Selective Demolition of a Family House from an Economic Perspective in Practice †

Abstract

1. Introduction

2. Description of the Approach to Waste Generated by Construction Activities

2.1. Construction and Demolition Waste and Building Valuation

- The amount of waste in budgets is often a figure based on the dismantling weights of the item. The method of calculating dismantling weights has a significant impact on the final value. The reality is often very different.

- Categorization of the expected type of waste, definition of the required budget item, etc. In general, some waste catalog numbers are grouped into larger units.

- The price for waste disposal is often difficult to predict from the perspective of the total bid price for the construction work. When valuing these items related to waste transfer and disposal, they are commonly treated as “superfluous” items that increase the total bid price of the construction work. It is common budgeting practice to deliberately undervalue these waste-related items in order to achieve a lower price for the work.

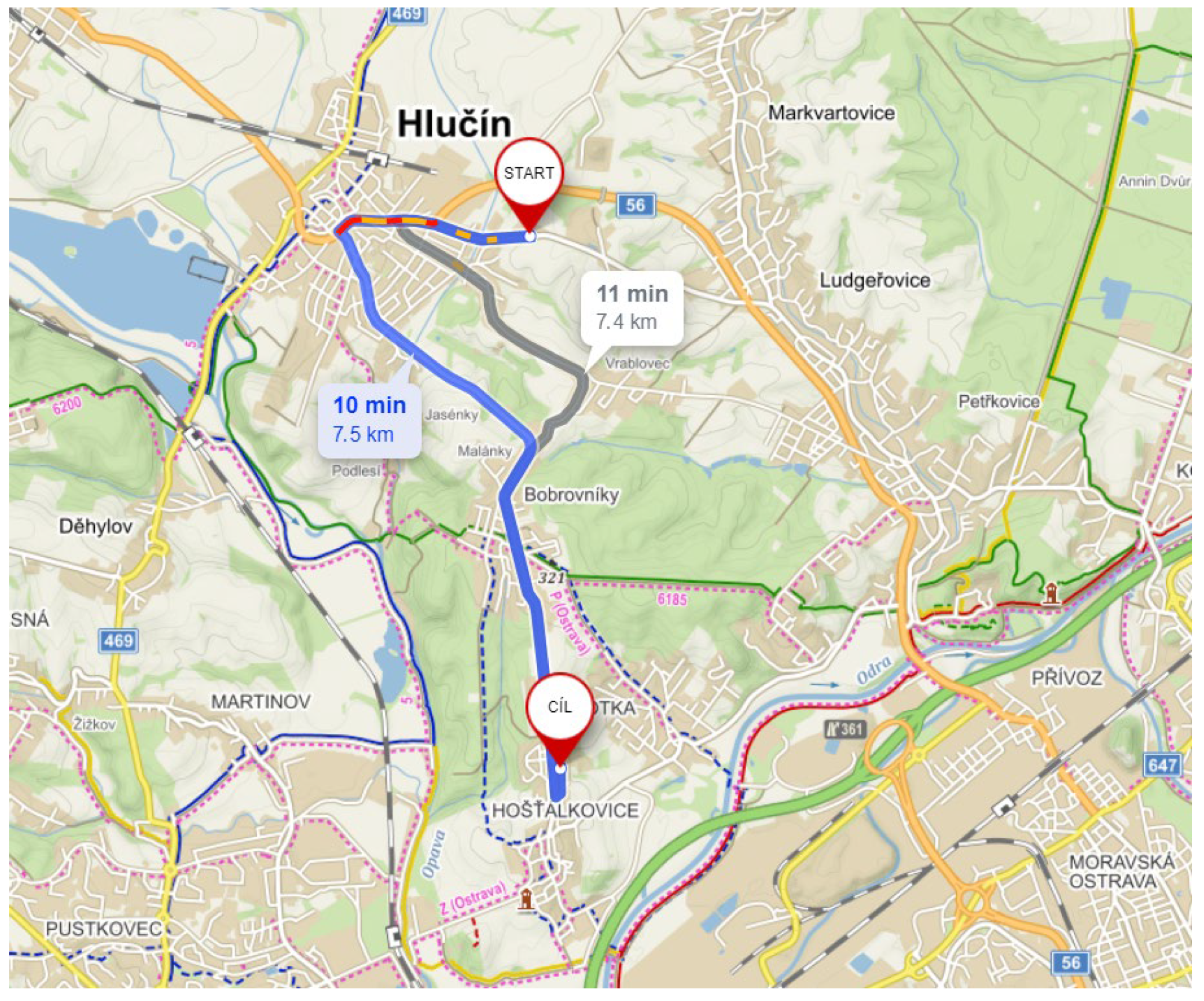

- Waste disposal also involves transportation costs, vehicle dimensions, volume, permitted weight, distance to the nearest landfill, recycling center, etc.

- The focus of all construction projects is the construction or renovation itself, and the investor always focuses on this part as much as possible, but waste disposal is an essential and often neglected part of the process. Given that public procurement tenders usually have clear rules, namely the lowest total price of the work, most planners and budget planners ask themselves how to deal with the above facts in construction tenders so that the total price is competitive.

2.2. Construction and Demolition Waste from the Perspective of the Waste Act

- The price for dismantling work would have to be determined, including the basic sorting of the demolished structure, i.e., higher costs for machinery and operators, extension of the duration of the work, supervision of the sorting itself, etc.

- There must be sufficient space on the construction site for the storage of individual types of waste, i.e., higher costs for construction site arrangement, extension of the duration of the work, and inspection activities.

