Challenges in Integrating Australian Sawmilling with Prefabrication Manufacturing Industry

Abstract

1. Introduction

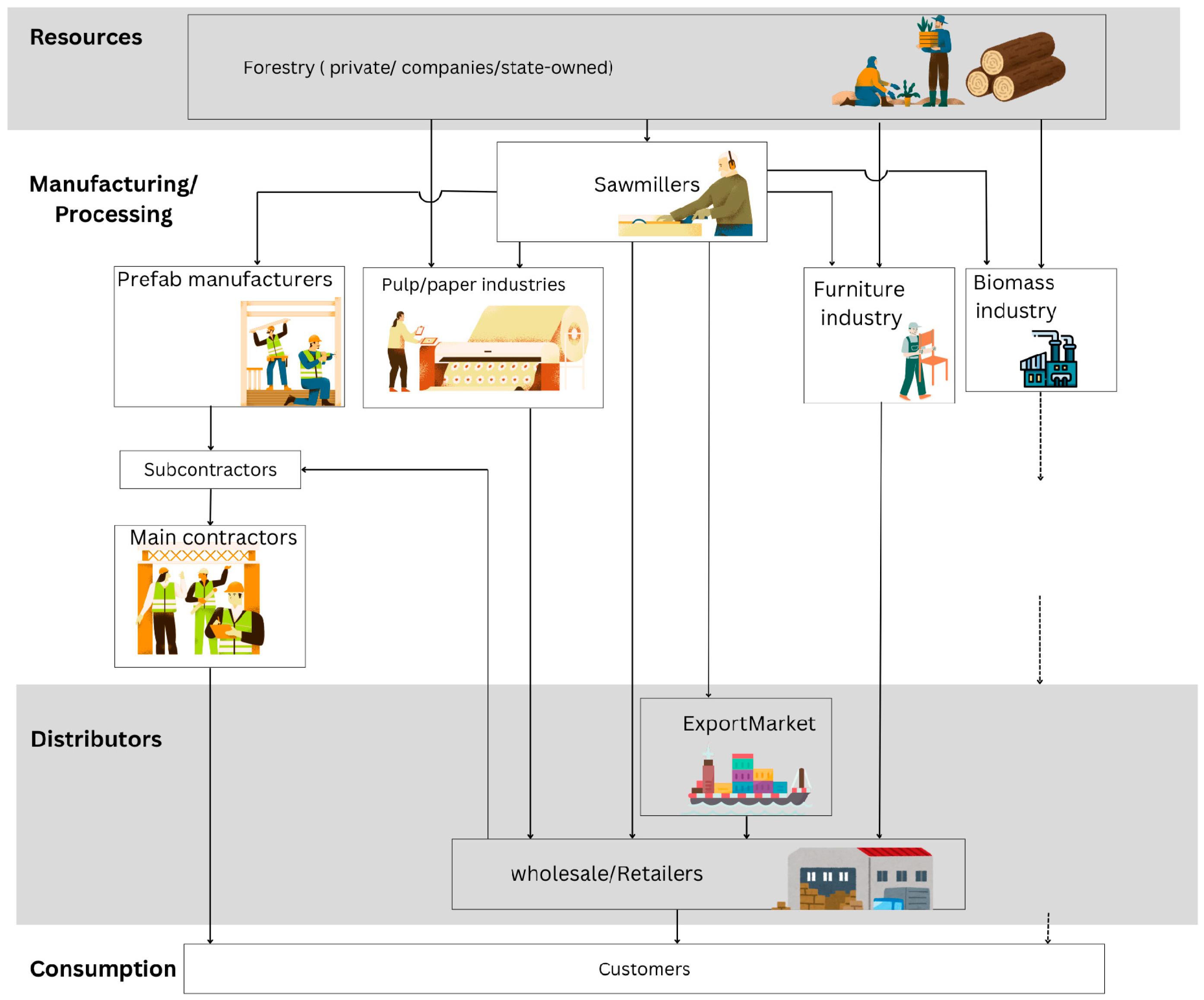

2. Background

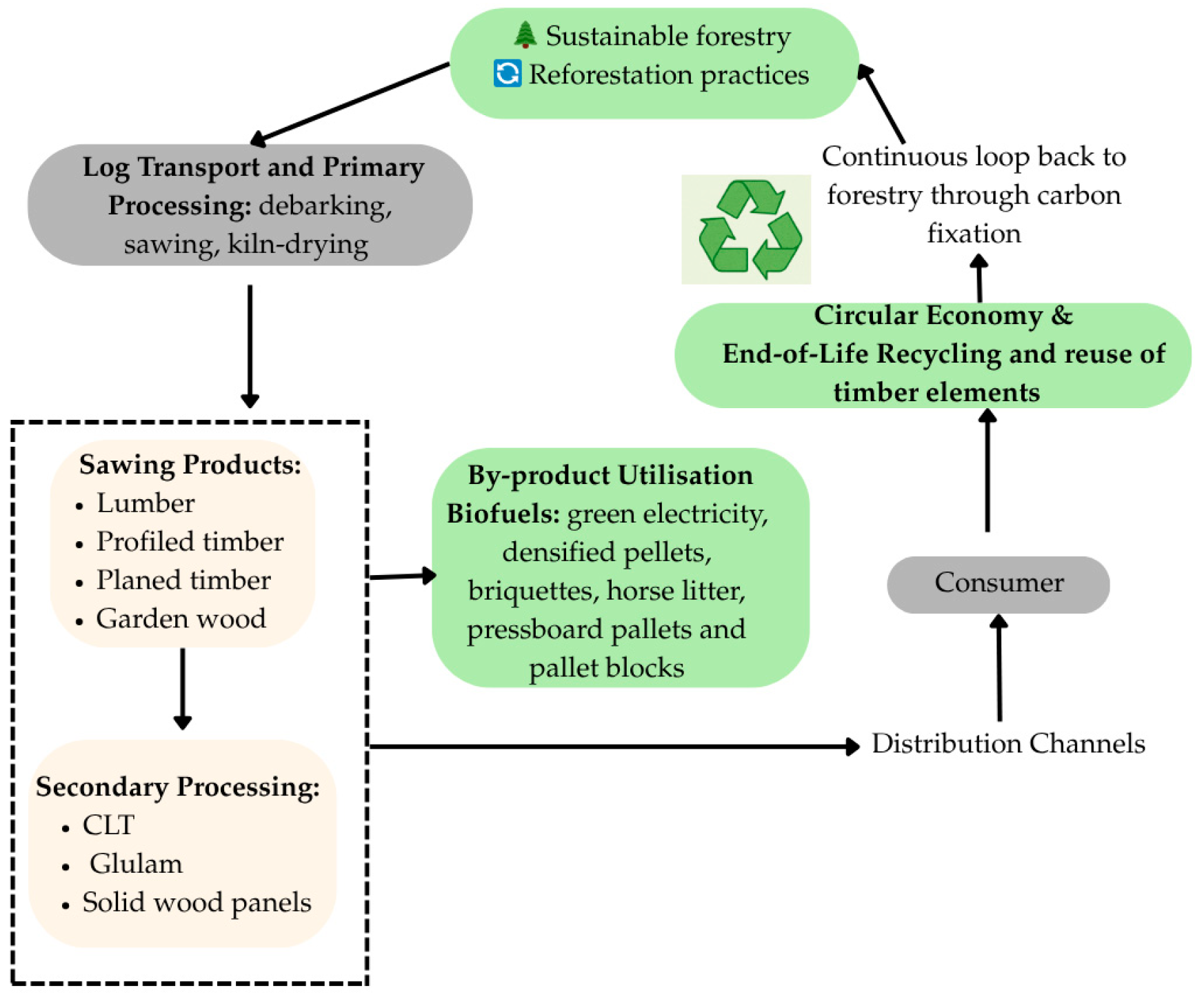

2.1. The Australian Timber Supply Chain Overview

2.2. Need for Integration in Timber Construction

3. Methodology

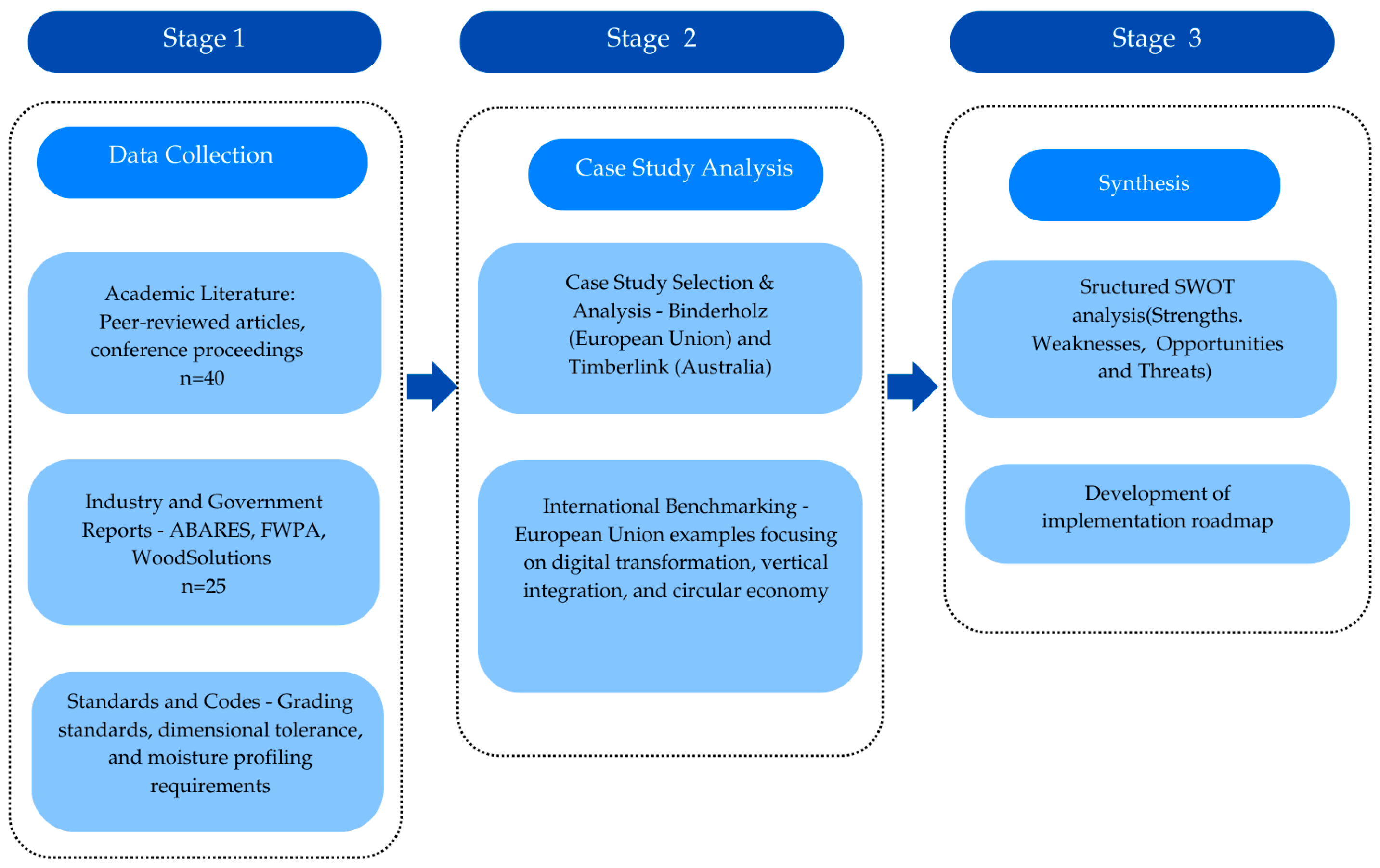

- Academic literature review: A systematic review of journal articles, conference proceedings, and scholarly reviews published between 2000 and 2025 was conducted using Scopus, Web of Science, and Google Scholar. Search terms included combinations of “sawmilling,” “prefabrication,” “engineered wood,” “digital timber supply chain,” and “integration.” Approximately 150 sources were initially screened, of which 40 were deemed directly relevant based on thematic alignment and methodological rigour.

- Industry and government reports: 25 documents published between 2000 and 2025 from key organisations, including the Australian Bureau of Agricultural and Resource Economics and Sciences (ABARES), Forest and Wood Products Australia (FWPA), and WoodSolutions, were reviewed for statistics, policy updates, and technical guidance tailored to the Australian timber sector.

- Standards and Codes: Australian standards were reviewed to understand grading, dimensional tolerance, moisture profiling, and compliance requirements that impact sawmill-prefab integration.

- Case study selection and analysis: To complement the thematic analysis, the study incorporates two illustrative case studies—Timberlink (Australia) and Binderholz (European Union). These cases were purposefully selected based on:

- •

- The presence of vertically integrated operations spanning sawing through to engineered and prefabricated products.

- •

- The availability of publicly documented digital and operational strategies that support integration.

- International benchmarking: Comparative insights were drawn from advanced timber industries in countries such as Austria and Germany. These included technical documents and institutional reports illustrating best practices in digital transformation, vertical integration, and circular economy adoption within sawmilling and prefabricated timber systems.

- A structured SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis was conducted to synthesise findings and identify the most influential internal and external factors affecting integration.

- Roadmap development: A strategic implementation roadmap was developed to translate key findings into actionable recommendations across eleven focus areas, supporting industry-wide integration between sawmilling and prefabrication.

