1. Introduction

Granulated ferrochrome slag (FeCr) is a by-product material of high-carbon ferrochromium metal, which is a primary component of stainless steel. Highway constructions consume large amounts of natural materials. In contrast, ferrochrome slag has excellent engineering properties, and it could be suitable as a road construction material. Ferrochrome slag seems to be a reasonable alternative material to be used as an aggregate in hot-mix asphalt (HMA) rather than to be disposed of. The literature indicates potential for this material to be used as an aggregate substitute in road constructions.

Ferrochrome (FeCr) slag is generated in electric arc furnaces at approximately 1500 °C; it forms when metal ores are melted and separated from impurities, resulting in the production of purified metal and a stable crystalline slag. After separation based on density, the molten slag is slowly air-cooled to form a dense, porous rock, with the porosity attributed to gas bubble formation during solidification [

1,

2].

FeCr slag exhibits several advantageous physical properties over natural aggregates, including good adhesion, high abrasion resistance, and the absence of clay or organic contaminants. Its rough and porous texture results in high water absorption capacity [

3]. Chemically, FeCr slag is considered environmentally safe and non-hazardous, making it a promising green alternative to natural aggregate materials [

1].

The use of slag in construction has historical precedence, dating back to road building in Roman-era England and, later, to railway construction in 19th century America [

4,

5]. Recent research supports the viability of FeCr slag in modern infrastructure. For instance, Yılmaz and Karaşahin [

3] demonstrated that FeCr slag, when used in granular pavement layers, offers mechanical properties equal to or better than those of natural limestone, showing reduced permanent deformation under triaxial testing. Similarly, Yılmaz and Kok [

6] found that FeCr slag performs satisfactorily as a coarse aggregate in dense asphalt mixtures, though its use as a total aggregate negatively impacted mix stability and stiffness.

With the introduction of the

Mechanistic–Empirical Pavement Design Guide (MEPDG), pavement design increasingly depends on dynamic modulus-based characterization and performance models, including rutting prediction tools [

7]. This shift emphasizes the importance of assessing alternative aggregates not only for structural adequacy but also for their long-term performance against key distresses such as rutting.

There are two FeCr plants in Oman producing approximately 355,000 tons of FeCr slag annually. Currently, a small amount of FeCr slag is efficiently utilized while the rest is disposed in landfills. The government charges the producers for this disposal.

The objective of this research is to assess the potential use of FeCr slag produced in Oman as a substitute for natural aggregates in hot-mix asphalt (HMA) for both bituminous base and wearing course layers. The study investigates the impact of partial and full replacement of natural aggregates with FeCr slag on the rutting performance of HMA mixtures using the MEPDG rutting model. Mix designs were developed according to the Superpave mix design method. Economic evaluation was conducted to determine the viability of the most promising mixture for local road construction applications.

2. Material Characterization

2.1. Physical Properties

Natural aggregate was obtained from a major expressway construction project north west of Muscat, the capital of Oman. Aggregate (Gabbro) quantities were obtained from the hot bins for both bituminous base and wearing course mixes. The performed physical tests are shown in

Table 1 for both the natural Gabbro and FeCr slag aggregate. The results indicate similar specific gravity for the natural aggregate and FeCr slag, with higher absorption of FeCr slag, indicating higher demand for the asphalt binder. The results of Fine Aggregate Angularity [

8] indicate the higher uncompacted void content of the FeCr slag, indicating the higher angularity and surface roughness of the FeCr slag. This can result in lower workability of the mix. The sand equivalent results indicated no fine particles in the FeCr slag.

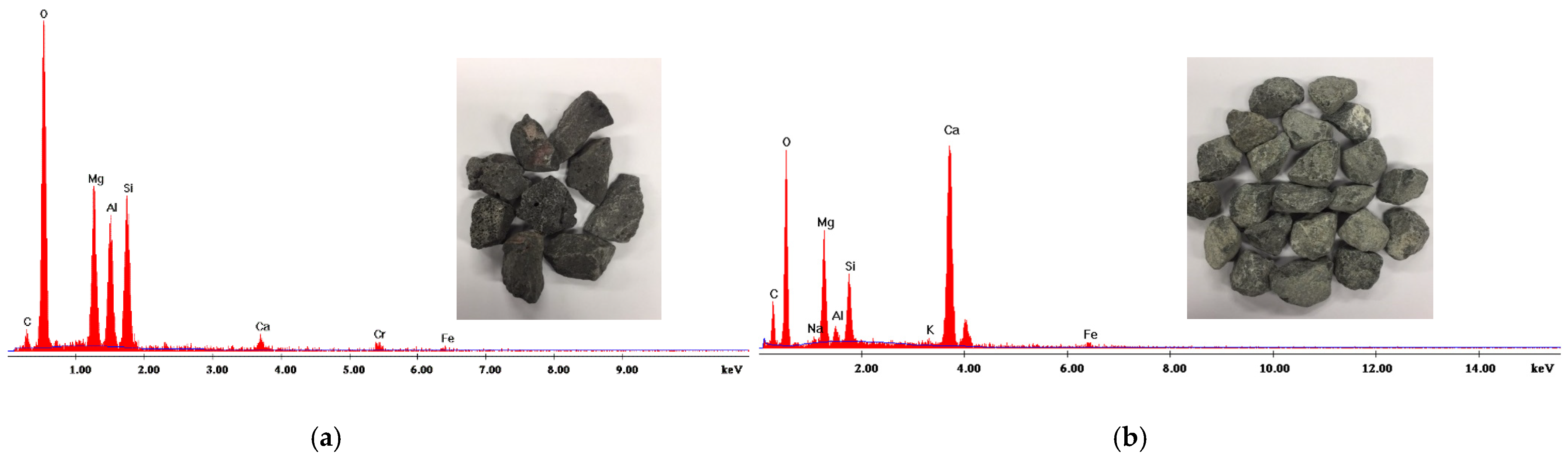

2.2. Chemical Properties

Chemical analysis of both the FeCr slag and natural aggregate was performed to determine the oxides. The classical wet chemical method was used to separate the silica followed by Flamed Atomic Absorption Spectrometry for the other oxides.

