Hybrid Rotor Noise Optimization †

Abstract

1. Introduction

2. State of the Art

3. Methodology

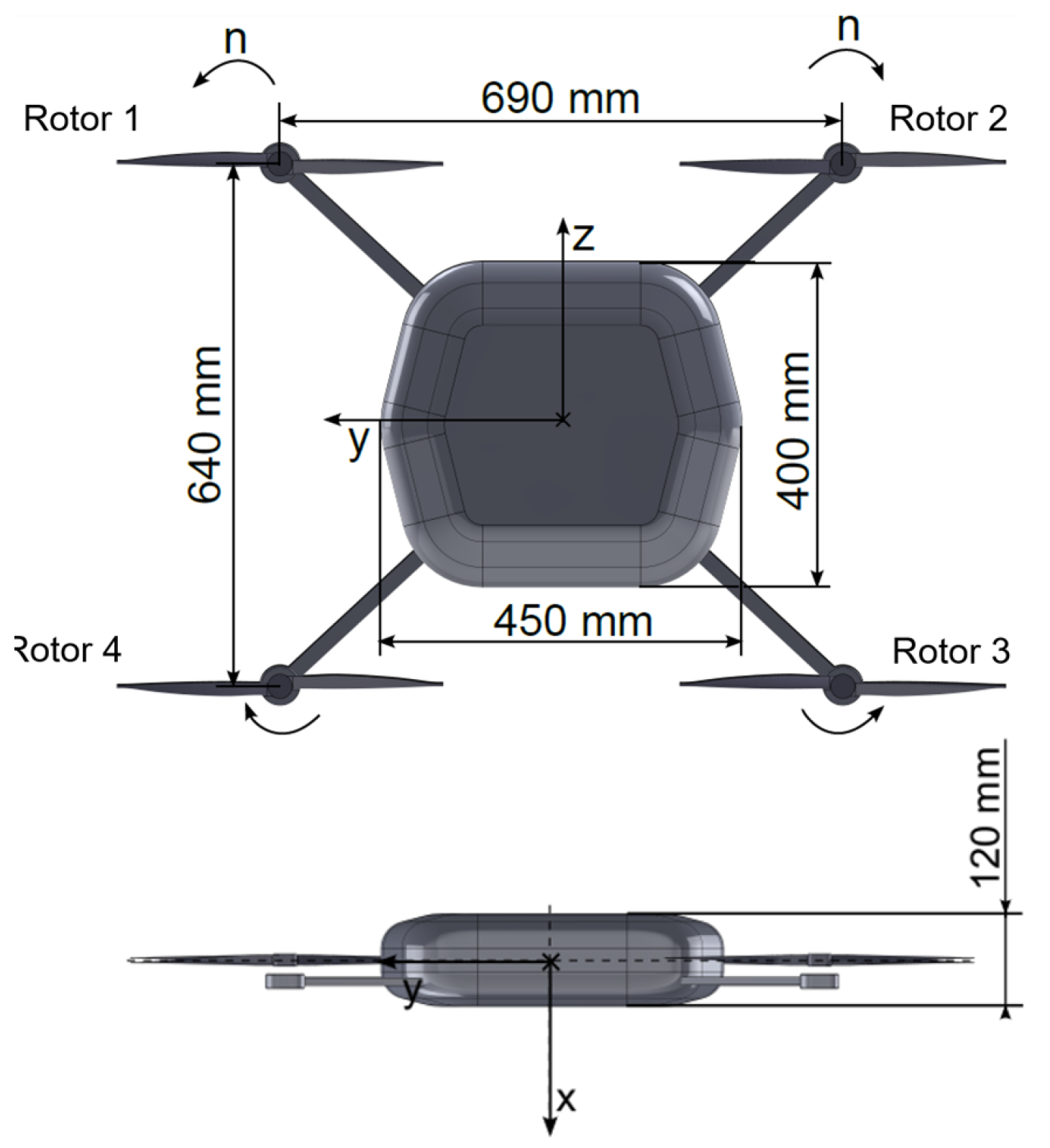

3.1. Conceptual Design Methodology