- Transportation of individual types of construction and demolition waste (CDW), i.e., higher costs for transportation and handling within the construction site.

- Transportation of individual types of CDW, i.e., higher costs for transportation and handling of sorted raw materials.

- Handling and preparation of CDW at the construction yard => higher costs for mechanization and transport within the construction yard.

- Transport of sorted waste for disposal and recycling.

- Fee for disposal or recycling according to individual types of waste.

3. Description of the Demolished Building

3.1. Stage No. 1—Dismantling Without the Use of Machinery, Manually

- Clearing out the building—furnishings, sanitary ware, carpets, linoleum, small carpentry elements (cabinets, shelves, etc.).

- Removal of windows and doors—windows, doors, removal of interior wooden door frames, door wings.

- Removal of roofing—ceramic tiles.

- Dismantling of wooden roof trusses.

- Removal of metal flashing—window sills, gutters, drainpipes, etc.

- Wood—left on the investor’s property for possible resale as firewood (roof trusses, floor coverings).

- Metal—door frames, window sills, roof flashing, railings—left on the investor’s property, intended for sale at a scrap yard.

- Glass—glass blocks, unsorted, minimal quantity.

- Mixed municipal waste—due to the long-term deterioration of the building, it was not possible to further sort the remaining waste. This generally consisted of carpets, plastics, rotten or painted wood, mattresses, cabinets, food leftovers (basement), etc.

3.2. Stage No. 2—Demolition of the Building Using Machinery

- Demolition of wall systems—brick, plaster, ceramic tiles.

- Demolition of ceiling structures—concrete, steel structures.

- Demolition of foundation structures—brick, concrete, stone.

4. Economic Balance Sheet

4.1. Selective Demolition with Storage in an Intermediate Dumping Site and In-House Waste Processing for the Purpose of Generating Revenue from Sales

- Worker, machine operators—determined based on actual hours worked, according to payroll;

- Wheel excavator, loader—determined based on machine operating logs—number of engine hours, fuel consumption;

- Truck—determined based on electronic logbook;

- Crusher—determined based on integrated scales and machine operating log.

- Availability of the machine during the period when the crushing was considered.

