Abstract

Rapid prototyping, particularly in 3D printing, has highlighted the potential of ramie fiber as a reinforcing material for filaments. However, ramie’s high hydrophilicity limits its compatibility. Chemical treatments such as NaOH alkalization and CH3COOH acetylation improve its mechanical and hydrophobic properties. FTIR analysis confirmed successful modifications, showing reduced -OH groups and the formation of carbonyl bands, enhancing hydrophobicity. Delignification reduces lignin while preserving cellulose structure. These modifications improve ramie fiber compatibility with polymer matrices, making it suitable for eco-friendly 3D printing filaments with enhanced mechanical and hydrophobic properties.

1. Introduction

Rapid prototyping, more commonly known as additive manufacturing (AM), is a method of creating layers of material to create precision components and products [1]. Pressure filament extruders are particularly useful in screening composite filament compositions for 3D printing. These extruders provide a simple, fast, and inexpensive way to obtain filaments up to 1 m long [2]. The FDM technique is very popular for product prototyping as a manufacturing process for industrial applications because it is easy to use, has low operating costs, and is environmentally friendly [3].

Ramie fiber, known for its high cellulose content (68–76 wt%) and impressive tensile strength (above 120 MPa), is a promising material for composite applications, particularly for enhancing mechanical durability. In the preliminary study of fragment simulating projectile (FSP) on epoxy-ramie composites, the strong mechanical properties of ramie fiber contributed to the composite’s ability to withstand ballistic impacts. However, the tests revealed that the ramie-epoxy composite failed upon impact, demonstrating the material’s limitations despite its potential to increase mechanical durability [4,5]. Mechanical performance is improved by the chemical treatment of fibers, which has a positive effect on the load transfer capability of the interfacial polymer. The increase in interfacial strength is influenced by the increase in cellulose so that the fiber becomes stronger [6]. Alkalization treatment changes the nature of natural fibers from hydrophilic to hydrophobic. This process removes lignin (wax) and hemicellulose from the fibers, resulting in a wax-like layer on the fiber surface. This layer can disrupt the bond between the fiber and the resin, making it imperfect [7]. However, the adhesion between the fiber and the matrix needs to be improved because the alkalization process alone is insufficient. For this reason, additional modification processes to the fibers need to be carried out. The weak interfacial bond between the fiber and matrix must be repaired by further processing. One process that can be used is acetylation. Acetylation treatment changes the nature of natural fibers from hydrophilic to hydrophobic. This process is carried out by adding reagents containing acetyl groups (CH3CO), such as acetic acid (CH3COOH) or acetic anhydride (CH3CO)2O. A chemical reaction occurs between the acetyl groups and the cellulose fibers, and also removes the hydroxyl groups in the fibers. As a result, the hydrophilic properties (ability to absorb water) of natural fibers are reduced. The acetylation treatment of natural fibers increases dimensional stability. Natural fibers that have been acetylated become more resistant to changes in shape and size due to changes in water content. By increasing resistance to environmental degradation, acetylation protects natural fibers from damage caused by fungi, bacteria and other microorganisms [8]. So the aim of this study is to determine the effect of alkalization using NaOH and acetylation with CH3COOH on the chemical structure, crystallinity, and hydrophobic properties of natural fibers for environmentally friendly 3D printing filament applications. The novelty of this study lies in the combined use of alkalization and acetylation treatments to enhance the properties of ramie fibers for environmentally friendly 3D printing filaments. By addressing the challenges of hydrophilicity and weak adhesion with the polymer matrix, this dual-treatment approach aims to improve the chemical structure, crystallinity, and hydrophobicity of ramie fibers. This study also emphasizes the potential environmental benefits and functional advancements of treated fibers, aligning with the growing demand for sustainable materials in additive manufacturing. The focus is to explore how these treatments influence the performance of ramie fibers, contributing to the development of high-quality, eco-friendly filaments for industrial applications.

2. Research Tools and Materials

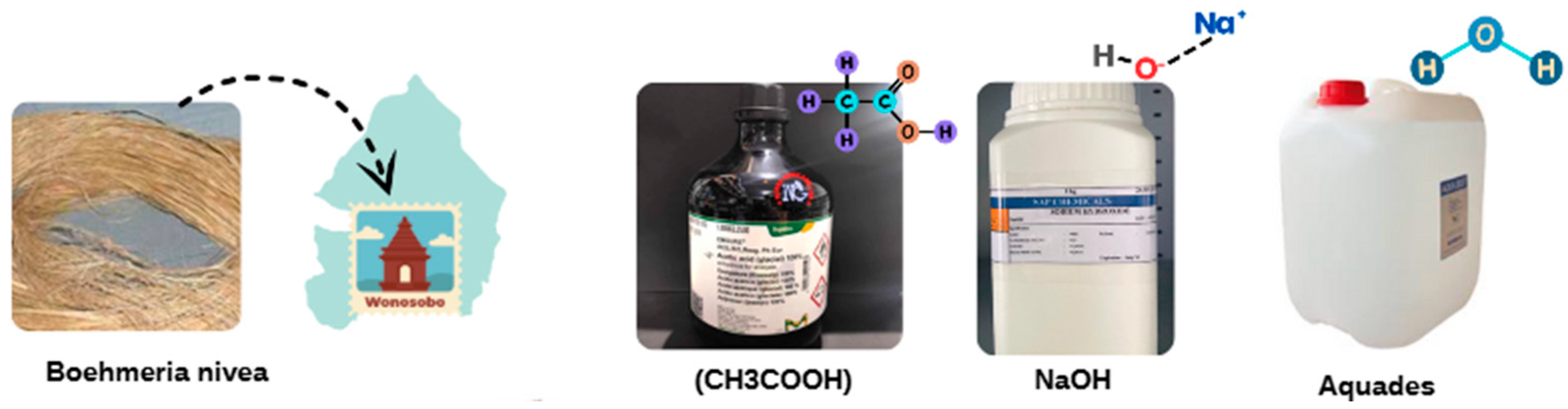

Figure 1 presents the materials in this study. The materials used in this study include ramie fiber (Boehmeria nivea) from Wonosobo, Central Java, spun manually as the main material. Polycaprolactone (PCL) with a molecular weight of 65,000 g/mol and a density of 1.2, obtained from Hengshui Haoye CO., LTD. (Hengshui, China) was used in the form of white pellets with a melting point of 60–62 °C. Acetic acid (CH3COOH) with a concentration of 5% was used in the acetylation process to modify the fiber. Maleic Anhydride is a mixture of polymer and fiber. In this study, 5% NaOH was used in the alkalization process of ramie fibers to increase their absorption and mechanical strength, while distilled water was used as a solvent to rinse the fiber after the alkalization process. Cardboard functioneds as a material to make grips in the fiber tensile testing. TEA was used as a solvent in the dilution of PCL with Maleic Anhydride.

Figure 1.

Research materials used.

