Effects of Reprocessing on Surface Oxidation and Microstructural Composition in Metal Injection-Molded Materials: Insights from SEM, EDX, and Metallographic Analysis †

Abstract

1. Introduction

2. Materials and Methods

2.1. Properties of the Studied Alloy

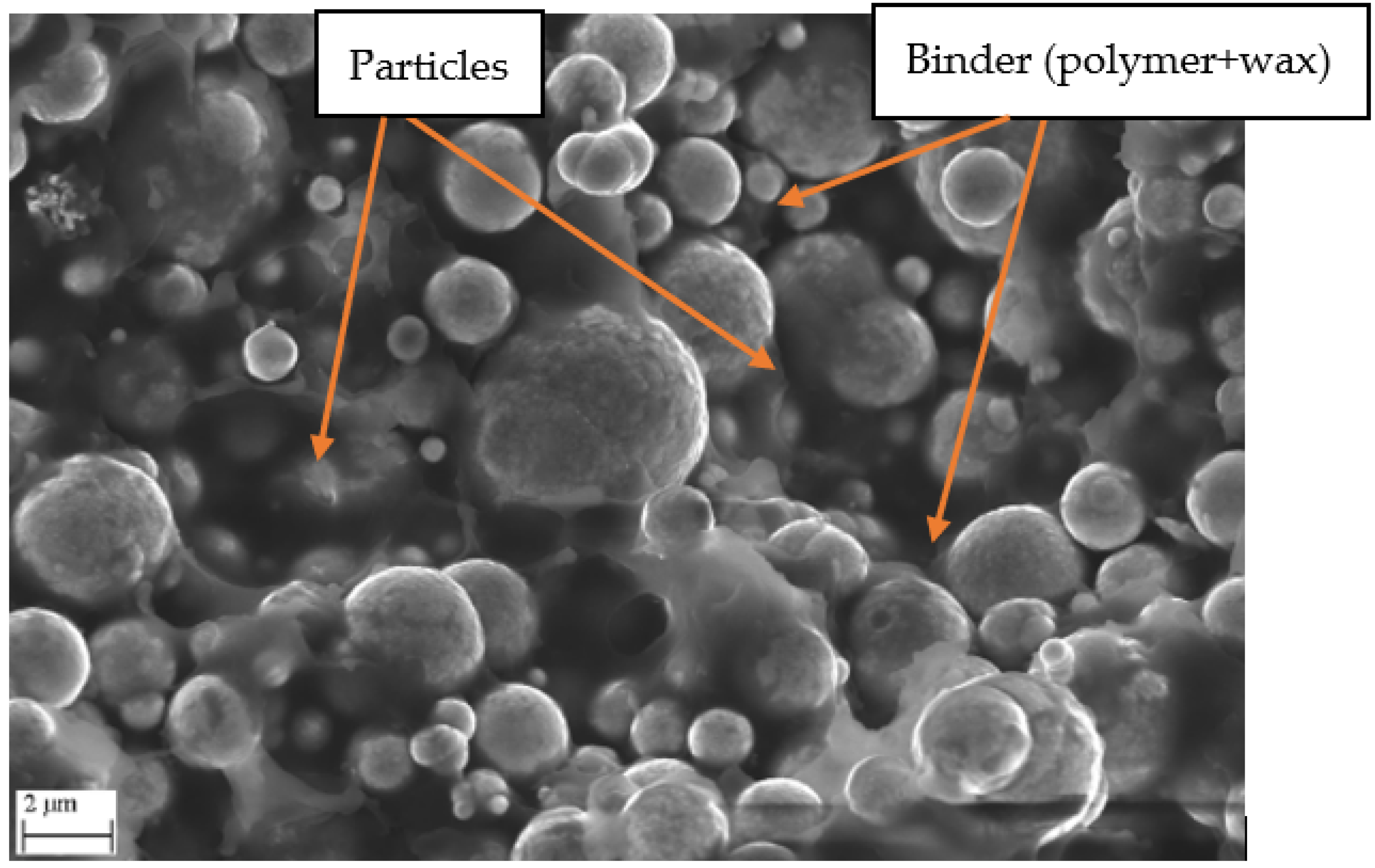

2.2. Binder System

- 55 wt.% paraffin wax;

- 25 wt.% polypropylene;

- 5 wt.% stearic acid;

- 15 wt.% carnauba wax.

