Abstract

Drying agricultural crops is essential for preserving them and extending their shelf life. Incorporating drying technology in food production has improved product quality and helped meet increasing food demands. Corn (Zea mays) is a major crop grown in Southeast Asia, used for food and livestock. The preservation of crop grains, such as rice and corn, heavily relies on efficient drying processes. Common corn varieties like sweet corn, wild violet corn, waxy corn, white corn, purple corn, and young corn are cereal grains that are often dried for various food products. The study of drying kinetics of these crops is crucial, because drying parameters significantly impact the drying process. This review discusses various factors affecting drying, including airflow, temperature, relative humidity, sample size, and initial moisture content. Understanding these parameters helps optimize the drying process to achieve better quality and efficiency. The review also examines several mathematical models that are used to describe drying kinetics. Models such as the Weibull and Peleg models, Midilli Kucuk model, and the Page and Modified Page models are analyzed for their effectiveness in evaluating design parameters. These models provide a scientific basis for improving drying techniques and ensuring consistency in food production. By presenting a comprehensive review of these aspects, this review aims to enhance the understanding of how to utilize drying technology effectively in food manufacturing and preservation, which can be vital for developing better preservation methods, improving product quality, and ultimately meeting the growing food demands.

1. Introduction

A variety of its multitude of nutritional components, corn is regarded as a vital agricultural product and is widely grown around the world. Fresh kernels of corn are highly susceptible to deterioration during storage because of their high water content, which can lower the concentration of nutrients. The samples’ enormous density and robust epidermal framework, nevertheless, reduces the effectiveness of water diffusion during treatment [1].

The primary component of livestock feed is corn, which is also converted into a wide range of food and commercial products, notably starch, sugars, oil from corn, commercial alcohol, and ethanol fuel. To minimize the duration of cultivation when two or more harvests are cultivated in a year and to lessen the danger of frost, insect, ailments, and kernel destruction during harvest, corn is often harvested with a moisture level of 22% to 35%—wet foundation [2].

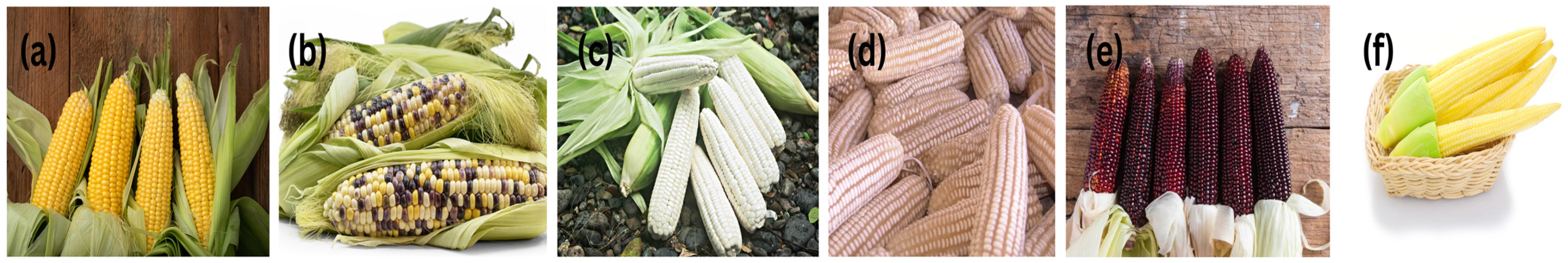

In the Philippines, corn is also regarded as a staple crop. The country has six common types of corn, this includes: (a) sweet corn, (b) wild violet corn, (c) white lagkitan, (d) Visayan white corn, (e) purple corn, and (f) young corn, as illustrated in Figure 1.

Figure 1.

Common corn (Zea mays) crops in the Philippines: (a) sweet corn, (b) wild violet corn, (c) white lagkitan, (d) Visayan white corn, (e) purple corn, and (f) young corn.

Sweet corn is a popular and widely consumed crop in the Philippines. It is a variant of common corn characterized by its tender, succulent kernels, and sweet flavor. Sweet corn has become a staple ingredient in various culinary dishes, including salads, soups, and side dishes. In recent years, the demand for sweet corn has significantly increased due to its nutritional value and versatility in cooking [3]. Therefore, understanding the drying kinetics of sweet corn is crucial to optimize the drying process and preserve its quality during storage. It exhibits specific characteristics that distinguish it from other varieties of corn. Firstly, sweet corn has a higher sugar content compared to field corn varieties [4]. This higher sugar content contributes to its sweet taste and unique flavor profile, making it a favored choice among consumers. Secondly, the kernels of sweet corn are relatively softer and more tender than those of field corn [1]. This softness enhances the eating experience and allows for easier extraction of the kernels for various food preparations. Another characteristic of sweet corn is its high moisture content, which makes it susceptible to spoilage during storage if not properly dried [5]. Therefore, efficient drying of sweet corn is essential to reduce its moisture content and prevent microbial growth or quality deterioration. The drying kinetics of sweet corn involve the process of moisture removal from the kernels through evaporation, leading to a decrease in water activity and preservation of the corn’s overall quality.