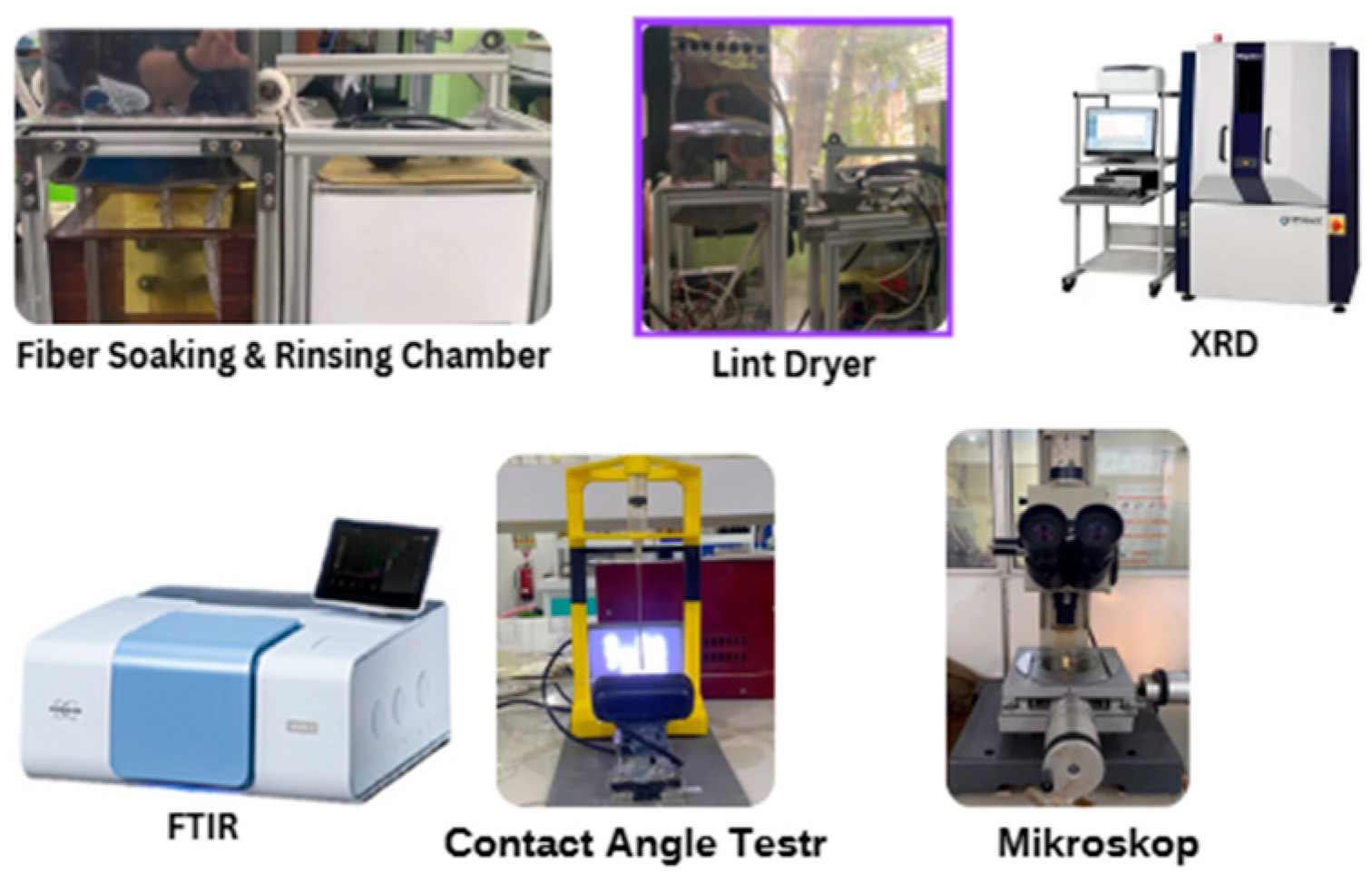

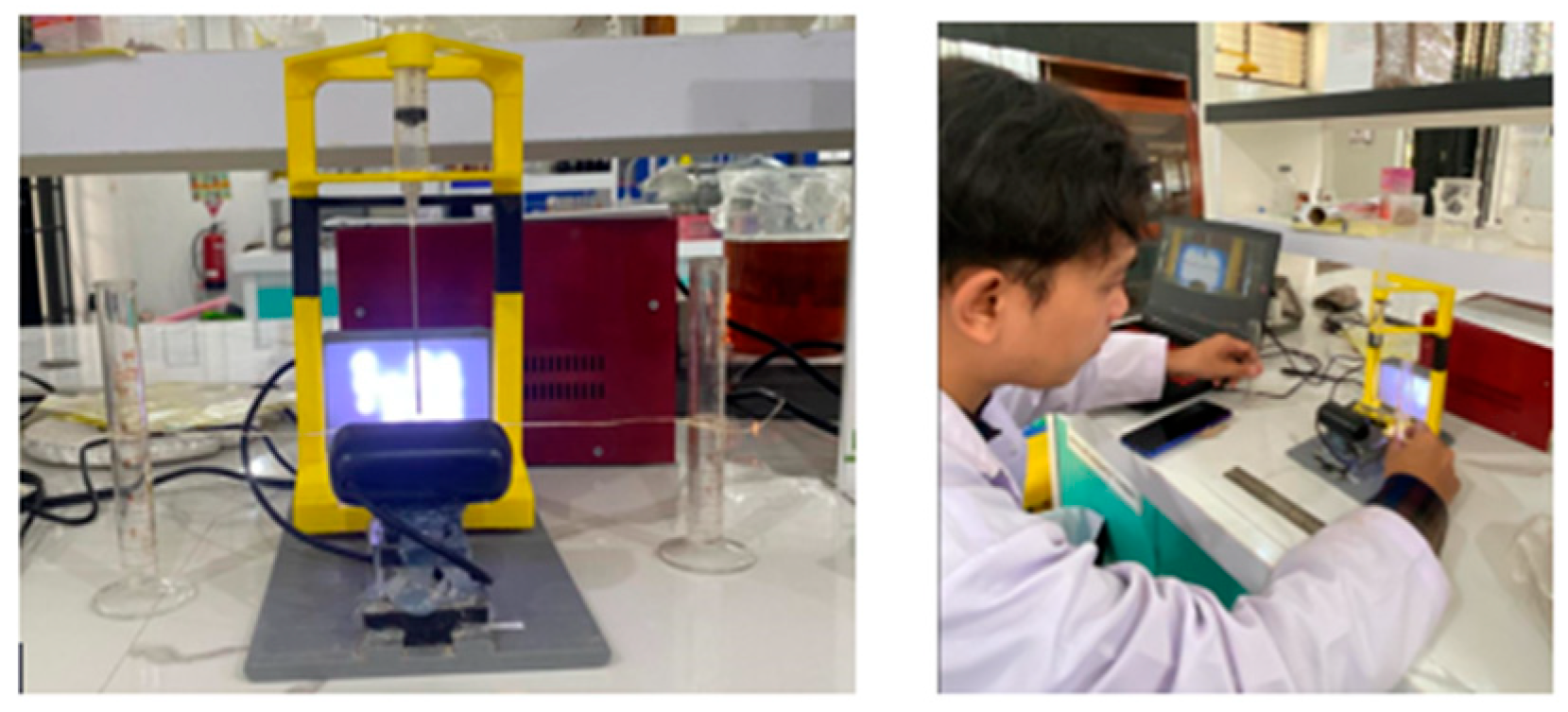

Figure 2 shows the tool used. The research procedure involved several important stages in the treatment of hemp fiber and filament formation. These were hemp fiber alkalization treatment, hemp fiber acetylation treatment, FTIR testing, XRD, contact angle, and morphology surface.

Figure 2.

Tools used.

3. Research Methods

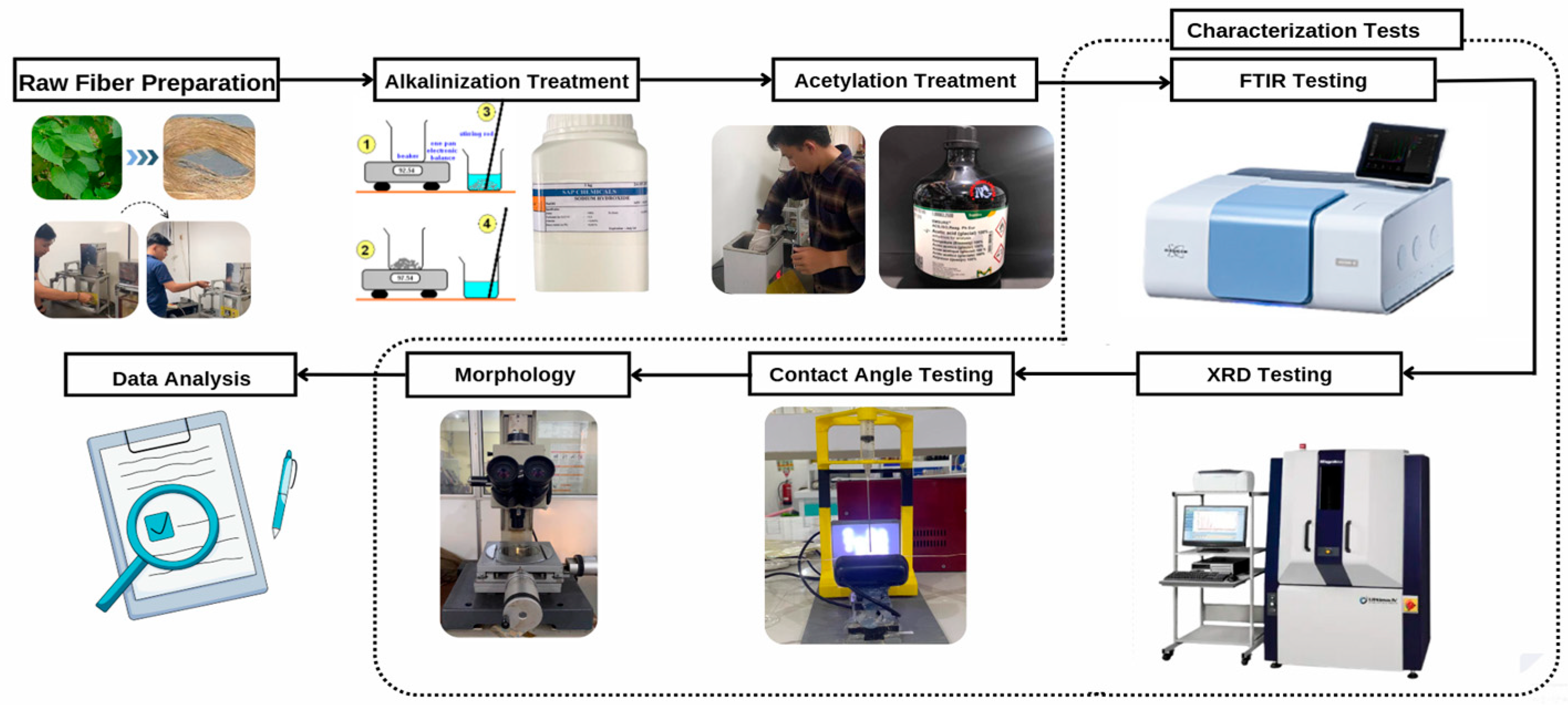

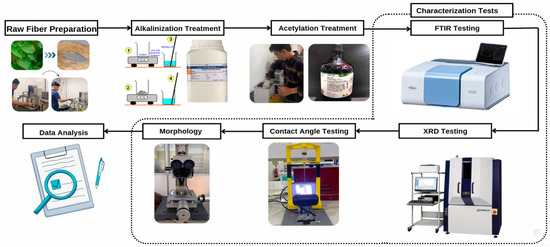

Figure 3 shows a flow diagram of the research process. The preparation of raw fibers began with cleaning and initial measurements, followed by an alkalinization treatment where the fibers were immersed in 5% NaOH for delignification. This was followed by an acetylation treatment, where the fibers were immersed in 5% CH3COOH to enhance hydrophobicity. Characterization tests were then conducted, including FTIR testing to analyze chemical bonds, XRD testing to assess crystallinity and structural changes, and contact angle testing to evaluate surface wettability. The data analysis compares the performance of treated versus untreated fibers to determine the effectiveness of the treatments.

