Asphalt Binder Rheological Performance Properties Using Recycled Plastic Wastes and Commercial Polymers

Abstract

1. Introduction

2. Methodology

2.1. Materials

2.2. Preparation and Testing of Polymer Asphalt Blends

2.3. Experimental Matrix

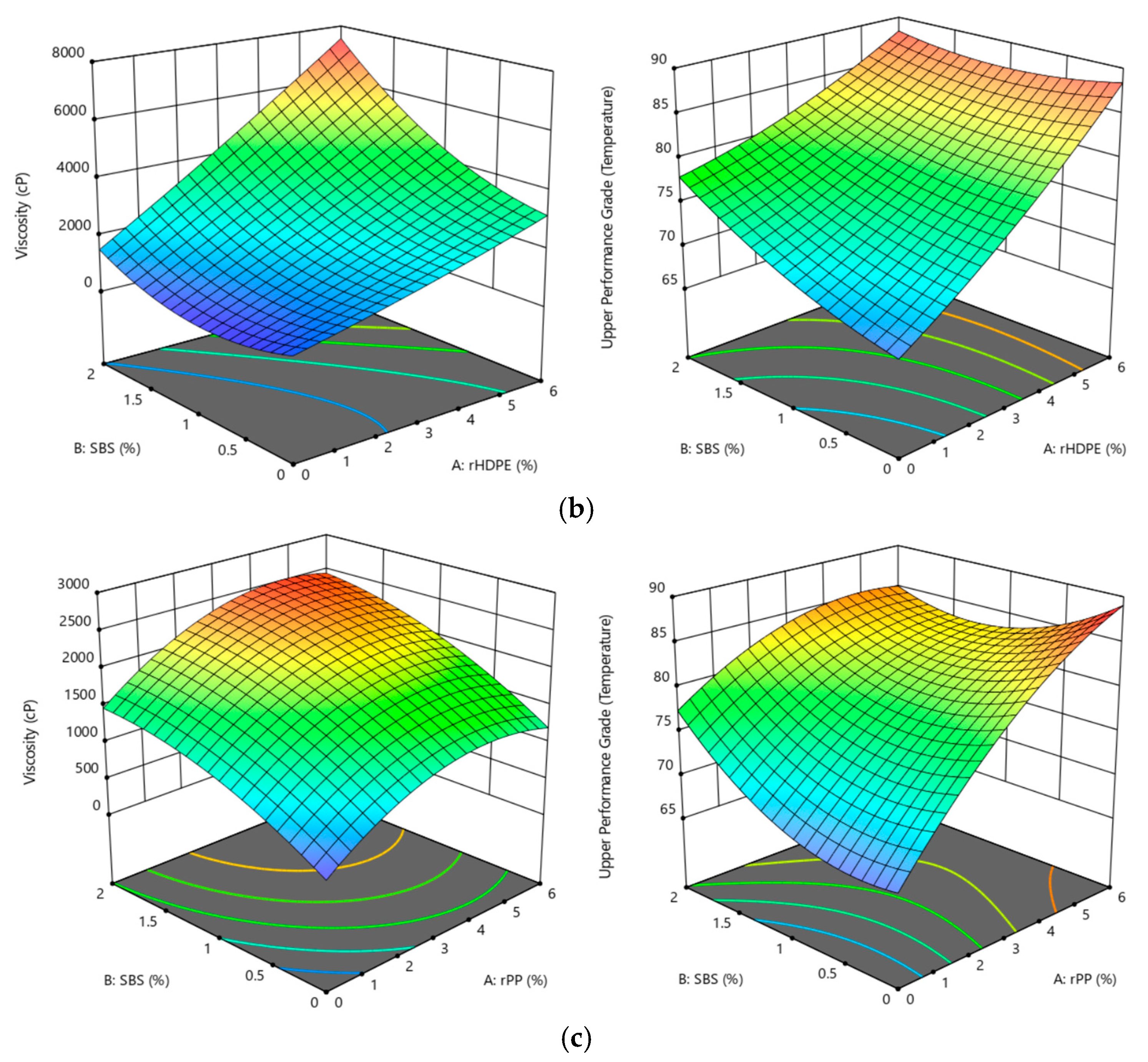

3. Design of Experiments Based on RSM

4. Results and Discussion

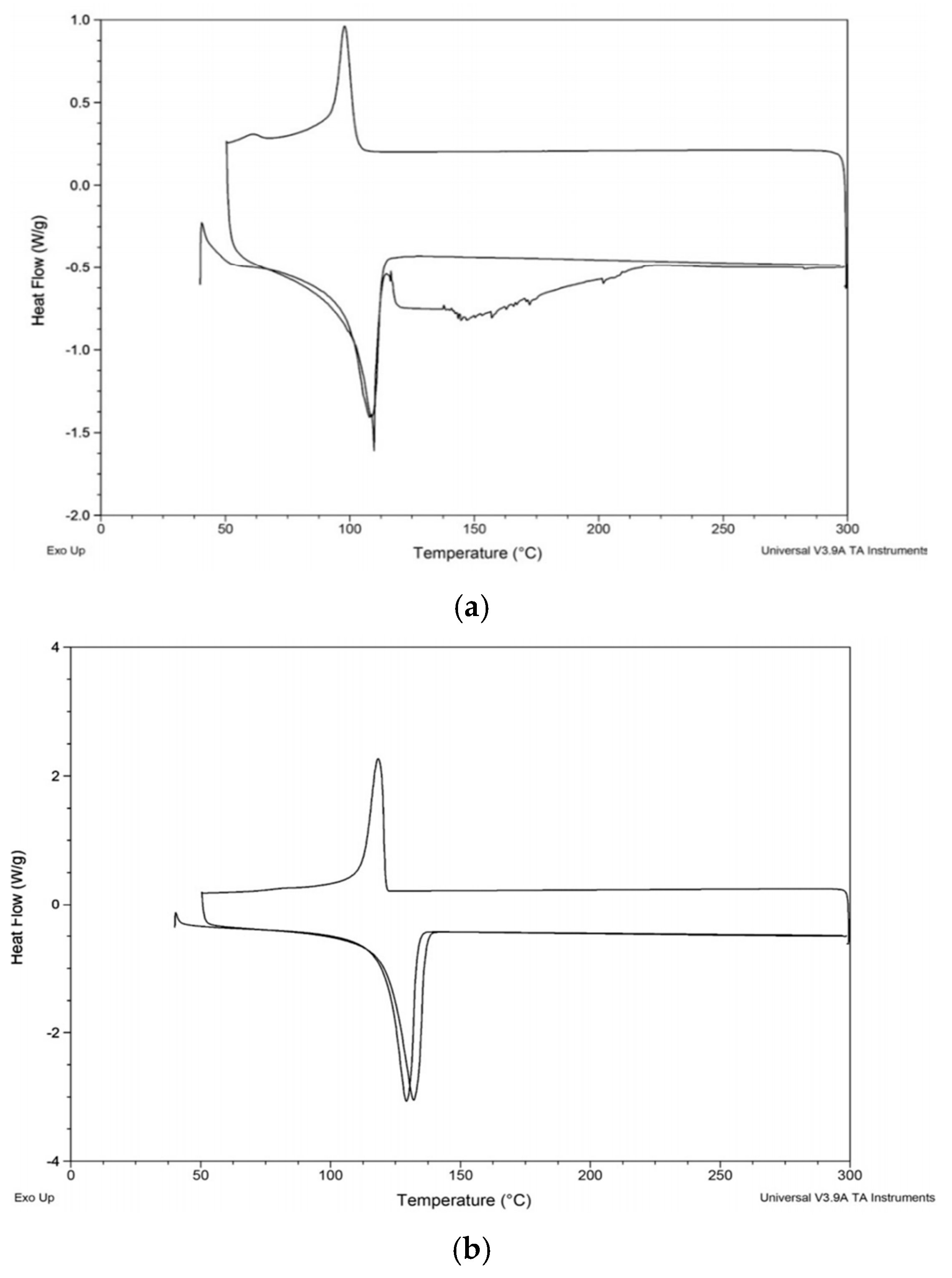

4.1. Recycled Plastic Waste Blending Temperature

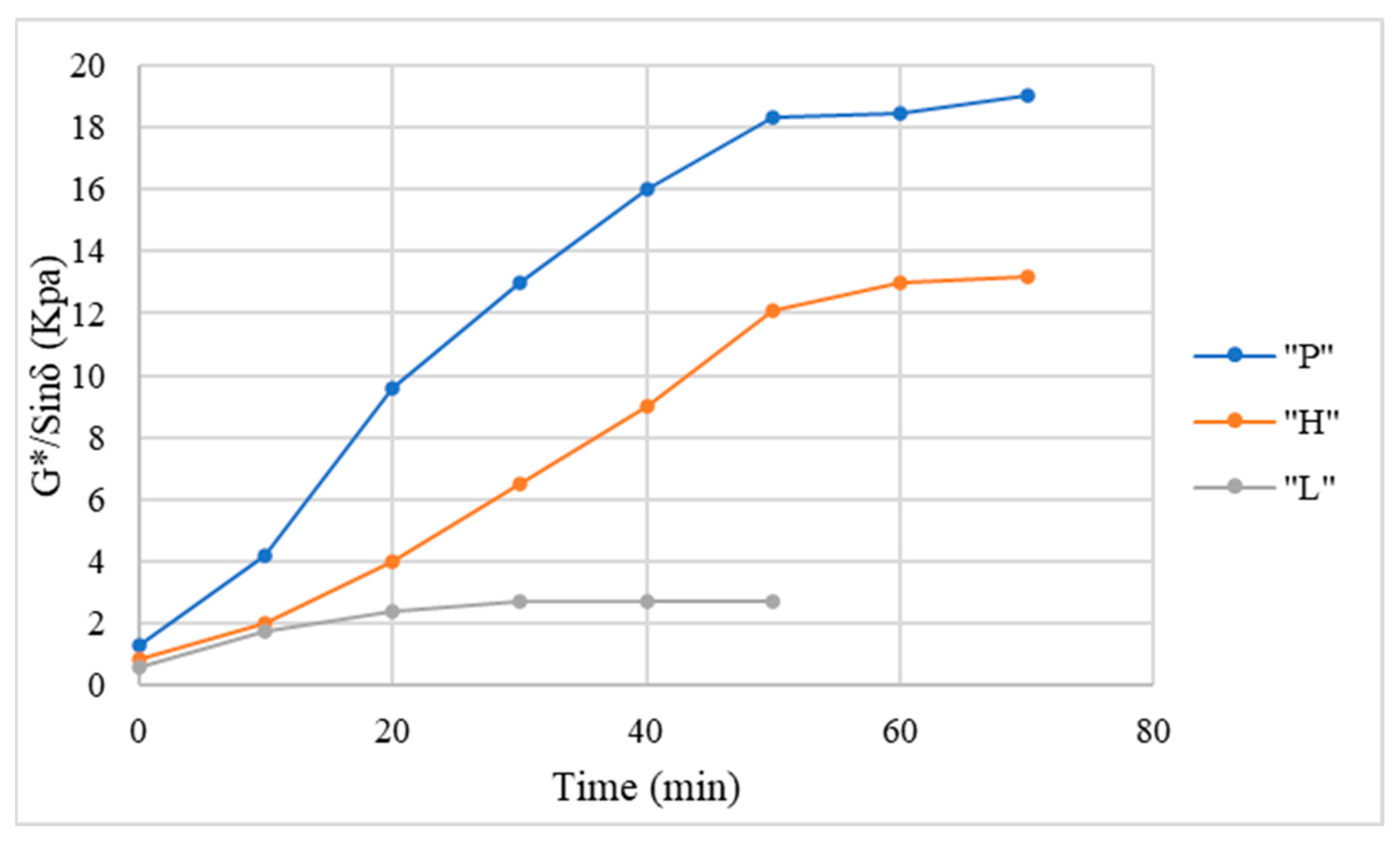

4.2. Optimum Polymers Blending Duration

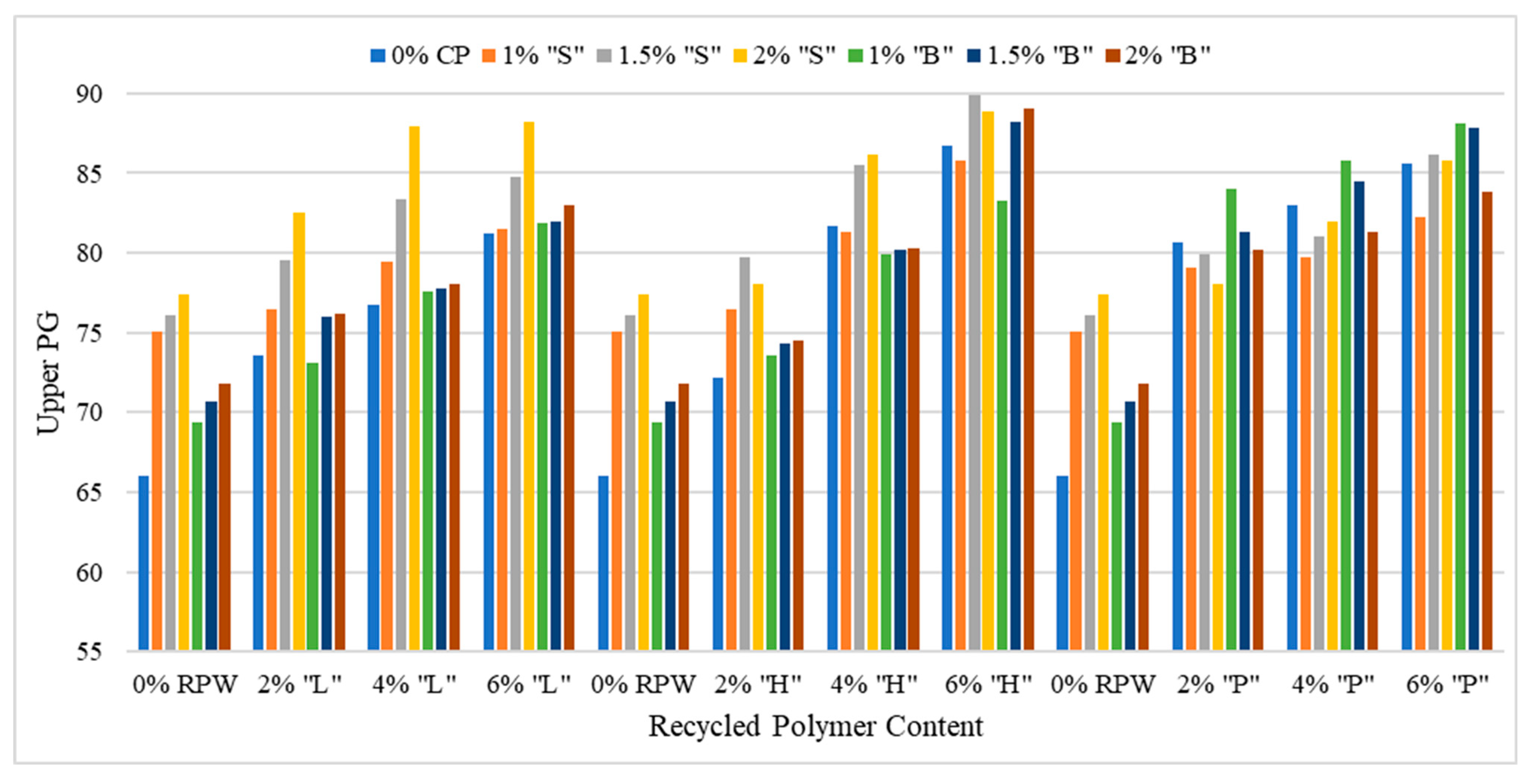

4.3. Performance Properties and Superpave Upper Performance Grade (UPG)

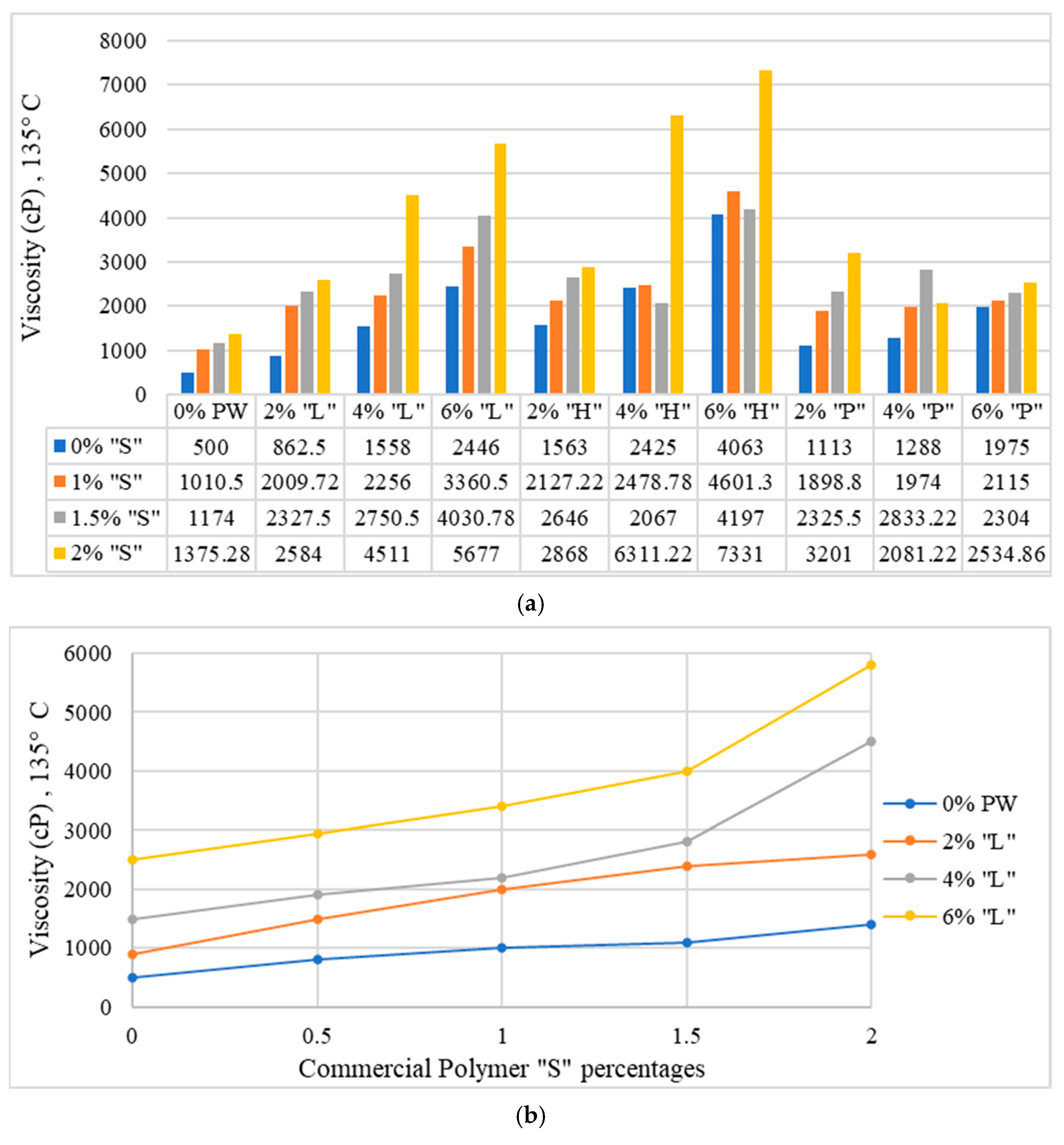

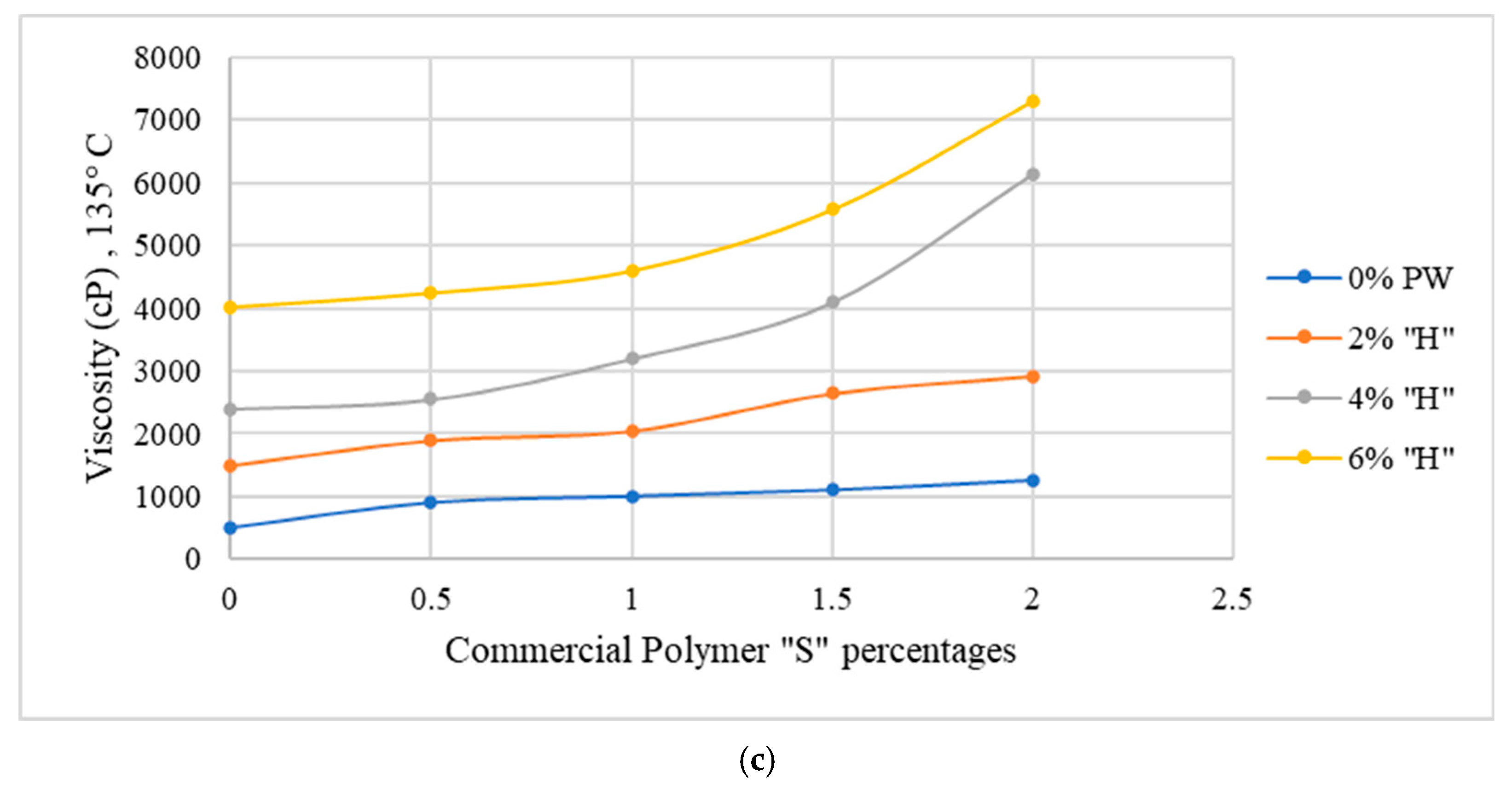

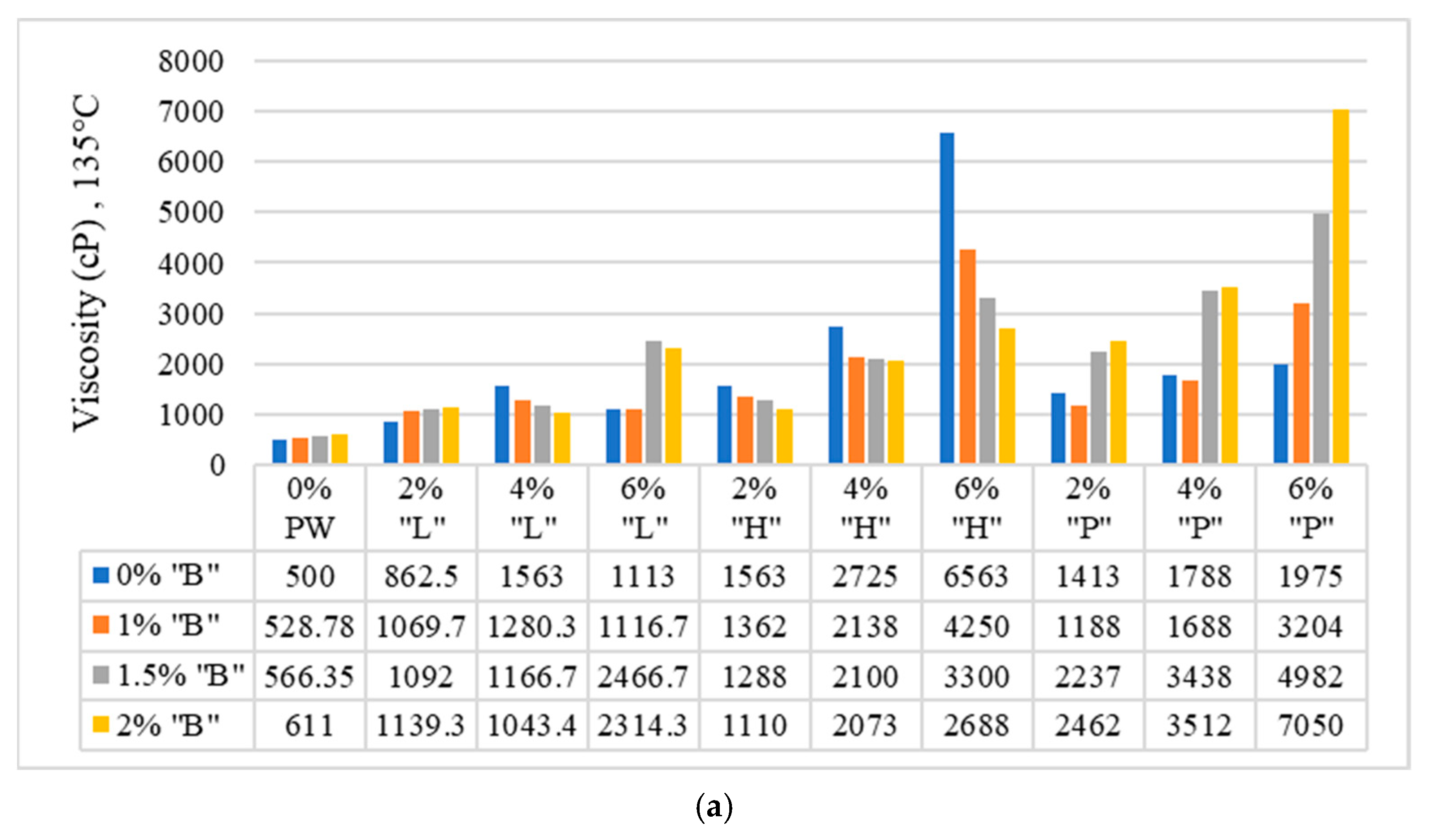

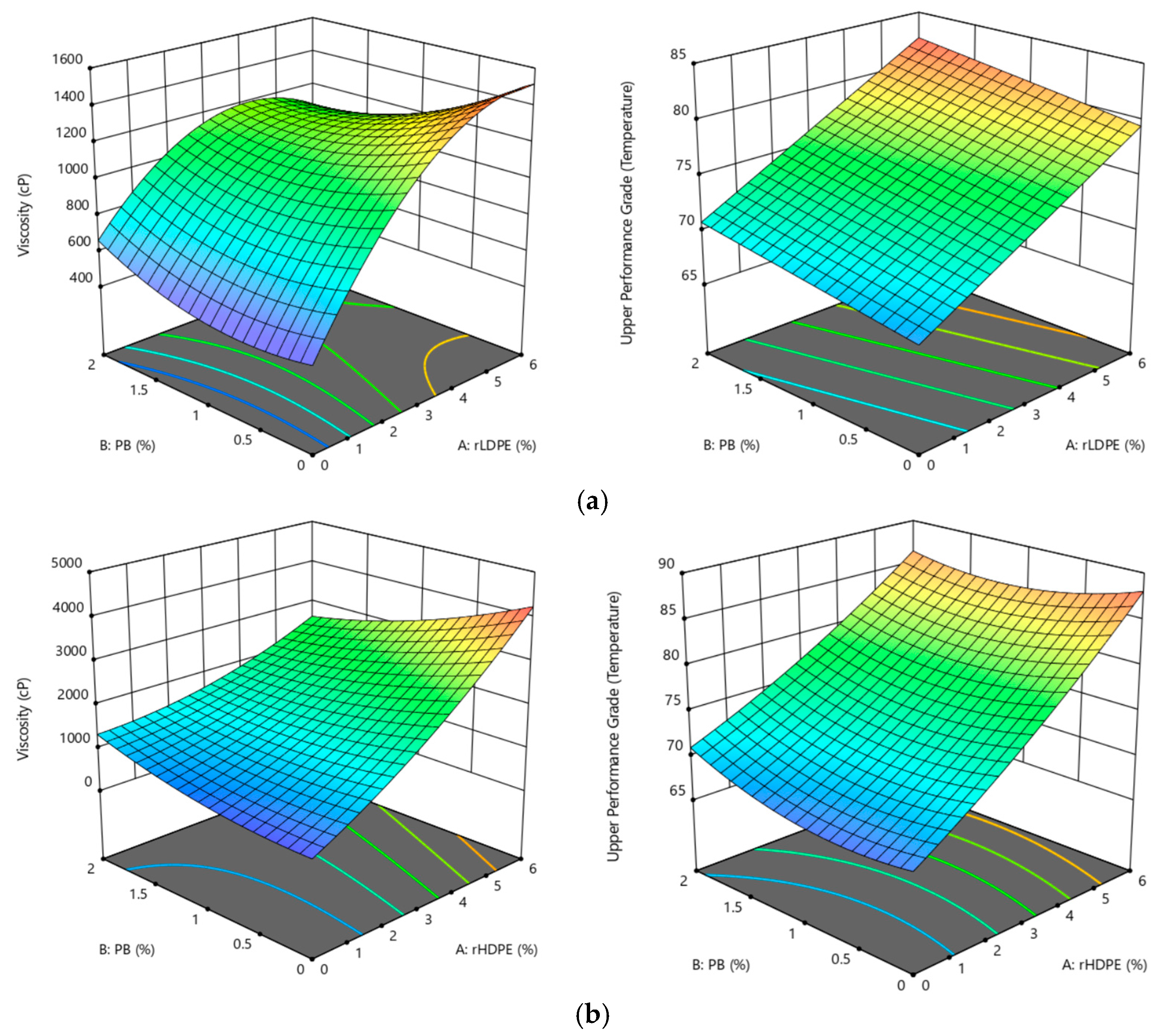

4.4. Rotational Viscosity Test Result

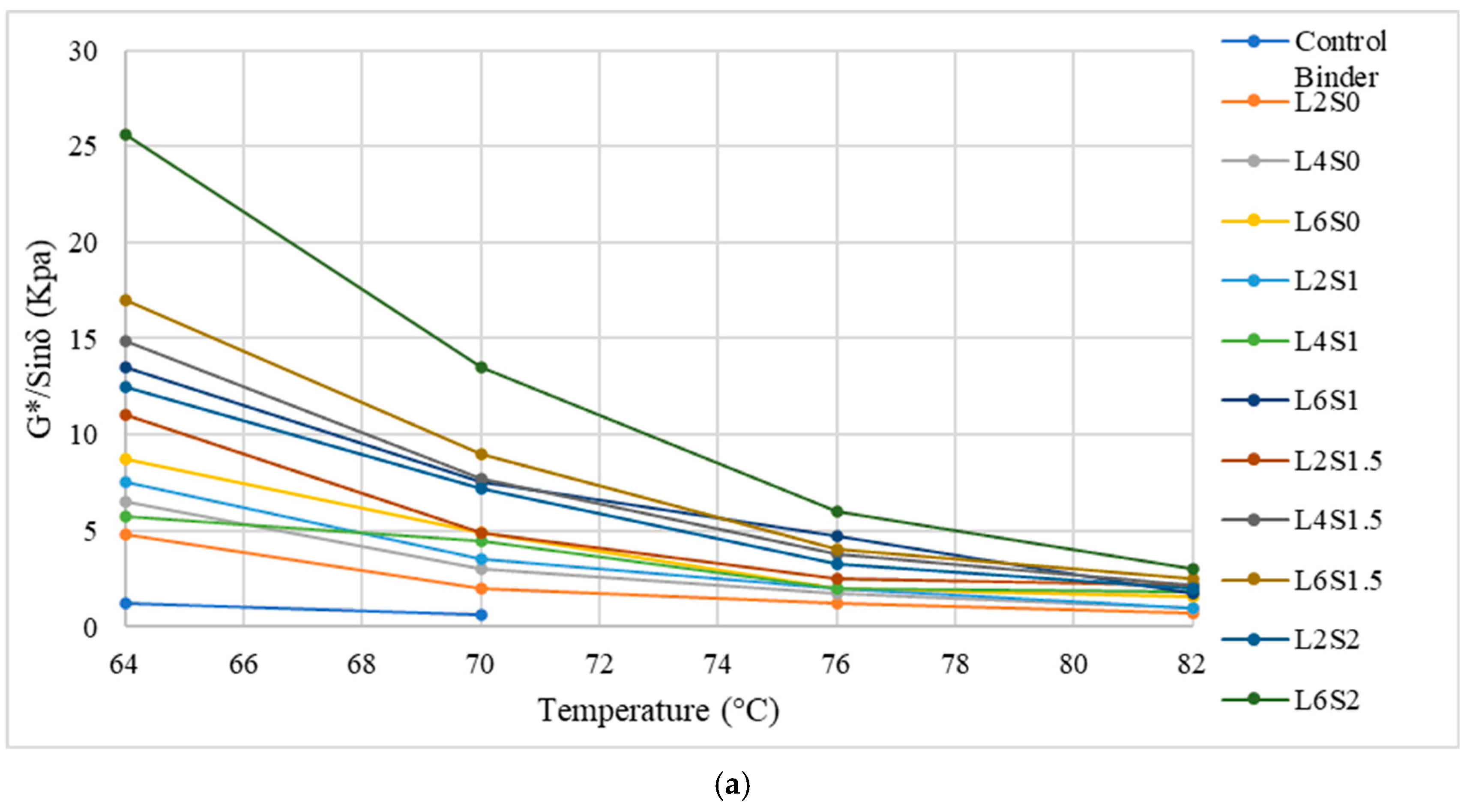

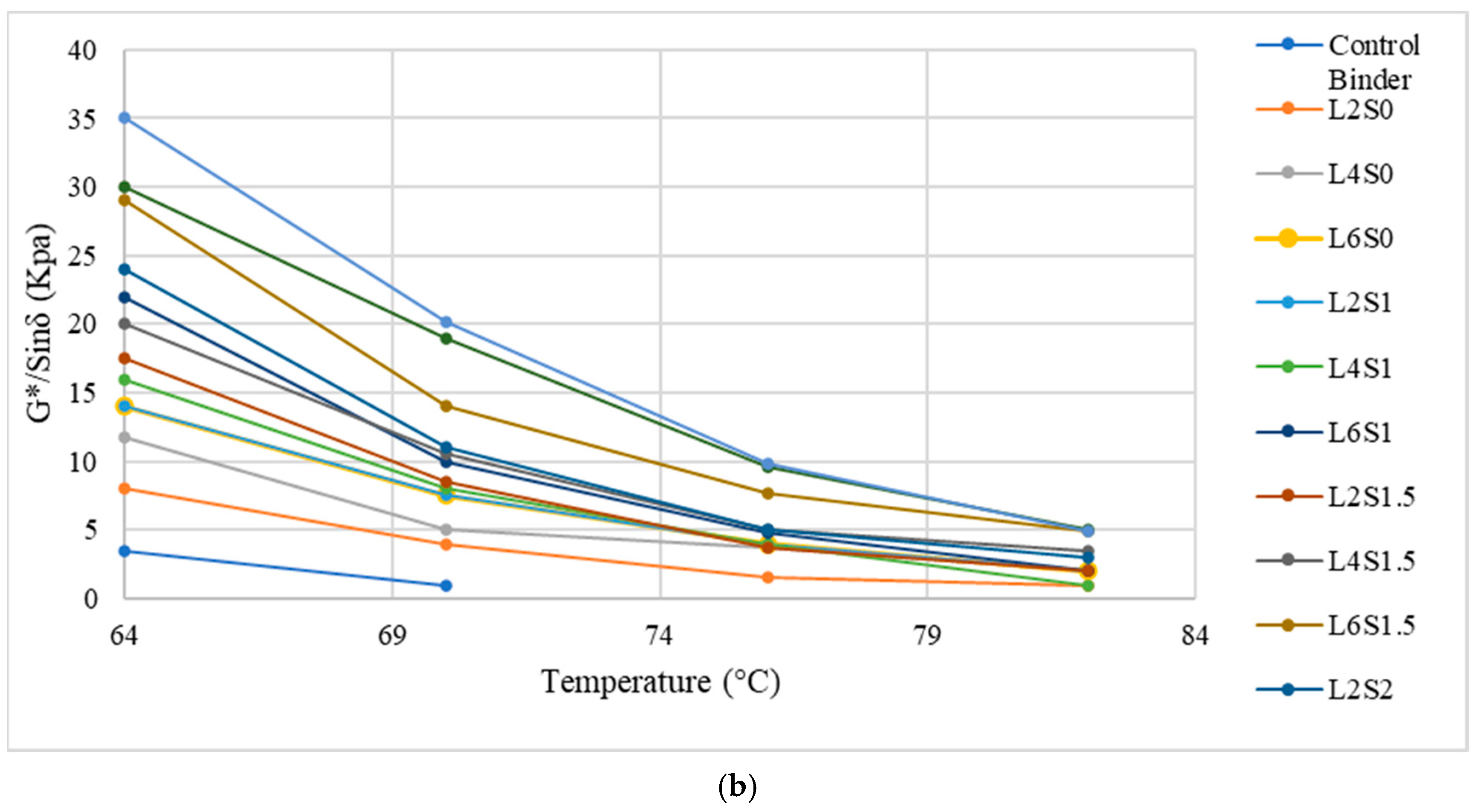