A typical Philippine corn variant known as wild violet corn has a mixture of white and purple kernels. When collected, it has a slightly sweet, slippery, and sticky texture. With development, the proportion of purple kernels rises. Additionally, wild violet does not bleed and keeps its color; in fact, the color intensifies. Traditional non-GMO breeding techniques were used to produce wild violet corn [6]. A mid-season bi-colored cultivar of corn from the Poaceae family, wild violet is known botanically as (Zea mays). Thin, pale-yellow threads known as silks serve as a layer that separates the husk and cob and are tightly woven into the multiple layers of dark light-colored green husks which the cobs are encased in [7].

White lagkitan is a common variety of corn cultivated in the Philippines. It is known for its unique characteristics and wide range of applications. White lagkitan is commonly used for making traditional Filipino delicacies such as kakanin (rice cakes) and other sweet treats. It plays a significant role in the culinary culture of the Philippines, particularly in regions where traditional desserts are highly valued. Understanding the drying kinetics of white lagkitan corn is crucial to optimize the drying process and preserve its quality during storage. Additionally, this corn possesses distinct characteristics that set it apart from other corn varieties [8]. Firstly, it is characterized by its translucent, pearly white kernels. These kernels are larger in size compared to regular corn varieties and have a unique starchy texture. The white lagkitan corn kernels have a higher amylose content. In addition to its appearance and texture, white lagkitan corn has a slightly sweet taste, enhancing the flavor of dishes it is used in. The natural sweetness of the kernels adds a delightful element to traditional Filipino desserts, making them even more enjoyable. This characteristic distinguishes white lagkitan corn from other corn varieties, making it a sought-after ingredient in local culinary traditions. Due to its high moisture content, white lagkitan corn requires proper drying to prevent spoilage and maintain its quality during storage. The drying kinetics of white lagkitan corn involve the removal of moisture through evaporation, leading to a decrease in water activity and preservation of the corn’s overall quality. Factors such as temperature, air velocity, relative humidity, and corn kernel size influence the drying process. It is important to determine the optimal drying conditions to achieve the desired moisture content while preserving the sensory attributes, nutritional value, and shelf life of white lagkitan corn.

White corn is a versatile staple food in the Philippines, particularly in Cebu, where it is used in various dishes and beverages. Unlike yellow corn, which is primarily used as animal feed, white corn serves as a crucial food source during tough times. With its elongated shape, numerous layers of husks, and a cob filled with hundreds of soft, juicy kernels, white corn offers a unique taste and texture. While its sweetness diminishes over time as sugars convert to starch, white corn remains a valuable and adaptable ingredient in Filipino cuisine.

Purple corn is another species of common corn crop in the Philippines. This species originated from Peru and has now become a common crop in Asia, Europe, and the United States. The purple corn consists of 85% grain and 15% cob. The purple corn contains an anthocyanin, called cyanidin-3-glucoside, which is what gives it its purple color [9]. Purple corn (Zea mays) is known for its sticky texture, which is similar to sticky rice; this texture is caused by the amylopectin contents in the endosperm of its kernel [10]. Due to its pigment, it can be used as a source of food coloring in the production of beverages, candies, and other similar products [11]. Purple corn is known in the food and pharmaceutical industries for the bioactive compounds that it contains. It contains anthocyanins such as cyanidin-3-O-glucoside, pelargonidin- 3-O-glucoside, peonidin 3-O-glucoside, and their malonylated forms [11]. Anthocyanins are bioactive compounds that have antioxidant properties which have benefits such as promoting the work of red blood cells, controlling sugar levels in diabetic patients, reducing the chance of cancer or decreasing the tumor, reducing inflammation, and enhancing the immune system [10]. Purple corn preservation is important especially because of the high amount of anthocyanin content (approx. 1642 mg per 100 g), the proper method is needed to avoid the degradation of the anthocyanin, which can easily be affected by pH levels, temperature, and light [10].

Young corn ears come from unfertilized cobs of corn crops, which are harvested before or right after the silk has emerged (about 1–3 cm) [12]. According to the Department of Agriculture, young corn sizes vary from 4 to 11 cm long and 0.8–1.8 cm in diameter, its color is slightly yellow to yellow. It is usually consumed as a vegetable due to its crisp texture. According to a study by [12], the protein and mineral levels in young corn cob is comparable to that of other vegetables such as cabbage, cauliflower, eggplant, and cucumber. Young corn cobs are also found to be highly perishable; therefore, the preservation method is crucial in maintaining its shelf life and keeping its nutrients intact [12].

