This section describes the equipment used, experimental setup, and measurement procedures. It provides a detailed overview of the measurement conditions, data acquisition methods, and subsequent data processing. All essential parameters required to replicate the experiment and evaluate its reliability are listed.

4.1. Equipment Used

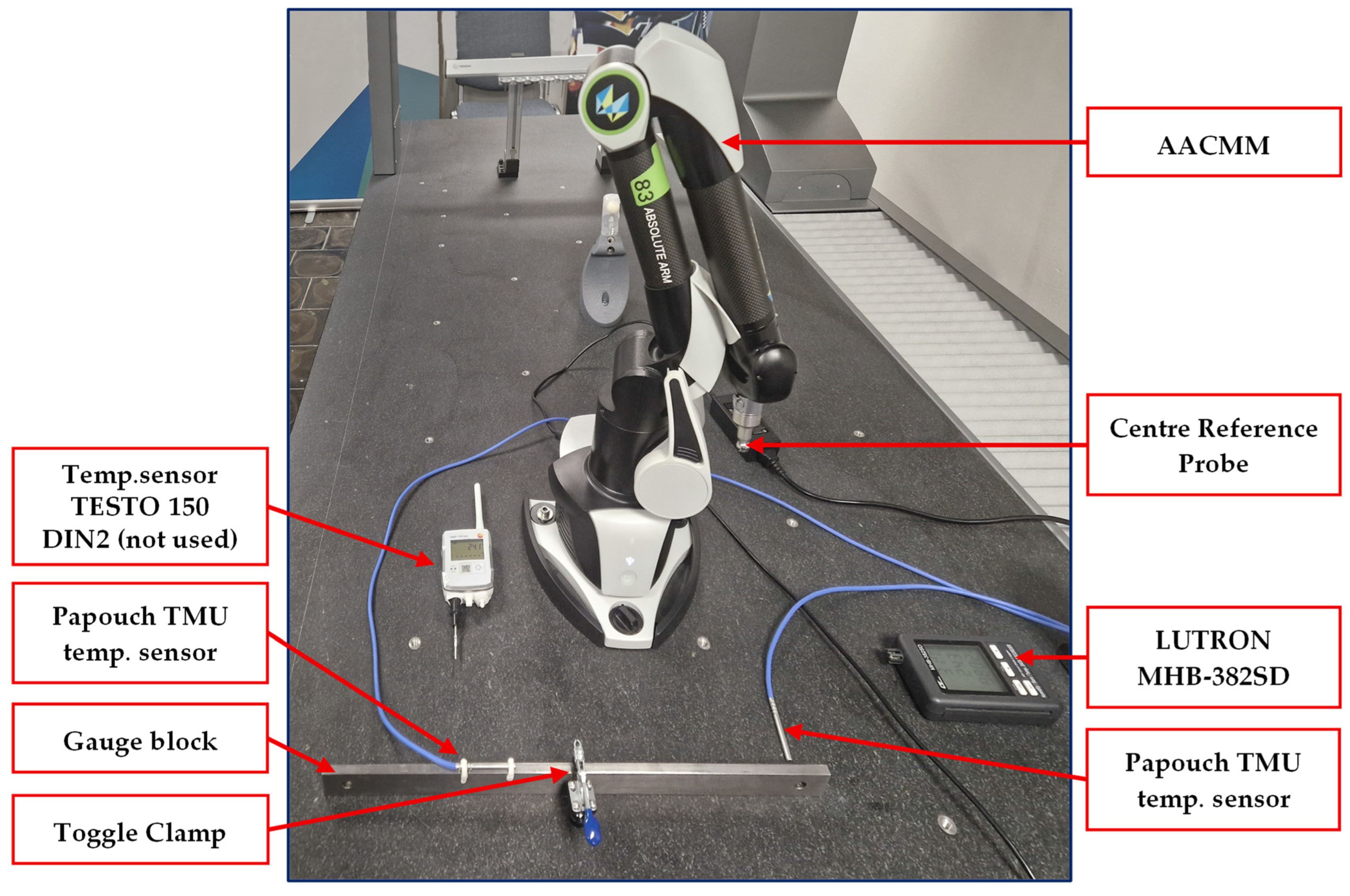

The experimental measurements were carried out using a Hexagon Absolute Arm 8312 AACMM (Prague, Czech Republic). This is a Compact model designed for contact measurements of small- and medium-sized components. Due to its small measurement volume and fast deployment, it is particularly suitable for confined spaces, such as direct application within a machine tool workspace. Typical applications of the Compact arm include small-machined parts, medical components, or small mold cavities.

In addition to the standard certification for AACMM according to ISO 10360-12:2016, the manufacturer also provides certification in accordance with ISO 10360-2:2009, similar to conventional. For the experiment, a steel contact probe, Centre Reference Probe TKJ L 50–ø 15 mm, was installed. Measurement results were evaluated using the PC-DMIS 2023.2 metrology software. Internal temperature readings of the measuring system were obtained using the system utility software RDS 6.4. [

19,

20]

The technical specifications of the AACMM, in terms of accuracy and operating conditions, are presented in

Table 1 and

Table 2. The stated accuracy values represent Maximum Permissible Error (MPE) values as defined by the acceptance test in accordance with ISO 10360-12:2016 and are specified by the manufacturer [

15].