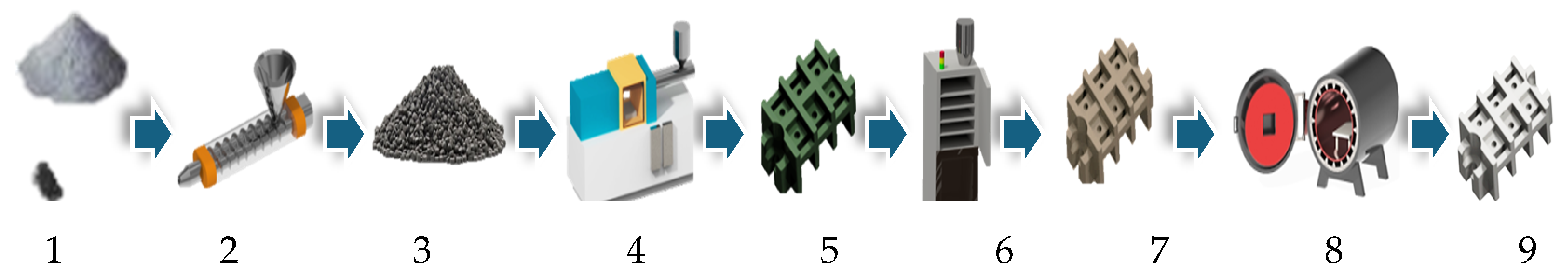

2.3. Production of the Test Specimen

2.4. Test Methods

3. Results and Discussions

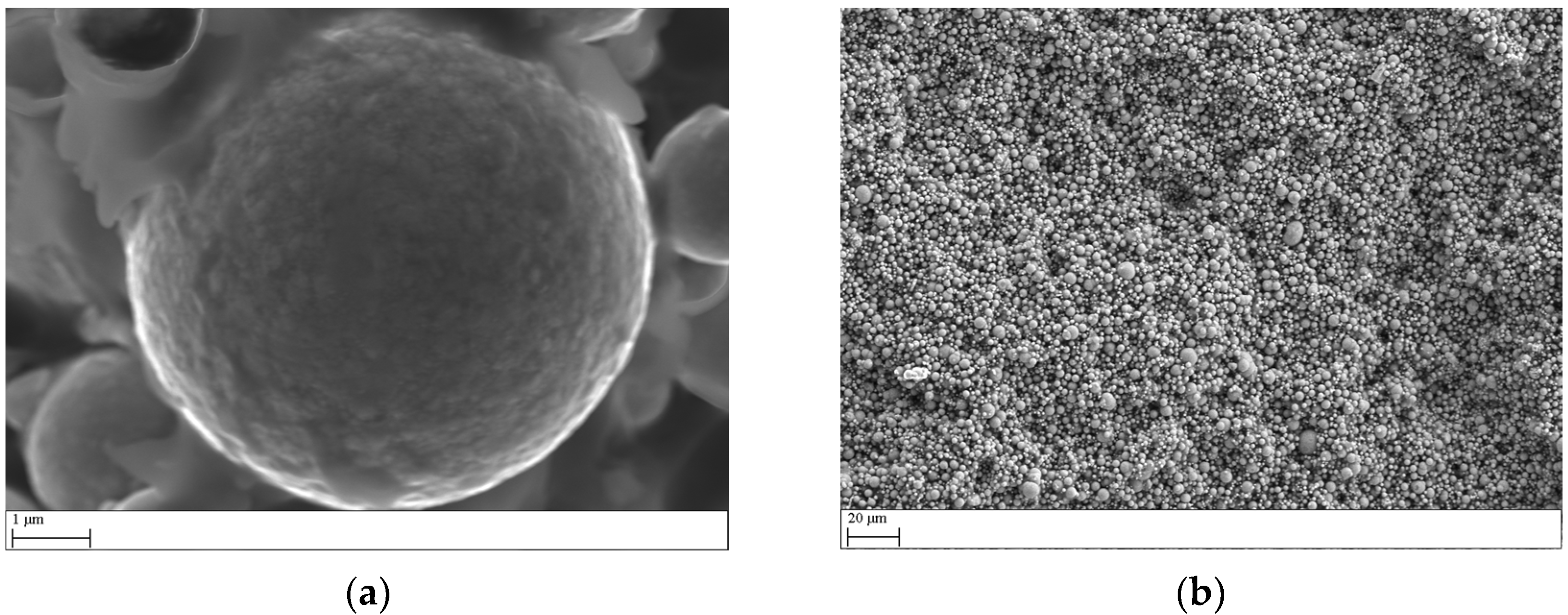

3.1. SEM Images

