1. Introduction

Handling 3D-printed digital casts—prototypes of the ballistic imprints discovered along the perimeter of ancient Pompeii [

1]—is striking. Although removed from their original context, the casts reveal the surface roughness and dimensions that evoke the force of impact, recalling the dramatic descriptions by Titus Flavius Josephus, who witnessed the Siege of Jerusalem in 70 AD [

2].

The artillery employed on that occasion was essentially identical to that used by Lucius Cornelius Sulla when he took Pompeii in 89 BC [

3]. The surviving stretch of wall, preserved beneath volcanic deposits from the 79 AD eruption and only excavated in the early twentieth century, now stands as the sole definitive evidence of the lethal capabilities of ballistae and catapults before Christ; the craters in the stone ashlars, caused by the violent impacts of limestone spherical projectiles and metallic arrows (

Figure 1), cannot be mistaken for damage sustained during World War II bombings, which have been documented in detail [

4].

Thus, confident in their secure dating, the direct examination of these cavities—grounded in foundational knowledge of Republican and Imperial poliorcetics—allows us to identify features that, despite ancient restorations and a century of atmospheric exposure, form the basis for sizing elastic torsion launchers, of which only a few fragmentary remains exist [

5,

6].

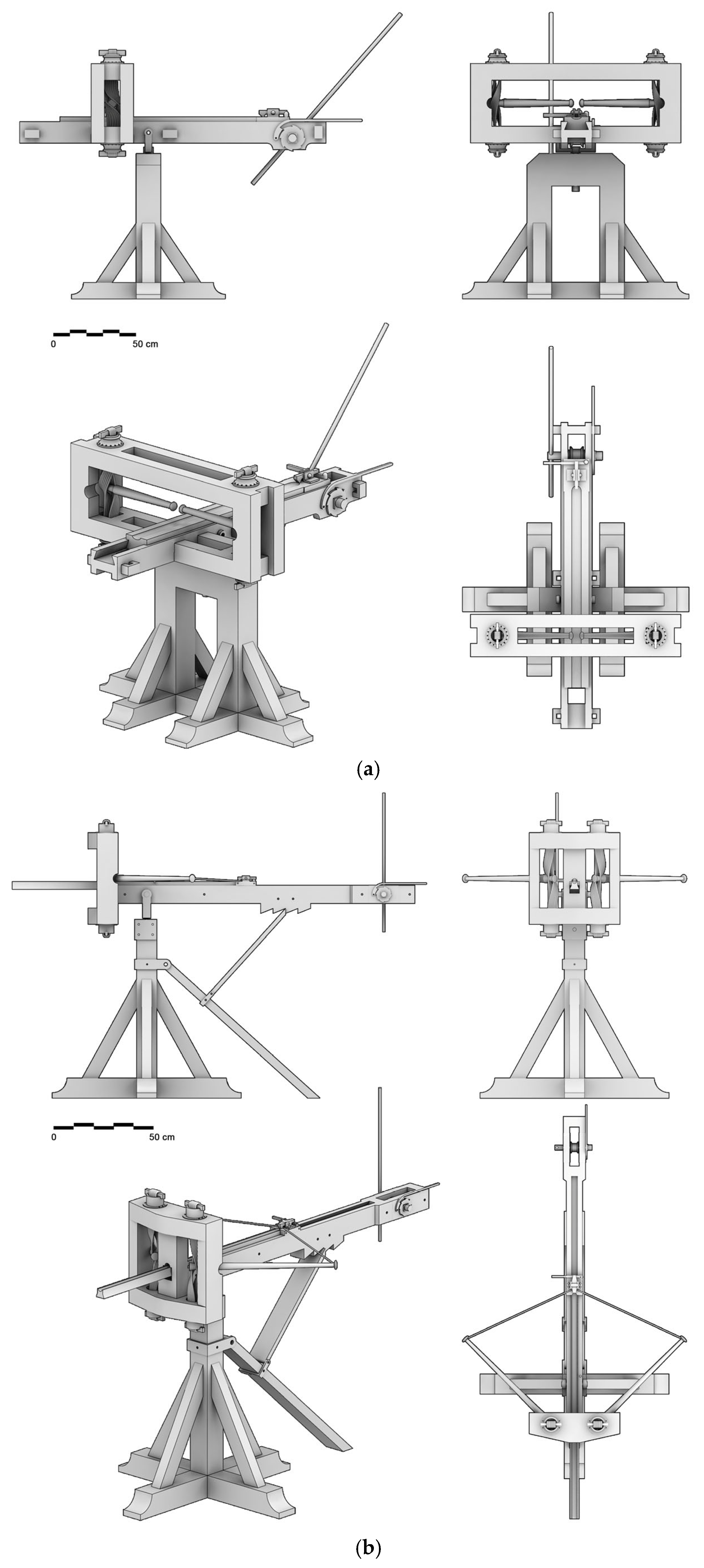

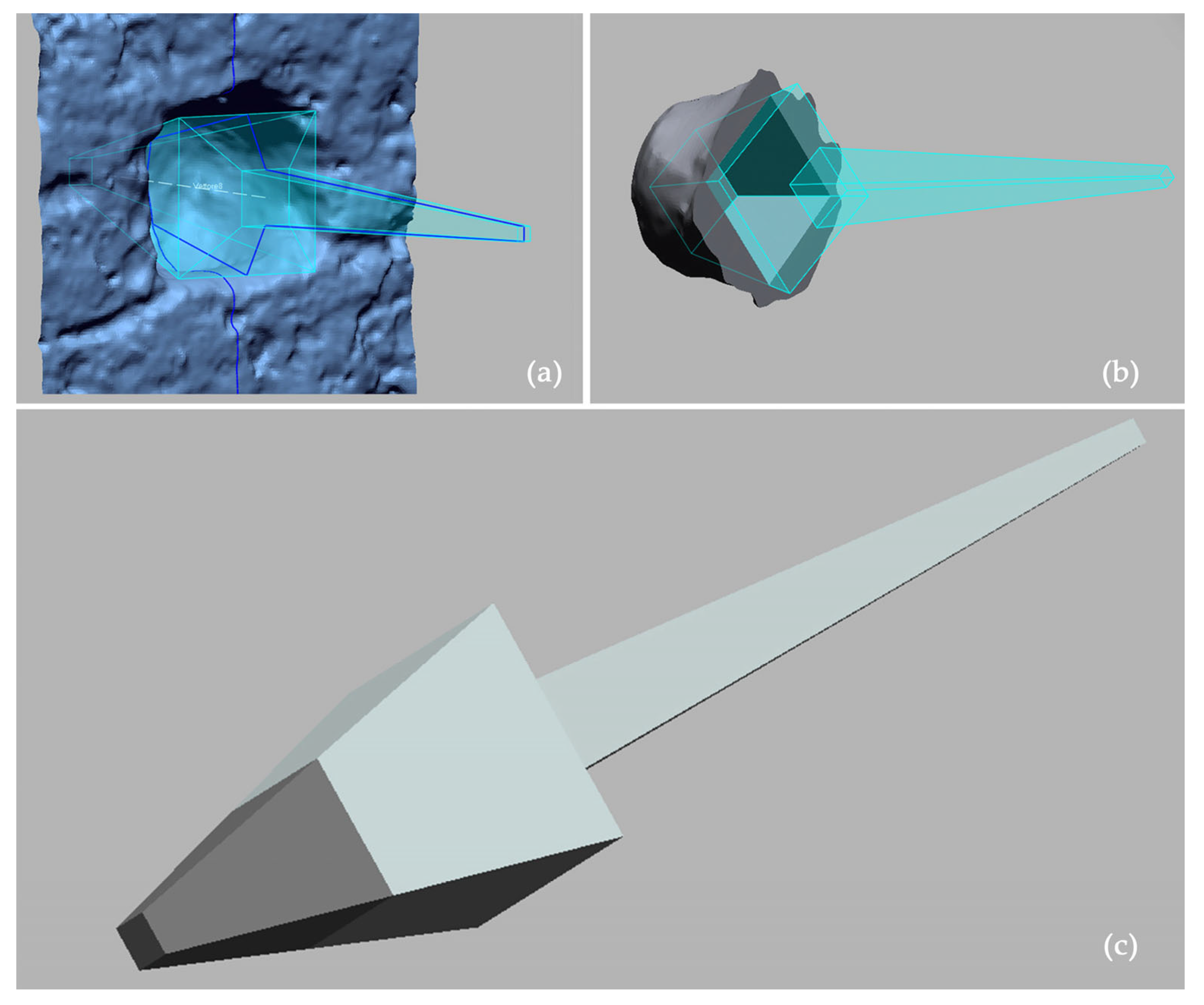

The design principles outlined by Philo of Byzantium (

Belopoeica, 3rd century BC) and later codified by Vitruvius in Book X of

De Architectura (1st century AD) enable the calculation of siege engine components according to a standard module (

Figure 2a,b)—the side of the “modiolus” (little module) equals the diameter of the flanges that secure the elastic bundles to the frame, a dimension from which ancient authors derived weapon power [

7].

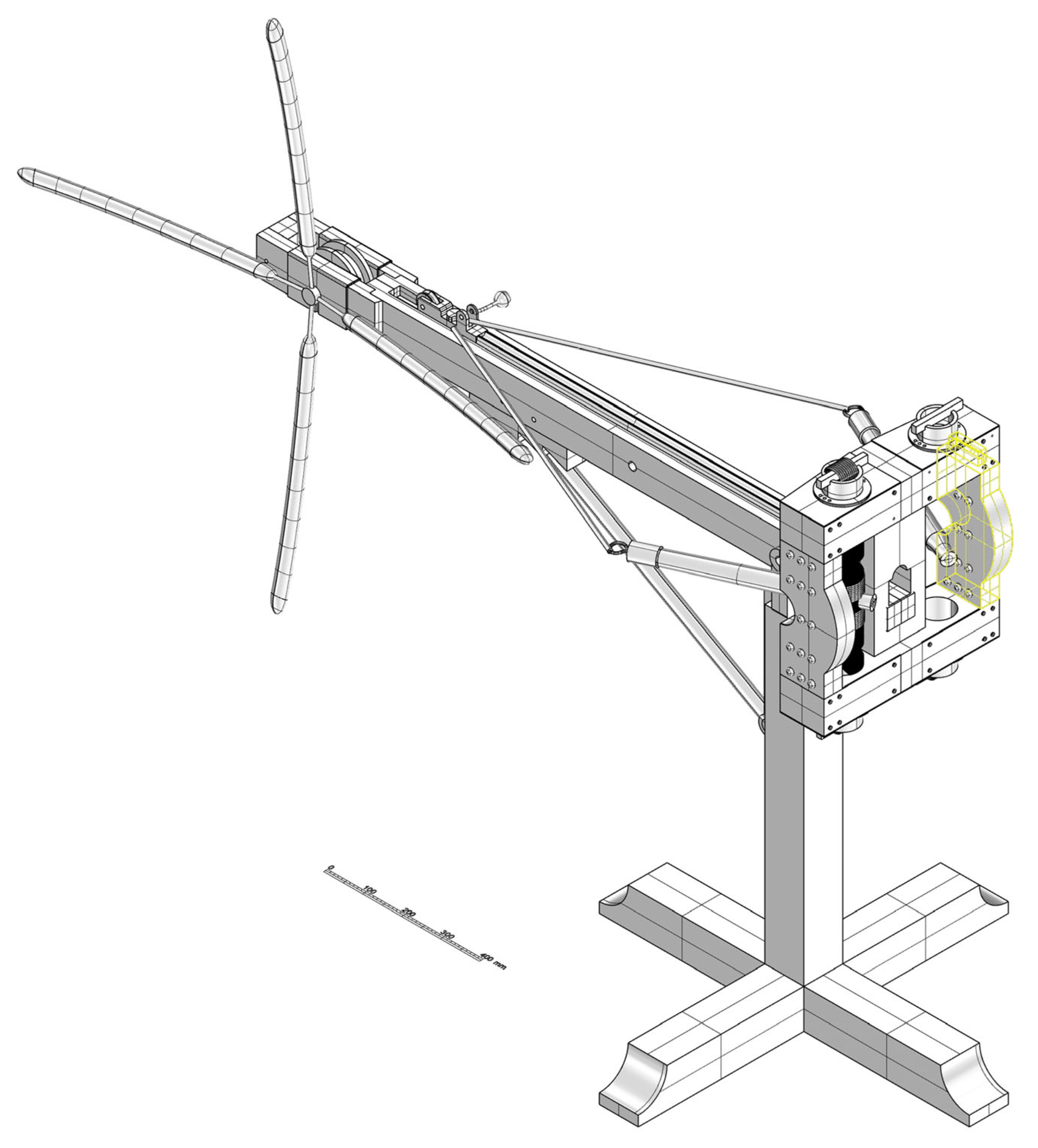

By measuring the bundle diameter, one can obtain firing parameters that can subsequently be partially validated through reverse engineering processes (

Figure 3).

