Characterization, Classification, Dry High-Intensity Magnetic Separation (DHIMS), and Re-Grinding Techniques to Improve the Mineral Performance of a Sn-Ta-Nb Mineral Concentrate †

Abstract

:1. Introduction

2. Material and Methods

3. Results and Discussion

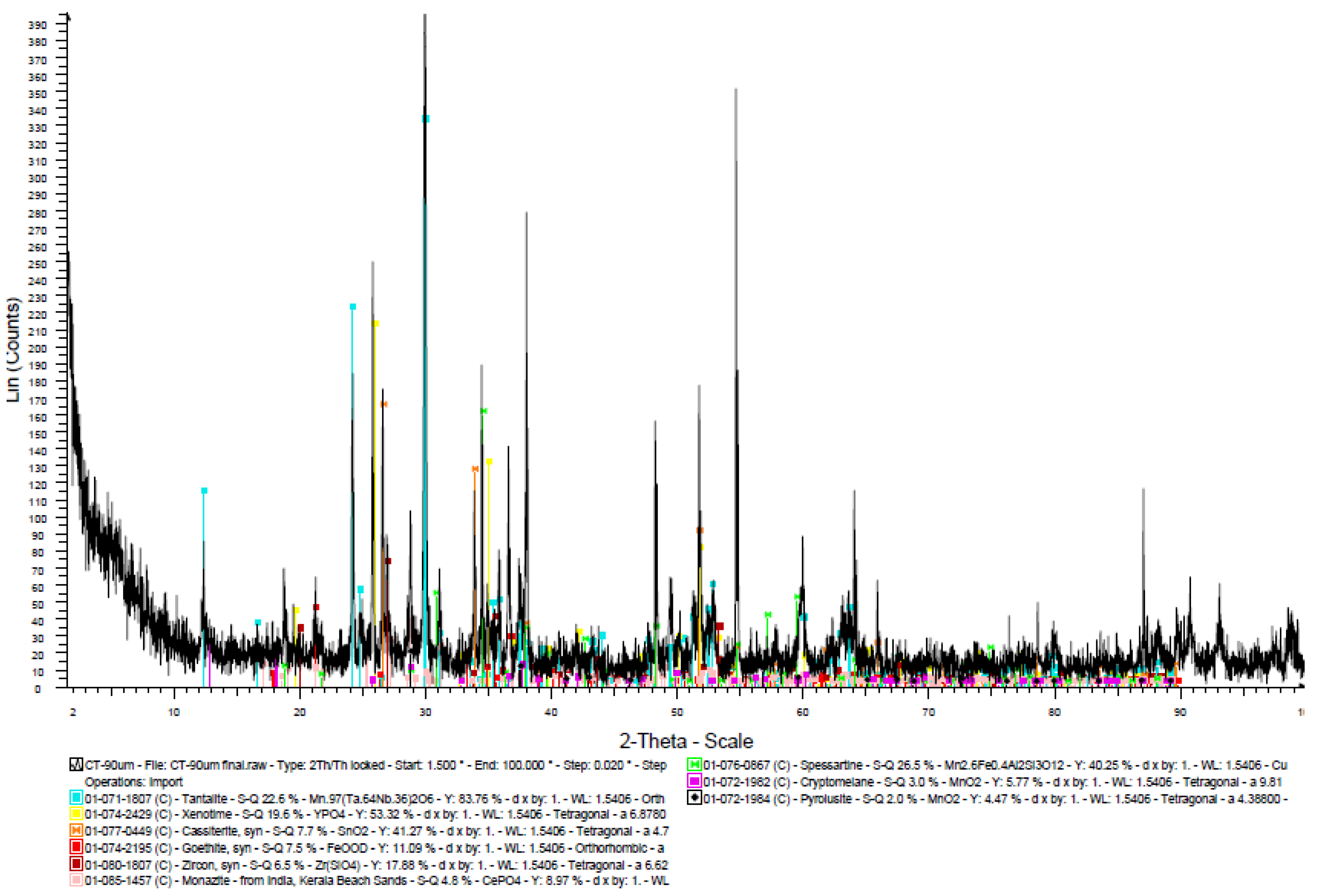

3.1. Characterization and Classification of the Sn, Ta, and Nb Primary Concentrate

3.2. Results of Laboratory Scale DHIMS Multifactorial Tests

3.2.1. Grades and Recoveries of the New Concentrates Obtained

3.2.2. Influence of Operational Parameters in DHIMS Tests

3.3. Regrinding of >150 µm Fraction

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- European Commission. Study on the Review of the List of Critical Raw Materials—Critical Raw Materials Factsheets; European Commission: Brussels, Belgium, 2017. [Google Scholar] [CrossRef]

- European Commission. Citical Raw Materials Resilience; Charting a Path toward Greater Security and Sustainability; COM(2020)474 final; European Commission: Brussels, Belgium, 2020. [Google Scholar] [CrossRef]

- Roskill. Tantalum. Retrieved March 19, 2020, from Outlook to 2029, 15th Edition. 2020. Available online: https://roskill.com/market-report/tantalum/ (accessed on 1 October 2020).