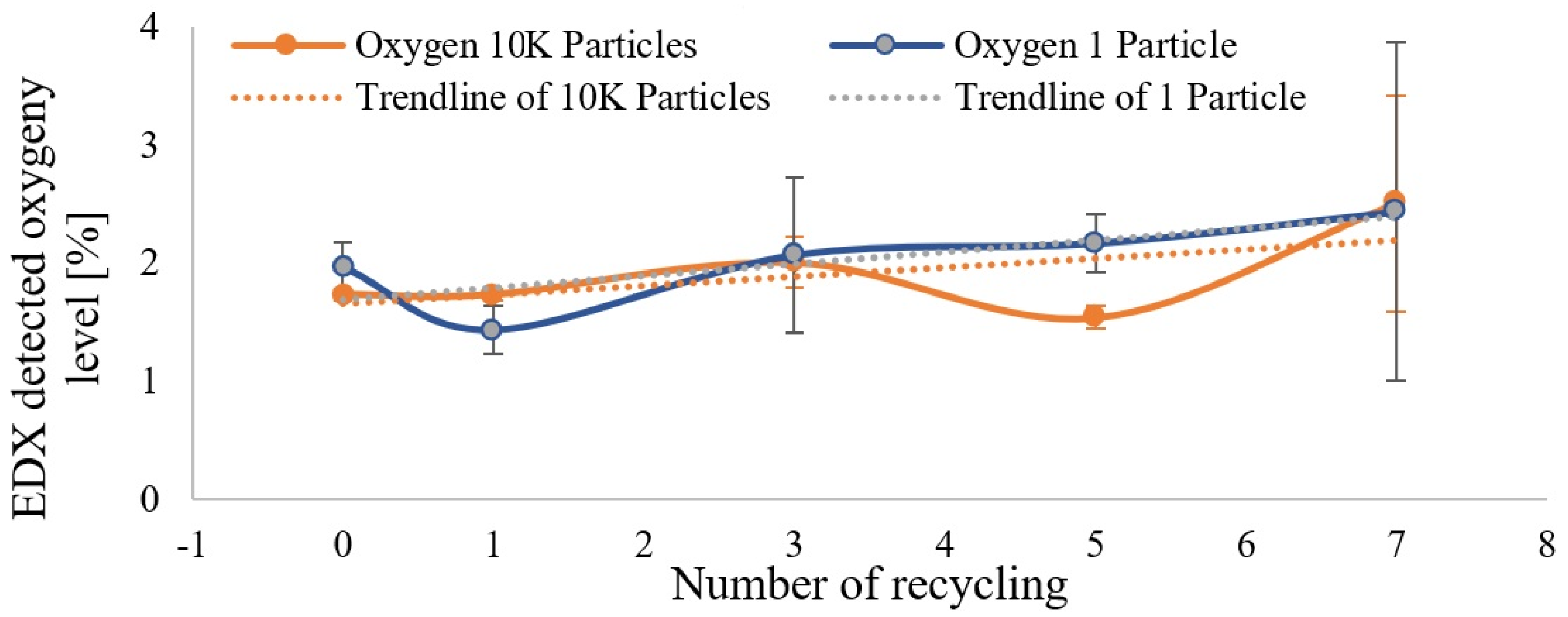

3.2. EDX-Based Spectroscopy

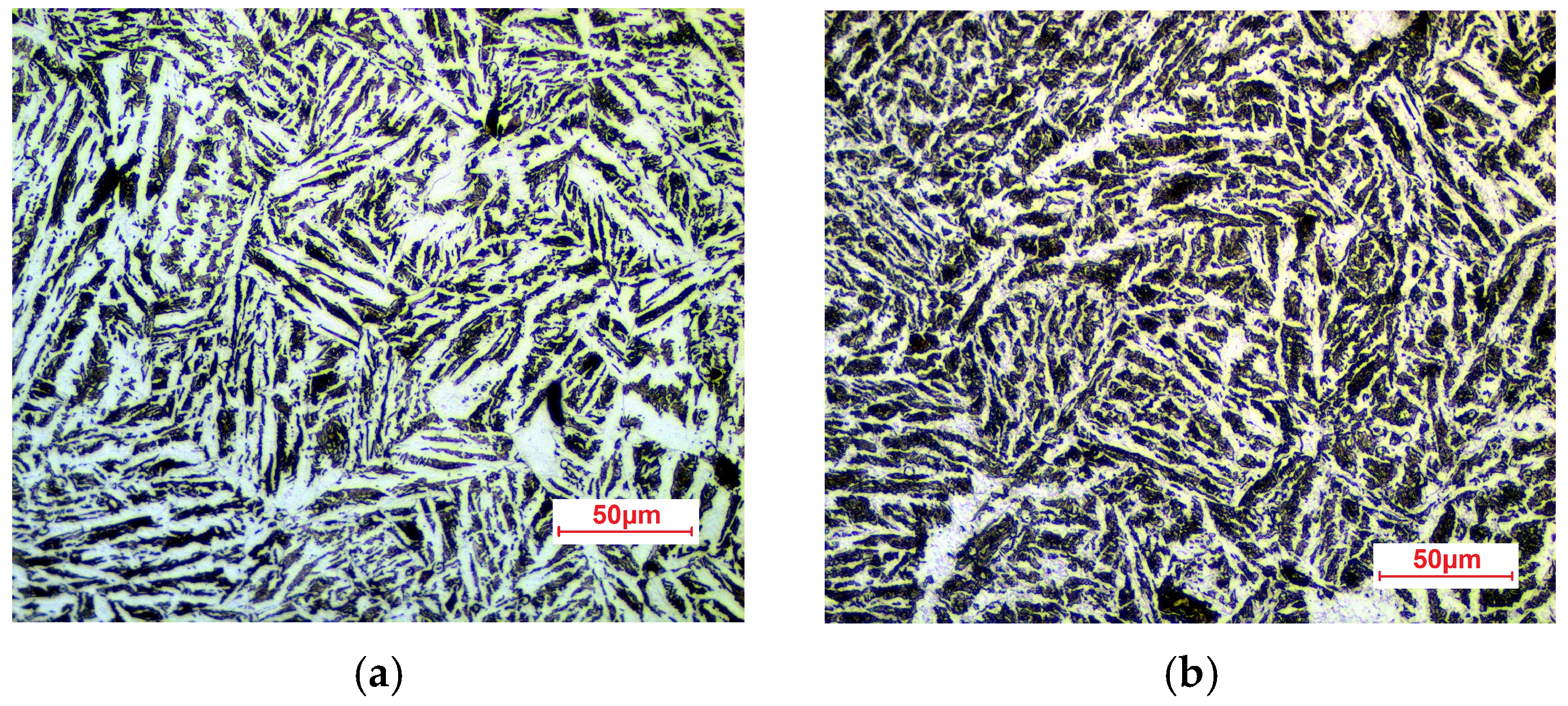

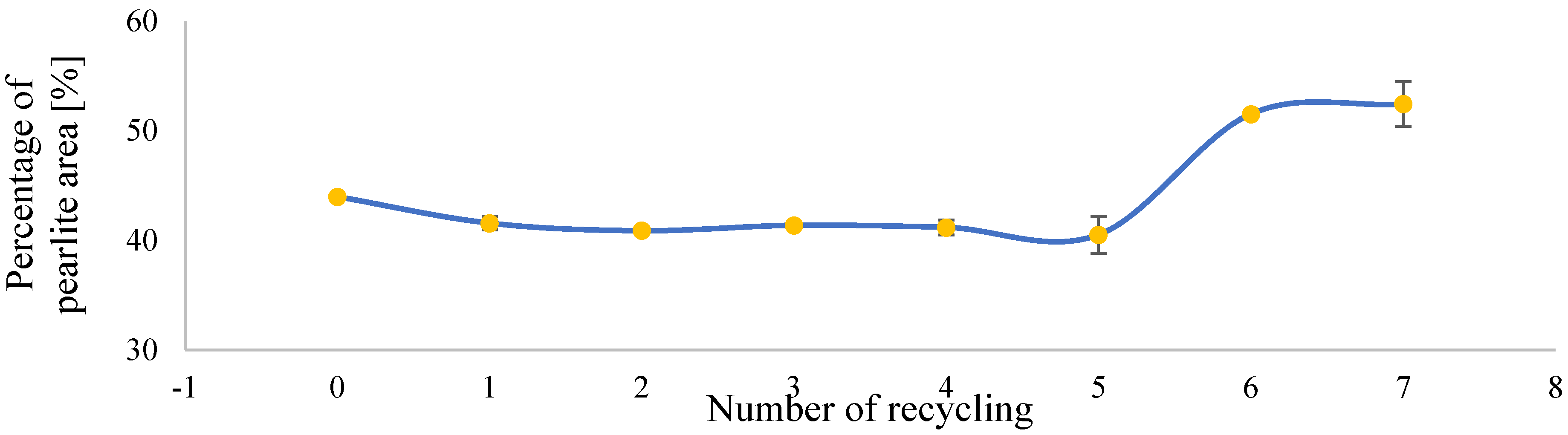

3.3. Metallographic Examination of Sintered Specimen

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Heaney, D.F. (Ed.) Handbook of Metal Injection Molding, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2019; Volume 636. [Google Scholar]