In order to prevent microbial development and deterioration, prolong shelf life, reduce packaging, and improve storage for simple transportation, drying procedures can assist in reducing the amount of moisture of food items. Understanding the basic transport structure and properly simulating or scaling up the entire process for modification or control of the operational parameters requires thin layer drying of components [13]. Two key factors influence the intricate nature of heat and mass transfer processes in a typical drying operation. The raw material’s initial level of moisture as well as the drying air temperature medium have an impact on the final product’s quality. Additionally, taking this into account while designing dryers may lead to the best process design, reduced resource use, and greater profitability [13,14]. Thus, the goal of this work is to evaluate several simulation studies of drying kinetics of corn as well as address the influence of drying process factors on the quality of the product.

2. Effects of Process Parameters on the Drying Rate of Common Corn Crops

The drying process plays a crucial role in preserving the quality and extending the shelf life of agricultural products such as common corn. Understanding the effects of process parameters on the drying rate of corn is essential for optimizing drying operations and achieving efficient moisture removal. Researchers of this study will explore the effects of temperature, air velocity, relative humidity, corn size, and air pressure on the drying rate of corn.

Facilitating the drying of different corn varieties requires the use of various drying techniques and optimized drying parameters, which are influenced by the type of drying equipment employed. Each corn variety, due to its unique physical and chemical properties, responds differently to drying conditions such as temperature, airflow rate, and drying duration, as emphasized in Table 1 Therefore, selecting the appropriate combination of drying equipment and parameters is essential to ensure effective moisture removal while preserving the nutritional and physical quality of the corn. Table 2 presents a comparative overview of the drying parameters associated with different drying equipment used for various corn types. This includes the optimum temperature range, initial and final moisture levels, and equipment-specific features that contribute to drying efficiency.

Table 1.

Summary of drying results of different drying studies.

Table 2.

Summary of effects of process parameters on drying of corn.