Figure 3.

Flowchart research process.

3.1. Alkalization Treatment

Figure 4 shows the alkalization process. Alkalization treatment is one type of chemical modification of the reinforcement, however, the, chemical modification of the reinforcement can also be peformed using NaOH solution. The alkalization process also plays a role in increasing cellulose levels and reducing hemicellulose and lignin levels so that it can increase the strength of hemp fiber yarn [9]. Based on previous research, optimal delignification at a NaOH concentration of 5% has good interfacial properties [10].

Figure 4.

Alkalization process of hemp fiber.

3.2. Hemp Fiber Acetylation Treatment Procedure

Figure 5 shows the acetylation process of the hemp fiber that underwent alkalization. The acetylation treatment process on natural fibers uses the addition of reagents with acetyl groups (CH3CO) such as; acetic acid (CH3COOH). A reaction occurs between the acetyl group and cellulose fibers, as well as a reaction to remove the hydroxyl group content which results in reduced hydrophilic properties/reduced water absorption in natural fibers [11]. The results showed that the natural rubber-coconut fiber composite treated with 5% acetylation chemical treatment had the highest strain value (62.11%) compared to the 10% and 15% treatments [12].

Figure 5.

Acetylation Process.

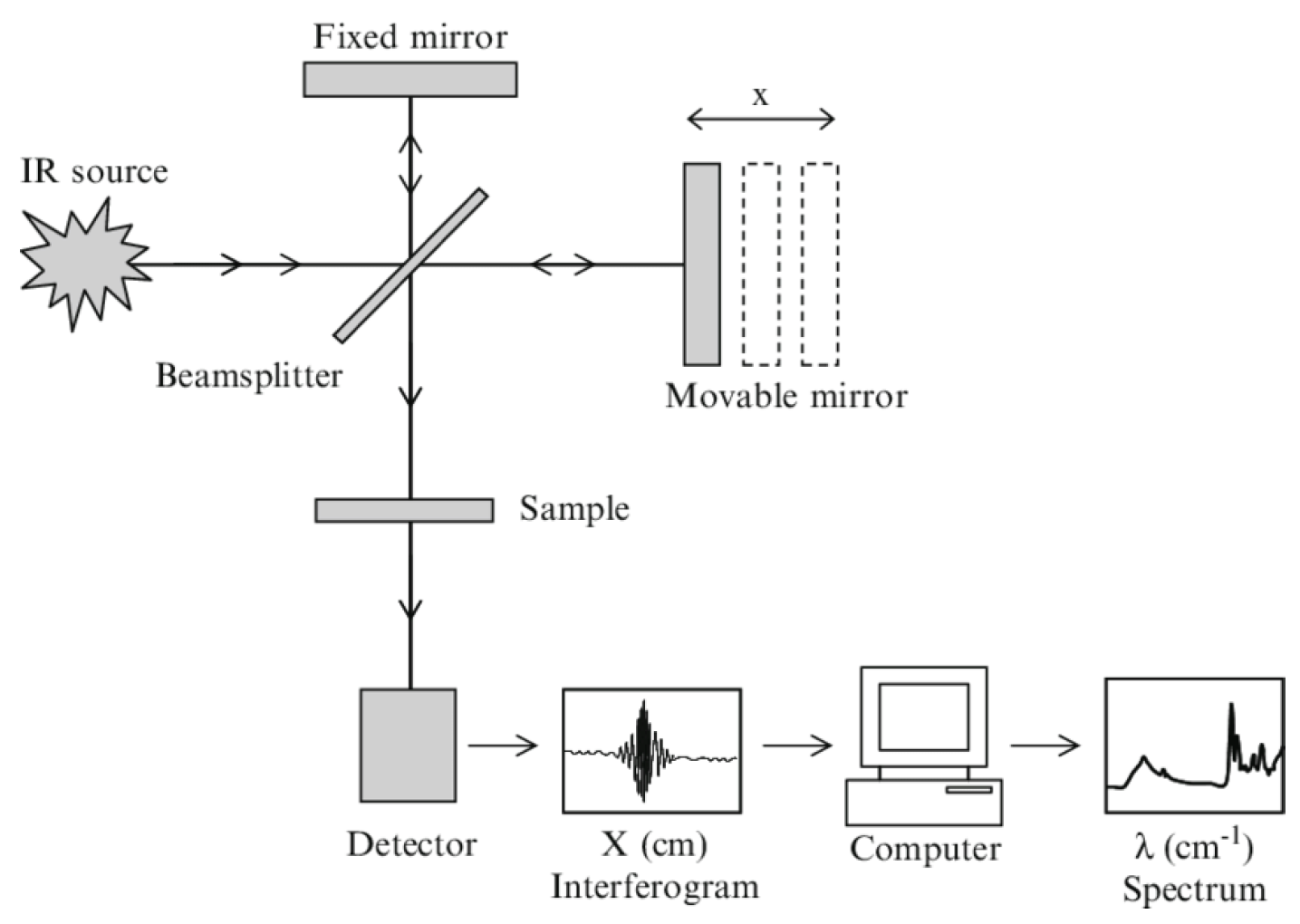

3.3. FTIR Test

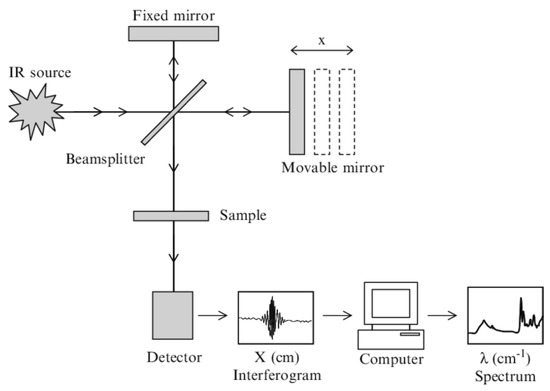

The FTIR testing in this study was carried out on filament specimens with and without treatment. FTIR testing was carried out to determine the chemical composition and chemical bonds contained in the hemp fiber filament. Chemical bonds in hemp fiber filaments can be identified by the wavenumbers produced. The standard used in FTIR testing of hemp fiber yarn is ASTM E1252 [13]. To obtain optimal characterization results in this test, a wavelength in the range of 400–4000 cm−1 was used. In FTIR, the sample is irradiated with infrared radiation and the sample absorbs radiation in the infrared light region. When there is resonance between the frequency of IR radiation and molecular vibrations, it causes a change in the dipole moment during the vibrations obtained, which is observed through infrared radiation.

Figure 6 shows a process scheme of FTIR. X-ray diffraction (XRD) is used to characterize material properties such as crystal structure and crystallite size [14]. A crystallinity test on the hemp fibers was conducted to understand the molecular structure and strength of the material. Crystallinity refers to the nature of the material that has a regular and organized molecular arrangement in the form of crystals. In natural fiber reinforcement fibers, crystallinity is very important because it can affect their physical and mechanical properties. The crystallinity index value (Crl) is obtained by the following equation.

where the diffraction intensity determined for the cellulose plane is the intensity measured at the crystalline peaks 2θ = 14.8°, 16.8°, and 22.8°. In addition, to find out the distance between crystal planes, you can use the following equation.

Figure 6.

Fourier transform infrared spectroscopy (FTIR) Scheme [15].

For composite applications, the crystallinity value of cellulose is an important parameter to determine the strength and stiffness of a fiber. Based on research conducted by Cai, (2016) using abaca fibers, the results of the XRD testing showed the intensity of wave reflection on the (101) and (002) planes [14].

3.4. Contact Angle Testing

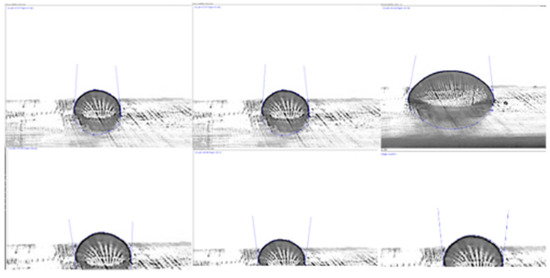

Figure 7 show the process of measuring the contact angle. Contact angle testing is carried out on hemp fiber yarn filaments. The purpose of contact angle testing is to determine the wettability properties of the hemp fiber yarn filament surface. The related wettability properties are used to provide an estimate of how far the matrix can spread and bond with the fibers when made into a composite.

Figure 7.

Contact angle testing.