3.2. Numerical Approach

3.3. Aerodynamic Validation

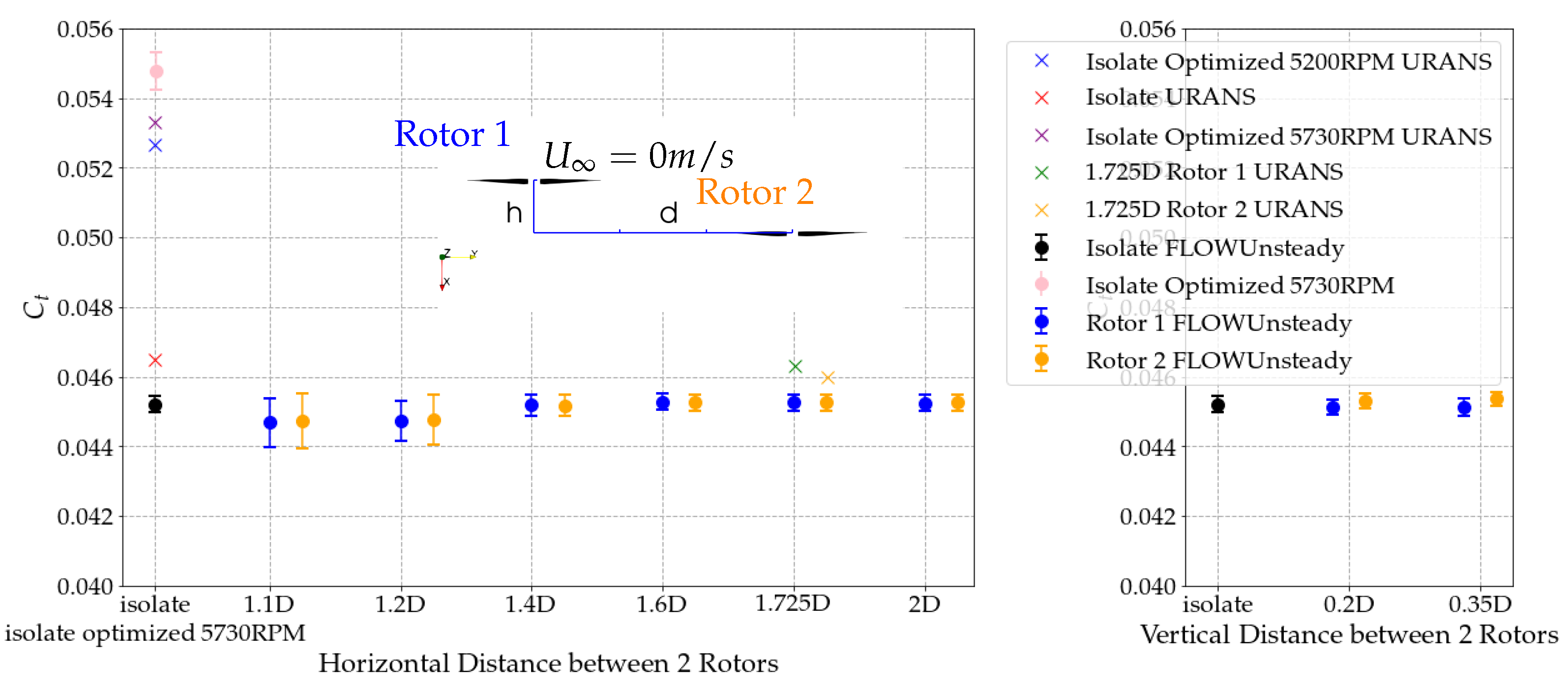

3.3.1. Rotor–Rotor Interaction

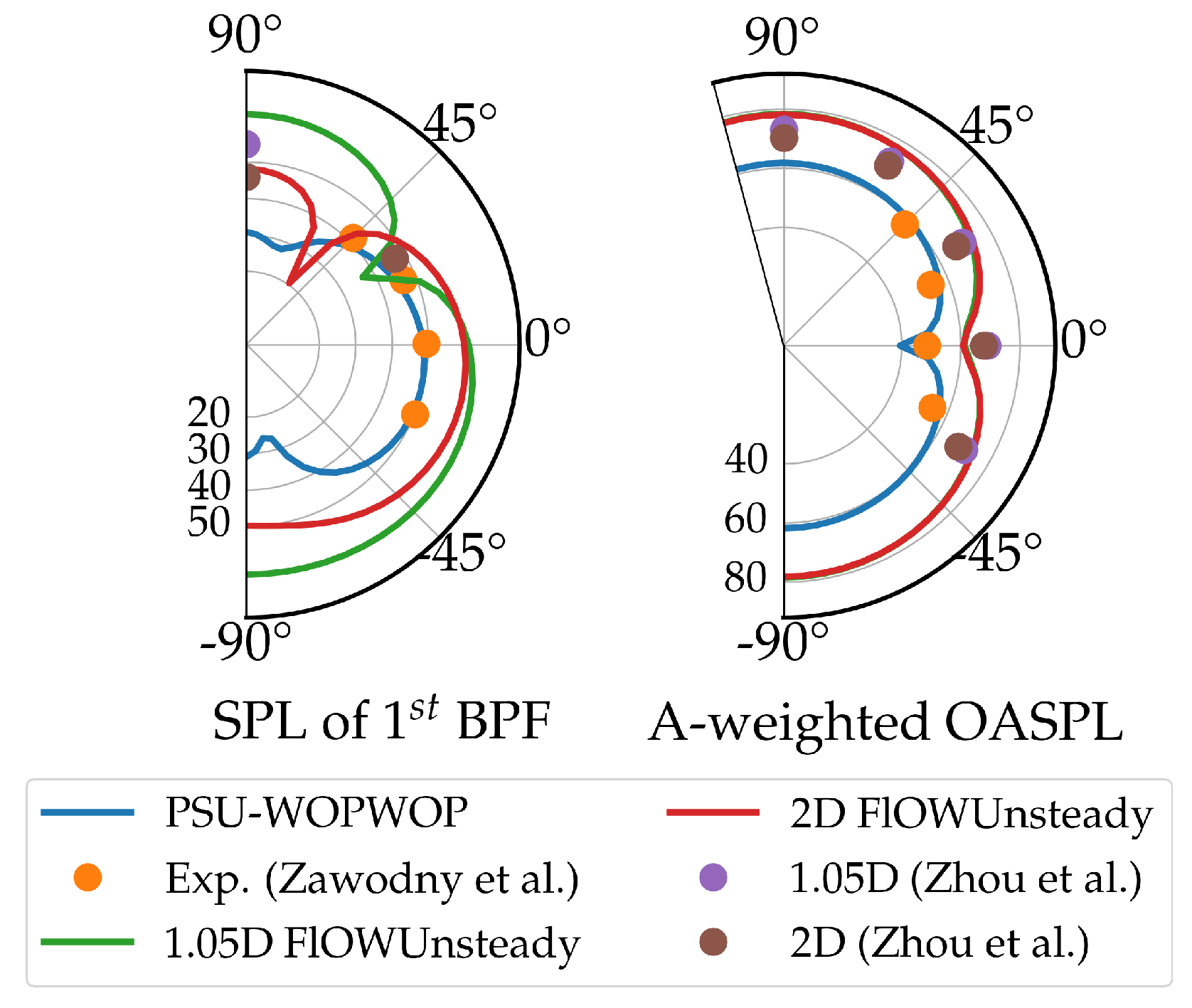

