Industry 4.0-Compliant IoT Supervisory System for Green Hydrogen Applications in Industrial and Domestic Sectors †

Abstract

1. Introduction

2. Materials and Methods

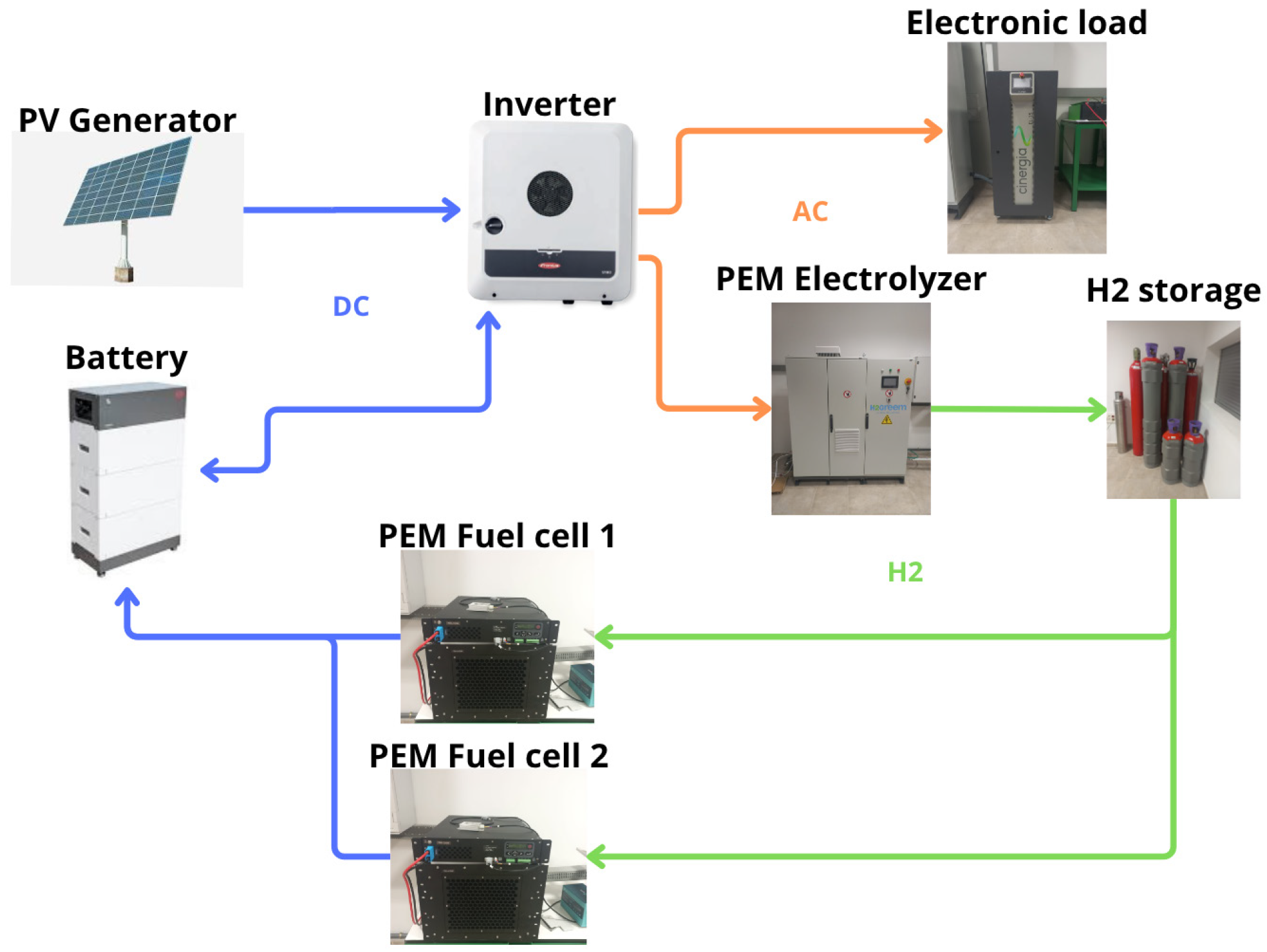

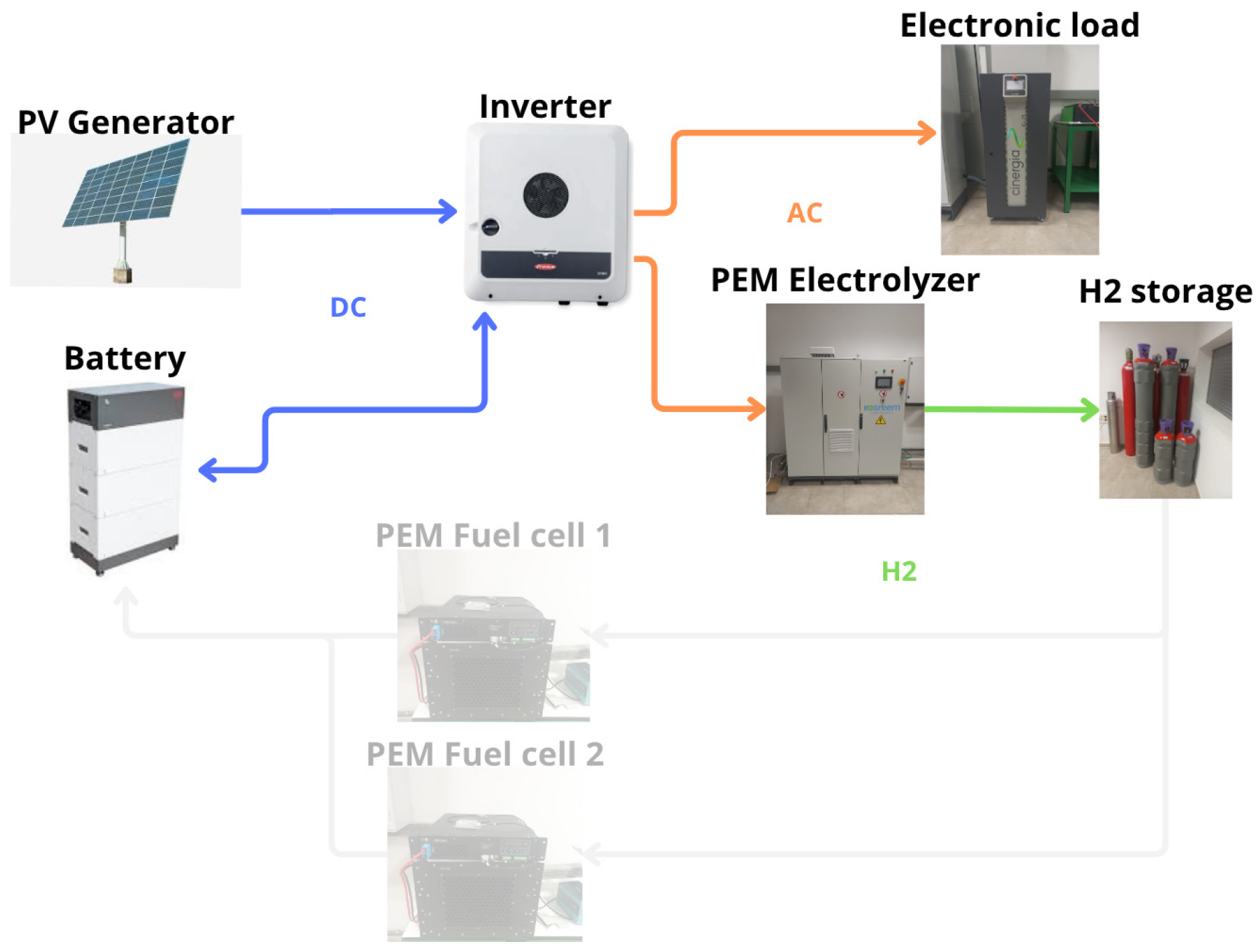

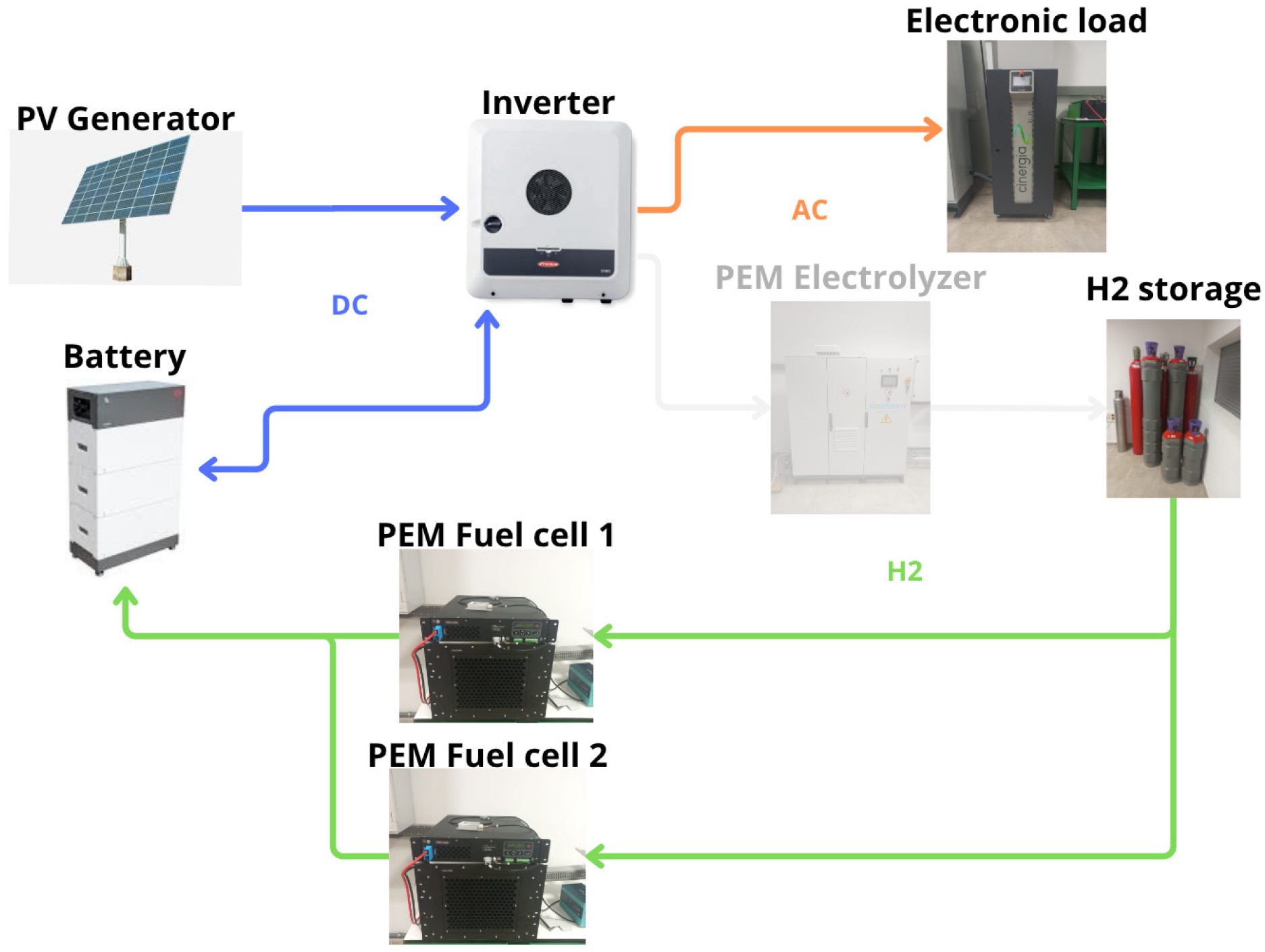

2.1. Pilot Plant

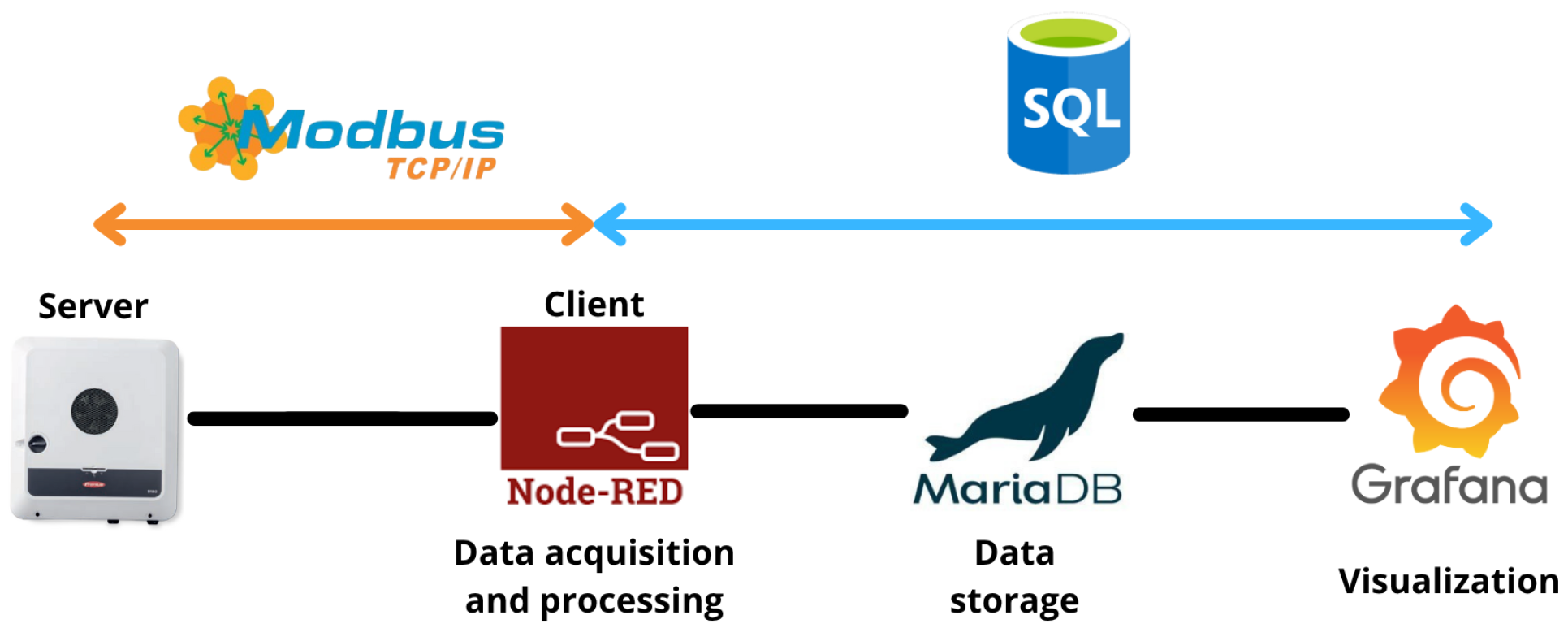