Table 2 shows the oxide composition of the aggregate and slag. The results show that the FeCr slag contains a significant amount of SiO

2, Al

2O

3 and a small amount of chromium oxide (Cr

2O

3). It has approximately 14% insoluble residue and very low loss on ignition (0.23%). On the other hand, the Gabbro aggregate contains a lesser amount of SiO

2 and a higher amount of CaO and has no insoluble residue. Gabbro had high loss on ignition (31.9%).

Figure 1 shows the Energy-dispersive X-ray spectroscopy (EDS) analysis for both of the aggregates, which is consistent with the relative presence of elements, identified in

Table 2.

2.3. Scanning Electron Microscope (SEM) and Surface Roughness

To examine the surface characteristics of both the FeCr slag and Gabbro aggregate, a scanning electron microscope (SEM) integrated with Scandium image analysis software (Ver. 5) was used.

Figure 2a,b show an SEM image at 100× magnification and the three-dimensional topography of both the FeCr slag and Gabbro.

Figure 2a shows the rougher surface of the FeCr slag as well as the higher number of voids in the particles. Both the SEM micrograph and surface topography indicate the rougher surface and higher number of particle voids in the FeCr slag compared with the natural aggregate. The roughness of both aggregate surfaces, as assessed using the average Z-value (surface elevation) for ten points, was estimated, resulting in a roughness index (Ra) defined by the following equation [

10]:

The roughness index was equal to 232.24 μm and 176.68 μm for the FeCr slag and Gabbro aggregate surface, respectively, with a corresponding coefficient of variation of 2.2% and 3.5%, respectively.

3. Mix Design and Dynamic Modulus Results

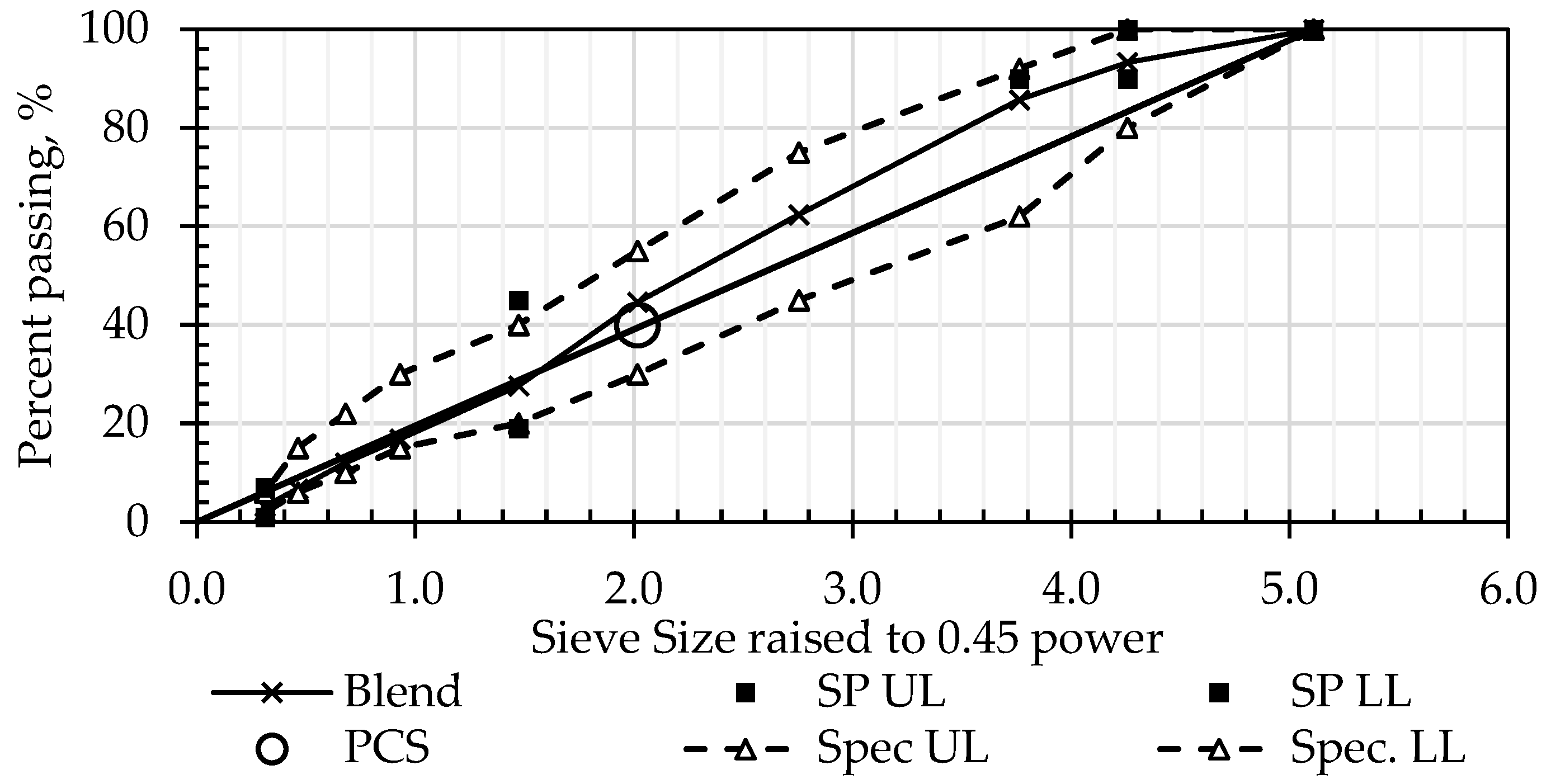

3.1. Mix Design

A large quantity of aggregate from four hot bins, in addition to mineral filler, was obtained for each of the bituminous base and wearing course mixes. The designed blend for both control mixes indicated a nominal maximum aggregate size (NMAS) of 25 mm and 19 mm for the bituminous base and wearing course mix, respectively. Mix designs were performed according to the Superpave mix design method [

9]. The control gradation was kept the same as in the road construction project. The gradation curve for the control mix, together with the Superpave control points (SP UL and SP LL) and the job-specific specification limits for both layers are shown in

Figure 3 and

Figure 4. The straight line represents the maximum density according to AASHTO M 323 [

9]. The primary control sieve (PCS) is also shown [

9].

