Abstract

This study aims to preview the possibilities for the modernization of pumped hydro energy storage systems, using actual engineering tools. The survey starts with a detailed analysis of the existing approaches and practices. Furthermore, a detailed methodology is developed and commented on in detail. The major aim of this methodology is to evaluate both the technical and economic aspects of the modernization and to obtain maximal output of the system. The methodology involves the assessment of the current state of the art of the examined structures, using virtual prototyping techniques that are later combined with reliability prediction and failure modes and effects analysis, to be used together with a financial analysis of possible solutions. A primer of experienced damage in existing infrastructure further demonstrates the developed methodology. Its examination shows possible rehabilitation methods that are commented on and targeted for future detailed evaluation.

1. Introduction

Hydropower is the largest source of renewable energy generation and has been in use for over 100 years, generating clean and affordable energy. It is the largest low-carbon and renewable electricity technology, with 1397 GW of global installed capacity and 4,408 TWh of electricity generation in 2022 [1]. The pumped hydro energy storage systems (PHESSs) provide regulation, spinning reserve, and approximately 96% of utility-scale energy storage worldwide. Hydropower-generated electricity has and continues to make an essential contribution to the economy, increasing energy access, and meeting green energy policies. It remains the single largest source of renewable electricity and accounted for 16 percent of all electricity generated across the globe in 2019—more than all other renewable sources combined [2]. On other hand, the PHESS is an important electricity storage technology [3,4]. It is an important member of the electrical network and supports the energy transition as it increases the security of the fuel supply by reducing dependency on energy imports and ensuring price stability. Hydroelectrical storage also plays an important role in balancing the future electrical network that would consist mainly of renewable energy sources. Its flexibility allows the integration of the other types of green energy production such as wind and solar power plants, ensuring grid stability to guarantee that electric demand can be met consistently [5].

Since 1895, when the first hydroelectrical generation unit was implemented in the commercial plant of Niagara Falls, USA, followed by the first PHESS near Schaffhausen, Switzerland, the installations worldwide have grown increasingly [6]. Аlmost 50% of all hydraulic power plants (HPPs) worldwide were originally commissioned more than 40 years ago, and many are approaching a critical stage of ageing [7,8]. The European Union (EU) installations present a similar situation [9]: most of the EU hydropower fleet was commissioned in 1970–1980, with a current HPP average age of 46 years [7]. Half of the installations are more than 30 years old, and a third of them are more than 40 years old, resulting in reduced performance and reliability of components [2]. These facts require modernization of the existing PHESSs, in addition to the development of new ones, and this is of strategic importance at the global scale [10,11,12]. The European Commission (EC) funded project Hydropower Europe, estimating that between EUR 190 and 324 million needs to be invested by funding schemes in the following topics: flexibility, optimization of operation, and maintenance [13], resilience of electro-mechanical equipment, resilience of infrastructures and operation, environmentally compatible solutions [14], and mitigation of global warming impacts [1]. Modernization aims to upgrade turbines and other equipment, expanding the capacity and lifespan of existing hydropower facilities, and supports national and European targets related to renewable energy production, and thus contributes to combating climate change and the security of the energy supply objectives of the EU. This could be achieved using different modernization concepts: rehabilitation (improving the performance through equipment replacement with the same technology, thereby extending useful life) [15], upgrade (improving the energy production through implementation of technologically modern and more efficient equipment) [16,17], and optimized automation [18] (new monitoring systems to establish a predictive maintenance approach) [19,20,21,22,23]. Another review [7] divides the possible strategies for modernization into those aiming at increasing the usable discharge (Q-strategy); others consider the net head (H-strategy), the efficiency (η-strategy), or the fraction of the year during which the plant operates (t-strategy). The first strategy aims either an increase in the annual inflow, or an increase in the maximum flow that can be discharged during the peak hours. The H-strategy mainly consists in reducing head losses in waterways and in increasing the dam heightening. The η-strategy faces an increasing demand from turbine designs that allow a wider range of operations (from part load to full load). The t-strategy allows an increase in the annual operating hours, e.g., by reducing outage and maintenance, reducing manual operation activities and increasing the automatized ones (by implementing digitalization), improving operation under transient conditions, and reducing the duration of the start and stop cycle [7].

This study aims to present an innovative methodology for modernization of an existing hydropower unit (HU), a component of the pumped hydroelectric energy storage system. It could be classified, according to the above described systems, as universal, as it supposes rehabilitation, with upgrade and optimization of the system. It is more or less an η-strategy that is targeted to improve and optimize the performance, together with increasing its life span.