The digital process used to capture and reconstruct the virtual casts, which are subsequently prototyped, integrates phases that are traditionally separate. Cyclic and interactive processes of analysis and synthesis follow one another within a single pipeline for data acquisition. These processes yield a collection of information useful for transferring content and fostering collaboration through Information and Communications Technology (ICT). Sharing these ontological structures provides users with informational platforms and (im)material spaces [

8] suitable for expanding their perceptual boundaries (Mixed Reality, MR). By introducing digital elements, advanced technologies promote not only visual inclusion but also the cognitive inclusion of users (Extended Reality, XR). It is therefore necessary to reconcile, on the same surveyed and processed models, the precision and accuracy required for documentation and study with the exemplification demanded by the sharing of results in progress and for future reference. Dedicated and interoperable platforms (Common Data Environment, CDE) widely engage users, facilitating access to resources for educational, social, and economic programs.

The primary question this paper seeks to address concerns a critical phase of the unique, cyclical and interactive process—the physical prototyping of digital casts selected as case studies, which represents a significant mode of operation and serves as a an opportunity for cultural exchange between research, education and the so-called Third Mission.

2. Materials and Methods

This research is based on graphic outputs derived from visual representations designed to produce digitally accessible content. Both expressive and conceptual—whether iconic or symbolic, survey- or design-based—the graphic results reflect an experience in which apparent antinomies dissolve into action, illustrating the interplay between existing work and future planning. As Migliari (2004) observes [

9], it is appropriate to provide the term “drawing” with wider connotations, to encompass the notion of “model”. It is certainly a model, as the prototype casts are derived from reality-based 3D processing. The process is a recording of the physical world as it appears at the moment of capture [

10].

The output of post-processing operations on point clouds acquired with active and passive sensors are models consisting of polygonal meshes. Exported at resolutions appropriate to their purpose, and free of holes or topological defects, these 3D models are adaptable to various applications, including effective dissemination via 3D printing.

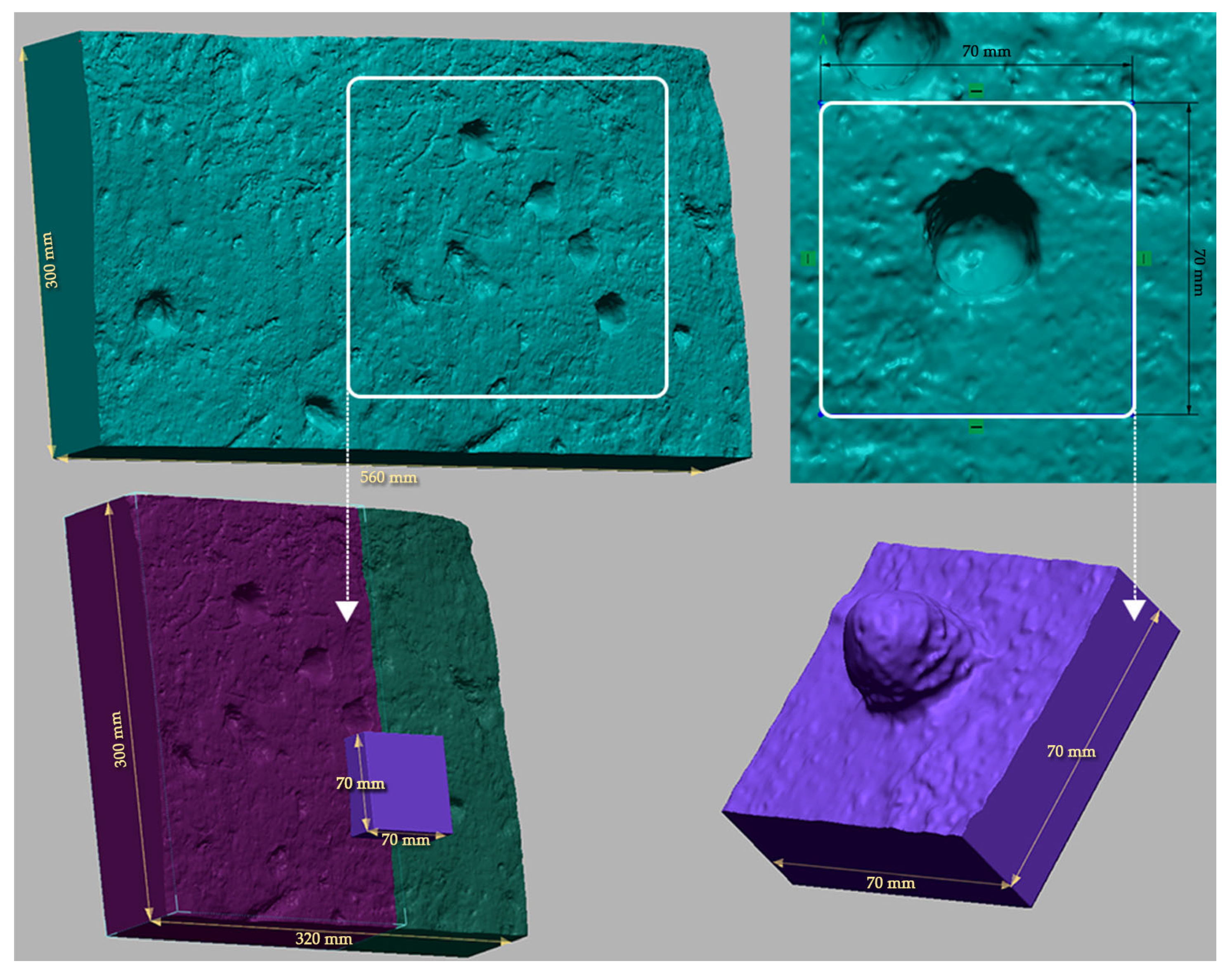

Photogrammetric reconstructions using Structure from Motion (SfM) precede the 3D prints of the impact case studies selected for the analysis. To preserve contextual integrity, the studied cavities were located in the approximately 300 m wall section between Vesuvio Gate and Ercolano Gate. This reference frame was necessary to locate the different elevations relative to the actual ground level and determine each projectile’s angle of incidence on the ashlars and the resulting crater geometry. Such data are essential to the subsequent mechanical tests that intend to support terminal ballistics calculations.