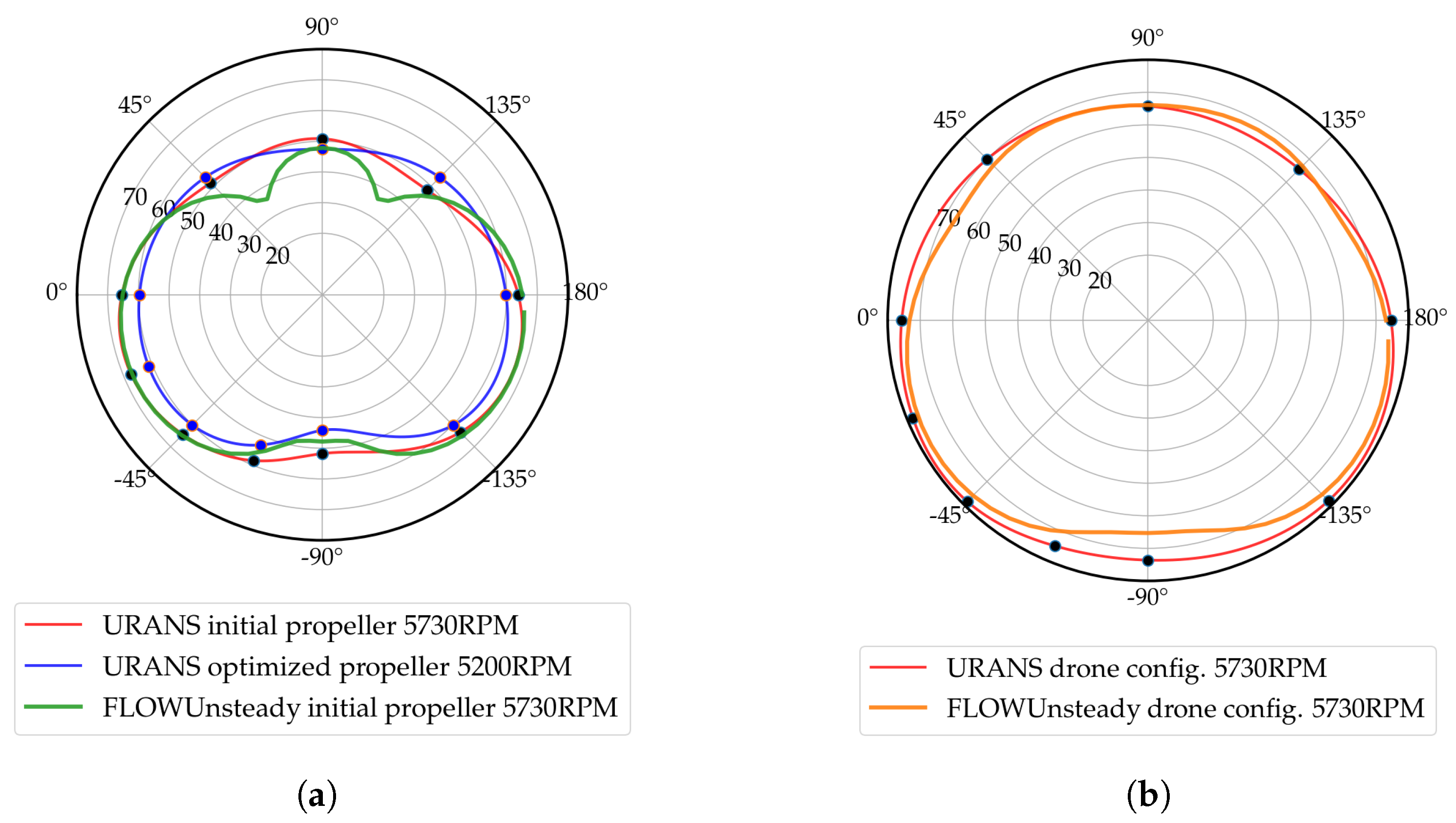

3.4. Acoustic Validation

4. Results

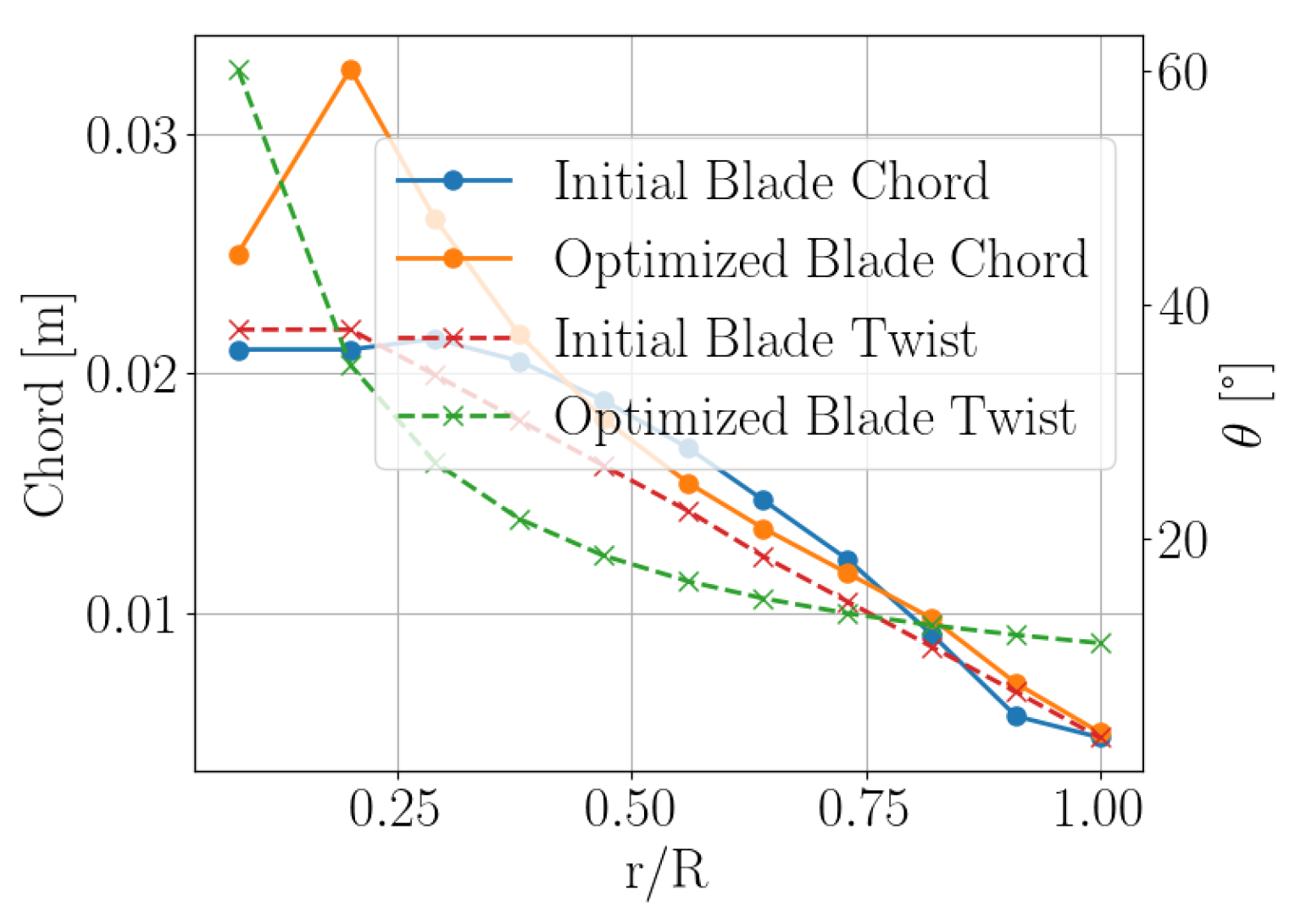

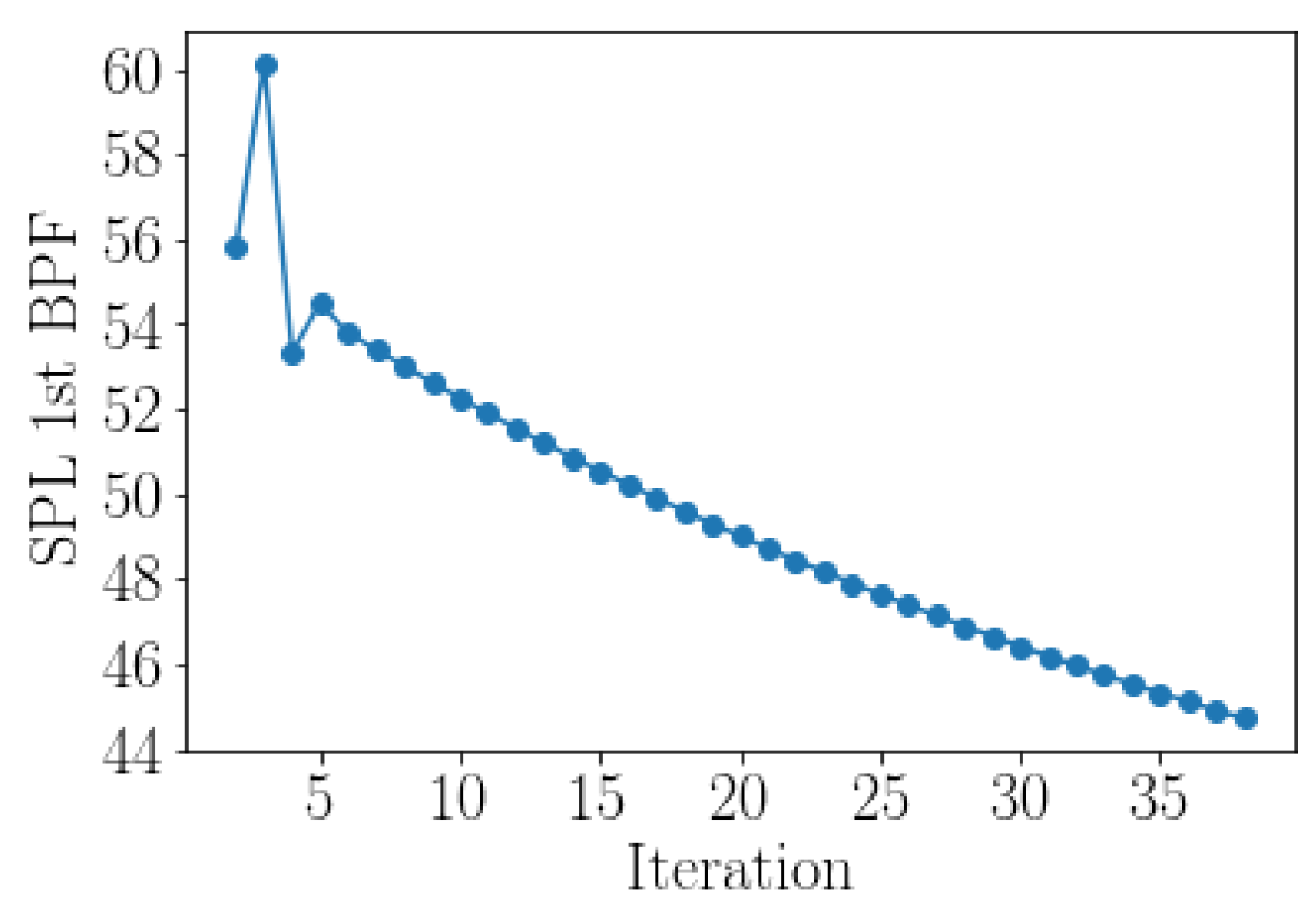