Eight mixes were designed in total, four for the base and four for the wearing course mix. The coarse fraction, the fine fraction, and the entire natural aggregate were replaced by FeCr slag, resulting in three mixes for each layer, in addition to the control mix. The mixes were labeled MD0, MD1 (coarse fraction replacement), MD2 (fine fraction replacement), and MD3 (100% aggregate replacement) for each of the bituminous base and wearing course mixes. The mix design was performed according to [

9] for ESALs ≥ 30 million ESALs (N

ini = 9, N

des = 125 and N

max = 205).

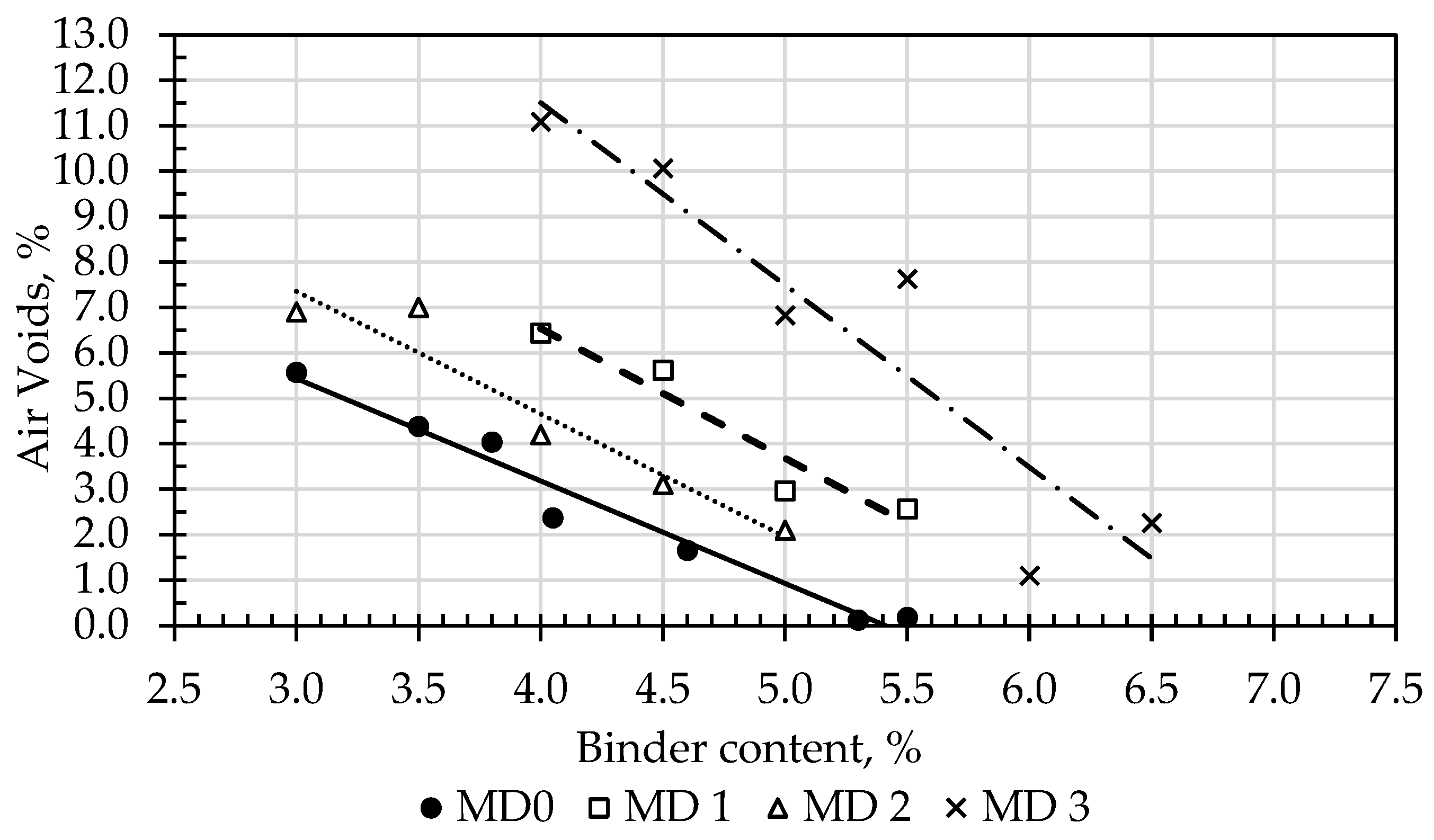

The resulting percentage of slag replacement was 55%, 44%, and 100% for the coarse, fine, and total replacement for the bituminous base course mixes. The corresponding replacement was 51%, 47%, and 100% for the wearing course. The binder content varied from 3% to 7% depending on the mix. Replicate samples were prepared at each trial binder content.

Figure 5 and

Figure 6 show the results of air void content. Both figures show the resulting higher number of air voids for MD1 and MD2. Different trend lines are shown for each mix. The number of air voids in MD3 was much higher. The design binder content was selected at 4% air voids. The resulting mix properties are shown in

Table 3 and

Table 4. The results indicated that the slag, with its higher angularity and rougher surface, was more difficult to compact, resulting in a higher VMA (MD 1 or MD2). A significant increase in VMA resulted in the case of MD3 (100% replacement). To satisfy the 4% air void requirement, higher binder content had to be used for both MD1 and MD2. More binder was used for MD3.

AASHTO T283 [

11] was used to determine the moisture susceptibility. The average results for the six sample sets are shown in

Table 5, which indicated that all mixes had a tensile strength ratio well above 80%, as required by AASHTO M323 [

9].

