Experimental Study of the Cross-Influence of Frost Morphology and Defrost Strategy on the Performance of Tube-Fin Evaporators of Household Refrigerators

Abstract

1. Introduction

2. Experimental Work

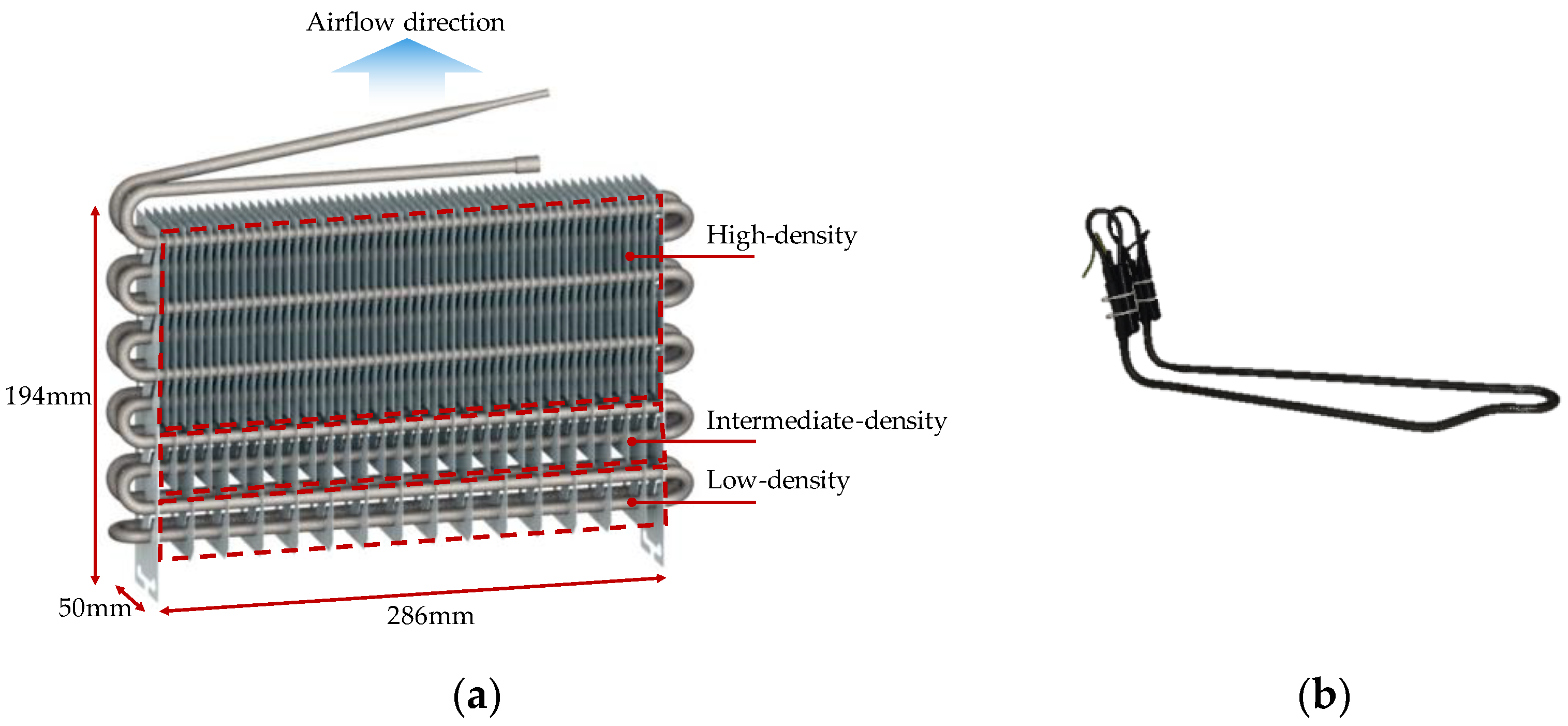

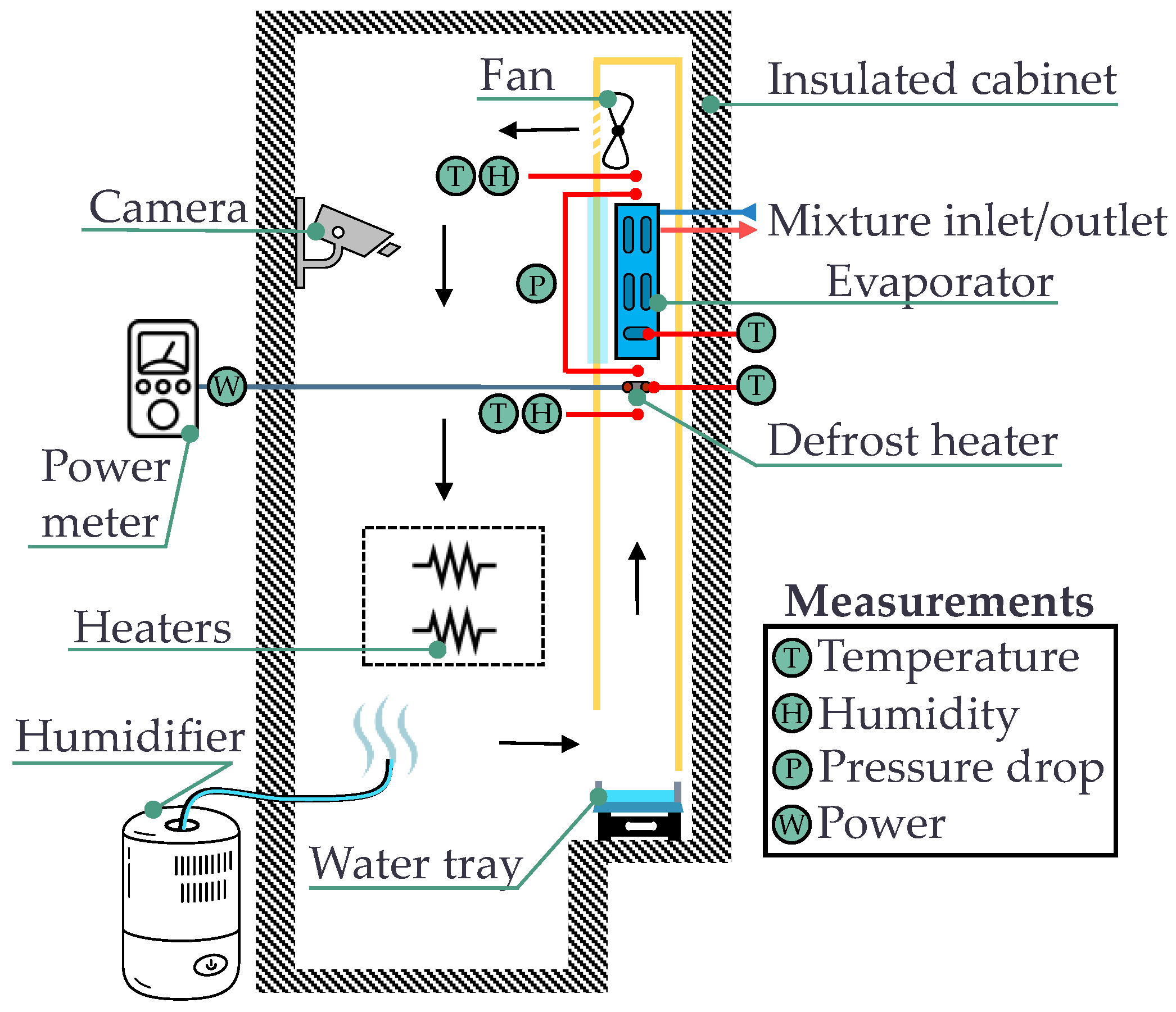

2.1. Apparatuses

2.1.1. Frost Formation Rig

2.1.2. Defrost Rig

2.2. Procedure

2.3. Image Acquisition

3. Results and Discussion

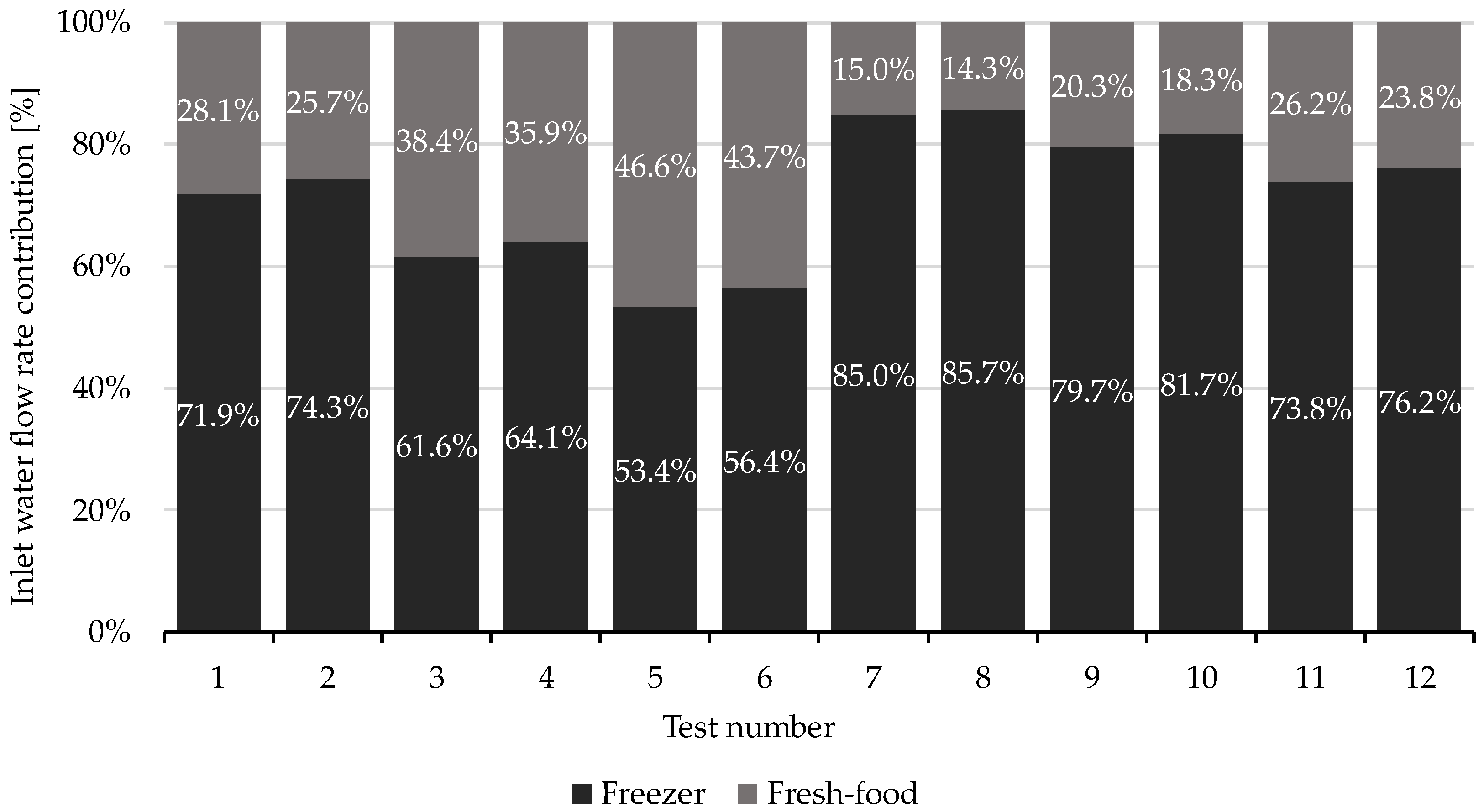

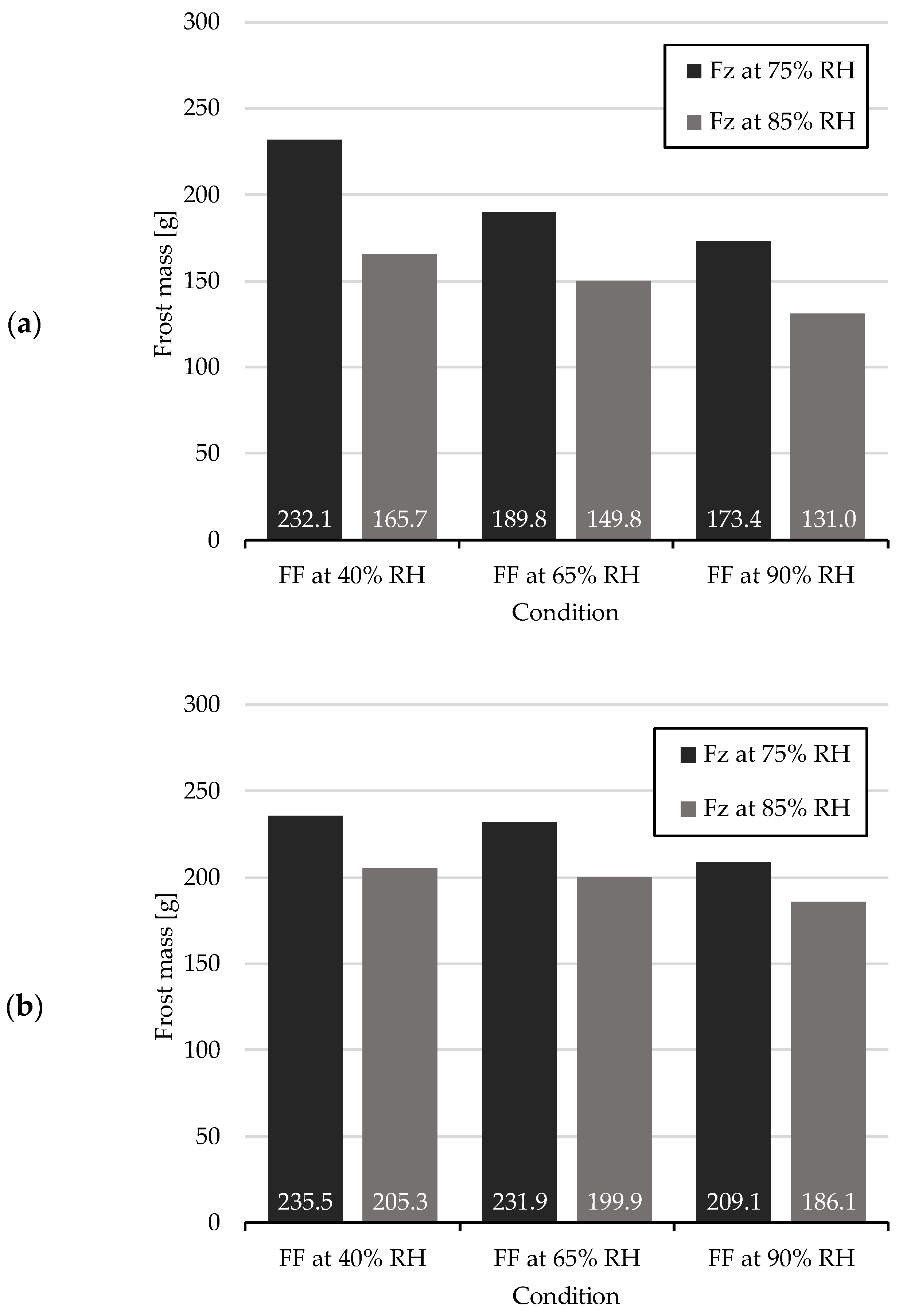

3.1. Frost Formation Results

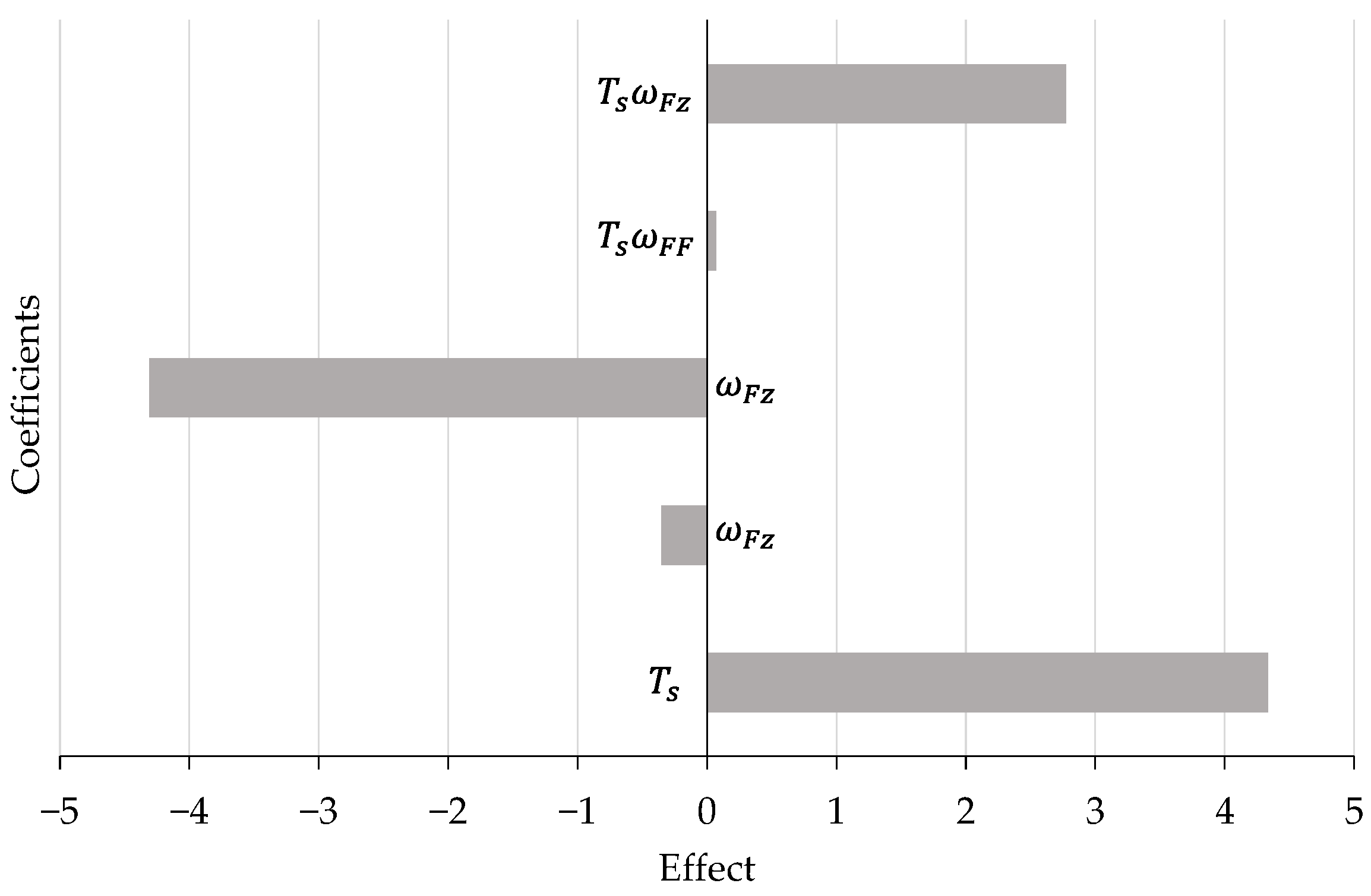

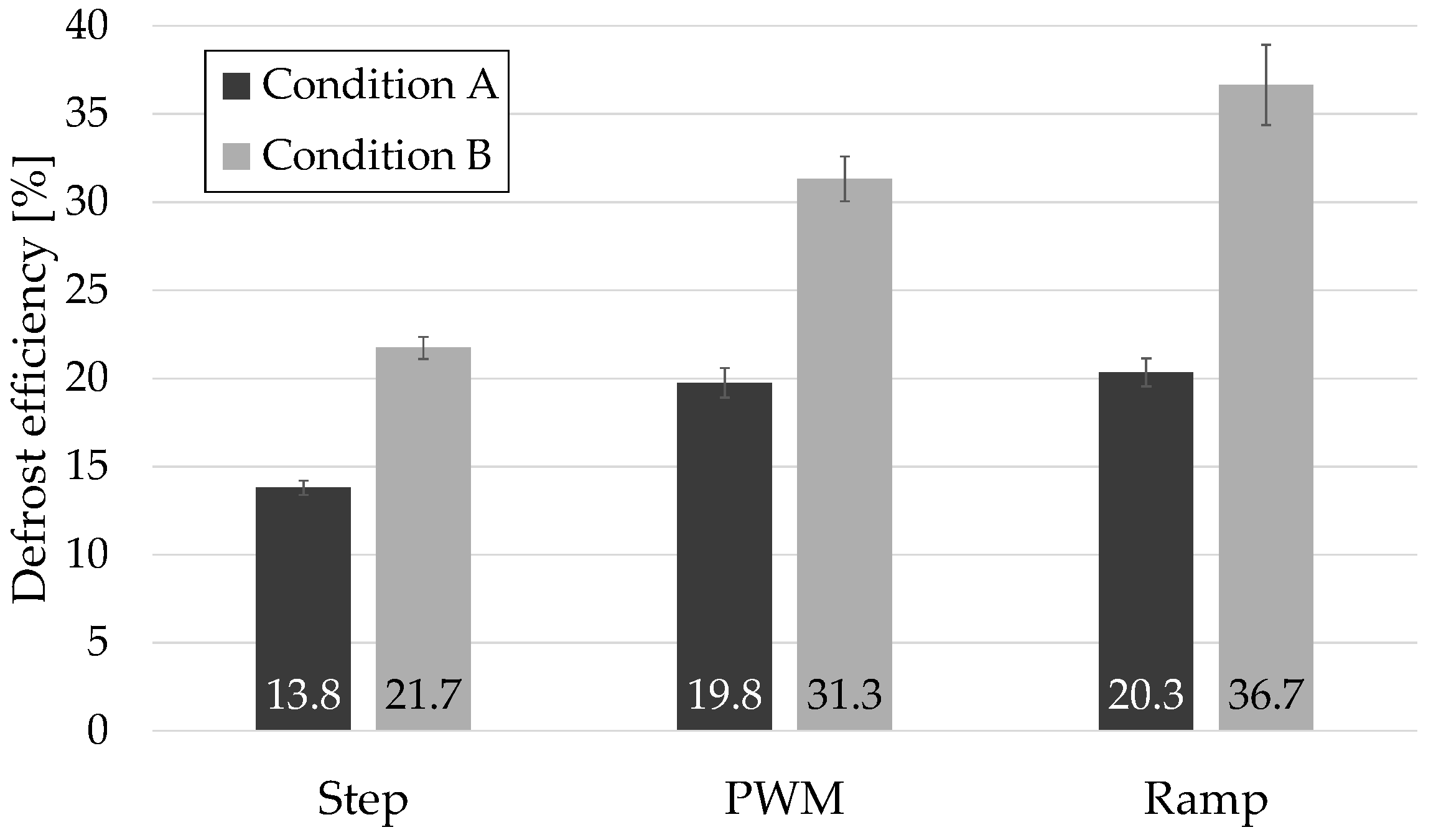

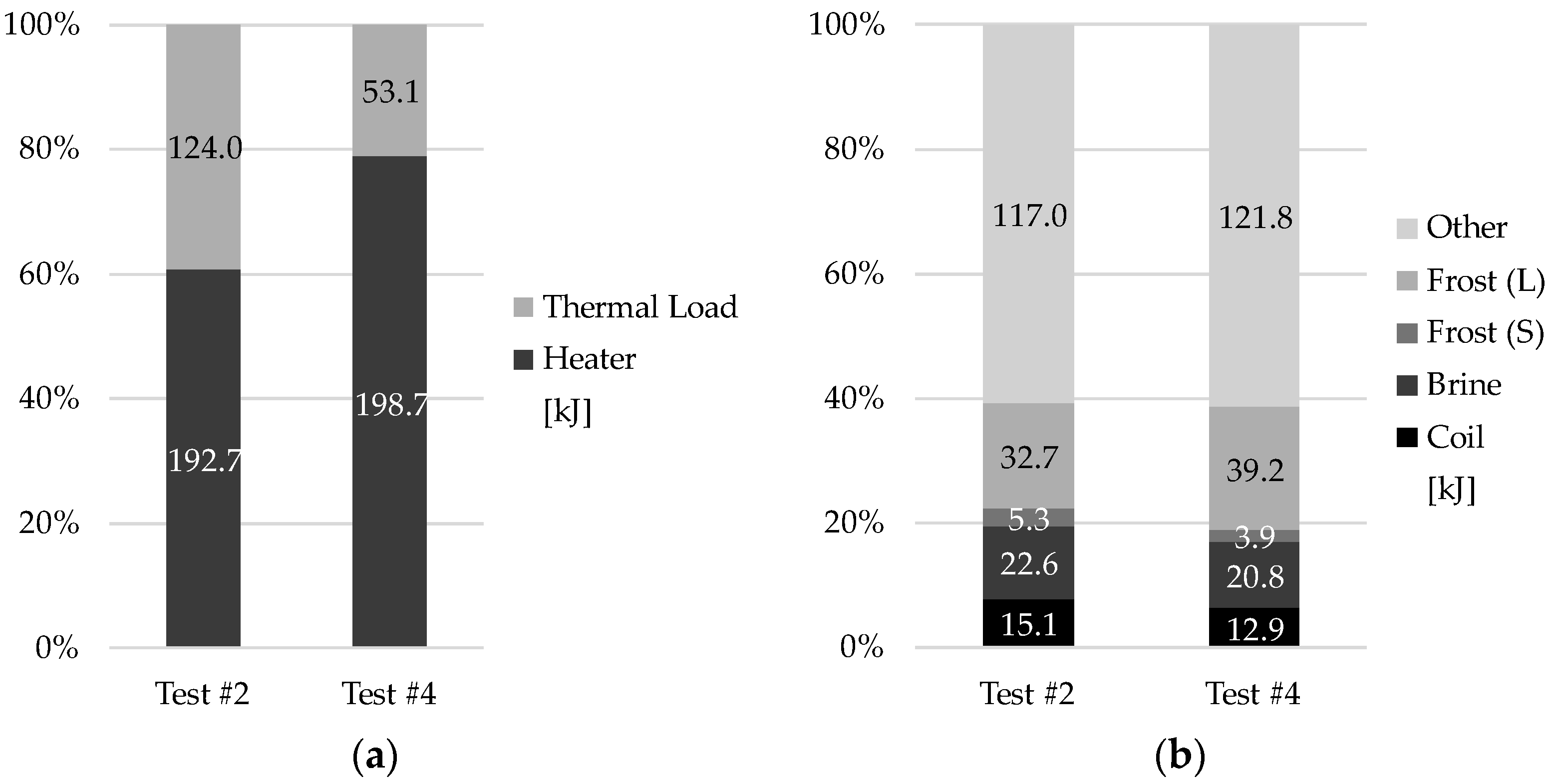

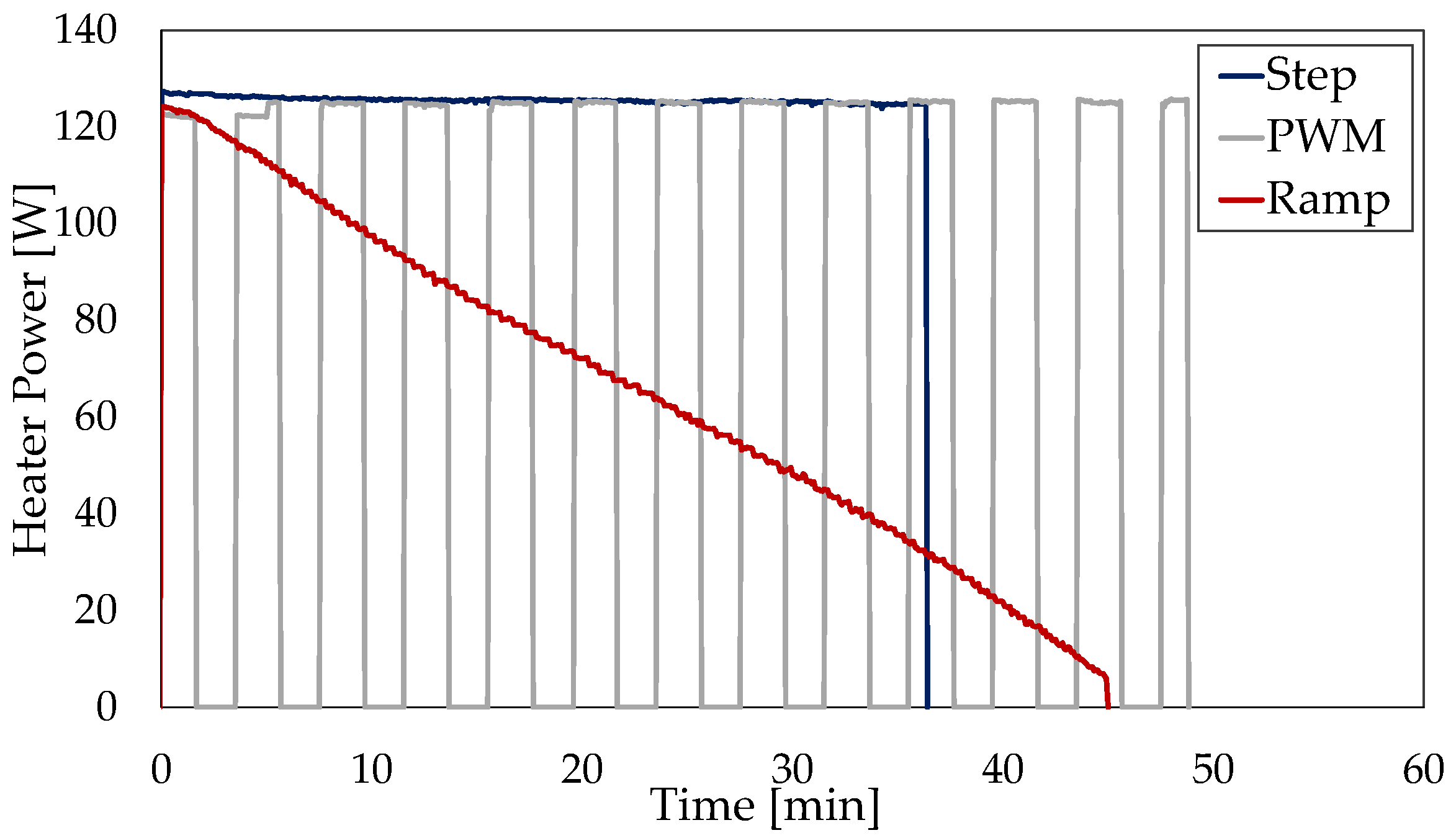

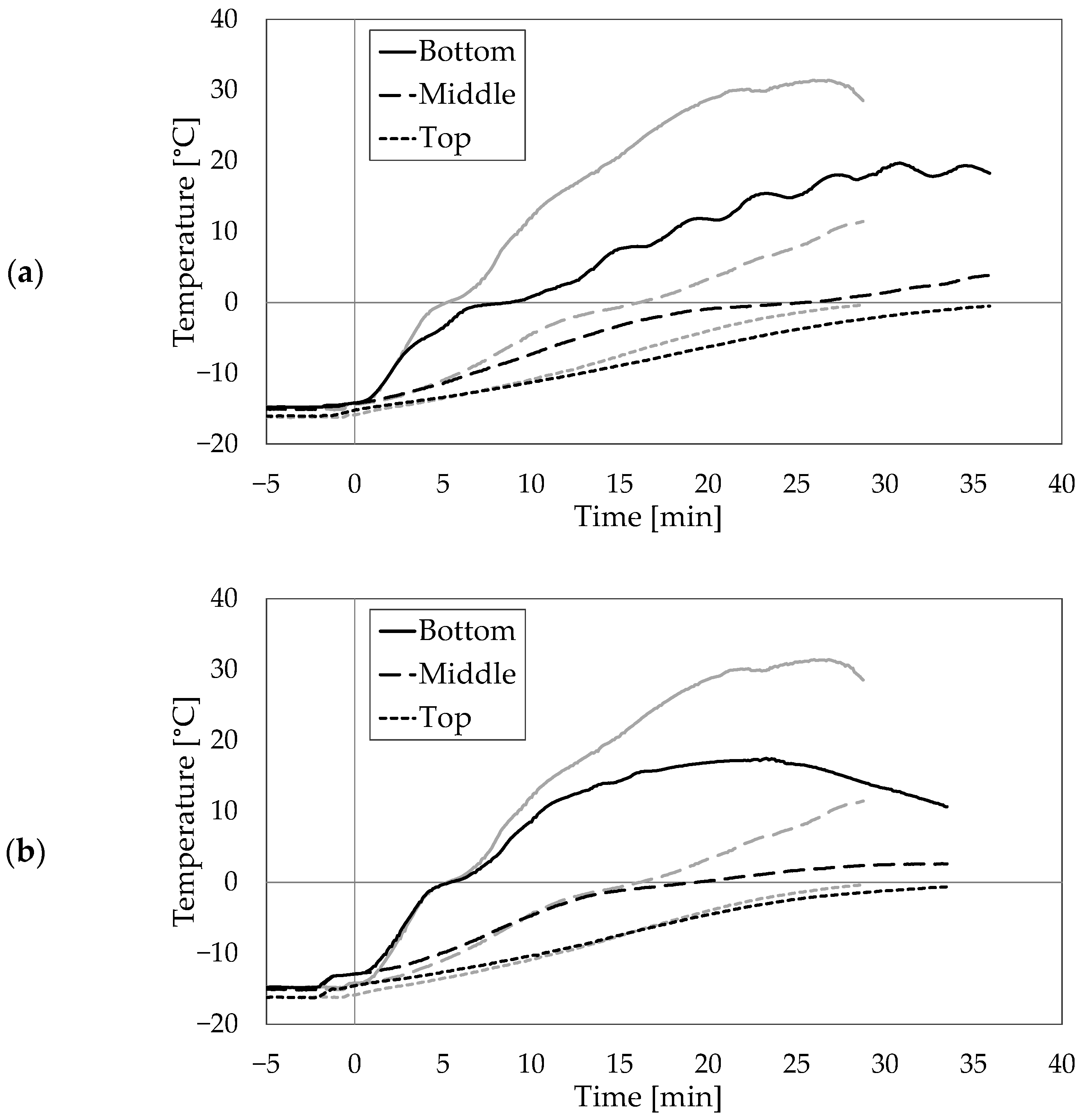

3.2. Defrost Results

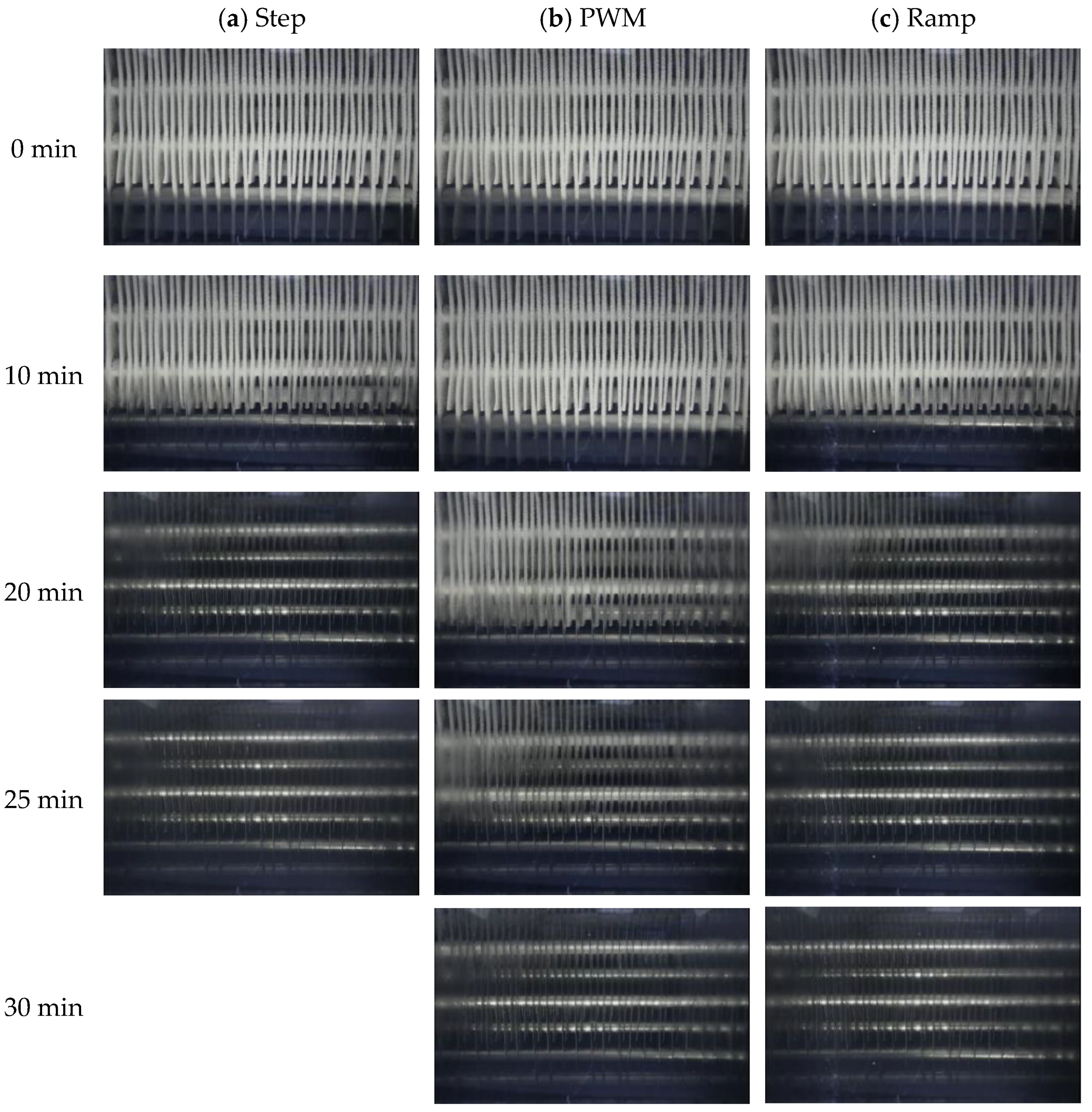

