1. Introduction

Nowadays, turbochargers (TCs) are indispensable in the transportation industry, playing a crucial role in meeting performance targets, reducing fuel consumption, and ensuring compliance with environmental regulations. However, due to their mechanical complexity and sensitivity to operational conditions, TCs are prone to nonlinear vibration issues, including both sub-synchronous and synchronous phenomena. These vibration behaviors are typically studied in controlled laboratory environments to gain a deeper understanding of how various physical parameters influence the spectral characteristics of rotor vibrations. Among the many factors that affect TC dynamics, lubricant quality and oil aging have received increasing research attention [

1,

2], as they significantly impact bearing performance alongside internal and external load conditions. As lubricating oil degrades over time due to thermal and mechanical stress, aged lubricants can exhibit altered rheological and tribological behavior, which in turn affects vibration responses.

Besser et al. [

3] provided a detailed methodology for producing artificially aged oils, employing both small- and large-scale alteration processes using different experimental techniques. Zhong et al. [

4] further investigated the influence of oil temperature on aged lubricants, showing that elevated inlet oil temperatures can measurably shift the vibration spectrum. Their results demonstrated that above 50 °C, synchronous vibrations, oil film instabilities, and whip phenomena become more prominent in the rotor system. Moreover, as oil temperature increases, the amplitude of rotor vibrations also tends to rise. Changes in lubricant properties can also alter the effective unbalance of the TC rotor, indirectly influencing its vibrational behavior. Zhang et al. [

5] explored this relationship, highlighting how temperature-induced unbalance shifts sub-synchronous vibration components across the frequency domain. Their study was supported by nonlinear simulations, wherein displacement and unbalance values were evaluated using SAE 15W40 lubricant. The computational frameworks used in these simulations are further elaborated in [

6,

7,

8].

Schweizer’s works [

9,

10] offer comprehensive insights into simulation techniques, particularly regarding oil whirl, whip, and synchronization phenomena in full-floating ring bearing systems. Using a Laval rotor-based mathematical model, both horizontal and vertical configurations were analyzed. The results illustrated how nonlinear dynamic effects and bifurcations emerge in response to changes in lubricant characteristics. Simulations were carried out horizontally with a vertical Laval rotor. As lubricant properties shift, understanding the degradation mechanisms becomes increasingly important. Tribological investigations serve as a valuable tool in this context. Jech et al. [

11] presented a notable example, examining wear behavior and tribofilm formation using ZDDP-additivated oils subjected to controlled degradation. Although such wear effects are relevant in turbocharger bearing systems, their influence on TC performance and lifespan remains underexplored.

In the present study, we investigate the influence of different altered lubricants on sub- and super-synchronous vibration behaviors in a turbocharger system. The lubricants were artificially aged and tested on a cold-gas test bench during rotor run-up and run-down phases. Special attention is given to hysteresis and bifurcation phenomena, and the role of lubricant additives in vibration behavior is also discussed. Lubricant additives are also noted, as are their effects on the vibration results. A secondary aim of this work is to generate high-integrity experimental data that can support nonlinear dynamic simulations and chaos theory-based vibration analysis. Given the limited number of studies addressing the vibrational implications of aged lubricants in turbocharger systems, this research contributes to a relatively underrepresented yet technically significant domain within vibration–acoustic engineering.

2. Materials and Methods

The three mandatory phases that define the methodology of the present research—planning, execution, and analysis—are governed by strict conditions. Accordingly, this section provides a comprehensive and detailed overview of the test bench environment, the experimental approach, and the methodology employed for data analysis and evaluation to facilitate a deeper understanding.