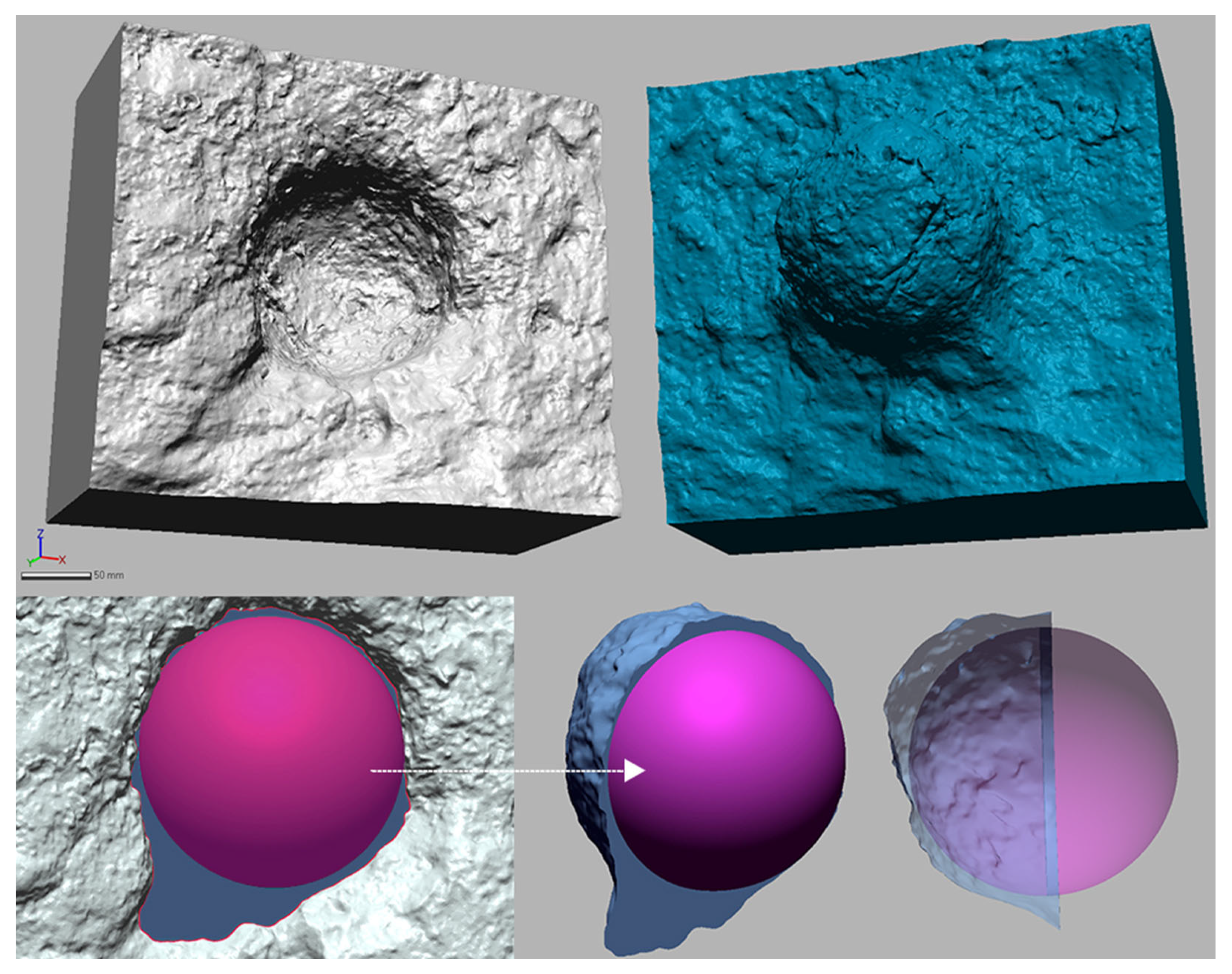

The polygonal mesh documents impact features in high detail and in a complete way. When analyzed with dedicated software for automatic surface characterization, it yields geometric primitives that allow us to hypothesize, with reasonable confidence, the most plausible shapes of the studied impacts (reverse modeling, RM).

The Finite Element Method (FEM) and Finite Element Analysis (FEA) will then validate these hypotheses and determine the launching power of the elastic torsion launchers, starting from the most significant and well-preserved examples, chosen because of the high circularity of the profile, diameter size, and depth.

Digital casts, saved in STL format (Stereo Lithography or Standard Tessellation Language), are used to prototype object geometry without preserving color or texture information.

Digital casts—both the negative molds (inverted geometry) and their positive casts (replica geometry of the cavity)—are extracted generally without color texture in the appropriate format for printing, usually the Stereo Lithography or Standard Tessellation Language (STL), and used to materially replicate the geometry of the object.

The use of an analog, continuous model that extends into physical space “provides not only visual perception but also haptic feedback (from the Greek word for Touch), material scent of which it is composed, and acoustic resonance, sharply contrasting with purely digital processing” [

11]. In this light, reliable 3D-printed copies of detailed digital casts confirm the advantages of historical maquettes based on technical drawings, even if they are not handmade with fine materials; beyond illustrating [

12] (p. 117) or persuading patrons [

13] (p. 40, 207), they can verify the structural behavior and coordination of each element [

14] (I, pp. 860–862), that is, helping in studying extreme scales [

15] (V, 18, p. 467) or guiding construction [

16]. Prototyped models thus open up new opportunities [

17].

In fact, 3D printing, while offering a choice, albeit a limited one, uses materials that are not perishable and limit cracking, deforming or shrinking over time, and they can be reprinted for purposes of reducing costs and time. In addition, since they derive from digital models, they enable real-time corrections and rapid, low-cost reprints. These rectifications and optimizations can support user inclusion [

18]—with proper attention, they compensate for some physical deficits [

19,

20] or can extract features of real complexity suitable for the understanding and enjoyment for younger or differently abled children.

We therefore ask how and to what extent these case studies can advance the field. In the context wherein case studies serve not as trivial applications but as an opportunity for dialogue, it is crucial to direct acquisition projects that can capture exceptionally irregular surfaces, such as impact craters, and to derive an inverse model that closely approximates reality. Ensuring dimensional and geometric reliability is critical for the quality of the subsequent steps.