3.2. Dynamic Modulus |E*| Results

Cylindrical specimens were prepared to test their dynamic modulus according to AASHTO T312 [

12]. The samples were cured according to AASHTO R30 [

13]. Testing was performed according to ASHTO T342 with three replicates [

14]. The testing temperatures and frequencies indicated in AASHTO PP61 [

15] were followed. Testing was performed at 4 °C, 20 °C, and 40 °C at frequencies of 10, 1, and 0.1 Hz, in addition to 0.01 Hz only for 40 °C.

The dynamic modulus master curves of the mixes were generated at the 21 °C reference temperature. Nonlinear regression analysis was performed on the testing results using the sigmoidal equation (Equations (2)–(4)) [

16]:

where |E*| = dynamic modulus, ω

r = reduced frequency in Hz, Max = limiting maximum modulus in ksi, Min = limiting minimum modulus in ksi, Β and γ = fitting parameters. The reduced frequency (ω

r) is calculated by using Arrhenius equation, Equation (3) [

16]:

where ω

r = reduced frequency at the reference temperature, ω = loading frequency at the test temperature, T

r = reference temperature in °K, T = test temperature in °K, ΔEa = activation energy (treated as the fitting parameter). The shift factor at a given temperature is computed using Equation (4) [

16]:

where a(T) = shift factor at temperature T, T

r = reference temperature in °K, and T = test temperature in °K.

Figure 7 and

Figure 8 show the resulting master curves at 21 °C for wearing and bituminous base course mixes, respectively. The fitting parameters with an R

2 and Se/Sy are shown in

Table 6 and

Table 7, respectively. The fitting parameters with an R

2 and the standard error ratio, which is the standard error of the estimate to the standard deviation of the logarithm of the average dynamic modulus value (Se/Sy), had an R

2 of at least 0.99 and a maximum Se/Sy of 0.05, as required by AASHTO PP61 [

16].

4. Pavement Modeling and Rutting Performance

4.1. Pavement Section

The pavement section used in this analysis was composed of a 50 mm layer of bituminous wearing course, 75 mm bituminous base course, crushed aggregate base course of 150 mm thickness, and a layer of crushed subbase over subgrade with a combined analysis thickness of 825 mm for the last two layers. The EverstressFE program [

17] was used to perform the analysis. Data from laboratory testing suggested that the subgrade and subbase layers were very close in terms of CBR values. They were combined into one layer with an estimated modulus of 137 MPa. The CBR value for the crushed base layer was found to be over 100%, and a modulus of 207 MPa was used to model this layer. Modulus (M

r) values were estimated from correlations of CBR and M

r in the 1993 AASHTO pavement design manual [

18].

4.2. Temperature Data

Pavement temperatures were obtained from an experimental test section. The pavement temperatures at a depth of 20 mm and 85 mm were used to represent the variable pavement temperatures in the top two layers.

Data were collected on an hourly basis for two years. The minimum and maximum temperatures recorded at 20 mm depth were 15.3 °C and 61.6 °C, respectively. The corresponding temperatures recorded at 85 mm depth were 17.7 °C and 56.2 °C, respectively. Temperatures were grouped in 4 °C intervals, resulting in 11 groups for the base course and 13 groups for the wearing course. The middle temperature value was used to represent each group. For each mix of bituminous base course and wearing course, the mid-range value of each temperature group was used to calculate the reduced frequency (ωr) using Equation (3). The reduced frequency was then used to calculate the modulus values from the master curve of each mix design at the mid-value for all temperature groups.

4.3. Finite Element Analysis

EverstressFE 1.0 finite element (FE) software was used to perform a load–deformation (and stress–strain) elastic analysis and to estimate the vertical elastic strain (ε

r) [

17]. The program uses finite elements to model the pavement section. The finite element modeled pavement section is shown in

Figure 9. Each layer is shown is a different color.

A standard axle of 18 kips (80 kN) with a dual wheel on each side was used for loading. For meshing, six elements were used for the top two layers and eight for the lower two layers. The modeled area was 900 by 900 mm in the X-Y direction. The Y-axis represents an axis of symmetry along half the loading axle. The boundary at Y =900 mm represents an axis of symmetry half way through the dual wheels. The other boundaries are modeled with infinite elements. The FEM model has been validated by the developer (Washington State DOT). The model has been further verified by comparing the FEM model results with results from the Shell BISAR program. The results of the used FE model can be considered excellent [

19].

Eight different cases of pavement analysis were conducted, one for each mix. Each case was analyzed for a number of times equal to the number of temperature group variation for that particular layer.

A total of 11 runs of stress–strain analysis were conducted for the base layer and 13 runs for the wearing course layer, based on the temperature groups. The vertical elastic strain was determined under the center of one of the wheel loads on either side of the 80 kN axle.

