1. Introduction

Additive manufacturing (AM), also known as three-dimensional (3D) printing, was established in the 1980s and has the capability of creating parts through sequential layering using a computer-aided design (CAD) model that involves complexity in geometry [

1,

2]. It has emerged as a rival to traditional manufacturing processes, particularly in the production of dental implants and other applications [

3]. VAT photopolymerization is one of the popular 3D printing methods in which liquid resin is selectively cured by ultraviolet (UV) light to form a solid layer [

4]. Polymers are the most widely used material in dental applications of additive manufacturing [

5]. They come in various forms, including sheets, powder, and resins. Technologies that utilize photopolymerization are essential for curing these resins to create solid components [

6] such as impression trays [

7,

8], dental base, and teeth [

9,

10,

11]. The rationale for polymerization relies on the utilization of initiators, monomers, and oligomers that cure when exposed to specific wavelengths of light [

12].

When there is complex part geometry and fierce market competition, stereolithography (SLA), which is based on photopolymerization, is a suitable option compared to other manufacturing technologies for prototypes [

13]. It is more appropriate for biomedical applications because of its better surface finish and low stair-stepping effect, sensitivity, and part accuracy [

14,

15] compared to other AM processes, allowing for the creation of exact designs for fixed partial dentures, crowns, and surgical guides [

16].

Many researchers are using this method to manufacture recently developed dental applications. For example, the California-based company Align Technology produces clear plastic aligner molds to correct the positioning of the teeth [

17].

Strength plays a significant role in creating rapid tooling, allowing components to endure high pressure during fitting tests. The typical approach to creating a high-strength part is the full factorial method, which is only appropriate when a limited number of variables need to be investigated. In contrast, the fractional factorial approach, a more straightforward, effective, and systematic approach provided by the Taguchi design of experiments (DOE), reduces the number of experimental runs and helps to save time [

18]. Consequently, the Taguchi method is a powerful tool for implementing DOE effectively [

19,

20].