4. Results

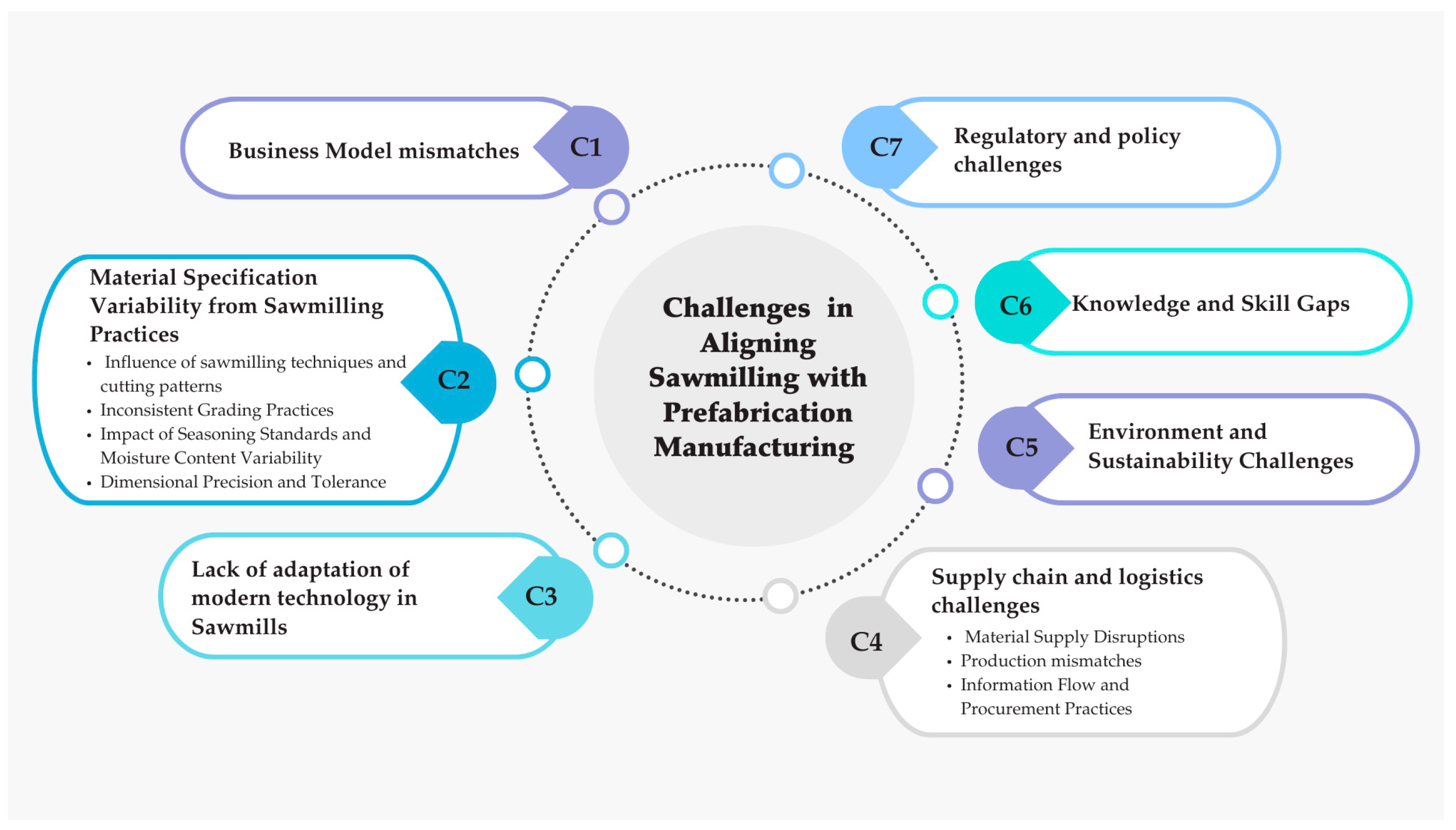

4.1. Challenges and Enablers in Aligning Sawmilling with Prefabrication Manufacturing

4.1.1. Business Model Mismatches (C1)

4.1.2. Material Specification Variability from Sawmilling Practices (C2)

- (A)

- Influence of sawmilling techniques and cutting patterns

| Category | Segment | Description |

|---|---|---|

| Product Type | Fixed Sawmill | Preferred for large-scale, high-volume timber processing with automated systems for efficiency and precision. |

| Portable Sawmill | Offers mobility and flexibility, suitable for on-site or small-scale operations but with lower production capacity. | |

| Type of Head rig | Circular Saw | Efficient and fast cutting with circular rotating blades, widely used in modern sawmilling. |

| Band Saw | Highly versatile with thin kerf blades, reducing material waste and improving cutting precision. | |

| Gang Saw | A gang saw has multiple blades to cut a log into multiple pieces at once. This is a high-production method, but less common. | |

| Mounting type | horizontal | Used in high-production sawmills for large-diameter log cutting with greater stability and efficiency. |

| vertical | Ideal for precision applications and compact workspaces, often used for resawing and specialized cuts. |

- (B)

- Inconsistent Grading Practices

- Visual grading: This method relies on the expertise of a trained grader who evaluates timber based on visible characteristics such as knots, grain deviations, and other defects. The Australian softwood visual grading rules are complex, specifying multiple stress grades. Due to the subjective nature of this method, variability may arise from differences in interpretation between graders.

- Machine grading: This approach uses non-destructive testing to measure timber properties such as stiffness and density. Machine grading is generally more consistent than visual grading, but results may vary due to differences in calibration, equipment type, and operational settings.

- Machine proofing grading: This method involves an initial sorting of timber into subgroups, followed by mechanical testing of each piece under a predetermined bending load (proof load). This ensures that every graded piece meets the required strength criteria.

- •

- F Grades—Used for both visually and machine-graded timber, F-grade classification is based on stress properties such as bending and tension strength.

- •

- MGP (Machine Graded Pine) Grades—Specifically assigned to machine-graded pine, focusing on modulus of elasticity (MOE) and strength properties.

- •

- A Grades—A visually graded mix of seasoned alpine and mountain ash, often used in high-strength applications.

- •

- GL Grades—Assigned to glue-laminated (glulam) timber, which consists of engineered wood products formed by bonding multiple layers of timber.

- •

- Appendix B of AS 4785.1 outlines permissible limits for machining imperfections and surface finish defects on exposed surfaces of softwood products.

- •

- Appendix C of AS 4785.1 defines acceptable limits for bow, spring, twist, and cup deformations.

- (C)

- Impact of Seasoning Standards and Moisture Content Variability

- •

- Kiln drying employs controlled heat and airflow to remove moisture quickly and consistently. It typically results in more uniform drying outcomes but requires significant energy input.

- •

- •

- Nailplates or mechanical fasteners may loosen as the timber shrinks.

- •

- Impact on adhesive performance.

- •

- Mould growth can occur when enclosed elements retain excess moisture.

- •

- Dimensional changes may cause misalignment or gaps, resulting in delays and rework.

- •

- AS/NZS 1080.1:1997 outlines the correct procedures for measuring moisture content in timber [40].

- •

- AS 4785.1:2002 defines acceptable moisture ranges for softwood timber products used in construction and prefabrication [39].

- •

- AS/NZS 4787:2001 guides assessing drying quality, including how to evaluate moisture distribution and residual drying stresses in seasoned timber [47].