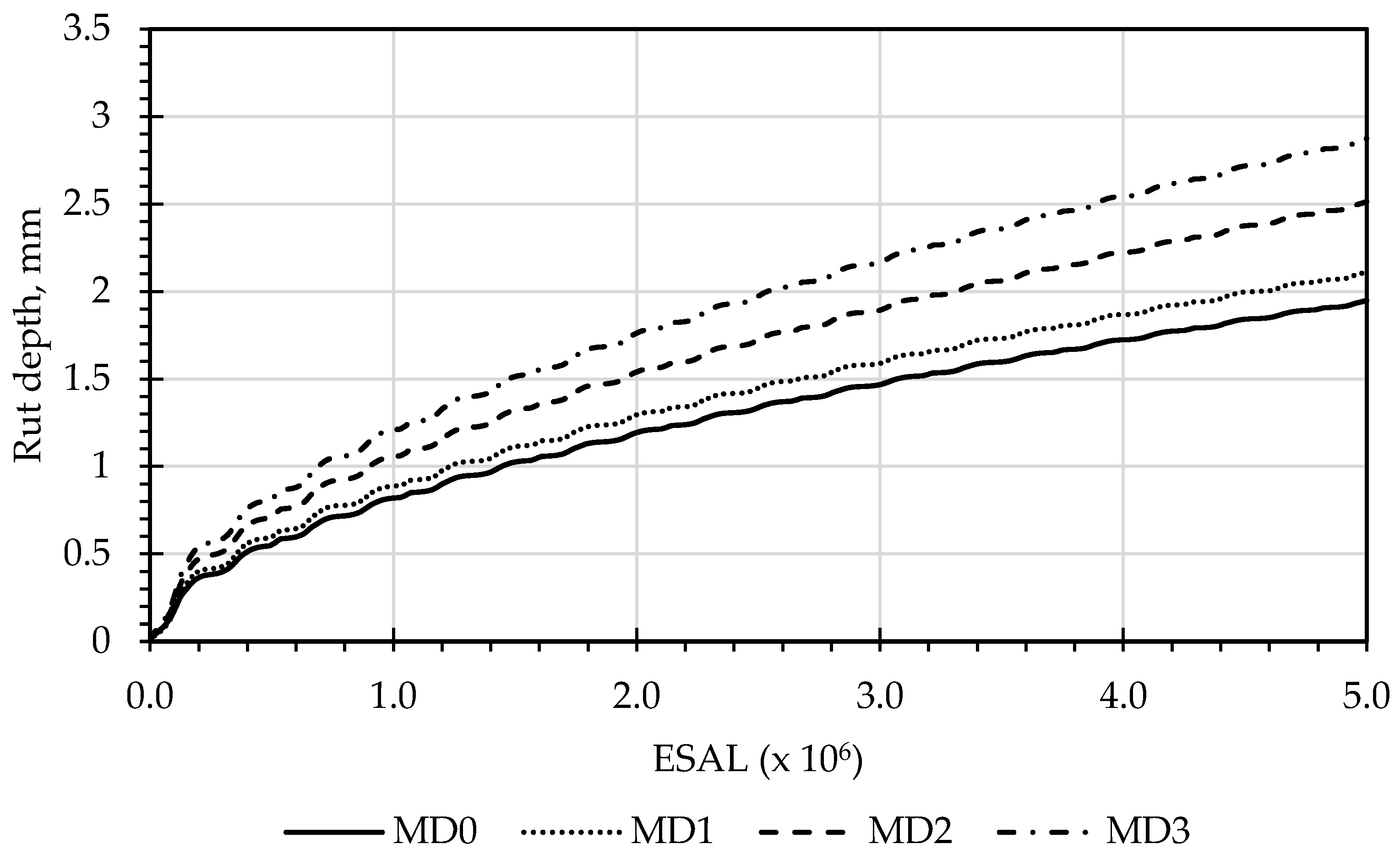

4.4. Rutting Performance

The

Mechanistic–Empirical Pavement Design Guide (MEPDG) rut model was used with a developed Excel VBA code to run 5 million ESALs over 20 years of hourly pavement temperature data. The temperature data were repeated every two years to accumulate 20 years of hourly data. The code locates the hourly temperature within a temperature group, for which the axial strain has been obtained from the load analysis. The rut model is applied to the predicted Δε

p. The analysis accumulates plastic strains over the analysis period. The “strain-hardening” approach was used as the pavement temperature varies from one temperature group to another [

7].

The wearing course and bituminous base course layers were divided into six sublayers and the base course was divided into four sublayers. Local calibration factors were utilized in the MEPDG rut model based on a previous study [

20]. The analysis results in the accumulated rut versus ESAL, as shown in

Figure 10 and

Figure 11.

The rut depth for MD0 with the bituminous base course was 1.9 mm at 5 million ESALs (

Figure 10). This value increased by 2.1 mm, 2.5 mm, and 2.9 mm for MD1, MD2, and MD3, respectively. The increase in asphalt content for the slag mixes, combined with the high temperature, appears to have an effect on increasing the rutting. The same pattern can be observed in

Figure 11 for the wearing course. MD0 had 1.4 mm of rutting. Rutting increased to 2.0 mm, 2.8, and 4.3 mm for MD1, MD2, and MD3, respectively. In both layers, the greatest increase in rutting resulted when the mix contained 100% FeCr slag. MD1 in both layers had the closest rut depth to MD0. Therefore, the mix was subjected to a leaching test and it was also used in the economic analysis in the following sections.

5. Economic Analysis

The rutting model indicated higher rutting for mixes containing FeCr slag compared with the control mix. In order to quantify the benefit of using FeCr slag, economic analysis was performed for MD1 and MD0. Pavement thickness for each layer, independently, was increased for the layer with MD1 mixes. The resulting rutting in each layer was estimated with a target to reach equal rutting to the control mix layer (MD0).

The thickness of the base course was increased from 75 mm to 85 mm and 95 mm while maintaining the wearing course thickness at 50 cm. On the other hand, the thickness of the wearing course layer was increased from 50 to 60 mm, 70 mm, and 80 mm, while the base course thickness was kept at 75 mm. The rutting analysis was performed in each of these cases to estimate the resulting rutting. The materials’ cost associated with the different pavement thicknesses was then estimated.

The local market was surveyed for material and landfill disposal costs. The asphalt binder price was found to be equivalent to 420 USD/t, the aggregate price for the asphalt mix was equivalent to 20.6 USD/t, and the landfill (tipping cost) was equivalent to 23.3 USD/t. For comparison, in the US, the binder price was estimated for 2025 to be 539 USD/t [

21]. The aggregate cost was estimated to be 28.5 USD/t [

22]. The lowest reported cost of landfill disposal for the slag was 45.25 USD/t of tipping fee [

23]. The analysis was based on local market prices. The cost of disposal is considered negative (savings) in cases in which the slag is not disposed of in landfills and is instead beneficially used. Based on the unit costs, the cost of materials for the bituminous base layer for the MD1 mix containing 45% aggregate, 55% slag, and 4.7% binder content is as follows (Equation (5)):

The cost per m

2 for the MD1 mix in the bituminous base and wearing course layers is shown in

Table 8. In order to compare material costs, MD1 thickness resulting in the same rutting was compared with MD0 with the original thickness. With the same rutting, the resulting material cost saving for the bituminous base layer with 90 mm thickness was found to be 44% as compared to the control mix with 75 mm thickness. On the other hand, the material cost saving for the MD1 wearing course with 90 mm thickness was 4% compared to MD0 with 50 mm layer thickness.

