communicate with each other and make intelligent control actions for each other. It should also be equipped with IT infrastructures for data collection and storage, and for effective knowledge integration []. A smart factory itself can be regarded as a complex smart product system on the shop floor, as it possesses some key characteristics of a smart product, such as intelligence, connectedness, service integration, and being data-driven []. For those who cannot fully implement smart factories due to financial and technical limitations, some affordable choices can be adopted. For example, Jung et al. [] discussed the essentials for developing “appropriate smart factories” for small and medium-sized enterprises (SMEs). Park et al. [] developed a digital-twin-based cyber physical production system architectural framework and demonstrated it in a “micro smart factory”.

4.3. Smart Factories for Mass Individualization

The characteristics and techniques of smart factories can contribute to manufacturing individualized products in the following ways:

- Process simulation and planning for individualized production

In an individualized manufacturing environment, each product is unique, and so is its corresponding manufacturing process. The digital manufacturing techniques embedded in smart factories (e.g., digital twins) can be used to simulate the individualized manufacturing process and support the ramp-up phases []. The digital twin used for process simulation can also be integrated with the digital design platform (as mentioned in Section 3) for visualization purposes, which can engage customers and help them understand how their design can be manufactured. In addition, it can be used to predict the manufacturing performances (e.g., cost, completion time), and such prediction results can be used for production planning and control. Aheleroff, Zhong, and Xu [] identified cutting-edge technologies for designing a digital twin reference model for mass individualization.

- Real-time process monitoring and quality control for individualized production

Smart factories are embedded with smart sensors and modern wireless communication techniques (e.g., 5G) to enable real-time interaction and cyber–physical integration []. For example, RFID tags can be used to record the real-time information of individual products during production, improving process transparency and traceability. This can also engage customers by offering them the opportunity to track and see their own products during the entire production process and to propose potential modifications. The sensors can also collect real-time product quality data (e.g., geometry) and machine health information. Exploiting real-time data and historical data (and simulated data) will enable effective process monitoring, anomality detection, quality control, and process adjustment (e.g., inspection, predictive maintenance), if necessary. For example, Söderberg et al. [] developed a digital twin for real-time geometry assurance in individualized production. Wree et al. [] conducted real-time image analysis by implementing neural networks in the controller for individualized production. Zhong et al. [] developed an RFID-enabled real-time manufacturing execution system for mass customization production.

Data analytics and machine learning methods play a significant role in exploiting the patterns in the data. For example, machine learning algorithms can be developed to discover the sophisticated relationship between production parameters (e.g., machine status data) and the performance metrics of interest (e.g., product quality) in complex manufacturing systems. Such a “process–quality” relation enables the early detection of anomalies and identification of the root cause. Since the data collected are massive, deep learning algorithms [] can be developed to better understand the patterns in such big data; since the products and their manufacturing processes are individualized, knowledge transfer techniques [] that can transfer historical data and knowledge to deal with problems in the new environment can be helpful.

- Operational decision-making and optimization in a dynamic environment

Due to the increasing complexity and uncertainties in the factory, the operational decision-making in smart factories needs to be adaptive to the dynamic manufacturing environment and to disturbances. Compared to traditional manufacturing systems that use a centralized control method, smart factories typically use a decentralized control strategy where smart entities (e.g., machines) can make smart local decisions rapidly. Multi-agent-based approaches can be developed to facilitate such decision-making []. For example, Leng et al. [] developed a smart multi-agent system for efficient task coordination under disturbances. Wang et al. [] developed a self-organized multi-agent system with an intelligent negotiation mechanism for agents to cooperate with each other.

- Human–machine collaboration for complex manufacturing tasks

Using human–machine collaboration that combines the high accuracy and repeatability of machines (e.g., robots) and the high flexibility and adaptability of workers will be useful to tackle the complex manufacturing tasks of individualized manufacturing []. In smart factories, smart sensors can not only monitor the machine status, but also provide real-time information about the human workers (e.g., wearable devices can be used to monitor the fatigue of a worker). This will help to facilitate the coordination between the machine and the human worker. In addition, effective human–machine interfaces can be designed in smart factories to facilitate the interaction between humans and machines [], and models that address the co-evolution of human skills and system performance can be developed [].

