1. Introduction

The proper design and maintenance of asphalt pavement will extend its service life and help it to maintain a satisfactory level of service. However, due to in-service conditions, asphalt pavements can be damaged by certain types of distresses. Pavement distresses, such as raveling, rutting, and fatigue cracking, worsen in severe climatic and loading conditions, such as high temperatures, elevated humidity levels, and high traffic loads on the pavement. The extreme arid climatic conditions of Kuwait and poor asphalt mix design characteristics have further accelerated the rate of deterioration of in-service asphalt pavements [

1]. To combat this issue, Kuwait’s Ministry of Public Works (MPW) adopted the Superpave asphalt mix design from the Qatari Construction Specifications, which considers both climate and traffic, unlike the Marshall mix design approach. However, the long-term performance of this newly adopted Superpave asphalt mix design must be evaluated to determine its long-term resistance to common pavement distresses [

2].

Mechanistic–empirical (ME) analysis is based on the theory of mechanics and predicts the responses of the pavement to the application of loads. The empirically derived models employ these pavement responses to forecast distress in terms of cracking and rutting. ME analysis can forecast asphalt pavement’s long-term performance over its design period. As a result, the objective of this study was to use a ME analysis to assess the resistance of the Superpave asphalt mixture against prevalent pavement distresses, including rutting and fatigue cracking. This ME study assisted in comprehending how the modified material properties impact pavement performance over time and if further modifications are required to the newly approved mix design procedure.

2. Methods and Materials

In this research study, the local raw materials were acquired from Kuwait to develop Superpave asphalt mix design. The raw material types and the desired number of samples were selected according to the General Specifications for Kuwaiti Roads and Highways (MPW) [

3] and the Qatar Construction Specifications [

4]. Only one aggregate source and one asphalt binder grade were used for this research study. The selected aggregate was Gabroo aggregate, and the evaluated properties met the ASTM standard requirements.

Figure 1 depicts the final aggregate gradation obtained for the Superpave mix design. Similarly, the asphalt binder properties were examined, and the final performance grade obtained following AASHTO M320 was PG 76-22 [

2].

After evaluating the raw materials, the Superpave mix was performed as per AASHTO M 323, where the optimum binder content selected was 4.1% (TWM) at 4% air voids meeting the required volumetrics shown in

Table 1.

After finalizing the mix design, performance testing such as dynamic modulus, cyclic fatigue, and stress sweep rutting tests were conducted for the Superpave asphalt mixture at the unconditioned state (UC) and moisture-conditioned at three freeze–thaw cycles (3-C). The engineering properties measured from these tests were used as the input parameters in the mechanistic–empirical analysis to predict the long-term pavement performance over 20 years.

Mechanistic–Empirical Analysis

The FlexPave

TM software was used to perform mechanistic–empirical analysis of the Superpave asphalt mixture at the UC state and after the 3-C state. FlexPave

TM is a modified linear viscoelastic pavement design for critical distresses (LVECD) based on the three-dimensional (3D) viscoelastic finite element technique (FEM) [

5].

3. Results and Discussion

The required input parameters for the ME analysis are climate data, traffic data, material properties, pavement structure, and performance criteria. Local climate information for Kuwait was taken from the MEERA-2 global climatic database. Currently, the MPW is updating its traffic data collection system, and the most recent traffic data is not available. Therefore, the traffic parameters used in the analysis were the default values, as shown in

Table 2. In Kuwait, there are currently no performance standards for rutting and fatigue cracking. Hence, the performance criteria used by researchers in neighboring countries with similar arid climate regions were considered.