- Hauck, P.A. Powder injection molding: Current and long term outlook. Int. J. Powder Metall. 2000, 36, 29–30. [Google Scholar]

- Petzoldt, F.; Eifert, H.; wig, T.H.; Kramer, L.; Veltl, G.; Pest, A. Broadening the Scope of MIM. Mater. Manuf. Process. 1997, 12, 691–711. [Google Scholar] [CrossRef]

- Ma, H.; Li, S.; Jin, Z.; Tian, Y.; Ren, F.; Zhou, Z.; Xu, W. Effect of 17-4PH stainless steel powders interaction on feedstocks. Powder Technol. 2020, 372, 204–211. [Google Scholar] [CrossRef]

- Omar, M.A.; Zainon, N. Powder Characterization, Mixing Behaviour and Rheological Properties of Magnesium Powder Feedstock for Metal Injection Moulding Process. Saudi J. Eng. Technol. 2020, 5, 509–514. [Google Scholar] [CrossRef]

- Bata, A.; Nagy, D.; Weltsch, Z. Effect of Recycling on the Mechanical, Thermal and Rheological Properties of Polypropylene/Carbon Nanotube Composites. Polymers 2022, 14, 5257. [Google Scholar] [CrossRef] [PubMed]

- Cheng, L.H.; Hwang, K.S.; Fan, Y.L. Molding Properties and Causes of Deterioration of Recycled Powder Injection Molding Feedstock. Metall. Mater. Trans. A 2009, 40, 3210–3216. [Google Scholar] [CrossRef]

- MatWeb Material Property Data. 4605 Low Alloy Steel [Internet]. Available online: https://www.matweb.com/search/datasheet.aspx?matguid=7f547e7b655f4e48a75409740309cb5a&ckck=1 (accessed on 18 March 2024).

- Optimim. [Internet]. Available online: https://optimim.com/en/metal-injection-molding-mim/material-options/low-alloy-steel/mim-4605-quenched-tempered-high-hardness (accessed on 13 May 2024).

- Narasimhan, K.S. Sintering of powder mixtures and the growth of ferrous powder metallurgy. Mater. Chem. Phys. 2001, 67, 56–65. [Google Scholar] [CrossRef]

| % | Fe | C | Ni | Mo | Si |

|---|---|---|---|---|---|

| Min. | remain | 0.4 | 1.5 | 0.2 | - |

| Max. | remain | 0.6 | 2.5 | 0.5 | 1.0 |

| Set Parameter | Value |

|---|---|

| Injection volume | 7.9–8.1 cm3 |

| Injection pressure | 1900–2100 bar |

| Holding time | 3–5 s |

| Holding pressure | 980–1070 bar |

| Cooling time | 13 s |

| Mold temperature | 50 °C |

| Melt temperature | 190 °C |

| Cycle time | 30 s |

| Total number of specimens produced | 287 pieces |

| Total production time | 11 h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ledniczky, G.; Tajti, F.; Marokházi, S.; Weltsch, Z. Effects of Reprocessing on Surface Oxidation and Microstructural Composition in Metal Injection-Molded Materials: Insights from SEM, EDX, and Metallographic Analysis. Eng. Proc. 2024, 79, 9. https://doi.org/10.3390/engproc2024079009

Ledniczky G, Tajti F, Marokházi S, Weltsch Z. Effects of Reprocessing on Surface Oxidation and Microstructural Composition in Metal Injection-Molded Materials: Insights from SEM, EDX, and Metallographic Analysis. Engineering Proceedings. 2024; 79(1):9. https://doi.org/10.3390/engproc2024079009

Chicago/Turabian StyleLedniczky, György, Ferenc Tajti, Sándor Marokházi, and Zoltán Weltsch. 2024. "Effects of Reprocessing on Surface Oxidation and Microstructural Composition in Metal Injection-Molded Materials: Insights from SEM, EDX, and Metallographic Analysis" Engineering Proceedings 79, no. 1: 9. https://doi.org/10.3390/engproc2024079009

APA StyleLedniczky, G., Tajti, F., Marokházi, S., & Weltsch, Z. (2024). Effects of Reprocessing on Surface Oxidation and Microstructural Composition in Metal Injection-Molded Materials: Insights from SEM, EDX, and Metallographic Analysis. Engineering Proceedings, 79(1), 9. https://doi.org/10.3390/engproc2024079009