3.3. Evaporator Visualization

4. Final Remarks

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

Nomenclature

| Roman Symbols | |

| A | Area [m2] |

| h | Convective heat transfer coefficient [W/m2-K] |

| E | Energy [kJ] |

| X | Generic Variable |

| m | Mass [g] |

| P | Pixel |

| W | Power [kW] |

| cp | Specific heat [kJ/kg-K] |

| T | Temperature [°C] |

| t | Time [s] |

| u | Uncertainty [variable unit] |

| Water latent heat of fusion [kJ/kg] | |

| Greek Symbols | |

| Absolute humidity [-] | |

| Efficiency [-] | |

| Thickness [m] | |

| Passage fraction [-] | |

| Relative Humidity [-] | |

| Subscripts | |

| a | Air |

| B | Black |

| s | Coil surface |

| d | Defrost |

| h | Defrost heater |

| Fz | Freezer |

| FF | Fresh-Food |

| f | Frost |

| b | Measurement instrument |

| sat | Saturation |

| r | Standard deviation |

| sup | Supersaturation |

| W | White |

| Superscripts | |

| * | Dimensionless normalized variable |

Appendix A

References

- UNEP; IEA. Cooling Emissions and Policy Synthesis Report; United Nations Environment Programme: Nairobi, Kenya; International Energy Agency: Paris, France, 2020; Available online: https://backend.orbit.dtu.dk/ws/portalfiles/portal/247572967/Full_Cooling_Synthesis_Report.pdf (accessed on 15 May 2025).

- Green Cooling Initiative. Global Greenhouse Gas Emissions from the RAC Sector; Green Cooling Initiative: Eschborn, Germany, 2024; Available online: https://www.green-cooling-initiative.org/country-data#!total-emissions/all-sectors/absolute (accessed on 15 May 2025).