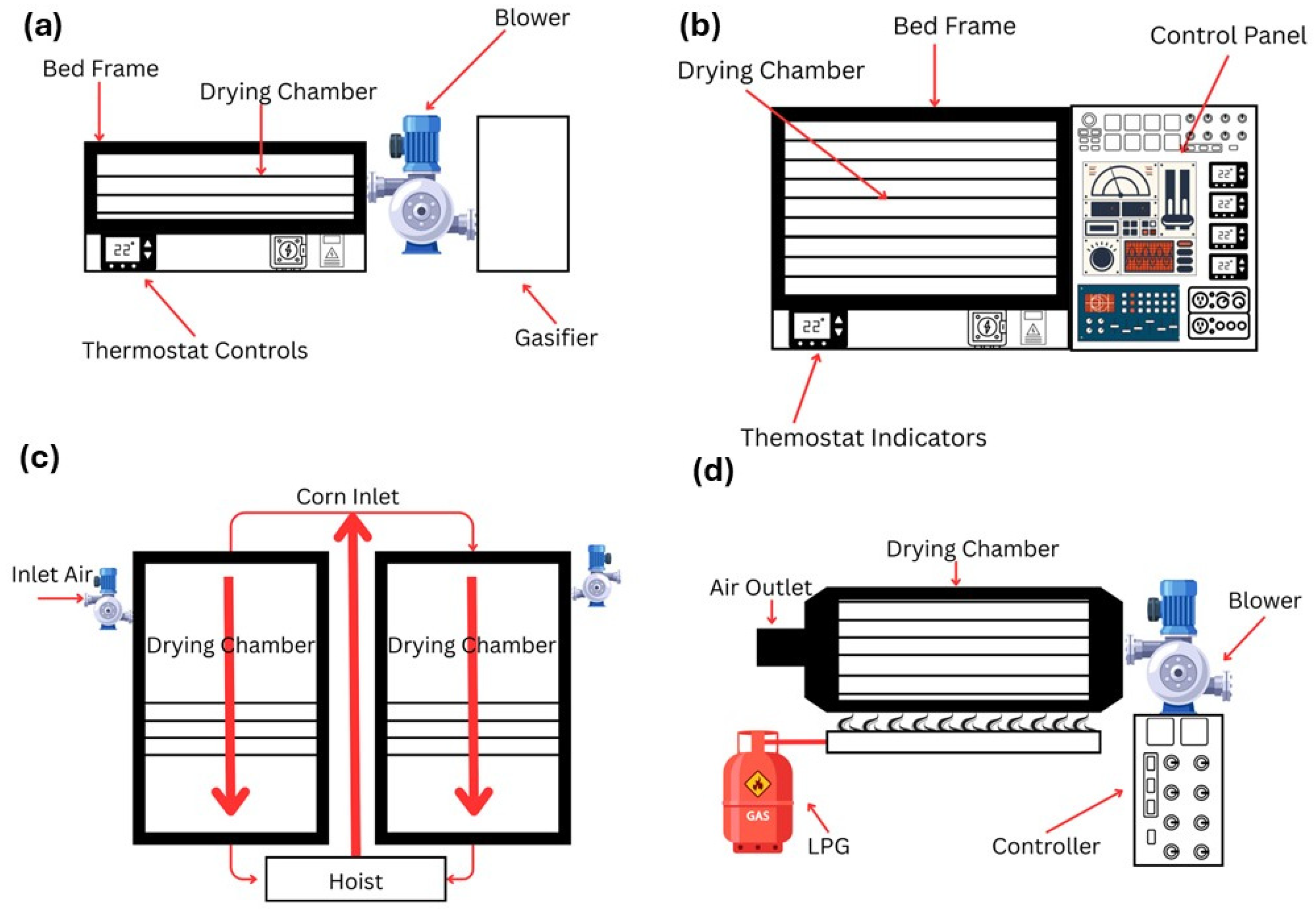

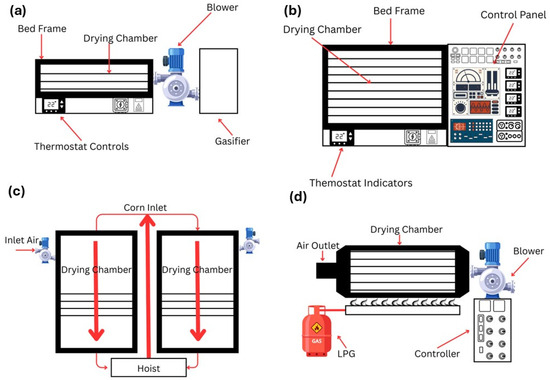

In addition, Figure 2 provides a schematic diagram of the drying equipment listed in Table 1. These diagrams illustrate the process flow and operating principles of each drying system, such as Bed Dryer, Microwave Dryer, Infrared Radiation-Counterflow Circulation (IRCC), and Hybrid Solar Dryer with Liquified Petroleum Gas (LPG) Dryer offering a visual representation of how heat and mass transfer occur during the drying operation. The schematics serve to clarify the role of each component in the drying process, highlighting differences in energy transfer mechanisms and drying efficiencies among the technologies.

Figure 2.

Schematic diagram and process flow of different drying equipment: (a) Bed Dryer, (b) Microwave Dryer, (c) Infrared Radiation-Counterflow Circulation (IRCC), (d) Hybrid Solar Dryer with Liquified Petroleum Gas (LPG) Dryer.

The study by Ogan [19], investigated the effects of temperature on the drying rate of corn. The findings revealed that as the temperature increased, the drying rate of corn also increased. This result suggests that temperature is a critical process parameter that significantly influences the drying rate of corn. Moreover, different optimal drying temperatures, depending on the type of dryer that was used, are presented in Table 1. These findings emphasize the importance of careful temperature control in corn drying processes to achieve efficient drying and minimize drying time. By optimizing the temperature, operators can enhance the drying rate and maintain the quality of corn crops.

Air velocity is another essential process parameter that impacts the drying rate of corn. Higher air velocities can enhance the rate of moisture evaporation from the corn surface, leading to faster drying. However, excessive air velocity may also cause undesirable effects such as damage to the corn kernels or uneven drying. Therefore, finding the optimal air velocity that ensures effective moisture removal without compromising corn quality is crucial. In a study, Tuncel et al. [20] explored the impact of air velocity on the drying rate of corn. The research demonstrated that higher air velocities resulted in increased drying rates. This phenomenon can be attributed to the enhanced airflow, which promotes effective moisture removal from the corn during the drying process. The study’s findings highlight the significance of air velocity as a crucial process parameter that can be optimized to improve the efficiency of corn drying. By controlling and adjusting the air velocity, operators can reduce drying time and maintain the quality of corn crops.

Relative humidity also plays a significant role in corn drying. A lower relative humidity promotes faster evaporation of moisture from the corn, resulting in a higher drying rate. However, maintaining excessively low relative humidity levels can cause excessive drying and adversely affect the corn’s texture and nutritional value. It is essential to strike a balance by controlling the relative humidity within an appropriate range to achieve optimal drying rates while preserving corn quality. The drying rates are highly affected by the humidity and moisture content of the materials [14]. In retrospect, the lower relative humidity levels facilitated faster drying rates. This can be attributed to the fact that reduced humidity creates a more favorable moisture gradient, allowing for efficient moisture transfer from the corn. Managing relative humidity during corn drying becomes crucial to enhance the drying rate and overall drying performance. By carefully controlling the humidity levels, operators can achieve efficient moisture removal and prevent undesirable quality changes in the corn crops.

