Characterizing Steam Penetration through Thermal Protective Fabric Materials

Abstract

:1. Introduction

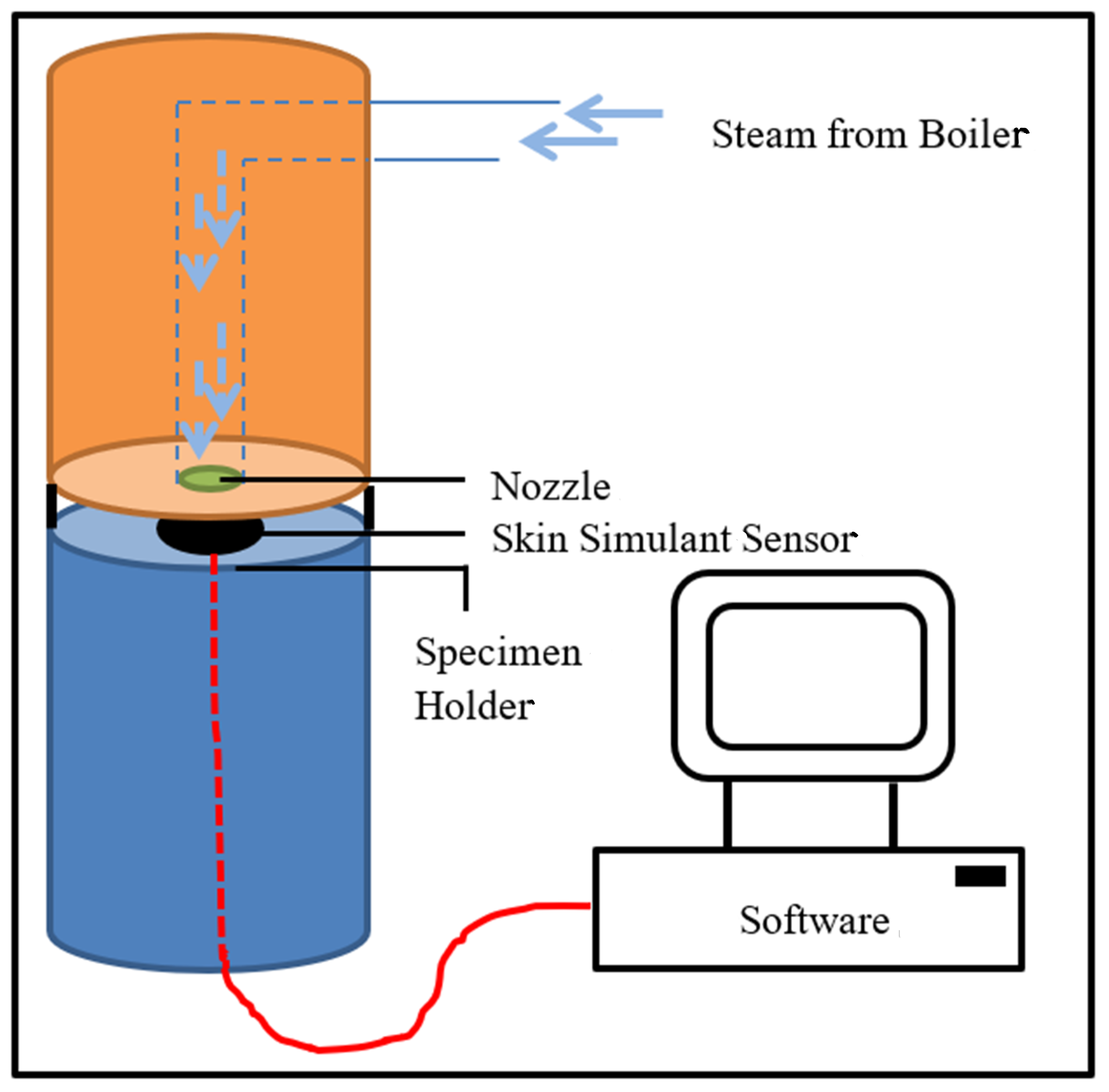

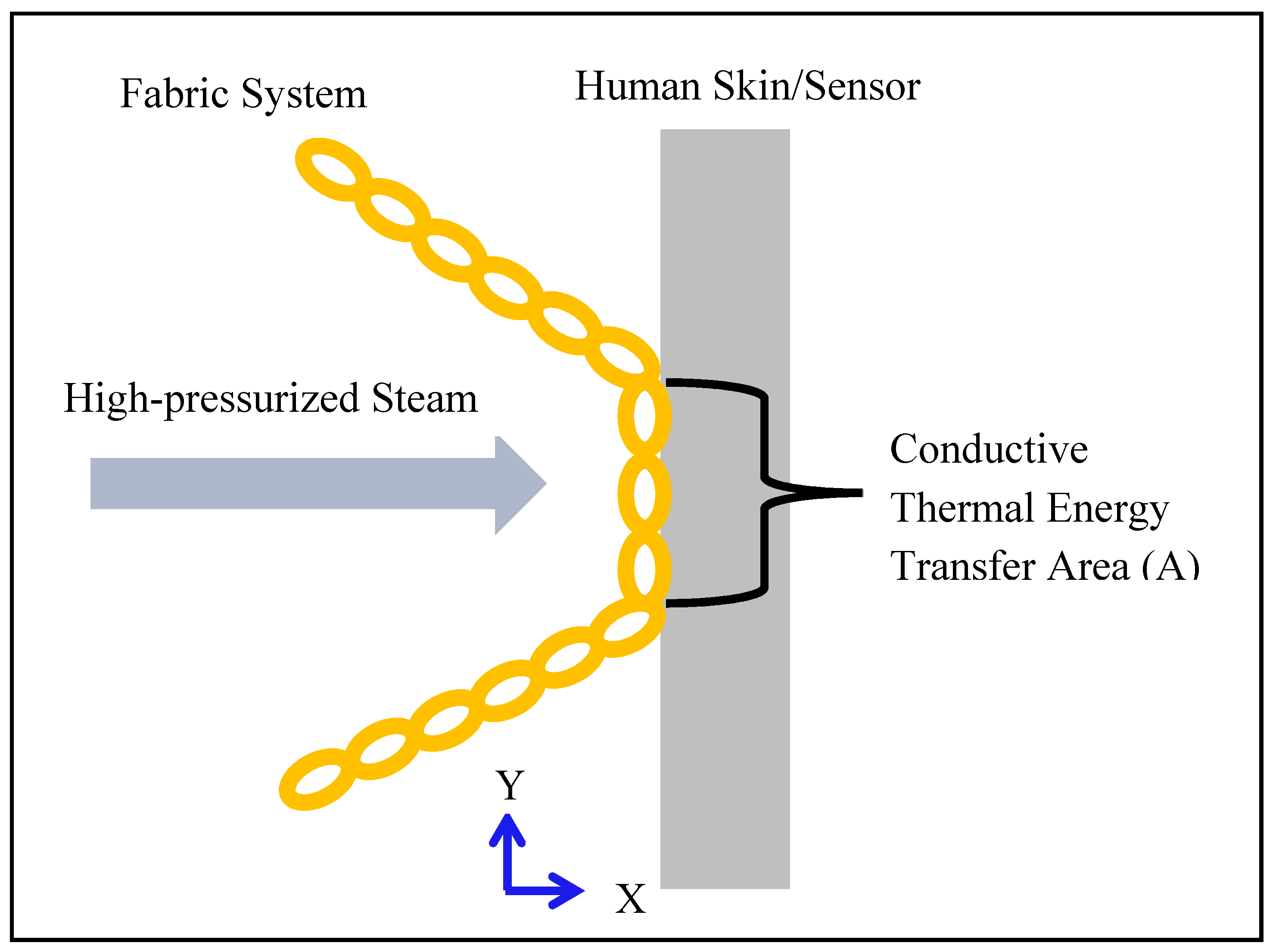

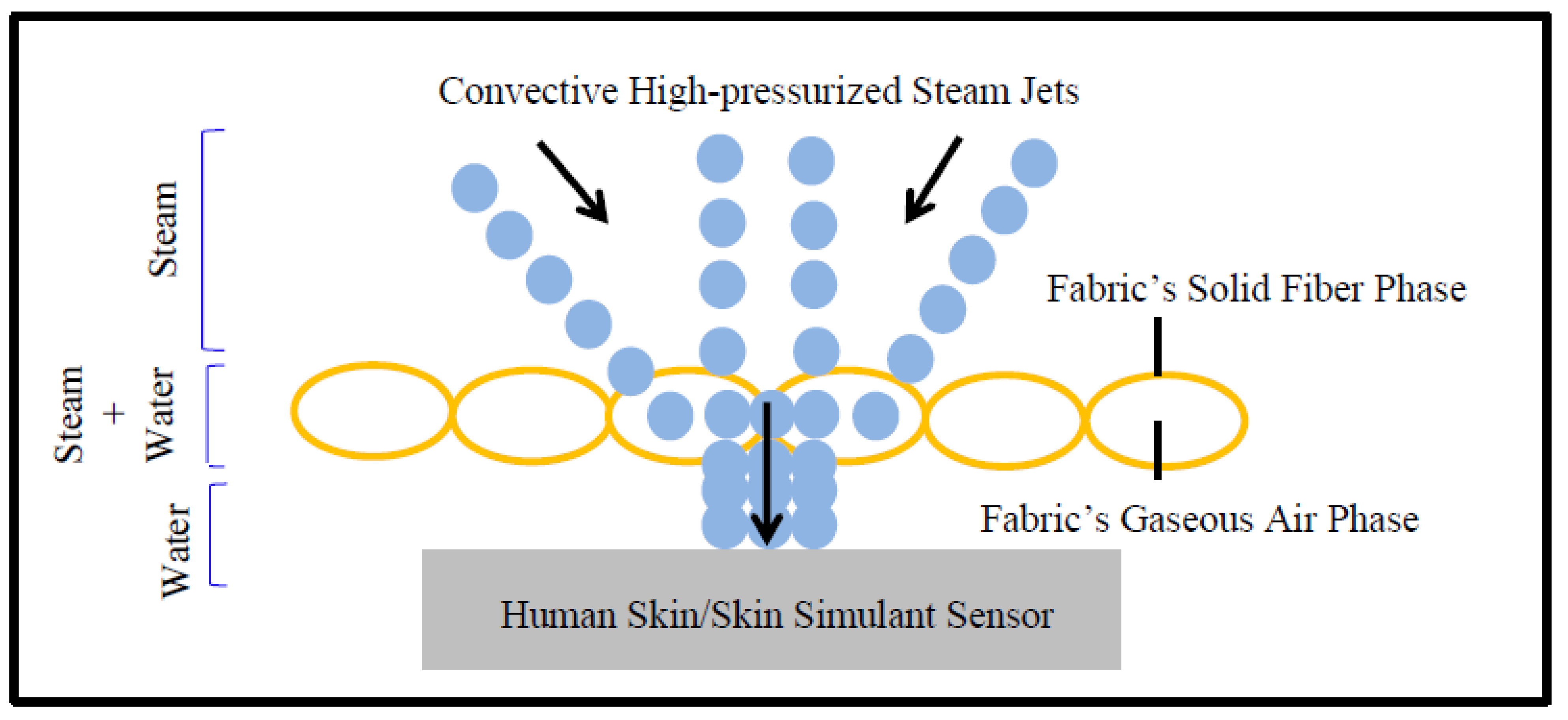

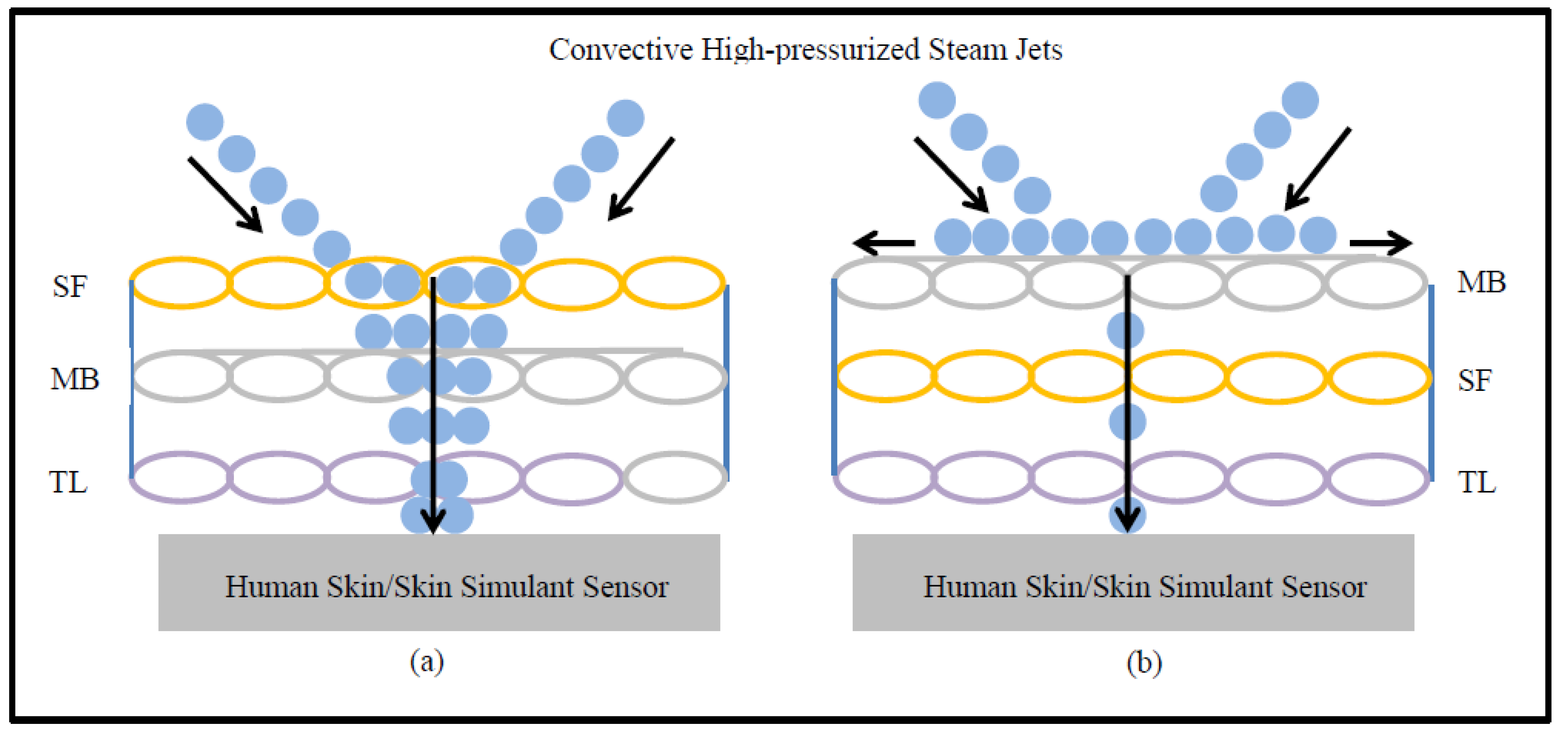

2. Materials and Methods

3. Results and Discussion

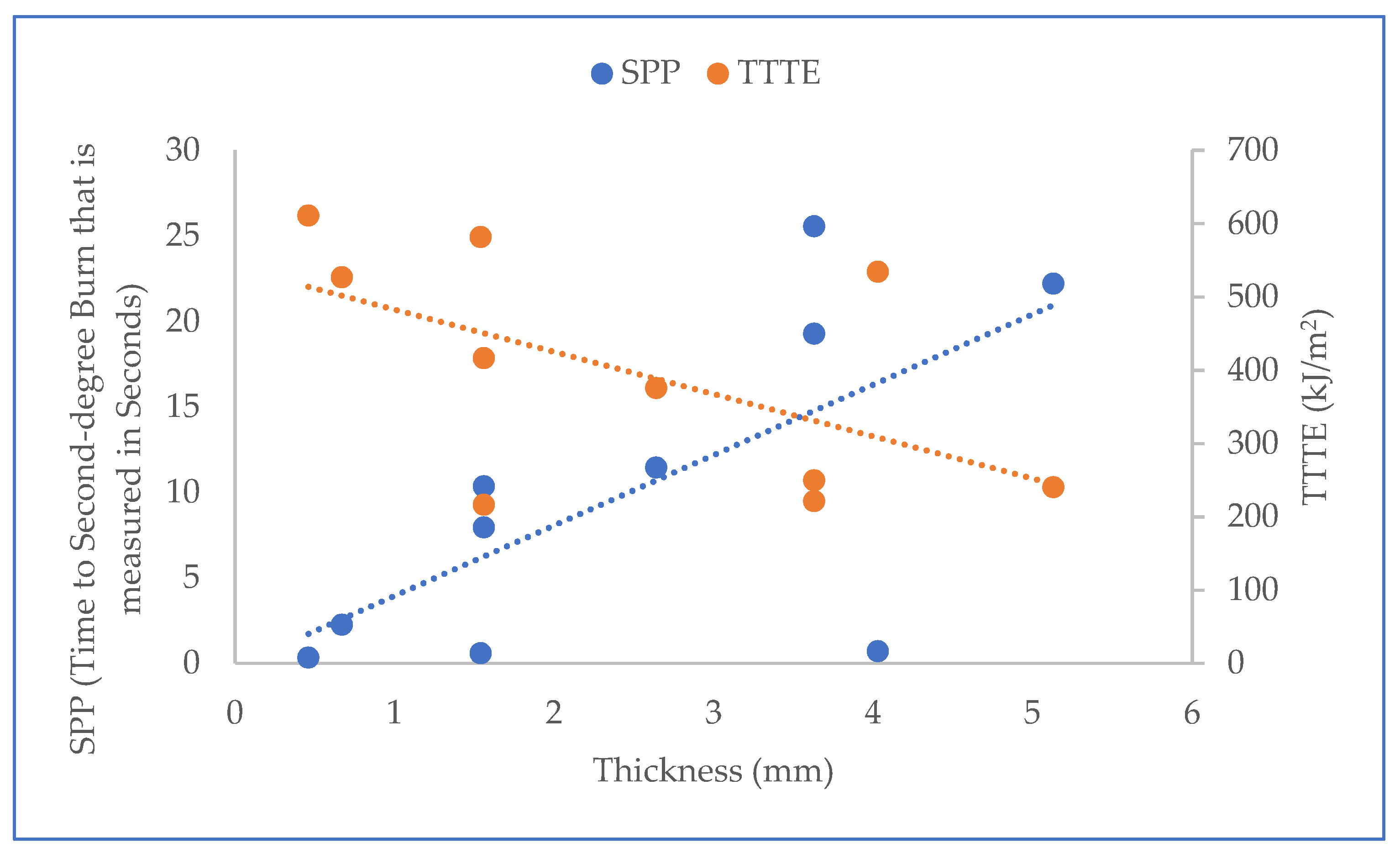

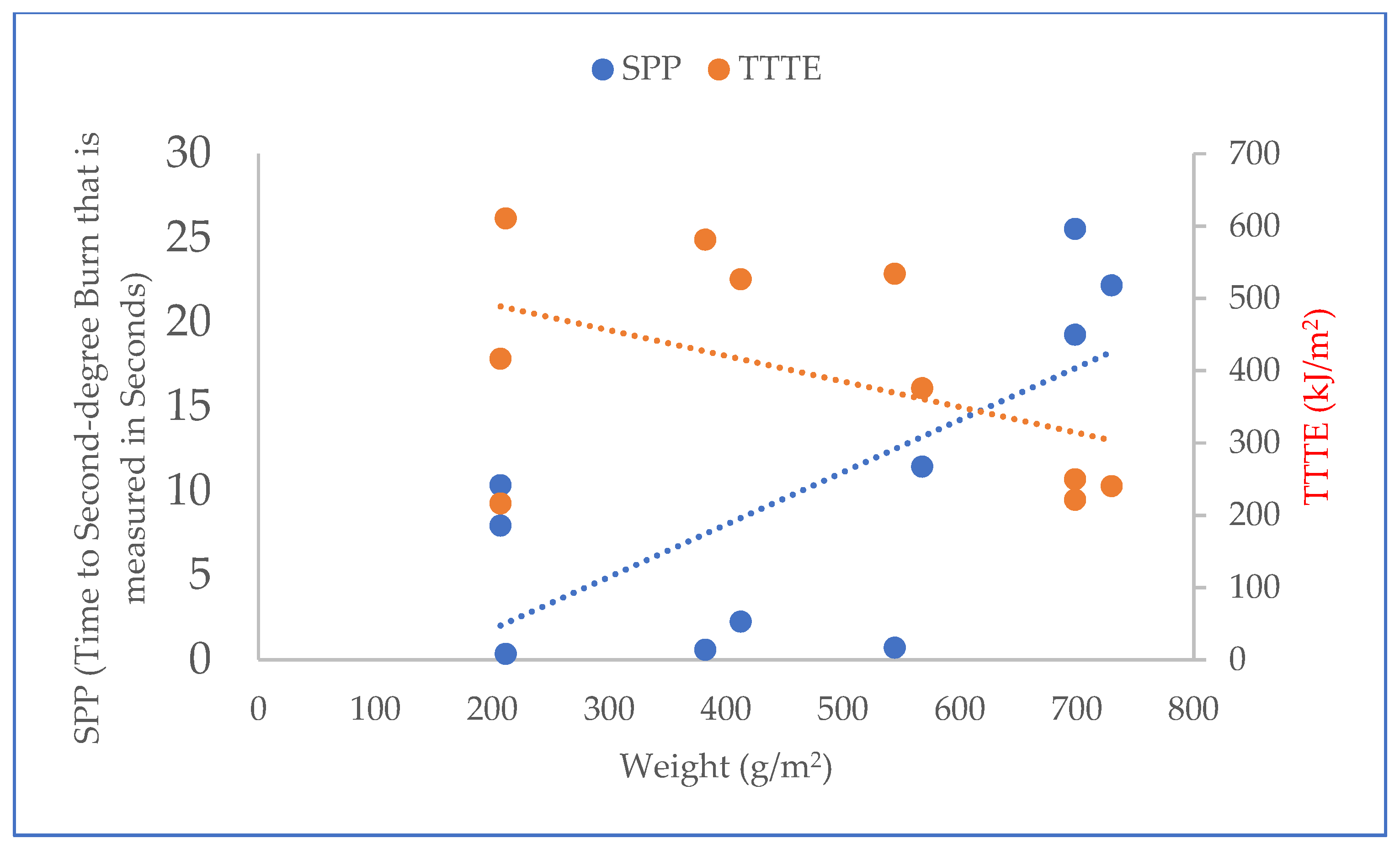

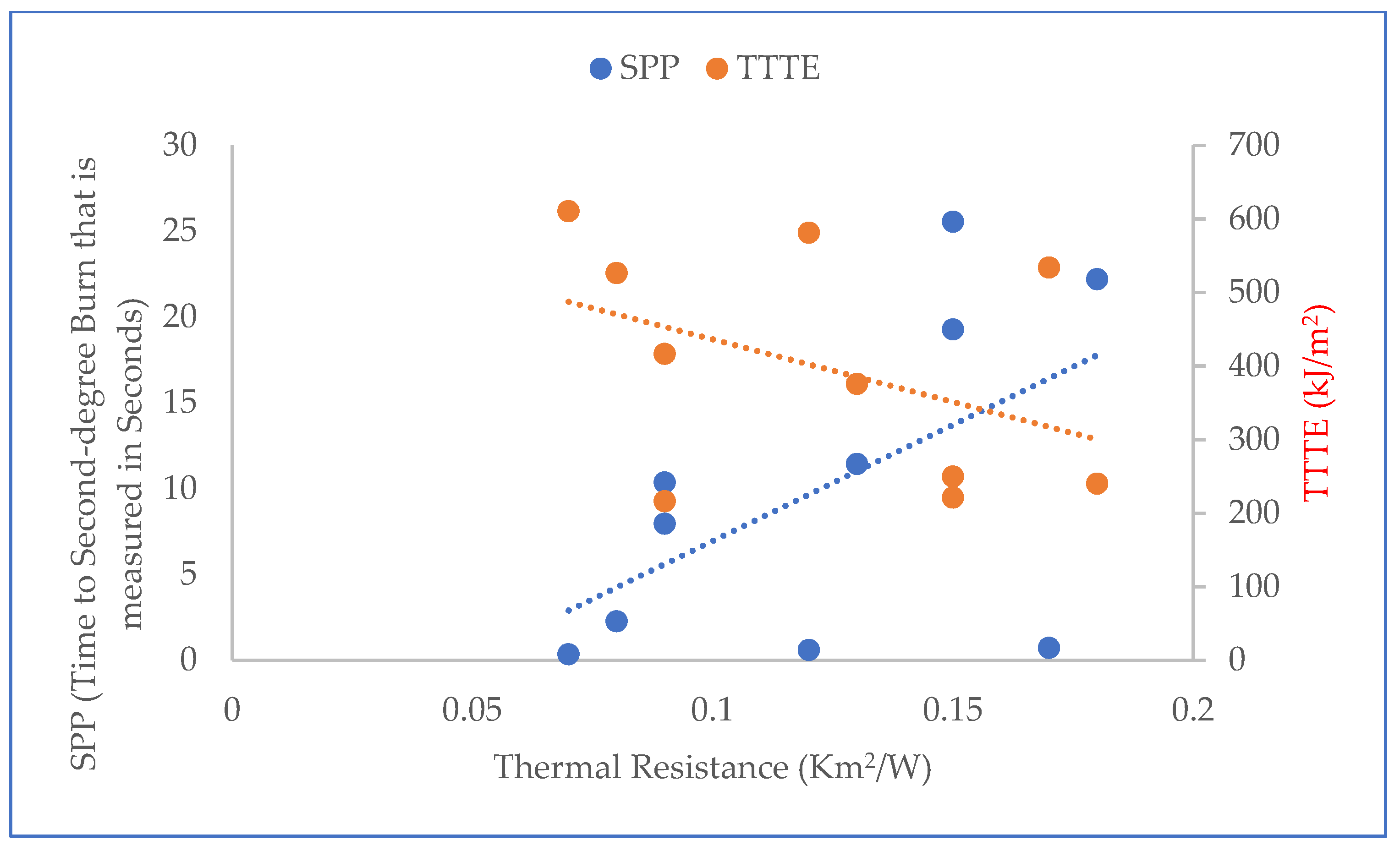

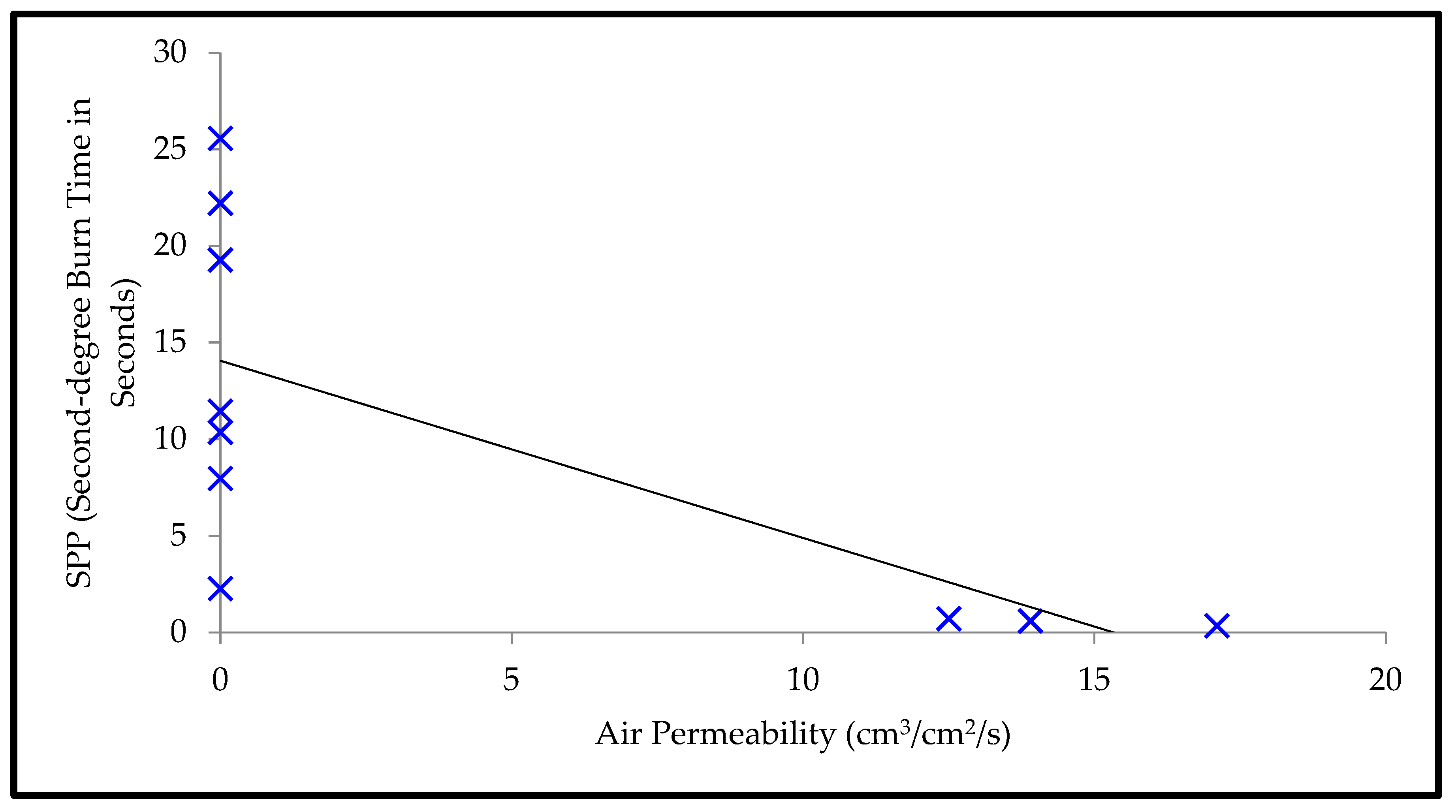

Effect of Fabric Features on SPP/TTTE

4. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Karter, M.J.; Molis, J.L. U.S. Firefighter Injuries—2011; National Fire Protection Association (NFPA): Quincy, MA, USA, 2012; Available online: http://www.tkolb.net/firereports/2012/2011ff_injuries.pdf (accessed on 5 July 2013).

- Fahy, R.F.; LeBlanc, P.R.; Molis, J.L. Firefighter Fatalities in the United States—2011; National Fire Protection Association (NFPA): Quincy, MA, USA, 2012; Available online: https://kstp.com/kstpImages/repository/cs/files/FirefighterFatalities.pdf (accessed on 5 July 2013).

- Mian, M.A.H.; Mullins, R.F.; Alam, B.; Brandigi, C.; Friedman, B.C.; Shaver, J.R.; Hassan, Z. Workplace-related burns. Ann. Burns. Fire. Disasters 2011, 24, 89–93. [Google Scholar]

- Keiser, C.; Becker, C.; Rossi, R.M. Moisture Transport and Absorption in Multilayer Protective Clothing Fabrics. Text. Res. J. 2008, 78, 604–613. [Google Scholar] [CrossRef]

- Keiser, C.; Rossi, R.M. Temperature Analysis for the Prediction of Steam Formation and Transfer in Multilayer Thermal Protective Clothing at Low Level Thermal Radiation. Text. Res. J. 2008, 78, 1025–1035. [Google Scholar] [CrossRef]

- Keiser, C, Wyss, P, Rossi, RM. Analysis of steam formation and migration in firefighters’ protective clothing using x-ray radiography. Int. J. Occup. Saf. Ergon. 