- (D)

- Dimensional Precision and Tolerance

4.1.3. Lack of Adaptation of Modern Technology in Sawmills (C3)

4.1.4. Supply Chain and Logistics Challenges (C4)

- (A)

- Material Supply Disruptions

- (B)

- Production mismatches

- (C)

- Information Flow and Procurement Practices

| Challenge Area | Traditional Practice | Digital-Integrated Practice | Tool/Technology |

|---|---|---|---|

| Inventory Management | Manual stocktaking; siloed data in sawmills and prefab plants | Real-time inventory visibility and automated restocking | RFID tagging, IoT sensors, cloud inventory systems |

| Procurement and Scheduling | Fragmented purchase orders and ad hoc scheduling | Coordinated demand forecasting and shared production timelines | CPFR (Collaborative Planning, Forecasting, Replenishment) |

| Communication Across the Chain | Email/phone-based updates; limited upstream-downstream visibility | Centralised, transparent communication across all supply chain actors | Common Data Environments (CDEs), BIM-based platforms |

| Quality Control and Feedback | Reactive defect reporting; no feedback loop to sawmill | Continuous monitoring of timber performance and traceability back to source | Digital twins, machine vision QC systems |

| Product Customisation | Standard bulk output disconnected from project-specific needs | Direct linking of CAD/CAM designs to sawmill sawing and treatment plans | BIM-CAM integration, digital cut lists |

| Payment and Contract Management | Paper contracts; delayed or partial payments | Real-time transaction execution with automated compliance checks | Smart contracts (Blockchain) |

| Transportation and Logistics | Manual load planning and low traceability | Route optimisation and digital tracking of timber deliveries | GPS-enabled freight, digital logistics platforms |

4.1.5. Environment and Sustainability Challenges (C5)

| Challenge | Strategy | Description | References |

|---|---|---|---|

| Waste Utilisation | Recycling residues for bioenergy, paper, and engineered wood Integrated waste management | Wood chips, sawdust, and bark are repurposed into various products like MDF, pellets, and biomass fuel. | [9,10] |

| High Carbon Footprint | Using biomass energy, solar drying, and optimising logistics | Kiln drying and transportation contribute significantly to emissions; alternative drying methods and fuel sources can reduce impact. | [50] |

| Sustainable Forestry Practices | Adopting FSC/PEFC-certified timber sourcing | Certified wood ensures responsible forest management, reducing deforestation risks and enhancing ecosystem conservation. | [13] |

| Resource Efficiency | Implementing circular economy principles in manufacturing | Prefabrication reduces material waste through precision cutting, reuse of offcuts, and waste minimization. | [5] |

| Waste Generation | Waste minimisation through precision cutting, off-site construction | Factory-based production ensures accurate cuts, reducing site-generated timber waste. | [5] |

| Energy Efficiency | Upgrading sawmill machinery and kiln drying optimisation | Installing energy-efficient sawmill motors and using heat recovery systems in kilns can significantly cut energy use. | [52] |

| Alternative Timber Utilisation | Expanding engineered wood product applications | Laminated veneer lumber (LVL) and cross-laminated timber (CLT) optimize raw material use and improve material efficiency. | [13] |

