Abstract

In Hungary, on-site mixed stabilization of cohesive soil is considered only as soil improvement not a proper pavement layer, therefore its bearing capacity is not taken into account when designing pavement. It was our hypothesis that on low-volume roads built on cohesive soil, lime or lime–cement stabilization can be an alternative to granular base layers. A case study was conducted to obtain initial results and to verify the research methodology. The efficacy of lime stabilization was evaluated across eight experimental road sections, with a view of assessing its structural and economic performance in comparison with crushed stone base layers reinforced with geo-synthetics. The results of the testing demonstrated elastic moduli of 120–180 MPa for the lime-stabilized layers, which closely matched the 200–280 MPa range observed for the crushed stone bases. The results demonstrated that lime stabilization offers a comparable load-bearing capacity while being the most cost-effective solution. Furthermore, this approach enhances sustainability by enabling the utilization of local soils, reducing reliance on imported materials, minimizing transport-related costs, and lowering carbon emissions. Lime stabilization provides a durable, environmentally friendly alternative for road construction, effectively addressing the challenges of material scarcity and rising construction costs while supporting infrastructure resilience. The findings highlight its potential to replace traditional base layers without compromising structural performance or economic viability.

1. Introduction

In Hungary, forest roads are permanent structures primarily built as routes for timber transport. Their geometry, drainage, and pavement are designed to meet the needs of logging trucks and machinery with the aim of all-year or extended trafficability. The pavement of the majority of the forest roads in the country was built as a macadam pavement or asphalt pavement on an aggregate base. On cohesive soils, a thin sandy gravel separation layer was usually built to prevent the pavement from being pushed into the subsoil. As the ecological and financial mindset and possibilities have changed, the need for new, eco-friendly, and economical pavement materials has risen. According to the national road construction standards, on cohesive soils, the aggregate subbase materials can be replaced by lime, or HRB (Hydraulic Road Binder) stabilization to improve the bearing properties of the soil. However, this improvement is considered only to reach the required minimum bearing capacity of the soil, and further improvements are neglected. Forest roads are built with a very tight budget and with the aim of minimizing the use of imported materials, and our aim was to prove that on-site stabilized soil can be a load-bearing part of the pavement of such roads and thus it can improve the cost efficiency and the sustainability of forest road construction.

In the first part of the research [1], the laboratory tests and the derived design parameters of lime- and HRB-stabilized cohesive soil samples, as well as the research results from the built pilot road sections are presented. The soil of the pilot road was identified as lean clay based on the plasticity index. The values of the cyclic CBR (California Bearing Ratio)-derived resilient moduli ranged from 118 to 128 MPa for soils stabilized with lime and lime–cement mixtures. On-site LWD (Light Weight Deflectometer) and FWD (Falling Weight Deflectometer) measurements were carried out to determine the elastic moduli of the stabilized soil. The resulting moduli were in accordance with the lab tests.

In this paper we present eight types of proposed pavements for low-volume roads built on cohesive soil. The eight pilot pavement sections were built with stabilized soil or granular layers as a subbase. Load-bearing capacity and economic data are presented, and a cost analysis is given to determine the optimal pavement structure for the site.

Lime stabilization is known to enhance the strength and stiffness of subgrade and subbase soils, significantly increasing the CBR and unconfined compressive strength (UCS). Tang et al. reported that the CBR of lateritic soils increased from approximately 79% to 162–215% after treatment with 3–9% lime, demonstrating a substantial improvement in load-bearing capacity compared to untreated granular bases [2]. Similarly, Dhar and Hussain found that with 5% lime content and 7-day curing, the CBR of expansive clay subgrade soils improved sufficiently to be considered for subbase applications, which could potentially eliminate or reduce the need for granular materials [3].

Field trials further support these findings. Little compared the in situ resilient moduli of aggregate base courses with and without 1% lime and found a significant increase in stiffness in lime-treated sections using FWD analysis [3]. Li et al. conducted a mechanistic-based comparison on low-volume roads, showing that lime-treated sections had consistently higher moduli and better performance than granular-only or geosynthetic-reinforced sections [4].

A comprehensive study by Pokkunuri et al. evaluated subgrade performance using both lime stabilization and granular base layers across varying pavement profiles in Thailand [5]. The study found that lime-stabilized sections achieved an average CBR increase of 20.9%, enabling a reduction in asphalt thickness from 120 mm to 90 mm, compared to control sections built on untreated granular subbases. This performance enhancement translated into a more sustainable pavement structure by reducing required natural resources and increasing bearing capacity [5].

Sood and Bansal conducted laboratory-based tests comparing untreated soil subgrades and lime-stabilized subgrades in terms of soaked CBR performance. The CBR of native soil (3%) increased to 8.62% with 3% lime and peaked at 10.42% with 5% lime. Beyond this point, performance plateaued or declined. These increases in bearing capacity directly translated into pavement crust thickness reductions of up to 240 mm when lime was used, offering a technical basis for replacing granular subbase layers with treated in situ materials [6].

Tan et al. further emphasize the dual benefits of lime and cement stabilization in improving subgrade performance [7]. Their review highlights that lime-treated soils typically show significant long-term strength gains due to pozzolanic activity, especially in clay-rich subgrades. The stabilized layers develop improved workability, moisture resistance, and structural integrity, making them functionally superior to conventional unbound granular bases under fluctuating moisture and load conditions [7].

