Enhancing Parabolic Trough Collector Performance Through Surface Treatment: A Comparative Experimental Analysis †

Abstract

1. Introduction

2. Problem Formulation and Experimental Procedure

2.1. Tilt Angle Calculations

2.1.1. Declination Angle

2.1.2. Solar Altitude Angle

2.1.3. Solar Azimuth Angle

2.1.4. Angle of Incidence

3. Results and Discussions

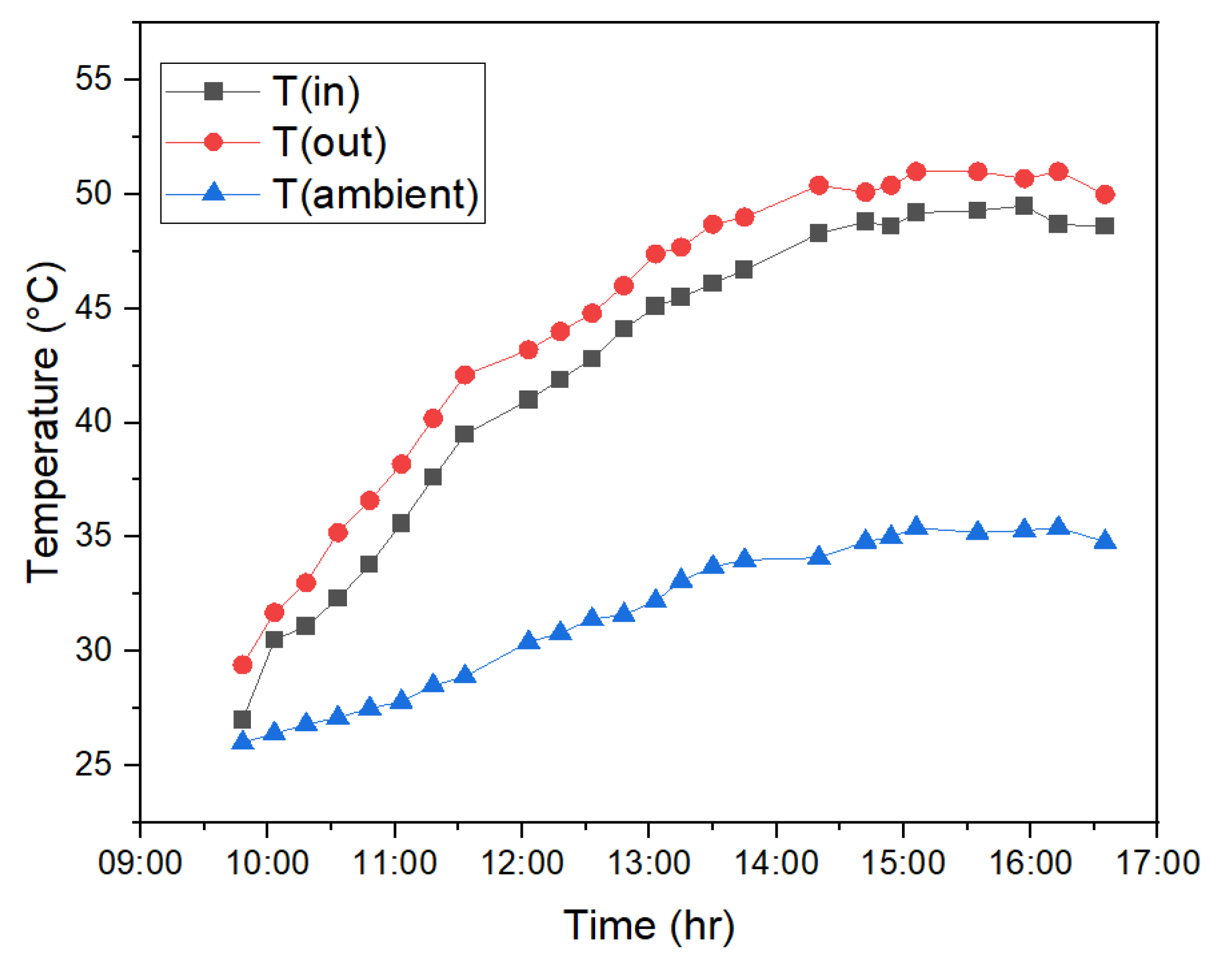

3.1. Laminar Flow

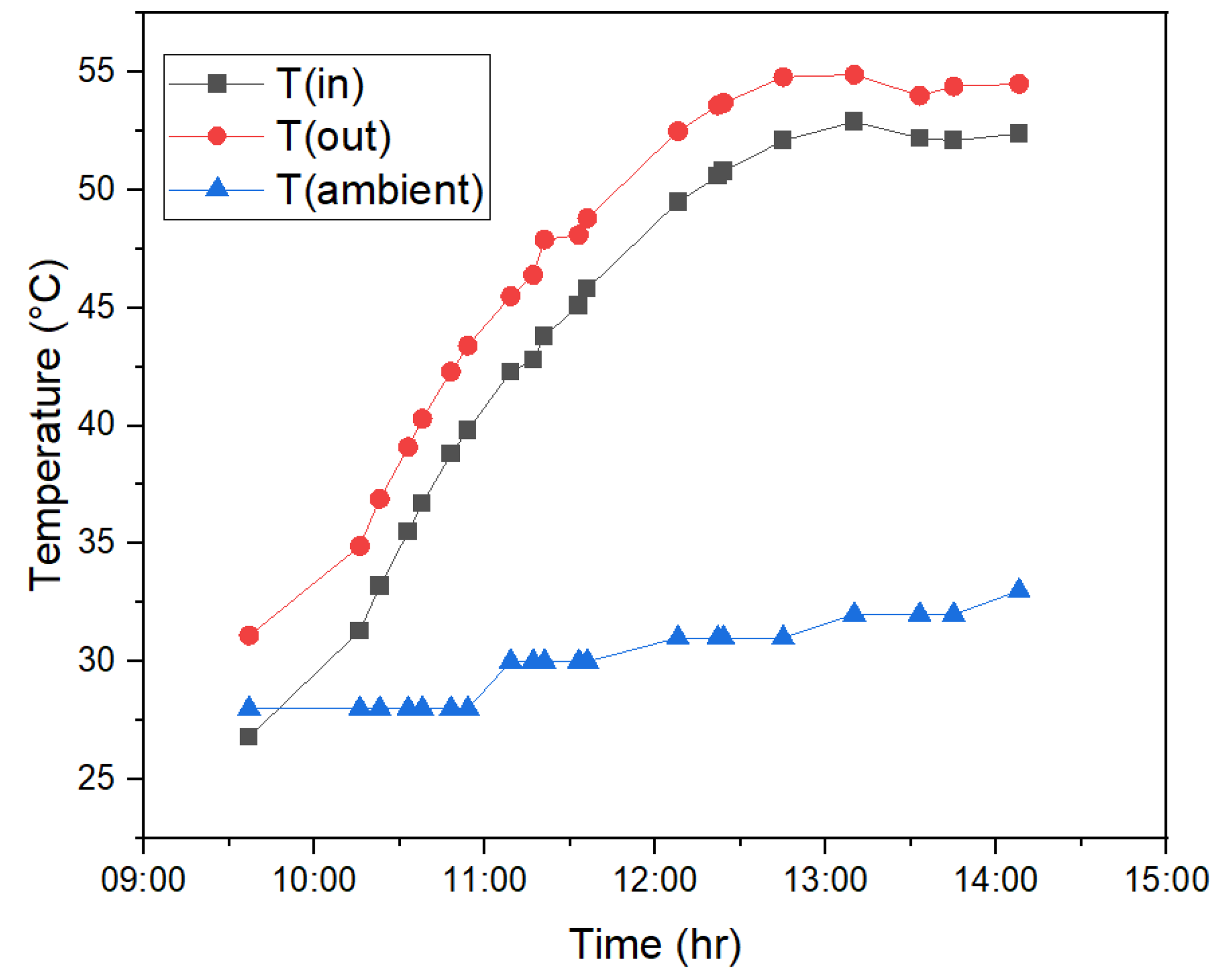

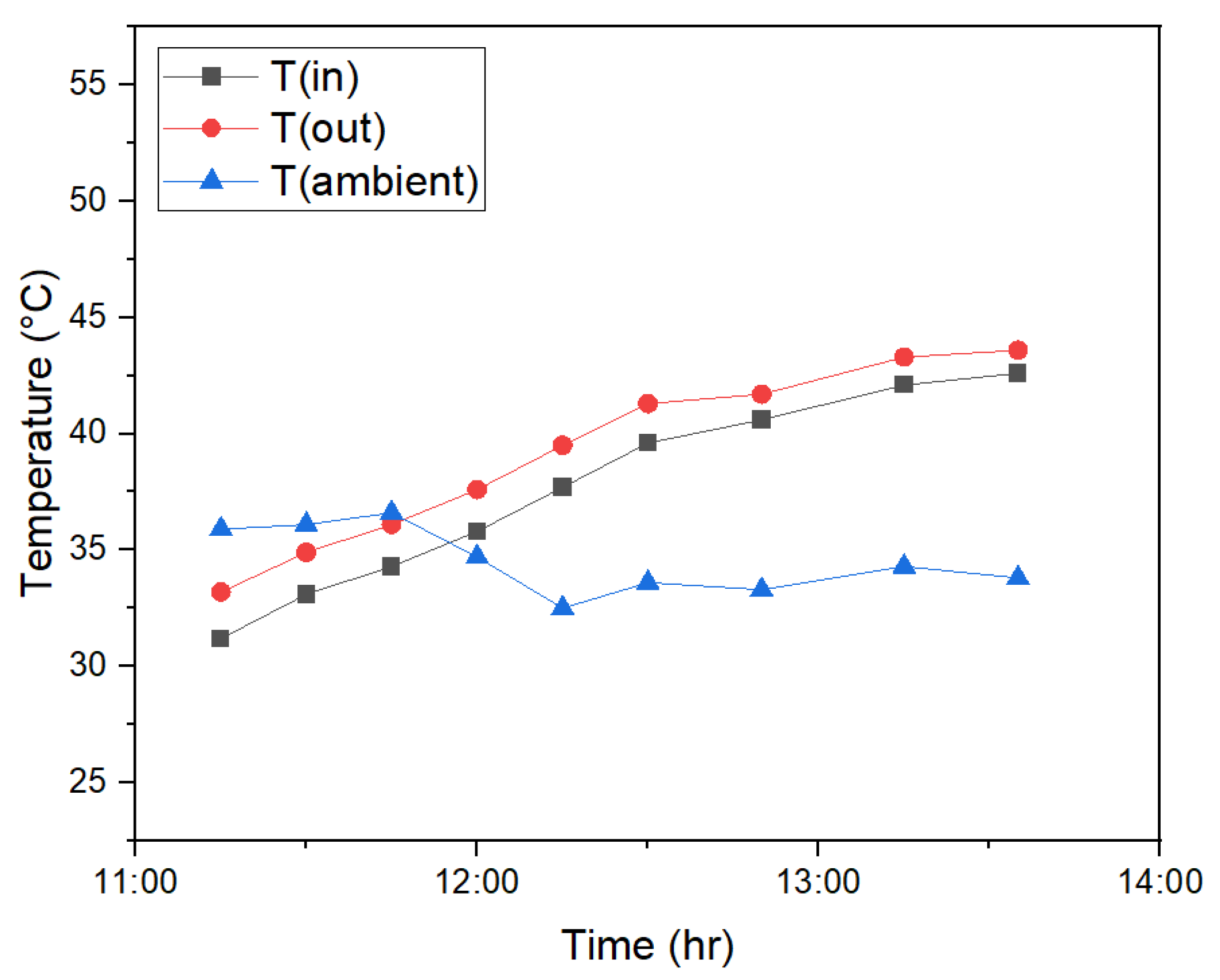

3.2. Turbulent Flow

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jebasingh, V.K.; Herbert, G.J. A review of solar parabolic trough collector. Renew. Sustain. Energy Rev. 2016, 54, 1085–1091. [Google Scholar] [CrossRef]