- In the case of concrete recycling, a more suitable grain size of the recycled material is achieved on the impact crusher, e.g., shape index.

| Preparation for Crushing, the Crushing Process Itself, etc. | Worker Hours/h | Engine Hours/Mh | Load/t | Total Distance/km | Fuel/L | Price/Unit/Euro | Total | Depreciation 20% of Operating Costs | Notes |

|---|---|---|---|---|---|---|---|---|---|

| Impact crusher CH2/2 | 10 | 501 | 4 EUR | 2004 EUR | |||||

| Loader—XCMG ZL 30 G | 12 | 144 | 1.4 EUR | 207.4 EUR | 41.5 EUR | ||||

| Wheel excavator CAT M316D, demolition hammer, demolition shears | 12 | 75 | 1.4 EUR | 105 EUR | 21 EUR | ||||

| Machine operator—excavator | 14 | 14 EUR | 196 EUR | ||||||

| Machine operator—loader | 14 | 14 EUR | 196 EUR | ||||||

| TOTAL COSTS | 2770.9 EUR | ||||||||

| Recalculation of costs for processing 1 ton of waste: 5.5 EUR/t | |||||||||

4.2. Selective Demolition with Disposal at a Landfill or Transfer to an Authorized Person

4.3. Comparison of the Approaches—In-House Recycling and Handover to an Authorized Person

5. Conclusions

- The possibility of storing construction and demolition waste varies greatly across the regions of the Czech Republic. This is due to both the availability of waste storage sites and the availability of recycling centers. The key factors are the cost of storing sorted construction and demolition waste and the transport distance.

- In the Moravian-Silesian Region, it is slightly more economically beneficial for construction companies to process sorted construction and demolition waste, provided they have their own dumping sites. The Moravian-Silesian Region has the lowest waste storage price.

- The economic impact of processing waste for the purpose of selling secondary products is higher in other regions of the Czech Republic.

- Due to the gradual reduction in landfilling, the reuse of construction and demolition waste will be desirable from the point of view of the unavailability of storage, as well as the economic burden or benefit for the building companies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Coelho, A.; de Brito, J. Economic Analysis of Conventional versus Selective Demolition—A Case Study. Resour. Conserv. Recycl. 2011, 55, 382–392. [Google Scholar] [CrossRef]

- Soto-Paz, J.; Arroyo, O.; Torres-Guevara, L.E.; Parra-Orobio, B.A.; Casallas-Ojeda, M. The Circular Economy in the Construction and Demolition Waste Management: A Comparative Analysis in Emerging and Developed Countries. J. Build. Eng. 2023, 78, 107724. [Google Scholar] [CrossRef]

- Christensen, T.B.; Johansen, M.R.; Buchard, M.V.; Glarborg, C.N. Closing the Material Loops for Construction and Demolition Waste: The Circular Economy on the Island Bornholm, Denmark. Resour. Conserv. Recycl. Adv. 2022, 15, 200104. [Google Scholar] [CrossRef]

- Pantini, S.; Rigamonti, L. Is Selective Demolition Always a Sustainable Choice? Waste Manag. 2020, 103, 169–176. [Google Scholar] [CrossRef]

- Caro, D.; Lodato, C.; Damgaard, A.; Cristóbal, J.; Foster, G.; Flachenecker, F.; Tonini, D. Environmental and Socio-Economic Effects of Construction and Demolition Waste Recycling in the European Union. Sci. Total Environ. 2024, 908, 168295. [Google Scholar] [CrossRef] [PubMed]

- Hasibuan, G.C.R.; Al Fath, M.T.; Yusof, N.; Dewi, R.A.; Syafridon, G.G.A.; Jaya, I.; Anas, M.R.; Syahrizal. Integrating Circular Economy into Construction and Demolition Waste Management: A Bibliometric Review of Sustainable Engineering Practices in the Built Environment. Case Stud. Chem. Environ. Eng. 2025, 11, 101159. [Google Scholar] [CrossRef]

