Vibration Analysis for Wind Turbine Prognosis with an Uncertainty Bayesian-Optimized Lightweight Neural Network †

Abstract

1. Introduction

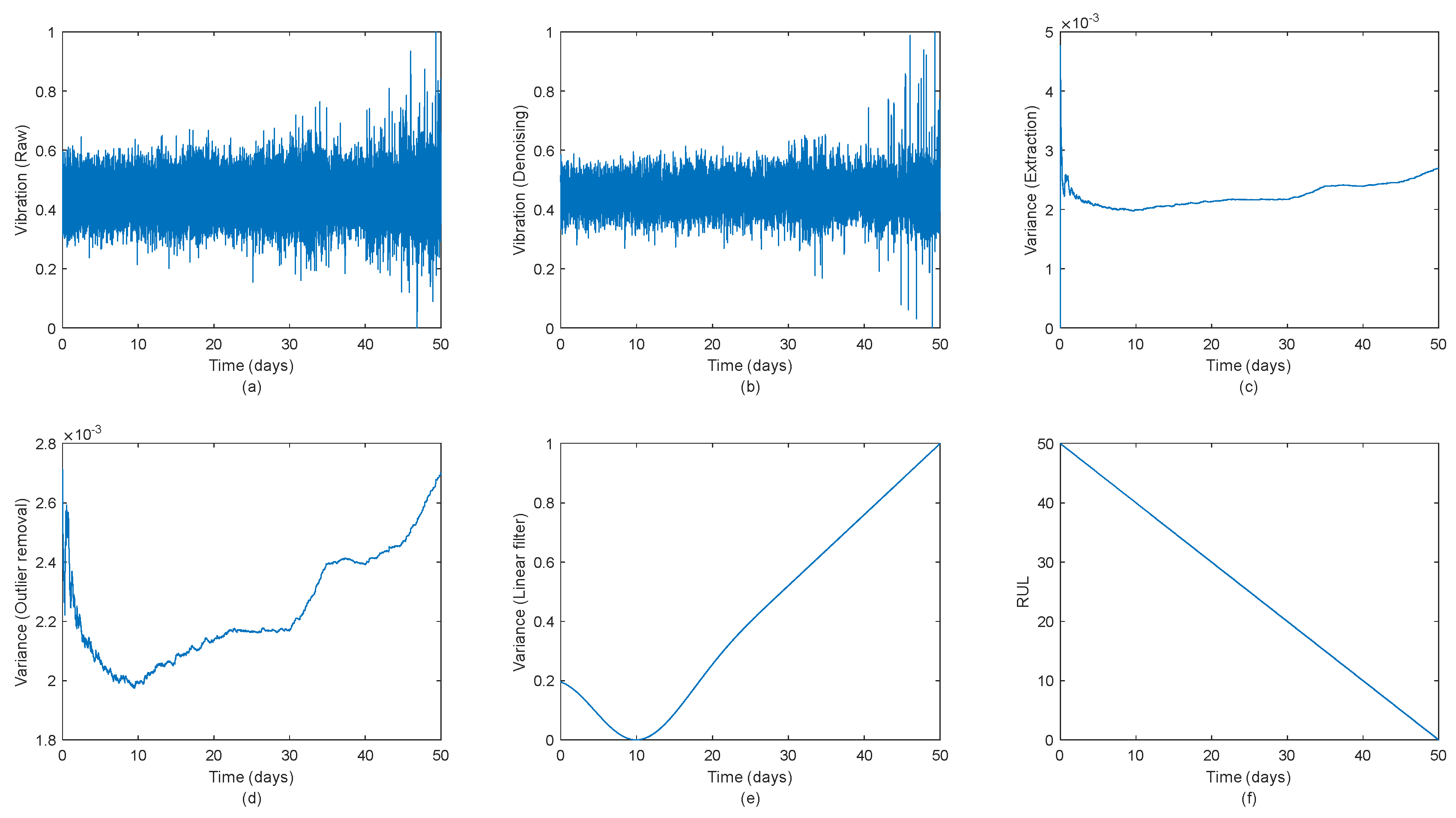

2. Materials

3. Methods

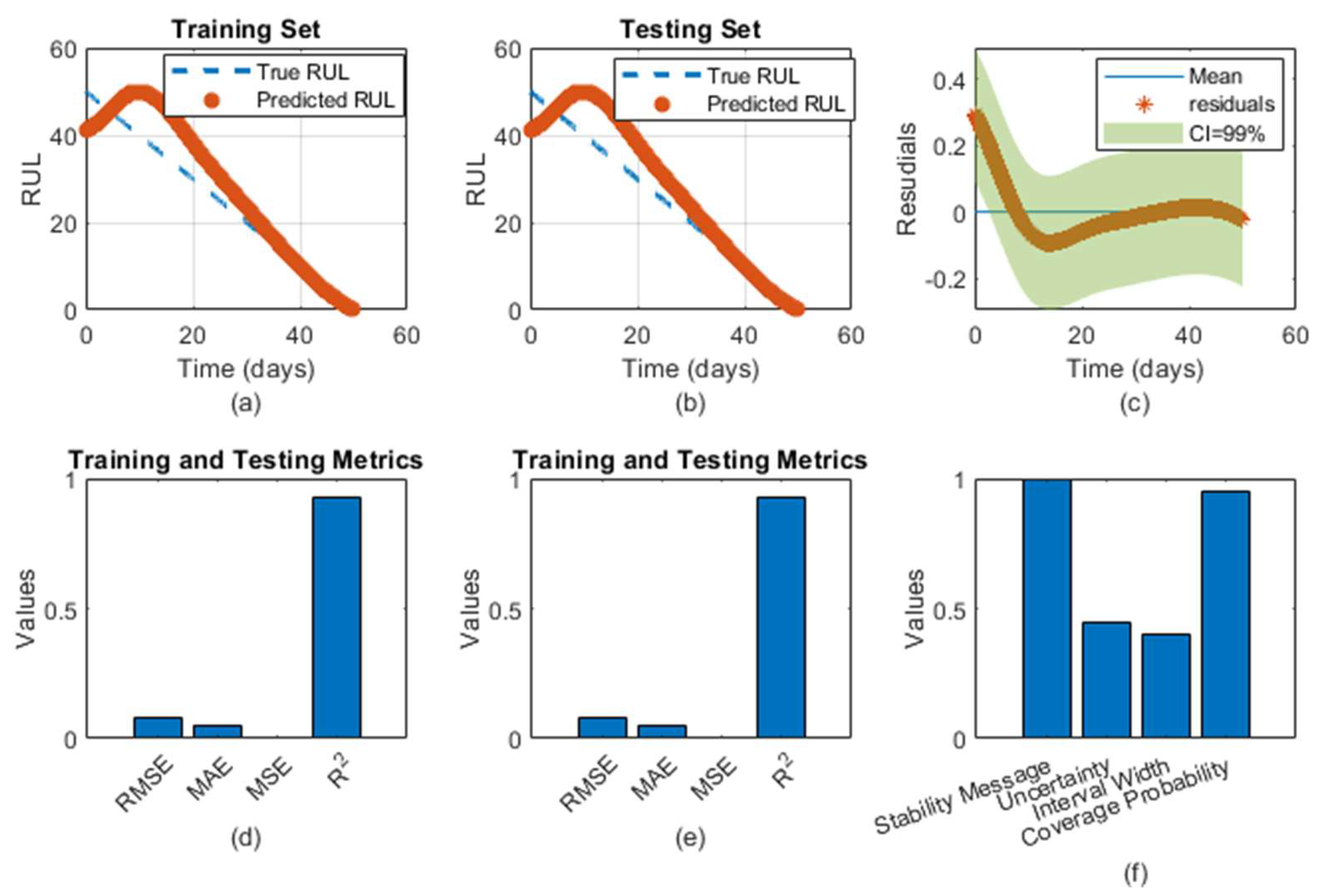

4. Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Leite, G.d.N.P.; Araújo, A.M.; Rosas, P.A.C. Prognostic Techniques Applied to Maintenance of Wind Turbines: A Concise and Specific Review. Renew. Sustain. Energy Rev. 2018, 81, 1917–1925. [Google Scholar] [CrossRef]

- Costa, Á.M.; Orosa, J.A.; Vergara, D.; Fernández-Arias, P. New Tendencies in Wind Energy Operation and Maintenance. Appl. Sci. 2021, 11, 1386. [Google Scholar] [CrossRef]

- Santiago, R.A.d.F.; Barbosa, N.B.; Mergulhão, H.G.; de Carvalho, T.F.; Santos, A.A.B.; Medrado, R.C.; Filho, J.B.d.M.; Pinheiro, O.R.; Nascimento, E.G.S. Data-Driven Models Applied to Predictive and Prescriptive Maintenance of Wind Turbine: A Systematic Review of Approaches Based on Failure Detection, Diagnosis, and Prognosis. Energies 2024, 17, 1010. [Google Scholar] [CrossRef]

- Berghout, T.; Benbouzid, M.; Amirat, Y. Interaction between Machine Learning and Maintenance Planning for Wind Energy Systems: A Theoretical Review and Analysis. In Proceedings of the 2nd Annual IEEE Industrial Electronics Society Online Conference (ONCON) 2023, Virtual, 8–10 December 2023; pp. 1–6. [Google Scholar]

- Liton Hossain, M.; Abu-Siada, A.; Muyeen, S.M. Methods for Advanced Wind Turbine Condition Monitoring and Early Diagnosis: A Literature Review. Energies 2018, 11, 1309. [Google Scholar] [CrossRef]

- Ding, F.; Tian, Z.; Jin, T. Maintenance Modeling and Optimization for Wind Turbine Systems: A Review. In Proceedings of the 2013 International Conference on Quality, Reliability, Risk, Maintenance, and Safety Engineering (QR2MSE), Chengdu, China, 15–18 July 2013; pp. 569–575. [Google Scholar] [CrossRef]