6. Leaching Potential

The Toxicity Characteristics Leaching Procedure (TCLP) was employed for a total of ten samples according to the USEPA method [

24] for both raw FeCr and the MD1 wearing course mix.

Table 9 shows the average results of the leaching test. All test results showed that the TCLP leaching values for all eight metals were much lower than the permissible limits [

25]. The leaching of total Cr was less than 1.0 mg/kg (equivalent to 1.0 mg/L), which is much lower than the permissible limits of the total (5.0 mg/L). Cr (VI) was not detected in any of the samples.

7. Conclusions

This study explored the feasibility of incorporating ferrochrome (FeCr) slag as a replacement for natural aggregate in asphalt concrete mixtures used in the bituminous base and wearing course layers. Four mix designs, one control and three mixes, with coarse, fine, and total aggregate replacement of FeCr slag were developed according to the Superpave mix design methodology. The aggregate gradation was kept the same across the four mixes for each layer. The study combined laboratory testing with finite element analysis (FEM) and Mechanistic–Empirical Pavement Design Guide (MEPDG) rutting predictions to provide pavement performance prediction. The environmental effect was assessed and a cost–benefit analysis was conducted. The following conclusions can be made:

FeCr slag exhibits higher angularity and surface roughness compared to natural aggregates, contributing to a higher number of voids in mineral aggregate (VMA) and increased binder content in the mix.

TCLP results showed that all of the leaching of the eight heavy metals, including total Cr and Cr(VI), was well below permissible leaching limits, indicating that it is environmentally safe.

Mixes with 100% aggregate replacement by FeCr slag approached the limits of acceptable mix design parameters, indicating reduced workability and potentially higher susceptibility to rutting due to elevated VMA and binder content.

Rutting resistance decreased as the proportion of FeCr slag increased, particularly when replacing fine or total aggregates. Replacing only the coarse fraction with FeCr slag at 51 and 55% of the total aggregate for both the wearing and bituminous base course respectively demonstrated better rutting performance compared to fine aggregate replacement, suggesting that it is the more favorable application.

Economic analysis indicated that using FeCr slag as a partial replacement, in the coarse fraction, can result in a cost-effective asphalt mix without compromising rutting performance relative to the control mix. For the same performance of rut depth, the use of FeCr slag in the bituminous base layer with 90 mm thickness resulted in material cost saving of 44% compared to the control mix with 75 mm thickness. Similarly, for the MD1 wearing course with 90 mm layer thickness, a cost saving of 4% was achieved relative to MD0 with 50 mm thickness.

Based on the findings, it is recommended that the asphalt mix includes FeCr slag to replace the coarse aggregate fraction. Recommendations for future work include investigations into different aggregate blend gradations for reducing air voids, VMA, and binder demand. It is also recommended to assess the effect of FeCr slag on pavement fatigue and low-temperature cracking resistance. One limitation of the current study is that the analysis was conducted assuming medium-level ESAL traffic; additional validation is required to confirm applicability under higher or lower traffic loading conditions.

Author Contributions

Conceptualization, H.F.H., K.A.-S. and K.A.-J.; methodology, H.F.H. and K.A.-S.; software, H.F.H.; writing—original draft preparation, S.A.A., K.A.-S. and H.F.H.; writing—review and editing, K.A.-J., K.A.-S. and H.F.H.; supervision, H.F.H. All authors have read and agreed to the published version of the manuscript.

Funding

The authors would like to acknowledge Sohar Port and Freezone (SOHAR), Oman, for funding this research project.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors upon request.

Conflicts of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Zelić, J. Properties of concrete pavements prepared with ferrochromium slag as concrete aggregate. Cem. Concr. Res. 2005, 35, 2340–2349. [Google Scholar] [CrossRef]

- Al-Jabri, K.; Shoukry, H.; Khalil, I.S.; Nasir, S.; Hassan, H.F. Reuse of waste ferrochrome slag in the production of mortar with improved thermal and mechanical performance. J. Mater. Civ. Eng. 2018, 30, 04018152. [Google Scholar] [CrossRef]

- Yılmaz, A.; Karaşahin, M. Mechanical properties of ferrochromium slag in granular layers of flexible pavements. Mater. Struct. 2009, 43, 309–317. [Google Scholar] [CrossRef]

- Emery, J.J. Slag utilization in pavement construction. In Extending Aggregate Resources; ASTM: West Conshohocken, PA, USA, 1982; pp. 95–118. [Google Scholar]

- Barišić, I.; Dimter, S.; Netinger, I. Possibilities of application of slag in road construction. Tech. Gaz. 2010, 17, 523–528. [Google Scholar]

- Yilmaz, M.; Kok, B.V. Effects of ferrochromium slag with neat and polymer modified binders in hot bituminous mix. Indian J. Eng. Mater. Sci. 2009, 16, 310–318. [Google Scholar]

- AASHTO. Mechanistic-Empirical Pavement Design Guide, A Manual of Practice, 2nd ed.; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015. [Google Scholar]

- AASHTO T304; Standard Method of Test for Uncompacted Void Content of Fine Aggregate. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015.

- AASHTO M323; Superpave Volumetric Mix Design. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015.

- Rao, G.A.; Prasad, B.K.R. Influence of the roughness of aggregate surface on the interface bond strength. Cem. Concr. Res. 2002, 32, 253–257. [Google Scholar] [CrossRef]

- AASHTO T283; Resistance of Compacted Asphalt Mixtures to Moisture-Induced Damage. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015.

- AASHTO T312; Preparing and Determining the Density of Hot-Mix Asphalt (HMA) Specimens by Means of the Superpave Gyratory Compactor. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015.

- AASHTO R30; Mixture Conditioning of Hot-Mix Asphalt (HMA). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015.

- AASHTO T342-15; Determining Dynamic Modulus of Hot Mix Asphalt (HMA). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015.

