Investigation of Membrane Fouling in Vacuum Membrane Distillation (VMD) Using Blocking Filtration Laws †

Abstract

:1. Introduction

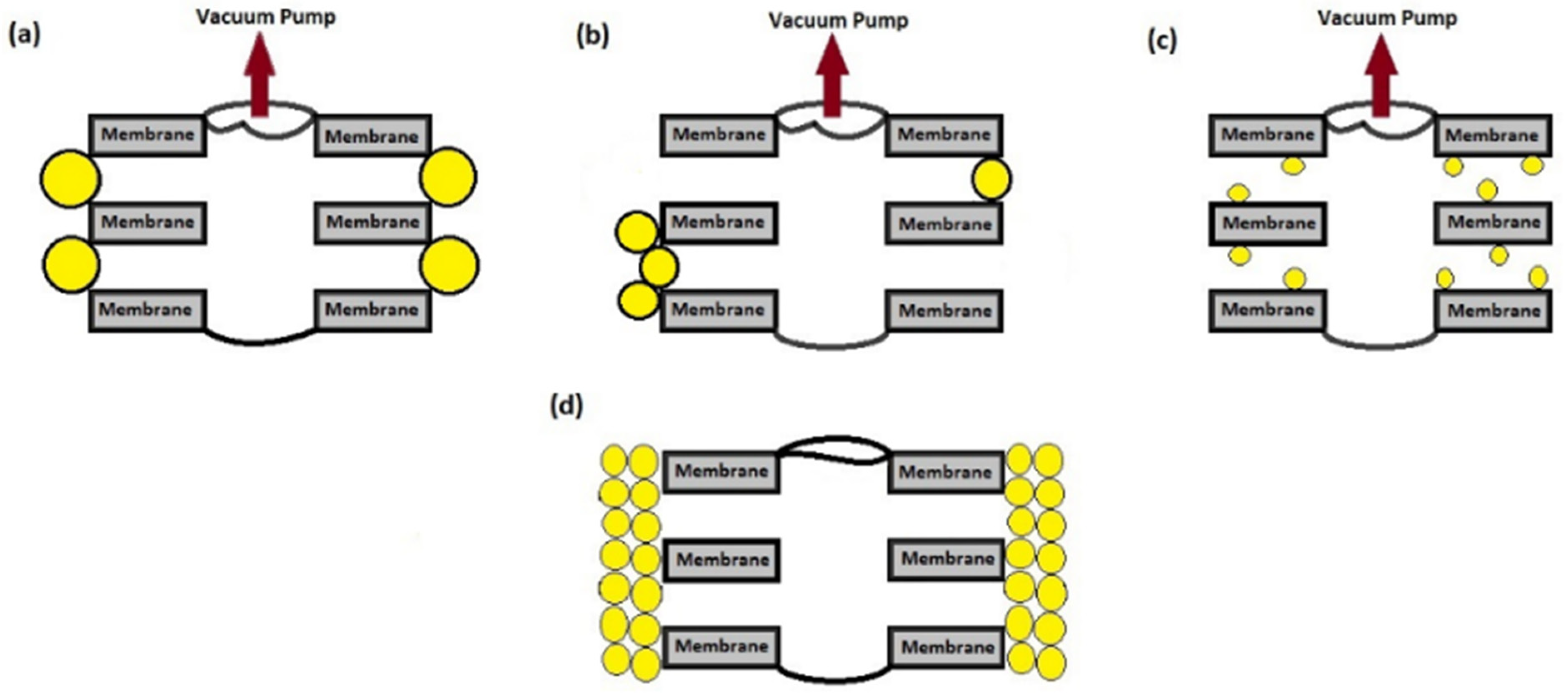

2. Modeling Procedure

3. Results and Discussion

3.1. Experiment 1

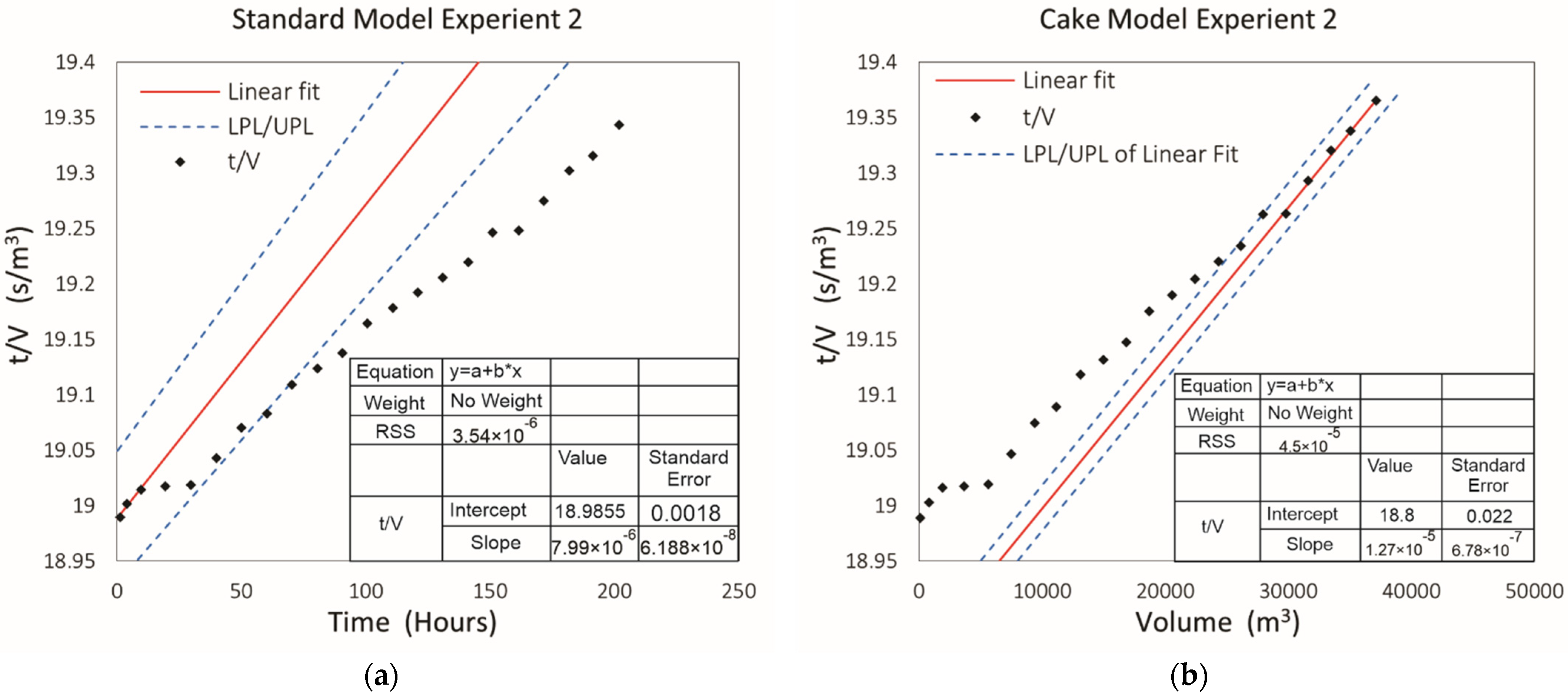

3.2. Experiment 2

3.3. Experiment 3

3.4. Experiment 4

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, H.; Shen, F.; Wang, J.; Wan, Y. Membrane fouling in vacuum membrane distillation for ionic liquid recycling:Interaction energy analysis with the XDLVO approach. J. Memb. Sci. 2018, 550, 436–447. [Google Scholar] [CrossRef]

- Yun, Y.; Ma, R.; Zhang, W.; Fane, A.G.; Li, J. Direct contact membrane distillation mechanism for high concentration NaCl solutions. Desalination 2006, 188, 251–262. [Google Scholar] [CrossRef]

- Pangarkar, B.L.; Thorat, P.V.; Parjane, S.B.; Abhang, R.M. Performance evaluation of vacuum membrane distillation for desalination by using a flat sheet membrane. Desalin. Water Treat. 2010, 21, 328–334. [Google Scholar] [CrossRef]

- Hermia, J. Constant Pressure Blocking Filtration Laws—Application To Power-law Non-newtonian Fluids. Inst. Chem. Engrs. Trans. 1982, 60, 183–187. [Google Scholar]

- Alsaadi, A.S.; Francis, L.; Amy, G.L.; Ghaffour, N. Experimental and theoretical analyses of temperature polarization effect in vacuum membrane distillation. J. Memb. Sci. 2014, 471, 138–148. [Google Scholar] [CrossRef] [Green Version]