2. A Methodology for PHESS Modernization

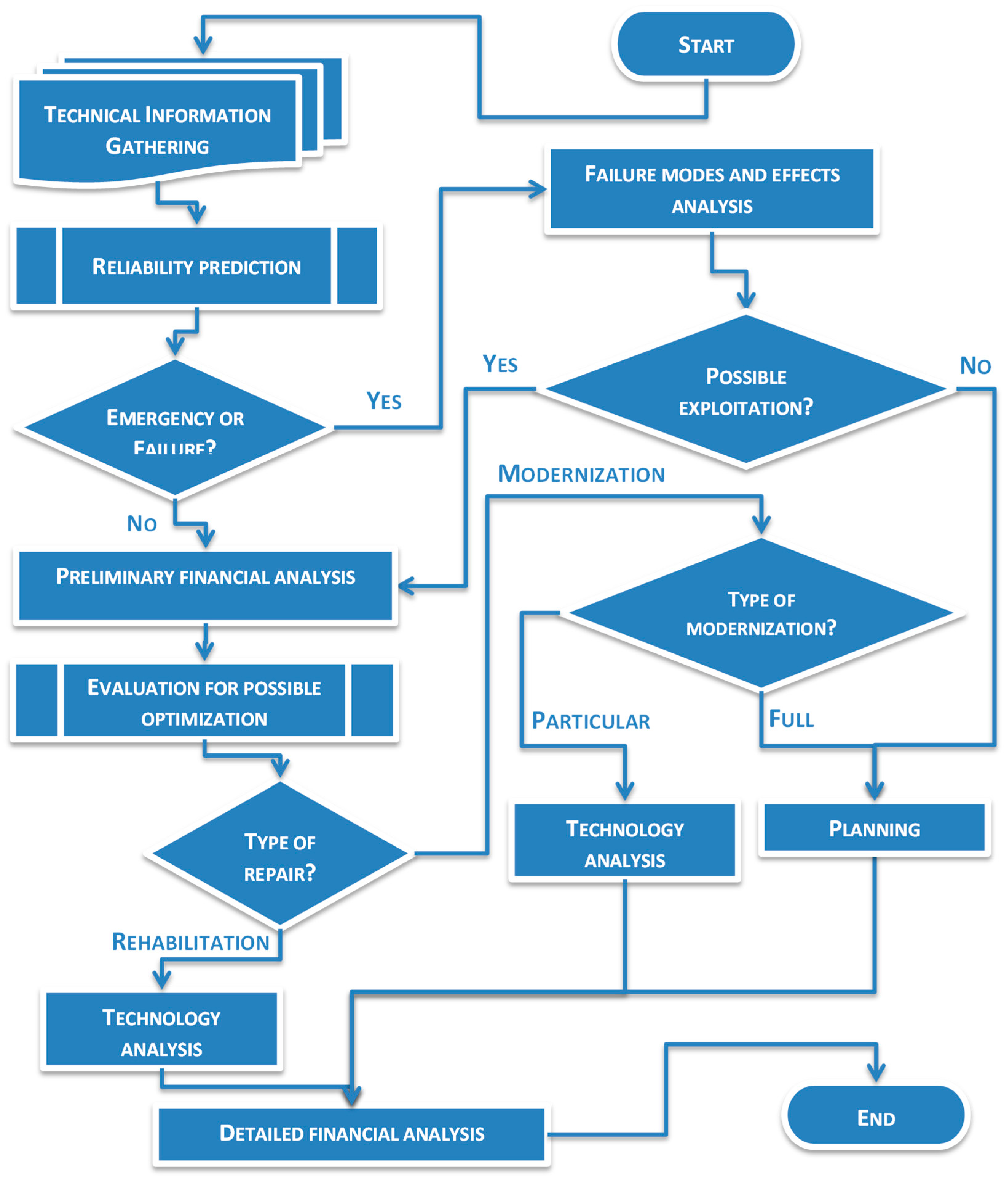

The review and analysis of existing methodologies, methods, and approaches for modeling and simulating such type of systems [24,25,26]—hydraulic turbomachines for electricity generation—led to the development of an innovative methodology for the modernization of the HU for electricity generation through engineering analysis. The methodology is schematized in the flowchart shown in Figure 1. Its major steps are as follows:

Figure 1.

Methodology for modernization of PHESS.

- Technical Information Gathering: It is planned to use a step-by-step approach when implementing the modernization of the HU, based on available technical data for the existing design of the system (drawings, technical documentation, reports, etc.), as well as information related to its previous operation (data logs from sensors and other devices, showing various work parameters).

- Reliability Prediction: The next step is related to the assessment of the residual resource of the hydraulic unit. It is related to the application of virtual prototyping technologies, allowing the possibility of further use of the facility to be assessed, and most importantly, for what period of time this is possible. This assessment also allows the identification of potential failure opportunities, as well as the preparation of a list of preliminary measures to restore the unit’s resource. This could be conducted through a detailed engineering analysis of HU system components, involving actual technologies as virtual prototyping to obtain input data for reliability prediction models. This system’s study is based on the knowledge of potential physics of failure and requires certain expertise.

- Check for Emergency or Failure: This step aims to assess the emergency of the current state of the PHESS. It is a crossroad for further actions and is based on the previous step data. This evaluation is based on expertise, inspection, and observations of the current state of all the components of the system. It uses also the data from the previous step, where the reliability parameters and, moreover, the remaining life resources of the system are considered. If it is concluded that the operational status of the system is not critical, the further steps are directed towards the optimization of its parameters. If there are any concerns about the safety of its operation, a detailed analysis of possible effects and their criticality needs to be conducted.

- Failure Modes and Effects Analysis (FMEA): In the event of a failure, an analysis of the possible reasons for its occurrence is performed. The results of this analysis provide valuable information that is used in the subsequent steps of the methodology. The analysis also provides information about the severity of the failure and whether repair is possible, or whether it is necessary to plan a complete modernization through a complete replacement of nodes or the entire hydro unit. FMEA or even FMECA (failure modes, effects and criticality analysis) are actual tools that are included in various standards to assure the safety of products and systems. This analysis could also be based also preliminary studies, such as fault tree analysis (FTA), which are prepared prior to starting HU exploitation.