- Na, B.; Webb, R.L. A fundamental understanding of factors affecting frost nucleation. Int. J. Heat Mass Transf. 2003, 46, 3797–3808. [Google Scholar] [CrossRef]

- Stoecker, W.F. How frost formation on coils affects refrigeration systems. Refrig. Eng. 1957, 65, 42–46. [Google Scholar]

- Ogawa, K.; Tanaka, N.; Takeshita, M. Performance improvement of plate fin-and-tube heat exchangers under frosting conditions. ASHRAE Trans. 1993, 99, 762–771. [Google Scholar]

- Jhee, S.; Lee, K.; Kim, W. Effect of surface treatments on the frosting/defrosting behavior of a fin-tube heat exchanger. Int. J. Refrig. 2002, 25, 1047–1053. [Google Scholar] [CrossRef]

- Zhang, P.; Hrnjak, P.S. Air-side performance evaluation of three types of heat exchangers in dry, wet and periodic frosting conditions. Int. J. Refrig. 2009, 32, 911–921. [Google Scholar] [CrossRef]

- Silva, D.L.; Hermes, C.J.L.; Melo, C. Experimental study of frost accumulation on fan-supplied tube-fin evaporators. Appl. Therm. Eng. 2011, 31, 1013–1020. [Google Scholar] [CrossRef]

- Knabben, F.T.; Hermes, C.J.L.; Melo, C. In-situ study of frosting and defrosting processes in tube-fin evaporators of household refrigerating appliances. Int. J. Refrig. 2011, 34, 2031–2041. [Google Scholar] [CrossRef]

- Borges, B.N.; Melo, C.; Hermes, C.J.L. Transient simulation of a two-door frost-free refrigerator subjected to periodic door opening and evaporator frosting. Appl. Energy 2015, 147, 386–395. [Google Scholar] [CrossRef]

- Pegallapati, A.S.; Ramgopal, M. Effect of heat transfer area distribution on frosting performance of refrigerator evaporator. Int. J. Heat Mass Transf. 2021, 175, 121317. [Google Scholar] [CrossRef]

- Ambriz, Y.A.A.; Ledesma, S.; Flores, J.M.B.; Mariscal, I.C.; Ojeda, D.L.A. Frost thickness estimation in a domestic refrigerator using acoustic signals and artificial intelligence. Exp. Sys. App. 2022, 201, 117071. [Google Scholar] [CrossRef]

- Xu, B.; Han, Q.; Chen, J.; Li, F.; Wang, N.; Li, D.; Pan, X. Experimental investigation of frost and defrost performance of microchannel heat exchangers for heat pump systems. Appl. Energy 2013, 103, 180–188. [Google Scholar] [CrossRef]

- Lee, W.; Kwon, O.K. Image processing for frost thickness measurement in fin-and-tube heat exchangers. Therm. Sci. Eng. Prog. 2021, 24, 100937. [Google Scholar] [CrossRef]