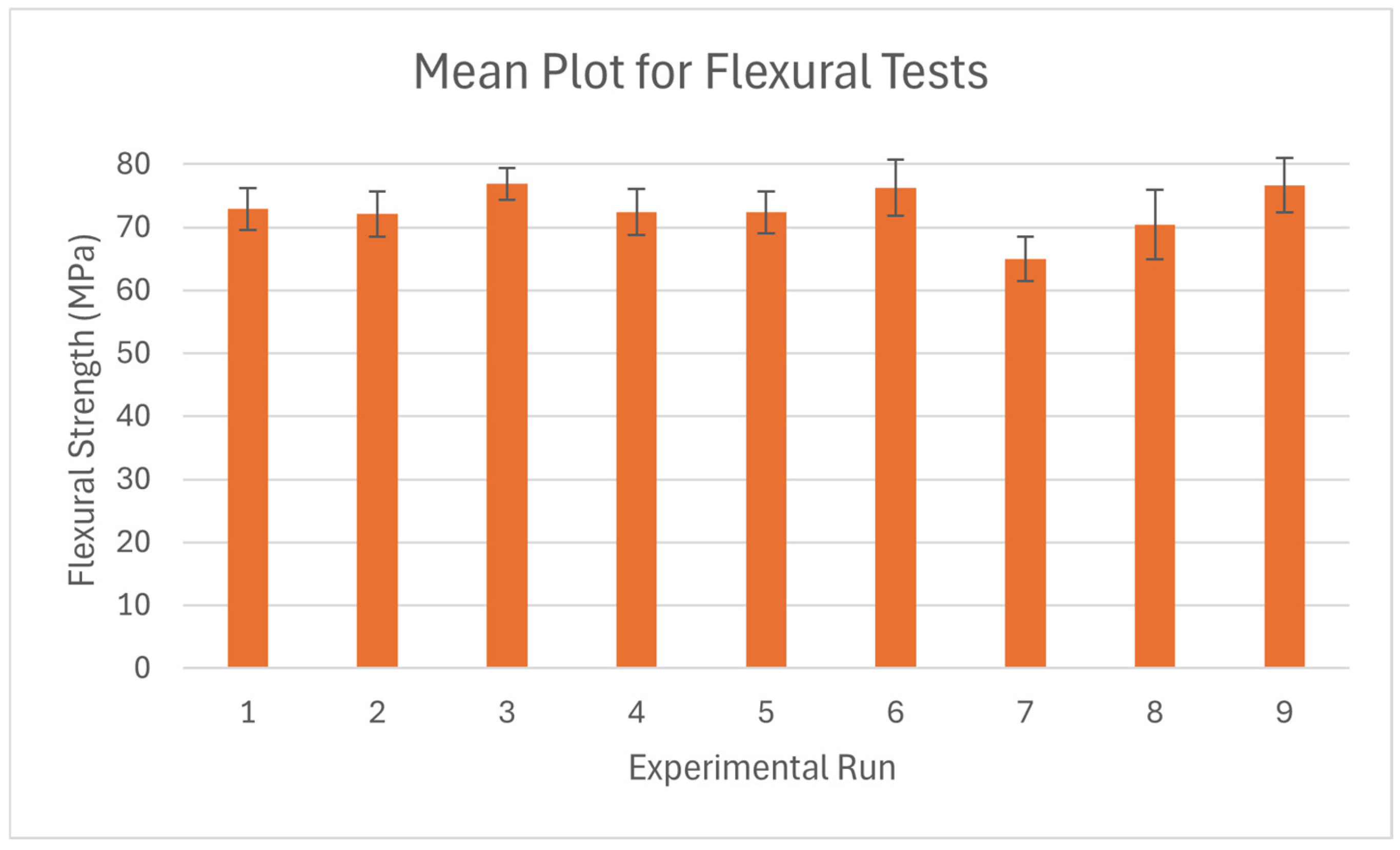

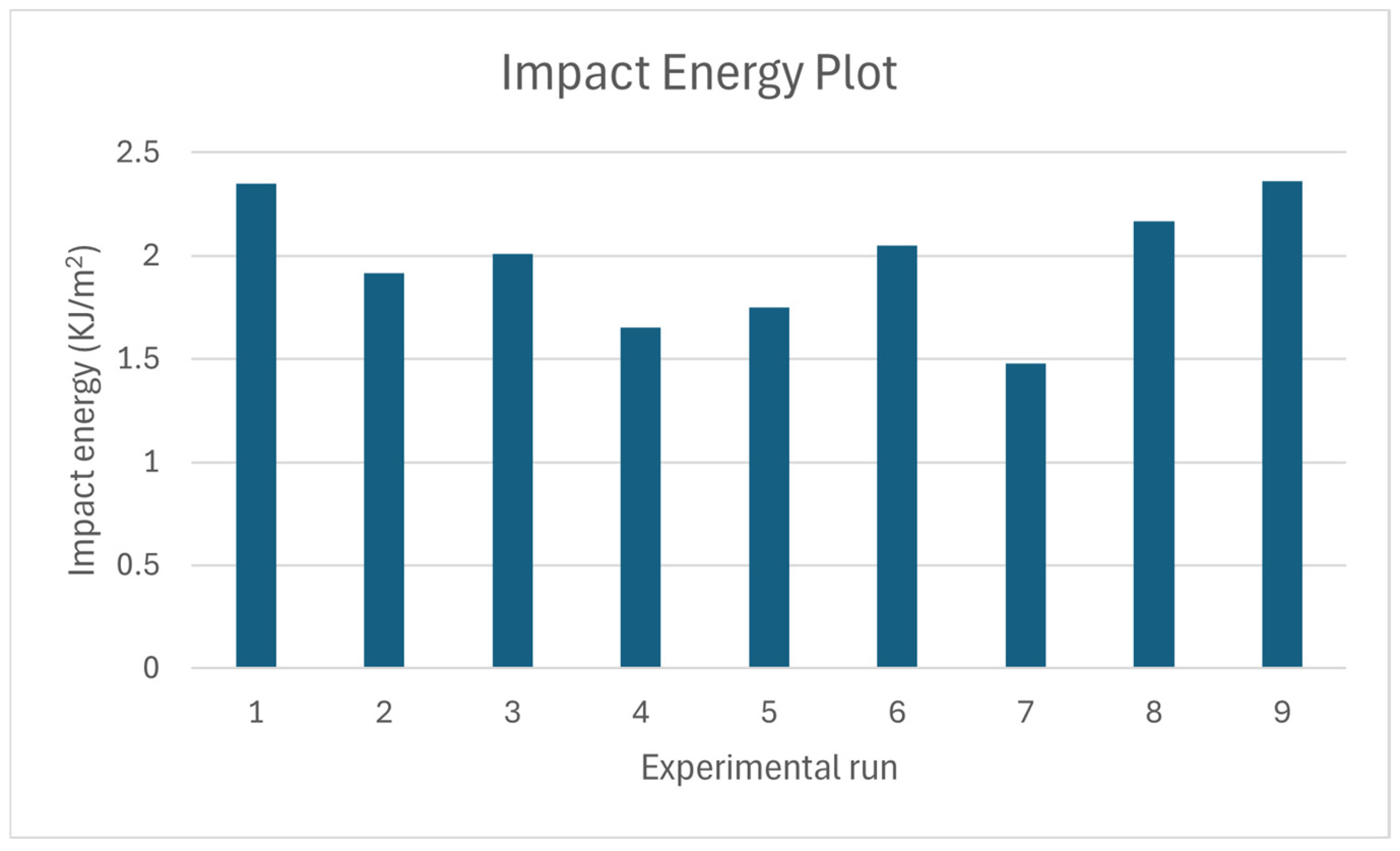

Many researchers have carried out different studies to analyze the influential parameters of different materials, yet very few studies have been conducted on biomedical materials. This research focuses on evaluating the mechanical characteristics of Anycubic dental non-castable resin under varying process parameters, such as layer thickness, build orientation, and exposure time, aiming determine the optimized values and the percentage contribution of each factor to the tensile, flexural, and impact strength. Additionally, developing a process model linking influential factors to response variables is a major focus of this research.