4. Results and Discussion

4.1. Fiber Function Group

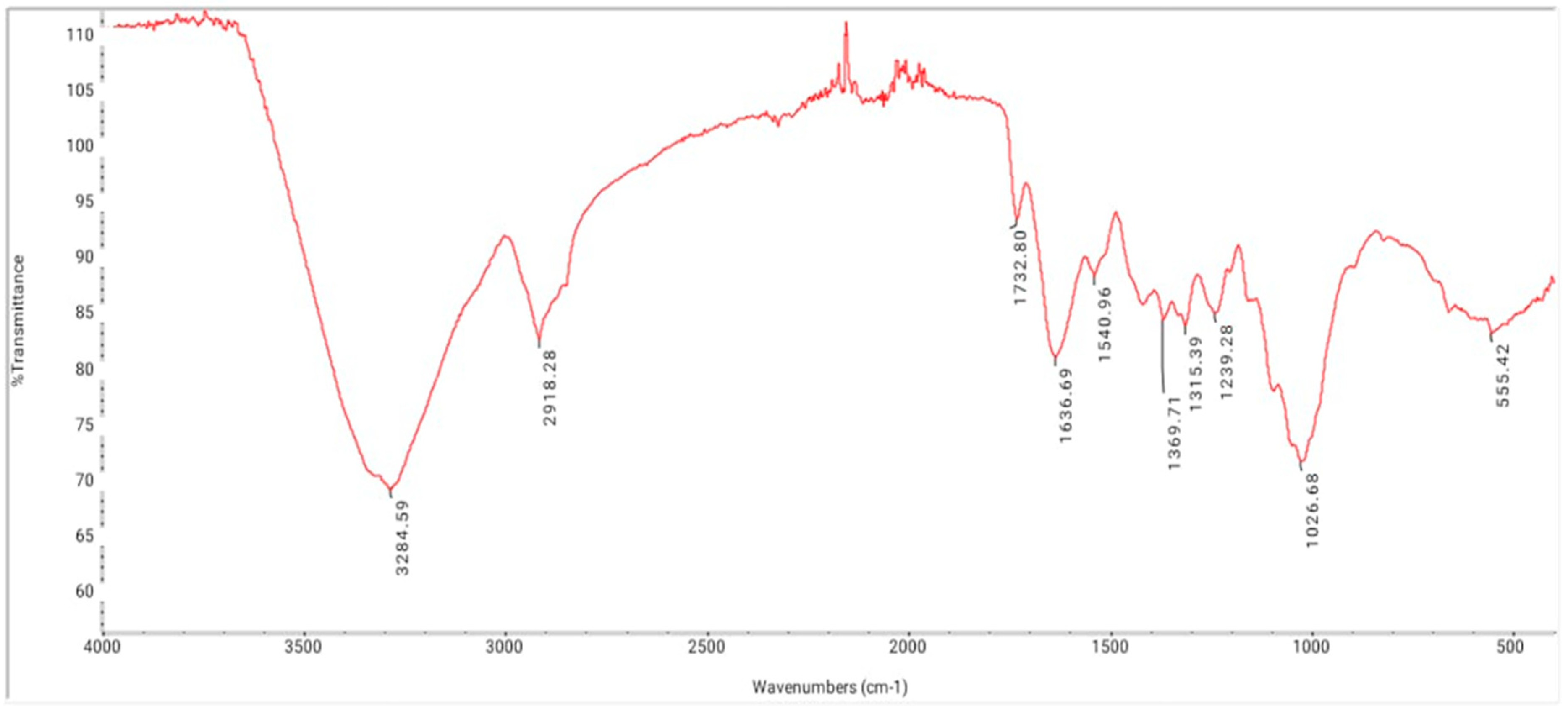

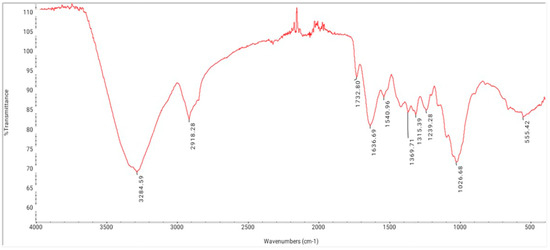

Figure 8 show a graph of the FTIR test results, while Table 1 shows a description of each wavenumber. The FTIR spectrum analysis of hemp fibers that have underwent delignification using NaOH solution and acetylation with CH3COOH shows significant success of chemical modification. The absorption band at 3284.59 cm−1 indicates the presence of hydroxyl groups (-OH) from cellulose or hemicellulose. The decrease in the intensity of this band after the acetylation process indicates that the hydroxyl group is involved in the acetylation reaction, which is in line with studies showing changes in the -OH group during chemical modification [16]. The absorption band at 2918.28 cm−1 is related to the C-H stretching of the methyl or methylene groups in cellulose, confirming that the organic structure of the hemp fiber is maintained even after modification [17]. The success of the acetylation process is indicated by the appearance of a carbonyl band (C=O) at 1732.80 cm−1, which indicates the formation of an ester from the acetylation reaction, consistent with the results of other studies that noted an increase in the carbonyl band as an indication of successful acetylation [18]. The C-O ester stretching band at 1239.28 cm−1 indicates the presence of ester bonds, strengthening the evidence that chemical modification has occurred and indicating the new properties of the ramie fiber after the acetylation process [19]. The delignification process is seen from the decrease in the intensity of the lignin aromatic band at 1540.96 cm−1, which indicates a significant reduction in lignin. Previous studies have also shown that the delignification process with NaOH is effective in reducing lignin content [20]. The band at 1636.69 cm−1 indicates the presence of bound water in the fiber structure, which plays an important role in the hygroscopic properties of ramie fiber; the presence of bound water may affect the interaction of fiber with the polymer matrix in subsequent applications [21]. The band at 1026.68 cm−1 represents the C-O-C stretch in the cellulose structure, indicating that the basic structure of cellulose is maintained even after modification [22]. Overall, the FTIR analysis confirmed that the delignification process significantly removed lignin and that the acetylation process produced esters that improved the hydrophobicity of the hemp fibers. This modification makes the hemp fibers more compatible with polymer matrices, making them potentially useful for applications such as 3D printing filaments [23].

Figure 8.

FTIR test results obtained by functional groups of ramie fibers under alkalization and acetylation treatment.

Table 1.

FTIR wavenumber analysis of chemical modifications in ramie fiber: presence of functional groups and structural changes.