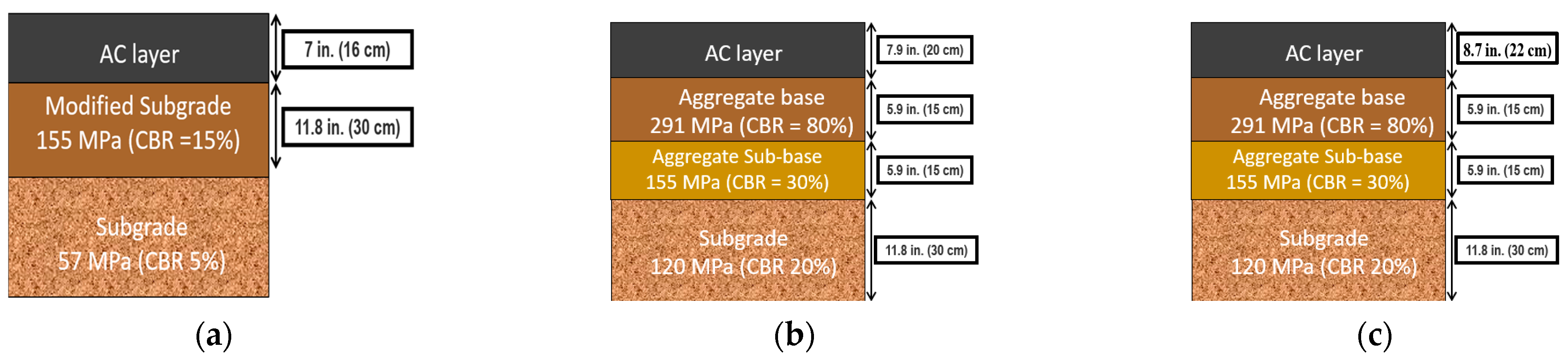

In this study, the thickness of the pavement was determined using the three methods listed in

Table 3. Method A employs a similar pavement structure built in Kuwait before 2012, but Method B employs the AASHTO Guide to the Design of Pavement Structures, 1993 (referred to as AASHTO 93). Method C employs a pavement structure similar to Method B, but the asphalt (AC) layer thickness is increased until the rutting and cracking performance criteria are met. The AC layer was assumed to be a single layer, and the analysis was conducted for the Superpave asphalt mixture at the UC state and after the 3-C, respectively.

Figure 2 shows the pavement structure used in the ME analysis for each method.

After inputting the above-mentioned parameters, the analysis was run using the FlexPave

TM software. An example of the results obtained for the cracking and rutting for design method A is shown in

Figure 3. Similarly, the analysis was performed for the other two design methods, and the final obtained results are discussed in

Table 4.

As illustrated in

Figure 3 and

Table 4, pavement sections constructed before 2012 in Kuwait were inadequately designed for 30 MESALS of traffic. The pavement constructed using Method B had a longer fatigue and rutting life, but it still required improvement to withstand the 20-year design traffic of 30 MESALS. Method C increased the asphalt pavement thickness until the pavement met the performance parameters for the Superpave asphalt mixture at the UC state. However, the pavement could only endure 5.5 years after the 3-C state indicating a durability issue in the mix design.

4. Conclusions and Recommendations

This study focused on the process and importance of conducting mechanistic–empirical analysis for the newly adopted Superpave asphalt mixture. Results showed that the newly adopted Superpave asphalt mixture enhanced the rutting and fatigue cracking resistances at the unconditioned state. However, fatigue cracking resistance under the moisture-conditioned state still needs further improvement for the newly modified Superpave asphalt mixture.

Author Contributions

T.A. and A.S. (Aditya Singh): Conceptualization, data curation, supervision, writing—original draft, software, and data analysis. E.H. and A.S. (Ahmad Saad): Conceptualization, investigation, methodology, data curation, writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research study was jointly funded by the Australian University-Kuwait and Kuwait Foundation for the Advancement of Sciences under project code CR20-15EV-01.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are available from the corresponding authors upon request.

Acknowledgments

The authors would like to acknowledge the great help and support provided by the Australian University-Kuwait.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ahmed, T.; Hajj, E.; Warrag, A.; Piratheepan, M. Postmortem evaluation of accelerated rate of raveling of in-service asphalt pavements in arid climatic conditions-case of Kuwait. Case Stud. Constr. Mater. 2021, 14, e00533. [Google Scholar] [CrossRef]

- Singh, A. Comprehensive Evaluation of Asphalt Mixtures in Arid Climatic Conditions. Master’s Thesis, University of Nevada, Reno, NV, USA, 2022. [Google Scholar]

- Hannah, A.; Prime, J.; Hassan, K.; Attia, M. Asphalt Wearing Course Pavement Investigation: Investigation into Pavement Raveling; Report No. RPN3225; Ministry of Public Works, Roads Administration: Kuwait City, Kuwait, 2015. [Google Scholar]

- Public Works Authority (Ashghal). Qatar Construction Specifications; Standard QCS.: Doha, Qatar, 2014. [Google Scholar]

- Pivetta, F. Development of Software Programs for Performance Related Specifications of Asphalt Concrete Pavements. Master’s Thesis, North Carolina State University, Raleigh, NC, USA, 2021. [Google Scholar]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).