Investigation of Wear Behavior for Innovative Cutting Tool in Machining AISI 304 Stainless Steel

Abstract

1. Introduction

2. Experimental Materials and Methods

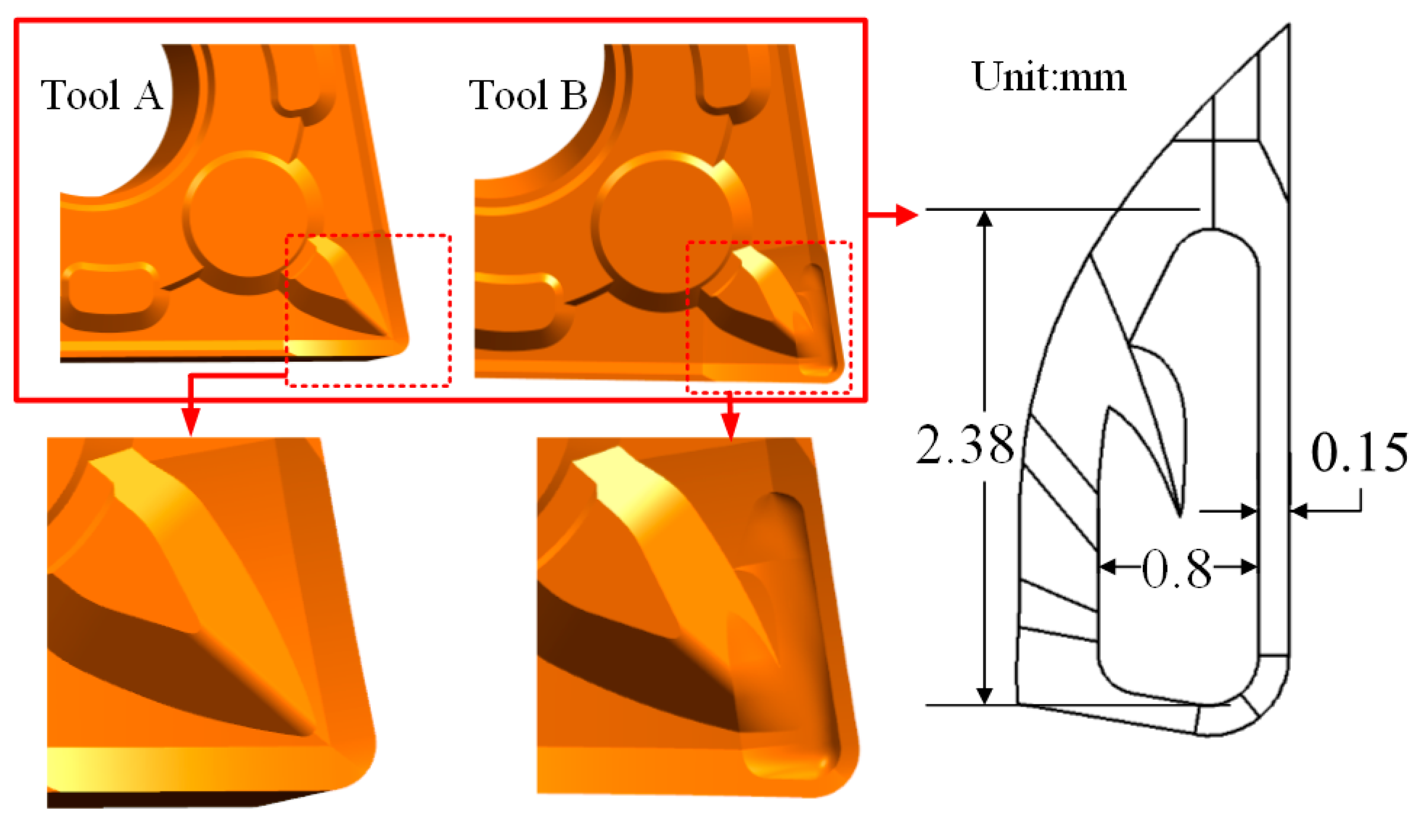

2.1. Cutting Tool Materials and Parameters