- AASHTO PP61-15; Developing Dynamic Modulus Master Curves for Asphalt Mixtures Using the Asphalt Mixture Performance Tester (AMPT). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015.

- NCHRP Project 09-29. Master Solver 2.2 Spreadsheet. Available online: http://onlinepubs.trb.org/onlinepubs/NCHRP/docs/NCHRP09-29_mastersolver2-2.xls (accessed on 25 June 2021).

- EverStressFE. Computer Software for 3D Finite Analysis of Flexible Pavement Structure; Version 1.0; University of Maine: Orono, ME, USA, 2009. [Google Scholar]

- AASHTO. AASHTO Guide for Design of Pavement Structures; American Association of State Highway and Transportation Officials: Washington, DC, USA, 1993. [Google Scholar]

- Al-Shamsi, K.; Hassan, H.F.; Mohammed, L.N. Effect of low VMA in hot mix asphalt on load-related cracking resistance. Constr. Build. Mater. 2017, 149, 386–394. [Google Scholar] [CrossRef]

- Hassan, H.F.; Al-Shamsi, K.; Al-Jabri, K. Effect of steel slag on the permanent deformation and life cycle cost of asphalt concrete pavements. Int. J. Pavement Res. Technol. 2024, 17, 1513–1530. [Google Scholar] [CrossRef]

- Washington State Department of Transportation (WSDOT). Asphalt Binder Reference Cost. Available online: https://wsdot.wa.gov/business-wsdot/contracts/about-public-works-contracts/payments-reporting/asphalt-binder-reference-cost (accessed on 15 April 2025).

- Auburn Concrete. Stone Aggregate Products. Available online: https://auburnconcrete.com/agg/products/stone/ (accessed on 15 April 2025).

- Environmental Research & Education Foundation (EREF). Analyzing Municipal Solid Waste Landfill Tipping Fees. Available online: https://erefdn.org/analyzing-municipal-solid-waste-landfill-tipping-fees/ (accessed on 15 April 2025).

- U.S. Environmental Protection Agency. Method 1311: Toxicity Characteristic Leaching Procedure. In Test Methods for Evaluating Solid Waste, Physical/Chemical Methods (SW-846), 3rd ed.; U.S. EPA: Washington, DC, USA, 1992. Available online: https://www.epa.gov/hw-sw846/sw-846-test-method-1311-toxicity-characteristic-leaching-procedure (accessed on 15 April 2025).

- U.S. Environmental Protection Agency. Identification and Listing of Hazardous Waste: Toxicity Characteristic. In Code of Federal Regulations; U.S. Government Publishing Office: Washington, DC, USA, 2023; Title 40, Part 261, Section 24 (40 CFR §261.24). Available online: https://www.ecfr.gov/current/title-40/chapter-I/subchapter-I/part-261/subpart-C/section-261.24 (accessed on 15 April 2025).

Figure 1.

Energy-dispersive X-ray spectroscopy (EDS) for (a) FeCr and (b) Gabbro aggregate.

Figure 1.

Energy-dispersive X-ray spectroscopy (EDS) for (a) FeCr and (b) Gabbro aggregate.

Figure 2.

SEM with Scandium image analysis software: (a) FeCr and (b) Gabbro aggregate.

Figure 2.

SEM with Scandium image analysis software: (a) FeCr and (b) Gabbro aggregate.

Figure 3.

Bituminous base course aggregate blend gradation.

Figure 3.

Bituminous base course aggregate blend gradation.

Figure 4.

Wearing course aggregate blend gradation.

Figure 4.

Wearing course aggregate blend gradation.

Figure 5.

Air voids for the bituminous base course mix.

Figure 5.

Air voids for the bituminous base course mix.

Figure 6.

Air voids for the bituminous wearing course mix.

Figure 6.

Air voids for the bituminous wearing course mix.

Figure 7.

|E*| master curves for the bituminous base course mixes at a reference temperature of 21 °C.

Figure 7.

|E*| master curves for the bituminous base course mixes at a reference temperature of 21 °C.

Figure 8.

|E*| master curves for wearing course mixes at a reference temperature of 21 °C.

Figure 8.

|E*| master curves for wearing course mixes at a reference temperature of 21 °C.

Figure 9.

Pavement section model for finite element analysis using EverStresFE.

Figure 9.

Pavement section model for finite element analysis using EverStresFE.

Figure 10.

Rut depth accumulation for bituminous base course mixes.

Figure 10.

Rut depth accumulation for bituminous base course mixes.

Figure 11.

Rut depth accumulation for wearing course mixes.

Figure 11.

Rut depth accumulation for wearing course mixes.

Table 1.

Properties of the natural aggregate and FeCr slag.

Table 1.

Properties of the natural aggregate and FeCr slag.

| Property | Natural Aggregate a, mm | FeCr | Spec b. |

|---|

| 37.5 | 20 | 10 | 0–6 |

|---|

| Specific Gravity | 2.889 | 2.880/

2.906 | 2.840/

2.887 | 2.794/

2.826 | 2.870 | - |

| Absorption c, % | 0.232 | 0.319/

0.336 | 0.560/

0.434 | 0.921/

0.525 | 2.00 | Max. 2% |

| FAA d,e, % | 45/46 | 57.1 | Min. 45% |

| Sand Equivalent e, % | 78/78 | 100 | Min. 50% |

| Flat and Elongate d,e, % | 0/0 | 0 | Max. 10% |

| Fractured Faces e, % | 100/100 | 100 | Min. 100% |

| LA Abrasion | 16 | 16/11 | 18/16 | - | 18 | Max. 25% |

Table 2.

Oxide composition of the FeCr slag and natural aggregate (Gabbro).

Table 2.

Oxide composition of the FeCr slag and natural aggregate (Gabbro).

| Agg. | Percent | mg/Kg | Acid Insoluble Residue | % Loss on Ignition |

|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Cr2O3 | MnO | Na2O | K2O | NiO |

|---|

| FeCr Slag | 34.36 | 14.53 | 3.29 | 0.65 | 1.69 | 2.62 | 0.034 | 0.048 | 0.03 | 179.3 | 14.19 | 0.23 |

| Gabbro | 20.21 | 3.38 | 1.46 | 26.5 | 1.54 | 0.09 | 0.02 | 0.08 | 0.03 | 61.88 | - | 31.9 |

Table 3.