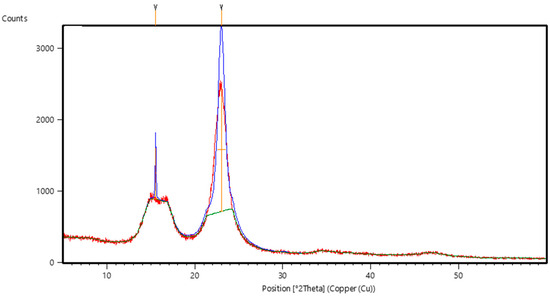

4.2. Kristalinitas Fiber

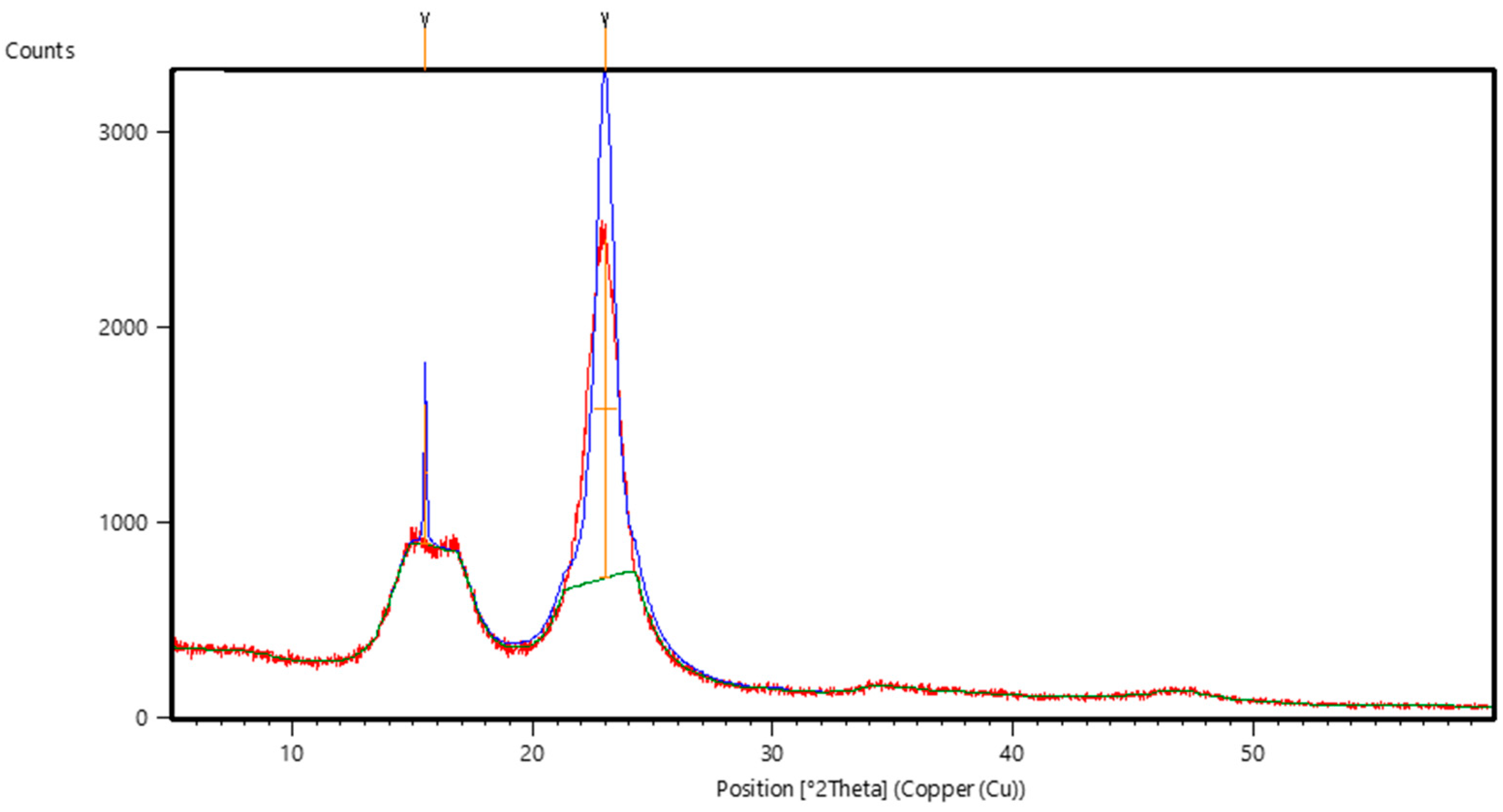

Figure 9 shows the XRD graph of the crystallinity results and Table 2 shows the XRD analysis of fiber crystallinity: peak positions, intensity, and d-spacing. The XRD analysis results of ramie fibers that underwent alkali treatment with NaOH and acetylation using CH3COOH show two main diffraction peaks at angles 2θ of 15.4971° and 22.9492°. The peak at 22.9492° has the highest relative intensity (100%) with a d-spacing of 3.8721 Å, which is typically associated with the (200) crystal plane of the cellulose I crystalline structure, according to Miller indices. Meanwhile, the peak at 15.4971° with a d-spacing of 5.7133 Å is linked to the (110) plane, representing the amorphous or semi-crystalline structure of cellulose. Both peaks reflect the crystalline and amorphous characteristics of ramie fibers.

Figure 9.

XRD result graph.

Table 2.

XRD Analysis Of Fiber Crystallinity: Peak Positions, Intensity, And D-Spacing.

The alkali treatment with NaOH aims to remove non-cellulosic components such as lignin and hemicellulose, which directly affect the amorphous structure of the fibers. The loss of amorphous components increases the intensity of the crystalline peak at 2θ = 22.9°, indicating that the cellulose crystal structure becomes more dominant. This is also indicated by a smaller FWHM (Full Width at Half Maximum) value at the 22.9° peak, signifying an increase in the orderliness of the crystalline structure due to the alkali treatment. This process causes the redistribution and alignment of cellulose molecules, thereby strengthening hydrogen bonding between chains within the crystal matrix [24,25].

The acetylation treatment using CH3COOH further modifies the hydroxyl (-OH) groups on cellulose, replacing them with acetyl (-COCH3) groups. This modification affects intramolecular hydrogen bonds, which can change the degree of crystallinity and enhance fiber hydrophobicity without disturbing the basic crystal structure. The diffraction pattern does not show any significant new peaks, indicating that the cellulose crystal structure remains dominant; however, there is a reduction in the amorphous peak around 2θ = 15.5°,indicating a decrease in non-cellulosic components [25].

The crystallinity of the fibers can be calculated from the ratio of crystalline peak intensity to the total area under the diffraction curve. The high intensity of the peak at 2θ = 22.9° compared to the amorphous peak at 2θ = 15.5° indicates an increase in crystallinity after alkali and acetylation treatments. The cellulose I crystal structure remains intact, with a more orderly molecular orientation [26].

The alkali treatment removes the amorphous structure from lignin and hemicellulose, leading to a reorientation of cellulose molecules into a more orderly arrangement. The XRD diffraction confirms that the intensity of the crystalline diffraction peak (200) increases, reflecting an enhancement in crystallinity. The non-cellulosic structure that previously acted as a barrier to X-ray diffraction was removed, allowing pure cellulose to be more visible in the XRD analysis [27]

Overall, these results indicate that alkali and acetylation treatments modify ramie fiber structure by removing amorphous components and enhancing cellulose molecular orderliness, as represented by the strengthening of crystalline diffraction peaks at 2θ = 22.9°. This process makes the fibers more structured and improves their mechanical properties [25].