3. Results: Virtual Casts and Reverse Modeling

Two types of case studies were surveyed, and accordingly two examples were selected, as follows:

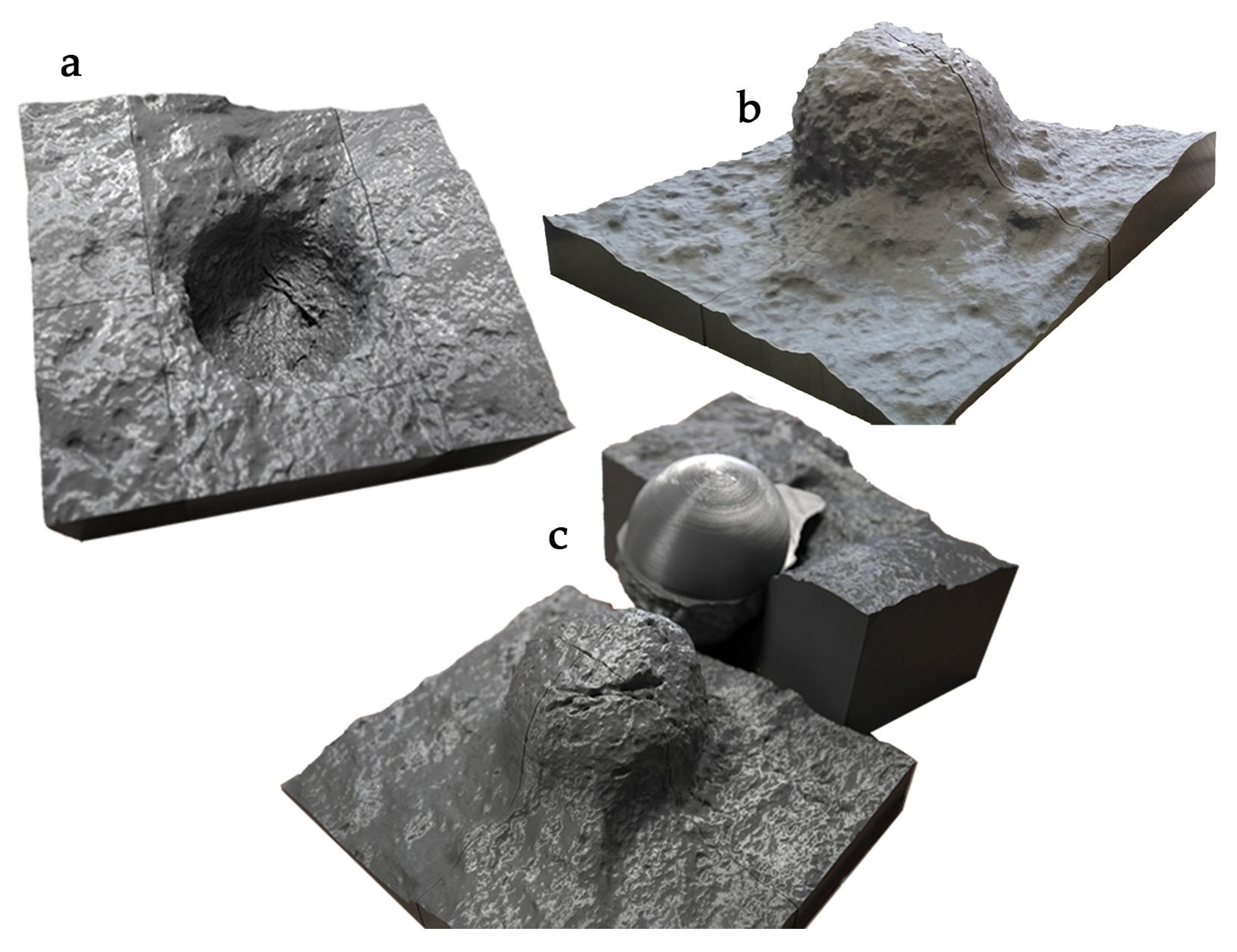

A cavity created by a stone projectile, together with its positive cast and the corresponding theoretical projectile (sphere), of which the maximum diameter was deduced from the cavity via geometric analysis of the surface (

Figure 4);