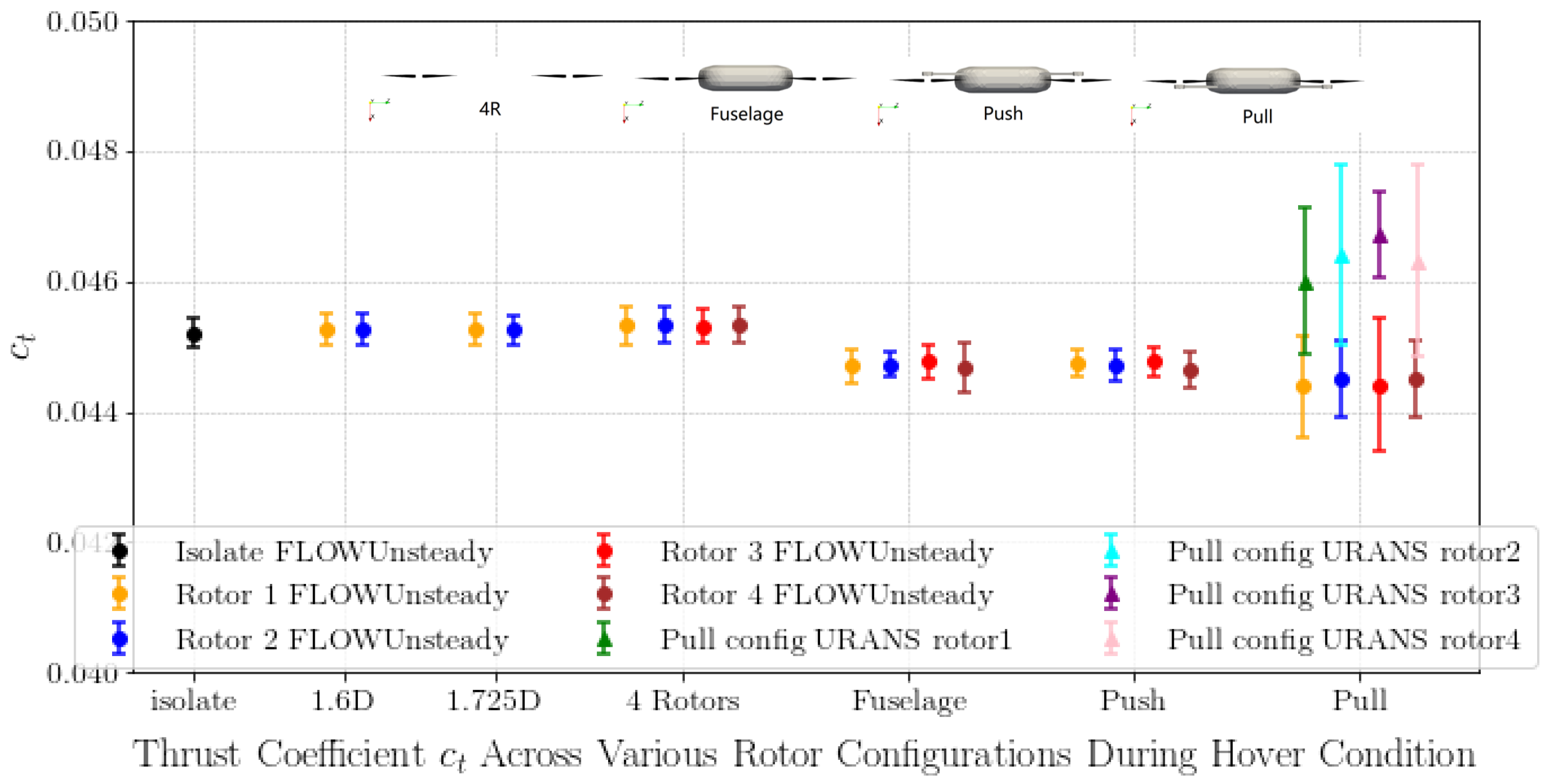

4.1. Aerodynamic Optimization

4.2. Preliminary Drone Configuration—Initial and Optimized Propeller Investigations

4.3. Isolated and Side-by-Side Aerodynamic and Acoustic Effects

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Candeloro, P.; Ragni, D.; Pagliaroli, T. Small-Scale Rotor Aeroacoustics for Drone Propulsion: A Review of Noise Sources and Control Strategies. Fluids 2022, 7, 279. [Google Scholar] [CrossRef]