In Brazil, the effects of different granular and chemical stabilization methods were examined in granular and slightly cohesive soils. It was found that the chemical treatment (hydrated lime or Portland cement) proved to be the most effective in increasing the resilient modulus of the test soils. The average modulus values ranged from 300 to 400 MPa and the average increase in CBR was almost 110% [8].

Jayalekshmi et al. reviewed the stabilization of lateritic soils using lime, cement, and their combination, highlighting lime’s effectiveness in improving UCS, soaked CBR, and OMC (Optimum Moisture Content) [9]. Lime-treated laterites frequently exceeded the 30% CBR threshold set by the Ministry of Road Transport and Highways of India, making them suitable for subbase applications. The study attributed these improvements to pozzolanic reactions that enhance strength and reduce plasticity, while also improving workability and moisture resistance. Economically and environmentally, lime-stabilized laterite was found to reduce dependence on imported aggregates and offer a cost-effective alternative for low-volume roads [9].

The durability of lime-stabilized soils is of great concern as this determines their interchangeability with granular subbases. It was found that water submersion and freeze–thaw cycles decrease the initial performance, but the performance stabilizes after a few cycles. Therefore, these stabilizations can provide load-bearing capacity throughout longer periods of time [10].

In a Swedish study, it was concluded that on clayey soils, mixed binders work even better than pure binders. It was found that amongst the specimens examined, the lime–ash–cement mix worked best. By mixing five types of binders (lime, cement, bio fly ash, energy fly ash, and slag) in different ratios, it is possible to adapt the mixture to a large variety of soils [11]. This finding was reinforced by Sambre et al., who found that the addition of fly-ash in 1:2–1:4 proportions to lime increased the CBR values of the stabilization [12].

Cost considerations are central to the selection of pavement subbase materials. Lime stabilization has consistently shown potential for reducing both initial construction costs and long-term maintenance needs. Hopkins et al. conducted a comparative life-cycle cost analysis on two Australian roads, showing that in situ lime stabilization (3%) offered similar structural capacity to full granular reconstruction at a significantly lower cost and shorter construction duration, with benefit–cost ratios ranging from 4.0 to 4.3 [13].

Ghaniazdeh et al. performed a mechanistic–empirical evaluation and found that lime stabilization could reduce construction costs by 9–12% while increasing the resilient modulus by a factor of four to five compared to untreated granular subgrades [14]. In another study, Ahmed et al. combined lime with sugarcane bagasse ash, resulting in a 16% reduction in construction cost and extending pavement life expectancy from 12 to 25 years [15].

As environmental considerations are gaining increasing importance, different kinds of secondary materials have been tested as road binders. The use of municipal solid waste incinerator ash proved to be an effective binder for unbound layer materials [16].

The world-wide results clearly show that on cohesive soils it is worth applying lime as a soil binder, because it improves the load-bearing capacity of the soil while being a more economical solution than imported granular material. In Hungary, the use of on-site soil stabilization as a base layer is not so common in low-volume road construction. Plant-mixed stabilization and granular base layers are common instead. It was our aim to compare the performance of traditional granular base layers and on-site mixed soil stabilizations built on slightly cohesive soil. On top of that, the cost and environmental effects of the two base types deserve comparison to decide whether the use of on-site stabilization is a good alternative to the granular bases. To obtain realistic cost and performance data for Hungary, a pilot road section was built with different pavement structures.

2. Materials and Methods

2.1. Pilot Road

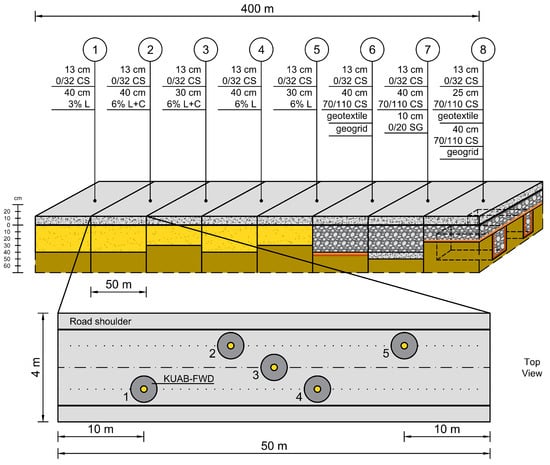

The pilot road built in 2019 consists of eight 50 m long, 4 m wide sections, each with a different pavement structure (Figure 1). The structural number of each section was designed to be the same to provide comparability. Five sections were stabilization-based, while two sections were aggregate-based with geosynthetic layers. Test section 7 represented the classic macadam pavement, where a thin sandy gravel layer provides separation from the cohesive soil. The crushed stone top layers were made of the same material along the road, but the thickness varied with the thickness of the base layers to maintain the overall pavement’s uniform structural number. The base layers of the experimental pavement sections built were constructed with the following parameters:

Figure 1.

Pilot road sections. CS: crushed stone, L: lime binder L + C: lime and Portland cement binder.