- Preliminary financial analysis: When no failure in the functionality of the hydropower unit has been identified, or there is a possibility of its exploitation (with a certain time resource), a preliminary financial analysis is performed. This step aims to determine an important aspect of the future rehabilitation or modernization—the financial dimension. The results should give a clear perspective ahead of further refurbishment or modernization that demonstrates the balance between investments and future financial outcomes.

- Evaluation for possible optimization: An assessment of the possibilities for optimization of the system is performed, giving the technical dimension of the entire process. A subsystems design review is needed to indicate possible variants that will lead to improvement of overall HU performance. It will also indicate whether modernization or rehabilitation will be performed.

- Check for modernization or rehabilitation: Financial and technical information are decisive for choosing the type of repair—rehabilitation or modernization. Rehabilitation is the process of renovating the system to achieve its compliance with the set parameters of the facility. Modernization refers to a complete modernization of the hydraulic part of the HU, leading to an improvement in the operational parameters. The choice should be based on the technical parameters that indicate the possibility of implementing the specific type of repair, and the financial ones—showing the effectiveness of such a step.

- Technology analysis: If rehabilitation or partial modernization is planned, the feasibility of the planned repair activities should be assessed by performing a technological analysis. When carrying out a complete modernization, its planning should be carried out.

- Detailed financial analysis: Regardless of the type of renovation, the activities should be completed with a detailed financial analysis.

3. Application in Practice—Discussion

In many hydroelectric plants, major equipment such as turbines, generators, turbine shut-off valves, and pressure control valves use specific designs that are sized for the head, flow, and capacity of the particular installation. Therefore, replacement equipment will require specialized designs from experienced manufacturers.

Documentation may be limited for existing installations, especially older installations, and field conditions may differ from the information available. This can create significant challenges that are difficult to anticipate when installing new equipment into an existing structure. Retrofitting existing equipment can reduce the number and severity of conflicts resulting from changed or undocumented field conditions.

When an existing component is repaired or upgraded, its connections to other components and the structure are known, and the repair work can be managed to ensure that these interfaces are not affected. The existing design is usually proven through operation throughout its service life, and operational experience with the equipment can inform a repair and upgrade plan to address specific problems without changing parts of the design that are operating reliably. New design carries the risk of omitting an important aspect or feature that has allowed the equipment to operate safely and reliably.

Hydropower plants have unique equipment, making it difficult to maintain a set of spare or standardized parts, and therefore replacing them is inherently challenging.

Hydropower operators should consider repairing and upgrading existing components, as the alternative is complete replacement with new equipment, which can be a significant financial investment.

Although there are cases where complete replacement of components makes sense, it is desirable to conduct an assessment and evaluation to assist in making successful decisions.