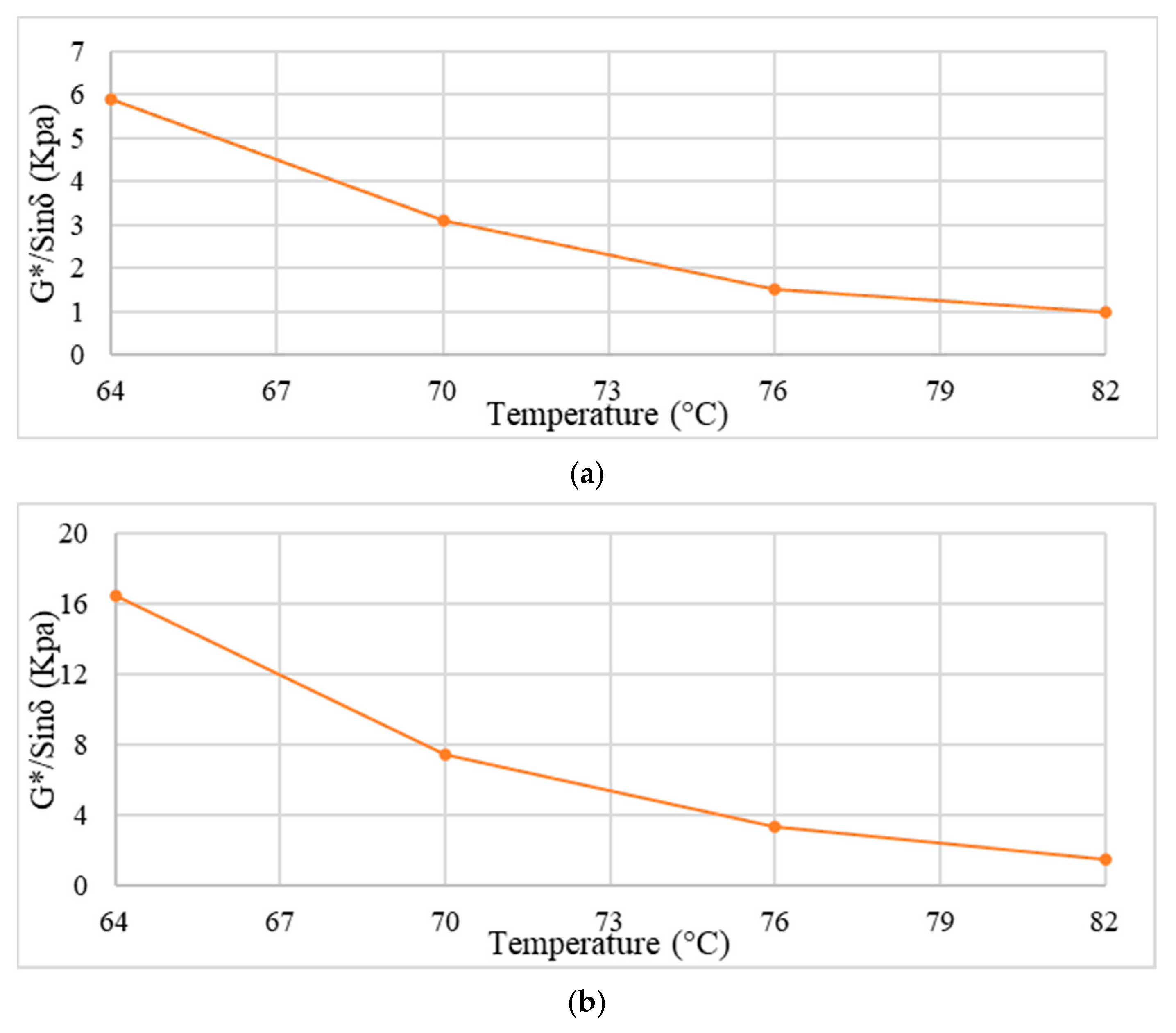

4.5. Modified Binder High Temperature Rutting Resistance

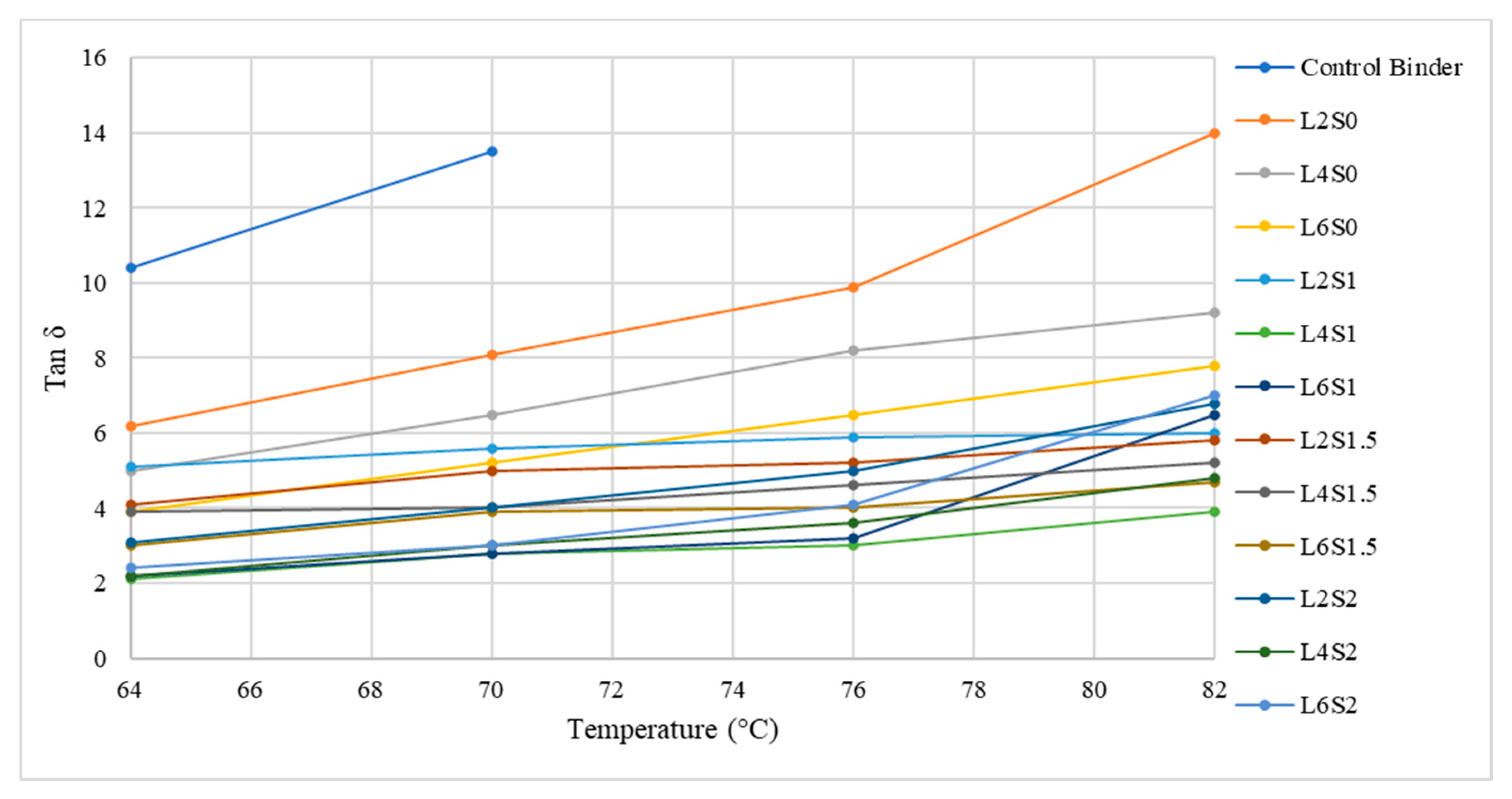

4.6. Viscoelastic Component Analysis from DSR Result

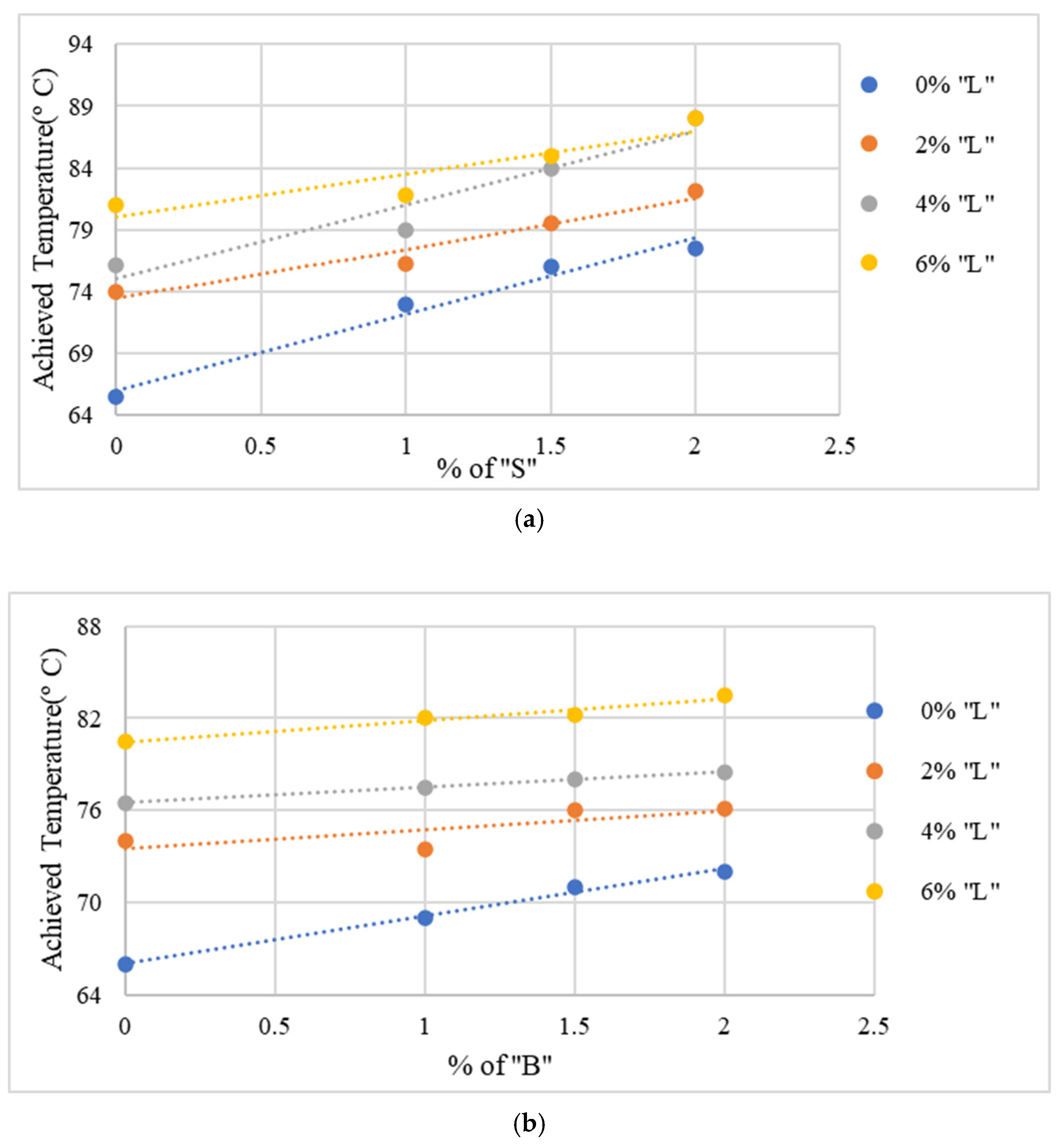

4.7. Actual PG at High Service Temperature

4.8. Effect of Recycled LDPE on Upper Performance Grade of SBS and Polybilt

4.9. Effect of HDPE on Upper Performance Grade of SBS and Polybilt Modified Binder

5. Statistical Analysis

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thompson, R.C.; Moore, C.J.; Vom Saal, F.S.; Swan, S.H. Plastics, the environment and human health: Current consensus and future trends. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2153–2166. [Google Scholar] [CrossRef]

- Kalantar, Z.N.; Karim, M.R.; Mahrez, A. A review of using waste and virgin polymer in pavement. Constr. Build. Mater. 2012, 33, 55–62. [Google Scholar] [CrossRef]