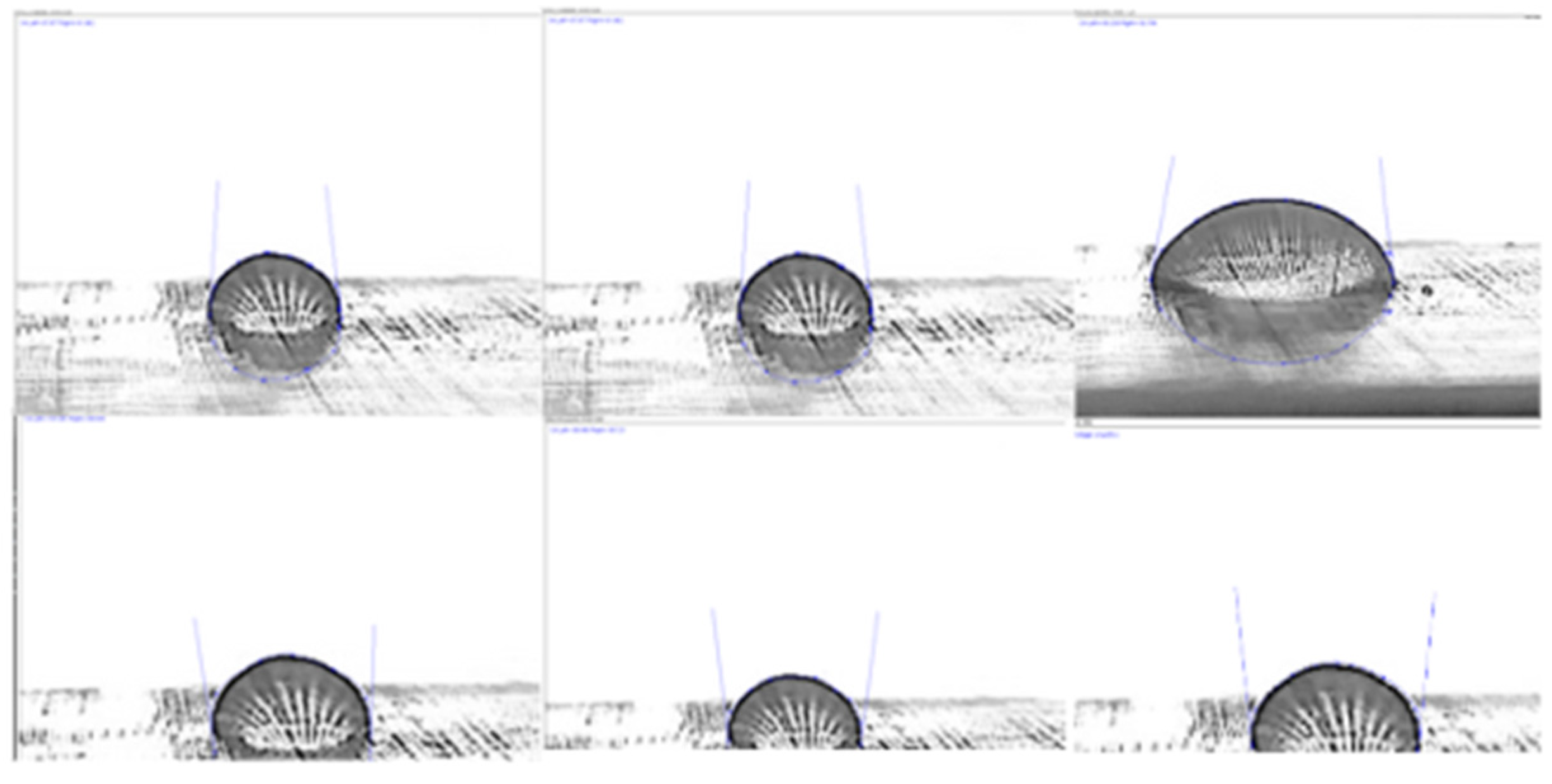

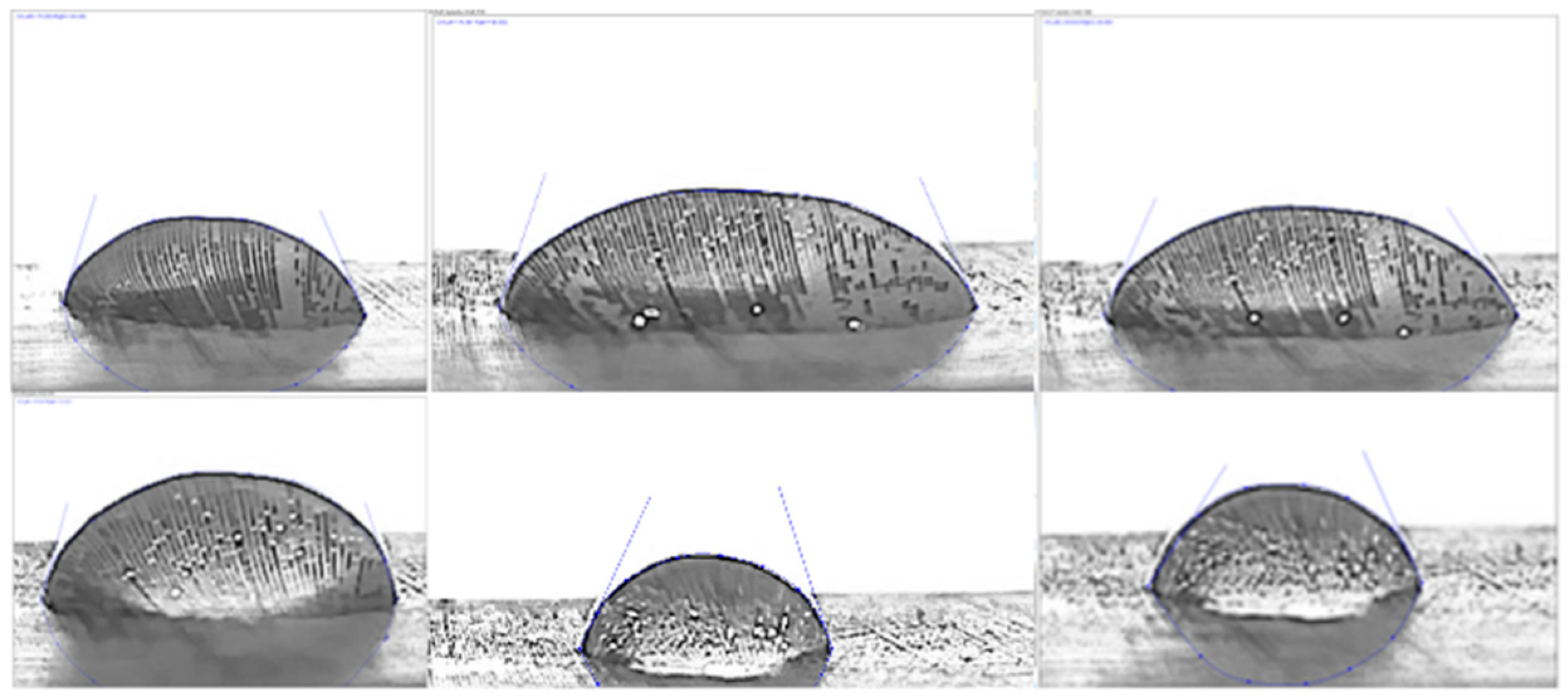

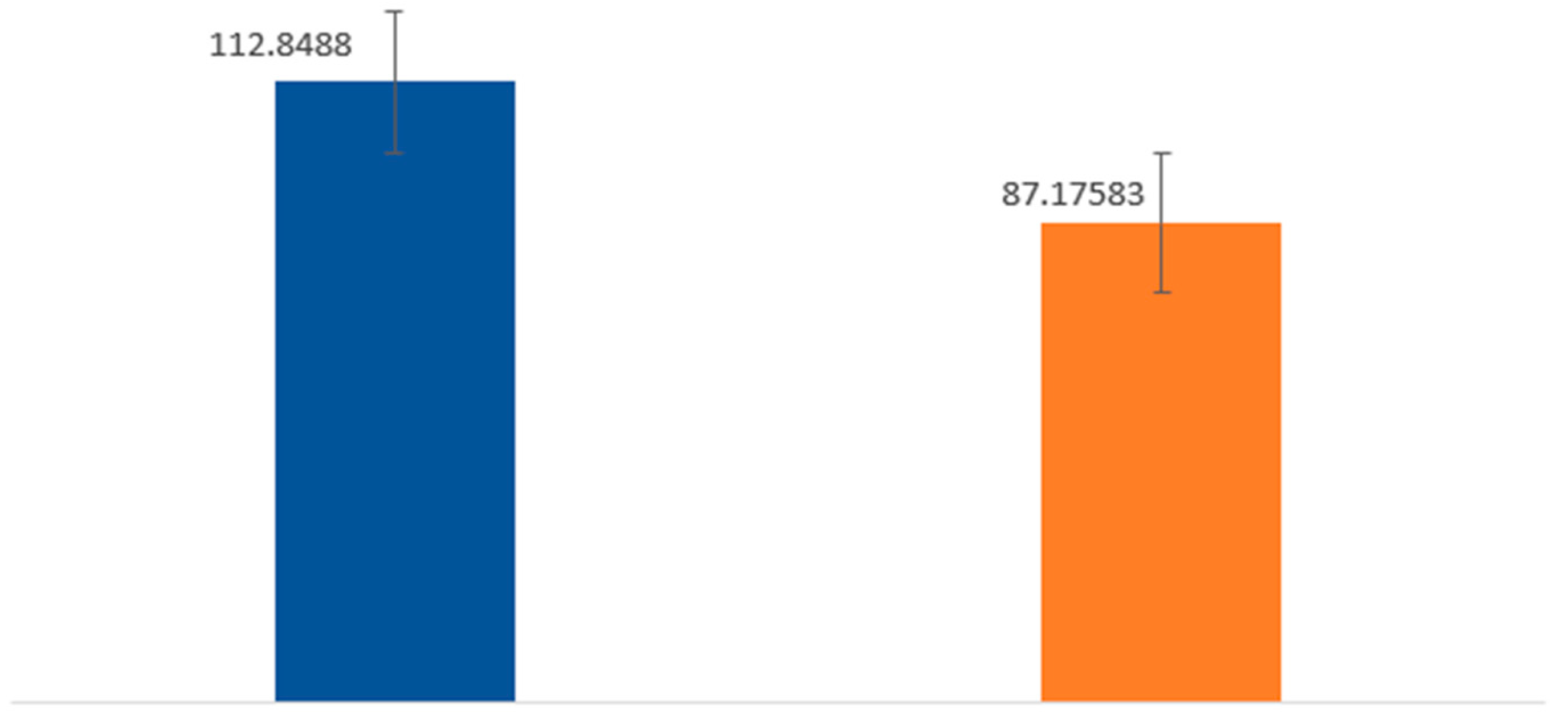

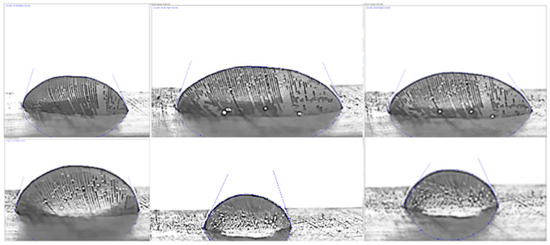

4.3. Hydrophobicity of Fiber

Figure 10 illustrates the delignification treatment, highlighting the changes in fiber characteristics after exposure to NaOH. Figure 11 shows the combined effect of delignification and acetylation treatments, emphasizing the enhancements in fiber hydrophobicity and surface morphology. Table 3 provides detailed contact angle calculations, which are essential for evaluating the wettability of the treated fibers. Finally, Figure 12 compares the contact angles for each treatment condition, offering a clear visualization of the differences in hydrophobicity between the various fiber treatments. In the analysis of fibers treated with both delignification and acetylation, the average contact angles ranged from approximately 106.62° to 118.79°. These values suggest a generally hydrophobic nature after treatment, indicating that the acetylation process effectively reduced the hydroxyl groups available for hydrogen bonding with water [28].

Figure 10.

Fiber treatment delignification.

Figure 11.

Fiber treatment delignification + acetylation.

Table 3.

Contact angle calculation.

Figure 12.

Comparison of contact angles for each treatment.

Notably, Point 4 exhibited the highest average contact angle (118.79°), suggesting that this treatment condition resulted in the most hydrophobic surface. This enhancement in hydrophobicity can be attributed to optimal acetylation conditions that maximized the replacement of hydroxyl groups with acetyl groups [29].

In contrast, fibers subjected solely to delignification showed average contact angles ranging from approximately 82.91° to 94.73°. These lower values indicate that while delignification improves surface cleanliness by removing non-cellulosic components like lignin and hemicellulose, it does not enhance hydrophobicity to the same extent as acetylation [30]. The retained wettability in delignified fibers may be advantageous for applications where moisture absorption is desired.

The findings underscore the importance of chemical treatments in modifying fiber properties for specific applications. The increased hydrophobicity of acetylated fibers makes them suitable for use in polymer composites where moisture resistance is critical [31]. Additionally, the enhanced interfacial adhesion due to increased hydrophobicity can improve the mechanical properties of composites used in 3D printing applications [28]. Conversely, delignified fibers may be more suitable for applications where moisture retention is beneficial, such as in certain types of biodegradable composites. The data indicates that while delignification improves fiber cleanliness and structural integrity, acetylation enhances hydrophobicity, making treated fibers suitable for various industrial applications.