4.4. Smart Collaborative Manufacturing Network

In addition to manufacturing within a single factory, the production of individualized products may rely on a network of multiple factories. Some companies can outsource manufacturing to third parties through a cloud manufacturing platform, in which case manufacturing can be regarded as a service. With IoT and cloud computing, the “connectedness” will evolve from a factory level to a network level to form a network of connected smart factories. A decentralized manufacturing network can be developed, where various manufacturers can share and integrate their manufacturing resources and information, collaborate with each other, and connect with customers. Torn and Vaneker [] proposed a method that can increase the capacities of SMEs to capitalize on mass individualization via collaboration in such a network. Qin and Lu [] proposed the concept of a self-organizing manufacturing network that has the functions of self-configuration, self-optimization, and self-healing. Hong et al. [] studied task allocation among multiple factories that can respond to dynamic modifications in customer demands. Yang et al. [] developed a full-connection model of product design and manufacturing in an IoT-enabled cloud manufacturing environment.

A significant challenge exists in the storage, sharing, and integration of the massive, heterogeneous, multi-source data generated during production and interaction in these networks. Data mining methods, such as industry knowledge graphs [], can be developed to generate knowledge and insights from these data. In addition, data security and trust issues may occur. All parties involved should make careful decisions regarding the types of data/information to share. Blockchain-based methods can be utilized to improve security and trust within such networks [].

5. Conclusions and Outlook

Mass individualization is a new manufacturing paradigm that will enable manufacturing enterprises to cost-effectively produce “one-of-a-kind” products, where each product fits the needs and desires of an individual customer. From a product design perspective, new design platforms and strategies need to be developed to actively and effectively engage customers to identify design solutions that accurately represent their needs. From a manufacturing perspective, it requires manufacturing systems that can produce a variety of individualized products simultaneously and cost-effectively, and that can respond to uncertainties and disturbances efficiently.

In the mass individualization paradigm, smart factories that take advantage of technological advancements in Industry 4.0/5.0 need to be built. We have discussed the relation between mass individualization and other emerging manufacturing paradigms and elaborated on how smart factories can improve the cost-effectiveness of the design and manufacturing of mass-individualized products. These are the technical enablers and foundations for mass individualization. Further research can continue to focus on the improvement of these techniques to further improve the cost-effectiveness of individualized production.

Mass individualization has the potential to enhance customer experience, strengthen innovation ecosystems, and benefit local economies. Despite these benefits, it is more complex and requires more effort (in terms of time and cost) from both customers and manufacturers. Mass individualization has been successfully implemented in some industry and lab case studies, but it is still in its early stage.

It is important to note that mass individualization is not a replacement for previous paradigms (e.g., mass production, mass customization). All of these paradigms can co-exist and complement each other. For example, an OAP platform can be a standardized product manufactured through mass production, while some modules can be customized or individualized. Enterprises should make strategic decisions regarding the best manufacturing paradigm(s) and techniques/practices to adopt by considering factors such as the customer requirements, product characteristics, return on investment, technology readiness, and competitive advantage. These factors can vary significantly in different cases. Future research directions will also involve identifying the key factors that promote/hinder the implementation of mass individualization in different industries and for different products, which may shed light on the general applicability of the mass individualization paradigm and on the most critical resources and capacity in which to invest.