- Regulation (EU) 2017/821 of the European Parliament and of the Council, 19 Official Journal of the European Union. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=OJ:L:2017:130:TOC (accessed on 18 September 2020).

- European Commission. European Commission, Report on Critical Raw Materials and the Circular Economy; Gislev, M., Groho, M., Eds.; European Commission: Brussels, Belgium, 2018. [Google Scholar] [CrossRef]

- García Polonio, F. El Interés Económico y Estratégico del Aprovechamiento de Metales Raros y Minerales Industriales Asociados, en el Marco Actuaal de la Minería Sostenible: La Mina de Penouta (Orense, España); Universidad Politécnica de Madrid: Madrid, Spain, 2015; Available online: http://oa.upm.es/42895/ (accessed on 11 September 2020).

- Llorens González, T.; Mateos Aquilino, V.; García Polonio, F. La mina de Penouta, minería sostenible para el abastecimiento de Ta & Nb en Europa. Recur. Miner. Crít. Semin. Soc. Esp. Mineral. 2019, 12. Available online: http://www.ehu.eus/sem/revista/seminarios_m.htm (accessed on 20 February 2019).

- Blengini, G.; Mathieux, F.; Mancini, L.; Nyberg, M.; Viegas, H. Recovery of Critical and Other Raw Materials from Mining Waste and Landfills: State of Play on Existing Practices; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar] [CrossRef]

- Llorens González, T.; García Polonio, F.; López Moro, F.J.; Fernández Fernández, A.; Sanz Contreras, J.L.; Moro Benito, M.C. Tin-tantalum-niobium mineralization in the Penouta deposit (NW Spain): Textural features and mineral chemistry to unravel the genesis and evolution of cassiterite and columbite group minerals in a peraluminous system. Ore Geol. Rev. 2017, 81, 79–95. [Google Scholar] [CrossRef]

- Ghorbani, Y.; Fitzpatrick, R.; Kinchington, M.; Rollinson, G.; Hegarty, P. A process mineralogy approach to gravity concentration of tantalum bearing minerals. Minerals 2017, 7, 194. [Google Scholar] [CrossRef]

- Alfonso, P.; Hamid, S.A.; Garcia-Valles, M.; Llorens, T.; López Moro, F.J.; Tomasa, O.; Calvo, D.; Guasch, E.; Anticoi, H.; Oliva, J.; et al. Textural and mineral-chemistry constraints on columbite-group minerals in the Penouta deposit: Evidence from magmatic and fluid-related processes. Mineral. Mag. 2018, 82 (Suppl. 1), S199–S222. [Google Scholar] [CrossRef]

- López-Moro, F.J.; García Polonio, F.; Llorens González, T.; Sanz Contreras, J.L.; Fernández Fernández, A.; Moro Benito, M.C. Ta and Sn concentration by muscovite fractionation and degassing in a lens-like granite body: The case study of the Penouta rare-metal albite granite (NW Spain). Ore Geol. Rev. 2017, 82, 10–30. [Google Scholar] [CrossRef]

| Test Nº | Size Fraction (µm) | Magnetic Field Intensity (A) | Roll Speed (rpm) |

|---|---|---|---|

| 1 | 150/0 | Low | High |

| 2 | 150/90 | Low | High |

| 3 | 150/90 | High | High |

| 4 | 150/90 | High | Low |

| 5 | 150/90 | Low | Low |

| 6 | 150/90 | Changing split inclination | |

| 7 | 90/0 | Low | High |

| 8 | 90/0 | High | High |

| 9 | 90/0 | High | Low |

| 10 | 90/0 | Low | Low |

| 11 | 90/0 | Changing split inclination | |

| Size | Retained Weight | Accumulated Weight | Grades (%) | |||||||

| (µm) | (g) | (%) | (%) | Sn | Ta2O5 | Nb2O5 | Fe2O3 | Al2O3 | MnO | SiO2 |

| 300 | 0.00 | 0.00 | 100.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| 212 | 3.30 | 0.28 | 99.2 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| 150 | 25.30 | 2.14 | 97.58 | 11.80 | 2.77 | 2.58 | 13.30 | 14.20 | 23.50 | 20.40 |

| 106 | 136.10 | 11.51 | 86.07 | 14.85 | 3.30 | 3.23 | 12.60 | 12.75 | 20.80 | 17.55 |