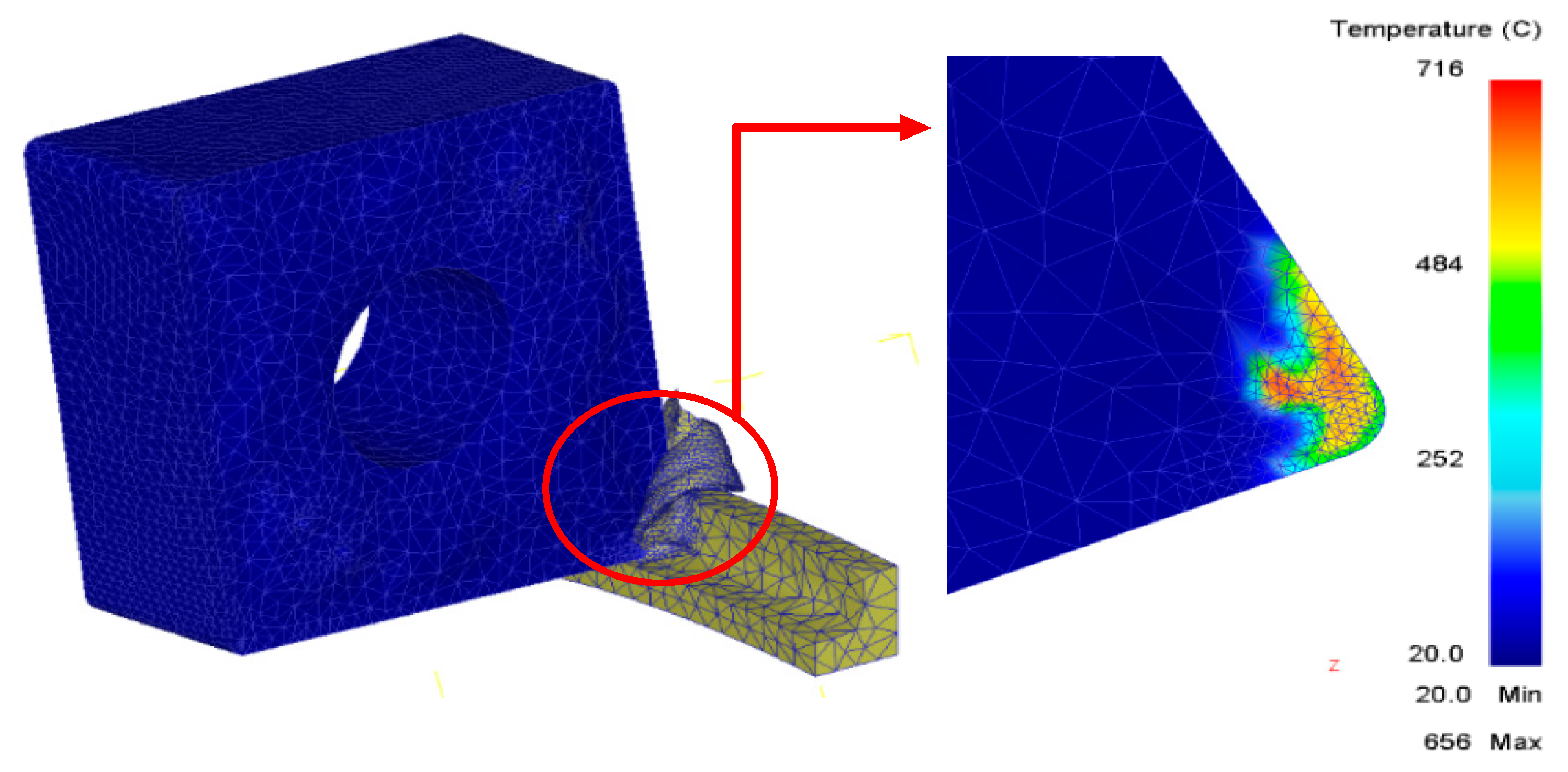

2.2. DEFORM Model Construction

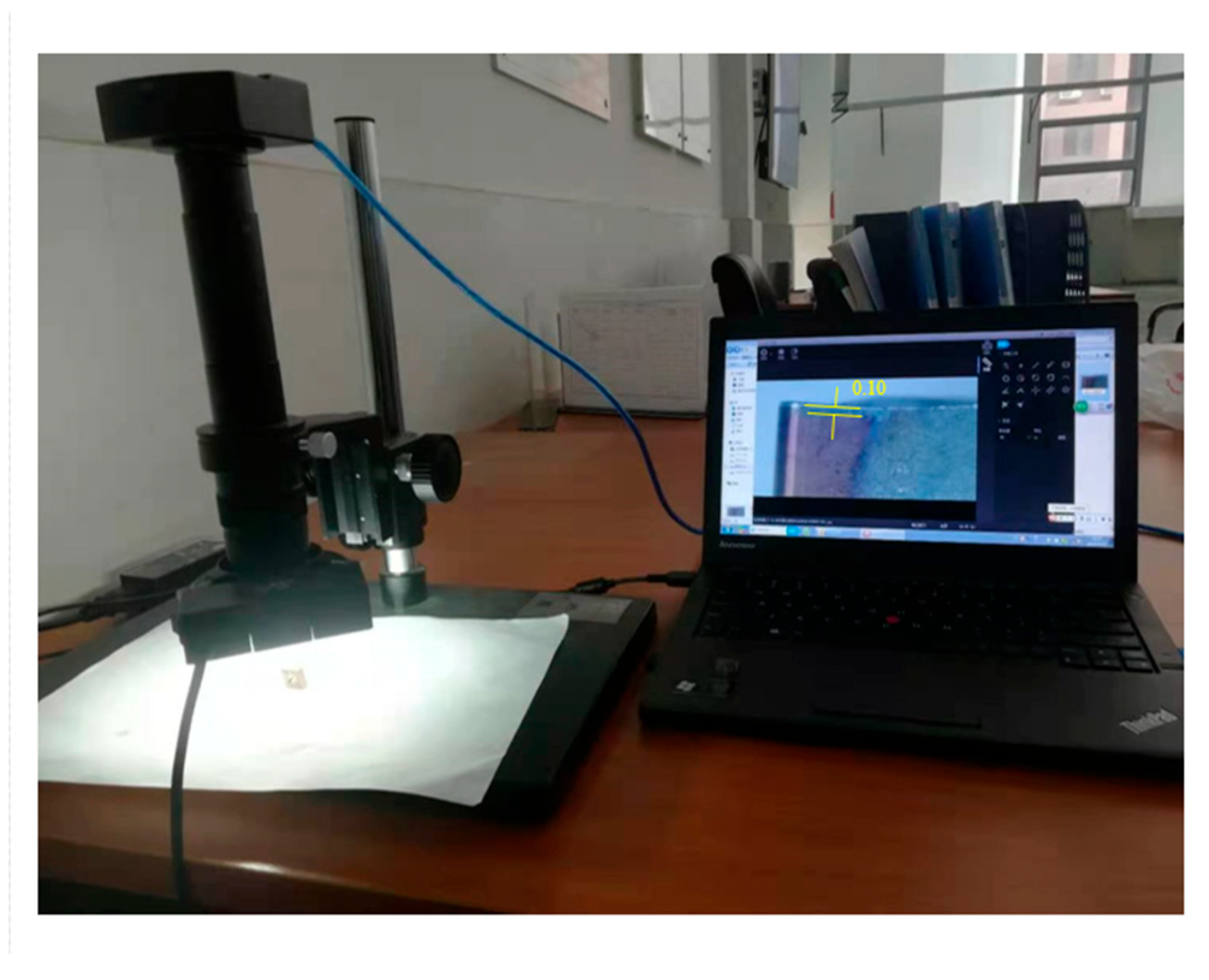

2.3. Cutting Force and Wear Measurement

3. Tool Cutting Experiments and Wear Research

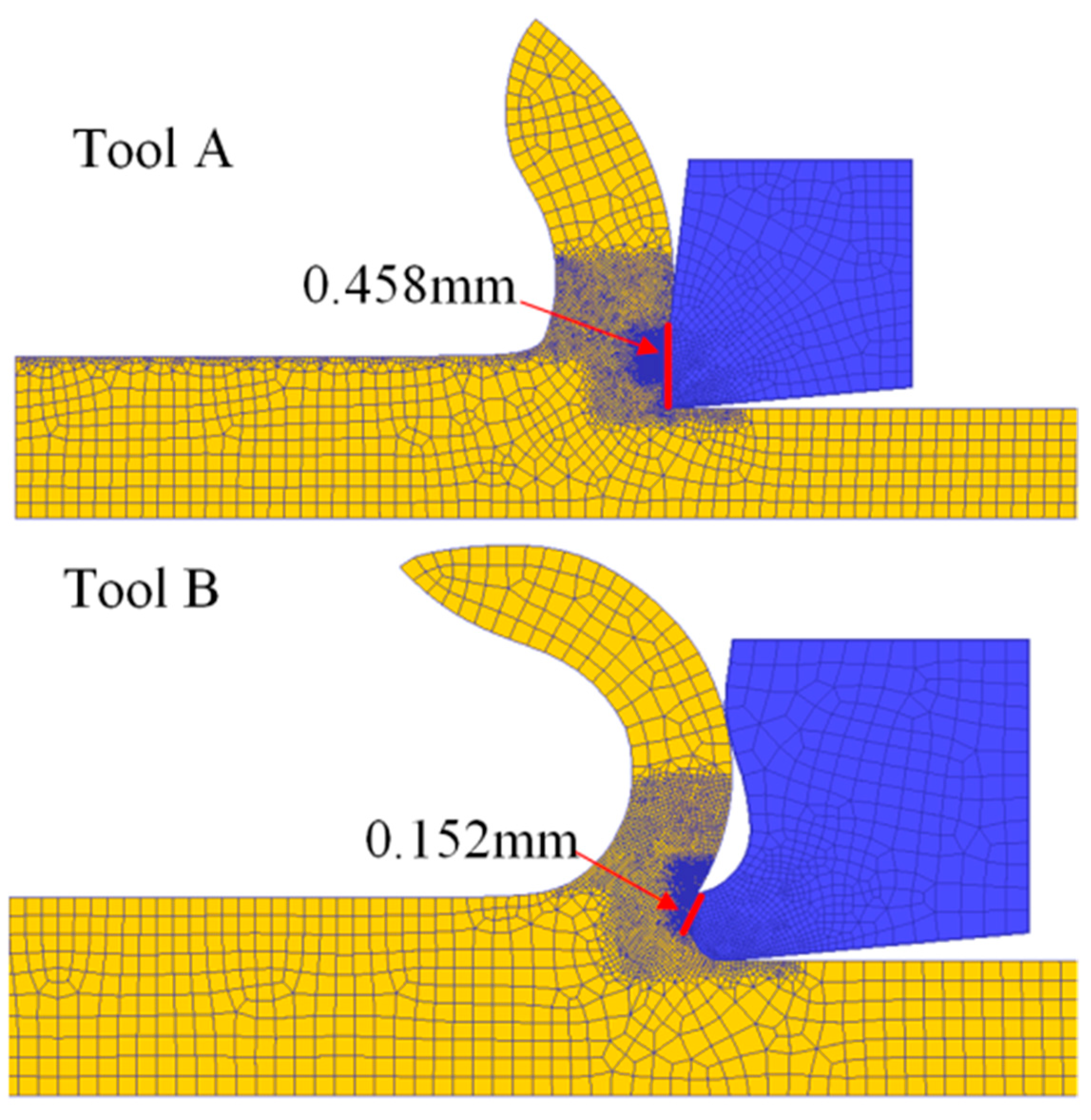

3.1. Simulation Results