- McMorland, J.; Flannigan, C.; Carroll, J.; Collu, M.; McMillan, D.; Leithead, W.; Coraddu, A. A Review of Operations and Maintenance Modelling with Considerations for Novel Wind Turbine Concepts. Renew. Sustain. Energy Rev. 2022, 165, 112581. [Google Scholar] [CrossRef]

- Helbing, G.; Ritter, M. Deep Learning for Fault Detection in Wind Turbines. Renew. Sustain. Energy Rev. 2018, 98, 189–198. [Google Scholar] [CrossRef]

- Tchakoua, P.; Wamkeue, R.; Ouhrouche, M.; Slaoui-Hasnaoui, F.; Tameghe, T.; Ekemb, G. Wind Turbine Condition Monitoring: State-of-the-Art Review, New Trends, and Future Challenges. Energies 2014, 7, 2595–2630. [Google Scholar] [CrossRef]

- Habibi, H.; Howard, I.; Simani, S. Reliability Improvement of Wind Turbine Power Generation Using Model-Based Fault Detection and Fault Tolerant Control: A Review. Renew. Energy 2019, 135, 877–896. [Google Scholar] [CrossRef]

- Lu, B.; Li, Y.; Wu, X.; Yang, Z. A Review of Recent Advances in Wind Turbine Condition Monitoring and Fault Diagnosis. In Proceedings of the 2009 IEEE Power Electronics and Machines in Wind Applications, Lincoln, NE, USA, 24–26 June 2009; pp. 1–7. [Google Scholar]

- Abdar, M.; Pourpanah, F.; Hussain, S.; Rezazadegan, D.; Liu, L.; Ghavamzadeh, M.; Fieguth, P.; Cao, X.; Khosravi, A.; Acharya, U.R.; et al. A Review of Uncertainty Quantification in Deep Learning: Techniques, Applications and Challenges. Inf. Fusion 2021, 76, 243–297. [Google Scholar] [CrossRef]

- Alves, D.S.; Daniel, G.B.; de Castro, H.F.; Machado, T.H.; Cavalca, K.L.; Gecgel, O.; Dias, J.P.; Ekwaro-Osire, S. Uncertainty Quantification in Deep Convolutional Neural Network Diagnostics of Journal Bearings with Ovalization Fault. Mech. Mach. Theory 2020, 149, 103835. [Google Scholar] [CrossRef]

- Elforjani, M.; Shanbr, S.; Bechhoefer, E. Detection of Faulty High Speed Wind Turbine Bearing Using Signal Intensity Estimator Technique. Wind Energy 2018, 21, 53–69. [Google Scholar] [CrossRef]

- Wu, J.; Chen, X.Y.; Zhang, H.; Xiong, L.D.; Lei, H.; Deng, S.H. Hyperparameter Optimization for Machine Learning Models Based on Bayesian Optimization. J. Electron. Sci. Technol. 2019, 17, 26–40. [Google Scholar] [CrossRef]

- Huang, G. Bin What Are Extreme Learning Machines? Filling the Gap Between Frank Rosenblatt’s Dream and John von Neumann’s Puzzle. Cognit. Comput. 2015, 7, 263–278. [Google Scholar] [CrossRef]

- Berghout, T.; Benbouzid, M. EL-NAHL: Exploring Labels Autoencoding in Augmented Hidden Layers of Feedforward Neural Networks for Cybersecurity in Smart Grids. Reliab. Eng. Syst. Saf. 2022, 226, 108680. [Google Scholar] [CrossRef]

- Poole, C. Beyond the Confidence Interval. Am. J. Public Health 1987, 77, 195. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Berghout, T.; Benbouzid, M. Vibration Analysis for Wind Turbine Prognosis with an Uncertainty Bayesian-Optimized Lightweight Neural Network. Eng. Proc. 2024, 82, 47. https://doi.org/10.3390/ecsa-11-20502

Berghout T, Benbouzid M. Vibration Analysis for Wind Turbine Prognosis with an Uncertainty Bayesian-Optimized Lightweight Neural Network. Engineering Proceedings. 2024; 82(1):47. https://doi.org/10.3390/ecsa-11-20502

Chicago/Turabian StyleBerghout, Tarek, and Mohamed Benbouzid. 2024. "Vibration Analysis for Wind Turbine Prognosis with an Uncertainty Bayesian-Optimized Lightweight Neural Network" Engineering Proceedings 82, no. 1: 47. https://doi.org/10.3390/ecsa-11-20502

APA StyleBerghout, T., & Benbouzid, M. (2024). Vibration Analysis for Wind Turbine Prognosis with an Uncertainty Bayesian-Optimized Lightweight Neural Network. Engineering Proceedings, 82(1), 47. https://doi.org/10.3390/ecsa-11-20502