Mix design results for the bituminous base course.

Table 3.

Mix design results for the bituminous base course.

| Mix ID | FeCr% | Va% | Pb% | VMA% | VFA% | DBR | %Gmm |

|---|

| Nini | Nmax |

|---|

| BC MD0 | 0 | 4% | 3.6 | 12.4 | 68 | 0.96 | 86.6 | 98.0 |

| BC MD1 | 55 | 4% | 4.7 | 14.4 | 72 | 0.80 | 85.8 | 95.9 |

| BC MD2 | 44 | 4% | 4.9 | 14.8 | 73 | 0.84 | 85.8 | 98.0 |

| BC MD3 | 100 | 4% | 6.1 | 17 | 78 | 0.64 | 85.6 | 98.4 |

| Superpave Specifications | - | 4% | - | Min. 12% | 65–75% | 0.60–1.20 | Max.

89% | Max.

98% |

Table 4.

Mix design results for the wearing course mix.

Table 4.

Mix design results for the wearing course mix.

| Mix ID | FeCr% | Va% | Pb% | VMA% | VFA% | DBR | %Gmm |

|---|

| Nini | Nmax |

|---|

| WC MD0 | 0 | 4% | 3.6 | 13.0 | 68 | 1.12 | 88.0 | 97.4 |

| WC MD1 | 51 | 4% | 4.9 | 14.6 | 74 | 0.92 | 86.4 | 97.9 |

| WC MD2 | 47 | 4% | 4.2 | 13.4 | 70 | 1.11 | 87.8 | 96.7 |

| WC MD3 | 100 | 4% | 5.9 | 16.8 | 78 | 0.74 | 86.3 | 98.9 |

Superpave

Specifications | - | 4% | - | Min. 13% | 65–75% | 0.60–1.20 | Max. 89% | Max. 98% |

Table 5.

Tensile strength ratio for both layers.

Table 5.

Tensile strength ratio for both layers.

| Mix ID | Tensile Strength Ratio (TSR%) |

|---|

| Wearing Course | Bit. Base Course |

|---|

| MD0 | 90.0 | 98.8 |

| MD1 | 91.5 | 85.3 |

| MD2 | 92.9 | 89.5 |

| MD3 | 100 | 89.1 |

Table 6.

Master curves fitting parameters for bituminous base course mixes.

Table 6.

Master curves fitting parameters for bituminous base course mixes.

| Mix ID | BC MD0 | BC MD1 | BC MD2 | BC MD3 |

|---|

| E* Max, ksi | 3587.17 | 3496.88452 | 3514.306 | 3405.492 |

| Min, Ksi | 17.712 | 22.956 | 15.5517 | 14.618 |

| Γ | −0.411 | −0.341 | −0.2863 | −0.247 |

| Β | −0.548 | −0.723 | −0.5459 | −0.526 |

| ΔEa | 152,321 | 161,764 | 161,276.9 | 169,456 |

| R2 | 0.991 | 0.998 | 0.991 | 0.993 |

| Se/Sy | 0.017 | 0.006 | 0.010 | 0.037 |

Table 7.

Master curves fitting parameters for wearing course mixes.

Table 7.

Master curves fitting parameters for wearing course mixes.

| Mix ID | WC MD0 | WC MD1 | WC MD2 | WC MD3 |

|---|

| E* Max, ksi | 3537.71 | 3482.66 | 3520.63 | 3404.22 |

| Min, Ksi | 8.7334 | 15.5586 | 10.5892 | 5.0114 |

| γ | −0.6578 | −0.5127 | −0.5564 | −0.5297 |

| β | −0.4738 | −0.5775 | −0.4197 | −0.396 |

| ΔEa | 172,008.3 | 192,884.1 | 211,711 | 211,015.8 |

| R2 | 0.992 | 0.998 | 0.990 | 0.994 |

| Se/Sy | 0.038 | 0.004 | 0.034 | 0.016 |

Table 8.

Material costs for both the bituminous base and wearing course layers.

Table 8.

Material costs for both the bituminous base and wearing course layers.

| Layer Property | Bituminous Base Course | Wearing Course |

|---|

| MD0 | MD1 | MD1 | MD1 | MD0 | MD1 | MD1 | MD1 | MD1 | MD1 |

|---|

| BSG | 2.440 | 2.424 | 2.456 | 2.422 |

| Pb, % | 3.6 | 4.7 | 3.6 | 4.9 |

| Slag percent by aggregate weight, % | 0 | 55 | 0 | 51 |

| Thickness, mm | 75 | 75 | 85 | 90 | 50 | 50 | 60 | 70 | 80 | 90 |

| Rutting at 5 million ESALs, mm | 1.9 | 2.1 | 2.0 | 1.9 | 1.4 | 2.0 | 2.2 | 2.0 | 1.7 | 1.4 |

| Cost/m2 of layer, $ | 6.4 | 3.0 | 3.4 | 3.6 | 4.3 | 2.3 | 2.8 | 3.2 | 3.7 | 4.1 |

| Cost saving, % | - | 53 | 47 | 44 | - | 47 | 36 | 25 | 14 | 4 |

Table 9.

Leachate test results for the asphalt mixtures according to USEPA regulatory limits.

Table 9.

Leachate test results for the asphalt mixtures according to USEPA regulatory limits.

| Heavy Metal | Results, mg/kg | USEPA Limits [25], mg/kg |

|---|

| Selenium (Se) | <0.3 | 1 |

| Lead (pb) | <1 | 5 |

| Mercury (Hg) | <0.01 | 0.2 |

| Arsenic (As) | <1 | 5 |

| Chromium (Cr) | <1 | 5 |

| Silver (Ag) | <1 | 5 |

| Barium (Ba) | <1 | 100 |

| Cadmium (Cd) | <0.3 | 1 |

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).