- Teuten, E.L.; Saquing, J.M.; Knappe, D.R.; Barlaz, M.A.; Jonsson, S.; Björn, A.; Rowland, S.J.; Thompson, R.C.; Galloway, T.S.; Yamashita, R. Transport and release of chemicals from plastics to the environment and to wildlife. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2027–2045. [Google Scholar] [CrossRef]

- Yildirim, Y. Polymer modified asphalt binders. Constr. Build. Mater. 2007, 21, 66–72. [Google Scholar] [CrossRef]

- Dalhat, M.; Al-Abdul Wahhab, H.I.; Al-Adham, K. Recycled plastic waste asphalt concrete via mineral aggregate substitution and binder modification. J. Mater. Civ. Eng. 2019, 31, 04019134. [Google Scholar] [CrossRef]

- Al-Abdul Wahhab, H.; Dalhat, M.; Habib, M. Storage stability and high-temperature performance of asphalt binder modified with recycled plastic. Road Mater. Pavement Des. 2017, 18, 1117–1134. [Google Scholar] [CrossRef]

- Hınıslıoğlu, S.; Ağar, E. Use of waste high density polyethylene as bitumen modifier in asphalt concrete mix. Mater. Lett. 2004, 58, 267–271. [Google Scholar] [CrossRef]