2. Materials and Methods

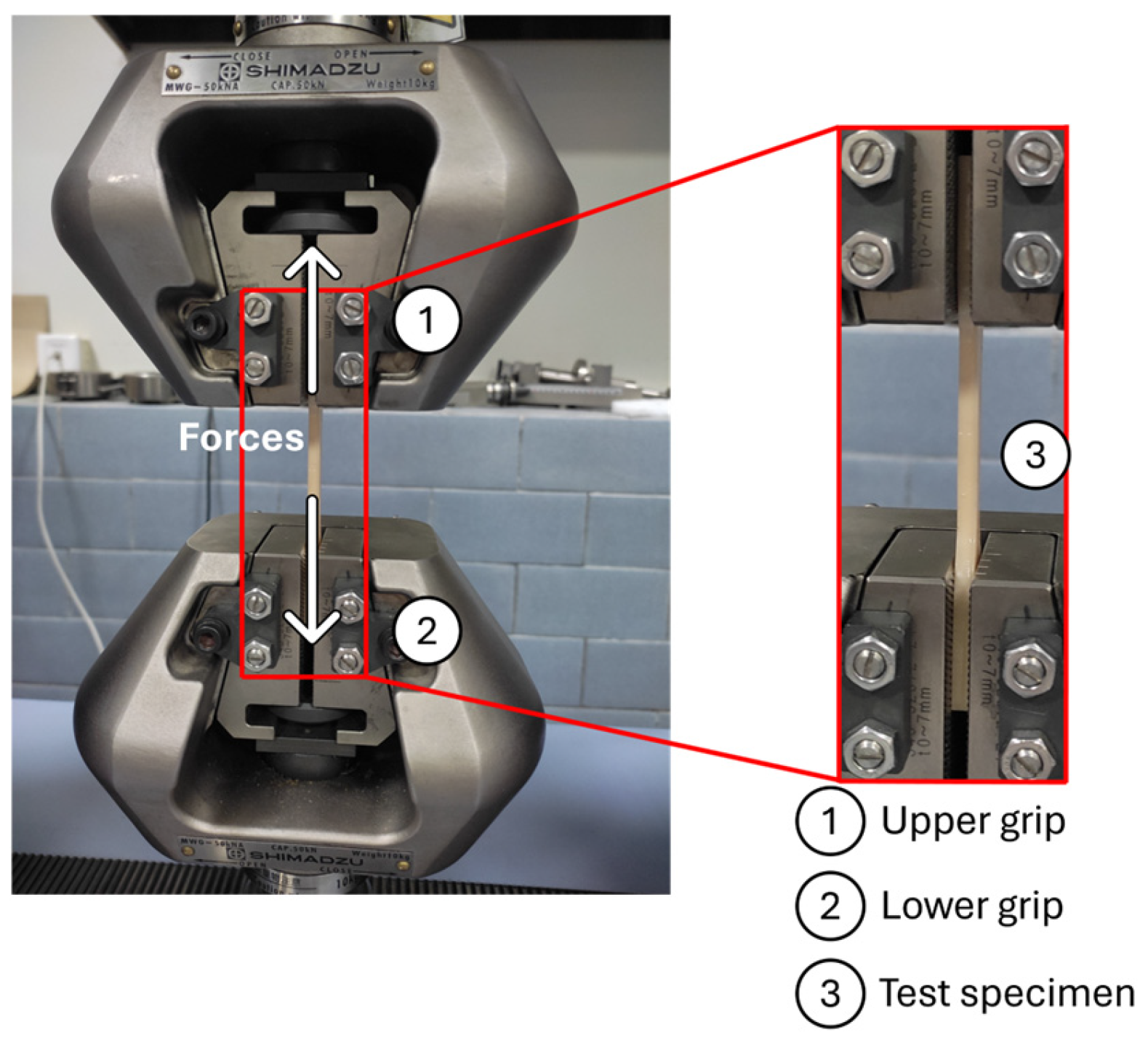

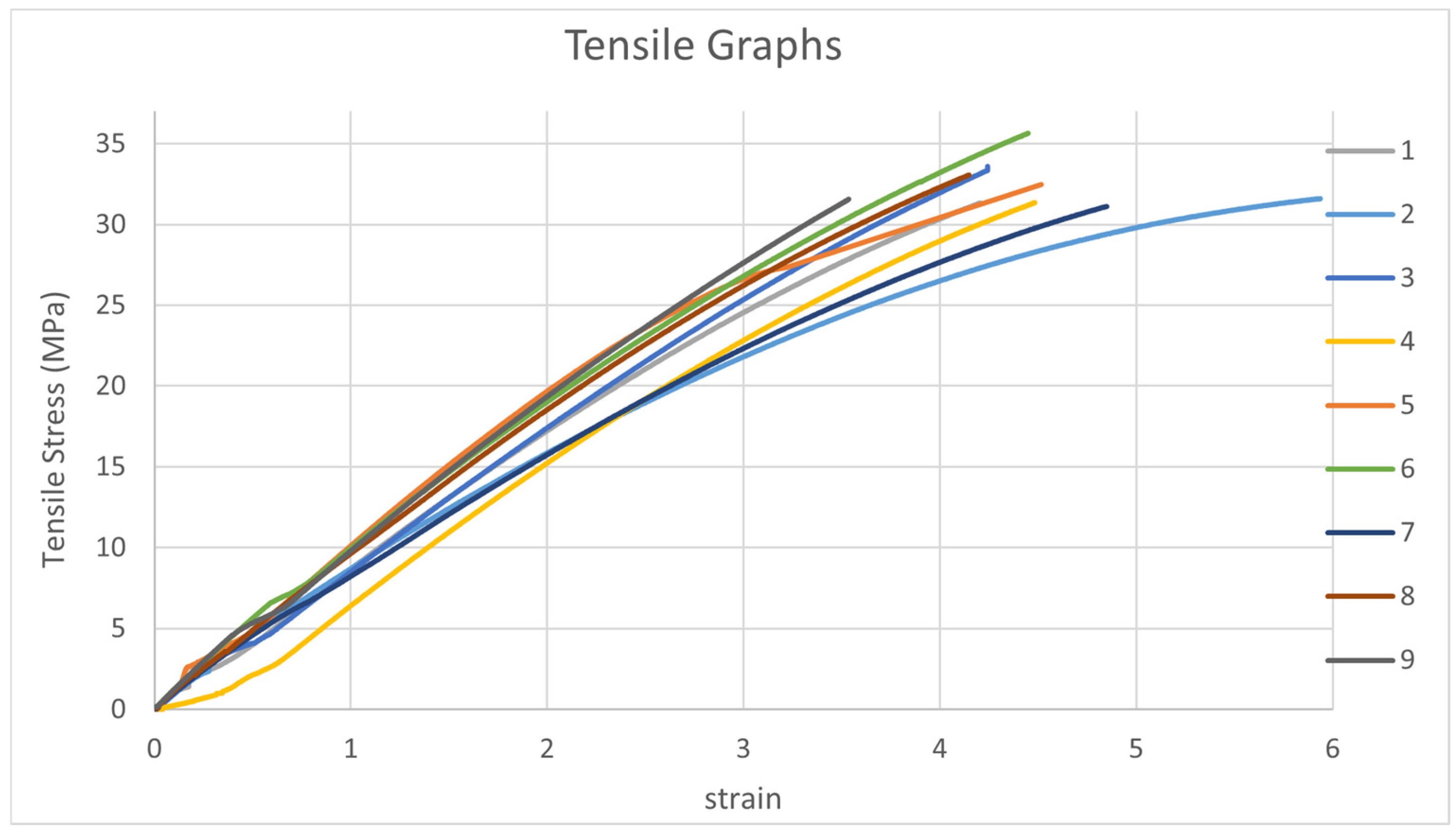

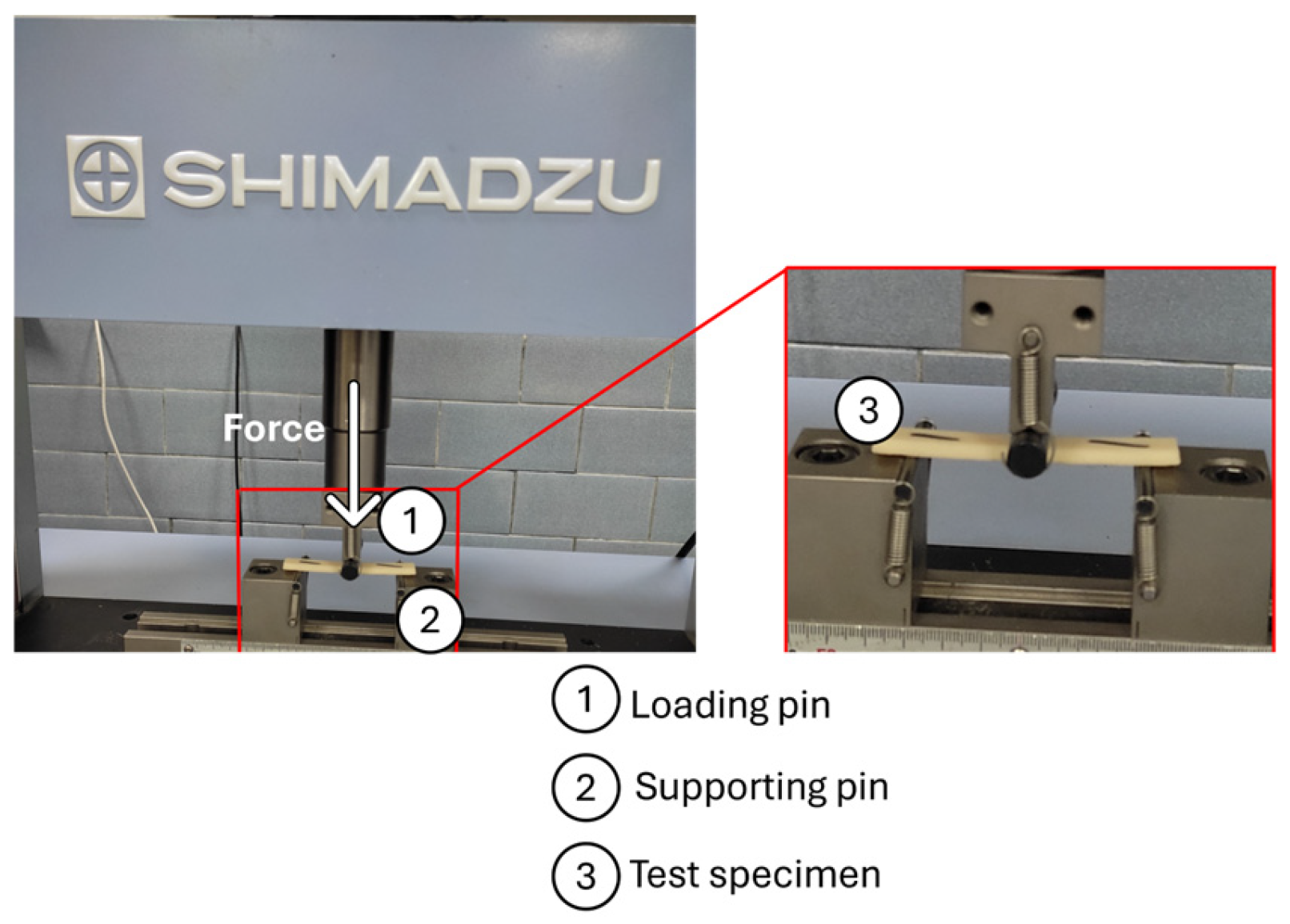

The test specimens, designed according to ASTM standards, i.e., D638-IV [

21], D790 [

22], and D256 [

23], were created using Autodesk Fusion 360. After the creation of the CAD model, layer thickness, build orientation, and exposure time were configured in the Chitubox program. Anycubic dental non-castable resin was used as the building material. Testing on the specimen was divided into three categories: tensile, flexural, and impact testing. Liquid resin was poured into the vat of the SLA apparatus, and the printer selectively polymerized the resin to 3D print the required CAD model by layer-by-layer deposition.