- 3 m/m% lime, 40 cm depth = 23.0 kg/m2

- 6 m/m% lime–Portland cement mixture (70–30%), 40 cm depth

- 6 m/m% lime–Portland cement mixture (70–30%), 30 cm depth

- 6 m/m% lime, 40 cm depth = 45.7 kg/m2

- 6 m/m% lime, 30 cm depth = 34.0 kg/m2

- crushed stone (40 cm) + geotextile + geogrid

- crushed stone (40 cm) + sandy gravel (10 cm)

- 25 cm crushed stone + geotextile + geogrid + extra crushed stone + geogrid under the wheel paths

In test sections 6 and 8, geotextile serves as a separation layer, while geogrid serves as a load distribution layer.

The 8 sections were designed to represent fundamental differences between the pavement structures and to provide for simple comparison between stabilization-based and aggregate-based structures.

2.2. Site

Eight pilot road sections were built on cohesive soil in Hungary to examine the in situ behavior of the proposed pavements. The location of the pilot road is 47°54′09.3″ N 19°59′20.7″ E, 460 m AMSL (Figure 2). Figure 3 shows different pavement types in different construction phases.

Figure 2.

Location of the pilot road. Source: Wikipedia.org/wiki/File:EU-Hungary.svg.

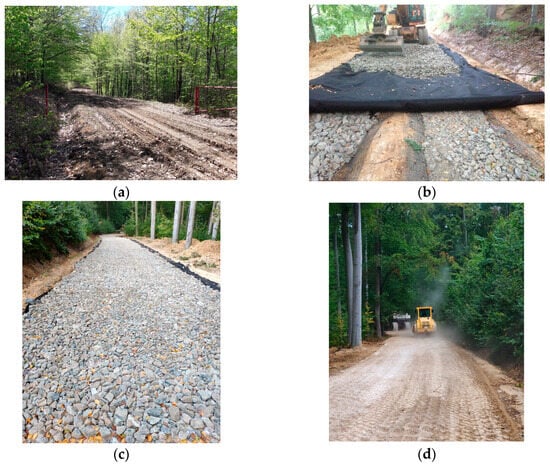

Figure 3.

Photos taken in different sections and construction phases: (a) The unpaved road; (b) Test section #8 under construction; (c) Finished base course of test section #6; (d) Soil stabilization.

The soil in the area was identified as lean clay based on the plasticity index (17.86%) and silty (30%) sand (70%), based on the grain size distribution diagram. The detailed soil mechanics results can be found in Primusz et al. [1].

2.3. Measurement of the Bearing Capacity

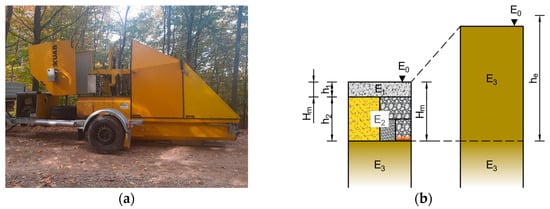

The bearing capacities of the pilot pavements were measured by a heavy falling weight deflectometer. The KUAB FWD (KUAB KONSULT & UTVECKLING AB, Kalmar, Sweden) equipment (Figure 4a) drops a 50 kN mass on a 30 cm diameter loading plate, thus creating a 15–22 ms long loading, and measures the resulting deflections of the pavement surface. The loading plate is segmented into four equal parts to provide the best possible fit for the current pavement deformations. The deflections are measured with geophones positioned 200, 300, 450, 600, 900, and 1200 mm away from the center of the loading plate. This way not only the central deflection but the whole deflection basin can be measured. One measurement consists of two consecutive drops. The first one is the conditioning drop that helps the plate to settle well. The readings from the second drop are used for the bearing capacity calculations.

Figure 4.

Determining the bearing capacity of the pavement: (a) The KUAB FWD equipment; (b) Model of the parameters used in the back-calculation method.

2.4. Fundamentals of Structural Performance Evaluation

To determine in situ stiffness, measurements were carried out using an FWD, and the elastic moduli (Young’s modulus, ) of the individual pavement layers were estimated using inverse calculation methods.

The PAVBACK v.6.03P program was utilized to analyze pavement behavior based on the Boussinesq–Odemark Method of Equivalent Thickness (MET), a method that calculates deflections, stresses, and strains within the pavement system [17]. The back-calculation of layer moduli or layer thicknesses, as well as the prediction of structural capacity, was performed through an iterative search algorithm aimed at minimizing the Root Mean Squared Error (RMSE) between the measured and calculated deflections. RMSE was computed based on either relative or absolute deflection differences, depending on the user-defined settings. The iterative optimization process was conducted using a modified version of the Levenberg–Marquardt non-linear least squares method (LMDIF).

The determination of layer moduli enables the quantitative assessment of the stiffness of the stabilized subgrade, the crushed stone base layer, and the bound pavement layers, as well as their respective contributions to the overall distribution capacity of the structure. Higher back-calculated modulus values typically indicate better compaction, more stable material structure, and more favorable performance under traffic loading. Based on the relative ratio and vertical distribution of the layer moduli, the structural load-bearing efficiency and the identification of critical layers can be evaluated.

During the processing of deflection data measured by the KUAB FWD device, the behavior of layers above the subgrade was modeled assuming linear elastic material behavior. The subgrade, defined as the lowermost -th layer, was treated as a non-linear (stress-sensitive) material, and its modulus was calculated using the following equation:

where denotes the principal stress resulting from dynamic loading, excluding static stresses induced by the self-weight of the material, and represents the reference stress (0.1 MPa). The parameter is a constitutive model coefficient with the same unit as , and is a dimensionless stress exponent typically ranging between .