2.1. Test Bench Environment and Measuring Infrastructure

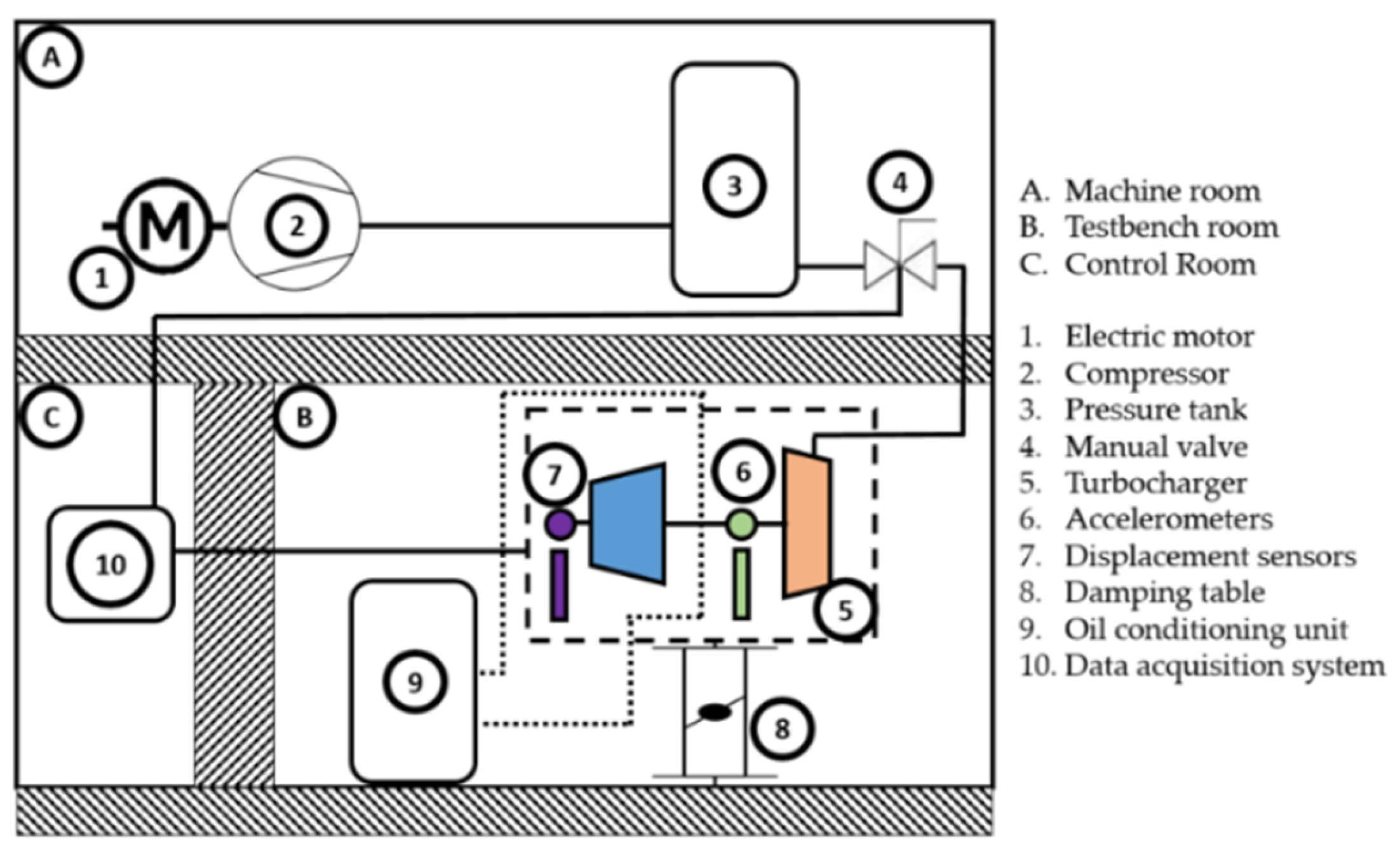

The used turbocharger test bench in this study is uniquely built and specialized for vibration- and resonance phenomena investigation and diagnostic (see

Figure 1). The selected turbocharger is driven by pressurized air, with its operation precisely controlled via a National Instruments (NI) CompactRIO control system. This setup enables the implementation of controlled ramp-up and ramp-down sequences essential for experimental procedures. A stable and accurately regulated lubricant supply is ensured through the integration of a mobile oil-conditioning unit (MOCU). MOCU plays a critical role in this research, as it facilitates the examination of lubrication characteristics under various operating conditions. The system allows for adjustable oil pressure and temperature, thereby enabling realistic replication of in-service operating scenarios.