2.1. Additive Manufacturing of Samples

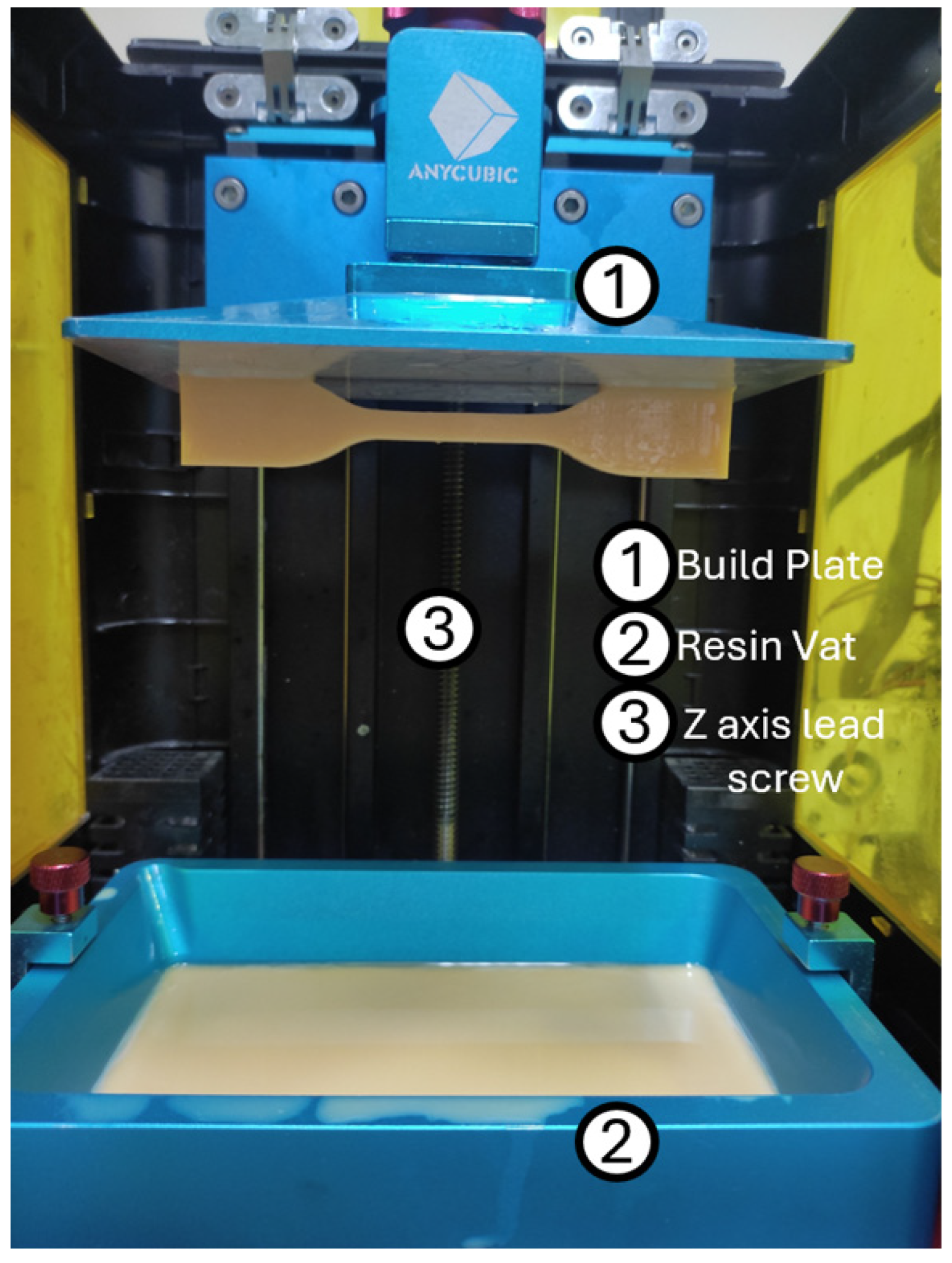

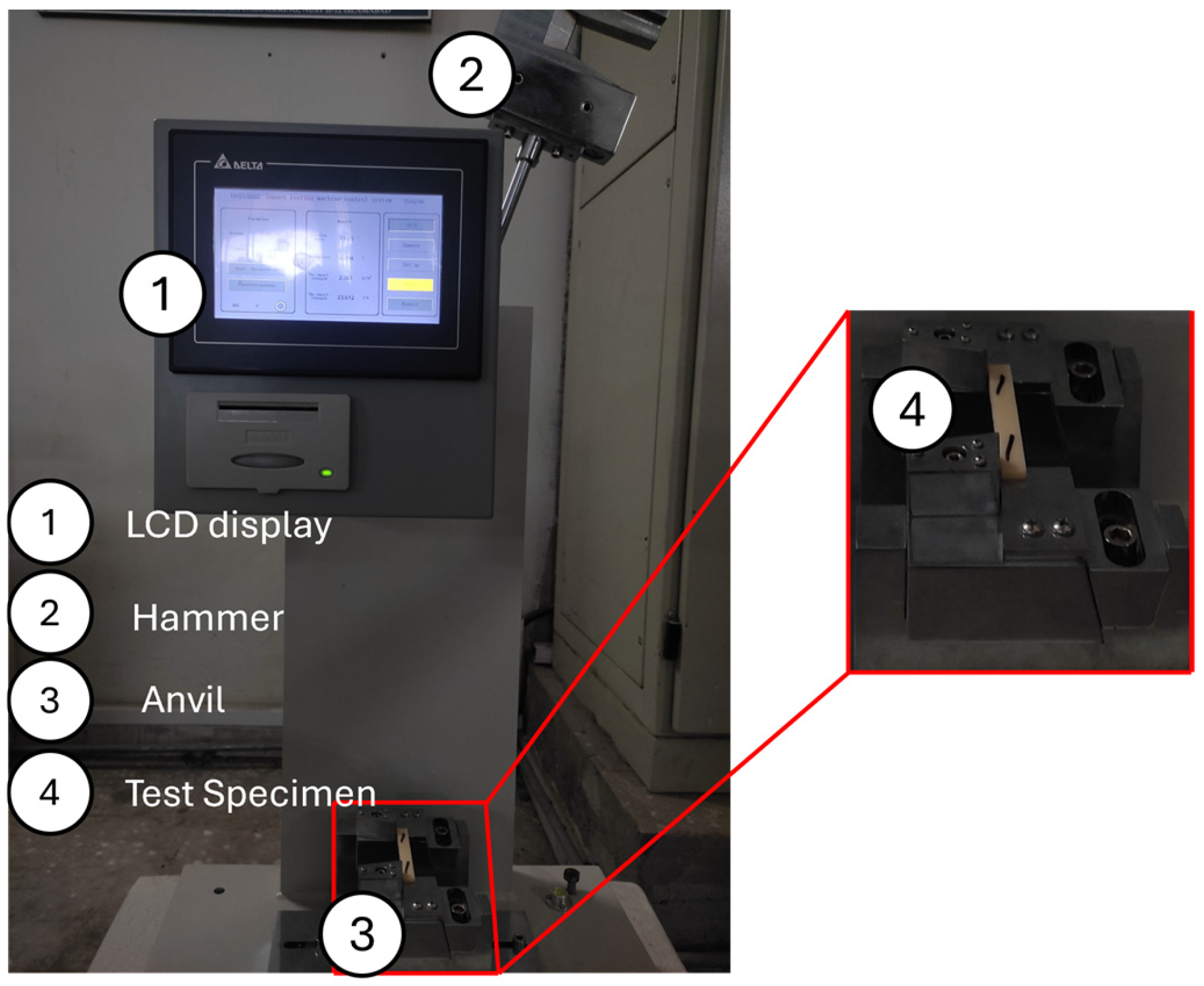

The Anycubic Photon S 3D printer, as shown in

Figure 1, was used to print tensile, flexural, and impact specimens. The printer uses 2K UV light LCDs of 405 nm installed under the vat to selectively polymerize the resin. The base plate of the printer moves upward, allowing resin to be deposited in a successive layer to form 3D objects.