- Ambriz, Y.A.A.; Ledesma, S.; Ojeda, D.L.A.; Flores, J.M.B. Accurate classification of frost thickness using visual information in a domestic refrigerator. Int. J. Refrig. 2023, 145, 256–263. [Google Scholar] [CrossRef]

- Shangwen, L.; Mengije, S.; Long, Z.; Xuan, Z.; Keke, S.; Jun, S. Experimental investigation of frost characteristics on vertical cold plate under forced convection influenced by surface temperature. Appl. Therm. Eng. 2023, 234, 121318. [Google Scholar] [CrossRef]

- Rahman, H.; Akbar, H.; Malik, A.N.; Nawaz, T.; Lazoglu, I. Effective image processing-based technique for frost detection and quantification in domestic refrigerators. Int. J. Refrig. 2024, 160, 217–228. [Google Scholar] [CrossRef]

- Kim, K.; Lee, K.S. Frosting and defrosting characteristics of a fin according to surface contact angle. Int. J. Heat Mass Transf. 2011, 54, 2758–2764. [Google Scholar] [CrossRef]

- Wang, F.; Liang, C.; Zhang, X. Visualization study of the effect of surface contact angle on frost melting process under different frosting conditions. Int. J. Refrig. 2016, 64, 143–152. [Google Scholar] [CrossRef]

- Sommers, A.D.; Napora, A.C.; Truster, N.L.; Caraballo, E.J.; Hermes, C.J.L. A semi-empirical correlation for predicting the frost density on hydrophilic and hydrophobic substrates. Int. J. Refrig. 2017, 74, 313–323. [Google Scholar] [CrossRef]

- Hou, Z.; Yang, Z.; Zhao, Y.; Zhao, X.; Sun, B.; Wang, G.; Xie, T. Study on the anti-frosting performance of hydrophobic fin with non-toxic for the R600a frost-free refrigerator. Appl. Therm. Eng. 2024, 238, 122033. [Google Scholar] [CrossRef]

- Piucco, R.O.; Hermes, C.J.L.; Melo, C.; Barbosa Júnior, J.R. A study of frost nucleation on flat surfaces. Exp. Therm. Fluid Sci. 2008, 32, 1710–1715. [Google Scholar] [CrossRef]

- Wang, Z.; Cui, W.; Li, L.; Zhan, C.; Zhang, Y. A numerical study of heterogeneous nucleation of ice crystals and frost layer growth on horizontal cold surfaces. Int. J. Heat Mass Transf. 2024, 228, 125604. [Google Scholar] [CrossRef]

- Silva, D.L.; Hermes, C.J.L.; Melo, C. Optimal defrost cycle for the air cooler revisited: A case study of fan-supplied tube-fin evaporators. Int. J. Refrig. 2018, 89, 142–148. [Google Scholar] [CrossRef]

- Hermes, C.J.L.; Boeng, J.; Da Silva, D.L.; Knabben, F.T.; Sommers, A.D. Evaporator frosting in refrigerating appliances: Fundamentals and applications. Energies 2021, 14, 5991. [Google Scholar] [CrossRef]

- Melo, C.; Knabben, F.T.; Pereira, P.V. An experimental study on defrost heaters applied to frost-free household refrigerators. Appl. Therm. Eng. 2013, 51, 239–245. [Google Scholar] [CrossRef]

- Bansal, P.; Fothergill, D.; Fernandes, R. Thermal analysis of the defrost cycle in a domestic freezer. Int. J. Refrig. 2010, 33, 589–599. [Google Scholar] [CrossRef]

- Yin, H.; Yang, Z.; Chen, A.; Zhang, N. Experimental research on a novel cold storage defrost method based on air bypass circulation and electric heater. Energy 2012, 37, 623–631. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, D.; Ding, G.; Ren, T.; Miao, S.; Han, X.; Noda, T. Improving defrosting performance by controlling frost distribution to match defrosting heat distribution in frost-free household refrigerators. Int. J. Refrig. 2017, 77, 136–148. [Google Scholar] [CrossRef]

- Zhao, R.; Huang, D.; Peng, X.; Qiao, L. Comprehensive measures to enhance electric heater defrosting (EHD) performance for household frost-free refrigerators. Int. J. Refrig. 2020, 111, 1–8. [Google Scholar] [CrossRef]

- Modarres, F.G.; Rasti, M.; Joybari, M.M.; Nasrabadi, M.R.F.; Nematollahi, O. Experimental investigation of energy consumption and environmental impact of adaptive defrost in domestic refrigerators. Measurement 2016, 92, 391–399. [Google Scholar] [CrossRef]

- Knabben, F.T.; Melo, C. An experimental study on the effect of a new defrosting strategy on the energy consumption of household refrigerators. In Proceedings of the International Refrigeration and Air Conditioning Conference; Purdue: West Lafayette, IN, USA, 2016; p. 1580. [Google Scholar]

- Yoon, Y.; Jeong, H.; Lee, K. Adaptive defrost methods for improving defrosting efficiency of household refrigerator. Energy Convers. Manag. 2018, 157, 511–516. [Google Scholar] [CrossRef]

- Jeong, H.; Byun, S.; Kim, D.R.; Lee, K. Power optimization for defrosting heaters in household refrigerators to reduce energy consumption. Energy Convers. Manag. 2021, 237, 114127. [Google Scholar] [CrossRef]

- Zhao, R.; Wang, Z.; Huang, D.; Shen, W.; Hu, H.; Tang, X. Electric-heater defrosting performance of frost-free refrigerator-freezer and its improvement by step-reduction power. Appl. Therm. Eng. 2023, 226, 120147. [Google Scholar] [CrossRef]

- Wang, T.; Chen, H.; Zheng, P.; Zhao, Y.; Yang, P.; Liu, Y. Experimental study on high-efficiency defrosting control logic for frost-free household refrigerators. Appl. Therm. Eng. 2025, 278, 127289. [Google Scholar] [CrossRef]

- Safikhani, H.; Esmaeili, F.; Rezvani, S. Extracting a smart model for determining defrost time in household refrigerators using a combination of CFD, experimental data, and GMDH type artificial neural network. Int. J. Refrig. 2025, 176, 52–65. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, Z.; Wang, Y.; Zhao, Y.; Shu, Y.; Zhao, X.; Sun, B.; Wang, G.; Xie, T. Defrost characteristics and performance improvement of electric heaters in R600a frost-free refrigerators. Thermal Sci. Eng. Prog. 2025, 58, 103219. [Google Scholar] [CrossRef]

- Otsu, N. A threshold selection method from gray-level histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

- Melo, F.S.; Cardoso, R.P.; Hermes, C.J.L. Quality and quantity trade-offs in clear ice making. Int. J. Refrig. 2024, 161, 94–100. [Google Scholar] [CrossRef]

- Kobayashi, T. On the habit of snow crystals artificially produced at low pressures. J. Meteorol. Soc. Jpn. 1958, 36, 193–208. [Google Scholar] [CrossRef]

- Da Silva, D.L. Frost formation on fan-supplied tube-fin evaporators: A visual and numerical analysis. In Proceedings of the International Refrigeration and Air Conditioning Conference; Purdue: West Lafayette, IN, USA, 2012; p. 1164. [Google Scholar]