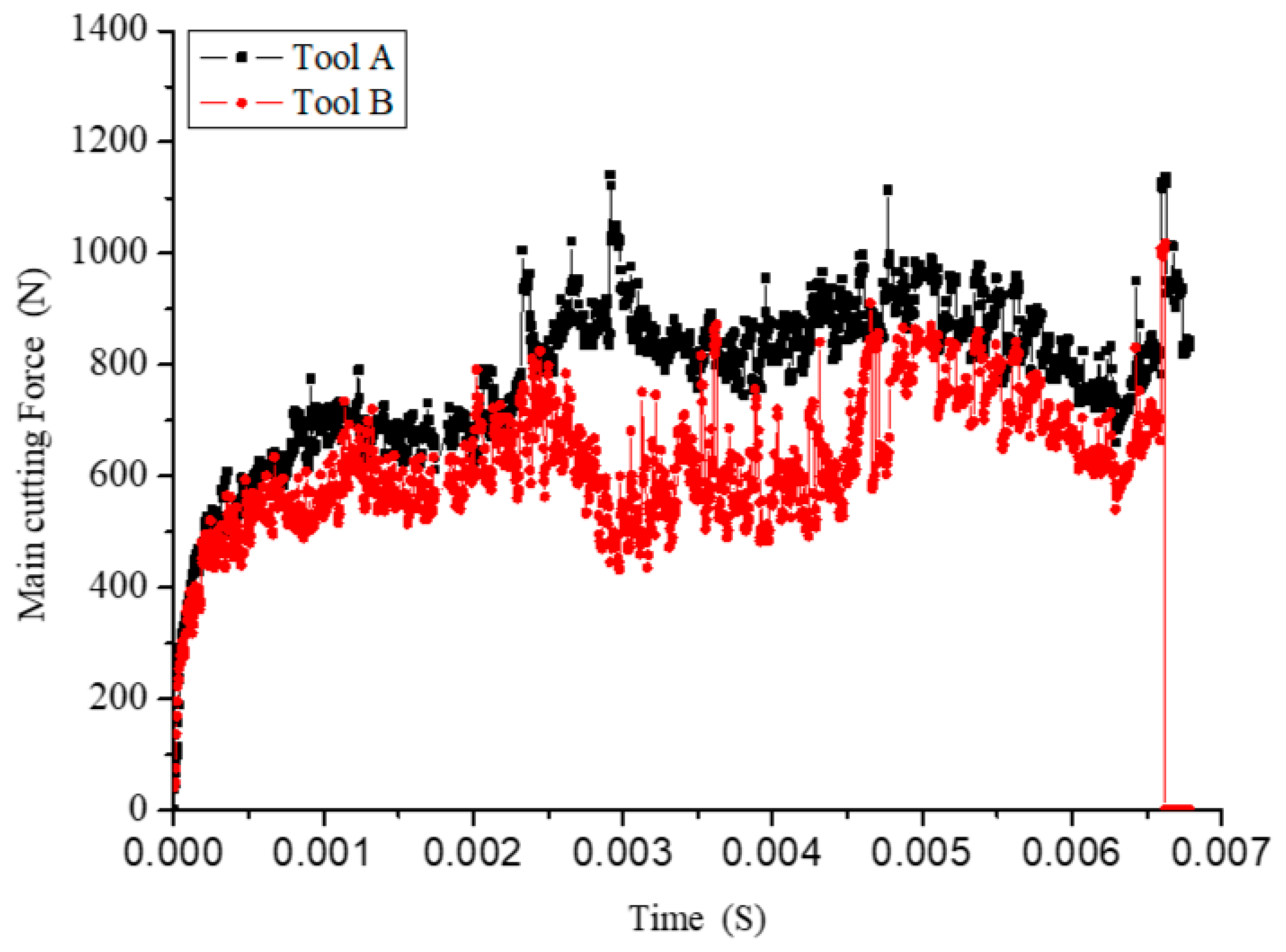

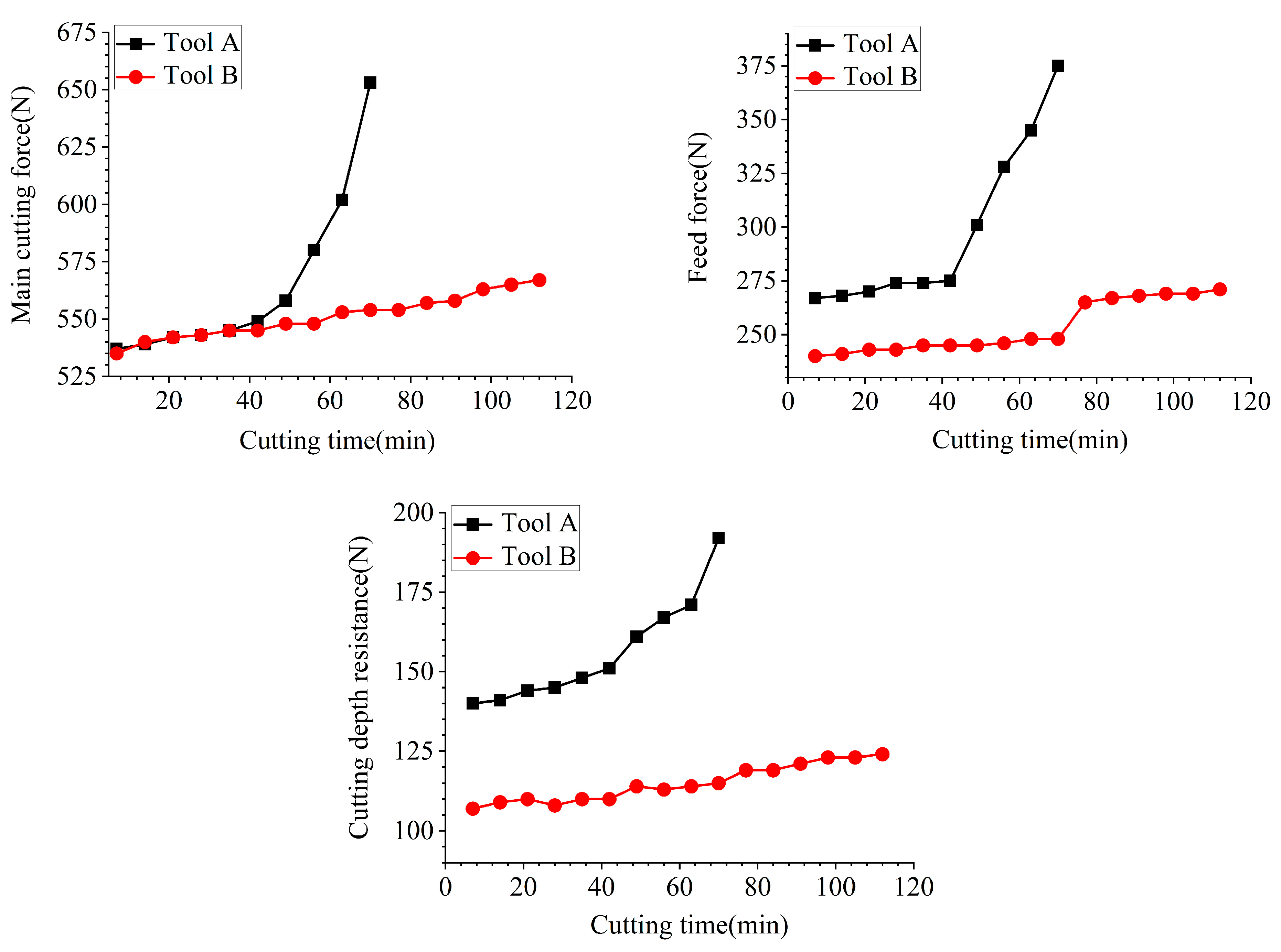

3.2. Comparison of Cutting Forces

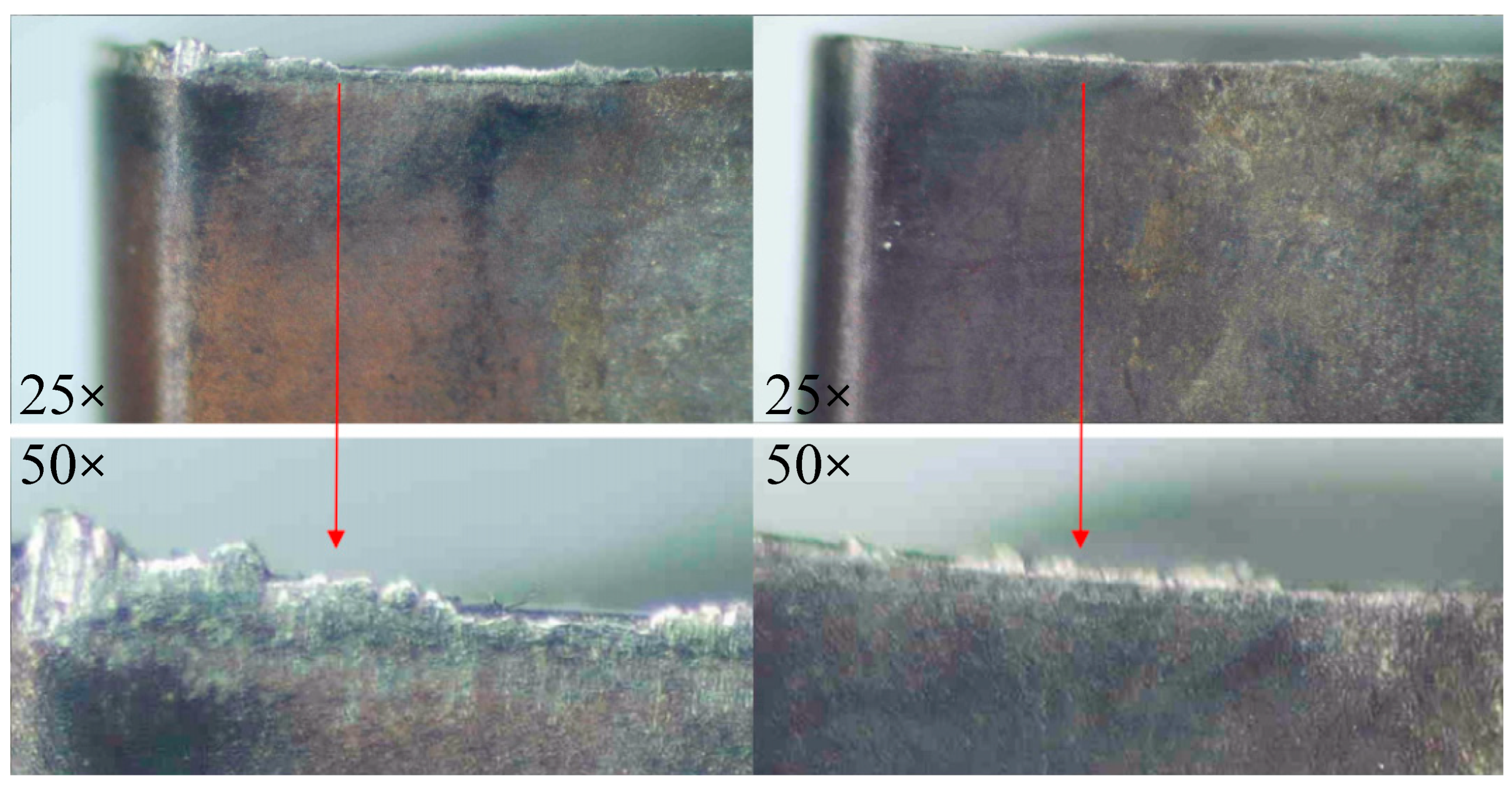

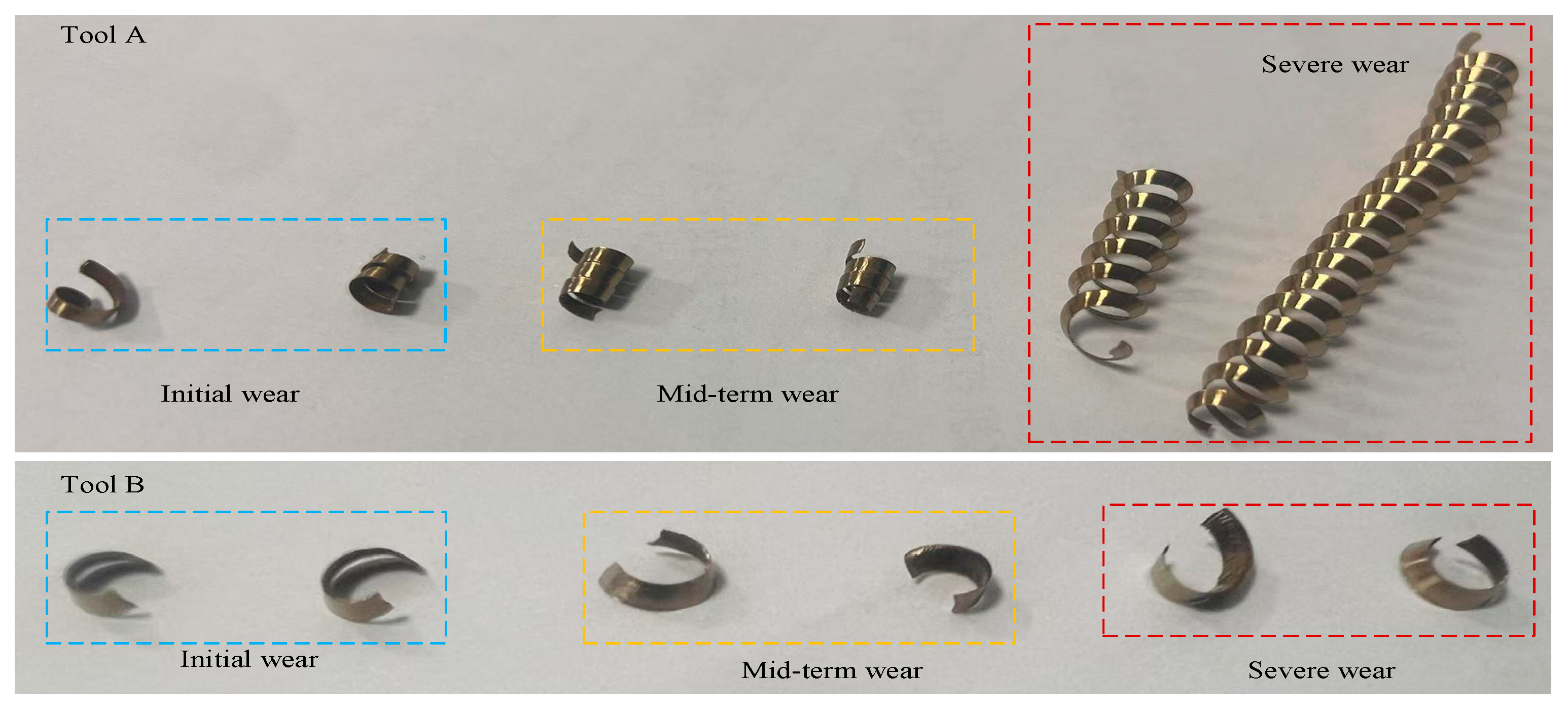

3.3. Comparison of Tool Wear Morphology

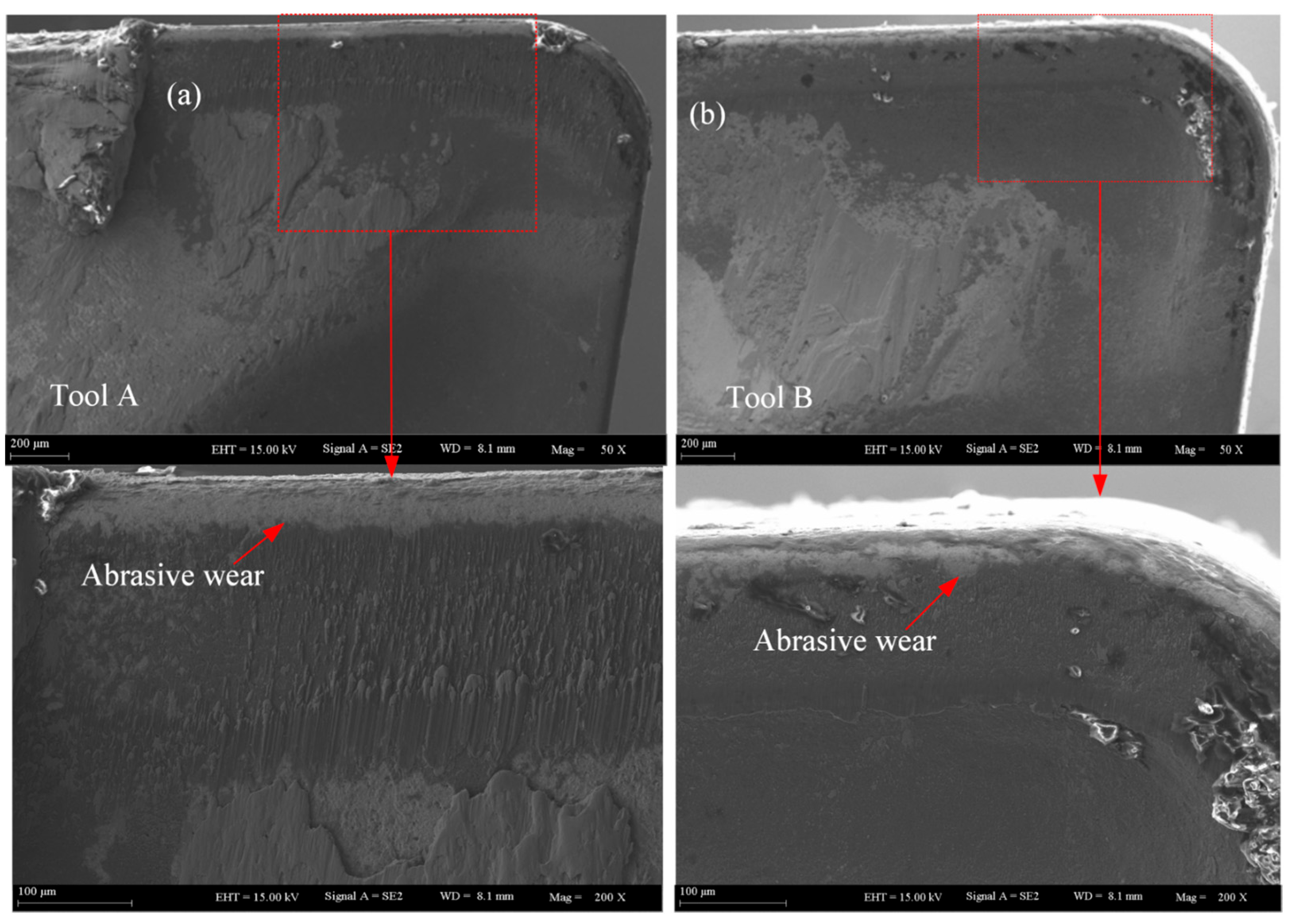