The thickness of the corn layer being dried is another important process parameter. Sun et al. [21] examined the effects of corn kernel size on the drying rate of corn in their study. The research demonstrated that smaller-sized corn kernels exhibited faster drying rates compared to larger-sized kernels. This can be attributed to the larger surface area-to-volume ratio of smaller kernels, which facilitates more efficient moisture evaporation. The findings indicate that corn kernel size is an important factor to consider when optimizing drying processes for corn. Thicker corn layers generally have a slower drying rate due to the increased resistance to moisture diffusion. On the other hand, thinner corn layers allow for faster and more efficient drying. Therefore, optimizing the corn layer thickness during the drying process is crucial for achieving desired drying rates and minimizing drying time.

The initial moisture content of the corn also affects the drying rate. Corn with higher initial moisture content requires more time and energy to reach the desired moisture level. Therefore, starting with lower initial moisture content can result in faster drying rates and improved overall efficiency. A study by Wang et al. [1] found that increasing air pressure speeds up corn drying. Higher pressure enhances water molecule movement, leading to faster moisture removal. This research emphasizes the importance of air pressure control for efficient corn drying.

Understanding the effects of process parameters on the drying rate of common corn crops is crucial for optimizing drying operations and maintaining product quality. The reviewed literature demonstrates that temperature, air velocity, relative humidity, corn kernel size, and air pressure are important process parameters that significantly influence the drying rate of corn. By carefully controlling and adjusting these parameters, operators can achieve efficient moisture removal, reduce drying time, and maintain the quality of corn crops. Further research and experimentation in this field will contribute to the development of more effective and efficient drying techniques for common corn crops.

For small-scale farming, it is essential to adapt various types of dryers and customize drying parameters to meet local conditions and resource availability. Drying technologies, such as cabinet dryers, drum dryers, small batch microwave dryers, and hybrid solar-thermal dryers (integrated with LPG or biomass burners), offer practical and scalable solutions for smallholder farmers. These systems are not only cost-effective but also allow flexibility in operation, making them well-suited for the diverse needs of rural communities. Understanding the principles of drying kinetics such as moisture diffusion, temperature influence, and air flow, enables small-scale users to adjust drying parameters like temperature, air velocity, and drying duration. These adjustments are crucial to achieving optimal drying performance, minimizing energy use, and maintaining the nutritional and physical quality of the corn. By aligning these parameters with the specific characteristics of the corn variety and the environmental conditions farmers can enhance the drying process effectively.

3. Effects of Pretreatment on the Drying Rate of Common Corn Crops

Pretreatment methods play a crucial role in modifying the properties of corn prior to the drying process. The study conducted by Marzuki et al. [23] examined the effects of blanching pretreatment on the drying rate of corn. The findings revealed that blanching corn before drying led to faster drying rates compared to untreated corn. This improvement can be attributed to the blanching process, which involves submerging the corn in boiling water for a short period. Blanching ruptures cell structures and removes surface moisture, thereby facilitating efficient moisture evaporation during the subsequent drying process. The study suggests that blanching pretreatment can be an effective method to enhance the drying rate of corn.

Similarly, the study conducted by Wang et al. [22], investigated the impact of steam blanching pretreatment on corn drying rates. The results demonstrated that steam blanching significantly increased the drying rate of corn compared to untreated corn. Steam blanching effectively deactivates enzymes and disrupts cell structures, allowing for faster moisture removal during drying. This study highlights the potential of steam blanching as a pretreatment method to enhance corn drying efficiency. Osmotic dehydration pretreatment is another approach that has been studied for its effects on corn drying rates. Deng et al. [24] conducted a study to examine the influence of osmotic dehydration pretreatment on corn drying rates. The findings showed that osmotically dehydrated corn exhibited faster drying rates compared to untreated corn. Osmotic dehydration reduces the initial moisture content of the corn, creating a more favorable moisture gradient for drying. This pretreatment method has the potential to improve the drying rate of corn.

Microwave pretreatment has also been investigated for its impact on corn drying rates. Song et al. [3] conducted a study to examine the effects of microwave pretreatment on corn drying rates. The results indicated that microwave pretreatment significantly enhanced the drying rate of corn compared to untreated corn. Microwave heating rapidly generates internal heat within the corn, promoting faster moisture evaporation during drying. Microwave pretreatment holds promise as an effective method to improve corn drying rates.

