Studies on Ceramic Wastes based Composites for Capacitors Applications †

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Synthesis of Composite Material

3. Results and Discussion

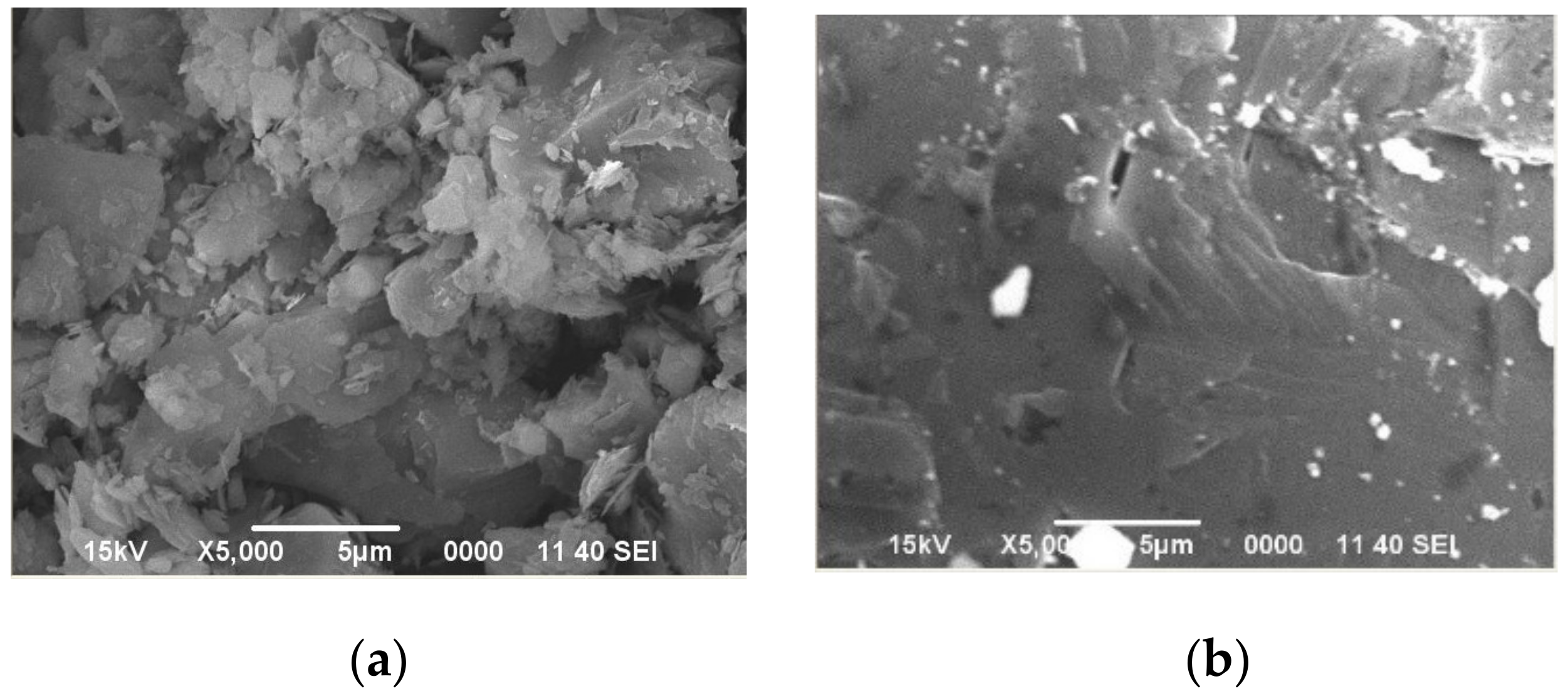

3.1. SEM Analysis

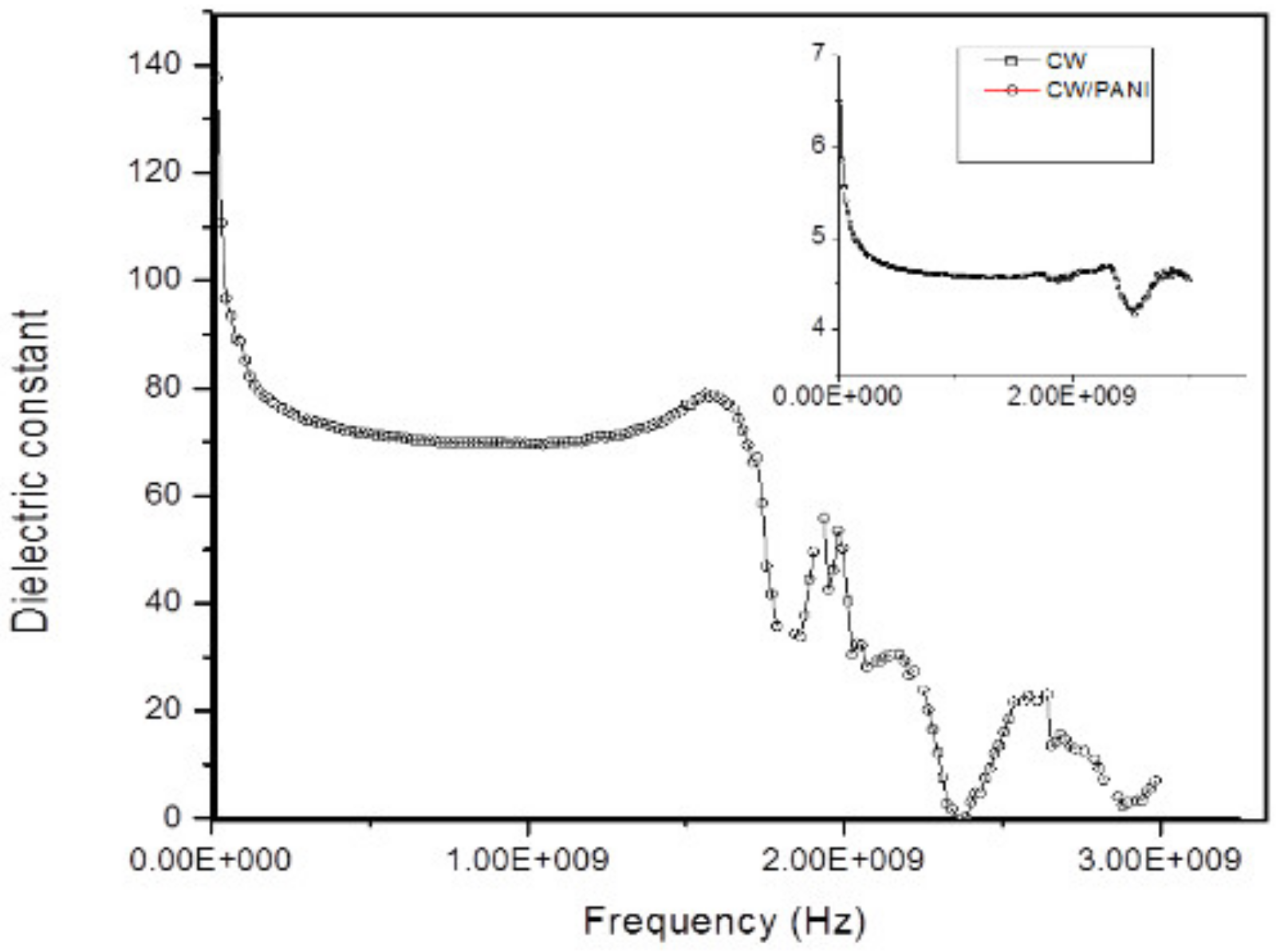

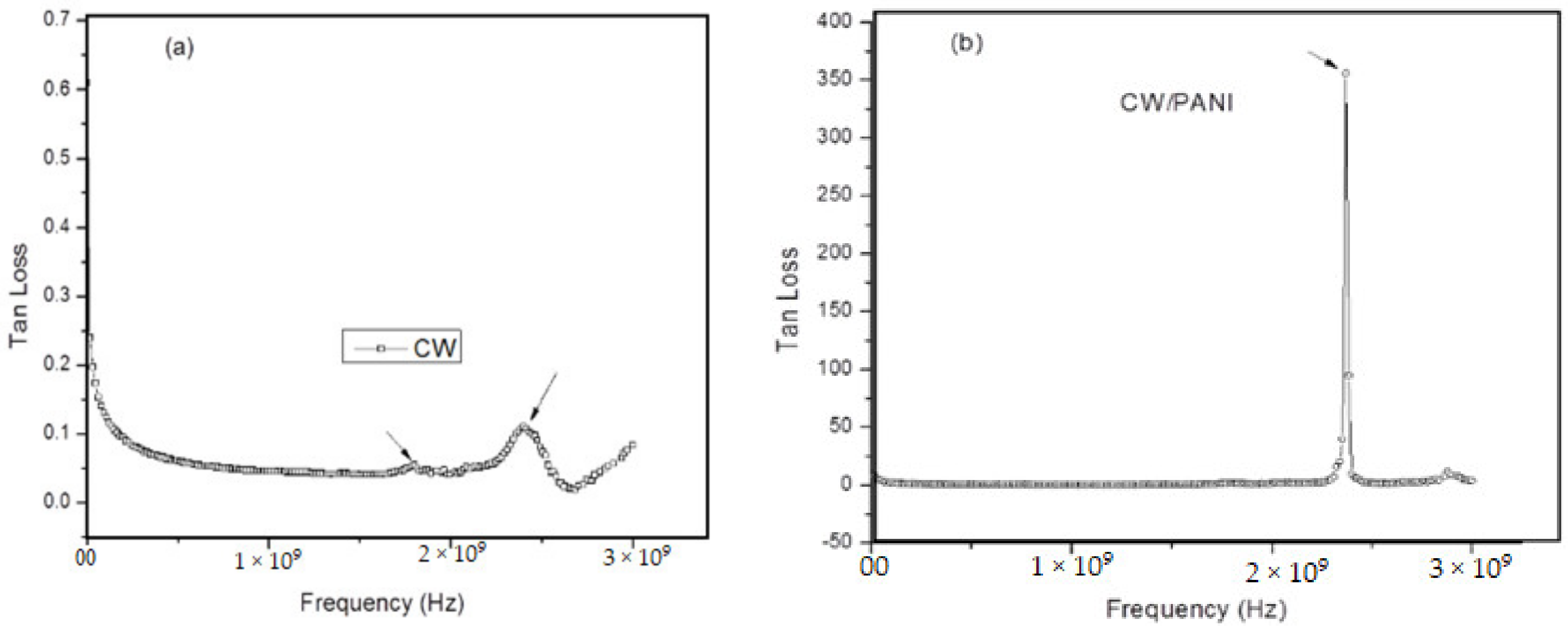

3.2. Dielectric Characteristics

3.2.1. Dielectric Permeability (ε′)

3.2.2. Tanδ (Dielectric Loss)

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chen, H.; Yen, T.; Chen, K. Use of building rubbles as recycled aggregates. Cem. Concr. Res. 2003, 33, 125. [Google Scholar] [CrossRef]

- Topçu, N.B.; Canbaz, M. Utilization of crushed tile as aggregate in concrete. Iran. J. Sci. Technol. 2007, 31, 561. [Google Scholar]

- Jingjie, C.; Xinfa, D.; Lingling, L.; Yingchao, D.; Stuart, H. Recycling of waste fly ash for production of porous mullite ceramic membrane supports with increased porosity. J. Eur. Ceram. Soc. 2014, 34, 3181. [Google Scholar]