For the purpose of vibration analysis, two uniaxial IMC AD1E060 (imc, Berlin, Germany) acceleration sensors were mounted on the turbocharger, oriented orthogonally (90 degrees apart) to capture multidirectional vibrations. One sensor was installed horizontally on the center housing, while the other was positioned vertically near the oil outlet section. In addition to the accelerometers, a rotational speed sensor (PTSM-H 5.3, Picoturn, Cambridgeshire, UK) was employed to monitor the turbo shaft speed with high accuracy. Signal acquisition was performed using an IMC Cronosflex CRFX-2000 GP (imc, Berlin, Germany) data acquisition system, configured with a sampling rate of 50 kHz per channel. This setup ensured the high temporal resolution necessary for capturing dynamic behavior in rotor and vibration analysis. Overall, the measurement instrumentation and setup were designed to deliver precise and reliable data, which is essential for accurate vibration diagnostics. The experimental configuration meets all operational requirements and provides a robust platform for the subsequent investigation of the turbocharger’s behavior under various altered lubricant conditions.

2.2. Experimental Design: DoE Method and Measured Operational Points

A precise, pre-planned measurement strategy is essential when dealing with a large number of potential operating points. In this study, the selection of measurement points is based on the relative importance of regions with high sensitivity, particularly in relation to the lubricant’s temperature and pressure. To efficiently explore the design space, a Central Composite Design (CCD) was employed (see

Figure 2). This design approach is particularly advantageous for modeling nonlinear interactions and capturing quadratic effects among input parameters. Although alternative methods such as the Face-Centered Central Composite Design (FCCD) could have been considered, the rotational speed—serving as the third variable—was held constant. It was characterized by a ramp-up and ramp-down profile, which was deliberately implemented to facilitate vibration analysis. As a result, the standard CCD approach was deemed more suitable for the scope and objectives of this investigation.

The selected nine operating points were deemed sufficient for the purposes of the vibrational analysis. The experimental design incorporates five levels for each of the two primary parameters, resulting in a fractional factorial design rather than a full-factorial approach, thereby optimizing measurement efficiency while maintaining model robustness. During testing, the chosen operating conditions avoided extreme or unstable regimes, focusing instead on stable regions to reliably characterize the system’s correlation map. To enhance accuracy and reproducibility, the previously mentioned controlled ramp in rotational speed was applied, ranging from 0 to 140.000 RPM. Each operating point was measured in duplicate and triplicate. Subsequent evaluation of the ramp profiles revealed that the maximum difference among repetitions remained within 5%, while the average difference was below 1%. Based on this high level of consistency, the ramp data were averaged prior to detailed data analysis.

2.3. Data Processing and Analysis Methodology

The pre-processing of the measured dataset was conducted using IMC Famos 2024 (version: R3) software in conjunction with supplementary Python-based (version: 3.11.11) analytical tools. The raw dataset comprised high-frequency measurements (sampled at 50 kHz) of acceleration, rotational speed (RPM), and oil temperature and pressure acquired from a high-fidelity experimental setup, which has been previously described. The separation of the RPM data into ramp-up and ramp-down segments was performed with particular care to ensure accurate evaluation of the order spectrum analysis maps, while maintaining the integrity and reliability of the results. For Order spectrum analysis fast Fourier transformation (FFT) must be applied to represent the corresponding vibration components in the order domain. The core objective of this study was to examine the correlation between fresh and altered lubricant conditions, specifically lubricants with an identical viscosity index, and their influence on the order spectrum characteristics. To achieve this, a tailored order tracking methodology was employed, capable of capturing and resolving critical rotational phenomena such as bifurcation speeds and order jumps in both sub-synchronous and super-synchronous regimes. This approach provides a robust framework for evaluating lubricant-induced changes in dynamic behavior with high temporal and spectral resolution. The bifurcation values were extracted using an additional order tracking algorithm developed specifically for this study. This algorithm isolates a narrow region within the order spectrum and identifies significantly elevated acceleration amplitudes relative to the rotational speed. The following execution steps represent (see

Figure 3) the constructed investigation flow chart plan of the data analysis for each lubricant.

The investigations on the vibration domain were conducted with various samples, including a fresh 0W-20 (Castrol Germany GmbH, Hamburg, Germany) oil, as well as a fresh and corresponding altered 5W-30 (AC2T research GmbH, Wiener Neustadt, Austria) lubricant. Certain physical properties, such as viscosity and density, must be pre-determined and summarized for further nonlinear calculations (see

Table 1). The methodology and results of the artificial alteration are described in detail in [

3]; hence, only a brief summary of key condition parameters is given in

Table 2. Chemical properties were determined via Fourier-transform infrared (FTIR) spectroscopy, or the applicable acid–base titrations, and the detailed method descriptions are available in [

3]. In general, the aged 5W-30 lubricant shows a close to complete depletion of (ZDDP) antiwear, antioxidants and a significant reduction in the total base number (TBN). Furthermore, considerable oxidation, nitration, and acidification (increase in the neutralization number—NN) are also visible. The condition of the aged 5W-30 lubricant very closely matches a real used oil after approx. 20,000 km of on-road utilization in a passenger car [

3].