- Panda, M.; Mazumdar, M. Utilization of reclaimed polyethylene in bituminous paving mixes. J. Mater. Civ. Eng. 2002, 14, 527–530. [Google Scholar] [CrossRef]

- Mamun, A.A.; Wahhab, H.A.-A.; Dalhat, M. Comparative evaluation of waste cooking oil and waste engine oil rejuvenated asphalt concrete mixtures. Arab. J. Sci. Eng. 2020, 45, 7987–7997. [Google Scholar] [CrossRef]

- Murphy, M.; O’mahony, M.; Lycett, C.; Jamieson, I. Recycled polymers for use as bitumen modifiers. J. Mater. Civ. Eng. 2001, 13, 306–314. [Google Scholar] [CrossRef]

- Al-Salem, S.; Abraham, G.; Al-Qabandi, O.; Dashti, A. Investigating the effect of accelerated weathering on the mechanical and physical properties of high content plastic solid waste (PSW) blends with virgin linear low density polyethylene (LLDPE). Polym. Test. 2015, 46, 116–121. [Google Scholar] [CrossRef]

- Athithan, V.; Natarajan, L.T. Reuse of plastic waste as building materials to enhance sustainability in construction: A review. Innov. Infrastruct. Solut. 2023, 8, 204. [Google Scholar] [CrossRef]

- Nawang, R.; Danjaji, I.; Ishiaku, U.; Ismail, H.; Ishak, Z.M. Mechanical properties of sago starch-filled linear low density polyethylene (LLDPE) composites. Polym. Test. 2001, 20, 167–172. [Google Scholar] [CrossRef]

- Luyt, A.; Molefi, J.; Krump, H. Thermal, mechanical and electrical properties of copper powder filled low-density and linear low-density polyethylene composites. Polym. Degrad. Stab. 2006, 91, 1629–1636. [Google Scholar] [CrossRef]

- Fahmy, E.A.; Youssef, A.M.; Ali, E.E.; Algabry, A.; Elbagalati, O. Evaluation of asphalt mixtures modified with polyethylene terephthalate (PET). Innov. Infrastruct. Solut. 2024, 9, 434. [Google Scholar] [CrossRef]

- Wahhab, H.A.-A.; Ali, M.; Asi, I.; AI-Dubabe, I. Adaptation of Shrp Performance Based Binder Specifications to the Gulf Countries; King Abdulaziz City for Science and Technology: Riyadh, Saudi Arabia, 1995. [Google Scholar]

- White, G.; Reid, G. Recycled waste plastic for extending and modifying asphalt binders. In Proceedings of the 8th Symposium on Pavement Surface Characteristics (SURF 2018), Brisbane, QLD, Australia, 2–4 May 2018; pp. 2–4. [Google Scholar]

- Jin, D.; Meyer, T.K.; Chen, S.; Boateng, K.A.; Pearce, J.M.; You, Z. Evaluation of lab performance of stamp sand and acrylonitrile styrene acrylate waste composites without asphalt as road surface materials. Constr. Build. Mater. 2022, 338, 127569. [Google Scholar] [CrossRef]

- Kim, Y.-M.; Kim, K. Evaluation of Thermal Aging Susceptibility of Recycled Waste Plastic Aggregates (Low-Density Polyethylene, High-Density Polyethylene, and Polypropylene) in Recycled Asphalt Pavement Mixtures. Polymers 2025, 17, 731. [Google Scholar] [CrossRef]