- Kostek, A.A.; Lößle, F.; Wickersheim, R.; Keßler, M.; Boisard, R.; Reboul, G.; Visingardi, A.; Barbarino, M.; Gardner, A.D. Experimental Investigation of UAV Rotor Aeroacoustics and Aerodynamics with Computational Cross-Validation. In Proceedings of the 48th European Rotorcraft Forum, Winterthur, Switzerland, 6–8 September 2022. [Google Scholar]

- Alvarez, E.J.; Mehr, J.; Ning, A. FLOWUnsteady: An Interactional Aerodynamics Solver for Multirotor Aircraft and Wind Energy. In Proceedings of the AIAA AVIATION 2022 Forum, Chicago, IL, USA & Virtual, 27 June–1 July 2022. [Google Scholar] [CrossRef]

- Gur, O.; Rosen, A. Comparison between blade-element models of propellers. Aeronaut. J. 2015, 112, 698–704. [Google Scholar] [CrossRef]

- Adkins, C.N.; Liebeck, R.H. Design of Optimum Propellers. J. Propuls. Power 1994, 10, 676–682. [Google Scholar] [CrossRef]

- Babetto, L.; Stumpf, E. Recent Development of a Conceptual Design Methodology for Unmanned Aerial Vehicles. In Proceedings of the AIAA Aviation Forum, Online, 2–6 August 2021. [Google Scholar] [CrossRef]

- Mahmuddin, F. Rotor Blade Performance Analysis with Blade Element Momentum Theory. Energy Procedia 2017, 105, 1123–1129. [Google Scholar] [CrossRef]

- Dudul, M.S.H.; Mahmud, M.S.; Islam, M.A. Low-Fidelity Aerodynamic Load Analysis of Helicopter Rotor in Hover. J. Aeronaut. Astronaut. Aviat. 2023, 55, 159–167. [Google Scholar] [CrossRef]

- Bohorquez, F.; Samuel, P.; Sirohi, J.; Pines, D.; Rudd, L.; Perel, R. Design, Analysis and Hover Performance of a Rotary Wing Micro Air Vehicle. J. Am. Helicopter Soc. 2003, 48, 80–90. [Google Scholar] [CrossRef]

- Kotwicz Herniczek, M.; Jee, D.; Sanders, B.; Feszty, D. Rotor blade optimization and flight testing of a small UAV rotorcraft. J. Unmanned Veh. Syst. 2019, 7, 325–344. [Google Scholar] [CrossRef]

- Hanson, D.B. Influence of Propeller Design Parameters on Far-Field Harmonic Noise in Forward Flight. AIAA J. 1980, 18, 1313–1319. [Google Scholar] [CrossRef]

- Hanson, D.B. Helicoidal Surface Theory for Harmonic Noise of Propellers in the Far Field. AIAA J. 1980, 18, 1213–1220. [Google Scholar] [CrossRef]

- Hanson, D.B. Near-field frequency-domain theory for propeller noise. AIAA J. 1985, 23, 499–504. [Google Scholar] [CrossRef]

- Alvarez, E.; Schenk, A.; Critchfield, T.; Ning, A. Rotor-on-Rotor Aeroacoustic Interactions of Multirotor in Hover. J. Am. Helicopter Soc. 2020, 4053, 1–12. [Google Scholar] [CrossRef]

- Thai, A.D.; de Paola, E.; Di Marco, A.; Stoica, L.G.; Camussi, R.; Tron, R.; Grace, S.M. Experimental and Computational Aeroacoustic Investigation of Small Rotor Interactions in Hover. Appl. Sci. 2021, 11, 10016. [Google Scholar] [CrossRef]

- Zhou, W.; Ning, Z.; Li, H.; Hu, H. An Experimental Investigation on Rotor-to-Rotor Interactions of Small UAV Propellers. In Proceedings of the 35th AIAA Applied Aerodynamics Conference, Denver, CO, USA, 5–9 June 2017. [Google Scholar] [CrossRef]