- Nakaya, U. Snow Crystals: Natural and Artificial; Harvard University Press: Cambridge, MA, USA, 1954; p. 522. [Google Scholar]

- Na, B.; Webb, R.L. New model for frost growth rate. Int. J. Heat Mass Transf. 2004, 47, 925–936. [Google Scholar] [CrossRef]

- Negrelli, S.; Hermes, C.J.L. A semi-empirical correlation for the thermal conductivity of frost. Int. J. Refrig. 2015, 58, 243–252. [Google Scholar] [CrossRef]

- Mohs, W.F.; Kulacki, F.A. Heat and Mass Transfer in the Melting of Frost, 1st ed.; Springer: Cham, Switzerland, 2015. [Google Scholar] [CrossRef]

| Authors | Ref. | Year | Heater Type | Range | Proposed Optimization |

|---|---|---|---|---|---|

| Bansal et al. | [27] | 2010 | Radiant | 30% | Setup |

| Knabben et al. | [9] | 2011 | Distributed | - | Setup |

| Yin et al. | [28] | 2012 | Radiant | 26–78% | Setup |

| Melo et al. | [26] | 2013 | Distributed, Radiant and Glass tube | 27–48% | Control |

| Knabben and Melo | [32] | 2016 | Distributed and Radiant | - | Setup and Control |

| Modarres et al. | [31] | 2016 | Distributed | - | Control |

| Li et al. | [29] | 2017 | Radiant | 29–41% | Setup |

| Yoon et al. | [33] | 2018 | Distributed and Radiant | 21–37% | Control |

| Zhao et al. | [30] | 2020 | Radiant | - | Setup |

| Jeong et al. | [34] | 2021 | Distributed and Radiant | 14–32% | Setup |

| Zhao et al. | [35] | 2023 | Radiant | 12–16% | Control |

| Wang et al. | [36] | 2025 | Radiant | - | Control |

| Safikhani et al. | [37] | 2025 | Radiant | - | Control |

| Zhang et al. | [38] | 2025 | Distributed and Radiant | 27–38% | Setup |

| Test [-] | [°C] | [°C] | [%] | [%] | [g/kg] | [g/kg] | [g/kg] |

|---|---|---|---|---|---|---|---|

| 1 | −25 | −18 | 40 | 75 | 2.00 | 0.58 | 0.33 |

| 2 | −25 | −18 | 40 | 85 | 2.00 | 0.65 | 0.40 |

| 3 | −25 | −18 | 65 | 75 | 3.26 | 0.58 | 0.46 |

| 4 | −25 | −18 | 65 | 85 | 3.26 | 0.65 | 0.53 |

| 5 | −25 | −18 | 90 | 75 | 4.53 | 0.58 | 0.58 |

| 6 | −25 | −18 | 90 | 85 | 4.53 | 0.65 | 0.65 |

| 7 | −15 | −8 | 40 | 75 | 2.00 | 1.43 | 0.47 |

| 8 | −15 | −8 | 40 | 85 | 2.00 | 1.62 | 0.64 |

| 9 | −15 | −8 | 65 | 75 | 3.26 | 1.43 | 0.60 |

| 10 | −15 | −8 | 65 | 85 | 3.26 | 1.62 | 0.77 |

| 11 | −15 | −8 | 90 | 75 | 4.53 | 1.43 | 0.72 |

| 12 | −15 | −8 | 90 | 85 | 4.53 | 1.62 | 0.90 |

| Test [-] | Control Strategy | [g/kg] | [°C] | [°C] |

|---|---|---|---|---|

| 1 | Step | 0.69 | −18 | −24 |

| 2 | PWM | 0.69 | −18 | −24 |

| 3 | Ramp | 0.69 | −18 | −24 |

| 4 | Step | 1.72 | −8 | −15 |

| 5 | PWM | 1.72 | −8 | −15 |

| 6 | Ramp | 1.72 | −8 | −15 |

| Test [-] | Frost Formation Time [h] | Defrost Duration [min] | [g] |

|---|---|---|---|

| 1 | 18.24 | 43.75 | 232.13 |

| 2 | 10.80 | 39.00 | 165.65 |

| 3 | 12.20 | 41.25 | 189.82 |

| 4 | 8.88 | 37.25 | 149.83 |

| 5 | 8.41 | 35.08 | 173.44 |

| 6 | 6.11 | 34.17 | 130.98 |

| 7 | 14.69 | 41.67 | 235.51 |

| 8 | 9.18 | 38.83 | 205.33 |

| 9 | 13.12 | 39.58 | 231.93 |

| 10 | 8.70 | 37.08 | 199.88 |

| 11 | 9.21 | 36.92 | 209.11 |

| 12 | 7.15 | 35.50 | 186.05 |

| Frosting | Defrosting | |||||||

|---|---|---|---|---|---|---|---|---|

| Test [-] | [°C] | [°C] | [%] | [g] | Strategy | Duration | [%] | [°C] |

| 1 | −17.9 | −24.5 | 0.70 | 97.1 | Step | 36 min20 s | 13.9 ± 0.4 | 264 |

| 2 | −17.9 | −24.1 | 0.70 | 98.0 | PWM | 48 min45 s | 19.8 ± 0.8 | 207 |

| 3 | −18.0 | −24.1 | 0.69 | 94.1 | Ramp | 44 min55 s | 20.3 ± 0.8 | 239 |

| 4 | −8.0 | −15.0 | 1.69 | 117.5 | Step | 26 min45 s | 21.7 ± 0.6 | 266 |

| 5 | −8.3 | −15.1 | 1.66 | 115.1 | PWM | 33 min55 s | 31.3 ± 1.3 | 209 |

| 6 | −8.1 | −15.3 | 1.69 | 122.4 | Ramp | 31 min30 s | 36.7 ± 2.3 | 230 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Braun, L.P.B.; Reis, R.G.; Nascimento, C.A.R.; Silveira, A.S.; Hermes, C.J.L. Experimental Study of the Cross-Influence of Frost Morphology and Defrost Strategy on the Performance of Tube-Fin Evaporators of Household Refrigerators. Thermo 2025, 5, 32. https://doi.org/10.3390/thermo5030032

Braun LPB, Reis RG, Nascimento CAR, Silveira AS, Hermes CJL. Experimental Study of the Cross-Influence of Frost Morphology and Defrost Strategy on the Performance of Tube-Fin Evaporators of Household Refrigerators. Thermo. 2025; 5(3):32. https://doi.org/10.3390/thermo5030032

Chicago/Turabian StyleBraun, Luiz P. B., Rodrigo G. Reis, Carlos A. R. Nascimento, Alexsandro S. Silveira, and Christian J. L. Hermes. 2025. "Experimental Study of the Cross-Influence of Frost Morphology and Defrost Strategy on the Performance of Tube-Fin Evaporators of Household Refrigerators" Thermo 5, no. 3: 32. https://doi.org/10.3390/thermo5030032

APA StyleBraun, L. P. B., Reis, R. G., Nascimento, C. A. R., Silveira, A. S., & Hermes, C. J. L. (2025). Experimental Study of the Cross-Influence of Frost Morphology and Defrost Strategy on the Performance of Tube-Fin Evaporators of Household Refrigerators. Thermo, 5(3), 32. https://doi.org/10.3390/thermo5030032