3.1. A Primer

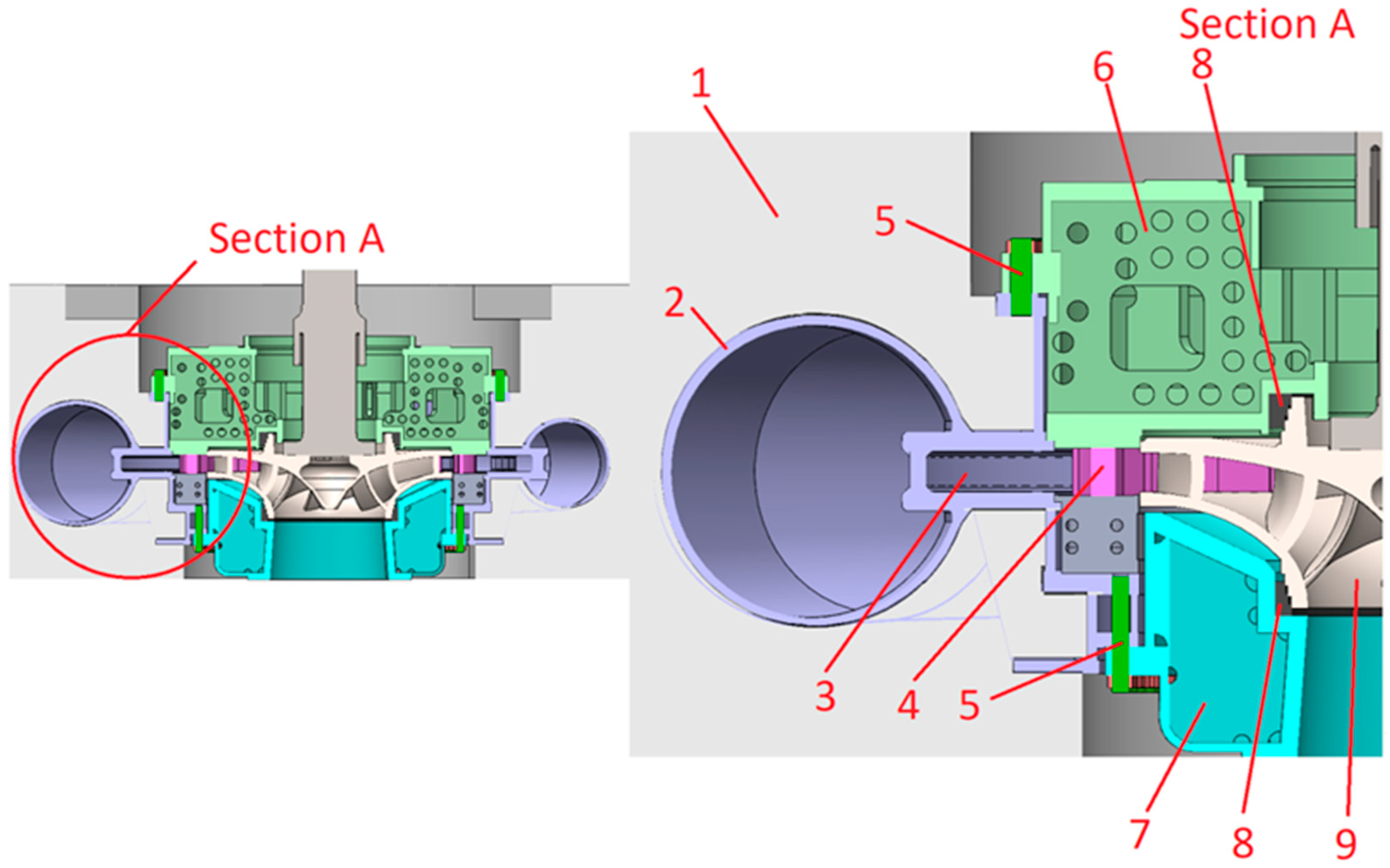

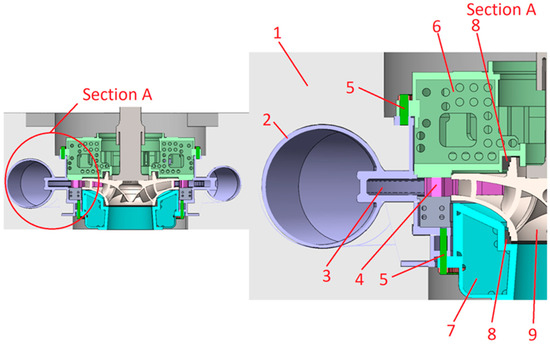

A typical example of a hydropower unit in a pumped hydro energy storage system is one using the Francis turbine—PHESS “Chaira” in Bulgaria. The first hydro unit of four in total for the PHESS “Chaira” began operation in 1992, and at that time it was one of the world’s largest heads. Usually, the Francis type of turbine is used for medium-head and relatively high-flow applications. Their special hydraulic characteristics result in relatively high-speed compact units. PHESS “Chaira” has a relatively high head, and it is a specific application of the Francis turbine and is used as a primer for the current study. The HU placement in the PHESS layout and the main components are shown in Figure 2. Typical failures of the main components of the hydraulic units are described as follows:

Figure 2.

PHESS layout and HU major components: 1—the concrete surrounding structure; 2—the spiral casing; 3—the stay vanes; 4—the guide vanes; 5—the bolts of the upper 6 and the lower 7 covers; 8—the seal; 9—the runner.

- Turbine runner: Various failures could occur with the components of the studied assembly. Mostly examined and rated are the failures of the turbine runner, and it is widely explored [27,28,29,30]. It is also the most important member of the efficiency definition of the system. Its design could be definitively a subject of optimization as the technology and design have been under intense development in recent years [31]. This component could be dismounted and could be either renovated or replaced.

- Guide vanes: These components are very close to the runner and have an influence over the system’s performance. They are used for regulation of the flow and generated power. Their failure mechanism could be related to the mechanism for their manipulation or to the structural damage over the vanes. Influences such as turbulence, secondary flow, leakage, and acceleration cause erosion in guide vanes. These failures are studied in various research works [32,33], together with the possibilities for design optimization [34].

- Stay vanes: They have structural influence over HU performance. Their force-deflection behavior is important and sometimes leads to failures [25]. Initiated cracks are very typical and lead to vibrations and are the usual reasons for repair and even for full rehabilitation [35]. Crack occurrence and propagation have been subjected to various studies over the years [36,37,38]. Numerous research studies have been conducted in the field of sediment erosion in hydro turbines, and this is another type of potential failure that needs repair [39]. Also, their design has been the subject of various studies, aiming to improve their performance as guides for the water flow [40,41].

- Concrete embedment: Recent incidents with the powerful PHESS of the Francis turbine type have imposed the necessity of a detailed analysis of the proper embedding of the spiral casing over the fundament of the HU and the reasons for its destruction [42]. Similarly, the most possible failures of the concrete embedment are related to cracks and to loosened contact with the spiral casing. It is important to note that this component is a subject of construction works, and its repair or optimization could be challenging, in addition to the recent technologies in the design of this component [43,44,45].

- Spiral casing: Spiral casing provides even distribution of flow at the inlet of the runner so as to achieve better performance of the runner [46]. This component is important for the overall performance of the HU and is also subject to failures. Cracks are usually initiated by starting from the stay vanes but could propagate through the spiral casing itself [47]. This component is tightly related to the concrete embedment, and its stress behavior depends on it [48].