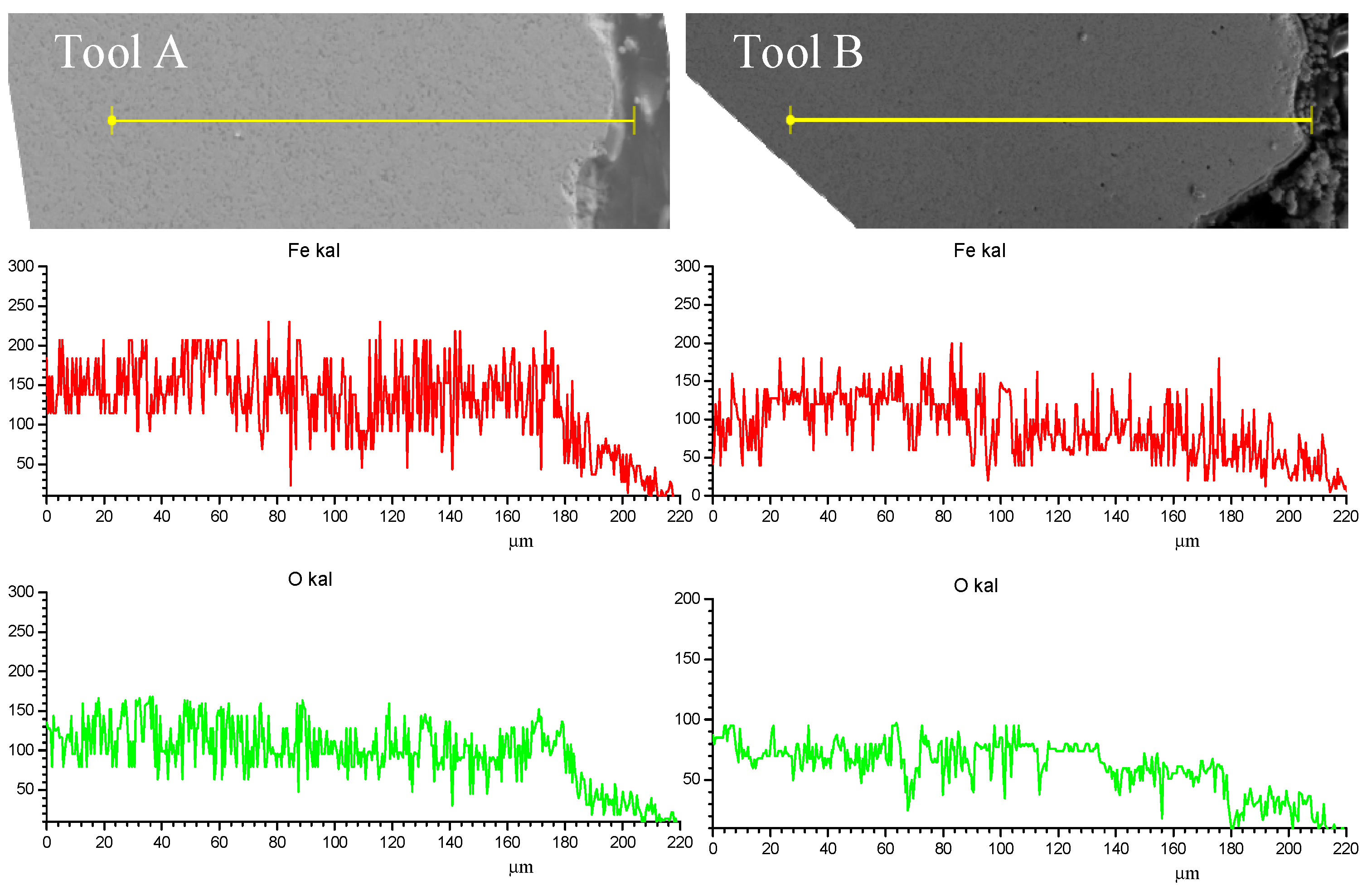

3.4. SEM Scanning and Line Scan Comparison of the Rake and Flank Faces of the Tools

3.5. Macroscopic Morphology Comparison of Tool Cutting Chips

4. Results and Discussion

5. Conclusions

- Compared to tool A, the introduction of micro-grooves in tool B resulted in larger rake angles and shear angles during the cutting process, the reduced plastic deformation of the chips, and decreased cutting energy input.

- Through surface morphology observation, the wear on the front and back faces of tool B was less severe than that of tool A, with shallower wear marks. Additionally, the distribution of primary elements and local energy spectrum analysis indicate that both the adhesive wear and oxidative wear on tool B are less severe than those on tool A.