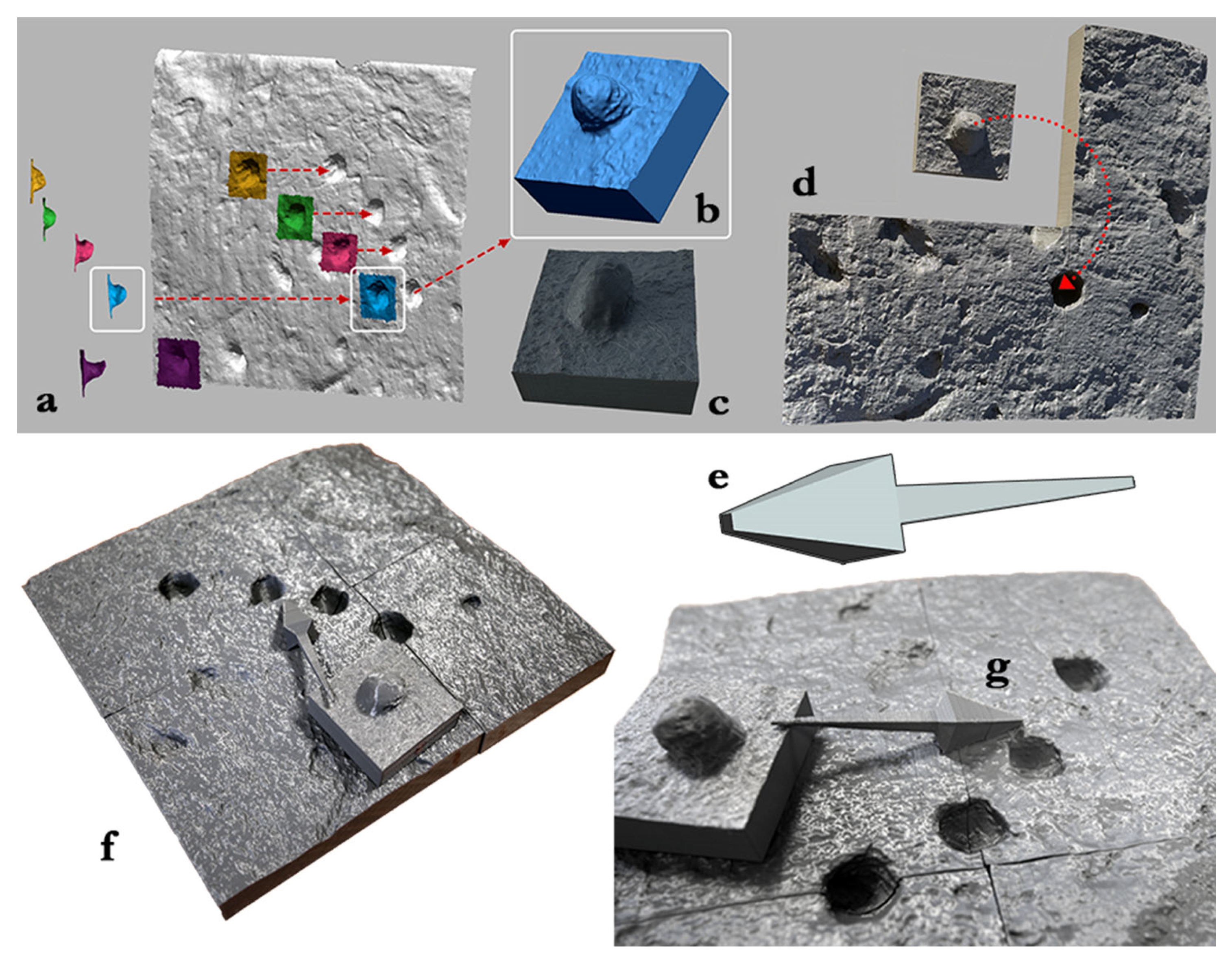

A series of fan-shaped cavities, likely produced by metal-tipped darts, together with its positive cast and a reconstructed theoretical dart (frustum of a square pyramid), modeled on the proportions of a Roman-period example that is still preserved (

Figure 5).

Figure 6 illustrates the study of the arrow tip chosen for prototyping.

For both examples, the high-resolution polygonal meshes of the impact craters were edited to close any holes and create a support platform. This platform was generated by Boolean operations (union, subtraction, or intersection) between the digital surface and a solid block, appropriately sized for single- or multi-part printing.

Several 3D-printing techniques [

21,

22] employ additive manufacturing with various materials and levels of detail. From an operational standpoint, the physical reproduction requires a geometry check: meshes must be watertight and manifold before printing. Since raw polygonal surfaces cannot be printed directly, models must be thickened and exported in a suitable format.

In order to prepare each cast model, we defined layer thickness, designed necessary supports, and arranged the nesting on the build plate. The process yielded smoothly finished pieces by printing the STL-converted models at 1:1 scale. We used an Anycubic Predator Fused Deposition Modeling (FDM) printer with PLA (Polylactic Acid) filament, set to a 0.2 mm layer height and 80 mm/s printing speed. Total print times are given in

Table 1, and the final prints for both case studies are shown in

Figure 7 and

Figure 8.

Printing at full scale and allowing later assembly—necessitated by complex overhangs, undercuts, protruding edges, and steep angles (or >45° to the build plate)—required dividing each cast into multiple magnet-joined segments (eight for the cavity cast, four for the mold, and five for the fan-shaped traces). This approach also resolved the challenge of reinserting the negative cast into its positive one, which would have been impossible with rigid material and without release-angle allowances.

4. Discussion

The physical 3D print of a digital model, like other representational forms, establishes an analogy with the original artifact despite being produced in different materials. As with its physical analog, the digital model records reality comprehensively through acquisition technologies (Range-Based Modeling (RBM) and Image-Based Modeling (IBM)) and modeling reconstruction techniques such as BIM—HBIM (Building Information Modeling). For practitioners versed in these tools, this approach yields a multifunctional artifact that integrates knowledge within a data-model ecosystem and supports subsequent heritage interventions.

The reliability of 3D models is certainly crucial. The optimization of workflows [

23,

24,

25], driven by ongoing hardware and software developments, remains a topic of debate. Standardizing common formats for widely used applications [

26], including photogrammetric ones based on SfM/MVS [

27], seems more like a necessity than an opportunity for the scientific community involved in the documentation of historical and artistic heritage.

In this broad field of application of new technologies for cultural heritage, photogrammetry software based on computer vision processes has permeated multiple scales of documentation, providing effective solutions to diverse problems [

28,

29,

30]. Integration into established pipelines has led to significant advancements in documentation, even in the architectural domain [

31,

32,

33,

34,

35,

36,

37,

38].

The digital model produced by integrating diverse acquisition methods provides the foundation for an artifact–knowledge pathway, within which rapid prototyping condenses key innovations. These advances lead to the development of new sectors in geometric modeling software as well as applications aimed at preparing 3D-printable files [

39]. Like all additive technologies, fused deposition modeling works in layers, with the minimum layer thickness depending on various factors such as the machine’s kinematics, the extrusion nozzle size, and the material used. Final prints must address surface imperfections, tolerance errors, anisotropy from layer orientation, and assembly challenges due to undercuts.

In the context of rapid development, limitations and opportunities must be carefully weighed. This is especially pertinent to recent advances in combining different representation techniques, such as the relation between traditional mesh surface representations and voxels. Voxels are novel units of a representation technique that associate volumetric pixels with the positions of a spatial grid. These volumetric pixels are numerical representations of volume and can be linked to properties such as color, opacity, material density, refractive index, position, force, time, velocity, and more.

As can be inferred, the voxel is a flexibly manipulable element that 3D printing can visualize to some extent by rendering the spatial grid in three dimensions. However, ongoing efforts aim to go further by enabling the accurate printing of voxels along with all their associated properties, to create increasingly complex materials with intrinsic characteristics—an approach often referred to as 4D printing.

Remaining within the field of 3D printing, the experiments presented—like any additive technology—highlight the challenges associated with printing carved or bas-relief works, namely, the indentations on the rough outer surface where the walls form a dihedral angle smaller than a right angle, known as undercuts.

5. Conclusions

The process makes use of digital methodologies that have now become established practices. The need for an acquisition strategy capable of ensuring the resolution required to faithfully reproduce rough cavities—sometimes consisting of holes just a few centimeters deep—represents a case study of interest, and paves the way for future developments. Central to the unified process, which links data acquisition, analysis, and dissemination within a single workflow, is the question this article seeks to address. The case study serves as a means to reflect on the cultural value of prototyping digital casts, highlighting how the printing of 3D models represents a significant mode of operation within a unique, cyclical, and interactive process that connects research, education, and the Third Mission.