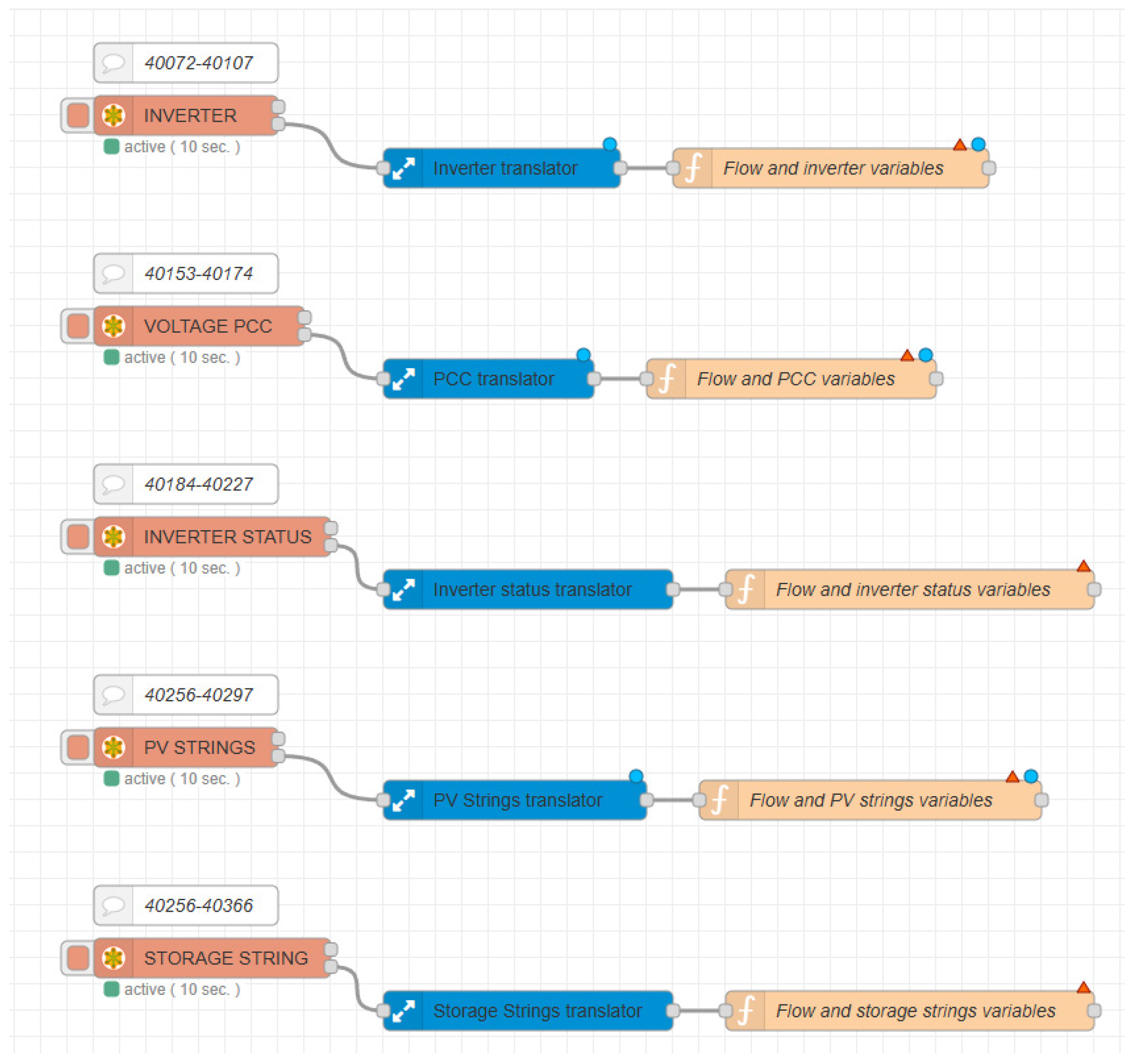

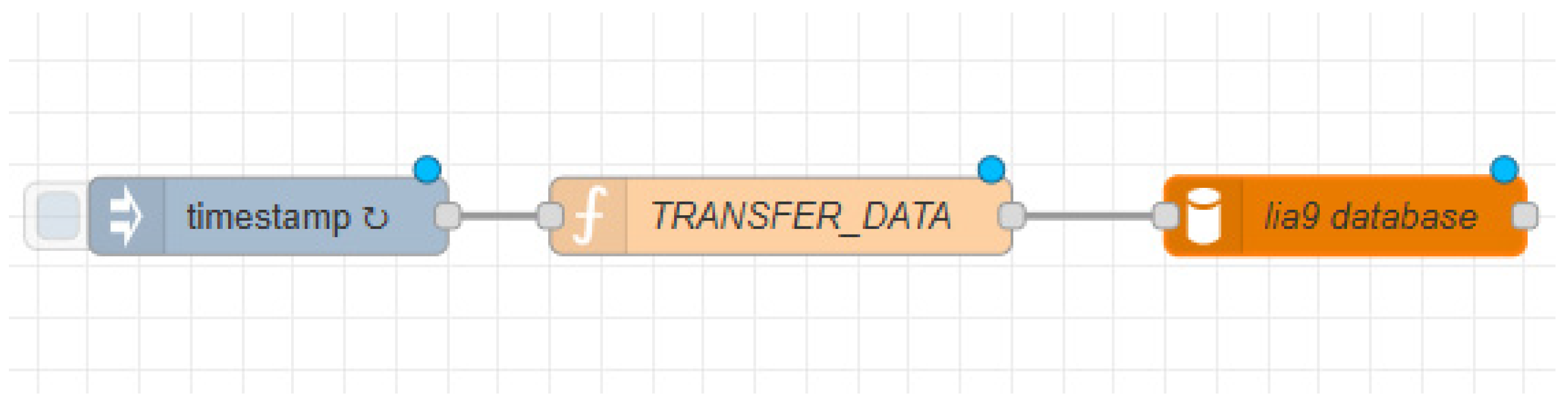

2.2. Supervisory System

- Lack of real-time visualization: The only real-time information available is a synoptic diagram representing power flows, which lacks key data required for comprehensive analysis.

- Paid subscription: This limits the ability to perform the visualization of several critical variables.

- Limited historical data access: For historical data visualization, the platform only provides a single chart in which the channels correspond to the selected variables. This representation format hinders the simultaneous analysis of multiple variables, posing a significant limitation in terms of usability and analytical depth.