Additional instrumentation was used to monitor environmental parameters during the experiment. Two TMU USB thermometers from Papouch (Prague, Czech Republic) were employed to measure air and surface temperatures. These sensors operate within a temperature range of −55 °C to +125 °C, with a resolution of 0.1 °C and an accuracy of ±0.5 °C in the range of −10 °C to +85 °C. The devices were connected to a PC and used in combination with Papouch Wix V 1.9.5.5 software for continuous data logging.

Further environmental conditions were monitored using the LUTRON MHB-382SD (Prague, Czech Republic) instrument, which is suitable for long-term laboratory monitoring. In addition to ambient temperature, it measures relative humidity in the range of 10–95% RH with an accuracy of ±3% and a resolution of 0.1% RH. The atmospheric pressure is measured over a range of 10 to 1100 hPa with a resolution of 0.1 hPa and an accuracy of ±2 hPa.

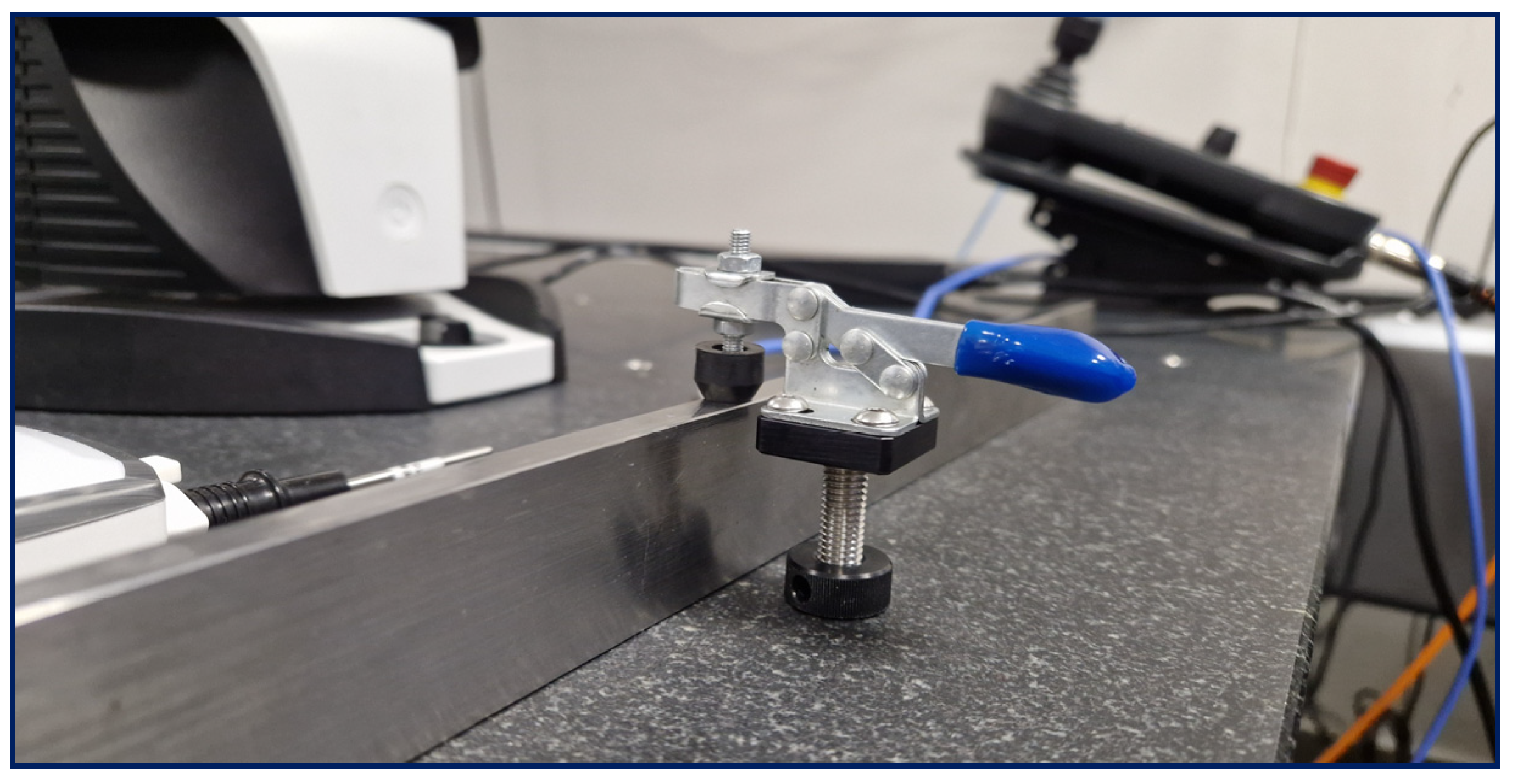

The reference standard used in this study is part of a set of steel gauge blocks (manufacturer: Hommel Hercules (Prague, Czech Republic; Grade K, range 50–500 mm), calibrated by the Czech Metrology Institute in 2011 (certificate No. 4031-KL-D0050-11). An overview of the reference standard is shown in

Figure 1. For the purposes of thermal expansion calculations, a linear coefficient of thermal expansion of α = 11 × 10

−6 K

−1 was used, corresponding to gauge blocks of larger nominal length. The gauge blocks were stored under controlled laboratory conditions in their original protective case and in the context of this experiment, they served as a stable reference for evaluating thermal effects. Its function in this study is not to provide an absolute length reference but to serve as a comparative standard for evaluating thermal effects. The gauge block was mechanically fixed to a granite metrology table using a dedicated clamping mechanism, the Hexagon Toggle Clamp (Prague Czech Republic, see

Figure 2).