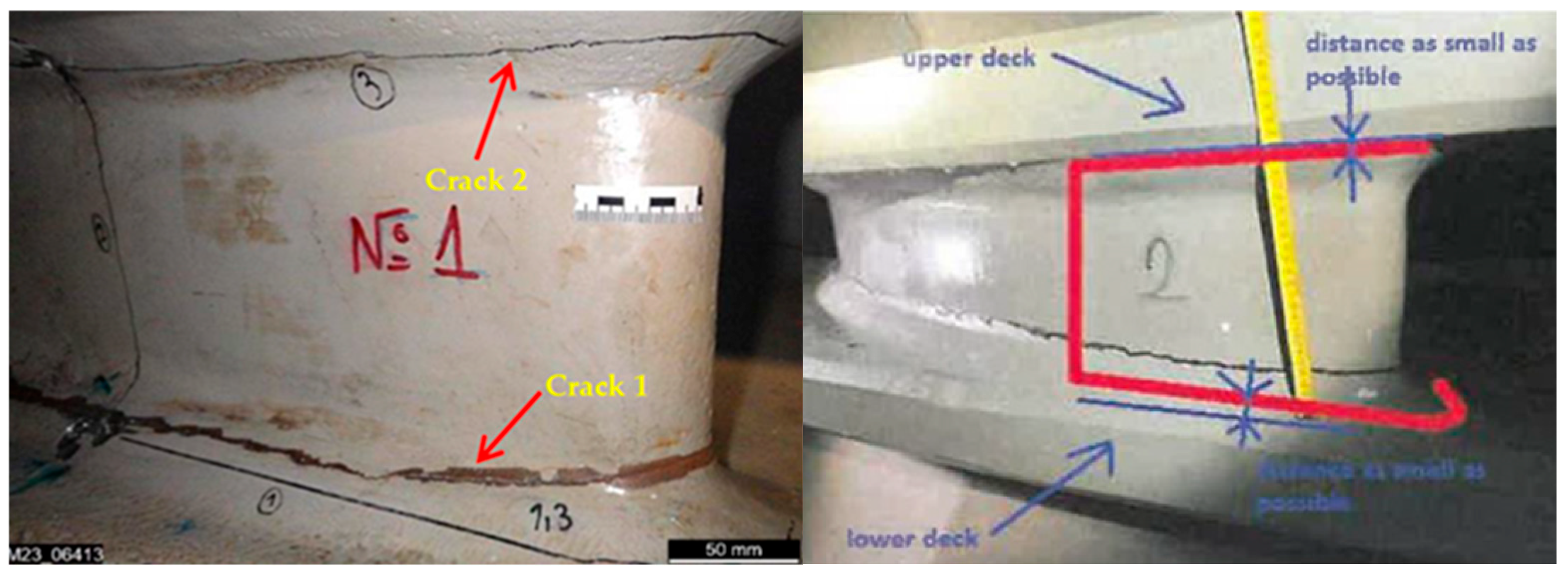

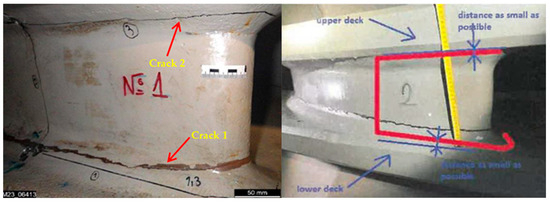

Further examinations are tightly related to the accident analysis of the PHESS “Chaira”, especially the failures of the Francis large-scale Hydraulic Unit No. 4 (HU4). The accident happened on 22 March 2022, when during the commissioning tests (75% load generator mode and generating power of 176 MW) of the unit increased noise and vibrations were detected, as well as an ingress of water in the turbine bearing. The block was stopped from the acceptance procedure. During a subsequent inspection a complete transversal failure of the integrity of eight out of ten stay vanes was detected, and the complete inoperability of HU4 was found (refer to Figure 3). The accident was investigated in detail and reported [25].

Figure 3.

PHESS “Chaira” HU4 investigation of stay vanes cracks.

The investigation was performed on the basis of the above-described methodology. It was started by a detailed review of the available technical information (data logs from sensors, observation reports, technical documentation, etc.), followed by a detailed reliability prediction analysis to determine the reliability parameters and the emergency of the failure. Failure modes and effects analysis was performed, as reported in [49]. The results give an answer to the question of the possibility of exploitation. The next steps, according to the developed methodology, are to perform a preliminary financial analysis and to evaluate the possible optimization. This is conducted by the owner, and it shows that further rehabilitation is a possible solution. The modernization is a possibility too, but the preliminary analysis shows that significant investments will be needed.

3.2. Technology Analysis

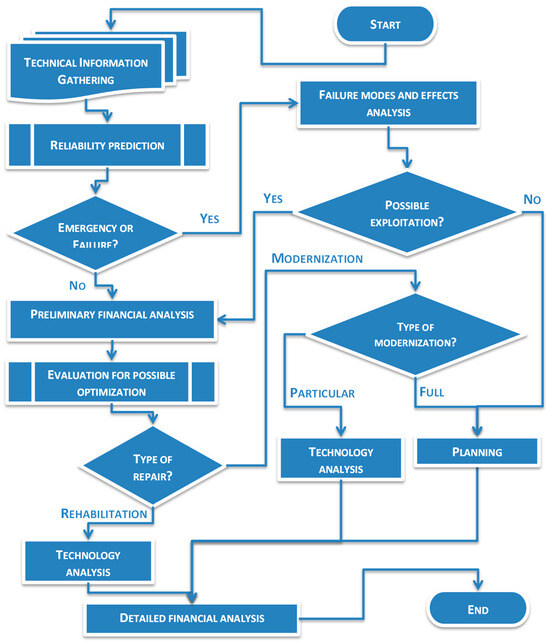

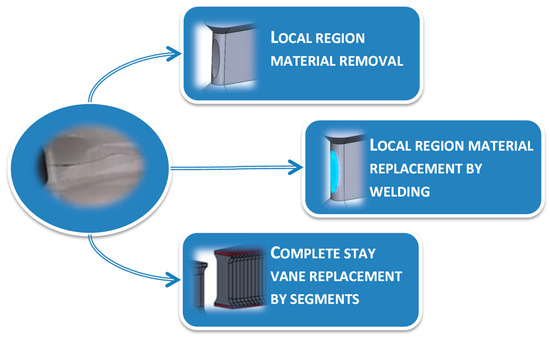

The performed technology analysis of the rehabilitation shows three possible options. They are shown in Figure 4 and are listed as follows:

Figure 4.