Furthermore, the study conducted by Jiang et al. [25], focused on the influence of ultrasonic pretreatment on corn drying rates. The findings revealed that ultrasonic pretreatment resulted in faster drying rates compared to untreated corn. Ultrasonic waves effectively disrupt cell structures and promote moisture migration, facilitating more efficient moisture evaporation during drying. This study suggests that ultrasonic pretreatment can be a promising approach to enhance corn drying rates. Pretreatment methods such as blanching, steam blanching, osmotic dehydration, microwave pretreatment, and ultrasonic pretreatment have all shown potential to enhance the drying rate of common corn crops. These methods modify the properties of corn, such as cell structures and moisture content, prior to the drying process, leading to improved efficiency in moisture removal and reduced drying time. By optimizing these pretreatment methods, operators can achieve efficient moisture removal, reduce drying time, and maintain the quality of corn crops. Continued research in this field will contribute to the development of advanced drying techniques for common corn crops, further improving agricultural processing and maximizing overall efficiency.

4. Drying Kinetics Modeling of Common Corn Crops

In view of the complicated physical phenomena inherent in the drying process, the study of drying kinetics in common corn is of outstanding importance. Achieving optimal drying conditions for corn is of paramount importance to the agri-food industry, as it directly impacts equipment selection, design, and operation. However, conducting large-scale experimental trials to determine the most appropriate drying parameters involves significant costs. In this context, the use of drying kinetics modeling proves to be an indispensable tool that allows a quantitative and systematic understanding of the physicochemical transformations that occur during the drying process. Through careful analysis and determination of the best fitting kinetic model equation, precise drying methods can be identified, and the drying process effectively controlled to ensure the production of high-quality corn products. With such a professional approach, significant advances in the processing of corn crops can be achieved, resulting in the creation of high-quality corn-based raw materials for diverse applications across all industries. The resulting drying rate models for common corn are displayed in Table 3. In the kinetic modeling of common corn, particularly sweet corn, Weibull and Peleg [26] models were considered to describe the change in moisture content during rehydration. The general form of Weibull and Peleg models is shown in the following equations:

where Xwt, Xwo, and Xeq stand for the average moisture content at any given instant in time t, the beginning moisture content, and the equilibrium moisture content, respectively. For this model, α and β are used to denote the kinetic parameters. Following rehydration, the product will behave as shown by α. With a drop in value and vice versa, the initial rate of rehydration accelerates.

Table 3.

Summary of kinetic modeling of common corn crops.

The k1 parameter represents the Peleg rate constant, and the k2 parameter, which is connected to the equilibrium moisture content, represents the Peleg capacity constant.

The work of Uriarte-Aceves and Sopade [27], on the hydration kinetics of commercial white maize demonstrate that the Peleg model correctly predicted the white maize’s hydration kinetics. In the equation that follows, the general form of the Peleg model is displayed:

where Mt is the moisture content after time t, M0 is the initial moisture content (g/100 g solids), t is the soaking time (h), K1 is the Peleg rate constant, K2 is the Peleg capacity constant and the equilibrium moisture at t → ∞: the drying rate model was described in the study of thin layer drying kinetics of corn in the dryer by Akowuah et al. [28]. The general equation of the Midilli Kucuk model has been presented in the following equation:

where MR—moisture ratio; Mt—the moisture content on dry basis at any drying time; Me—the equilibrium moisture content on dry basis; Mo—the initial moisture content on dry basis.

The Lewis and Page model equation shown in the following equation was given in the study by Mondal et al. [29], on modeling the dehydration and color degradation kinetics of corn kernels for mixed-flow dryers.

where MR—moisture ratio and k are the drying constants.

From Kumar and Saha [30], the mathematical model used to study the drying kinetics of corn was the modified Page model.

Shown below is the equation on calculation of moisture content on dry basis:

wherein, Mt is the percent dry basis moisture content at time t, W0 is the initial weight of the sample in grams, W1 is the dry matter content of the sample in grams, and W is the amount of evaporated moisture in grams.

The study of Charmongkolpradit et al. [10], studied the effects of temperature in the preservation of anthocyanin from purple waxy corn using a tunnel dryer. The moisture content in from the grains of the corn was calculated in a wet basis equation:

wherein, Mw is the percent wet basis moisture content of the sample, W is the initial mass of the sample in kilograms, d is the dried mass of the sample in kilograms.

5. Conclusions

The drying process has an importance in maintaining quality and prolonging the shelf life of produce from agriculture like common corn. Studying about how parameters of the process affect drying rates of common corn crops is critical for controlling drying procedures as well as preserving the quality of the product. According to the reviewed literature, the temperature, airflow, humidity percentage, corn measurement, and air pressure are all vital variables in the process, which influence corn drying rate substantially. It can ensure efficient extraction of moisture, minimize drying time, as well as preserve corn crop quality by properly managing and changing these parameters as needed. More studies and testing in this area will help devise more efficient and effective drying procedures for common corn crops.