- The presence of micro-grooves alters the tool–chip contact state, reducing the length of the tool–chip friction zone. As a result, the energy generated by tool–chip friction decreases, leading to lower cutting temperatures, reduced chip plastic deformation, and improved chip breaking.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Li, Z.; Jiang, M.; Guo, X.; Zhang, K. Improving the frictional properties of the tool/chip interface of micro-textured ceramics tools by using electromagnetic-assisted nanofluids. Mater. Today Commun. 2024, 39, 109017. [Google Scholar] [CrossRef]

- Zou, P.; Zhou, L.; Yang, Z.; Ren, B.; Wang, X. Effect of texture location in tool-chip friction region on cutting performance in turning AISI 304. Int. J. Adv. Manuf. Technol. 2024, 132, 2787–2805. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, R.; Kumar, S.; Verma, P. A review on machining performance of AISI 304 steel. Mater. Today Proc. 2022, 56, 2945–2951. [Google Scholar] [CrossRef]

- Junaidh, A.P.; Yuvaraj, G.; Peter, J.; Bhuvaneshwari, V.; Karthik, K. Influence of process parameters on the machining characteristics of austensite stainless steel (AISI 304). Mater. Today Proc. 2018, 5, 13321–13333. [Google Scholar] [CrossRef]

- Maharana, H.S.; Kumar, R.; Murty, S.N.; Ramkumar, J.; Mondal, K. Surface micro-texturing of dual phase steel and copper by combining laser machining and electrochemical dissolution. J. Mater. Process. Technol. 2019, 273, 116260. [Google Scholar] [CrossRef]

- Jianxin, D.; Wenlong, S.; Hui, Z. Design, fabrication and properties of a self-lubricated tool in dry cutting. Int. J. Mach. Tools Manuf. 2009, 49, 66–72. [Google Scholar] [CrossRef]

- Jianxin, D.; Ze, W.; Yunsong, L.; Ting, Q.; Jie, C. Performance of carbide tools with textured rake-face filled with solid lubricants in dry cutting processes. Int. J. Refract. Met. Hard Mater. 2012, 30, 164–172. [Google Scholar] [CrossRef]

- Xu, Y.; Zheng, Q.; Abuflaha, R.; Olson, D.; Furlong, O.; You, T.; Tysoe, W.T. Influence of dimple shape on tri-bofilm formation and tribological properties of textured surfaces under full and starved lubrication. Tribol. Int. 2019, 136, 267–275. [Google Scholar] [CrossRef]

- Romano, J.M.; Garcia-Giron, A.; Penchev, P.; Dimov, S. Triangular laser-induced submicron textures for function-alising stainless steel surfaces. Appl. Surf. Sci. 2018, 440, 162–169. [Google Scholar] [CrossRef]

- Liu, W.; Ni, H.; Chen, H.; Wang, P. Numerical simulation and experimental investigation on tribological perfor-mance of micro-dimples textured surface under hydrodynamic lubrication. Int. J. Mech. Sci. 2019, 163, 105095. [Google Scholar] [CrossRef]

- Choi, Y.; Lee, J. A study on the effects of surface dimple geometry on fretting fatigue performance. Int. J. Precis. Eng. Manuf. 2015, 16, 707–713. [Google Scholar] [CrossRef]

- Schneider, J.; Braun, D.; Greiner, C. Laser textured surfaces for mixed lubrication: Influence of aspect ratio, textured area and dimple arrangement. Lubricants 2017, 5, 32. [Google Scholar] [CrossRef]

- Xu, R.; Yongfeng, Y. Effect of micro-texture of flank surface on broaching force and surface quality of workpiece. Appl. Surf. Sci. 2020, 146558. [Google Scholar] [CrossRef]

- Xie, Z.; Li, J.; Tian, Y.; Du, P.; Zhao, B.; Xu, F. Theoretical and experimental study on influences of surface texture on lubrication performance of a novel bearing. Tribol. Int. 2024, 193, 109351. [Google Scholar] [CrossRef]

- Arulkirubakaran, D.; Senthilkumar, V.; Kumawat, V. Effect of micro-textured tools on machining of Ti-6Al-4V alloy: An experimental and numerical approach. Int. J. Refract. Met. Hard Mater. 2016, 54, 165–177. [Google Scholar] [CrossRef]

- Musavi, S.H.; Sepehrikia, M.; Davoodi, B.; Niknam, S.A. Performance analysis of developed micro-textured cut-ting tool in machining aluminum alloy 7075-T6: Assessment of tool wear and surface roughness. Int. J. Adv. Manuf. Technol. 2022, 119, 3343–3362. [Google Scholar] [CrossRef]

- Ahmed, S.; Sagor, S.I.; Akbar, N.I.; Mahmud, M.M.; Mostofa, M.G. The influence of a newly developed refrigeration cycle based workpiece cooling method in milling AISI 304 stainless steel. Results Eng. 2023, 20, 101616. [Google Scholar] [CrossRef]

- França, P.H.; Barbosa, L.M.; Fernandes, G.H.; Machado, Á.R.; Martins, P.S.; da Silva, M.B. Internally cooled tools: An eco-friendly approach to wear reduction in AISI 304 stainless steel machining. Wear 2024, 554, 205490. [Google Scholar] [CrossRef]

- Roy, N.A.P.; Rao, K.J.; Amrita, M. Influence of tool micro-texturing, cooling conditions and cutting conditions on workpiece surface integrity and tool condition. J. Micromanuf. 2025, 25165984241308627. [Google Scholar] [CrossRef]

- Elajrami, Z.; Shi, G. Microtextured tools with cooling technology: A concise review. Int. J. Adv. Manuf. Technol. 2024, 135, 5071–5084. [Google Scholar] [CrossRef]

- Deng, J.; Lian, Y.; Wu, Z.; Xing, Y. Performance of femtosecond laser-textured cutting tools deposited with WS2 solid lubricant coatings. Surf. Coat. Technol. 2013, 222, 135–143. [Google Scholar] [CrossRef]

- Das, A.; Bajpai, V. Turning insert with lubricating passage along the normal plane for minimization of friction, cutting force and tool wear. J. Manuf. Process. 2023, 101, 141–155. [Google Scholar] [CrossRef]

- Hu, J.; Wei, J.; Feng, X.; Liu, Z. Research on Wear of Micro-Textured Tools in Turning GH4169 during Spray Cooling. Lubricants 2023, 11, 439. [Google Scholar] [CrossRef]

- Shi, Y.; Zheng, J.; Peng, C.; Guo, L.; Shi, W.; Feng, P.; Zhao, R. An investigation into the impact of tool surface texture on the cutting property of nickel-based superalloys under MQL conditions. Int. J. Adv. Manuf. Technol. 2025, 139, 6157–6172. [Google Scholar] [CrossRef]

- Pascal, V.; Jannis, S.; Zabel, A.; Dirk, B. Influence of cutting tool coating on rake and flank face temperatures by operando pyrometric temperature measurement during orthogonal turning of AISI 316L. Wear 2025, 571, 205848. [Google Scholar]

- Guo, L.; Liang, Z.Q.; Du, Y.C.; Sun, Y.H.; Shi, J.L.; Zhang, R.; Su, Z.P. Study on the cutting performance of AlTiN/AlTiSiN composite coating tool in deep-hole pull boring tool of GH4169. Tribol. Int. 2025, 202, 110236. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, P.; Zhang, L.; Liu, H.; Jiang, Y.; Zhang, D.; Jiang, L. Continuous directional water transport on the peristome surface of Nepenthes alata. Nature 2016, 532, 85–89. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Li, G. A new method for producing “Lotus Effect” on a biomimetic shark skin. J. Colloid Interface Sci. 2012, 388, 235–242. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Su, Y.; Hou, X.; Hong, M. Directional sliding of water: Biomimetic snake scale surfaces. Opto-Electron. Adv. 2021, 4, 210008-1. [Google Scholar] [CrossRef]