4.1.6. Knowledge and Skill Gaps (C6)

4.1.7. Regulatory and Policy Challenges (C7)

4.2. Case Studies

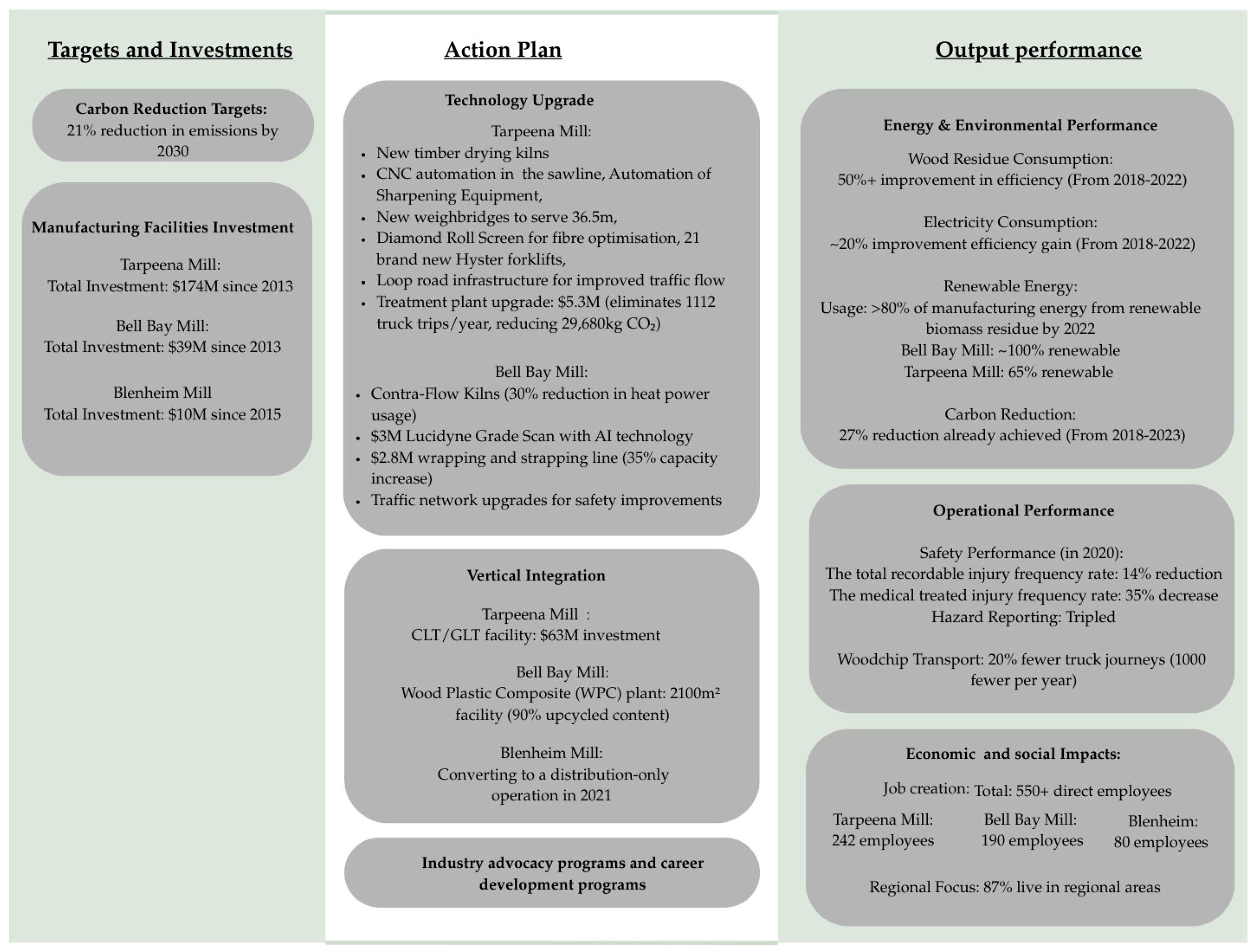

4.2.1. Timberlink’s Integrated CLT Plant (Australia)

- (a)

- Consistent Feedstock—they control the quality of boards going into CLT, adjusting drying and grading as necessary.

- (b)

- Reduced Transportation—boards do not have to be shipped to a separate facility, saving cost and emissions.

- (c)

- Value Addition—the sawmill moves up the value chain, capturing more profit per cubic meter of wood by selling prefabricated panels instead of just sawn timber.

4.2.2. Technological Transformation and Vertical Integration at Binderholz (Austria-Based)

- (a)

- Smart Manufacturing and Automation.

- (b)

- Digital Integration and Industry 4.0 Systems

- (c)

- Vertical Integration and Product Diversification

- (d)

- Sustainability and Circular Economy

4.3. SWOT Analysis and Key Influential Factors

5. Discussion

6. Conclusions and Key Recommendations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Whittle, L.; Downham, R. Upscaling the Australian softwood sawmill industry: Feasibility and implications for future plantation investment. In ABARES Research Report; Australian Government Department of Agriculture, Fisheries and Forestry: Canberra, Australia, 2019. Available online: https://www.agriculture.gov.au/abares/research-topics/forests/forest-economics/forest-economic-research/upscaling-the-australian-softwood-sawmill-industry (accessed on 1 July 2025).

- Kumar, A.; Dhiman, B.; Sharma, D. Sustainability and applications of timber as a structural material: A review. Int. Res. J. Eng. Technol. 2020, 7, 1868–1872. [Google Scholar]

- Shirmohammadi, M. Study of the hygroscopic properties of three Australian wood species used as solid wood and composite products. Eur. J. Wood Wood Prod. 2023, 81, 1495–1512. [Google Scholar] [CrossRef]

- Forest & Wood Products Australia. Future Market Dynamics and Potential Impacts on Australian Timber Imports; Available online: https://fwpa.com.au/report/future-market-dynamics-and-potential-impacts-on-australian-timber-imports-final-report/FWPA: Melbourne, Australia, 2022; (accessed on 1 August 2025).