For the heating of the metrological laboratory, a 1500 W electric oil radiator was used. The room cooling was provided by a Dolceclima Air Pro 13 A+ air conditioning unit (Prague, Czech Republic). The experimental arrangement is shown in

Figure 3.

4.2. Methodology

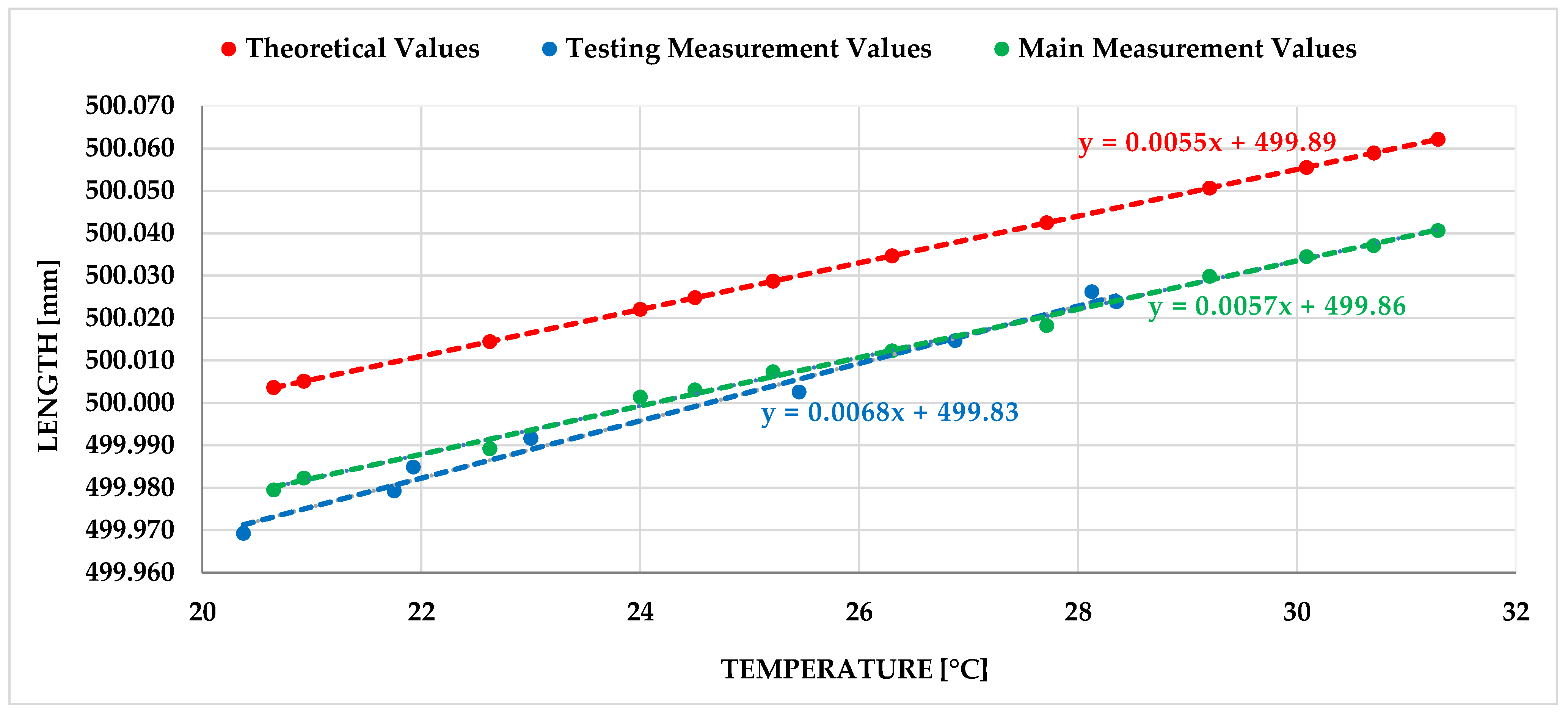

In the initial phase of the experiment, a test measurement campaign was designed with the objective of determining the achievable temperature limits, the time required for heating and cooling the laboratory, and the duration necessary for system thermal stabilization. This phase also served to test the appropriate operator position during measurement as well as the most suitable measurement strategy.

At this stage, no fixed measurement procedure was applied, temperature stabilization was not enforced, and the temperature changes occurred relatively rapidly due to the need to test the capabilities of both the electric radiator and the air conditioning unit. A portion of the measurements was also conducted under natural ambient temperature conditions in the laboratory. The pilot tests were carried out in March 2025.