| Linearized Form | n | Assumption | |

|---|---|---|---|

| Standard Blocking | 1.5 | Deposition of particles smaller than the pore size resulting in smaller pores | |

| Intermediate Blocking | 1 | Particles super-impose on each other. | |

| Complete Blocking | 2 | Membrane pores are completely sealed off by the particles | |

| Cake filtration | 0 | Particles deposit on membrane-feed interface forming a cake layer |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bibi, W.; Asif, M.; Rabbi, J. Investigation of Membrane Fouling in Vacuum Membrane Distillation (VMD) Using Blocking Filtration Laws. Eng. Proc. 2021, 12, 82. https://doi.org/10.3390/engproc2021012082

Bibi W, Asif M, Rabbi J. Investigation of Membrane Fouling in Vacuum Membrane Distillation (VMD) Using Blocking Filtration Laws. Engineering Proceedings. 2021; 12(1):82. https://doi.org/10.3390/engproc2021012082

Chicago/Turabian StyleBibi, Wajeeha, Muhammad Asif, and Jawad Rabbi. 2021. "Investigation of Membrane Fouling in Vacuum Membrane Distillation (VMD) Using Blocking Filtration Laws" Engineering Proceedings 12, no. 1: 82. https://doi.org/10.3390/engproc2021012082

APA StyleBibi, W., Asif, M., & Rabbi, J. (2021). Investigation of Membrane Fouling in Vacuum Membrane Distillation (VMD) Using Blocking Filtration Laws. Engineering Proceedings, 12(1), 82. https://doi.org/10.3390/engproc2021012082