Author Contributions

Conceptualization, Y.K. and X.G.; formal analysis, Y.K. and X.G.; investigation, X.G. and Y.K.; resources, X.G. and Y.K.; writing—original draft preparation, Y.K. and X.G.; writing—review and editing, X.G. and Y.K.; visualization, Y.K. and X.G.; supervision, Y.K.; project administration, Y.K. and X.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data sharing not applicable.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Koren, Y. The invention of reconfigurable manufacturing systems—A survey of RMS early patents. Manuf. Lett. 2022, 33, 51–53. [Google Scholar] [CrossRef]

- Koren, Y.; Gu, X.; Badurdeen, F.; Jawahir, I.S. Sustainable living factories for next generation manufacturing. Procedia Manuf. 2018, 21, 26–36. [Google Scholar] [CrossRef]

- Hu, S.J. Evolving paradigms of manufacturing: From mass production to mass customization and personalization. Procedia CIRP 2013, 7, 3–8. [Google Scholar] [CrossRef]

- Sikhwal, R.K.; Childs, P.R. Towards mass individualisation: Setting the scope and industrial implication. Des. Sci. 2021, 7, e16. [Google Scholar] [CrossRef]

- Jiang, P.; Leng, J.; Ding, K.; Gu, P.; Koren, Y. Social manufacturing as a sustainable paradigm for mass individualization. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 230, 1961–1968. [Google Scholar] [CrossRef]

- Gu, X.; Koren, Y. Mass-Individualisation–the twenty first century manufacturing paradigm. Int. J. Prod. Res. 2022, 60, 7572–7587. [Google Scholar] [CrossRef]

- Koren, Y. The Global Manufacturing Revolution: Product-Process-Business Integration and Reconfigurable Systems; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Koren, Y.; Barhak, J.; Pasek, Z. Method and Apparatus for Re-Configurable Vehicle Interior Design and Business Transaction. U.S. Patent Application 11/326,069, 5 July 2007. [Google Scholar]

- Kopelman, S. Negotiating Genuinely: Being Yourself in Business; Stanford University Press: Redwood City, CA, USA, 2014. [Google Scholar]

- XPeng P5. Available online: https://en.wikipedia.org/wiki/XPeng_P5 (accessed on 30 September 2023).

- Siegbert, R.; Yesildag, N.; Frings, M.; Schmidt, F.; Elgeti, S.; Sauerland, H.; Behr, M.; Windeck, C.; Hopmann, C.; Queudeville, Y. Individualized production in die-based manufacturing processes using numerical optimization. Int. J. Adv. Manuf. Technol. 2015, 80, 851–858. [Google Scholar] [CrossRef]

- Kang, H.S.; Do Noh, S.; Son, J.Y.; Kim, H.; Park, J.H.; Lee, J.Y. The FaaS system using additive manufacturing for personalized production. Rapid Prototyp. J. 2018, 24, 1486–1499. [Google Scholar] [CrossRef]

- Koren, Y.; Hu, S.J.; Gu, P.; Shpitalni, M. Open-architecture products. CIRP Ann. 2013, 62, 719–729. [Google Scholar] [CrossRef]

- Würtz, G.; Ardilio, A.; Lasi, H.; Warschat, J. Towards mass individualization: Life-cycle oriented configuration of time-variable product-service systems. In Proceedings of the 2013 Proceedings of PICMET’13: Technology Management in the IT-Driven Services (PICMET), San Jose, CA, USA, 28 July–1 August 2013. [Google Scholar]

- Koren, Y. The local factory of the future for producing individualized products. Bridge 2021, 51, 20–26. [Google Scholar]

- Shang, X.; Liu, X.; Xiong, G.; Cheng, C.; Ma, Y.; Nyberg, T.R. Social manufacturing cloud service platform for the mass customization in apparel industry. In Proceedings of the 2013 IEEE International Conference on Service Operations and Logistics, and Informatics, Dongguan, China, 28–30 July 2013; pp. 220–224. [Google Scholar]

- Ding, J.; Wang, M.; Zeng, X.; Qu, W.; Vassiliadis, V.S. Mass personalization strategy under Industrial Internet of Things: A case study on furniture production. Adv. Eng. Inform. 2021, 50, 101439. [Google Scholar] [CrossRef]