2010, 16, 217–229. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mandal, S.; Song, G.; Ackerman, M.; Paskaluk, S.; Gholamreza, F. Characterization of textile fabrics under various thermal exposures. Text. Res. J. 2013, 83, 1005–1019. [Google Scholar] [CrossRef]

- Shoda, A.; Wang, C.Y.; Cheng, P. Simulation of constant pressure steam injection in a porous medium. Int. Commun. Heat. Mass. 1998, 25, 753–762. [Google Scholar] [CrossRef]

- Jalbani, S.; Ackerman, M.; Crown, E.; Keulen, M.; Song, G. Performance of Protective Clothing and Equipment: Emerging Issues and Technologies STP-1544; ASTM International: West Conshohocken, PA, USA, 2012; Volume 9, p. 329. [Google Scholar]

- Sarma, B.P. Epidemiology and man-days loss in burn injuries amongst workers in an oil industry. Burns 2001, 27, 475–480. [Google Scholar] [CrossRef]

- Kahn, S.A.; Patel, J.H.; Lentz, C.W.; Bell, D.E. Firefighter Burn Injuries: Predictable Patterns Influenced by Turnout Gear. J. Burn. Care. Res. 2012, 33, 152–156. [Google Scholar] [CrossRef]

- Rossi, R. Fire fighting and its influence on the body. Ergonomics. 2003, 46, 1017–1033. [Google Scholar] [CrossRef] [PubMed]

- Shalev, I.; Barker, R.L. Analysis of Heat Transfer Characteristits of Fabrics in an Open Flame Exposure. Text. Res. J. 1983, 53, 475–482. [Google Scholar] [CrossRef]

- Song, G.; Paskaluk, S.; Sati, R.; Crown, E.M.; Dale, D.J.; Ackerman, M. Thermal protective performance of protective clothing used for low radiant heat protection. Text. Res. J. 2011, 81, 311–323. [Google Scholar] [CrossRef]

- Mandal, S.; Song, G. An Empirical Analysis of Thermal Protective Performance of Fabrics Used in Protective Clothing. Ann. Occup. Hyg. 2014, 58, 1065–1077. [Google Scholar] [PubMed] [Green Version]