Author Contributions

Conceptualization, A.R.; methodology, all authors; software, S.B.; formal analysis and investigation, A.R.; writing—original draft preparation, A.R.; writing—review and editing, S.B.; supervision, A.R.; funding acquisition, A.R.; photogrammetric survey: A.R., S.B. and other members of the UniVanvitelli Team; laser scanner survey, meshing and 3D model elaboration: S.B.; 3D modeling and geometric analysis, S.B.; 3D prints, C.F. Material preparation was performed with different software, in particular Agisoft Metashape (S.B.); Leica Geosystems Cyclone TLS cloud processing and registration (S.B.); 3D Systems Geomagic Design X meshing and processing of polygonal mesh (S.B.); Adobe Photoshop CC elaboration of figures (S.B.). All authors have read and agreed to the published version of the manuscript.

Funding

Claudio Formicola was supported by a scholarship co-financed by DM 118/23 PNRR (M4C1—Inv. 3.4 TDA). This research was supported by the project “SCORPiò-NIDI”, CUP B53D23022100006 (DD n. 1012/2023), funded by the Italian Ministry of Research under the PRIN (call DD n. 104/2022) funding initiative.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Research data are available upon request.

Acknowledgments

The authors would like to express their gratitude to the management and the appointed officials of the offices of the Pompeii Archaeological Park for granting authorizations for site access and survey operations.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| 3D | Three-Dimensional |

| BIM/HBIM | Building Information Modeling/Heritage Building Information Modeling |

| CDE | Common Data Environment |

| FEA | Finite Element Analysis |

| FDM | Fused Deposition Modeling |

| FEM | Finite Element Method |

| IBM | Range-Based Modeling |

| ICT | Information and Communications Technology |

| MR | Mixed Reality |

| RM | Reverse Modeling |

| PLA | Polylactic Acid |

| RBM | Range-Based Modeling |

| SfM | Structure from Motion |

| STL | Stereo Lithography or Standard Tessellation Language |

| XR | Extended Reality |

References

- Rossi, A. The Survey of the Ballistic Imprints for a Renewed Image of Unearthed Pompeii. Nexus Netw. J. 2024, 26, 307–324. [Google Scholar] [CrossRef]

- Vitucci, G. (Ed.) La Guerra Giudaica di Giuseppe Flavio; Mondadori: Milano, Italy, 1989; ISBN 88-04-32627-1. [Google Scholar]

- Russo, F.; Russo, F. 89 A.C. Assedio a Pompei: La Dinamica e le Tecnologie Belliche Della Conquista Sillana di Pompei; Edizioni Flavius: Pompei, Italy, 2005; ISBN 88-88419-32-2. [Google Scholar]

- y García, L.G. Danni di Guerra a Pompei. Una Dolorosa Vicenda Quasi Dimenticata. Con Numerose Notizie sul «Museo Pompeiano» Distrutto nel 1943; Studi della Soprintendenza archeologica di Pompei; L’Erma di Bretschneider: Roma, Italy, 2006; ISBN 88-8265-369-2. [Google Scholar]

- Russo, F. L’artiglieria Delle Legioni Romane. Le Macchine da Guerra che Resero Invincibile L’esercito Romano; Istituto Poligrafico e Zecca dello Stato: Roma, Italy, 2004; ISBN 978-88-240-3444-9. [Google Scholar]

- Rossi, A.; Formicola, C.; Barsanti, S.G. Ingegna Romana. Dalle fonti ai modelli, dai reperti alle ricostruzioni. Diségno 2024, 14, 229–238. [Google Scholar] [CrossRef]

- Marsden, E.W. Greek and Roman Artillery: Technical Treatises; Clarendon Press: Oxford, UK, 1971; ISBN 978-0-19-814269-0. [Google Scholar]

- Brusaporci, S. Architectural Heritage Imaging: When Graphical Science Meets Model Theory. Disegnarecon 2023, 16, 1–4. [Google Scholar] [CrossRef]

- Migliari, R. (Ed.) Disegno Come Modello. Riflessioni del Disegno nell’età Informatica; Edizioni Kappa: Roma, Italy, 2004; ISBN 88-7890-605-0. [Google Scholar]

- Cipriani, L.; Fantini, F. Digitalization Culture vs Archaeological Visualization: Integration of Pipelines and Open Issues. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2017, XLII-2-W3, 195–202. [Google Scholar] [CrossRef]

- Sdegno, A.; Cabezos-Bernal, P.M. Oblique Analog Models. Diségno 2024, 14, 7–21. [Google Scholar] [CrossRef]

- Manetti, A. Vita di Filippo Brunelleschi. Preceduta da la Novella del Grasso; De Robertis, D., Tanturli, G., Eds.; Edizioni Il Polifilo: Milano, Italy, 1976. [Google Scholar]

- Filarete. Trattato di Architettura; Grassi, L., Ed.; Edizioni Il Polifilo: Milano, Italy, 1972. [Google Scholar]

- Alberti, L.B. L’architettura (De re Aedificatoria); Edizioni Il Polifilo: Milano, Italy, 1966; ISBN 978-88-7050-101-8. [Google Scholar]

- Millon, H.; Munshower, S.S. (Eds.) An Architectural Progress in the Renaissance and Baroque: Sojourns In and Out of Italy, 1st ed.; Penn State Department of Art History: University Park, PA, USA, 2002; ISBN 978-0-915773-07-7. [Google Scholar]

- Millon, H.A.; Smyth, C.H. Michelangelo Architetto. La facciata di San Lorenzo e la cupola di San Pietro; Olivetti: Milano, Italy, 1988. [Google Scholar]

- Millon, H.A. I modelli architettonici nel Rinascimento. In Rinascimento: Da Brunelleschi a Michelangelo. La Rappresentazione Dell’architettura; Millon, H.A., Magnago Lampugnani, V., Eds.; Bompiani: Milano, Italy, 1994; pp. 19–72. ISBN 88-452-2266-7. [Google Scholar]

- De Luca, V.; Gatto, C.; Liaci, S.; Corchia, L.; Chiarello, S.; Faggiano, F.; Sumerano, G.; De Paolis, L.T. Virtual Reality and Spatial Augmented Reality for Social Inclusion: The “Includiamoci” Project. Information 2023, 14, 38. [Google Scholar] [CrossRef]