- Leng, J.; Ruan, G.; Song, Y.; Liu, Q.; Fu, Y.; Ding, K.; Chen, X. A loosely-coupled deep reinforcement learning approach for order acceptance decision of mass-individualized printed circuit board manufacturing in industry 4.0. J. Clean. Prod. 2021, 280, 124405. [Google Scholar] [CrossRef]

- Monostori, L.; Kádár, B.; Bauernhansl, T.; Kondoh, S.; Kumara, S.; Reinhart, G.; Sauer, O.; Schuh, G.; Sihn, W.; Ueda, K. Cyber-physical systems in manufacturing. CIRP Ann. 2016, 65, 621–641. [Google Scholar] [CrossRef]

- Esmaeilian, B.; Behdad, S.; Wang, B. The evolution and future of manufacturing: A review. J. Manuf. Syst. 2016, 39, 79–100. [Google Scholar] [CrossRef]

- Kusiak, A. Smart manufacturing. Int. J. Prod. Res. 2018, 56, 508–517. [Google Scholar] [CrossRef]

- Jardim-Goncalves, R.; Romero, D.; Grilo, A. Factories of the future: Challenges and leading innovations in intelligent manufacturing. Int. J. Comput. Integr. Manuf. 2017, 30, 4–14. [Google Scholar]

- Wang, B.; Tao, F.; Fang, X.; Liu, C.; Liu, Y.; Freiheit, T. Smart manufacturing and intelligent manufacturing: A comparative review. Engineering 2021, 7, 738–757. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Liu, A.; Kusiak, A. Data-driven smart manufacturing. J. Manuf. Syst. 2018, 48, 157–169. [Google Scholar] [CrossRef]

- Xu, X. From cloud computing to cloud manufacturing. Robot. Comput. Integr. Manuf. 2012, 28, 75–86. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent manufacturing in the context of industry 4.0: A review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, X. Industry 4.0 and cloud manufacturing: A comparative analysis. J. Manuf. Sci. Eng. 2017, 139, 034701. [Google Scholar] [CrossRef]

- Huang, S.; Wang, B.; Li, X.; Zheng, P.; Mourtzis, D.; Wang, L. Industry 5.0 and Society 5.0—Comparison, complementation and co-evolution. J. Manuf. Syst. 2022, 64, 424–428. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Mourtzis, D. The Metaverse in Industry 5.0: A Human-Centric Approach towards Personalized Value Creation. Encyclopedia 2023, 3, 1105–1120. [Google Scholar] [CrossRef]

- Leng, J.; Sha, W.; Wang, B.; Zheng, P.; Zhuang, C.; Liu, Q.; Wuest, T.; Mourtzis, D.; Wang, L. Industry 5.0: Prospect and retrospect. J. Manuf. Syst. 2022, 65, 279–295. [Google Scholar] [CrossRef]

- Jovane, F.; Yoshikawa, H.; Alting, L.; Boer, C.R.; Westkamper, E.; Williams, D.; Tseng, M.; Seliger, G.; Paci, A.M. The incoming global technological and industrial revolution towards competitive sustainable manufacturing. CIRP Ann. 2008, 57, 641–659. [Google Scholar] [CrossRef]

- Joshi, K.; Venkatachalam, A.; Jawahir, I.S. A new methodology for transforming 3R concept into 6R concept for improved product sustainability. In Proceedings of the IV Global Conference on Sustainable Product Development and Life Cycle Engineering, Sao Carolos, Brazil, 3–6 October 2006; pp. 3–6. [Google Scholar]

- Gupta, S.; Jain, S.K. A literature review of lean manufacturing. Int. J. Manag. Sci. Eng. Manag. 2013, 8, 241–249. [Google Scholar] [CrossRef]

- Boër, C.R.; Redaelli, C.; Boër, D.; Gatti, M.T. Mass customization and personalization: A way to improve sustainability beyond a common paradox. In Customization 4.0: Proceedings of the 9th World Mass Customization & Personalization Conference (MCPC 2017), Aachen, Germany, 20–21 November 2017; Springer: Cham, Switzerland, 2018; pp. 237–250. [Google Scholar]