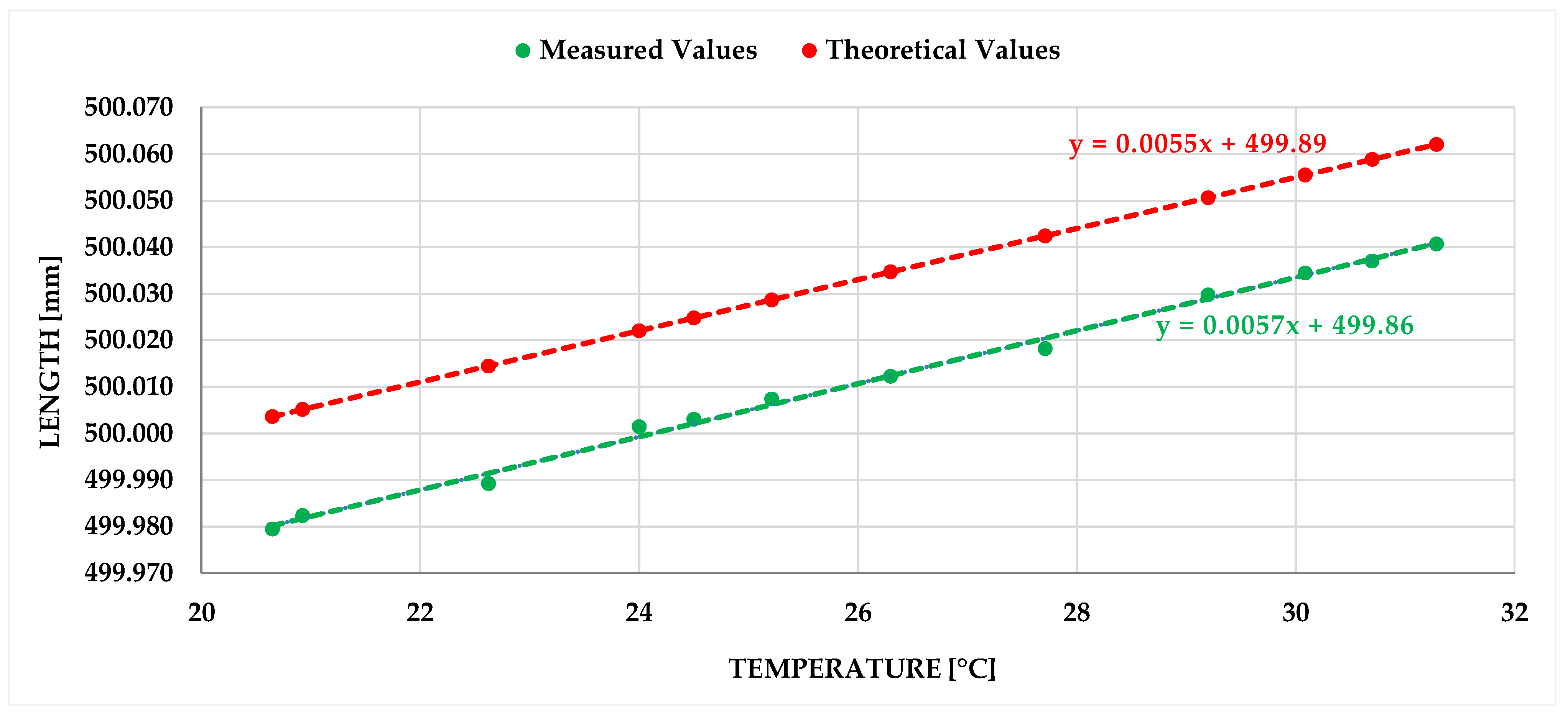

Based on the evaluation of the test phase, it was concluded that the minimum and maximum achievable ambient temperatures were approximately 20 °C and 29 °C, respectively. A total of eight measurements were performed during this phase. The corresponding ambient temperatures recorded during each measurement are summarized in

Table 3.

Based on the results of the test phase, a detailed measurement plan for the main experiment was established. The goal was to implement smoother temperature transitions with smaller increments and to achieve the longest possible stabilization time at each temperature level. Given the experimental objective of evaluating the temperature dependence of measurement results, the aim was to cover as many temperature levels as possible within the selected range (approximately 20–29 °C).

The methodology included two measurement blocks per day, spaced 12 h apart. A single 12 h block was considered sufficient to allow thermal equilibrium between the ambient air, the AACMM, and the steel gauge block. Continuous temperature monitoring was essential for ensuring environmental stability. Therefore, two Papouch TMU thermometers were used—one placed in the measurement zone and the other mounted directly onto the gauge block.

The laboratory environment was carefully controlled to avoid undesired thermal transitions, and the system was considered thermally stabilized when the temperature variation did not exceed 0.2 °C [

1]. The shortest recorded thermal stabilization time was 3 h and 6 min, while the longest stabilization time occurred at the maximum temperature level and lasted 12 h and 6 min.

The temperature levels at which the final measurements were performed are listed in

Table 4.

A simple measurement program was created in the PC-DMIS software. The length of the gauge block was evaluated as the distance between two planes. Each measurement at a given temperature level was repeated 12 times to ensure statistical reliability.

