5G-Enabled E-Textiles Based on a Low-Profile Millimeter-Wave Textile Antenna †

Abstract

:1. Introduction

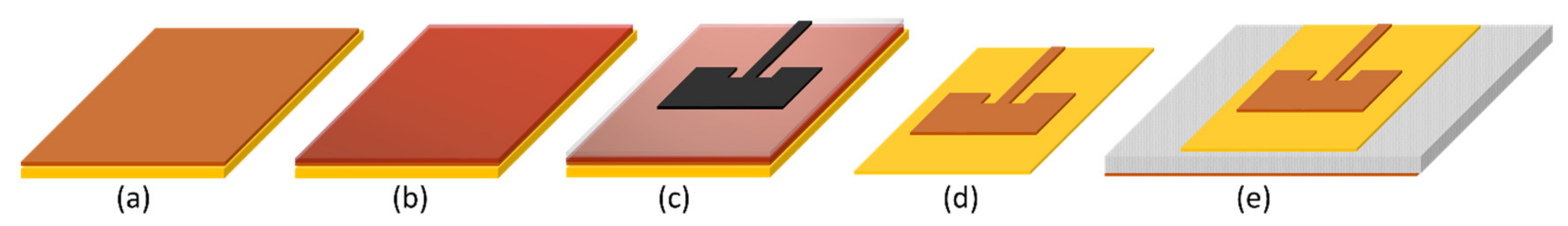

2. E-Textile mmWave Antenna Fabrication

3. mmWave E-Textile Antenna Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hall, P.; Hao, Y. Antennas and Propagation for Body-Centric Wireless Communications, 2nd ed.; Artech: Morristown, NJ, USA, 2012. [Google Scholar]

- Rappaport, T.S.; Sun, S.; Mayzus, R.; Zhao, H.; Azar, Y.; Wang, K.; Wong, G.N.; Schulz, J.K.; Samimi, M.; Gutierrez, F. Millimeter Wave Mobile Communications for 5G Cellular: It Will Work! IEEE Access 2013, 1, 335–349. [Google Scholar] [CrossRef]

- Chahat, N.; Zhadobov, M.; Muhammad, S.A.; le Coq, L.; Sauleau, R. 60-GHz Textile Antenna Array for Body-Centric Communications. IEEE Trans. Antennas Propag. 2013, 61, 1816–1824. [Google Scholar] [CrossRef]

- Wagih, M.; Hilton, G.S.; Weddell, A.S.; Beeby, S. Broadband Millimeter-Wave Textile-Based Flexible Rectenna for Wearable Energy Harvesting. IEEE Trans. Microw. Theory Tech. 2020, 68, 4960–4972. [Google Scholar] [CrossRef]

- Wagih, M.; Komolafe, A.; Hillier, N. Screen-Printable Flexible Textile-Based Ultra-Broadband Millimeter-Wave DC-Blocking Transmission Lines Based on Microstrip-Embedded Printed Capacitors. IEEE J. Microw. 2021, 2, 162–173. [Google Scholar] [CrossRef]

- Wagih, M.; Hilton, G.S.; Weddell, A.S.; Beeby, S. Millimeter Wave Power Transmission for Compact and Large-Area Wearable IoT Devices based on a Higher-Order Mode Wearable Antenna. IEEE Internet Things J. 2021. [Google Scholar] [CrossRef]

- Kimionis, J.; Georgiadis, A.; Daskalakis, S.N.; Tentzeris, M.M. A printed millimetre-wave modulator and antenna array for backscatter communications at gigabit data rates. Nat. Electron. 2021, 4, 439–446. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wagih, M.; Hilton, G.S.; Weddell, A.S.; Beeby, S. 5G-Enabled E-Textiles Based on a Low-Profile Millimeter-Wave Textile Antenna. Eng. Proc. 2022, 15, 13. https://doi.org/10.3390/engproc2022015013

Wagih M, Hilton GS, Weddell AS, Beeby S. 5G-Enabled E-Textiles Based on a Low-Profile Millimeter-Wave Textile Antenna. Engineering Proceedings. 2022; 15(1):13. https://doi.org/10.3390/engproc2022015013

Chicago/Turabian StyleWagih, Mahmoud, Geoff S. Hilton, Alex S. Weddell, and Steve Beeby. 2022. "5G-Enabled E-Textiles Based on a Low-Profile Millimeter-Wave Textile Antenna" Engineering Proceedings 15, no. 1: 13. https://doi.org/10.3390/engproc2022015013

APA StyleWagih, M., Hilton, G. S., Weddell, A. S., & Beeby, S. (2022). 5G-Enabled E-Textiles Based on a Low-Profile Millimeter-Wave Textile Antenna. Engineering Proceedings, 15(1), 13. https://doi.org/10.3390/engproc2022015013