- Xu, L.; Yang, L.; Yang, S.; Xu, Z.; Lin, G.; Shi, J.; Guo, Y. Earthworm-inspired ultradurable superhydrophobic fab-rics from adaptive wrinkled skin. ACS Appl. Mater. Interfaces 2021, 13, 6758–6766. [Google Scholar] [CrossRef]

- Heinrichs, J.; Mikado, H.; Kawakami, A.; Wiklund, U.; Kawamura, S.; Jacobson, S. Wear mechanisms of WC-Co cemented carbide tools and PVD coated tools used for shearing Cu-alloy wire in zipper production. Wear 2019, 420, 96–107. [Google Scholar]

- Grigoriev, S.N.; Volosova, M.A.; Okunkova, A.A.; Fedorov, S.V.; Hamdy, K.; Podrabinnik, P.A.; Porvatov, A.N. Wire tool electrode behavior and wear under discharge pulses. Technologies 2020, 8, 49. [Google Scholar] [CrossRef]

- Xi, Y.; Bermingham, M.; Wang, G.; Dargusch, M. SPH/FE modeling of cutting force and chip formation during thermally assisted machining of Ti6Al4V alloy. Comput. Mater. Sci. 2014, 84, 188–197. [Google Scholar] [CrossRef]

- Wu, Q.; Zhang, L. Microstructure-based three-dimensional characterization of chip formation and surface genera-tion in the machining of particulate-reinforced metal matrix composites. Int. J. Extrem. Manuf. 2020, 2, 045103. [Google Scholar]

- Liu, G.; Shah, S.; Özel, T. Material ductile failure-based finite element simulations of chip serration in orthogonal cutting of titanium alloy Ti-6Al-4V. J. Manuf. Sci. Eng. 2019, 141, 041017. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, J.; Xu, X.; Zhao, W. Experimental study on fracture mechanism transformation in chip segmenta-tion of Ti-6Al-4V alloys during high-speed machining. J. Mater. Process. Technol. 2018, 257, 132–140. [Google Scholar] [CrossRef]

- Wu, J.; Zhan, G.; He, L.; Zou, Z.; Zhou, T.; Du, F. Tribological performance of micro-groove tools of improving tool wear resistance in turning AISI 304 process. Materials 2020, 13, 1236. [Google Scholar] [CrossRef]

- Zou, Z.; He, L.; Jiang, H.; Zhan, G.; Wu, J. Development and analysis of a low-wear micro-groove tool for turning Inconel 718. Wear 2019, 420, 163–175. [Google Scholar] [CrossRef]

- Chen, G.; Caudill, J.; Ren, C.; Jawahir, I.S. Numerical modeling of Ti-6Al-4V alloy orthogonal cutting considering microstructure dependent work hardening and energy density-based failure behaviors. J. Manuf. Process. 2022, 82, 750–764. [Google Scholar] [CrossRef]

- Gupta, M.K.; Korkmaz, M.E.; Sarıkaya, M.; Krolczyk, G.M.; Günay, M.; Wojciechowski, S. Cutting forces and temperature measurements in cryogenic assisted turning of AA2024-T351 alloy: An experimentally validated simulation approach. Measurement 2022, 188, 110594. [Google Scholar] [CrossRef]

- Wu, J.; He, L.; Wu, Y.; Zhou, C.; Zou, Z.; Zhan, G.; Zhang, X. Enhancing wear resistance and cutting performance of a long-life micro-groove tool in turning AISI 201. Coatings 2021, 11, 1515. [Google Scholar] [CrossRef]

- Liu, Z.H.; Wu, J.X. Study on Cutting Performance of Micro Groove Tool in Turning AISI 304 and Surface Quality of the Workpiece. Coatings 2022, 12, 1326. [Google Scholar] [CrossRef]

- Şirin, Ş. Investigation of the performance of cermet tools in the turning of Haynes 25 superalloy under gaseous N2 and hybrid nanofluid cutting environments. J. Manuf. Process. 2022, 76, 428–443. [Google Scholar] [CrossRef]

- Fan, L.; Deng, Z.; Gao, X.; He, Y. Cutting performance of micro-textured PCBN tool. Nanotechnol. Precis. Eng. 2021, 4, 023004. [Google Scholar] [CrossRef]

- Pang, M.; Yang, H.; Li, Y.; Wang, Z.; Ma, L.; Su, J.; Hayat, M. Effect of micro-grooved texture on cutting performance of tool under dry condition. Int. J. Mod. Phys. B 2022, 36, 2240070. [Google Scholar] [CrossRef]

- Ge, F.; Yu, Z.; Li, Y.; Wang, X.; Wu, Q.; Yang, S.; Xu, J. Tool-chip contact characteristics during micro-cutting of compacted graphite iron (CGI) with textured tools. J. Manuf. Process. 2023, 99, 592–604. [Google Scholar] [CrossRef]

| Geometric Angle | Tool Angle | Rake Angle | Clearance Angle | Main Cutting Edge Angle | End Cutting Edge Angle | Inclination Angle |

|---|---|---|---|---|---|---|

| Value (°) | 80 | 7 | 7 | 95 | −5 | −5 |

| Cutting Speed Vc (m/min) | Feed Rate f (mm) | Cutting Depth ap (mm) | |

|---|---|---|---|

| Tool A | 120 | 0.15 | 1.5 |

| Tool B |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Hu, W.; Zhang, Y.; Wu, Y.; Wu, C.; Yang, Z. Investigation of Wear Behavior for Innovative Cutting Tool in Machining AISI 304 Stainless Steel. Eng 2025, 6, 248. https://doi.org/10.3390/eng6090248

Wu J, Hu W, Zhang Y, Wu Y, Wu C, Yang Z. Investigation of Wear Behavior for Innovative Cutting Tool in Machining AISI 304 Stainless Steel. Eng. 2025; 6(9):248. https://doi.org/10.3390/eng6090248

Chicago/Turabian StyleWu, Jinxing, Wenhao Hu, Yi Zhang, Yanying Wu, Changcheng Wu, and Zuode Yang. 2025. "Investigation of Wear Behavior for Innovative Cutting Tool in Machining AISI 304 Stainless Steel" Eng 6, no. 9: 248. https://doi.org/10.3390/eng6090248

APA StyleWu, J., Hu, W., Zhang, Y., Wu, Y., Wu, C., & Yang, Z. (2025). Investigation of Wear Behavior for Innovative Cutting Tool in Machining AISI 304 Stainless Steel. Eng, 6(9), 248. https://doi.org/10.3390/eng6090248