- Jiang, P.; Leng, J.; Ding, K. Social manufacturing: A survey of the state-of-the-art and future challenges. In Proceedings of the 2016 IEEE International Conference on Service Operations and Logistics, and Informatics (SOLI), Beijing, China, 10–12 July 2016; pp. 12–17. [Google Scholar]

- Leng, J.; Jiang, P.; Liu, C.; Wang, C. Contextual self-organizing of manufacturing process for mass individualization: A cyber-physical-social system approach. Enterp. Inf. Syst. 2020, 14, 1124–1149. [Google Scholar] [CrossRef]

- Zhou, Y.; Xiong, G.; Nyberg, T.; Mohajeri, B.; Bao, S. Social manufacturing realizing personalization production: A state-of-the-art review. In Proceedings of the 2016 IEEE International Conference on Service Operations and Logistics, and Informatics (SOLI), Beijing, China, 10–12 July 2016; pp. 7–11. [Google Scholar]

- Wang, Y.; Ma, H.; Yang, J.; Wang, K. Industry 4.0: A way from mass customization to mass personalization production. Adv. Manuf. 2017, 5, 311–320. [Google Scholar] [CrossRef]

- Tseng, M.M.; Jiao, R.J.; Wang, C. Design for mass personalization. CIRP Ann. 2010, 59, 175–178. [Google Scholar] [CrossRef]

- Tao, F.; Sui, F.; Liu, A.; Qi, Q.; Zhang, M.; Song, B.; Guo, Z.; Lu, S.C.; Nee, A.Y. Digital twin-driven product design framework. Int. J. Prod. Res. 2019, 57, 3935–3953. [Google Scholar] [CrossRef]

- Zheng, P.; Yu, S.; Wang, Y.; Zhong, R.Y.; Xu, X. User-experience based product development for mass personalization: A case study. Procedia CIRP 2017, 63, 2–7. [Google Scholar] [CrossRef]

- Zhou, F.; Ji, Y.; Jiao, R.J. Affective and cognitive design for mass personalization: Status and prospect. J. Intell. Manuf. 2013, 24, 1047–1069. [Google Scholar] [CrossRef]

- Berry, C.; Wang, H.; Hu, S.J. Product architecting for personalization. J. Manuf. Syst. 2013, 32, 404–411. [Google Scholar] [CrossRef]

- Tan, C.; Hu, S.J.; Chung, H.; Barton, K.; Piya, C.; Ramani, K.; Banu, M. Product personalization enabled by assembly architecture and cyber physical systems. CIRP Ann. 2017, 66, 33–36. [Google Scholar] [CrossRef]

- Chen, Y.; Peng, Q.; Gu, P. Methods and tools for the optimal adaptable design of open-architecture products. Int. J. Adv. Manuf. Technol. 2018, 94, 991–1008. [Google Scholar] [CrossRef]

- Zheng, P.; Xu, X.; Yu, S.; Liu, C. Personalized product configuration framework in an adaptable open architecture product platform. J. Manuf. Syst. 2017, 43, 422–435. [Google Scholar] [CrossRef]

- Tan, C.; Chung, H.; Barton, K.; Hu, S.J.; Freiheit, T. Incorporating customer personalization preferences in open product architecture design. J. Manuf. Syst. 2020, 56, 72–83. [Google Scholar] [CrossRef]

- Gu, X.; Koren, Y. Manufacturing system architecture for cost-effective mass-individualization. Manuf. Lett. 2018, 16, 44–48. [Google Scholar] [CrossRef]

- Zhang, X.; Ming, X.; Bao, Y. A flexible smart manufacturing system in mass personalization manufacturing model based on multi-module-platform, multi-virtual-unit, and multi-production-line. Comput. Ind. Eng. 2022, 171, 108379. [Google Scholar] [CrossRef]

- Lanz, M.; Tuokko, R. Concepts, methods and tools for individualized production. Prod. Eng. 2017, 11, 205–212. [Google Scholar] [CrossRef]