- Rocha, P.F.; Ferreira, N.O.; Pimenta, F.; Pereira, N.B. Impacts of Prefabrication in the Building Construction Industry. Encyclopedia 2023, 3, 28–45. [Google Scholar] [CrossRef]

- Bylund, D. Enabling Prefabricated Timber Building Systems for Class 2 to 9 Buildings; Forest & Wood Products Australia (FWPA): Melbourne, Australia, 2017; Available online: https://fwpa.com.au/report/enabling-prefabricated-timber-building-systems-in-commercial-construction-pna324-1314/ (accessed on 3 July 2025).

- Woods, T.; Houghton, J. More Houses Sooner: Finding the Australian Dream; Forest & Wood Products Australia (FWPA): Melbourne, Australia, 2025; Available online: https://fwpa.com.au/report/more-houses-sooner/ (accessed on 3 July 2025).

- Whittle, L. Snapshot of Australia’s Forest Industry. In ABARES Insight; Australian Bureau of Agricultural and Resource Economics and Sciences, Department of Agriculture: Canberra, Australia, 2019. Available online: https://www.agriculture.gov.au/abares/products/insights/snapshot-of-australias-forest-industry (accessed on 7 July 2025).

- Wong, J.; Tasker, J.; Black, S. ABARES National Wood Processing Survey 2021–22. In ABARES Technical Report; Australian Bureau of Agricultural and Resource Economics and Sciences: Canberra, Australia, 2024. [Google Scholar] [CrossRef]

- Dissanayake, D.M.H.; Samarawickrama, S.; Gunewardena, T.; Mendis, P. Towards sustainable timber construction: A case study of waste generation, management, and circular strategies in Australian sawmilling and prefabrication manufacturing. In Proceedings of the 14th World Conference on Timber Engineering (WCTE 2025), Brisbane, Australia, 22–26 June 2025; pp. 2338–2346. [Google Scholar] [CrossRef]

- Dissanayake, H.; Gunawardena, T.; Mendis, P. Adaptation of connection systems for integration with engineered wood products in buildings: A systematic review. Buildings 2023, 15, 1131. [Google Scholar] [CrossRef]

- Thomas, D.; Ding, G.; Crews, K. Sustainable timber use in residential construction: Perception versus reality. WIT Transactions on Ecology and the Environment 2014, 186, 399–407. [Google Scholar] [CrossRef]

- Makkonen, M.; Sundqvist-Andberg, H. Customer value creation in B2B relationships: Sawn timber value chain perspective. J. For. Econ. 2017, 29, 94–106. [Google Scholar] [CrossRef]