- Bonifazi, G.; Grosso, C.; Palmieri, R.; Serranti, S. Current Trends and Challenges in Construction and Demolition Waste Recycling. Curr. Opin. Green Sustain. Chem. 2025, 53, 101032. [Google Scholar] [CrossRef]

- Czech Republic. Act No. 541/2020 Coll., on Waste; Collection of Laws: Prague, Czech Republic, 23 December 2020; No. 222.

| Construction Type | Waste—Cat. No. | Name of Waste | Volume in m3 Amount m2 | Disposal Method |

|---|---|---|---|---|

| Roof covering | 170103 | Tiles and ceramic products | 280 m2 | Landfill disposal |

| Perimeter walls | 170107 | Mixtures or separate fractions of concrete, bricks, tiles, and ceramic products not listed under number 17 01 06 | 230 m3 | Landfill disposal |

| Concrete structures, staircases, foundations | 170101 | Concrete | 36 m3 | Recycling |

| Metals | 1704xx | Metals (including their alloys) | 5 t | Recycling |

| Wood | 170201 | Wood | 0.5 t | Landfill disposal |

| Glass | 170202 | Glass | Recycling | |

| Other municipal waste | 200301 | Mixed communal waste | Landfill disposal |

| Selective Demolition FH | Worker Hours/h | Engine Hours/Mh | Load/t | Total Distance/km | Fuel/L | Price/Unit/Euro | Total/Euro | Depreciation (20% of Operating Costs) |

|---|---|---|---|---|---|---|---|---|

| Wheel excavator CAT M316D, demolition hammer, demolition shears | 80 | 500 | EUR 1.4 | EUR 700 | EUR 140 | |||

| Truck, MAN 6 × 6, load capacity 12 t | 789 | 951 | 520 | EUR 1.4 | EUR 728 | EUR 145.60 | ||

| Loader—Kramer 280 | 5 | 64 | EUR 1.4 | EUR 89.60 | EUR 17.90 | |||

| Machine operator—driver, loader | 108 | EUR 14.0 | EUR 1512 | |||||

| Machine operator—excavator | 117 | EUR 14.0 | EUR 1638 | |||||

| Unskilled laborer | 234 | EUR 10.0 | EUR 2340 | |||||

| TOTAL COSTS INCLUDING DEPRECIATION | EUR 7311.1 | |||||||

| Selective Demolition Output | Unit | Recycling | Dumping Site Disposal | Landfill Disposal | Landfill Fee in EUR/t | Total Costs |

|---|---|---|---|---|---|---|

| Mixtures or separate fractions of concrete, bricks, tiles, and ceramic products not listed under 17 01 06 (170107) with a higher brick content | T | 406 | 406 | EUR | ||

| Concrete (170101) | T | 95 | 95 | EUR | ||

| Costs associated with handling at intermediate dumping site | EUR 1002 | |||||

| Wood (170201) | m3 | 9 | EUR | |||

| Mixtures or separate fractions of concrete, bricks, tiles, and ceramic products not listed under 17 01 06 (170107) | T | 274 | EUR 15.8 | EUR 4329.2 | ||

| Mixed construction and demolition waste (170904) | T | 5 | EUR 95.2 | EUR 476 | ||

| TOTAL COSTS FOR LANDFILL DISPOSAL | EUR 5807.20 | |||||

| Name | Unit of Meas. | Quant. | Price/Unit of Measure | Total Price |

|---|---|---|---|---|

| Brick rubble 0/16 | t | 406 | 2 EUR | 812 EUR |

| Recycled concrete | t | 95 | 6 EUR | 570 EUR |

| TOTAL | 1382 EUR |

| Selective Demolition FH | Worker Hours/h | Engine Hours/Mh | Load/t | Total Distance/km | Fuel/L | Price/Unit/Euro | Total | Depreciation 20% of Operating Costs |

|---|---|---|---|---|---|---|---|---|

| Wheel excavator CAT M316D, demolition hammer, demolition shears | 80 | 500 | 1.4 EUR | 700 EUR | 140 EUR | |||