4.3. Theoretical Basis

Thermal drift represents one of the main systematic sources of uncertainty in AACMMs. This phenomenon arises due to variations in ambient or internal temperature, which cause thermal expansion or contraction of the structural components of the arm—primarily its segments and joints. Since these parts are typically made of metals or composite materials with non-zero coefficients of thermal expansion, heating or cooling leads to slight geometric deformation of the arm. Although not directly observable during operation, this deformation causes the measured coordinates to gradually shift over time, even if the measured object remains stationary and the arm is not moved.

Thermal drift is typically time-dependent—it becomes more pronounced during transient phases after power-on or temperature fluctuations, before thermal equilibrium is achieved. It may be caused not only by environmental changes but also by internal heat generation in components such as motors, encoders, or bearings, which results in thermal gradients across the arm. These gradients lead to non-uniform mechanical behavior and difficult-to-predict structural deformations. The result is a discrepancy between the actual and indicated position of the probe tip, which can reach several tenths of a millimeter even under small temperature variations.

Since this is a systematic effect, it cannot be eliminated by simple repetition of measurements. Thermal drift thus has a significant impact on both accuracy and repeatability, and in longer measurement sequences, it may lead to incorrect conclusions about the dimensional properties of the measured part. To mitigate this effect, AACMMs are equipped with various structural and algorithmic compensation mechanisms. On the structural side, materials with low thermal expansion coefficients, such as carbon fiber composites, are commonly used. In addition, a set of integrated temperature sensors is often embedded in the arm, enabling software-based thermal compensation using empirical or regression-based models, or more recently, neural network. However, the exact principles of these algorithms are typically not disclosed by manufacturers.