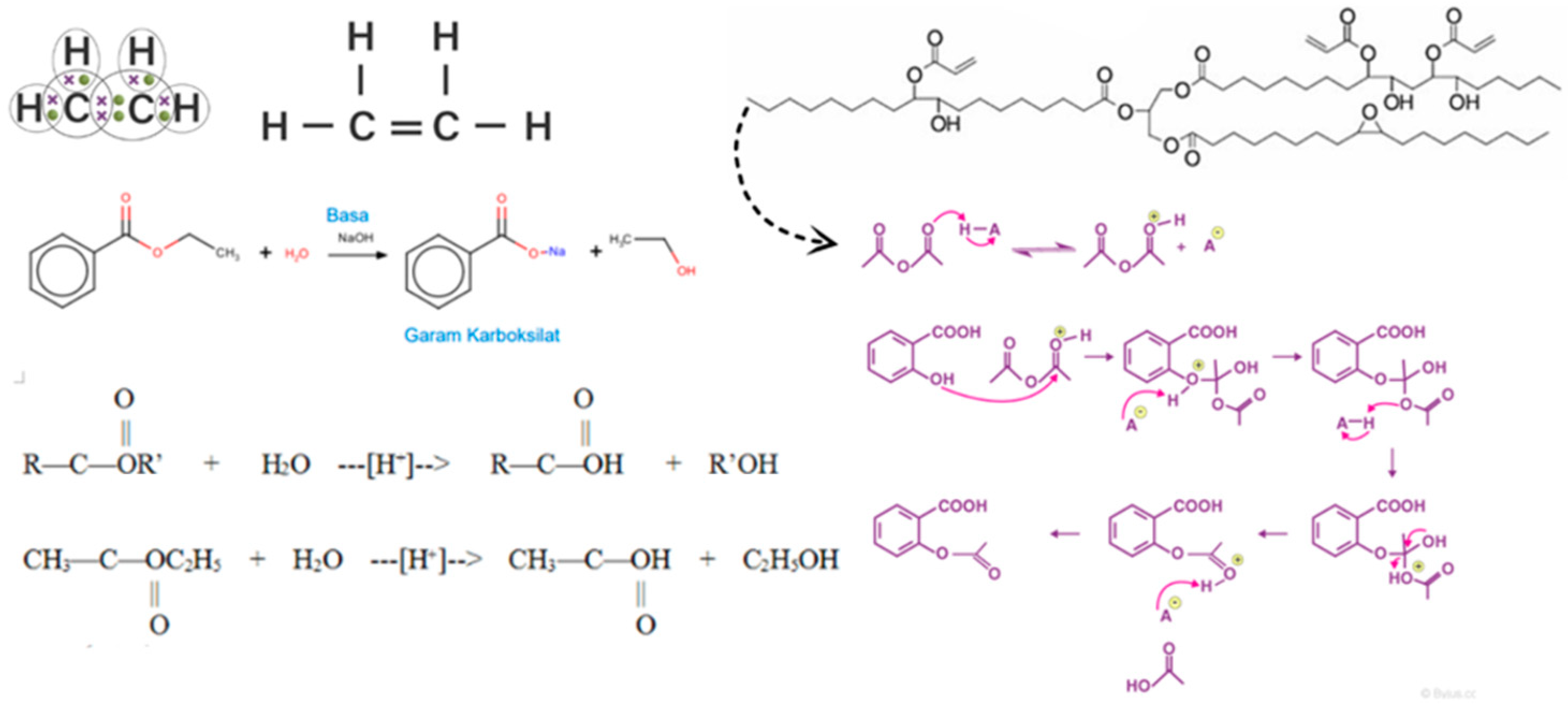

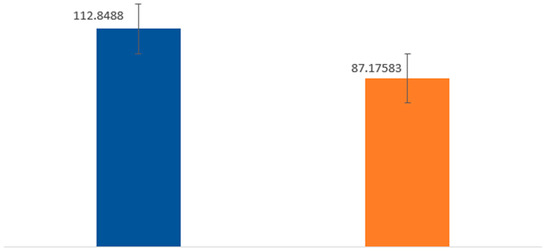

Figure 13 illustrates the chemical reactions involved in the alkalization and acetylation processes. In the alkalization reaction, the interaction of hydroxyl groups (OH) on the fiber with hydroxide ions (OH-) from NaOH, which replace the hydroxyl groups of cellulose, produces Cell-O −Na+ complex ions and water and surface impurities such as wax or pectin as by-products. In the acetylation treatment, water absorption decreases, non-crystalline fiber constituents are removed, smooth fiber surfaces are produced, and stress transfer efficiency is increased. The double bond C=C opens and forms a covalent bond with other molecules, increasing the strength of the compost interface bond [32].

Figure 13.

Chemical reactions in alkalization and acetylation.

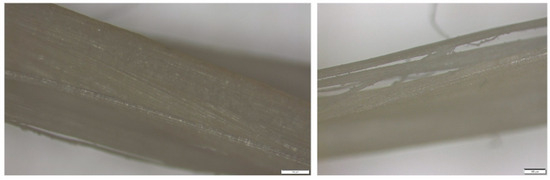

4.4. Fiber Morphology

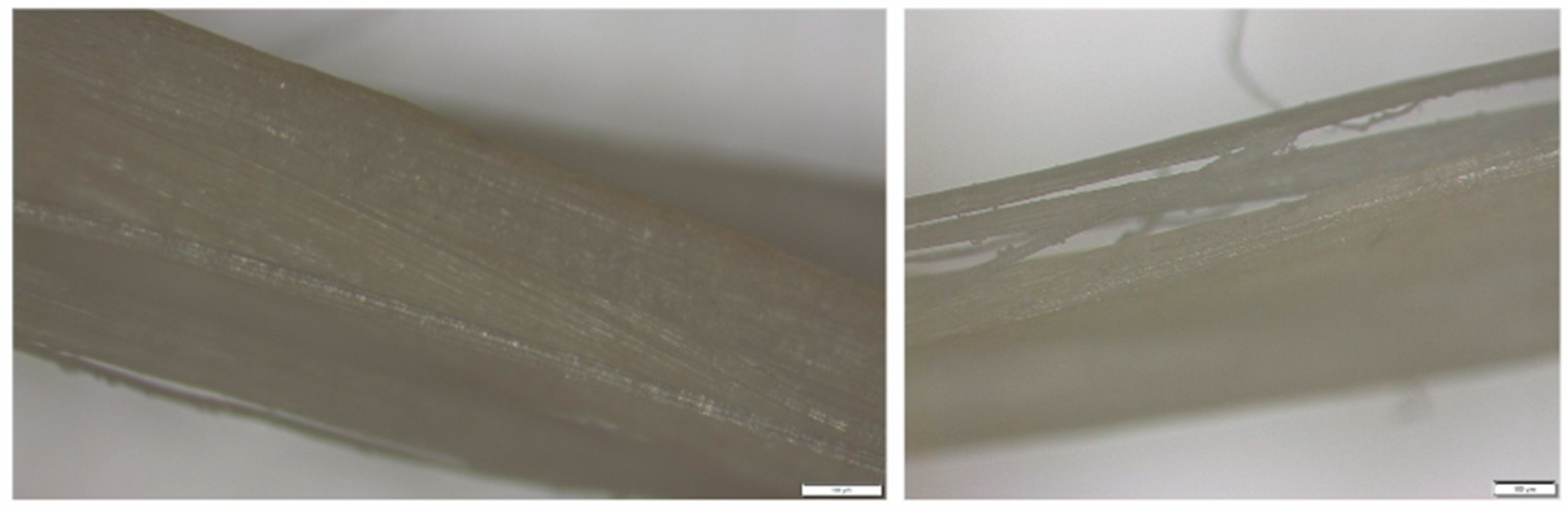

Figure 14 displays the fiber morphology before and after the alkalization and acetylation treatments. The figure visually compares the structural changes in the fiber surface, highlighting the effects of these chemical processes. The image above shows the results of microstructure observations of fibers that have underwent alkalization and acetylation processes. Both images represent the effects of chemical treatment on the surface and structure of the fiber. The alkalization process using NaOH solution functions to remove non-cellulose compounds, such as lignin, hemicellulose, and other impurities. This produces fibers that are richer in cellulose with a more dominant crystalline structure. A more regular fiber surface shows an increase in mechanical quality, making it more suitable for technical material applications such as composites. Fibers that underwent the alkalization stage continued with the acetylation process. The results show a modification on the fiber surface, with several layers of the fiber wall starting to separate or open. The acetylation process modifies the hydroxyl groups in cellulose into ester groups through a reaction with acetic anhydride or acetic acid. This modification provides hydrophobic properties to the fiber, thereby increasing its resistance to water. The appearance of the fiber shows a combination of a smooth structure and open areas, indicating changes in the fiber wall due to chemical reactions.

Figure 14.

Alkalization and acetylation fiber morphology.

4.5. Potential as 3D Printing Filament

The chemical treatment of fibers, including delignification using NaOH solution and acetylation with CH3COOH, shows the great potential of fibers as filament matrix candidates for environmentally friendly 3D printing applications. Based on FTIR analysis, it can be seen that delignification successfully reduced the lignin content significantly, as indicated by a decrease in the intensity of the lignin aromatic band at 1540.96 cm−1. This process also maintains the basic structure of cellulose, as indicated by the C-O-C band at 1026.68 cm−1. Further acetylation modifies the hydroxyl group (-OH) into an ester group (-COO), marked by the appearance of a carbonyl band at 1732.80 cm−1 and C-O stretching at 1239.28 cm−1, indicating the success of chemical modification. This modification provides hydrophobic properties to the fibers, as indicated by an increase in the average contact angle to more than 106° compared to fibers that only underwent delignification.

The XRD analysis showed an increase in fiber crystallinity after chemical treatment, indicated by an increase in the intensity of the diffraction peak at 2θ = 22.9° representing the crystal structure of cellulose I. This increase indicates the restructuring of cellulose molecules to become more regular, thus improving the mechanical properties of the fiber. NaOH treatment removes amorphous components such as lignin and hemicellulose, while further acetylation improves the water resistance of the fiber by replacing hydroxyl groups with acetyl groups. The combination of these properties makes the fiber more compatible with the polymer matrix in 3D printing filament applications.

The improved hydrophobic properties, more regular structure, and good interaction with the polymer matrix indicate that the treated fiber is not only environmentally friendly but also has great potential for use in 3D printing filaments. These characteristics support the development of composite materials that are resistant to moisture, have high mechanical strength, and are sustainable, suggesting that they can replace synthetic-based materials that are less environmentally friendly in the additive manufacturing industry.