| Truck, MAN 6x6, load capacity 12 t | 789 | 1025 | 520 | 1.4 EUR | 728 EUR | 145.6 EUR | ||

| Loader—Kramer 280 | 5 | 64 | 1.4 EUR | 89.6 EUR | 17.9 EUR | |||

| Machine operator—driver, loader | 125 | 14 EUR | 1750 EUR | |||||

| Machine operator—excavator | 117 | 14 EUR | 1638 EUR | |||||

| Unskilled laborer | 234 | 10 EUR | 2340 EUR | |||||

| TOTAL COSTS | 7549.1 EUR | |||||||

| Selective Demolition Output | Unit | Recycling | Dumping Site Dispos. | Landfill Disposal | Landfill Fee in EUR/t | Total Costs |

|---|---|---|---|---|---|---|

| Mixtures or separate fractions of concrete, bricks, tiles, and ceramic products not listed under 17 01 06 (170107) | t | 680 | 15.8 EUR | 10,744 EUR | ||

| Concrete (170101) | t | 95 | 3.2 EUR | 304 EUR | ||

| Wood (170201) | m3 | 9 | EUR | EUR | ||

| Mixed construction and demolition waste (170904) | t | 5 | 95.2 EUR | 476 EUR | ||

| TOTAL COSTS | 11,524 EUR | |||||

| Total costs of selective demolition with in-house recycling | 15,818.8 EUR exc. VAT |

| Estimated revenue from recycled materials | −1382 EUR exc. VAT |

| Total including estimated revenue | 14,436.8 EUR exc. VAT |

| Note: Processing CDW within a single economic entity is cost-effective if a recycling yard is available or if recycling can be carried out directly on the construction site. In the case of concrete recycled material, effective crushing and sorting can achieve a very high purity of input material, which can be used to replace natural aggregate in fresh concrete. Possible risks arise from legislation relating to waste management, regular testing and analysis of CDW, etc. | |

| Total costs of selective demolition with disposal at landfills and recycling yards | 19,125.16 EUR exc. VAT |

| THE DIFFERENCE IN COSTS BETWEEN THE DIFFERENT APPROACHES TO THE ENTIRE RECYCLING PROCESS IN OUR SPECIFIC CASE IS 4688.4 EUR EXCLUDING VAT | |

| RECALCULATION OF COSTS FOR PROCESSING 1 TON OF WASTE (total waste volume 789 tons) | |

| Selective demolition with in-house recycling | 20 EUR exc. VAT/t |

| Selective demolition with disposal at a landfill and recycling facilities | 24.24 EUR exc. VAT/t |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Foltýn, J.; Václavík, V.; Dvorský, T.; Eštoková, A.; Široký, T.; Jaš, M.; Kubín, T. Selective Demolition of a Family House from an Economic Perspective in Practice. Eng. Proc. 2025, 116, 26. https://doi.org/10.3390/engproc2025116026

Foltýn J, Václavík V, Dvorský T, Eštoková A, Široký T, Jaš M, Kubín T. Selective Demolition of a Family House from an Economic Perspective in Practice. Engineering Proceedings. 2025; 116(1):26. https://doi.org/10.3390/engproc2025116026

Chicago/Turabian StyleFoltýn, Jan, Vojtěch Václavík, Tomáš Dvorský, Adriana Eštoková, Tomáš Široký, Martin Jaš, and Tomáš Kubín. 2025. "Selective Demolition of a Family House from an Economic Perspective in Practice" Engineering Proceedings 116, no. 1: 26. https://doi.org/10.3390/engproc2025116026

APA StyleFoltýn, J., Václavík, V., Dvorský, T., Eštoková, A., Široký, T., Jaš, M., & Kubín, T. (2025). Selective Demolition of a Family House from an Economic Perspective in Practice. Engineering Proceedings, 116(1), 26. https://doi.org/10.3390/engproc2025116026