- Aysegül, G.; Mária, O.; Jan, P. Synthesis and characterization of red mud/polyaniline composites: Electrical properties and thermal stability. Eur. Polym. J. 2007, 43, 2471. [Google Scholar]

- Aminudin, A.; Mohd, M.Y.; Malik, A.A.; Khairul, A.I. Polymeric composite based on waste material for high voltage outdoor application. Int. J. Electr. Power Energy Syst. 2013, 45, 346. [Google Scholar]

- Khalil, A.A.; Tawfik, A.; Hegazy, A.A.; El-Shahat, M.F. Effect of some waste additives on the physical and mechanical properties of gypsum plaster composites. Constr. Build. Mater. 2014, 68, 580. [Google Scholar] [CrossRef]

- Kaiser, H.R.; Akbar, Z.K. Other Non-Metallic Products-Glass and Ceramics. 2011; pp. 1–15.

- Badapanda, T.; Senthil, V.; Anwar, S.; Cavalcante, L.S.; Batista, N.C.; Longo, E. Structural and dielectric properties of polyvinyl alcohol/barium zirconium titanate polymer/ceramic composite. Curr. Appl. Phys. 2013, 13, 1490. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sohail, M.; Omer, M.; Adnan; Sayed, M.G.; Shahzad, A.; Ullah, I.; Ahmad, A. Studies on Ceramic Wastes based Composites for Capacitors Applications. Eng. Proc. 2021, 12, 108. https://doi.org/10.3390/engproc2021012108

Sohail M, Omer M, Adnan, Sayed MG, Shahzad A, Ullah I, Ahmad A. Studies on Ceramic Wastes based Composites for Capacitors Applications. Engineering Proceedings. 2021; 12(1):108. https://doi.org/10.3390/engproc2021012108

Chicago/Turabian StyleSohail, Mohammad, Muhammad Omer, Adnan, Main Gul Sayed, Adnan Shahzad, Ihsan Ullah, and Aziz Ahmad. 2021. "Studies on Ceramic Wastes based Composites for Capacitors Applications" Engineering Proceedings 12, no. 1: 108. https://doi.org/10.3390/engproc2021012108

APA StyleSohail, M., Omer, M., Adnan, Sayed, M. G., Shahzad, A., Ullah, I., & Ahmad, A. (2021). Studies on Ceramic Wastes based Composites for Capacitors Applications. Engineering Proceedings, 12(1), 108. https://doi.org/10.3390/engproc2021012108