Furthermore, accurate techniques for drying can be established and the drying process effectively overseen by rigorous investigation and derivation of the best appropriate kinetic model equation to assure the manufacture of premium corn commodities. Significant advances in corn cultivation and processing can be made with such a professional approach, leading in the production of high-quality maize-based raw materials for broad applications throughout all industries.

It is recommended that industries adopt optimum drying procedures based on empirical models to improve product uniformity and energy efficiency. Researchers are encouraged to investigate advanced modeling methodologies and real-time monitoring technologies in order to develop sustainable and scalable drying systems for wide-ranging agricultural applications.

Author Contributions

Conceptualization, R.V.R. and A.S.; formal analysis, investigation, data curation, writing—original draft preparation, M.A.J., K.A.J., C.E.M. and M.A.P.; writing—review and editing, R.V.R. and C.E.; supervision, R.V.R., C.E. and A.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

We would like to acknowledge the support of Adamson University (AdU)-Chemical Engineering Department, and the De La Salle University (DLSU).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wang, H.; Zhang, S.; Fan, H.; Zhang, M.; Hu, N.; Yang, H. Modeling and experimental study on drying characteristics of corn particles with hot air in downward moving bed. Fluids 2023, 8, 63. [Google Scholar] [CrossRef]

- Song, G.; Choudhary, R.; Watson, D.G. Microwave drying kinetics and quality characteristics of corn. J. Agric. Biol. Eng. 2013, 6, 90–99. [Google Scholar]

- Singh, I.; Langyan, S.; Yadava, P. Sweet Corn and Corn-Based Sweeteners. Sugar Tech 2014, 16, 144–149. [Google Scholar] [CrossRef]

- Mabasso, G.A.; Siqueira, V.C.; Resende, O.; Quequeto, W.D.; Schoeninger, V.; Simeone, M.L.F.; Martins, E.A.S.; Crippa, D.S. The effect of intermittent drying with variable resting times on quality parameters of corn obtained after storage. LWT 2023, 182, 114855. [Google Scholar] [CrossRef]

- Owusu-Sekyere, E.; Obeng-Akrofi, G.; Akowuah, J.; Maier, D. Performance Analysis and Drying Kinetics of Maize in an AflaSTOP Dryer. Open J. Appl. Sci. 2021, 11, 327–342. [Google Scholar] [CrossRef]

- Types of Philippine Corn (Mais). Pepper. Ph. Available online: https://pepper.ph/blog/6-types-philippine-corn-mais (accessed on 26 July 2024).

- Collen, C. Wild Violet Sweetcorn Hits the Market. Fruitnet. 2020. Available online: https://www.fruitnet.com/eurofruit/wild-violet-sweetcorn-hits-the-market/180798.article (accessed on 26 July 2024).

- Hernandez, J.A.; Tuaño, A.P.P.; Juanico, C.B. Development and characterization of the nutritional profile and microbial safety of rice-nixtamalized corn grits blends as potential alternative staple for household consumption. Future Foods 2022, 5, 100127. [Google Scholar] [CrossRef]

- Cristianini, M.; Guillén Sánchez, J.S. Extraction of bioactive compounds from purple corn using emerging technologies: A review. J. Food Sci. 2020, 85, 862–869. [Google Scholar] [CrossRef]

- Char Mongkolpradit, S.; Somboon, T.; Phatchana, R.; Sang-aroon, W.; Tanwanichkul, B. Influence of drying temperature on anthocyanin and moisture contents in purple waxy corn kernel using a tunnel dryer. Case Stud. Therm. Eng. 2021, 25, 100886. [Google Scholar] [CrossRef]

- Kim, H.Y.; Lee, K.Y.; Kim, M.; Hong, M.; Deepa, P.; Kim, S. A Review of the Biological Properties of Purple Corn (Zea mays L.). Sci. Pharm. 2023, 91, 6. [Google Scholar] [CrossRef]

- Rosli, W.I.W.; Jauharah, C.M.Z.C.A.; Robert, S.D.; Aziz, A.I. Young corn ear enhances nutritional composition and unchanged physical properties of chiffon cake. APCBEE Procedia 2014, 8, 277–281. [Google Scholar] [CrossRef]

- Inyang, U.E.; Oboh, I.O.; Etuk, B.R. Kinetic models for drying techniques-food materials. Adv. Chem. Engineer. Sci. 2018, 8, 27–48. [Google Scholar] [CrossRef]

- Cosme-De Vera, F.H.; Soriano, A.N.; Dugos, N.P.; Rubi, R.V.C. A comprehensive review on the drying kinetics of common tubers. Appl. Sci. Eng. Prog. 2021, 8, 27–48. [Google Scholar]