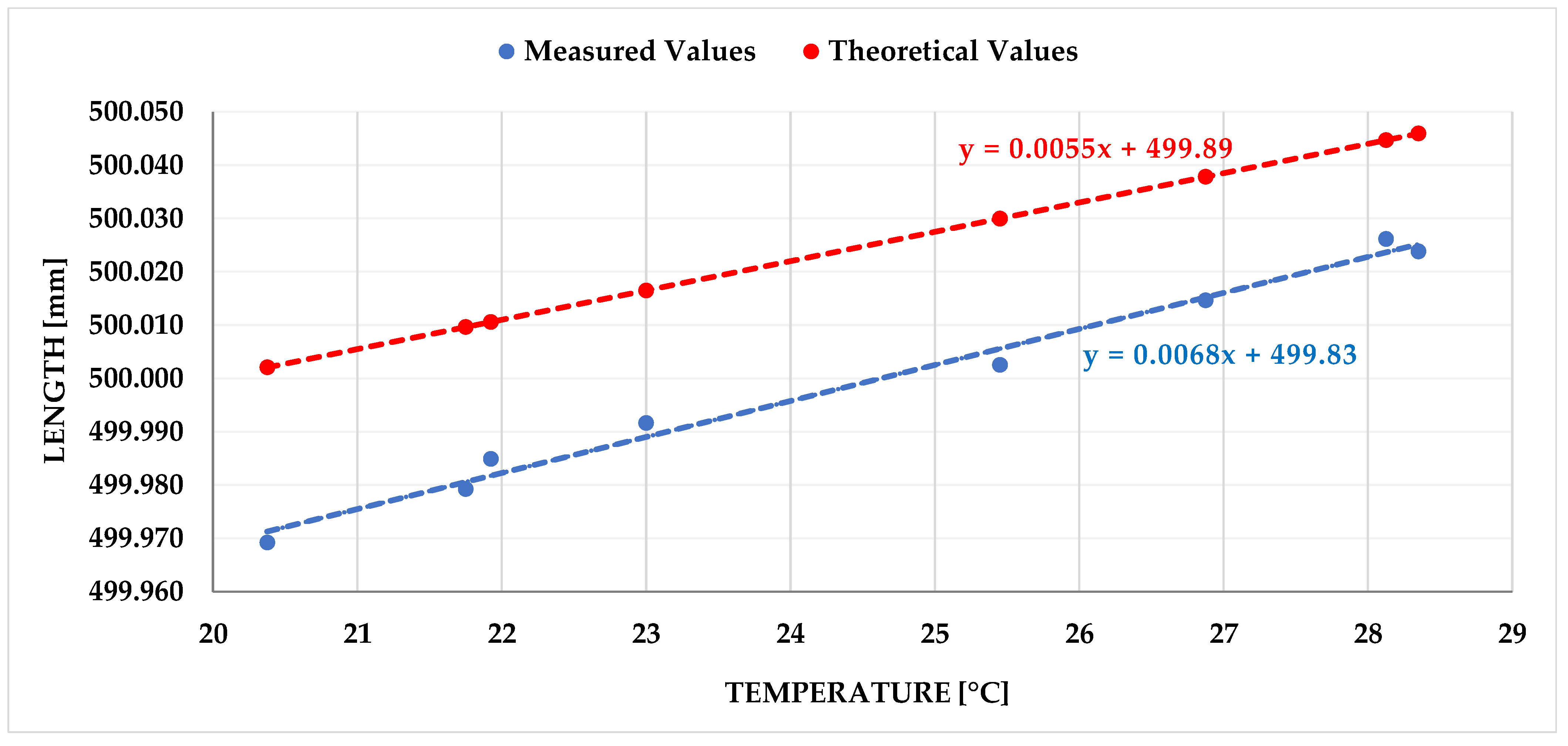

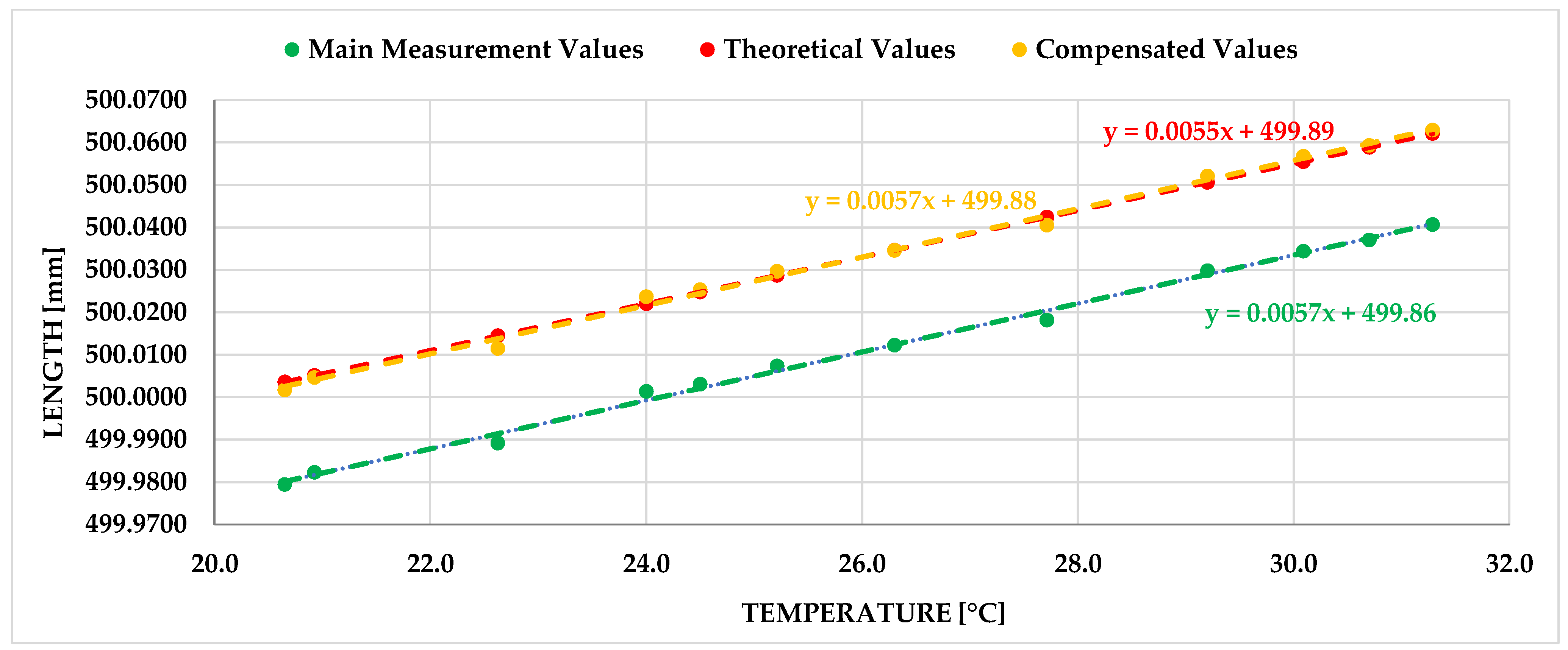

To evaluate the dependence of the measured length on ambient temperature, the method of linear regression was selected, as most engineering materials exhibit approximately linear thermal expansion within the typical range of technical temperatures. The linear regression model describes the relationship between the independent variable (temperature) and the dependent variable (measured length) in the following form:

where

β1 represents the slope of the regression line and

β0 its intercept with the y-axis. In the context of this analysis, the slope has a clear physical interpretation as the effective thermal expansion coefficient of the entire measurement path, i.e., not only the gauge block but also the associated components of the measuring system. The intercept corresponds to the hypothetical length at zero temperature and may indicate a systematic offset or calibration error.

The linear model thus enables the quantification of the difference between the theoretical expansion of a known material and the actual measured value, which can reveal, for example, thermal dilation of the AACMM or other mechanical influences. The model also serves as a basis for further calculations, such as estimating the effect of temperature variations on measurement uncertainty or designing compensation coefficients. The quality of the fit was assessed using the coefficient of determination R2, which expresses to what extent the data variability can be explained by the regression model. A high value of this indicator confirms the suitability of the chosen approach and supports the assumption of linear dependence within the specified conditions.

In this study, the regression equations are presented as deterministic lines without an explicit residual term. Deviations in individual data points from the model were considered only through the calculation of the R

2 value. The resulting equations thus serve primarily to interpret trends and compare them with theoretical models. Type A uncertainty was not derived from the residuals of the regression analysis but was determined independently based on repeated measurements, as the standard deviation of the mean, in accordance with the GUM recommendations [

21]. This approach corresponds to common metrological practice, where the goal is to quantify the statistical dispersion of measured values regardless of the applied dependency model.