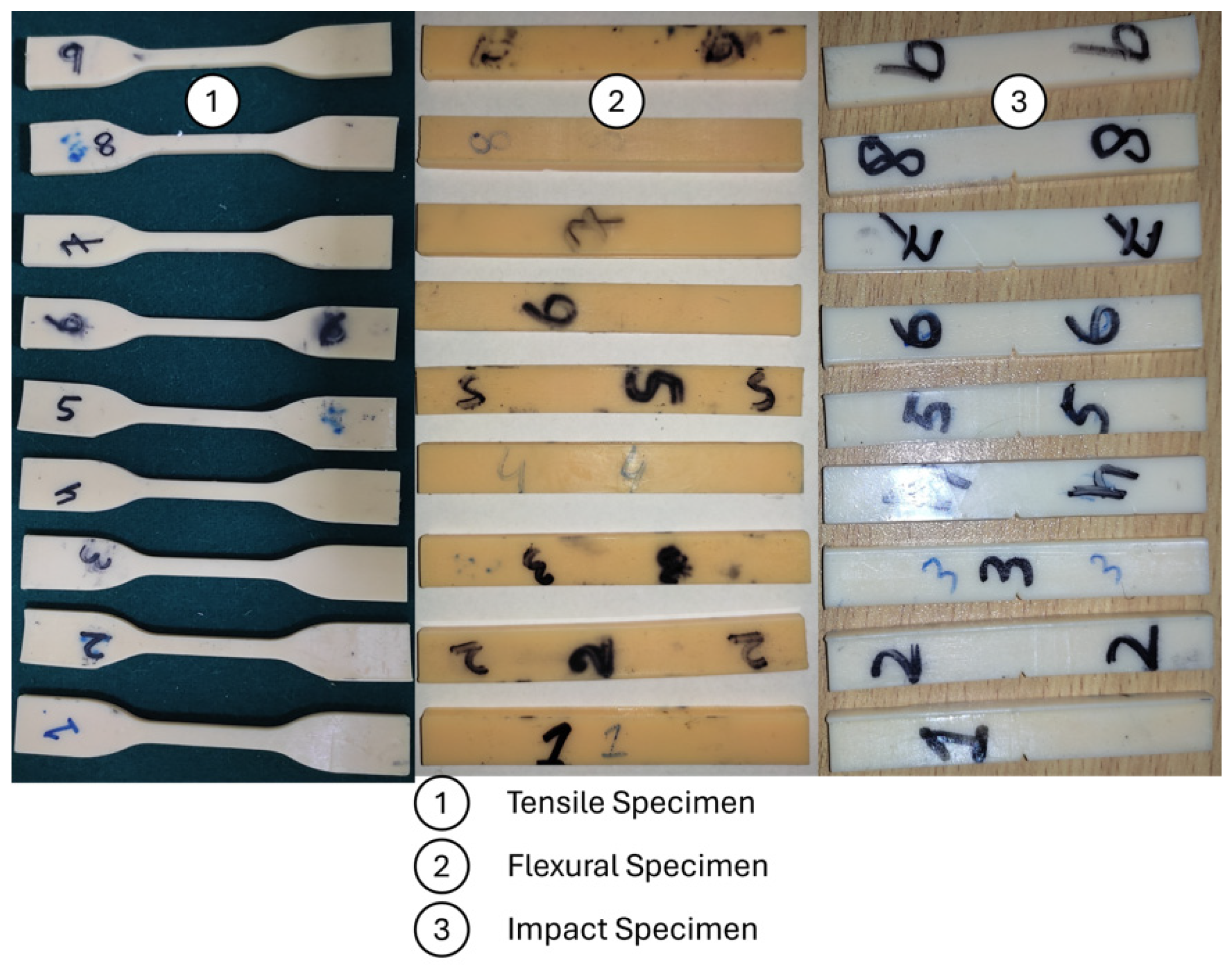

Three specimens for each setting in the L9 orthogonal array were printed at a temperature of 25 Celsius and a relative humidity of 69% for tensile, flexural, and impact studies. All specimens are tested in green conditions. Nine samples, printed with different settings according to the L9 orthogonal array, are shown in

Figure 2.

2.2. Design of Experiments

To investigate the influence of parameters on mechanical properties, a DOE approach was devised using the Taguchi method which enables researchers and scientists to effectively study multiple parameters impacting a single output and facilitates the precise presentation of the response output [

24].

Based on the literature [

23,

25], the process parameters and their levels were first identified as part of the research’s methodology. These include layer thickness (0.1, 0.125, 0.15 mm), build orientation comprising flat, side, and vertical configuration (F, S, V), and exposure time (7, 13, 14 s). The degree of freedom (DOF) was calculated from Equation (1), based on the number of process parameters and their corresponding levels. The L9 orthogonal array was chosen because the total DOF was 6, satisfying the requirement for more experiments than DOF, and can accommodate three parameters and three levels, as shown in

Table 1.

where L

i is the level of an individual parameter.