- Karyadi, J.N.W.; Purnomo, A.; Masithoh, R.E.; Ayuni, D. Design of bed dryer for sweet corn seeds (Zea mays saccharata L.). IOP Conf. Ser. Earth Environ. Sci. 2021, 653, 12121. [Google Scholar] [CrossRef]

- Liu, H.; Liu, H.; Liu, H.; Zhang, X.; Hong, Q.; Chen, W.; Zeng, X. Microwave drying characteristics and drying quality analysis of corn in China. Processes 2021, 9, 1511. [Google Scholar] [CrossRef]

- Li, C.; Li, B.; Huang, J.; Li, C. Energy and exergy analyses of a combined infrared radiation-counterflow circulation (IRCC) corn dryer. App. Sci. 2020, 10, 6289. [Google Scholar] [CrossRef]

- Suherman, S.; Hadiyanto, H.; Yahya, H.F.; Rahayu, E.; Asy-Syaqiq, M.A.; Prasetiyono, B.W.H.E.; Setiadi, A. A study on the performance of corn grain dryer using hybrid solar drying with liquefied petroleum gas. Food Res. 2024, 8, 24–32. [Google Scholar] [CrossRef]

- Ogan, T.B. Effects of Temperature on the Drying Rate of Corn (Zea mays). J. Agric. Eng. 2021, 45, 112–120. [Google Scholar]

- Tuncel, N.B.; Yilmaz, N.E.Ş.E.; Kocabiyik, H.; Oztürk, N.; Tunçel, M. The effects of infrared and hot air drying on some properties of corn (Zea mays). J. Food Agric. Environ. 2010, 8, 63–68. [Google Scholar]

- Sun, L.-X.; Liu, S.-X.; Wang, J.-X.; Wu, C.-L.; Li, Y.; Zhang, C.-Q. The effects of grain texture and phenotypic traits on the thin-layer drying rate in maize (Zea mays L.) inbred lines. J. Integr. Agric. 2016, 15, 317–325. [Google Scholar] [CrossRef]

- Wang, H.O.; Fu, Q.Q.; Chen, S.J.; Hu, Z.C.; Xie, H.X. Effect of hot-water blanching pretreatment on drying characteristics and product qualities for the novel integrated freeze-drying of apple slices. J. Food Qual. 2018, 2018, 1–12. [Google Scholar] [CrossRef]

- Marzuki, S.U.; Pranoto, Y.; Khumsap, T.; Nguyen, L.T. Effect of blanching pretreatment and microwave-vacuum drying on drying kinetics and physicochemical properties of purple-fleshed sweet potato. J. Food Sci. Technol. 2021, 58, 2884–2895. [Google Scholar] [CrossRef] [PubMed]

- Deng, L.-Z.; Mujumdar, A.S.; Zhang, Q.; Yang, X.-H.; Wang, J.; Zheng, Z.-A.; Gao, Z.-J.; Xiao, H.-W. Chemical and physical pretreatments of fruits and vegetables: Effects on drying characteristics and quality attributes—A comprehensive review. Crit. Rev. Food Sci. Nutr. 2019, 59, 1408–1432. [Google Scholar] [CrossRef] [PubMed]

- Jiang, C.; Wan, F.; Zang, Z.; Zhang, Q.; Ma, G.; Huang, X. Effect of an ultrasound pre-treatment on the characteristics and quality of far-infrared vacuum drying with Cistanche slices. Foods 2022, 11, 866. [Google Scholar] [CrossRef]

- Nayi, P.; Kumar, N.; Kachchadiya, S.; Chen, H.-H.; Singh, P.; Shrestha, P.; Pandiselvam, R. Rehydration modeling and characterization of dehydrated sweet corn. Food Sci. Nutr. 2023, 11, 3224–3234. [Google Scholar] [CrossRef] [PubMed]

- Uriarte-Aceves, P.M.; Sopade, P.A. Hydration kinetics of commercial white maize (Zea mays L.) hybrids, and associations with grain intrinsic and wet-milling properties. J. Cereal Sci. 2021, 101, 103279. [Google Scholar] [CrossRef]

- Akowuah, J.O.; Bart-Plange, O.; Dzisi, K.A. Thin layer mathematical modeling of white maize in a mobile solar-biomass hybrid dryer. Res. Agr. Eng. 2021, 67, 74–83. [Google Scholar] [CrossRef]

- Mondal, M.H.T.; Akhtaruzzaman, M.; Sarker, M.S.H. Modeling of dehydration and color degradation kinetics of maize grain for mixed flow dryer. J. Agric. Food Res. 2022, 9, 100359. [Google Scholar] [CrossRef]

- Kumar, P.; Saha, D. Drying Kinetics of Maize Cob Using Mathematical Modelling. J. Agri. Eng. 2021, 58, 40–49. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).