| 63 | 434.30 | 36.74 | 49.32 | 26.50 | 5.05 | 4.99 | 8.59 | 7.32 | 12.75 | 13.40 |

| 45 | 330.10 | 27.93 | 21.40 | 41.50 | 6.06 | 5.13 | 3.15 | 1.80 | 4.64 | 7.19 |

| 38 | 118.90 | 10.06 | 11.34 | 45.10 | 5.94 | 4.69 | 1.73 | 0.58 | 2.32 | 6.30 |

| 0 | 134.00 | 11.34 | 0.00 | 52.30 | 5.93 | 4.19 | 1.22 | 0.11 | 1.44 | 4.99 |

| Total: | 1182.00 | 100.00 | Calculated feed grade: | 33.75 | 5.25 | 4.64 | 6.08 | 5.04 | 9.28 | 10.59 |

| D80 (µm): | 99 | |||||||||

| Size (µm) | Distribution of Metal Content (%) | |||||||||

| Sn | Ta2O5 | Nb2O5 | Fe2O3 | Al2O3 | MnO | SiO2 | ||||

| 300 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |||

| 212 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |||

| 150 | 0.75 | 1.13 | 1.19 | 4.68 | 6.04 | 5.42 | 4.12 | |||

| 106 | 5.07 | 7.24 | 8.02 | 23.85 | 29.16 | 25.82 | 19.08 | |||

| 63 | 28.85 | 35.05 | 39.51 | 51.88 | 53.42 | 50.51 | 46.50 | |||

| 45 | 34.34 | 32.05 | 30.88 | 14.46 | 9.98 | 13.97 | 18.96 | |||

| 38 | 13.44 | 11.39 | 10.17 | 2.86 | 1.16 | 2.52 | 5.99 | |||

| 0 | 17.57 | 12.82 | 10.24 | 2.27 | 0.25 | 1.76 | 5.34 | |||

| Total: | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | |||

| Mineral | Ta2O5 | SnO2 | Nb2O5 | SiO2 | Fe2O3 | MnO | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Test No. | G | R | G | R | G | R | G | R | G | R | G | R |

| (%) | (%) | (%) | (%) | (%) | (%) | |||||||

| 1 | 12.20 | 57.62 | 7.10 | 2.95 | 12.65 | 76.76 | 8.97 | 30.87 | 8.74 | 65.87 | 12.71 | 79.18 |

| 2 | 10.33 | 68.18 | 3.34 | 2.09 | 11.10 | 89.39 | 13.44 | 52.81 | 12.01 | 83.44 | 17.36 | 96.14 |

| 3 | 10.15 | 68.09 | 3.33 | 2.11 | 11.02 | 88.59 | 13.83 | 55.02 | 12.13 | 83.38 | 17.51 | 95.22 |

| 4 | 8.80 | 69.82 | 26.99 | 19.18 | 8.79 | 85.61 | 9.41 | 49.87 | 7.62 | 78.34 | 10.84 | 89.55 |

| 5 | 8.79 | 68.96 | 28.09 | 19.82 | 8.78 | 85.97 | 9.31 | 50.78 | 7.50 | 78.38 | 10.66 | 90.97 |

| 6 | 11.71 | 70.11 | 7.29 | 3.87 | 12.21 | 91.88 | 10.13 | 42.86 | 9.47 | 80.89 | 13.86 | 97.86 |

| 7 | 13.66 | 67.78 | 10.09 | 4.23 | 13.21 | 89.42 | 6.30 | 25.49 | 6.83 | 71.40 | 10.04 | 92.31 |

| 8 | 13.47 | 67.80 | 10.77 | 4.61 | 13.61 | 90.95 | 6.15 | 24.76 | 6.65 | 70.24 | 9.75 | 91.11 |

| 9 | 8.89 | 76.07 | 39.01 | 28.59 | 8.23 | 91.63 | 5.47 | 36.89 | 4.37 | 76.75 | 6.01 | 94.01 |

| 10 | 9.03 | 76.34 | 37.93 | 26.69 | 8.42 | 94.08 | 5.38 | 35.81 | 4.38 | 77.93 | 6.03 | 95.78 |

| 11 | 13.13 | 68.24 | 13.65 | 5.93 | 13.24 | 91.15 | 5.36 | 22.51 | 5.89 | 69.52 | 8.69 | 90.58 |

| Mineral | Ta2O5 | SnO2 | Nb2O5 | SiO2 | Fe2O3 | MnO | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Test No. | G | R | G | R | G | R | G | R | G | R | G | R |