- Calandriello, A.; D’Acunto, G.; Gigliotti, G.C. Tactile Translations: Algorithmic Modelling for Museum Inclusiveness. In Graphic Horizons; Hermida González, L., Xavier, J.P., Amado Lorenzo, A., Fernández-Álvarez, Á.J., Eds.; Springer Nature: Cham, Switzerland, 2024; pp. 308–315. [Google Scholar]

- Nigro, L.; Montanari, D.; Sabatini, S.; De Giuseppe, M.; Benedettucci, F.M.; Lucibello, S.; Fattore, L.; Trebbi, L.; Nejat, B.; Rinaldi, T. Caress the pharaoh. The tactile reproduction of Ramses II’s “mummy” in the Sapienza University Museum of the Near East, Egypt and Mediterranean. J. Cult. Herit. 2024, 67, 158–163. [Google Scholar] [CrossRef]

- Sable, U.; Borlepwar, P.T. Recent Developments in the Field of Rapid Prototyping: An Overview. In Proceedings of the International Conference on Intelligent Manufacturing and Automation; Vasudevan, H., Kottur, V.K.N., Raina, A.A., Eds.; Springer: Singapore, 2019; pp. 511–519. [Google Scholar]

- Kantaros, A.; Ganetsos, T.; Petrescu, F.I.T. Three-Dimensional Printing and 3D Scanning: Emerging Technologies Exhibiting High Potential in the Field of Cultural Heritage. Appl. Sci. 2023, 13, 4777. [Google Scholar] [CrossRef]

- Guidi, G.; Frischer, B.D. 3D Digitization of Cultural Heritage. In 3D Imaging, Analysis and Applications; Liu, Y., Pears, N., Rosin, P.L., Huber, P., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 631–697. ISBN 978-3-030-44070-1. [Google Scholar]

- Ferdani, D.; Ronchi, D.; Fanini, B.; Manganelli Del Fà, R.; d’Annibale, E.; Bordignon, A.; Pescarin, S. Brancacci Chapel in Florence: Surveying and Real-Time 3D Simulation for Conservation and Communication Purposes. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2023, XLVIII-M-2–2023, 535–540. [Google Scholar] [CrossRef]

- Grasso, N.; Spadavecchia, C.; Di Pietra, V.; Belcore, E. LiDAR and SfM-MVS Integrated Approach to Build a Highly Detailed 3D Virtual Model of Urban Areas. In Proceedings of the 9th International Conference on Geographical Information Systems Theory, Applications and Management; SCITEPRESS—Science and Technology Publications: Prague, Czech Republic, 2023; pp. 128–135. [Google Scholar]

- Foschi, R.; Fallavollita, F.; Apollonio, F.I. Quantifying Uncertainty in Hypothetical 3D Reconstruction-A User-Independent Methodology for the Calculation of Average Uncertainty. Heritage 2024, 7, 4440–4454. [Google Scholar] [CrossRef]

- Attenni, M.; Bartolomei, C.; Inglese, C.; Ippolito, A.; Morganti, C.; Predari, G. Low cost survey and heritage value. SCIRES-IT—Sci. Res. Inf. Technol. 2018, 7, 115–132. [Google Scholar] [CrossRef]

- Gaiani, M.; Apollonio, F.I.; Fantini, F. Evaluating Smartphones Color Fidelity and Metric Accuracy for the 3D Documentation of Small Artifacts. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2019, XLII-2-W11, 539–547. [Google Scholar] [CrossRef]

- Apollonio, F.I.; Fantini, F.; Garagnani, S.; Gaiani, M. A Photogrammetry-Based Workflow for the Accurate 3D Construction and Visualization of Museums Assets. Remote Sens. 2021, 13, 486. [Google Scholar] [CrossRef]

- Peinado-Santana, S.; Hernández-Lamas, P.; Bernabéu-Larena, J.; Cabau-Anchuelo, B.; Martín-Caro, J.A. Public Works Heritage 3D Model Digitisation, Optimisation and Dissemination with Free and Open-Source Software and Platforms and Low-Cost Tools. Sustainability 2021, 13, 13020. [Google Scholar] [CrossRef]

- Bevilacqua, M.G.; Russo, M.; Giordano, A.; Spallone, R. 3D Reconstruction, Digital Twinning, and Virtual Reality: Architectural Heritage Applications. In Proceedings of the 2022 IEEE Conference on Virtual Reality and 3D User Interfaces Abstracts and Workshops (VRW), Christchurch, New Zealand, 12–16 March 2022; pp. 92–96. [Google Scholar]

- Menaguale, O. Digital Twin and Cultural Heritage—The Future of Society Built on History and Art. In The Digital Twin; Crespi, N., Drobot, A.T., Minerva, R., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 1081–1111. ISBN 978-3-031-21343-4. [Google Scholar]

- Fascia, R.; Barbieri, F.; Gaspari, F.; Ioli, F.; Pinto, L. From 3D Survey to Digital Reality of a Complex Architecture: A Digital Workflow for Cultural Heritage Promotion. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2024, XLVIII-2-W4-2024, 205–212. [Google Scholar] [CrossRef]

- Grazianova, M.; Mesaros, P. Cultural heritage management from traditional methods to digital systems: A review from bim to digital twin. E3S Web Conf. 2024, 550, 01015. [Google Scholar] [CrossRef]

- Gabellone, F. Digital Twin: A new perspective for cultural heritage management and fruition. Acta IMEKO 2022, 11, 1–7. [Google Scholar] [CrossRef]

- Grieves, M.W. Digital Twins: Past, Present, and Future. In The Digital Twin; Crespi, N., Drobot, A.T., Minerva, R., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 97–121. ISBN 978-3-031-21343-4. [Google Scholar]

- Luther, W.; Baloian, N.; Biella, D.; Sacher, D. Digital Twins and Enabling Technologies in Museums and Cultural Heritage: An Overview. Sensors 2023, 23, 1583. [Google Scholar] [CrossRef] [PubMed]

- Mousavi, Y.; Gharineiat, Z.; Karimi, A.A.; McDougall, K.; Rossi, A.; Gonizzi Barsanti, S. Digital Twin Technology in Built Environment: A Review of Applications, Capabilities and Challenges. Smart Cities 2024, 7, 2594–2615. [Google Scholar] [CrossRef]

- Gonizzi Barsanti, S.; Marini, M.R.; Malatesta, S.G.; Rossi, A. Evaluation of Denoising and Voxelization Algorithms on 3D Point Clouds. Remote Sens. 2024, 16, 2632. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).