- Sun, G.; Yoo, H.S.; Zhang, X.S.; Pan, N. Radiant Protective and Transport Properties of Fabrics Used by Wildland Firefighters. Text. Res. J. 2000, 70, 567–573. [Google Scholar] [CrossRef]

- Mandal, S.; Song, G.; Gholamreza, F. A novel protocol to characterize the thermal protective performance of fabrics in hot-water exposure. J. Ind. Text. 2016, 46, 279–291. [Google Scholar] [CrossRef]

- Mandal, S.; Song, G. Characterization of protective textile material for thermal hazard. In Proceedings of the Fiber Society Spring Conference, Hung Hum, Hong Kong, 23–25 May 2011. [Google Scholar]

- Mandal, S.; Lu, Y.; Song, G. Characterization of thermal protective clothing under hot-water and pressurized steam exposure. In Proceedings of the The 2013 Herman and Myrtle Goldstein Student Paper Competition organized by American Association of Textile Chemists and Colorists (AATCC), Greenville, SC, USA, 9–11 April 2013. [Google Scholar]

- Rossi, R.; Indelicato, E.; Bolli, W. Hot Steam Transfer Through Heat Protective Clothing Layers. Int. J. Occup. Saf. Ergon. 2004, 10, 239–245. [Google Scholar] [CrossRef] [Green Version]

- Mandal, S.; Lu, Y.; Wang, F.; Song, G. Characterization of Thermal Protective Clothing under Hot Water and Pressurized Steam Exposure. AATCC J. Res. 2014, 1, 7–16. [Google Scholar] [CrossRef]

- Su, Y.; Li, R.; Song, G.; Dong, H. Thermal Protective Performance of Membrane material Used in Protective Clothing against Hot Water and Steam; Iowa State University Digital Press: Ames, IA, USA, 2017; Volume 74, p. 1. [Google Scholar]

- He, J.; Lu, Y.; Yang, J. Quantification of the energy storage caused dual performance of thermal protective clothing containing with moisture exposed to hot steam. Energy Sci. Eng. 2019, 7, 2585–2595. [Google Scholar] [CrossRef] [Green Version]

- He, J.; Sun, L.; Lu, Y. Effects of Radiant Heat and Frictional Abrasion on Thermal Protective Performance of Clothing Against High Pressurized Steam. Cloth. Text. Res. J. 2021, 1–14. [Google Scholar] [CrossRef]

- Desruelle, A.; Schmid, B.; Montmayeur, A. Technical Report. 2002. Available online: https://apps.dtic.mil/sti/citations/ADP012415 (accessed on 20 November 2021).

- Su, Y.; Li, R.; Song, G.; Li, J.; Xiang, C. Modeling steam heat transfer in thermal protective clothing under hot steam exposure. Int. J. Heat Mass Transf. 2018, 120, 818–829. [Google Scholar] [CrossRef]

- ASTM D 1777; Standard Test Method for Thickness of Textile Materials. ASTM International: West Conshohocken, PA, USA, 1996.

- ASTM D 3776; Standard Test Method for Mass per Unit Area (Weight) of Fabric. ASTM International: West Conshohocken, PA, USA, 2009.

- ASTM D 1518; Standard Test Method for Thermal Resistance of Batting Systems Using A Hot Plate. ASTM International: West Conshohocken, PA, USA, 2011.

- ASTM D 737; Standard Test Method for Air Permeability of Textile Fabrics. ASTM International: West Conshohocken, PA, USA, 2004.

- Epps, H.H.; Leonas, K.K. Pore Size and Air Permeability of Four Nonwoven Fabrics. Int. Nonwovens J. 2020. [Google Scholar] [CrossRef]

- Maisel, E. The Three P’s: Porosity, Permeability and Permeance. Available online: https://thefiberwire.com/2016/04/07/the-three-ps-porosity-permeability-and-permeance/ (accessed on 20 November 2021).

- Scheidegger, A.L. The Physics of Flow Through Porous Media; University of Toronto Press: Toronto, ON, USA, 1974. [Google Scholar]

- Mandal, S.; Song, G. Thermal sensors for performance evaluation of protective clothing against heat and fire: A review. Text. Res. J. 2015, 85, 101–112. [Google Scholar] [CrossRef]

- Mandal, S.; Camenzind, M.; Annaheim, S.; Rossi, R.M. Evaluation of heat and flame protective performance of clothing using manikins. In Manikins Textile Evaluation; Woodhead Publishing: Sawston, UK, 2017. [Google Scholar] [CrossRef]

- Guan, M.; Annaheim, S.; Camenzind, M.; Li, J.; Mandal, S.; Psikuta, A.; Rossi, R.M. Moisture transfer of the clothing–human body system during continuous sweating under radiant heat. Text. Res. J. 2019, 89, 4537–4553. [Google Scholar] [CrossRef]

- Mandal, S.; Annaheim, S.; Camenzind, M.; Rossi, R.M. Characterization and modelling of thermal protective performance of fabrics under different levels of radiant-heat exposures. J. Ind. Text. 2018, 48, 1184–1205. [Google Scholar] [CrossRef]

- Guan, M.; Psikuta, A.; Camenzind, M.; Li, J.; Mandal, S.; Michel Rossi, R.; Annaheim, S. Effect of perspired moisture and material properties on evaporative cooling and thermal protection of the clothed human body exposed to radiant heat. Text. Res. J. 2019, 89, 3663–3676. [Google Scholar] [CrossRef]

- Mandal, S.; Annaheim, S.; Capt, A.; Greve, J.; Camenzind, M.; Rossi, R.M. A categorization tool for fabric systems used in firefighters’ clothing based on their thermal protective and thermo-physiological comfort performances. Text. Res. J. 2018, 89, 3244–3259. [Google Scholar] [CrossRef]