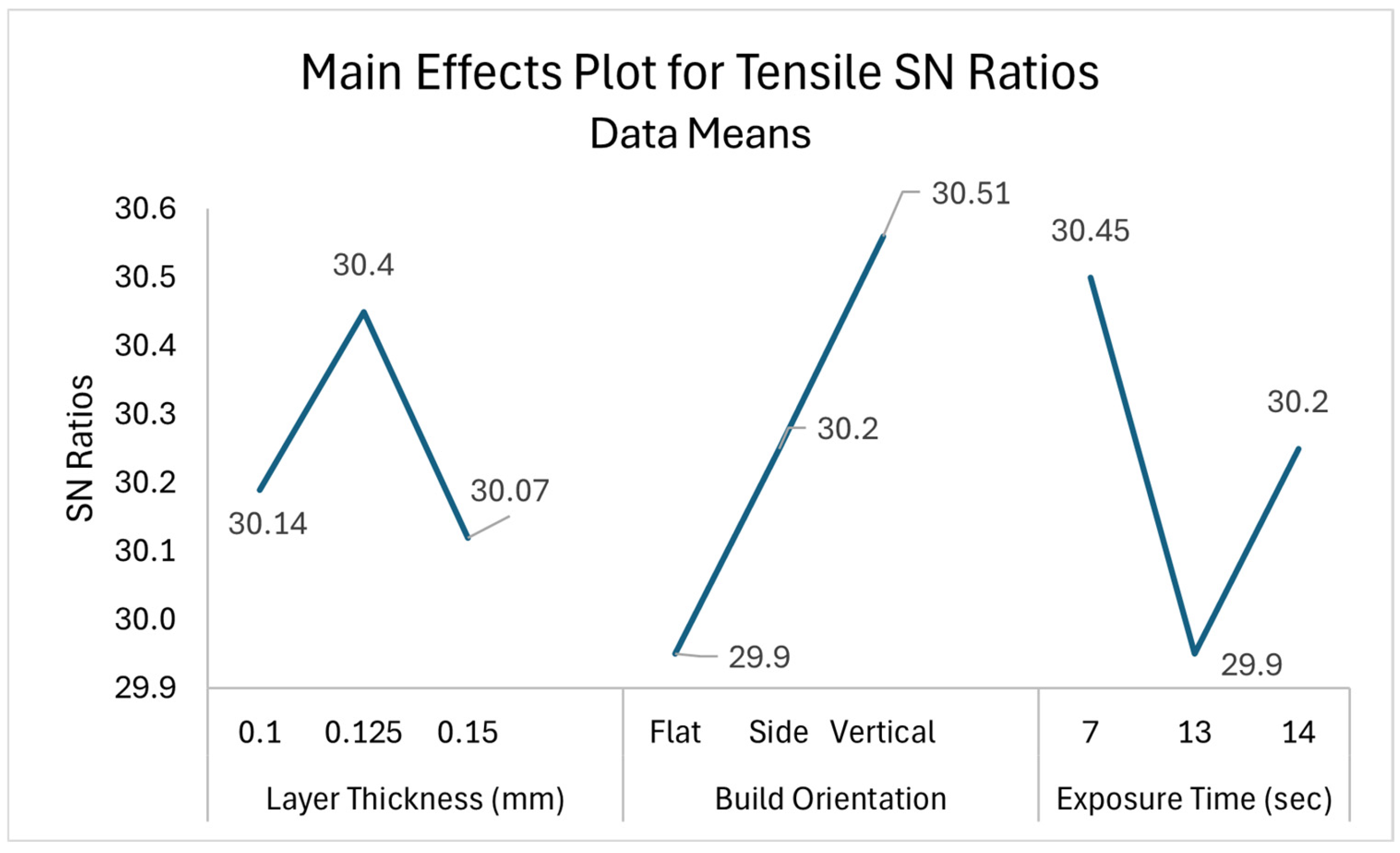

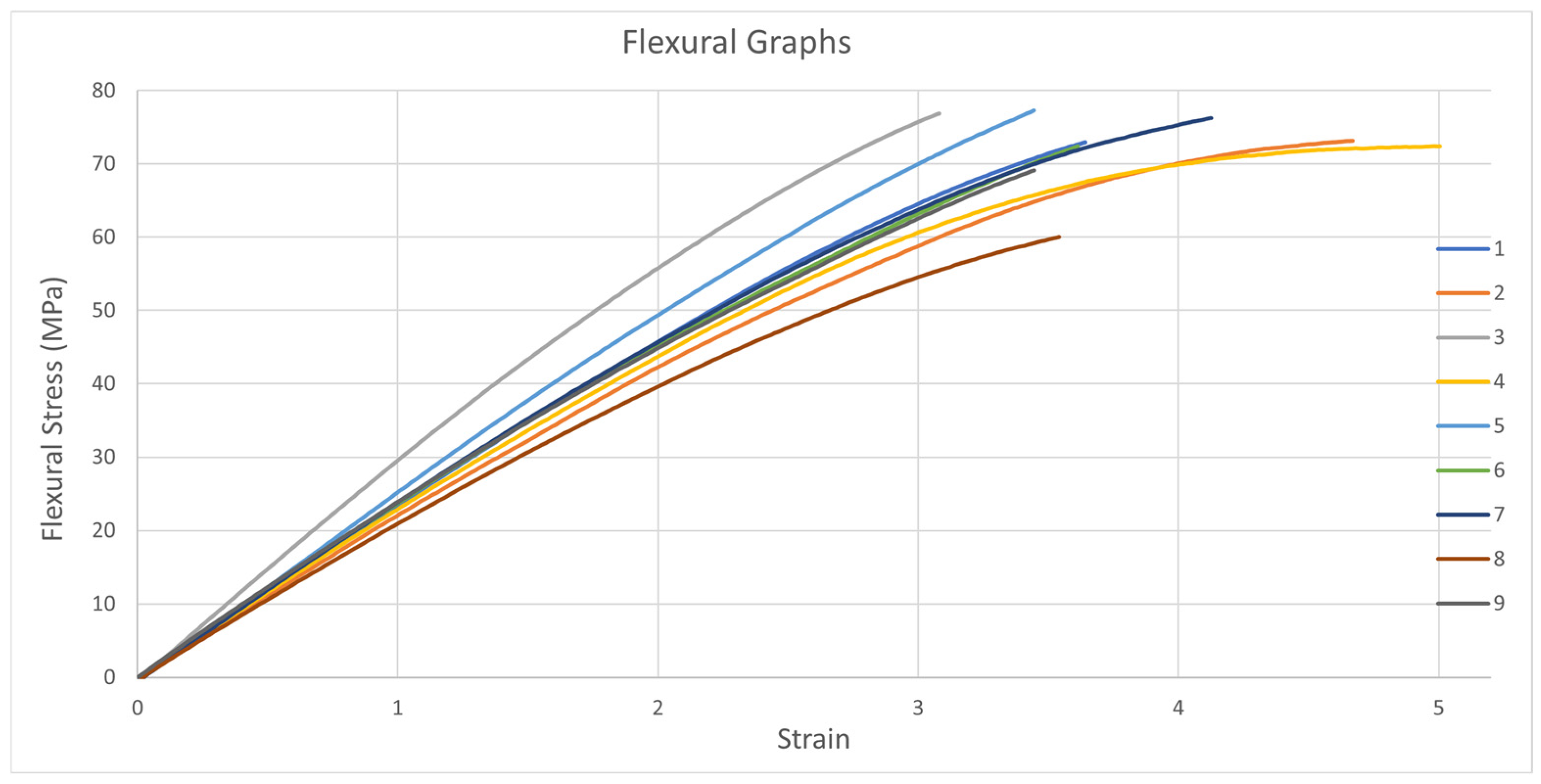

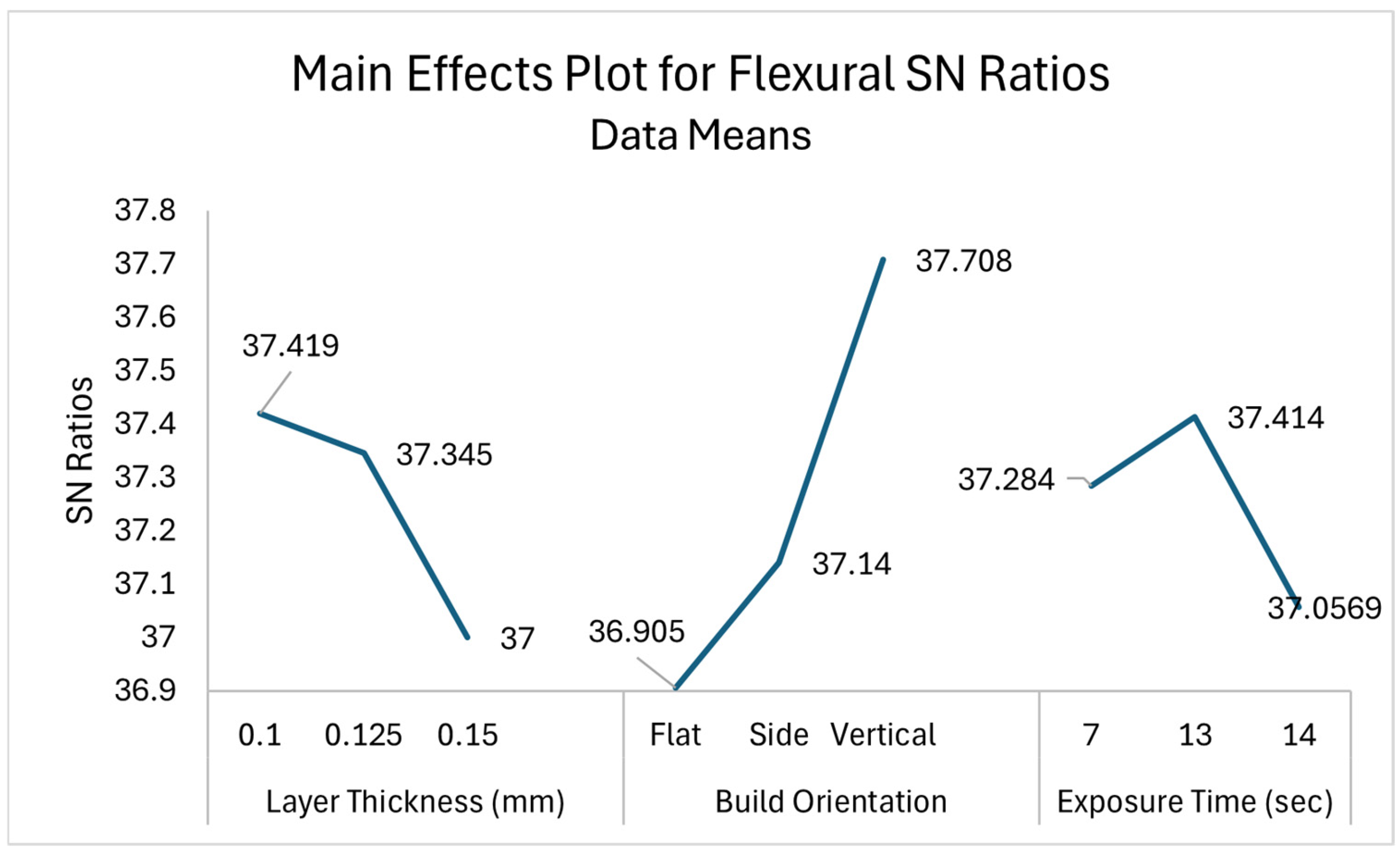

SN ratios were computed after experimental findings, and a confirmation test was conducted to validate the results. Minitab software version 21.2 was used to generate the SN curve, analyze variance, and calculate the percentage contribution of each factor to the response variable.

Taguchi proposes several types of characteristics, including “smaller the better,” “larger the better,” and “nominal the better.” Each characteristic is suited for different types of desirable responses, e.g., for defects and surface roughness, the smaller the better is used, while for responses that need to be maximized such as strength, speed, etc., the larger the better is preferred [

26]. The larger the better was selected as the response variable for mechanical properties, and a regression model was created to establish the relationships between the process parameters and the response variables (tensile, flexural, and impact strength).

4. Regression Model

In several disciplines, including finance, engineering, and the social sciences, regression models can be used to describe correlations between variables. Minitab software 21.2 was used to create a regression model between the response variable and independent variables. An L9 orthogonal array was first created in the software and then a dependent variable column was inserted which includes experimental values. The nonlinear regression model was selected to create a regression model for tensile, flexural, and impact tests by appointing layer thickness and exposure time as independent variables, and strength as a dependent variable.

Three regression models as shown in Equations (2)–(4) were created for tensile, flexural, and impact strength, respectively. Since vertical build orientation possesses a maximum contribution to strength, the regression model predicts values for vertical build orientation only. This model helps designers and engineers to predict the part strength before actual experimentation.

Residuals plot for tensile, flexural, and impact strength are given in

Figure 15. These plots confirm the independent nature and a random distribution of residuals which suggest that the model is a good fit for predicting these strengths.