Possible rehabilitation of stay vane cracks.

- Local region material removal—This option aims to eliminate the material where the crack is propagated. The main target is to stop further crack propagation and to remove the stress concentrator. This solution requires detailed assessment of the capacity of the remaining material to withstand workloads. Usually, this is conducted using virtual prototyping to simulate the structural behavior of the stay vane under workloads. This also could affect the flow parameters of the stay vane, and additional computational fluid dynamics (CFD) simulations to evaluate the change in the shape of this component are required.

- Local region material replacement by welding—This option includes removing the compromised material and additional welding to restore the original shape. This typical procedure for stay vane repair relies on the substitution of the compromised material with new material, while also eliminating the crack. The controversial specifics of this type of repair are related to the question regarding the structural rigidity of the new design. This, again, could be evaluated by simulations of a prepared virtual prototype, aiming to determine the structural behavior of the new design.

- Complete stay vane replacement by segments—The third approach is to replace the complete stay vane. This technology is based on an initial cut of the entire stay vane and on additional welding of separate plates that form the stay vane. This multicomponent structure has a similar rigidity to the original one but requires more repair works. It is the focus for further research.

4. Conclusions

An analysis and evaluation of existing approaches for the modernization of pumped hydro energy storage systems were performed. The research included a wide review of the available research studies; it focused on the impacts of the modernization and reported on existing experience and possible applications. Furthermore, the developed methodology for PHESS modernization was presented. It gives a clear view of the various options and possible approaches to the repair, rehabilitation, or optimization of an existing system, using contemporary engineering tools as virtual prototyping.

The methodology described in detail is a basis for further studies, and this is demonstrated by a primer—a hydraulic unit modernization in PHESS “Chaira” in Bulgaria. The examined application concerns stay vane damage and its possible rehabilitation. This is a good demonstration and will be continued in detail in further studies.

Author Contributions

Conceptualization, G.T.; methodology, T.T. and K.K.; software, K.K.; validation, T.T. and K.K.; formal analysis, G.T. and T.T.; investigation, T.T.; resources, G.T. and T.T.; data curation, K.K.; writing—original draft preparation, K.K.; writing—review and editing, T.T. and K.K.; visualization, K.K.; supervision, G.T.; project administration, G.T.; funding acquisition, G.T. All authors have read and agreed to the published version of the manuscript.

Funding

This study is financed by the European Union-Next Generation EU, through the National Recovery and Resilience Plan of the Republic of Bulgaria, project No. BG-RRP-2.004-0005.

Informed Consent Statement

The data presented in this study are available upon request from the corresponding author.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to relation to public funding specifics.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| PHESS | Pumped Hydro Energy Storage Systems |

| HPP | Hydraulic Power Plants |

| EU | European Union |

| EC | European Commission |

| HU | Hydropower Unit |

| FMEA | Failure Modes and Effects Analysis |

| FMECA | Failure Modes, Effects and Criticality Analysis |

| FTA | Fault Tree Analysis |

| CFD | Computational Fluid Dynamics |

References

- Centre, J.R. Hydropower and Pumped Hydropower Storage in the European Union; Publications Office of the European Union: Luxembourg, 2023.

- Morgado, D.; Troja, N.; Kadyrzhanova, A.; Samuel, D. Hydropower Modernization Needs in Asia; Asian Infrastructure Investment Bank: Beijing, China, 2020.

- Huertas-Hernando, D.; Farahmand, H.; Holttinen, H.; Kiviluoma, J.; Rinne, E.; Söder, L.; Menemenlis, N. Hydro power flexibility for power systems with variable renewable energy sources: An IEA Task 25 collaboration. In Advances in Energy Systems: The Large-Scale Renewable Energy Integration Challenge, WIREs Energy and Environment; Wiley Online: Hoboken, NJ, USA, 2017; p. 240. [Google Scholar]

- Kougias, I.; Aggidis, G.; Avellan, F.; Deniz, S.; Lundin, U.; Moro, A.; Muntean, S.; Novara, D.; Perez-Díaz, J.I.; Quaranta, E.; et al. Analysis of emerging technologies in the hydropower sector. Renew. Sustain. Energy Rev. 2019, 113, 109257. [Google Scholar] [CrossRef]

- Peng, L.; He, G.; Lin, J. Role of Pumped Hydro Storage in China’s Power System Transition; Univerisity of California: Berkeley, CA, USA, 2024. [Google Scholar]

- Nikolaos, P.C.; Fafalakis, M.; Katsaprakakis, D. A Review of Pumped Hydro Storage Systems. Energies 2023, 15, 4516. [Google Scholar] [CrossRef]

- Quaranta, E.; Aggidis, G.; Boes, R.M.; Comoglio, C.; De Michele, C.; Patro, E.R.; Georgievskaia, E.; Harby, A.; Kougias, I.; Muntean, S.; et al. Assessing the energy potential of modernizing the European hydropower fleet. Energy Convers. Manag. 2021, 116, 114655. [Google Scholar] [CrossRef]

- Uria Martinez, R.; Johnson, M.; Shan, R. US Hydropower Market Report (January 2021 Edition); Oak Ridge National Lab. (ORNL): Oak Ridge, TN, USA, 2021. [Google Scholar]

- Kougias, I. Hydropower Technology Development Report 2018; EUR 29912 EN; Publications Office of the European Union: Luxembourg, 2019.