After evaluating the dependence of the gauge block length on ambient temperature using the linear regression model, the next objective was to determine the measurement uncertainty throughout the experiment. The measurements were conducted under laboratory conditions in order to simulate typical usage of the measuring device at various temperatures, with an emphasis on assessing the influence of the AACMM itself. It is assumed that if the gauge block has a known thermal expansion coefficient, any additional length changes due to temperature variation can be attributed to the measuring system—i.e., the AACMM and other components. This assumption is particularly important in cases where direct calibration of the measuring device at different temperatures is not available or where it is necessary to estimate the expanded uncertainty under current conditions. In this analysis, type A uncertainty was determined according to GUM recommendations as the standard deviation of the mean from repeated measurements. A potential systematic influence of the AACMM, demonstrated by the regression analysis, would be considered as a component of type B uncertainty.

In the calculation of measurement uncertainty, the standard procedure according to GUM was followed, taking into account the information provided by Moona et al. [

21,

22]. In practical processing and evaluation, the required quantity is ideally measured at least ten times, under the assumption that the components forming the combined standard uncertainty

uc follow a normal probability distribution N(μ,σ

2). From the measured dataset

xi, the arithmetic mean is calculated according to Equation (2).

The type A standard uncertainty

uA depends on the number of measurements

n performed and decreases as the number of measurements

n increases. For independent (uncorrelated) measured values,

uA is related to the sample mean and is calculated using Equation (3), which defines the standard deviation of the sample mean. Equation (3) may alternatively be expressed in terms of the sample standard deviation

sx.

The uncertainty

uA is caused by the variation in measured values. In the case of a small number of measurements (

n < 10), the value determined by Equation (3) is not very reliable. If the measurement uncertainty is to be evaluated using the type A method according to GUM, measurements should be repeated at least 10 times. In Czech literature, there is a procedure based on TPM 0051:93 Determining Uncertainties in Measurements for

n ≥ 2, which was also applied in this calculation [

23]:

where the values of the correction coefficient

K depend on the number of measurements

n and are given in

Table 5.

To calculate the combined standard uncertainty

uC, it is also necessary to determine the type B uncertainty

uB. The uncertainty

uB does not depend on the number of measurements but is derived by standardizing the possible sources of uncertainty

zj. The individual components of uncertainty that form

uB are identified under the assumption that they are uncorrelated.

or each source, a range of deviations ±Δ

zjmax from the nominal value is estimated in such a way as to minimize the probability of exceeding the interval. Furthermore, the probability distribution corresponding to the deviations Δ

z within the interval ±Δ

zjmax is assessed, and the individual uncertainties

uzj (i.e., the contributions to the type B uncertainty

uB) are determined.

where the coefficient

cj denotes the sensitivity coefficient and the value

χ is determined based on the selected approximation. The values of

χ correspond to the ratio

where

σ2 is the variance of the respective distribution, as listed in the following overview:

χ = 3 (2) for a normal distribution,

χ = for a triangular (Simpson’s) distribution,

χ = for a bimodal triangular distribution,

χ = 1 for a bimodal Dirac distribution,

χ = for a uniform (rectangular) distribution,

χ = 2.04; 2.19; 2.32 for a trapezoidal distribution.

The standard combined uncertainty

uC is calculated from the type A and type B uncertainties under the assumption that the input quantities are uncorrelated. The calculation is performed according to Equation (7):

In the case of an AACMM, the foundation of its inherent uncertainty is determined during the manufacturing and assembly of the system itself. Errors originating from individual AACMM components—such as systematic encoder errors—accumulate during both measurement and calibration. The uncertainties of an AACMM can generally be divided into two main categories:

Kinematic errors, which are related to the physical structure and motion of the AACMM. These include inaccuracies in segment lengths, where the actual segment length differs from that defined in the kinematic model. Further sources are twisting errors, manifesting as deviations in segment orientation, and errors in the zero position, referring to inaccuracies in defining the initial AACMM position. These factors have a significant impact on the accuracy of position and orientation determination.

Non-kinematic errors, which result from factors independent of the AACMM’s kinematics. Deformations of the segments due to their own weight or external forces may cause shifts in measured points. Temperature-induced errors—arising from dimensional changes caused by thermal expansion of the AACMM components—can substantially affect measurement accuracy, especially in environments with fluctuating temperatures.

Given that an AACMM is a portable measurement system (MS) designed for use in various, often demanding, metrological environments, these conditions significantly affect the measurement uncertainty. Temperature fluctuations are particularly critical and must be taken into account when determining the final measurement uncertainty. This assumption is fundamental to this study. Humidity and atmospheric pressure may influence the AACMM’s electronic components, which is why these parameters were also monitored throughout the measurements. However, current AACMMs are commonly rated up to IP54 protection level by manufacturers, indicating that the system itself is not critically affected by humidity. This also applies to dust and contamination. In dusty environments, it is necessary to clean both the part and the measuring probe to minimize the impact of contamination on the measurement uncertainty.

In typical industrial applications of AACMMs, it is also important to monitor vibrations and shocks, which can lead to instability and measurement errors. Since this study was conducted in a laboratory environment, this source of uncertainty was not considered.

Because AACMMs are manually operated systems, the operator is an essential source of uncertainty. The user’s experience and knowledge of the equipment also play a key role in minimizing errors and ensuring consistent results. Human factors contributing to uncertainty include the applied probing force, measurement stability, selection of probe points, probe orientation, and measurement strategy. This influence was evaluated during the preliminary testing phase and minimized by selecting an experienced operator, an appropriate working position, and a suitable measurement strategy.