The analysis of the fibers treated with delignification and acetylation highlights the significant improvements in their structural, chemical, and functional properties, making them suitable for environmentally friendly 3D printing applications. Delignification removes non-cellulosic components, enhancing fiber cleanliness and mechanical properties, while acetylation modifies the fibers by replacing hydroxyl groups with acetyl groups, increasing hydrophobicity and water resistance. FTIR and XRD analyses confirm the success of these treatments, showing enhanced crystallinity and the incorporation of acetyl groups. The treated fibers, with their improved hydrophobicity, crystallinity, and compatibility with polymers, offer a sustainable alternative to synthetic materials, supporting the development of high-performance 3D printing filaments and advancing sustainable industrial practices.

5. Conclusions

The FTIR analysis of delignified and acetylated ramie fibers confirms successful chemical modification. The reduction in -OH groups (3284.59 cm−1) and the emergence of carbonyl (C=O) bands (1732.80 cm−1) indicate effective ester formation during acetylation, enhancing the fibers’ hydrophobic properties. The delignification process significantly reduces lignin (1540.96 cm−1), while preserving the cellulose structure (1026.68 cm−1). These modifications improve fiber compatibility with polymer matrices, making them suitable for applications like 3D printing filaments. This study highlights the potential of ramie fibers for eco-friendly composite materials with enhanced mechanical and hydrophobic properties.

Author Contributions

Preparation of initial draft includes conceptualization, methodology, investigation, formal analysis, data curation, and writing—original draft preparation: M.N.R.; Supervision, review, and feedback: S.S. and P.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Education and Culture, Republic of Indonesia.

Institutional Review Board Statement

Not applicable. This study did not involve humans or animals that require ethical review or approval.

Informed Consent Statement

Not applicable. This study did not involve human participants.

Data Availability Statement

The data that support the findings of this study are available upon request from the corresponding author. The data are not publicly available due to privacy or ethical restrictions.

Acknowledgments

Thanks to BIMA, Ministry of Higher Education, Science, and Technology of the Republic of Indonesia, LPPM ITS, SIMPEL ITS, Metallurgy Laboratory, Department of Mechanical Engineering ITS, and Department of Engineering Physics.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Parandoush, P.; Lin, D. A review on additive manufacturing of polymer-fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Podgorski, R.; Wojasiński, M.; Trepkowska-Mejer, E.; Ciach, T. A simple and fast method for screening production of polymer-ceramic filaments for bone implant printing using commercial fused deposition modelling 3D printers. Biomater. Adv. 2023, 146, 213317. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.E. Rami Fiber Reinforced PLA Composites for 3D Printing Applications. Polym. Compos. 2018, 3969–3977. [Google Scholar]

- Laksono, A.D.; Rozikin, M.N. Potential of ironwood powder and bamboo powder as environmentally friendly particle paper applications—A review. Mech. Eng. 2021, 267–274. [Google Scholar]

- Mukhammad, A.F.H.; Mujiyono, M.; Nurhadiyanto, D.; Hassan, S.A.; Riyadi, T.W.B. Preliminary study of fragment simulating projectile on epoxyramie composite. J. Phys. Conf. Ser. 2019, 1446, 012001. [Google Scholar] [CrossRef]

- Kondo, Y. Analysis of Lignin, Cellulose, and Hemicellulose Content of Coconut Fiber Due to Alkali Treatment. INTEK Res. J. 2018. [Google Scholar]

- Pratama, Y.Y. Effect of Alkali Treatment, Fiber Volume Fraction and Fiber Length on the Tensile Strength of Coconut Fiber Composites. Sci. J. Ind. Eng. 2014, 8–15. [Google Scholar]

- Oladele Isiaka, O. Acetylation Treatment for the Batch Processing of Natural Fibers: Effects on Constituents, Tensile Properties and Surface Morphology of Selected Plant Stem Fibers; Department of Mechanical, Landmark University: Omu-Aran, Nigeria, 2020. [Google Scholar]

- Jamilah, U.L.; Sujito, S. The improvement of ramie fiber properties as composite materials using alkalization treatment: NaOH Concentration. J. Sains Mater. Indones. 2021, 22, 2. [Google Scholar] [CrossRef]

- Parusha, O.A.; Rozikin, M.N.; Laksono, A.D.; Tajalla, G.U.N.; Putri, N.A.; Rochim, F.M.F. Characterization of Bark-Midrib Fibers using Chemical Treatment Variations as Reinforcement in Bark-Midrib Fiber Composites. J. SPECTA 2019, 3, 36–45. [Google Scholar]

- Ali, A.; Shaker, K.; Nawab, Y.; Jabbar, M.; Hussain, T.; Militky, J.; Baheti, V. Hydrophobic treatment of natural fibers and their composites—A review. J. Ind. 2018, 47, 2153–2183. [Google Scholar] [CrossRef]

- Aji, A.T. Study of the effect of chemical treatment of coconut fiber on the tensile strength of coir fiber composites. Lampung Lampung Univeristal. 2021. [Google Scholar]

- E1252-98(2021); Standard Practice for General Techniques for Obtaining Infrared Spectra for Qualitative Analysis. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- Raval, N. Importance of Physicochemical Characterization of Nanoparticles in Pharmaceutical Product Development. In Basic Fundamentals of Drug Delivery; Academic Press: Cambridge, MA, USA, 2019. [Google Scholar]

- Ojeda, J.J.; Dittrich, M. Fourier Transform Infrared Spectroscopy for Molecular Analysis of Microbial Cells. Methods Mol. Biol. 2012, 881, 187–211. [Google Scholar] [PubMed]

- Asriza, R.O.; Nurhadini, F.; Arkan, F. Synthesis and Characterization of Cellulose Acetate from α-Cellulose of Paper Waste. Indones. J. Fundam. Appl. Chem. 2023, 8, 82–87. [Google Scholar] [CrossRef]

- Sarie, O.N.; Rahmawati, Y.; Taufany, F.; Nurkhamidah, S. The Effects of NaOH Concentration on the Delignification Process of Natural Fibers. ASEAN Eng. J. 2024, 4, 137–142. [Google Scholar]

- Hassan, M.; Abdurrahman, A.; Aliyu, B.S. Chemical Modification of Natural Fibers: A Review. J. Nat. Fibers 2021, 18, 789–803. [Google Scholar]

- Zhang, Y.; Wang, H.; Liu, J. Delignification and Characterization of Natural Fiber Reinforced Composites. Compos. Sci. Technol. 2022, 108–115. [Google Scholar]

- Kumar, S.; Prasad, K. FTIR Spectroscopy Analysis of Natural Fiber Composites. Mater. Today Proc. 2019, 103–107. [Google Scholar]

- Keshk, S.; El-Sayed, M.; El-Sherif, M.A. Effect of Delignification on the Physical and Chemical Properties of Natural Fibers: A Review on the Use of NaOH in Fiber Treatment Processes for Enhanced Performance in Composites Manufacturing. Bioresources 2016, 12, 8734–8754. [Google Scholar]

- Li, Y.; Zhang, X.; Liu, Z. Characterization of Cellulose Nanofibers from Sugar Palm Fiber: A Study on the Effects of Delignification and Mercerization Treatments on Fiber Properties and Morphology Using FTIR and SEM Techniques. BioResources 2020. [Google Scholar]

- Dewi, R.; Santoso, J.; Supriyadi, S. Characterization of Cellulose Acetate from Agricultural Waste Using FTIR Spectroscopy for Bioplastics Applications: A Review on Recent Advances and Future Perspectives in Sustainable Materials Development. J. Clean. Prod. 2023. [Google Scholar]

- Arianto, B.V. Study on the Effect of NaOH Concentration and Alkali Treatment Temperature on Ramie Fiber (Boehmeria Nivea) as Composite Reinforcement; Institut Teknologi Sepuluh Nopember: Surabaya, Indonesia, 2024. [Google Scholar]

- Ilyas, R.; Kusmono, K.; Hidayati, S. A Preliminary Study of Extraction and Characterization of Nanocrystalline Cellulose NCC from Ramie Fiber. J. Mater. Process. Charact. 2018, 41–45. [Google Scholar]

- Kusmono, K.; Ilyas, R.; Hidayati, S. The Improvement of Ramie Fiber Properties as Composite Materials Using Alkali Treatment: NaOH Concentration. J. Sains Mater. Indones. 2020, 22, 62. [Google Scholar]

- Mansikkamäki, P.; Lahtinen, M.; Rissanen, K. Morphological change induced with NaOH-water solution for ramie fiber. J. Appl. Polym. Sci. 1996, 60, 919–922. [Google Scholar]

- Matuana, L.M.; Stark, N.M. Acetylation treatment effects on moisture absorption properties of wood fiber reinforced polypropylene composites. Compos. Sci. Technol. 2015, 113, 1–8. [Google Scholar]

- Olakanmi, E.; Strydom, C.A. Chemical modification of natural fibers using acetic anhydride: A review on its effects on physical properties and performance in polymer composites. J. Mater. Sci. Res. 2016, 1–11. [Google Scholar]

- Chen, Y.; Zhang, Y.; Wang, C. Effects of chemical modification on the properties of natural fibers: A review. Materials 2016, 873. [Google Scholar]

- Gardner, D.J.; Han, J.; Wang, L. Wood fiber–plastic composites: A review on their mechanical properties and performance. Compos. Part A Appl. Sci. Manuf. 2015, 68, 1–14. [Google Scholar]

- Dwi, S.R.I. The Effect of Stirring Speed and Addition of Poly Vinyl Alcohol (PVA) and Sodium Dodecyl Sulfate (SDS) on the Encapsulation of Flaxseed Oil in Urea-Formaldehyde for Self-Healing Coating Applications. J. Teknol. 2024. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).