3. Results

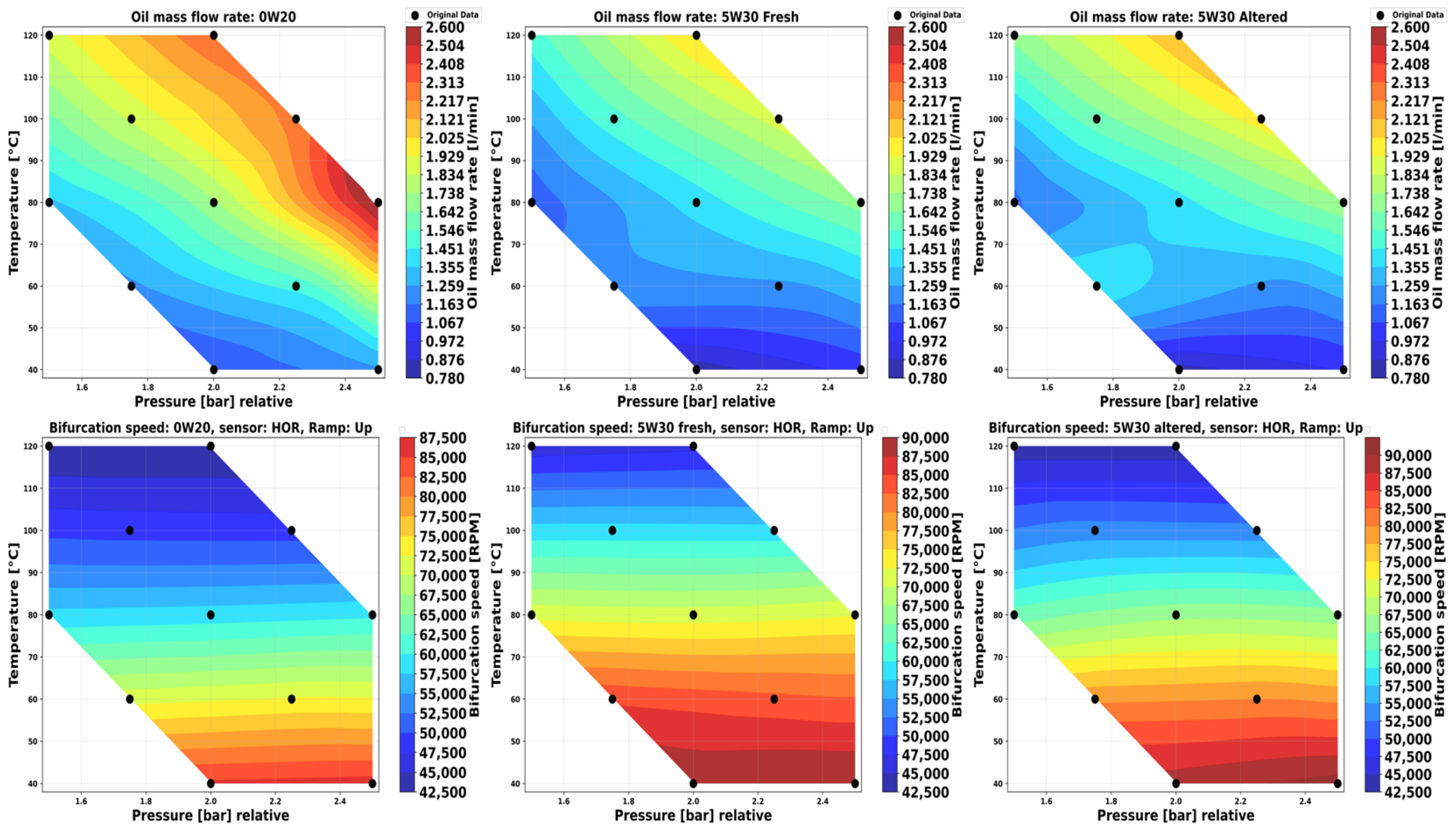

In this section of the paper, a summary of the key findings is presented based on the previously outlined measurement and data analysis methods. Given the broad scope of potential research avenues, the focus has been narrowed to investigating the bifurcation speed differences and the variation in the oil volumetric flow rate. The measurements were conducted using a consistent methodology across all lubricant types, ensuring that the correlation between datasets at the same duty point is adequate for analysis. For the bifurcation speed analysis, separate sections were examined for the ramp-up and ramp-down phases, revealing differences between these phases, a phenomenon that has been well-documented in prior studies. However, the extent of these differences, particularly in relation to the changes induced by varying lubricants, has not been explored in sufficient depth. Bifurcation behavior is influenced by various physical factors, some of which were investigated in this study, such as the inlet temperature and pressure of the lubricants (specific values of which are provided in a previous section). Following data evaluation, the observed diversity and differences in bifurcation speeds (see

Figure 4) were found to be sufficiently significant across the sampled lubricants, indicating potential for establishing correlations with the tested parameters in future analyses.

A consistent color scheme was applied across all result images to enable clear comparison. The visualizations reveal that the highest bifurcation speed occurs when fresh 5W30 lubricant is used. To enhance both visualization and analytical accuracy, interpolation was performed between the originally measured data points. The bifurcation speed amplitude reaches its maximum at elevated temperatures when comparing fresh 0W20 and 5W30 lubricants. The fresh 5W30 lubricant demonstrates a broader region of maximum bifurcation speed amplitude in both ramp-up and ramp-down scenarios. When comparing fresh and altered 5W30 lubricants, it is evident that the alteration process shifts the temperature at which the maximum bifurcation speed occurs to lower values. For a more rigorous comparison, the data were evaluated quantitatively (see

Table 3), focusing on the designated temperature corresponding to the peak bifurcation speed. Since pressure significantly influences the phenomenon, the evaluation was performed along the main diagonal of the pressure-temperature matrix, where the paired values are as follows: 40 °C—2.5 bar, 60 °C—2.25 bar, 80 °C—2.0 bar, 100 °C—1.75 bar, and 120 °C—1.5 bar. The main diagonal contains the highest density of data points, making it the most efficient path for comparative analysis.