The non-linear material behavior described by Equation (1) may be observed in deflection measurements obtained using an FWD, even when the subgrade exhibits nominally linear elastic behavior. This phenomenon is attributed to the dynamic nature of FWD loading, wherein the finite duration of the load impulse imposes limitations on the depth of subgrade that is compressed during the measurement process.

The surface modulus is defined as the equivalent half-space modulus that would produce the same surface deflection as that observed in a multi-layered pavement system (Figure 4b). When plate loading is applied to a material governed by the constitutive law described in Equation (1), the surface modulus is computed using the following expression:

If the half-space behaves linearly, then , and . It should also be emphasized that may reach 1.5 to 2.0 times the material modulus of the respective layer when the material exhibits moderate-to-strong nonlinearity, with values ranging between −0.25 and −0.5. This has significant implications for the estimation of subgrade modulus when it is inferred from the surface modulus.

In the PAVBACK program, the parameters , and are calculated based on the measured deflections [17]. The equivalent thickness represents the transformation of a multi-layered pavement structure into a homogeneous, single-layer model. Based on these parameters, estimates can be made for subgrade compressive stress, vertical strain, and the so-called effective structural number of the pavement structure, denoted as .The value of is computed using Equation from Volume 2 of the 1986 AASHTO Guide for Design of Pavement Structures [18,19], as follows:

where is the equivalent layer thickness, is a correction factor (taken as 0.8 for linear subgrade behavior and 1.0 for nonlinear subgrade), is the surface modulus, and is the Poisson’s ratio.

This equation is used to estimate the overall structural capacity of the pavement system, which can be expressed as a single value, and the structural number, which is based on the surface modulus determined from dynamic FWD testing. The surface modulus reflects the behavior of the lower pavement layers (particularly the subgrade) but is interpreted as a global, averaged property. The Poisson’s ratio provides a correction to the modulus to account for the effects of the three-dimensional stress state.

The output parameters of the PAVBACK program include the individual layer thicknesses, normalized modulus values, tensile stress and strain at the bottom of the bound layer, compressive stress and strain at the top of the subgrade, equivalent thicknesses for the pavement layers, the AASHTO-based effective structural number (), as well as the relative and absolute RMSE values and the calculated surface deflections.

The equivalent thicknesses computed based on the modulus values are intended to enable the comparison of layers composed of different materials and exhibiting different behaviors through a unified metric. This approach allows for the comparison of alternative layer configurations under equivalent load-bearing conditions, or for the optimization of layer thicknesses as a function of other parameters, such as stabilization content. The use of equivalent thickness is particularly beneficial when different pavement structures are to be considered structurally equivalent for the purposes of design or rehabilitation decision-making.

To provide a comprehensive characterization of pavement performance, the effective structural number () was employed. During the computation of , layer parameters derived from back-calculated moduli were considered. As a result, the obtained structural number can be interpreted not only as a theoretical indicator but also as a metric that reflects the actual structural behavior. The comparison of values enabled performance-based ranking of pavement sections constructed with different stabilization methods and facilitated the identification of the most favorable configurations.

2.5. Fatigue Life Estimation

The service life of each experimental pavement structure was estimated in terms of equivalent single-axle load (ESAL) repetitions using the AASHTO design equation [20,21]:

where : predicted 18-kip (80 kN) equivalent single-axle load repetitions, : standard normal deviation for reliability level (95% = −1.645), : combined standard error of the traffic prediction and performance prediction, where typical values are 0.40 to 0.50 for flexible pavement, : structural number of pavement, : difference between initial and terminal serviceability index (typical values are 1.5–2.0), and : subgrade resilient modulus (in psi).

Since in Hungary the standard axle load is 100 kN rather than 80 kN, the value of obtained from the above formula was divided by a conversion factor of to account for the increased axle load magnitude.

This expression effectively integrates both subgrade strength and pavement structural capacity into a single metric, which serves as a technically sound basis for ranking the performance of the experimental pavement configurations. However, beyond the engineering aspects, economic considerations are equally important in the overall evaluation.

2.6. Composite-Index-Based Pavement Evaluation

Composite indices are employed to consolidate both economic and technical considerations into a single metric. The first index calculated was the Cost–Life Ratio (CLR), which reflects the ratio between construction cost and service life:

where HUF (ISO 4217) denotes Hungarian forint currency.

Lower CLR values indicate more cost-effective pavement solutions. This indicator accounts for material usage only indirectly, through its influence on construction cost. Soil stabilization techniques make use of in situ materials, thereby significantly reducing the need for transporting and incorporating imported crushed stone.

To explicitly capture this positive effect, the Material Efficiency Index (MEI) was introduced. This index considers service life (expressed in ESAL), construction cost (in HUF/m2), and the amount of imported material through layer thickness:

The resulting unit of the index is HUF/m/ESAL. This value indicates the combined cost and material demand per equivalent single-axle load repetition. The lower the MEI, the more favorable the cost–material–lifetime balance of the given pavement configuration.

3. Results and Evaluation

A comprehensive analysis revealed substantial disparities among the eight experimental pavement configurations in terms of service life, structural performance, and construction costs. The evaluation was based on estimated fatigue life (expressed in ESAL), the effective structural number (), equivalent layer thicknesses, and the unit cost per equivalent axle load (HUF/ESAL). Furthermore, an assessment was conducted to evaluate the quantity of incorporated materials and their sustainability implications. This assessment focused particularly on the distinction between locally stabilized and imported-material-dependent layer assemblies.