- Haartveit, E.Y.; Kozak, R.A.; Maness, T.C. Supply chain management mapping for the forest products industry: Three cases from western Canada. J. For. Prod. Bus. Res. 2004, 1, 1–30. [Google Scholar]

- Juslin, H.; Hansen, E. Strategic Marketing in Global Forest Industries, 3rd ed.; Oregon State University: Corvallis, OR, USA, 2018. [Google Scholar]

- Lähtinen, K.; Toppinen, A. Financial performance in Finnish large- and medium-sized sawmills: The effects of value-added creation and cost-efficiency seeking. J. For. Econ. 2008, 14, 289–305. [Google Scholar] [CrossRef]

- Brege, S.; Nord, T.; Sjöström, R.; Stehn, L. Value-added strategies and forward integration in the Swedish sawmill industry: Positioning and profitability in the high-volume segment. Scand. J. For. Res. 2010, 25, 482–493. [Google Scholar] [CrossRef]

- Wallis, L.; Millaniyage, K.P.; Fleming, G. A Case Study: Commercial Building with Solid Timber Products in Tasmania; Report; University of Tasmania: Dynnyrne, Australia, 2024. [Google Scholar]

- AS 2082—2007; Timber—Hardwood—Visually Stress-Graded for Structural Purposes. Standards Australia: Sydney, Australia, 2007.

- AS 2858—1974; Timber—Softwood—Visually Stress-Graded for Structural Purposes. Standards Australia: Sydney, Australia, 1974.

- AS/NZS 1748; Timber—Mechanically Stress-graded for Structural Purposes. Standards Australia: Sydney, Australia; Standards New Zealand: Wellington, New Zealand, 2011.

- AS 3519—1998; Timber—Proof Graded—Structural Purposes. Standards Australia: Sydney, Australia, 1998.

- AS/NZS 2269; Plywood—Structural. Standards Australia: Sydney, Australia; Standards New Zealand: Wellington, New Zealand, 2012.

- AS/NZS 4357; Structural Laminated Veneer lumber. Standards Australia: Sydney, Australia; Standards New Zealand: Wellington, New Zealand, 2007.

- AS/NZS 1328.1; Glued Laminated Structural timber—Performance Requirements and Minimum Production Requirements. Standards Australia: Sydney, Australia; Standards New Zealand: Wellington, New Zealand, 1999.

- AS 3818.3—2000; Timber—Heavy Structural Products—Visually Stress-Graded for Structural Purposes. Standards Australia: Sydney, Australia, 2000.

- AS 3818.11—2010; Timber—Heavy Structural Products—Round Timber—Stress-Graded. Standards Australia: Sydney, Australia, 2010.

- Vilkovský, P.; Klement, I.; Vilkovská, T. The impact of the log-sawing patterns on the quantitative and qualitative yield of beech timber (Fagus sylvatica L.). Appl. Sci. 2023, 13, 8262. [Google Scholar] [CrossRef]

- Cook, S.; Ghavidel, A.; Zhou, J. Dimensional stability and mechanical performance of face-glued spruce-pine-fir and Douglas-fir studs. Drewno. Pr. Nauk. Doniesienia Komun. = Wood. Res. Pap. Rep. Announc. 2024, 67, 32. [Google Scholar] [CrossRef]

- De Fégely, R. Sawing Regrowth and Plantation Hardwoods with Particular Reference to Growth Stresses. Part B: Survey Results; Forest & Wood Products Research & Development Corporation: Collingwood, Australia, 2004; Available online: https://fwpa.com.au/wp-content/uploads/2004/03/PN02.1308-sawing-regrowth-part-B-WEB.pdf (accessed on 5 July 2025).

- Nolan, G.; Innes, T.; Redman, A.; McGavin, R. Australian Hardwood Drying Best Practice Manual. Part 1; Forest and Wood Products Australia: Melbourne, Australia, 2003. [Google Scholar]

- WoodSolutions. Sawn Timber. Available online: https://www.woodsolutions.com.au/wood-species/wood-products/sawn-timber (accessed on 9 August 2025).

- Hwang, S.W.; Isoda, H.; Nakagawa, T.; Sugiyama, J. Flexural anisotropy of rift-sawn softwood boards induced by the end-grain orientation. J. Wood Sci. 2021, 67, 14. [Google Scholar] [CrossRef]

- Washusen, R. Processing Methods for Production of Solid Wood Products From Plantation Grown Eucalyptus Species of Importance to Australia; Forest and Wood Products Australia: Melbourne, Australia, 2013; Available online: https://fwpa.com.au/report/processing-methods-for-production-of-solid-wood-products-from-plantation-grown-eucalyptus-species-of-importance-to-australia/ (accessed on 9 August 2025).

- Steele, P.; Wade, M.; Bullard, S.; Araman, P. Relative kerf and sawing variation values for some hardwood sawing machines. For. Prod. J. 1992, 42, 33–39. [Google Scholar]

- Meulenberg, V.; Mats, E.; Svensson, M. Thin kerf cutting forces of frozen and non-frozen Norway spruce and Scots pine wood. Wood Mater. Sci. Eng. 2021, 16, 414–420. [Google Scholar] [CrossRef]

- Verified Market Research. Sawmill Machinery Market: Market Size, Status & Forecast to 2032. 2025. Available online: https://www.verifiedmarketresearch.com/product/sawmill-machinery-market/ (accessed on 9 August 2025).