The maximum difference in bifurcation speed between the investigated lubricants, specifically 0W20 and fresh 5W30, occurs at 80 °C, where the bifurcation speed increases by 17.47%. When comparing 0W20 to the altered 5W30 lubricant, the maximum difference also appears at 80 °C, albeit with a slightly lower increase of 11.96%. Finally, when comparing fresh and altered 5W30 lubricants, the greatest difference is observed at 100 °C, where the bifurcation speed of the fresh lubricant exceeds that of the altered version by 8.21%. Additional analyses were performed on the cleaned measurement dataset, including the evaluation of oil volume flow rate variations. However, these results are not presented in this study due to publication length constraints and the extensive nature of the associated data.

4. Discussion and Conclusions

Further investigation is required to determine the exact influence of individual physical factors on bifurcation and other vibrational phenomena. This includes targeted studies such as viscosity measurements and in-depth FTIR spectroscopy analysis. Future work may also explore the established dataset using advanced numerical and statistical methods, such as Analysis of Variance (ANOVA) and machine learning approaches, including neural networks. These tools could enable predictive modeling of bifurcation behavior and oil volume or mass flow rate based on lubricant properties and rotor system parameters. Comparisons between altered and fresh lubricants could be extended to include additional perspectives, such as thermodynamic behavior. The current dataset, which includes oil inlet and outlet temperatures from the MOCU system, offers a valuable resource for future investigations aiming to establish stronger correlations between thermal behavior and vibrational characteristics. The results presented in this study contribute to a deeper understanding of the vibrational behavior of turbomachinery systems when operating with various lubricants of differing properties. The findings underscore the critical importance of proper lubricant selection and monitoring in maintaining system integrity, detecting degradation, and predicting wear. The measurement methodology and experimental sequence developed in this research are fully reproducible in a controlled laboratory environment. However, future efforts should include more realistic test conditions—such as in-vehicle measurements—to obtain even more representative data and enhance the real-world applicability of the conclusions drawn. The correlation between lubricant viscosity and rotor instability is demonstrated in this study; however, a precise mathematical characterization will be addressed in future work.