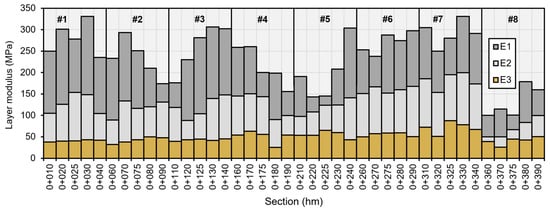

As illustrated in Figure 5, the back-calculated layer moduli for each test section are presented, as determined from the FWD measurements. The values for the subgrade (), the base layer (), and the crushed stone surface () are displayed separately for each structure.

Figure 5.

Layer moduli of the experimental pavement sections at the FWD measurement points.

The measured moduli, ranging between 130 and 290 MPa, are consistent with published ranges for unbound crushed stone layers. According to Dong [22] and Paul [23], the elastic modulus of compacted, non-cemented granular bases typically falls within the 100–300 MPa range, depending on compaction quality, particle size distribution, and the influence of overlying layers. The observed values fall within the mid-to-upper range of this interval, indicating that the placed crushed stone was well compacted and exhibited favorable interlayer bonding with the underlying materials.

Layer moduli for soils stabilized with lime or lime–cement have been reported in the international literature over a broad range. Typical values are 200–400 MPa for lime-only stabilization [24], and 400–800 MPa or even near 1000 MPa for cement-modified mixtures [25,26,27]. The time-dependent nature of pozzolanic reactions, the mineralogical composition of the soil, and construction practices are key influencing factors for the development of these modulus values.

In the present study, field stabilization using 3% and 6% lime content resulted in back-calculated moduli of 120–125 MPa based on in situ FWD data. These values are significantly lower than those reported in the literature. This discrepancy can be attributed to the less favorable physical characteristics of the stabilized soil (e.g., gradation, moisture content, and density), which may have inhibited the development of pozzolanic bonding. Additionally, forestry road construction is often carried out under non-ideal site and logistical constraints, where construction discipline and quality control may fall short of highway-construction standards (e.g., mixing uniformity, compaction, and curing conditions). Unfortunately, we lack contemporaneous measurements of moisture content during and after construction, as well as records of curing/aftercare practices; this uncertainty further limits direct comparability with idealized literature values and may also contribute to the lower back-calculated moduli.

Subgrade modulus values () ranged from 40 to 55 MPa, which is typical of weak to moderately strong subgrades. However, the value of 70 MPa measured in pavement section 7 was notably higher than in other locations. This was likely due to localized variations in soil quality, compaction level, or moisture content.

Table 1 summarizes the detailed measurement results, including average modulus values and standard deviations for each layer.

Table 1.

Back-calculated layer stiffness characteristics and construction costs of the experimental pavement structures; x = mean, s = standard deviation.

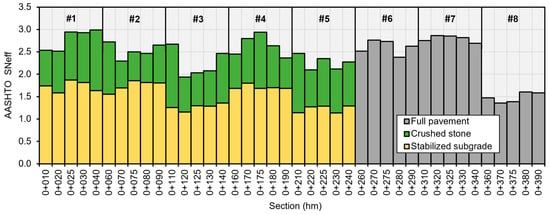

Figure 6 illustrates the effective structural number () calculated for each experimental pavement configuration in accordance with the AASHTO guidelines. The results reveal clear distinctions in structural behavior among the different layer compositions. For the structures composed solely of lime- or lime–cement-stabilized subgrades without a crushed stone surface course, the average structural number was only 1.5. This relatively low value indicates limited load distribution capacity due to the absence of a stiff, load-spreading upper layer.

Figure 6.

Effective structural number of experimental pavement sections at FWD measurement points. Full pavement means that measurements were taken at the top of the finished structure, while for soil stabilization structures, measurements were also taken directly on the stabilization.

In contrast, pavement configurations constructed with conventional layering or reinforced with geosynthetics yielded values ranging from 2.5 to 2.9. These higher values reflect more effective composite action between layers and demonstrate the beneficial contribution of surface or reinforcing elements to overall structural capacity. An exception was observed in Pavement Structure No. 8, where reinforcement was applied exclusively in the wheel paths. As a result, the overall structural number remained comparable to that of unreinforced, stabilized soil structures and did not exhibit a meaningful increase.

Another important observation is that in cases where stabilized base layers were covered with a crushed stone surface course, the effective structural number increased by an average of 0.9. This finding supports the role of the crushed stone layer in enhancing the stiffness and load-bearing capacity of the upper pavement system, particularly in scenarios where the substructure alone is insufficient in strength. The observed improvement in structural number can be attributed not only to the increased modulus of the surface layer () but also to improved mechanical interaction and stress distribution between layers, as confirmed by previous studies [24,26]. Overall, the inclusion of a crushed stone surface course above stabilized soil layers resulted in a significant enhancement of structural behavior, as evidenced by the measured increases in .