| (%) | (%) | (%) | (%) | (%) | (%) | |||||||

| 1 | 1.84 | 27.12 | 75.06 | 97.51 | 0.41 | 7.78 | 6.56 | 70.89 | 0.62 | 14.61 | 0.13 | 2.53 |

| 2 | 2.01 | 26.37 | 75.57 | 93.73 | 0.58 | 9.25 | 6.36 | 49.62 | 0.84 | 11.59 | 0.29 | 3.19 |

| 3 | 1.95 | 25.00 | 76.96 | 93.40 | 0.49 | 7.50 | 6.34 | 48.28 | 0.72 | 9.47 | 0.21 | 2.19 |

| 4 | 2.13 | 24.93 | 73.91 | 77.48 | 0.78 | 11.18 | 6.56 | 51.28 | 0.88 | 13.35 | 0.51 | 6.21 |

| 5 | 2.15 | 25.13 | 73.91 | 77.61 | 0.80 | 11.67 | 6.58 | 53.42 | 0.86 | 13.37 | 0.52 | 6.61 |

| 6 | 1.89 | 25.76 | 78.23 | 94.39 | 0.41 | 7.07 | 6.27 | 60.37 | 0.61 | 11.86 | 0.12 | 1.93 |

| 7 | 1.85 | 26.81 | 76.58 | 93.96 | 0.37 | 7.13 | 6.67 | 78.87 | 0.57 | 17.43 | 0.11 | 2.96 |

| 8 | 1.85 | 26.93 | 77.34 | 95.57 | 0.38 | 7.26 | 6.70 | 77.81 | 0.58 | 17.67 | 0.11 | 2.97 |

| 9 | 1.65 | 18.67 | 74.17 | 71.30 | 0.35 | 5.12 | 7.52 | 67.25 | 0.53 | 12.35 | 0.11 | 2.28 |

| 10 | 1.65 | 19.17 | 74.68 | 72.33 | 0.34 | 5.21 | 7.63 | 69.90 | 0.54 | 13.23 | 0.10 | 2.19 |

| 11 | 1.79 | 26.26 | 75.57 | 92.72 | 0.36 | 6.96 | 6.73 | 79.90 | 0.55 | 18.36 | 0.10 | 2.95 |

| Time (min) | Pass Weight through | P80 | Distribution of Metal Content (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 100 µm (%) | (µm) | Sn | Ta2O5 | Nb2O5 | Al2O3 | Fe2O3 | MnO | SiO2 | |

| 0.5 | 11.20 | 218 | 26.26 | 21.07 | 20.44 | 5.59 | 7.45 | 5.45 | 7.13 |

| 2.5 | 17.60 | 197 | 38.25 | 30.81 | 29.66 | 8.77 | 11.67 | 8.91 | 11.39 |

| 5.00 | 22.40 | 192 | 43.74 | 36.57 | 34.43 | 12.93 | 16.53 | 13.13 | 15.60 |

| 10.0 | 30.90 | 185 | 51.09 | 46.81 | 43.13 | 20.75 | 26.47 | 22.14 | 23.05 |

| 15.00 | 32.90 | 184 | 50.39 | 47.47 | 43.93 | 24.44 | 29.89 | 25.54 | 26.49 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nava, J.; Llorens, T.; Menéndez-Aguado, J. Characterization, Classification, Dry High-Intensity Magnetic Separation (DHIMS), and Re-Grinding Techniques to Improve the Mineral Performance of a Sn-Ta-Nb Mineral Concentrate. Environ. Sci. Proc. 2021, 6, 10. https://doi.org/10.3390/iecms2021-09344

Nava J, Llorens T, Menéndez-Aguado J. Characterization, Classification, Dry High-Intensity Magnetic Separation (DHIMS), and Re-Grinding Techniques to Improve the Mineral Performance of a Sn-Ta-Nb Mineral Concentrate. Environmental Sciences Proceedings. 2021; 6(1):10. https://doi.org/10.3390/iecms2021-09344

Chicago/Turabian StyleNava, Jennire, Teresa Llorens, and Juan Menéndez-Aguado. 2021. "Characterization, Classification, Dry High-Intensity Magnetic Separation (DHIMS), and Re-Grinding Techniques to Improve the Mineral Performance of a Sn-Ta-Nb Mineral Concentrate" Environmental Sciences Proceedings 6, no. 1: 10. https://doi.org/10.3390/iecms2021-09344

APA StyleNava, J., Llorens, T., & Menéndez-Aguado, J. (2021). Characterization, Classification, Dry High-Intensity Magnetic Separation (DHIMS), and Re-Grinding Techniques to Improve the Mineral Performance of a Sn-Ta-Nb Mineral Concentrate. Environmental Sciences Proceedings, 6(1), 10. https://doi.org/10.3390/iecms2021-09344