Author Contributions

Conceptualization, M.B. and M.P.; methodology, M.B.; software, M.B.; validation, M.B. and M.P.; formal analysis, M.P.; investigation, M.B.; resources, A.A.; data curation, M.B.; writing—original draft preparation, M.B. and A.A.; writing—review and editing, M.P.; visualization, M.B.; supervision, M.P.; project administration, M.B.; funding acquisition, M.P. and A.A. All authors have read and agreed to the published version of the manuscript.

Funding

This article was published under the framework of the project “Production Validation of Synthetic Fuels in Industry-University-Collaboration”, project number “ÉZFF/956/2022-ITM_SZERZ”. The presented results were partially realized as part of the COMET Centre InTribology (FFG no. 906860), a project of the “Excellence Centre for Tribology” (AC2T research GmbH). InTribology is funded within the COMET—Competence Centres for Excellent Technologies Pro-gramme by the federal ministries BMIMI and BMWET, as well as the federal states of Niederöster-reich and Vorarlberg, based on financial support from the project partners involved. COMET is managed by The Austrian Research Promotion Agency (FFG).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data are available upon request from the corresponding author.

Conflicts of Interest

Adam Agocs was employed by the company AC2T Research GmbH and declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Nagy, A.L.; Rohde-Brandenburger, J.; Zsoldos, I. Artificial Aging Experiments of Neat and Contaminated Engine Oil Samples. Lubricants 2021, 9, 63. [Google Scholar] [CrossRef]

- Tóth-Nagy, C.; Szabó, Á.I. Experimental Investigation of the Friction Modifying Effects of Graphene and C60 Fullerene Used as Nanoadditives in Engine Lubricating Oil Performed on an Oscillating Tribometer. Period. Polytech. Transp. Eng. 2023, 51, 257–262. [Google Scholar] [CrossRef]

- Besser, C.; Agocs, A.; Ronai, B.; Ristic, A.; Repka, M.; Jankes, E.; McAleese, C.; Dörr, N. Generation of Engine Oils with Defined Degree of Degradation by Means of a Large Scale Artificial Alteration Method. Tribol. Int. 2019, 132, 39–49. [Google Scholar] [CrossRef]

- Zhong, X.; Huang, Y.; Bin, G.; Chen, A. Effect of the Inlet Oil Temperature on Vibration Characteristics of the High-Speed Turbocharger Rotor System. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 235, 2086–2098. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, W.; Wei, D.; Wang, G.; Xu, J.; Liu, K. Dynamic Stability of Unbalance-Induced Vibration in a Turbocharger Rotor-Bearing System with the Nonlinear Effect of Thermal Turbulent Lubricating Fluid Film. J. Sound Vib. 2022, 528, 116909. [Google Scholar] [CrossRef]

- Cao, Z.; Guo, H.; Cheng, Z.; Men, R.; Zhang, Z.; Wang, T. Nonlinear Dynamics Characteristics of a Tilting Pad Journal Bearing Supported Turbocharger. Nonlinear Dyn. 2024, 19, 16941–16961. [Google Scholar] [CrossRef]

- Li, F.; Li, X.; Liu, J.; Shang, D.; Ma, H. Nonlinear Vibration Analysis of the Shaft-Bearing-Pedestal Coupled System with Inclined Shaft Current Damage. Nonlinear Dyn. 2023, 111, 15853–15872. [Google Scholar] [CrossRef]

- Tian, L. Investigation Into Nonlinear Dynamics of Rotor-Floating Ring Bearing System in Automotive Turbochargers. Ph.D. Thesis, University of Sussex, Brighton, UK, 2012. [Google Scholar]

- Schweizer, B. Oil Whirl, Oil Whip and Whirl/Whip Synchronization Occurring in Rotor Systems with Full-Floating Ring Bearings. Nonlinear Dyn. 2009, 57, 509–532. [Google Scholar] [CrossRef]

- Schweizer, B. Dynamics and Stability of Turbocharger Rotors. Arch. Appl. Mech. 2009, 80, 1017–1043. [Google Scholar] [CrossRef]

- Jech, M.; Hofer, A.; Tomastik, C.; Wopelka, T.; Gachot, C. Influence of Artificially Altered Engine Oil on Tribofilm Formation and Wear Behaviour of Grey Cast Cylinder Liners. Lubricants 2023, 11, 476. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).