The remaining service life of the pavement structures was also estimated using Equation (4). Pavement Structure No. 7 demonstrated the highest predicted service life (148,539 ESALs) and the lowest unit cost (0.072 HUF/ESAL). This structure included not only a crushed stone base layer but also a 10 cm thick sand–gravel separation and improvement layer, and it was constructed on the strongest subgrade ( MPa). Despite its outstanding technical performance, this configuration required the largest volume of imported materials due to the inclusion of the crushed stone and filter layers, resulting in high transportation demands and associated environmental burdens. Such designs are primarily justified in conditions of high traffic loading or particularly favorable subgrade conditions. However, from a sustainability perspective, their general applicability remains questionable, especially in areas with weak soils or environmental sensitivity.

Structures constructed with lime-stabilized subgrades—particularly Structures No. 4 and No. 1—exhibited balanced performance. Structure No. 4 achieved a service life of 45,813 ESALs at a specific cost of 0.133 HUF/ESAL. Similarly, Structure No. 1 provided solid bearing performance with 38,872 ESALs and 0.156 HUF/ESAL, despite being built on a weaker subgrade ( MPa). It is important to emphasize that lime stabilization utilizes local soil, thereby minimizing the volume of imported material and significantly reducing transportation requirements compared to crushed stone layers. According to the literature, this results in clear environmental benefits, including lower CO2 emissions, reduced energy consumption, and more efficient use of local resources [28]. Lime stabilization can therefore be considered among the most sustainable solutions, particularly under medium loading conditions and heterogeneous subgrade conditions.

In contrast, the lime–cement-stabilized structures (Structures No. 2 and No. 3) delivered lower-than-expected performance. Structure No. 2 achieved a service life of 23,113 ESALs with a unit cost of 0.256 HUF/ESAL, while Structure No. 3 performed considerably below expectations (11,280 ESALs, 0.553 HUF/ESAL). Although lime–cement stabilization theoretically provides higher mechanical strength than lime alone, the measurements did not confirm this advantage. Furthermore, cement production and use are associated with high greenhouse gas emissions, negatively impacting environmental sustainability [29]. From a technical perspective, the application of such methods may only be justified under conditions of particularly weak or problematic soils.

The evaluation of geogrid-reinforced structures yielded a range of outcomes. Structure No. 6, which consists of a crushed stone base combined with geotextile and geogrid, demonstrated an acceptable service life (40,044 ESALs). However, its unit cost was 0.268 HUF/ESAL, which is considerably higher than that of the lime-stabilized alternatives. The structure was constructed entirely from imported materials, including an industrial product called geogrid, which has a greater transportation and manufacturing footprint, thus making it less sustainable. Conversely, Structure No. 8 demonstrated substantial performance shortcomings, exhibiting a service life of merely 882 ESALs and a cost of 14.22 HUF/ESAL. Consequently, the project was deemed to be technically, economically, and environmentally unviable. The substandard performance was presumably attributable to an insufficient layer configuration and an inadequate implementation of reinforcement, which was confined to the wheel paths.

A comparative assessment of structures was conducted using two complementary indicators: the Material Efficiency Index (MEI) and the Cost–Life Ratio (CLR). These indicators were selected to provide an integrated evaluation of technical, economic, and sustainability aspects. MEI incorporates a multifaceted set of metrics, including construction cost, the quantity of imported materials (expressed through layer thickness in meters), and the predicted service life. In contrast, CLR prioritizes cost efficiency relative to lifespan, offering a distinct perspective on the evaluation of construction projects. According to the findings of the present analysis, the lime-stabilized structures identified as Nos. 4 and 1 demonstrated the most optimal MEI values. This is attributable to the unique combination of their low material demand and relatively extended service life. These structures also demonstrated high CLR performance; however, Structure No. 7 exhibited the highest level of cost efficiency due to its exceptional durability. However, the substantial material usage and transportation requirements of Structure No. 7 led to an unfavorable MEI value.

In conclusion, lime stabilization using in situ soils offers the optimal balance between cost efficiency, durability, and sustainability. Lime–cement stabilization did not demonstrate sufficient technical advantages to justify the added environmental burden. The economic viability of geogrid-reinforced solutions is contingent upon their implementation in meticulously designed systems and under optimal subgrade conditions. However, it is imperative to acknowledge the substantial material consumption and ecological implications inherent in their application. The reference structure (No. 7) is notable for its longevity; however, its viability is contingent upon specific site conditions, owing to its substantial material requirements and reliance on subgrade strength.

4. Conclusions

Based on the comparative evaluation of the eight experimental pavement structures, substantial differences were identified in terms of structural performance, predicted service life, and cost efficiency. The layer moduli derived from FWD measurements and the calculated AASHTO effective structural numbers () confirmed that structures incorporating crushed stone surfacing provided significant structural benefits, resulting in an average increase of 0.9 in . The moduli of the crushed stone layers (130–290 MPa) were consistent with values reported in the literature, whereas the lime-stabilized subgrade layers exhibited lower modulus values (120–125 MPa), primarily due to suboptimal particle size distribution and limited soil reactivity.

The best overall performance was achieved by Structure No. 7, which exhibited an outstanding service life (148,539 ESALs), albeit at the cost of significant material input and environmental burden. In contrast, the lime-stabilized Structures No. 1 and No. 4 showed favorable cost–life and sustainability indicators, with minimal demand for imported materials. The lime–cement-stabilized alternatives did not deliver meaningful performance improvements and were associated with a considerably larger environmental footprint. Geogrid-reinforced structures proved effective only under specific design and site conditions.