- Keiser, C. Steam Burns Moisture Management in Firefighter Protective Clothing. Ph.D. Thesis, Swiss Federal Institute of Technology ETH, Zurich, Switzerland, 2007. [Google Scholar]

- Lienhard, J.H.; Lienhard, J.H. A Heat Transfer Textbook, 4th ed.; Dover Publication: New York, NY, USA, 2011; pp. 111–152. [Google Scholar]

- Rossi, R.; Traugott, Z. Influence of humidity on the radiant, convective and contact heat transmission through protective clothing materials. In Proceedings of the Fifth International Symposium on Performance of Protective Clothing: Improvement through Innovation, San Francisco, CA, USA, 25–27 January 1994. [Google Scholar]

- Murtaza, G.; Batcheller, J.; Crown, E.M.; Ackerman, M.Y. Development of thermal protective fabrics for steam and hot water protection. In Proceedings of the 108th Institute of Textile Science Scientific Session, Qubec, QC, Canada, 21 November 2011. [Google Scholar]

| Constructional Attributes | Fabric Types | |||||

|---|---|---|---|---|---|---|

| A (Shell Fabric) | B (Shell Fabric) | C (Thermal Liner) | D (Thermal Liner) | E (Thermal Liner) | F (Moisture Barrier) | |

| Fiber Content | Kevlar®-PBI | Fire-retardant cotton fabric with Water Repellent Finish | Nomex® (100%) | Nomex® (100%) | Nomex® (100%) | Nomex®-III (100%) with Polyurethane Coating |

| Weave Structures | Plain weave, rip-stop woven | Plain weave with finished surface | Plain weave Nomex® layer quilted to two thin Nomex® oriented webs | Plain weave Nomex® layer quilted to Nomex® needle-felted batt | Plain weave Nomex layer quilted to Nomex scrim, needle-felted batt and scrim | Plain weave Nomex backcoated with polyurethene film |

| Thickness(mm) a | 0.46 | 0.67 | 1.08 | 2.07 | 3.57 | 1.10 |

| Weight (g/m2) b | 211.5 | 412.5 | 170.6 | 301.5 | 332.7 | 185.5 |

| Fabric Properties | Fabric Systems | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Single-Layered | Double-Layered | Triple-Layered | ||||||||

| A | B | AC | AE | AF | FA | AFC | AFD | AFE | FAD | |

| Thickness(mm) a | 0.46 | 0.67 | 1.54 | 4.03 | 1.56 | 1.56 | 2.64 | 3.63 | 5.13 | 3.63 |

| Weight (g/m2) | 211.5 | 412.5 | 382.1 | 544.2 | 207 | 207 | 567.6 | 698.5 | 729.7 | 698.5 |

| Thermal Resistance (Km2/W) b | 0.07 | 0.08 | 0.12 | 0.17 | 0.09 | 0.09 | 0.13 | 0.15 | 0.18 | 0.15 |

| Air Permeability (cm3/cm2/s) c | 17.1 | 0 | 13.9 | 12.5 | 0 | 0 | 0 | 0 | 0 | 0 |

| Steam Penetration Parameters | Fabric Systems | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Single-Layered | Double-Layered | Triple-Layered | ||||||||

| A | B | AC | AE | AF | FA | AFC | AFD | AFE | FAD | |

| SPP (Second-degree Burn Time in Seconds) | 0.34 | 2.26 | 0.59 | 0.71 | 7.95 | 10.35 | 11.44 | 19.27 | 22.2 | 25.55 |

| TTTE (kJ/m2) | 610.6 | 526.5 | 581.3 | 533.9 | 416.3 | 216.2 | 375.5 | 249.6 | 240.2 | 221.2 |

| SPP/Thickness (Second-degree Burn Time in Seconds/mm) | 0.74 | 3.37 | 0.38 | 0.18 | 5.10 | 6.63 | 4.33 | 5.31 | 4.33 | 7.04 |

| Protective Performance | Fabric Systems | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Single-Layered | Double-Layered | Triple-Layered | |||||||||

| A | B | AC | AE | AF | FA | AFC | AFD | AFE | FAD | ||

| Second-degree Burn Time in Seconds | Flame | 2.87 | 12.3 | 12.0 | 16.5 | 9.01 | 5.18 | 11.5 | 15.8 | 20.6 | 15.4 |

| Radiant Heat | 4.49 | 7.62 | 11.5 | 24.2 | 9.89 | 7.90 | 17.3 | 23.3 | 28.7 | 20.6 | |

| Fabric Properties | SPP | TTTE | ||

|---|---|---|---|---|

| T-Stat | p-Value | T-Stat | p-Value | |

| Thickness | 2.60 | 0.03 | −1.95 | 0.08 |

| Weight | 2.71 | 0.02 | −1.52 | 0.17 |

| Thermal Resistance | 1.90 | 0.09 | −1.31 | 0.2 |

| Air Permeability | −2.65 | 0.001 | 3.56 | 0.007 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mandal, S.; Song, G. Characterizing Steam Penetration through Thermal Protective Fabric Materials. Textiles 2022, 2, 16-28. https://doi.org/10.3390/textiles2010002

Mandal S, Song G. Characterizing Steam Penetration through Thermal Protective Fabric Materials. Textiles. 2022; 2(1):16-28. https://doi.org/10.3390/textiles2010002

Chicago/Turabian StyleMandal, Sumit, and Guowen Song. 2022. "Characterizing Steam Penetration through Thermal Protective Fabric Materials" Textiles 2, no. 1: 16-28. https://doi.org/10.3390/textiles2010002

APA StyleMandal, S., & Song, G. (2022). Characterizing Steam Penetration through Thermal Protective Fabric Materials. Textiles, 2(1), 16-28. https://doi.org/10.3390/textiles2010002