- Koren, Y.; Wang, W.; Gu, X. Value creation through design for scalability of reconfigurable manufacturing systems. Int. J. Prod. Res. 2017, 55, 1227–1242. [Google Scholar] [CrossRef]

- Koren, Y.; Hill, R.L. Integrated Reconfigurable Manufacturing System. U.S. Patent 6,920,973, 26 July 2005. [Google Scholar]

- Ivanov, D.; Sokolov, B.; Chen, W.; Dolgui, A.; Werner, F.; Potryasaev, S. A control approach to scheduling flexibly configurable jobs with dynamic structural-logical constraints. IISE Trans. 2021, 53, 21–38. [Google Scholar] [CrossRef]

- Zuehlke, D. SmartFactory—Towards a factory-of-things. Annu. Rev. Control 2010, 34, 129–138. [Google Scholar] [CrossRef]

- Strozzi, F.; Colicchia, C.; Creazza, A.; Noè, C. Literature review on the ‘Smart Factory’ concept using bibliometric tools. Int. J. Prod. Res. 2017, 55, 6572–6591. [Google Scholar] [CrossRef]

- Osterrieder, P.; Budde, L.; Friedli, T. The smart factory as a key construct of industry 4.0: A systematic literature review. Int. J. Prod. Econ. 2020, 221, 107476. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Internet of things for smart factories in industry 4.0, a review. Internet Things Cyber-Phys. Syst. 2023, 3, 192–204. [Google Scholar] [CrossRef]

- Pech, M.; Vrchota, J.; Bednář, J. Predictive maintenance and intelligent sensors in smart factory. Sensors 2021, 21, 1470. [Google Scholar] [CrossRef]

- Zenkert, J.; Weber, C.; Dornhöfer, M.; Abu-Rasheed, H.; Fathi, M. Knowledge integration in smart factories. Encyclopedia 2021, 1, 792–811. [Google Scholar] [CrossRef]

- Tomiyama, T.; Lutters, E.; Stark, R.; Abramovici, M. Development capabilities for smart products. CIRP Ann. 2019, 68, 727–750. [Google Scholar] [CrossRef]

- Jung, W.; Kim, D.; Lee, H.; Lee, T.; Yang, I.; Youn, B.D.; Zontar, D.; Brockmann, M.; Brecher, C.; Ahn, S. Appropriate smart factory for SMEs: Concept, application and perspective. Int. J. Precis. Eng. Manuf. 2021, 22, 201–215. [Google Scholar] [CrossRef]

- Park, K.T.; Lee, J.; Kim, H.; Noh, S.D. Digital twin-based cyber physical production system architectural framework for personalized production. Int. J. Adv. Manuf. 2020, 106, 1787–1810. [Google Scholar] [CrossRef]

- Chryssolouris, G.; Mavrikios, D.; Papakostas, N.; Mourtzis, D.; Michalos, G.; Georgoulias, K. Digital manufacturing: History, perspectives, and outlook. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2009, 223, 451–462. [Google Scholar] [CrossRef]

- Aheleroff, S.; Zhong, R.Y.; Xu, X. A digital twin reference for mass personalization in industry 4.0. Procedia CIRP 2020, 93, 228–233. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A. Digital twins and cyber–physical systems toward smart manufacturing and industry 4.0: Correlation and comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Söderberg, R.; Wärmefjord, K.; Carlson, J.S.; Lindkvist, L. Toward a Digital Twin for real-time geometry assurance in individualized production. CIRP Ann. 2017, 66, 137–140. [Google Scholar] [CrossRef]

- Wree, C.; Raßmann, R.; Daâs, J.; Bause, F.; Schönfeld, T. Real-time image analysis with neural networks on industrial controllers for individualized production. In International Workshop on Service Orientation in Holonic and Multi-Agent Manufacturing; Springer: Cham, Switzerland, 2021; pp. 471–481. [Google Scholar]