The comparative assessment also revealed that the depth of the stabilized layer had a more pronounced influence on pavement performance than the binder dosage alone. Structures No. 1, 2, and 4, all stabilized to a depth of 40 cm, consistently ranked among the top performers according to the modified Material Efficiency Index (MEI), even though lime–cement mixtures are theoretically stronger and more costly. In contrast, Structures No. 3 and No. 5, which were stabilized to only 30 cm despite using the same binder concentration, performed significantly worse. These findings suggest that the spatial extent of stabilization—particularly under weaker subgrade conditions—plays a critical role in determining long-term bearing capacity. From both an economic and sustainability perspective, future applications should therefore prioritize optimizing layer thickness rather than merely increasing the binder content.

Overall, the results support the conclusion that in situ soil stabilization, especially with lime, represents a highly viable approach for constructing sustainable, cost-effective, and structurally reliable pavement systems—particularly in low- to medium-traffic networks. As the research focused on one pilot road, the results are limited to similar soils and to a similar climate. The number of sections built did not make statistically backed results available. In order to give county-wide recommendations, a large-scale research program should be conducted that widens the scope on characteristic cohesive soils and climate regions of Hungary. Further research is recommended—as it was not the scope of the present study—to investigate the long-term evolution of the modulus in stabilized layers, to refine structural coefficients, and to conduct detailed life-cycle assessments of environmental impacts. Based on the findings, lime stabilization conducted on-site aligns well with the objectives of sustainable and economical road construction.

Author Contributions

Conceptualization, J.P. and P.P.; methodology, J.P. and P.P.; formal analysis, C.T. and P.P.; resources, C.T.; data curation, P.P.; writing—original draft preparation, B.K. and P.P.; writing—review and editing, B.K. and P.P.; visualization, B.K. and P.P.; supervision, J.P. All authors have read and agreed to the published version of the manuscript.

Funding

Egererdő cPlc. financed the construction of the experimental pavement sections presented in the study. Carmeuse Hungária Ltd. provided the binder for the laboratory tests. This article was supported by the RRF-2.1.2-21-2022-00011 project, financed by the Government of Hungary within the framework of the Recovery and Resilience Facility.

Data Availability Statement

Dataset available on request from the authors.

Acknowledgments

The authors hereby express their gratitude towards Judit Kaszala from Egererdő Plc for providing invaluable data for the cost analysis and supporting the research in multiple other ways.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of the data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| AASTHO | American Association of State Highway and Transportation Officials |

| CBR | California Bearing Ratio |

| CLR | Cost–Life Ratio |

| ESAL | Equivalent Single-Axle Load |

| FWD | Falling Weight Deflectometer |

| HRB | Hydraulic Road Binder |

| HUF | Hungarian Forints (currency) |

| LMDIF | Levenberg–Marquardt Non-linear Least Squares Method |

| LWD | Light Weight Deflectometer |

| MEI | Material Efficiency Index |

| MET | Boussinesq–Odemark Method of Equivalent Thickness |

| OMC | Optimum Moisture Content |

| PSI | Present Serviceability Index |

| RMSE | Root Mean Square Error |

| UCS | Unconfined Compressive Stress |

References

- Primusz, P.; Kisfaludi, B.; Péterfalvi, J. Using Cyclic CBR Method to Determine Resilient Modulus of Hydraulic Binder Stabilised Road Pavement Base Layers. Croat. J. For. Eng. 2024, 45, 125–138. [Google Scholar] [CrossRef]

- Tang, K.; Zeng, F.; Shi, L.; Zhu, L.; Chen, Z.; Zhang, F. Mechanical Behavior of Hydrated-Lime–Liquid-Stabilizer-Treated Granular Lateritic Soils. Sustainability 2023, 15, 5601. [Google Scholar] [CrossRef]

- Dhar, S.; Hussain, M. The strength and microstructural behavior of lime stabilized subgrade soil in road construction. Int. J. Geotech. Eng. 2021, 15, 471–483. [Google Scholar] [CrossRef]

- Walker, D.D., Jr.; Hardy, T.B.; Hoffman, D.C.; Stanley, D.D. Comparison of In-Situ Resilient Moduli of Aggregate Base Courses with and Without Low Percentages of Lime Stabilization. In Innovations and Uses for Lime; ASTM International: West Conshohocken, PA, USA, 1992; pp. 8–22. ISBN 978-0-8031-1436-4. [Google Scholar]

- Pokkunuri, G.R.; Sinha, R.K.; Verma, A.K. Field Studies on Expansive Soil Stabilization with Nanomaterials and Lime for Flexible Pavement. Sustainability 2023, 15, 15291. [Google Scholar] [CrossRef]

- Bansal, S.; Sood, S. Chandigarh Evaluation of Construction Materials for Soil Stabilization in Road Making Industry—A Techno Economic Study. Int. J. Eng. Res. Technol. 2015, 4, 404–410. [Google Scholar] [CrossRef]

- Tan, E.H.; Zahran, E.M.M.; Tan, S.J. A review of chemical stabilisation in road construction. IOP Conf. Ser. Mater. Sci. Eng. 2020, 943, 12005. [Google Scholar] [CrossRef]

- Albuquerque Filho, L.H.; Casagrande, M.D.T.; Almeida, M.S.D.S.; Costa, W.G.S.; Santana, P.R.L.D. Mechanical Performance and Life Cycle Assessment of Soil Stabilization Solutions for Unpaved Roads from Northeast Brazil. Sustainability 2024, 16, 9850. [Google Scholar] [CrossRef]