- Mahmoud, M.; Ramadan, M.; Naher, S.; Pullen, K.; Olabi, A.G. The impacts of different heating systems on the environment: A review. Sci. Total Environ. 2021, 766, 142625. [Google Scholar] [CrossRef] [PubMed]

- Bellos, E.; Tzivanidis, C.; Antonopoulos, K.A. A detailed working fluid investigation for solar parabolic trough collectors. Appl. Therm. Eng. 2017, 114, 374–386. [Google Scholar] [CrossRef]

- Hebbal, U.; Soragaon, B.; Rathnakar, G.; Das, A.N.M.; Thippeswamy, L.R.; Nagabhushana, N.; Prasad, C.D.; Aden, A.A. Principal difficulties with parabolic trough collector systems and performance-boosting strategies: A comprehensive review. Int. J. Thermofluids 2024, 25, 101009. [Google Scholar] [CrossRef]

- Fernández-García, A.; Zarza, E.; Valenzuela, L.; Pérez, M. Parabolic-trough solar collectors and their applications. Renew. Sustain. Energy Rev. 2010, 14, 1695–1721. [Google Scholar] [CrossRef]

- Alghamdi, F.A.M. Performance Analysis of a Parabolic Trough Solar Collector. Master’s Thesis, Department of Mechanical and Civil Engineering, Florida Institute of Technology, Melbourne, FL, USA, 2019. Available online: https://repository.fit.edu/etd/1020 (accessed on 30 June 2025).