- Jun, L.; Yuxia, Z.; Yuzhen, Z. The research of GMA-g-LDPE modified Qinhuangdao bitumen. Constr. Build. Mater. 2008, 22, 1067–1073. [Google Scholar] [CrossRef]

- Köfteci, S.; Ahmedzade, P.; Kultayev, B. Performance evaluation of bitumen modified by various types of waste plastics. Constr. Build. Mater. 2014, 73, 592–602. [Google Scholar] [CrossRef]

- Al-Abdul Wahhab, H.; Ramadhan, R. Prediction of pavement rutting in the Eastern Saudi Arabia. Arabian J. Sci. Eng 1990, 15, 385–402. [Google Scholar]

- Nautiyal, A.; Sharma, S. Methods and factors of prioritizing roads for maintenance: A review for sustainable flexible pavement maintenance program. Innov. Infrastruct. Solut. 2022, 7, 190. [Google Scholar] [CrossRef]

- Garcia-Morales, M.; Partal, P.; Navarro, F.; Gallegos, C. Effect of waste polymer addition on the rheology of modified bitumen. Fuel 2006, 85, 936–943. [Google Scholar] [CrossRef]

- García-Morales, M.; Partal, P.; Navarro, F.; Martínez-Boza, F.; Gallegos, C.; González, N.; González, O.; Muñoz, M. Viscous properties and microstructure of recycled eva modified bitumen. Fuel 2004, 83, 31–38. [Google Scholar] [CrossRef]

- Al-Adham, K.; Baig, M.G.; Wahhab, H.A.-A. Prediction of dynamic modulus for elastomer-modified asphalt concrete mixes at desert environment. Arab. J. Sci. Eng. 2019, 44, 4141–4149. [Google Scholar] [CrossRef]

- Wen, Z.; Xie, Y.; Chen, M.; Dinga, C.D. China’s plastic import ban increases prospects of environmental impact mitigation of plastic waste trade flow worldwide. Nat. Commun. 2021, 12, 425. [Google Scholar] [CrossRef]

- Wu, S.; Montalvo, L. Repurposing waste plastics into cleaner asphalt pavement materials: A critical literature review. J. Clean. Prod. 2021, 280, 124355. [Google Scholar] [CrossRef]

- Movilla-Quesada, D.; Raposeiras, A.; Silva-Klein, L.; Lastra-González, P.; Castro-Fresno, D. Use of plastic scrap in asphalt mixtures added by dry method as a partial substitute for bitumen. Waste Manag. 2019, 87, 751–760. [Google Scholar] [CrossRef]

- Chanda, M.; Roy, S.K. Plastics Technology Handbook; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Giustozzi, F.; Boom, Y.J. Use of Road-Grade Recycled Plastics for Sustainable Asphalt Pavements: Overview of the Recycled Plastic Industry and Recycled Plastic Types; Transportation Research Board: Washington, DC, USA, 2021. [Google Scholar]

- Liang, M.; Xin, X.; Fan, W.; Wang, H.; Jiang, H.; Zhang, J.; Yao, Z. Phase behavior and hot storage characteristics of asphalt modified with various polyethylene: Experimental and numerical characterizations. Constr. Build. Mater. 2019, 203, 608–620. [Google Scholar] [CrossRef]

- Edike, U.E.; Ameh, O.J.; Dada, M.O. Performance of polymer bricks produced with plastic waste. Innov. Infrastruct. Solut. 2023, 8, 51. [Google Scholar] [CrossRef]

- Larrain, M.; Van Passel, S.; Thomassen, G.; Van Gorp, B.; Nhu, T.T.; Huysveld, S.; Van Geem, K.M.; De Meester, S.; Billen, P. Techno-economic assessment of mechanical recycling of challenging post-consumer plastic packaging waste. Resour. Conserv. Recycl. 2021, 170, 105607. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Jamal, M.; Gravina, R.; Giustozzi, F. Recycled plastic as bitumen modifier: The role of recycled linear low-density polyethylene in the modification of physical, chemical and rheological properties of bitumen. J. Clean. Prod. 2020, 266, 121988. [Google Scholar] [CrossRef]

- Shagiakhmetova, E.; Medyanik, Y.; Gimadieva, L.; Vakhitova, D.; Yarullina, I. Economic efficiency of plastic recycling plant construction. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 890, p. 012114. [Google Scholar]

- Vargas, M.A.; Vargas, M.A.; Sánchez-Sólis, A.; Manero, O. Asphalt/polyethylene blends: Rheological properties, microstructure and viscosity modeling. Constr. Build. Mater. 2013, 45, 243–250. [Google Scholar] [CrossRef]

- Attaelmanan, M.; Feng, C.P.; Al-Hadidy, A. Laboratory evaluation of HMA with high density polyethylene as a modifier. Constr. Build. Mater. 2011, 25, 2764–2770. [Google Scholar] [CrossRef]

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer modification of bitumen: Advances and challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef]

- Baditha, A.K.; Goli, A.K.; Amaranatha Reddy, M.; Sudhakar Reddy, K. Thermal, rheological, and aging characterization of ethylene vinyl acetate polymer modified asphalt binder. Innov. Infrastruct. Solut. 2024, 9, 325. [Google Scholar] [CrossRef]

- Bonicelli, A.; Calvi, P.; Martinez-Arguelles, G.; Fuentes, L.; Giustozzi, F. Experimental study on the use of rejuvenators and plastomeric polymers for improving durability of high RAP content asphalt mixtures. Constr. Build. Mater. 2017, 155, 37–44. [Google Scholar] [CrossRef]

- Padhan, R.K.; Sreeram, A. Enhancement of storage stability and rheological properties of polyethylene (PE) modified asphalt using cross linking and reactive polymer based additives. Constr. Build. Mater. 2018, 188, 772–780. [Google Scholar] [CrossRef]

- Roman, C.; Cuadri, A.A.; Liashenko, I.; García-Morales, M.; Partal, P. Linear and non-linear viscoelastic behavior of SBS and LDPE modified bituminous mastics. Constr. Build. Mater. 2016, 123, 464–472. [Google Scholar] [CrossRef]

- Costa, L.M.; Silva, H.M.; Peralta, J.; Oliveira, J.R. Using waste polymers as a reliable alternative for asphalt binder modification–Performance and morphological assessment. Constr. Build. Mater. 2019, 198, 237–244. [Google Scholar] [CrossRef]

- Fenouillot, F.; Cassagnau, P.; Majesté, J.-C. Uneven distribution of nanoparticles in immiscible fluids: Morphology development in polymer blends. Polymer 2009, 50, 1333–1350. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Fakirov, S. Nano-and Micro-Mechanics of Polymer Blends and Composites; Hanser Munich: Munich, Germany, 2009. [Google Scholar]

- Wang, Y.; Polaczyk, P.; He, J.; Lu, H.; Xiao, R.; Huang, B. Dispersion, compatibility, and rheological properties of graphene-modified asphalt binders. Constr. Build. Mater. 2022, 350, 128886. [Google Scholar] [CrossRef]

- ASTM D 4402; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. American Society for Testing and Materials: West Conshohocken, PA, USA, 2015.

- ASTM D 2872-12; Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test). American Society for Testing and Materials: West Conshohocken, PA, USA, 2012.

- Zahid, M.; Shafiq, N.; Isa, M.H.; Gil, L. Statistical modeling and mix design optimization of fly ash based engineered geopolymer composite using response surface methodology. J. Clean. Prod. 2018, 194, 483–498. [Google Scholar] [CrossRef]

- Feng, X.; Tufail, R.F.; Zahid, M. Experimental investigation and statistical modeling of FRP confined RuC using response surface methodology. Civ. Eng. J. 2019, 5, 268–283. [Google Scholar] [CrossRef]

- Rafiq, W.; Napiah, M.; Habib, N.Z.; Sutanto, M.H.; Alaloul, W.S.; Khan, M.I.; Musarat, M.A.; Memon, A.M. Modeling and design optimization of reclaimed asphalt pavement containing crude palm oil using response surface methodology. Constr. Build. Mater. 2021, 291, 123288. [Google Scholar] [CrossRef]

- Hamzah, M.O.; Gungat, L.; Golchin, B. Estimation of optimum binder content of recycled asphalt incorporating a wax warm additive using response surface method. Int. J. Pavement Eng. 2017, 18, 682–692. [Google Scholar] [CrossRef]

- Zulkernain, N.H.; Gani, P.; Ng, C.C.; Uvarajan, T. Optimisation of mixed proportion for cement brick containing plastic waste using response surface methodology (RSM). Innov. Infrastruct. Solut. 2022, 7, 183. [Google Scholar] [CrossRef]

- Akhlaghi, Y.G.; Ma, X.; Zhao, X.; Shittu, S.; Li, J. A statistical model for dew point air cooler based on the multiple polynomial regression approach. Energy 2019, 181, 868–881. [Google Scholar] [CrossRef]

- Mofokeng, T.G.; Ojijo, V.; Ray, S.S. The influence of blend ratio on the morphology, mechanical, thermal, and rheological properties of PP/LDPE blends. Macromol. Mater. Eng. 2016, 301, 1191–1201. [Google Scholar] [CrossRef]