- Jayalekshmi, A.S.; Fernandez, L.; Faustine, A.; Anjana, A.; Pai, R.R. Laterite as a base and subbase material for flexible pavement—A review. Sustain. Agri. Food Environ. Res. 2022, 10. [Google Scholar] [CrossRef]

- Li, S.; Liu, S.; Zhang, T.; Wang, Z.; Zhao, W. Experimental study on the durability and microstructural characteristics of lime-stabilized silty clay in seasonally frozen region. Constr. Build. Mater. 2025, 463, 140158. [Google Scholar] [CrossRef]

- Lindh, P.; Lemenkova, P. Geotechnical Properties of Soil Stabilized with Blended Binders for Sustainable Road Base Applications. Constr. Mater. 2023, 3, 110–126. [Google Scholar] [CrossRef]

- Sambre, T.; Endait, M.; Patil, S. Sustainable soil stabilization of expansive soil subgrades through lime-fly ash admixture. Discov. Civ. Eng. 2024, 1, 65. [Google Scholar] [CrossRef]

- Hopkins, C.; Cameron, D.; Rahman, M.M. On Site Improvement of Fines-Rich Unbound Granular Materials with Hydrophobic Polymer and Lime. Sustainability 2021, 13, 13479. [Google Scholar] [CrossRef]

- Ghanizadeh, A.R.; Salehi, M.; Mamou, A.; Koutras, E.I.; Jalali, F.; Asteris, P.G. Investigation of Subgrade Stabilization Life-Extending Benefits in Flexible Pavements Using a Non-Linear Mechanistic-Empirical Analysis. Infrastructures 2024, 9, 33. [Google Scholar] [CrossRef]

- Ahmed, A.; El-Emam, M.; Ahmad, N.; Attom, M. Stabilization of Pavement Subgrade Clay Soil Using Sugarcane Ash and Lime. Geosciences 2024, 14, 151. [Google Scholar] [CrossRef]

- Vaitkus, A.; Škulteckė, J.; Šernas, O. A Test Road with Unbound Base and Sub-Base Course from MSWI Bottom Ash Mixtures. Buildings 2023, 13, 1311. [Google Scholar] [CrossRef]

- Furber, A.M. PAVBACKTM, Version 6.03P; Deflection Back calculation Software Operating Guide and Documentation; 2021, Copyright 2021 Arthur M. Furber, Jr. PE All rights reserved 7/25/2021.

- AASHTO Guide for Design of Pavement Structures; American Association of State Highway and Transportation Officials: Washington, DC, USA, 1986.

- Timm, D.H.; Robbins, M.M.; Tran, N.; Rodezno, C. Recalibration Procedures for the Structural Asphalt Layer Coefficient in the 1993 Aashto Pavement Design Guide; National Center for Asphalt Technology, Auburn University: Auburn, AL, USA, 2014; p. 40. [Google Scholar]

- AASHTO Guide for Design of Pavement Structures; American Association of State Highway and Transportation Officials: Washington, DC, USA, 1993; Volume 1.

- Abdollahi, S.F.; Lanotte, M.; Kutay, M.E. AASHTO 1993 Plus: An Alternative Procedure for the Calculation of Structural Asphalt Layer Coefficients. Int. J. Pavement Eng. 2022, 24, 2118273. [Google Scholar] [CrossRef]

- Dong, J. Investigation of Aggregates Size Effect on the Stiffness of Lime and/or Cement Treated Soils. Ph.D. Thesis, École des Ponts ParisTech, Paris, France, 2013. [Google Scholar]

- Paul, D. Characterisation of Lightly Stabilised Granular Materials by Various Laboratory Testing Methods. Ph.D. Thesis, University of South Australia, Adelaide, Australia, 2012. [Google Scholar]

- Mallela, J.; Von Quintus, H.; Smith, K.L. Consideration of Lime-Stabilized Layers in Mechanistic-Empirical Pavement Design; The National Lime Association: Arlington, VA, USA, 2004; p. 38. [Google Scholar]

- Mandal, T. Fatigue Behavior and Modulus Growth of Cementitiously Stabilized Pavement Layers. Ph.D. Thesis, University of Wisconsin, Madison, WI, USA, 2013. [Google Scholar]

- Moazami, D.; Yusoff, Z.M.; Muniandy, R. Effect of Stabilizers on Stiffness Modulus of Soil Layers: A Review. Int. J. Phys. Sci. 2013, 8, 1145–1151. [Google Scholar]

- Kakrasul, J.I.; Parsons, R.L.; Han, J. Lime Kiln Dust for Treated Subgrades; U.S. Department of Transportation: Washington, DC, USA, 2017. [Google Scholar]

- Liu, N.; Wang, Y.; Bai, Q.; Liu, Y.; Wang, P.S.; Xue, S.; Yu, Q.; Li, Q. Road life-cycle carbon dioxide emissions and emission reduction technologies: A review. J. Traffic Transp. Eng. (Engl. Ed.) 2022, 9, 532–555. [Google Scholar] [CrossRef]

- Piechowicz, K.; Szymanek, S.; Kowalski, J.; Lendo-Siwicka, M. Stabilization of Loose Soils as Part of Sustainable Development of Road Infrastructure. Sustainability 2024, 16, 3592. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).