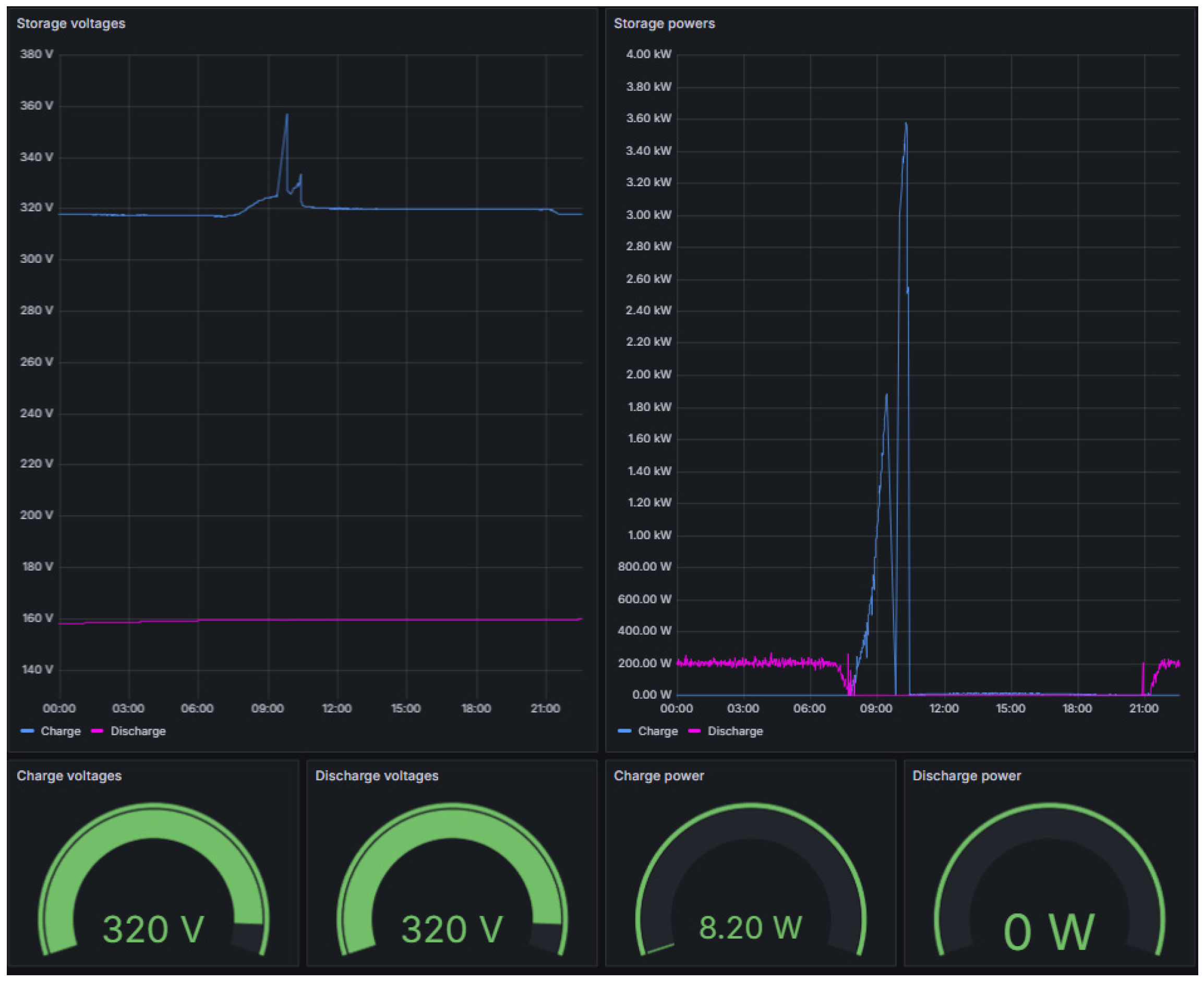

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- do Amaral, J.V.S.; dos Santos, C.H.; Montevechi, J.A.B.; de Queiroz, A.R. Energy Digital Twin Applications: A Review. Renew. Sustain. Energy Rev. 2023, 188, 113891. [Google Scholar] [CrossRef]

- Folgado, F.J.; Calderón, D.; González, I.; Calderón, A.J. Review of Industry 4.0 from the Perspective of Automation and Supervision Systems: Definitions, Architectures and Recent Trends. Electronics 2024, 13, 782. [Google Scholar] [CrossRef]

- Solaria S6P335 PV Panel Datasheet. Available online: https://suelosolar.com/images/39385622.pdf (accessed on 30 July 2025).

- Fronius Symo GEN24 Plus 10.0 Power Inverter Datasheet. Available online: https://krannich-solar.com/fileadmin/user_upload/TR/Products/Inverter/Fronius/Fronius_Symo_GEN24_Plus__6.0__8.0__10.0_.pdf (accessed on 30 July 2025).

- BYD Battery Box Premium HVS 7.7 Datasheet. Available online: https://bydbatterybox.com/uploads/downloads/BBOX_HVS_Datasheet_ES_V1.0_240703_L-6690809ed9771.pdf (accessed on 30 July 2025).

- Cinergia El+vAC 15 Programmable Electronic Load Datasheet. Available online: https://cinergiapower.com/en/products/el-ac (accessed on 31 July 2025).

- LPGREEM PEM Electrolyzer Datahseet. Available online: https://h2greem.com/wp-content/uploads/2025/04/Technical-Data-Sheet-LPGREEM-2.pdf (accessed on 30 July 2025).