Another factor playing a crucial role in measurement accuracy and uncertainty is the probing system. Inaccuracies of tactile probes can result from manufacturing tolerances, wear, or improper calibration. These errors can lead to significant deviations in measurement results, particularly when measuring small or complex geometries. For the experiment, a Center Reference Probe was selected due to its high stiffness and presumed accuracy. Considering the known thermal expansion coefficient of steel and the stylus length, the thermal contribution of the probe was estimated to be an order of magnitude smaller than other primary components of the combined uncertainty. Therefore, it was considered negligible in this study.

A theoretical source of uncertainty when using AACMMs is also the selection of the metrological software used for processing and evaluating measured data. The software algorithms that process data from the probe can potentially contribute to measurement uncertainty. However, the developers of major reliable metrological platforms used with coordinate-measuring equipment currently state that the influence of the software itself on measurement results is negligible. This source of uncertainty was therefore not considered in this study [

22,

24,

25,

26,

27,

28].

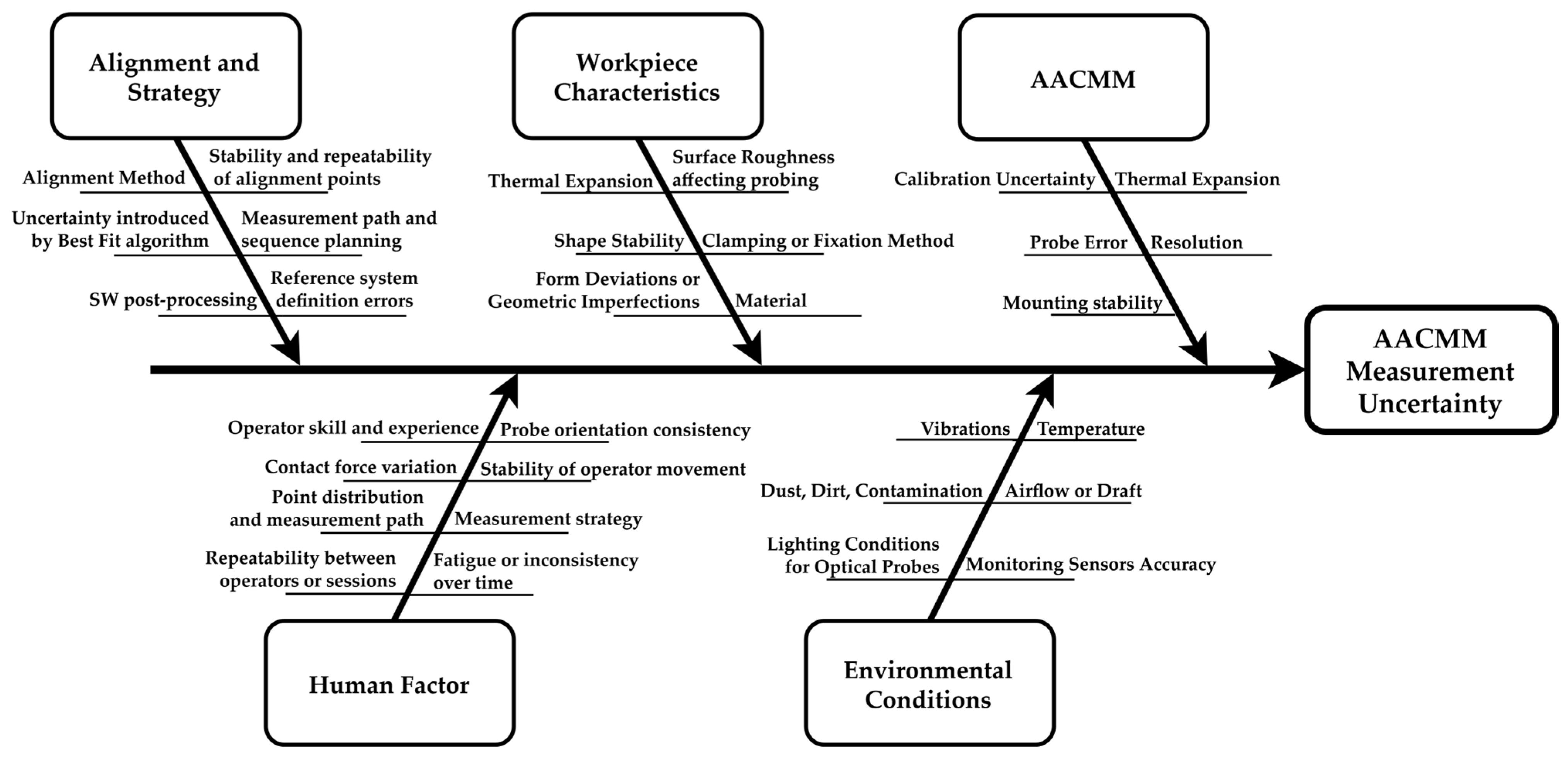

The fishbone diagram in

Figure 4 illustrates the potential sources of type B uncertainty in measurements performed with an AACMM.