- Suppan, D.K.; Subramanian, R.S. Performance analysis of parabolic trough solar collector by varying the absorber surface. Int. J. Ambient Energy 2020, 43, 1528–1532. [Google Scholar] [CrossRef]

- Alamr, M.A.; Gomaa, M.R. A review of Parabolic Trough Collector (PTC): Application and performance comparison. Int. J. Appl. Sci. Dev. 2022, 1, 24–26. [Google Scholar] [CrossRef]

- Olson, K.D.; Talghader, J.J. Solar selective coating optimization for direct steam generation parabolic trough designs. Sol. Energy 2016, 124, 82–88. [Google Scholar] [CrossRef]

- Yang, H.; Wang, Q.; Huang, Y.; Feng, J.; Ao, X.; Hu, M.; Pei, G. Spectral optimization of solar selective absorbing coating for parabolic trough receiver. Energy 2019, 183, 639–650. [Google Scholar] [CrossRef]

- Tabassum, S.; Sharmin, L.; Bashar, M.S.; Rahaman, M.; Debnath, S.C.; Khanam, M. Design and analysis of parabolic trough solar water heating system. J. Archit. Environ. Struct. Eng. Res. 2019, 2, 1–6. [Google Scholar] [CrossRef]

- Byiringiro, J.; Chaanaoui, M.; Hammouti, B. Thermal performance enhancement of a novel receiver for parabolic trough solar collector. Interactions 2025, 246, 13. [Google Scholar] [CrossRef]

- Vician, P.; Palacka, M.; Ďurčanský, P.; Jandačka, J. Determination of optimal position of solar trough collector. Procedia Eng. 2017, 192, 941–946. [Google Scholar] [CrossRef]

| Name | Property | Value | Unit |

|---|---|---|---|

| Density | P | 997 | Kg/m3 |

| Specific Heat Capacity | Cp | 4.18 | KJ/Kg·k |

| Dynamic Viscosity | µ | 0.890 | mPa·s |

| Boiling Point | Tb | 100 | °C |

| Parameter | Notation and Unit | Value |

|---|---|---|

| Length of Parabolic Collector | Lp (m) | 1.91 |

| Length of Copper Tube | Lt (m) | 1.91 |

| Rim Angle | Ψ (degrees) | 45–90 |

| Collector Tube Outer Diameter | do (m) | 0.026 |

| Collector Tube Internal Diameter | di (m) | 0.025 |

| Aperture Area | Ap (m2) | 1.30 |

| Concentration Ratio | CR | 8.33 |

| Thermal Conductivity of Copper | K (W/m·K) | 401 |

| Absorptivity of Black-Painted Copper Tube | α | 0.95 |

| Chromium Reflectance | ρ | 0.90 |

| Variable | Device | Value | Accuracy | Rangle |

|---|---|---|---|---|

| Temperature, °C | Digital Thermometer | 1.91 | ±0.1 | −50–110 |

| Solar Radiation W/m2 | Light Dependent Resistor | 1.91 | ±10 | 0–2000 |

| Water Flowrate L/m | Digital Turbine Water Flow Sensor | 45–90 | ±0.5 | 1–30 |

| Dimensions (m) | Measuring Tape | 0.026 | ±1 | 0–100 |

| Time | |

|---|---|

| 9:00 | 41.41 |

| 9:30 | 35.23 |

| 10:00 | 29.17 |

| 10:30 | 23.37 |

| 10:45 | 20.64 |

| 11:00 | 18.09 |

| 11:45 | 15.83 |

| 12:00 | 13.99 |

| 12:15 | 12.76 |

| 12:30 | 12.33 |

| 12:45 | 12.76 |

| 13:00 | 13.99 |

| 13:15 | 15.83 |

| 13:30 | 18.09 |

| 13:45 | 20.64 |

| 14:00 | 23.37 |

| 14:30 | 26.23 |

| 15:00 | 29.17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, A.; Malik, N.M.; Irfan, M. Enhancing Parabolic Trough Collector Performance Through Surface Treatment: A Comparative Experimental Analysis. Eng. Proc. 2025, 111, 30. https://doi.org/10.3390/engproc2025111030

Rahman A, Malik NM, Irfan M. Enhancing Parabolic Trough Collector Performance Through Surface Treatment: A Comparative Experimental Analysis. Engineering Proceedings. 2025; 111(1):30. https://doi.org/10.3390/engproc2025111030

Chicago/Turabian StyleRahman, Abdullah, Nawaf Mehmood Malik, and Muhammad Irfan. 2025. "Enhancing Parabolic Trough Collector Performance Through Surface Treatment: A Comparative Experimental Analysis" Engineering Proceedings 111, no. 1: 30. https://doi.org/10.3390/engproc2025111030

APA StyleRahman, A., Malik, N. M., & Irfan, M. (2025). Enhancing Parabolic Trough Collector Performance Through Surface Treatment: A Comparative Experimental Analysis. Engineering Proceedings, 111(1), 30. https://doi.org/10.3390/engproc2025111030