- Zhong, R.Y.; Dai, Q.Y.; Qu, T.; Hu, G.J.; Huang, G.Q. RFID-enabled real-time manufacturing execution system for mass-customization production. Robot. Comput. Integr. Manuf. 2013, 29, 283–292. [Google Scholar] [CrossRef]

- Wang, J.; Ma, Y.; Zhang, L.; Gao, R.X.; Wu, D. Deep learning for smart manufacturing: Methods and applications. J. Manuf. Syst. 2018, 48, 144–156. [Google Scholar] [CrossRef]

- Bang, S.H.; Ak, R.; Narayanan, A.; Lee, Y.T.; Cho, H. A survey on knowledge transfer for manufacturing data analytics. Comput. Ind. 2019, 104, 116–130. [Google Scholar] [CrossRef]

- Bidmead, J.; Bhatiani, S.; Xu, X. Decentralized factory control based on multi-agent technologies. In Proceedings of the 2022 IEEE 18th International Conference on Automation Science and Engineering (CASE), Mexico City, Mexico, 20–24 August 2022; pp. 307–311. [Google Scholar]

- Leng, J.; Chen, Z.; Sha, W.; Ye, S.; Liu, Q.; Chen, X. Cloud-edge orchestration-based bi-level autonomous process control for mass individualization of rapid printed circuit boards prototyping services. J. Manuf. Syst. 2022, 63, 143–161. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Zhang, D.; Li, D.; Zhang, C. Towards smart factory for industry 4.0: A self-organized multi-agent system with big data based feedback and coordination. Comput. Netw. 2016, 101, 158–168. [Google Scholar] [CrossRef]

- Li, S.; Wang, R.; Zheng, P.; Wang, L. Towards proactive human–robot collaboration: A foreseeable cognitive manufacturing paradigm. J. Manuf. Syst. 2021, 60, 547–552. [Google Scholar] [CrossRef]

- Kumar, N.; Lee, S.C. Human-machine interface in smart factory: A systematic literature review. Technol. Forecast. Soc. Chang. 2022, 174, 121284. [Google Scholar] [CrossRef]

- Li, X.; Nassehi, A.; Wang, B.; Hu, S.J.; Epureanu, B.I. Human-centric manufacturing for human-system coevolution in Industry 5.0. CIRP Ann. 2023, 72, 393–396. [Google Scholar] [CrossRef]

- Torn, I.; Vaneker, T.H. Mass personalization with Industry 4.0 by SMEs: A concept for collaborative networks. Procedia Manuf. 2019, 28, 135–141. [Google Scholar] [CrossRef]

- Qin, Z.; Lu, Y. Self-organizing manufacturing network: A paradigm towards smart manufacturing in mass personalization. J. Manuf. Syst. 2021, 60, 35–47. [Google Scholar] [CrossRef]

- Hong, Q.; Chen, Z.; Dong, C.; Xiong, Q. A dynamic demand-driven smart manufacturing for mass individualization production. In Proceedings of the 2021 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Melbourne, Australia, 17–20 October 2021; pp. 3297–3302. [Google Scholar]

- Yang, C.; Lan, S.; Shen, W.; Huang, G.Q.; Wang, X.; Lin, T. Towards product customization and personalization in IoT-enabled cloud manufacturing. Clust. Comput. 2017, 20, 1717–1730. [Google Scholar] [CrossRef]

- Li, X.; Zheng, P.; Bao, J.; Gao, L.; Xu, X. Achieving cognitive mass personalization via the self-X cognitive manufacturing network: An industrial knowledge graph-and graph embedding-enabled pathway. Engineering 2023, 22, 14–19. [Google Scholar] [CrossRef]

- Leng, J.; Ye, S.; Zhou, M.; Zhao, J.L.; Liu, Q.; Guo, W.; Cao, W.; Fu, L. Blockchain-secured smart manufacturing in industry 4.0: A survey. IEEE Trans. Syst. Man Cybern. Syst. 2020, 51, 237–252. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).