- Vu, X.D.; Nguyen, A.T.; Nha, T.L.; Chu, Q.; Dinh, C.T. Numerical Aerodynamic and Aeroacoustic Analysis of Toroidal Propeller Designs. Int. J. Aviat. Sci. Technol. 2024, 5, 20–33. [Google Scholar] [CrossRef]

- König, R.; Babetto, L.; Gerlach, A.; Fels, J.; Stumpf, E. Prediction of perceived annoyance caused by an electric drone noise through its technical, operational and psychoacoustic parameters. J. Acoust. Soc. Am. 2024, 156, 1929–1941. [Google Scholar] [CrossRef] [PubMed]

- Alvarez, E.J.; Ning, A. Stable Vortex Particle Method Formulation for Meshless Large-Eddy Simulation. AIAA J. 2024, 62, 637–656. [Google Scholar] [CrossRef]

- Brentner, K.S.; Farassat, F. Modeling aerodynamically generated sound of helicopter rotors. Prog. Aerosp. Sci. 2003, 39, 83–120. [Google Scholar] [CrossRef]

- Brooks, T.F.; Pope, D.S.; Marcolini, M.A. Airfoil Self-Noise and Prediction; NASA Reference Publication NASA-RP-1218; NASA Langley Research Center: Hampton, VA, USA, 1989. [Google Scholar]

- Zawodny, N.S.; Boyd, D.D., Jr.; Burley, C.L. Acoustic Characterization and Prediction of Representative, Small-Scale Rotary-Wing Unmanned Aircraft System Components. In American Helicopter Society (AHS) Annual Forum; NASA Langley Research Center: Hampton, VA, USA, 2016. [Google Scholar]

- Borst, H. Summary of Propeller Design Procedures and Data. Volume 1: Aerodynamic Design and Installation; Technical Report No. 73-34A-VOL-1; U.S. Army Air Mobility Research and Development Laboratory: Rosemont, PA, USA, 1973. [Google Scholar]

- Glauert, H. Airplane Propellers; Springer: Berlin/Heidelberg, Germany, 1935; pp. 169–360. [Google Scholar]

- Betz, A. Screw Propellers with Minimum Energy Loss; Technical Translation; NRC, Division of Mechanical Engineering: Rockville, MD, USA, 1958. [Google Scholar]

- Kümmel, A.; Breitsamter, C. Multi-disciplinary framework for propeller blade design. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1024, 012060. [Google Scholar] [CrossRef]

- Kümmel, A.; Breitsamter, C. Efficient Aerodynamic and Aeroacustic Optimization of Propeller Sections Using Bayesian Methods. In New Results in Numerical and Experimental Fluid Mechanics XIII: Contributions to the 22nd STAB/DGLR Symposium; Springer: Berlin/Heidelberg, Germany, 2021; pp. 365–375. [Google Scholar] [CrossRef]

- Kümmel, A.; Stuhlpfarrer, M.; Pölzlbauer, P.; Breitsamter, C. Propeller Blade Shape Optimization with a Hybrid BEMT/CFD Approach in “New Results in Numerical and Experimental Fluid Mechanics XII”. In New Results in Numerical and Experimental Fluid Mechanics XII: Contributions to the 21st STAB/DGLR Symposium, Darmstadt, Germany, 2018; Dillmann, P.D.D.A., Heller, D.G., Krämer, P.D.E., Wagner, P.D.C., Tropea, P.D.C., Jakirlić, P.D.S., Eds.; Notes on Numerical Fluid Mechanics and Multidisciplinary Design; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; pp. 362–371. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mandl, P.; Babetto, L.; Stumpf, E.; Breitsamter, C. Hybrid Rotor Noise Optimization. Eng. Proc. 2025, 90, 94. https://doi.org/10.3390/engproc2025090094

Mandl P, Babetto L, Stumpf E, Breitsamter C. Hybrid Rotor Noise Optimization. Engineering Proceedings. 2025; 90(1):94. https://doi.org/10.3390/engproc2025090094

Chicago/Turabian StyleMandl, Philipp, Laura Babetto, Eike Stumpf, and Christian Breitsamter. 2025. "Hybrid Rotor Noise Optimization" Engineering Proceedings 90, no. 1: 94. https://doi.org/10.3390/engproc2025090094

APA StyleMandl, P., Babetto, L., Stumpf, E., & Breitsamter, C. (2025). Hybrid Rotor Noise Optimization. Engineering Proceedings, 90(1), 94. https://doi.org/10.3390/engproc2025090094