- Goldberg, J.; Espeseth Lier, O. Rehabilitation of Hydropower: An Introduction to Economic and Technical Issues; Water Papers; World Bank: Washington, DC, USA, 2011.

- Van Vuuren, S.J.; Blersch, C.L.; Van Dijk, M. Modelling the feasibility of upgrading hydropower to existing South African dams. Water SA 2011, 37, 679–692. [Google Scholar] [CrossRef][Green Version]

- Lia, L.; Aas, M.N.; Killingtveit, Å. Increased generation from upgrading and extension projects. Int. J. Hydropower Dams 2017, 24, 75–78. [Google Scholar]

- Mongird, K.; Viswanathan, V.; Balducci, P.; Alam, J.; Fotedar, V.; Koritarov, V.; Hadjerioua, B. An Evaluation of Energy Storage Cost and Performance Characteristics. Energies 2020, 13, 3307. [Google Scholar] [CrossRef]

- Koukouvinis, P.; Anagnostopoulos, J. State of the Art in Designing Fish-Friendly Turbines: Concepts and Performance Indicators. Energies 2023, 16, 2661. [Google Scholar] [CrossRef]

- Michel, B. Hydro turbines rehabilitation. In Encyclopédie de l’énergie; Association des Encyclopédies de l’Environnement et de l’Énergie: Grenoble, France, 2016. [Google Scholar]

- David, I.; Stefanescu, C.; Ioan, V. A simplified example to upgrading of a hydropower plant through re-equipment and extension with a pump-hydro-storage-unite. Trans. Hydrotech. 2020, 65. [Google Scholar]

- Rehman, S.; Al-Hadhrami, A.; Luai, M.; Alam, M. Pumped hydroenergy storage system: A technological review. Renew. Sustain. Energy Rev. 2015, 44, 586–598. [Google Scholar] [CrossRef]

- Bozorg-Haddad, O.; Ashofteh, P.-S.; Rasoulzadeh-Gharibdousti, S.; Mariño, M. Optimization Model for Design-Operation of Pumped-Storage and Hydropower Systems. J. Energy Eng. 2014, 140, 04013016. [Google Scholar] [CrossRef]

- Deane, J.; Ó Gallachóir, B.; McKeogh, E. Techno-economic review of existing and new pumped hydro energy storage plant. Renew. Sustain. Energy Rev. 2010, 14, 1293–1302. [Google Scholar] [CrossRef]

- Muntean, S.; Susan-Resiga, R.; Goede, E.; Baya, A.; Terzi, R.; Tîrşi, C. Scenarios for refurbishment of a hydropower plant equipped with Francis turbines. Renew. Energy Environ. Sustain. 2016, 1, 30. [Google Scholar] [CrossRef]

- Kiene, S.; Linkevics, O. Simplified Model for Evaluation of Hydropower Plant Conversion into Pumped Storage Hydropower Plant. Latv. J. Phys. Tech. Sci. 2021, 58, 108–120. [Google Scholar] [CrossRef]

- Malakov, I.; Zaharinov, V. Optimization of size ranges of technical products. Appl. Mech. Mater. 2016, 859, 194–203. [Google Scholar] [CrossRef]

- Vacheva, G.; Stanchev, P.; Hinov, N. Optimal Load Schedule in Medium Sized Enterprises. In Proceedings of the 16th Electrical Engineering Faculty Conference, BulEF 2024, Varna, Bulgaria, 19–22 September 2024. [Google Scholar]

- Mohammadi, M.; Hajidavalloo, E.; Behbahani-Nejad, M.; Mohammadi, M.; Alidadi, S.; Mohammadi, A. Francis Turbine Draft Tube Troubleshooting during Operational Conditions Using CFD Analysis. Water 2023, 15, 2794. [Google Scholar] [CrossRef]

- Todorov, G.; Kralov, I.; Kamberov, K.; Sofronov, Y.; Zlatev, B.; Zahariev, E. Investigation and Identification of the Causes of the Unprecedented Accident at the “Chaira” Pumped Hydroelectric Energy Storage. Water 2024, 16, 3393. [Google Scholar] [CrossRef]

- Dorji, U.; Ghomashchi, R. Hydro turbine failure mechanisms: An overview. Eng. Fail. Anal. 2014, 44, 136–147. [Google Scholar] [CrossRef]

- Frunzaverde, D.; Muntean, S.; Marginean, G.; Câmpian, V.; Marsavina, L.; Terzi, R.; Şerban, V. Failure analysis of a Francis turbine runner. IOP Conf. Ser. Earth Environ. Sci. 2010, 12, 012115. [Google Scholar] [CrossRef]

- Luna-Ramírez, A.; Campos-Amezcua, A.; Dorantes-Gómez, O.; Mazur-Czerwiec, Z.; Muñoz-Quezada, R. Failure analysis of runner blades in a Francis hydraulic turbine—Case study. Eng. Fail. Anal. 2016, 59, 314–325. [Google Scholar] [CrossRef]