- Zhang, K.; Zhong, L.; Gao, J.; Li, L.; Cao, L.; Chen, G. Temperature dependence of crystalline structure and DC performance in LLDPE/HDPE blending material. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 754–759. [Google Scholar] [CrossRef]

- Zhang, G.; Nam, C.; Petersson, L.; Jämbeck, J.; Hillborg, H.; Chung, T.M. Increasing polypropylene high temperature stability by blending polypropylene-bonded hindered phenol antioxidant. Macromolecules 2018, 51, 1927–1936. [Google Scholar] [CrossRef]

- Sengul, C.E.; Oruc, S.; Iskender, E.; Aksoy, A. Evaluation of SBS modified stone mastic asphalt pavement performance. Constr. Build. Mater. 2013, 41, 777–783. [Google Scholar] [CrossRef]

- Guerrero-Martin, C.A.; Montes-Pinzon, D.; Meneses Motta da Silva, M.; Montes-Paez, E.; Guerrero-Martin, L.E.; Salinas-Silva, R.; Camacho-Galindo, S.; Fernandes Lucas, E.; Szklo, A. Asphaltene precipitation/deposition estimation and inhibition through nanotechnology: A comprehensive review. Energies 2023, 16, 4859. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons Inc.: New York, NY, USA, 2001; Volume 1997, pp. 200–201. [Google Scholar]

- Myers, R.H.; Montgomery, D.C.; Anderson-Cook, C.M. Response Surface Methodology: Process and Product Optimization Using Designed Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Khan, M.I.; Sutanto, M.H.; Napiah, M.B.; Khan, K.; Rafiq, W. Design optimization and statistical modeling of cementitious grout containing irradiated plastic waste and silica fume using response surface methodology. Constr. Build. Mater. 2021, 271, 121504. [Google Scholar] [CrossRef]

- Bala, N.; Napiah, M.; Kamaruddin, I.; Danlami, N. Optimization of nanocomposite modified asphalt mixtures fatigue life using response surface methodology. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018; Volume 140, p. 012064. [Google Scholar]

- Memon, A.M.; Sutanto, M.H.; Napiah, M.; Khan, M.I.; Rafiq, W. Modeling and optimization of mixing conditions for petroleum sludge modified bitumen using response surface methodology. Constr. Build. Mater. 2020, 264, 120701. [Google Scholar] [CrossRef]

- Bala, N.; Napiah, M.; Kamaruddin, I. Nanosilica composite asphalt mixtures performance-based design and optimisation using response surface methodology. Int. J. Pavement Eng. 2020, 21, 29–40. [Google Scholar] [CrossRef]

| Polymer Type | Code | Origin | Class | Chemical Composition | Melting Point (°C) | Density (g/cm3) |

|---|---|---|---|---|---|---|

| rLDPE | L | Waste | Plastomer | Branched Polyethylene | 130 | 0.941 |

| rHDPE | H | Waste | Plastomer | Line Polyethylene | 150 | 0.952 |

| rPP | P | Waste | Plastomer | Isotactic PP | 160 | 0.943 |

| SBS | S | Commercially | Elastomer | Aromatic styrene blocks | 180 | 1.061 |

| Polybilt | B | Commercially | Plastomer | Ethylene vinyl acetate | 140 | 0.942 |

| Recycled Plastic Waste | RPW Percentage | “S” | “B” | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 0% | 1% | 1.5% | 2% | 0% | 1% | 1.5% | 2% | ||

| “L” | 0% | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| 2% | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| 4% | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| 6% | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| “H” | 0% | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| 2% | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| 4% | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| 6% | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| “P” | 0% | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| 2% | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| 4% | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| 6% | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Factors | Units | Code | Levels | ||

|---|---|---|---|---|---|

| −α | 0 | +α | |||

| Recycled Plastic Waste (RPW) | % | X1 | 0 | 4 | 6 |

| Commercial Polymer (CP) | % | X2 | 0 | 1.5 | 2 |

| Recycled Plastic Waste | Blend Temperature | Symbolic Representation | Code |

|---|---|---|---|

| rLDPE | 160 °C |  | L |

| rHDPE | 180 °C |  | H |

| rPP | 190 °C |  | P |

| Polymers | Temperature (°C) | Time (min) |

|---|---|---|

| “L” | 160 | 30 |

| “H” | 180 | 60 |

| “P” | 190 | 50 |

| “S” | 180 | 60 |

| “B” | 145 | 60 |

| “S” + “L” | 180 | 60 |

| “S” + “H” | 180 | 60 |

| “S” + “P” | 190 | 60 |

| “B” + “L” | 160 | 60 |

| “B” + “H” | 180 | 60 |

| “B” + “P” | 190 | 60 |

| Upper PG | “L” | “S” | “L” | “S” | “L” | “S” |

|---|---|---|---|---|---|---|

| 82 °C | 6% | 0.6% | 4% | 1.2% | 2% | 2% |

| 76 °C | 4% | 0% | 2% | 0.6% | 2% | 1.5% |

| Upper PG | “H” | “S” | “H” | “S” | “H” | “S” |

|---|---|---|---|---|---|---|

| 82 °C | 4% | 0.5% | 2% | 1% | - | - |

| 76 °C | 4% | 0% | 2% | 0.6% | 2% | 1.5% |

| Responses | Viscosity (“L” and “S”) | UPG (“L” and “S”) | Viscosity (“H” and “S”) | UPG (“H” and “S”) | Viscosity (“P” and “S”) | UPG (“P” and “S”) |

|---|---|---|---|---|---|---|

| R2 | 0.97 | 0.82 | 0.95 | 0.91 | 0.91 | 0.84 |

| Adjusted R2 | 0.96 | 0.80 | 0.93 | 0.85 | 0.86 | 0.76 |

| Predicted R2 | 0.95 | 0.76 | 0.88 | 0.74 | 0.72 | 0.62 |

| Adequate Precision | 38.93 | 18 | 23.5 | 14.6 | 15.6 | 9.82 |

| F-value | 143 | 31.22 | 44.36 | 19.19 | 19.57 | 10.57 |

| p-value | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| Model | Significant | Significant | Significant | Significant | Significant | Significant |

| Lack of fit (F- and p-value) | Not-significant | Not-significant | Not-significant | Not-significant | Not-significant | Not-significant |

| 4.27 | 0.56 | 4.74 | 2.18 | 3.15 | 0.79 | |

| 0.0645 | 0.77 | 0.056 | 0.206 | 0.06 | 0.49 | |

| Final model | Quadratic | Quadratic | Quadratic | Quadratic | Quadratic | Quadratic |

| Responses | Viscosity (“L” and “B”) | UPG (“L” and “B”) | Viscosity (“H” and “B”) | UPG (“H” and “B”) | Viscosity (“P” and “B”) | UPG (“P” and “B”) |

|---|---|---|---|---|---|---|

| R2 | 0.86 | 0.91 | 0.86 | 0.88 | 0.94 | 0.77 |

| Adjusted R2 | 0.79 | 0.89 | 0.84 | 0.86 | 0.92 | 0.71 |

| Predicted R2 | 0.61 | 0.86 | 0.80 | 0.80 | 0.74 | 0.61 |

| Adequate Precision | 11.4 | 23.6 | 8.81 | 18.07 | 21.7 | 13 |

| F-value | 12.74 | 65.71 | 8.66 | 47.68 | 36.44 | 13.84 |

| p-value | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| Model | Significant | Significant | Significant | Significant | Significant | Significant |

| Lack of fit (F- and p-value) | Not-significant | Not-significant | Not-significant | Not-significant | Not-significant | Not-significant |

| 2.39 | 1.22 | 2.13 | 2.63 | 4.64 | 4.39 | |

| 0.180 | 0.43 | 0.46 | 0.15 | 0.058 | 0.06 | |

| Final model | Quadratic | Quadratic | Quadratic | Quadratic | Quadratic | Quadratic |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdul Wahhab, H.I.A.; Rafiq, W.; Habib, M.A.; Babalghaith, A.M.; Abdulrahman, S.; Shahzad, S. Asphalt Binder Rheological Performance Properties Using Recycled Plastic Wastes and Commercial Polymers. Constr. Mater. 2025, 5, 75. https://doi.org/10.3390/constrmater5040075

Abdul Wahhab HIA, Rafiq W, Habib MA, Babalghaith AM, Abdulrahman S, Shahzad S. Asphalt Binder Rheological Performance Properties Using Recycled Plastic Wastes and Commercial Polymers. Construction Materials. 2025; 5(4):75. https://doi.org/10.3390/constrmater5040075

Chicago/Turabian StyleAbdul Wahhab, Hamad I. Al, Waqas Rafiq, Mohammad Ahsan Habib, Ali Mohammed Babalghaith, Suleiman Abdulrahman, and Shaban Shahzad. 2025. "Asphalt Binder Rheological Performance Properties Using Recycled Plastic Wastes and Commercial Polymers" Construction Materials 5, no. 4: 75. https://doi.org/10.3390/constrmater5040075

APA StyleAbdul Wahhab, H. I. A., Rafiq, W., Habib, M. A., Babalghaith, A. M., Abdulrahman, S., & Shahzad, S. (2025). Asphalt Binder Rheological Performance Properties Using Recycled Plastic Wastes and Commercial Polymers. Construction Materials, 5(4), 75. https://doi.org/10.3390/constrmater5040075