- Horizon 2.5kW PEM Fuel Cell T-Series Datasheet. Available online: https://www.horizoneducational.com/2-5kw-fuel-cell-t-series/p1578 (accessed on 30 July 2025).

- Folgado, F.J.; González, I.; Calderón, A.J. Data Acquisition and Monitoring System Framed in Industrial Internet of Things for PEM Hydrogen Generators. Internet Things 2023, 22, 100795. [Google Scholar] [CrossRef]

- He, W.; Baig, M.J.A.; Iqbal, M.T. An Open-Source Supervisory Control and Data Acquisition Architecture for Photovoltaic System Monitoring Using ESP32, Banana Pi M4, and Node-RED. Energies 2024, 17, 2295. [Google Scholar] [CrossRef]

- Martone, A.; D’Ambrosio, A.; Ferrucci, M.; Cembalo, A.; Romano, G.; Zazzaro, G. Sensor-Based Monitoring Data from an Industrial System of Centrifugal Pumps. Data 2025, 10, 91. [Google Scholar] [CrossRef]

- Herrera, V.A.S.; de Araújo, H.P.; Penteado, C.G.; Gazziro, M.; Carmo, J.P. Low-Cost Embedded System Applications for Smart Cities. Big Data Cogn. Comput. 2025, 9, 19. [Google Scholar] [CrossRef]

- Node-RED Web Page. Available online: https://nodered.org (accessed on 30 July 2025).

- MariaDB Foundation Web Page. Available online: https://mariadb.org (accessed on 30 July 2025).

- Grafana Web Page. Available online: https://grafana.com (accessed on 30 July 2025).

- Modbus Organization. Available online: http://www.modbus.org/ (accessed on 30 July 2025).

- Jaloudi, S. Communication Protocols of an Industrial Internet of Things Environment: A Comparative Study. Future Internet 2019, 11, 66. [Google Scholar] [CrossRef]

- González, I.; Calderón, A.J.; Portalo, J.M. Innovative Multi-Layered Architecture for Heterogeneous Automation and Monitoring Systems: Application Case of a Photovoltaic Smart Microgrid. Sustainability 2021, 13, 2234. [Google Scholar] [CrossRef]

- Node-RED Modbus Node. Available online: https://flows.nodered.org/node/node-red-contrib-modbus (accessed on 30 July 2025).

- Node-RED Buffer-Parser Node. Available online: https://flows.nodered.org/node/node-red-contrib-buffer-parser (accessed on 30 July 2025).

- Node-RED Mysql Node. Available online: https://flows.nodered.org/node/node-red-node-mysql (accessed on 30 July 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Folgado, F.J.; Millán, P.; Calderón, D.; González, I.; Calderón, A.J.; Calderón, M. Industry 4.0-Compliant IoT Supervisory System for Green Hydrogen Applications in Industrial and Domestic Sectors. Eng. Proc. 2025, 118, 37. https://doi.org/10.3390/ECSA-12-26610

Folgado FJ, Millán P, Calderón D, González I, Calderón AJ, Calderón M. Industry 4.0-Compliant IoT Supervisory System for Green Hydrogen Applications in Industrial and Domestic Sectors. Engineering Proceedings. 2025; 118(1):37. https://doi.org/10.3390/ECSA-12-26610

Chicago/Turabian StyleFolgado, Francisco Javier, Pablo Millán, David Calderón, Isaías González, Antonio José Calderón, and Manuel Calderón. 2025. "Industry 4.0-Compliant IoT Supervisory System for Green Hydrogen Applications in Industrial and Domestic Sectors" Engineering Proceedings 118, no. 1: 37. https://doi.org/10.3390/ECSA-12-26610

APA StyleFolgado, F. J., Millán, P., Calderón, D., González, I., Calderón, A. J., & Calderón, M. (2025). Industry 4.0-Compliant IoT Supervisory System for Green Hydrogen Applications in Industrial and Domestic Sectors. Engineering Proceedings, 118(1), 37. https://doi.org/10.3390/ECSA-12-26610