- Saeed, R.A. Analysis of Fatigue Failure of Francis Turbine Runner at Derbendikhan Hydropower Station. Sulaimani J. Eng. Sci. 2017, 4, 7–13. [Google Scholar] [CrossRef]

- Adhikari, M.; Poudel, L. Fatigue Analysis of Francis Turbine Runner as a Result of Flow-induced Stresses. In Proceedings of IOE Graduate Conference, Pokhara, Nepal, 18 December 2019. [Google Scholar]

- Zheng, X.; Zhao, Y.; Zhang, H.; Pu, Y.; Li, Z.; Guo, P. Optimization and Performance Analysis of Francis Turbine Runner Based on Super-Transfer Approximate Method under Multi-Energy Complementary Conditions. Sustainability 2022, 14, 10331. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, Z. Failure mechanism of turbine guide vane and oxide composition analysis on the surface of failure vane cracks. Eng. Fail. Anal. 2020, 117, 104763. [Google Scholar] [CrossRef]

- Song, X.; Zhou, X.; Song, H.; Deng, J.; Wang, Z. Study on the Effect of the Guide Vane Opening on the Band Clearance Sediment Erosion in a Francis Turbine. J. Mar. Sci. Eng. 2022, 10, 396. [Google Scholar] [CrossRef]

- Koirala, R.; Zhu, B.; Neopane, H.P. Effect of Guide Vane Clearance Gap on Francis Turbine Performance. Energies 2016, 9, 275. [Google Scholar] [CrossRef]

- Neto, A.; Gissoni, H.; Gonçalves, M.; Cardoso, R.; Jung, A.; Meneghini, J. Engineering diagnostics for vortex-induced stay vanes cracks in a Francis turbine. IOP Conf. Ser. Earth Environ. Sci. 2016, 49, 072017. [Google Scholar] [CrossRef]

- Aronson, A.Y.; Zabelkin, V.M.; Pylev, I.M. Causes of cracking in stay vanes of Francis turbines. Hydrotech. Constr. 1986, 20, 241–247. [Google Scholar] [CrossRef]

- Goldwag, E.; Berry, D.G. Von Karman vortexes cause stay vane cracking on propeller turbines at the Little Long Generating Station of Ontario Hydro. ASME J. Eng. Power 1968, 67, 213–217. [Google Scholar] [CrossRef]

- Gummer, J.H.; Hensman, P.C. A Review of Stayvane Cracking in Hydraulic Turbines. Int. Water Power DamConstr. 1992, 44, 32–42. [Google Scholar]

- Noon, A.A.; Kim, M.-H. Erosion wear on Francis turbine components due to sediment flow. Wear 2017, 378–379, 126–135. [Google Scholar] [CrossRef]

- Singh, P.M.; Chen, Z.; Hwang, Y.-C.; Kang, M.-G.; Choi, Y.-D. Performance characteristic investigation and stay vane effect on Ns100 inline francis turbine. J. Adv. Mar. Eng. Technol. 2016, 40, 397–402. [Google Scholar] [CrossRef]

- Vu, T.; Nennemann, B.; Ausoni, P.; Farhat, M.; Avellan, F. Unsteady CFD Prediction of von Kármán Vortex Shedding in Hydraulic Turbine Stay Vanes. In Proceedings of the Hydro 2007, Granada, Spain, 15–17 October 2007. [Google Scholar]

- Todorov, G.; Kralov, I.; Kamberov, K.; Zahariev, E.; Sofronov, Y.; Zlatev, B. An Assessment of the Embedding of Francis Turbines for Pumped Hydraulic Energy Storage. Water 2024, 16, 2252. [Google Scholar] [CrossRef]

- Zhang, Q.L.; Wu, H.G. Embedment of steel spiral cases in concrete: China’s experience. Renew. Sustain. Energy Rev. 2017, 72, 1271–1281. [Google Scholar] [CrossRef]

- Zhang, Q.L.; Wu, H.G. Effect of compressible membrane’s nonlinear stress-strain behavior on spiral case structure. Struct. Eng. Mech. 2012, 42, 73–93. [Google Scholar] [CrossRef]

- Zhang, Q.L.; Hu, C.; Hu, L.; Wu, H.G. Compression-resilience responses of commonly used membrane materials in spiral case structures of hydroelectric power plants: Experimental investigation. J. Mater. Civ. Eng. 2018, 30, 06018005. [Google Scholar] [CrossRef]

- Dahal, D.R.; Chitrakar, S.; Kapali, A.; Thapa, B.S.; Neopane, H.P. Design of Spiral Casing of Francis Turbine for Micro Hydro Applications. IOP Conf. Ser. J. Phys. 2019, 1266, 012013. [Google Scholar] [CrossRef]

- Price, J.W. The failure of the Dartmouth turbine casing. Int. J. Press. Vessel. Pip. 1998, 75, 559–566. [Google Scholar] [CrossRef]

- Jena, J.; Basa, B.; Panda, S. Stress Analysis Arround Spiral Casing of Francis Turbine of a Hydel Power House by Finite Element Method. In Proceedings of the Conference: International Conference on Structural Engineering and Mechanics, Rourkela, India, 20–22 December 2013. [Google Scholar]

- Todorov, G.; Kralov, I.; Kamberov, K.; Sofronov, Y.; Zlatev, B.; Zahariev, E. Failure Modes and Effect Analysis of Turbine Units of Pumped Hydro Energy Storage Systems. Energies 2025, 18, 1885. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).