- WoodSolutions. Structural Grading. Available online: https://www.woodsolutions.com.au/structural-grading (accessed on 9 August 2025).

- AS 4785.1:2002; Timber—Hardwood—Sawn and Round—Part 1: Sawn and Milled Products. Standards Australia: Sydney, Australia, 2002.

- AS/NZS 1080.1:1997; Timber—Methods of Test—Method 1: Moisture Content. Standards Australia/Standards New Zealand: Sydney, Australia, 1997.

- AS 5607:2022; Timber—Methods for Sampling and Analysis of Timber Preservative-Treated Timber Products. Standards Australia: Sydney, Australia, 2022.

- Forest & Wood Products Australia. FWPA Standard G02 Recycled Timber–Visually Graded Decorative Products. 2025. Available online: https://fwpa.com.au/codes-standards/draft-fwpa-standard-g02-recycled-timber-visually-graded-decorative-products/ (accessed on 9 August 2025).

- AS 1720.1:2010; Timber Structures—Design Methods. Standards Australia: Sydney, Australia, 2010.

- Shanks, J. Biased Position Testing for Verification of Structural Softwood; Forest & Wood Products Australia: Melbourne, Australia, 2024; Available online: https://fwpa.com.au/report/biased-position-testing-for-verification-of-structural-softwood/ (accessed on 20 July 2025).

- Boughton, G. Background & Guidance: AS/NZS 1748 Series 2011; Forest & Wood Products Australia: Melbourne, Australia, 2024; Available online: https://fwpa.com.au/standards-activities/background-guidance-as-nzs-1748-series-2011/ (accessed on 9 August 2025).

- Swedish Wood. Joinery Handbook for Softwood Furniture Production, 2nd ed.; Swedish Wood: Stockholm, Sweden, 2020. [Google Scholar]

- AS/NZS 4787:2001; Timber—Appearance Grade—Hardwood. Standards Australia/Standards New Zealand: Sydney, Australia, 2001.

- Akinnawonu, O.; Rameezdeen, R. Enhancing material durability and sustainability: Investigating timber moisture management in timber storage facilities. In Proceedings of the 14th World Conference on Timber Engineering (WCTE 2025), Brisbane, Australia, 22–26 June 2025. [Google Scholar] [CrossRef]

- Long, H.; Luo, X.; Liu, J.; Dong, S. The analysis and application of installation tolerances in prefabricated construction based on the dimensional chain theory. Buildings 2023, 13, 1799. [Google Scholar] [CrossRef]

- Williams, S.; Pattinson, R.; Wilcox, C.; Ball, A. Independent Performance Review: Final Report; Forest & Wood Products Australia: Melbourne, Australia, 2021; Available online: https://www.fwpa.com.au/wp-content/uploads/2021/03/210304_FWPA_performance_review_FINAL.pdf (accessed on 9 July 2025).

- Nasir, V.; Rahimi, S.; Mohammadpanah, A.; Hansen, E.; Sassani, F. Intelligent lumber production (Sawmill 4.0): Opportunities, challenges, and pathways to adoption. In Integrated Systems: Data Driven Engineering; Springer Nature: Cham, Switzerland, 2024; pp. 213–231. [Google Scholar] [CrossRef]

- Fredriksson, M.; Berglund, A.; Broman, O. Validating a crosscutting simulation program based on computed tomography scanning of logs. Eur. J. Wood Wood Prod. 2015, 73, 143–150. [Google Scholar] [CrossRef]

- Belley, D.; Duchesne, I.; Vallerand, S.; Barrette, J.; Beaudoin, M. Computed tomography (CT) scanning of internal log attributes prior to sawing increases lumber value in white spruce (Picea glauca) and jack pine (Pinus banksiana). Can. J. For. Res. 2019, 49, 1516–1524. [Google Scholar] [CrossRef]

- Rummukainen, H.; Makkonen, M.; Uusitalo, J. Economic value of optical and X-ray CT scanning in bucking of Scots pine. Wood Mater. Sci. Eng. 2021, 16, 178–187. [Google Scholar] [CrossRef]

- Nasir, V.; Cool, J. A review on wood machining: Characterization, optimization, and monitoring of the sawing process. Wood Mater. Sci. Eng. 2018, 15, 1–16. [Google Scholar] [CrossRef]

- Nasir, V.; Dibaji, S.; Alaswad, K.; Cool, J. Tool wear monitoring by ensemble learning and sensor fusion using power, sound, vibration, and AE signals. Manuf. Lett. 2021, 30, 32–38. [Google Scholar] [CrossRef]

- Nasir, V.; Kooshkbaghi, M.; Cool, J. Sensor fusion and random forest modelling for identifying frozen and green wood during lumber manufacturing. Manuf. Lett. 2020, 26, 53–58. [Google Scholar] [CrossRef]

- Nasir, V.; Kooshkbaghi, M.; Cool, J.; Sassani, F. Cutting tool temperature monitoring in circular sawing: Measurement and multi-sensor feature fusion-based prediction. Int. J. Adv. Manuf. Technol. 2021, 112, 2413–2424. [Google Scholar] [CrossRef]

- Nasir, V.; Mohammadpanah, A.; Cool, J. The effect of rotation speed on the power consumption and cutting accuracy of guided circular saw: Experimental measurement and analysis of saw critical and flutter speeds. Wood Mater. Sci. Eng. 2020, 15, 140–146. [Google Scholar] [CrossRef]

- Rahimi, S.; Avramidis, S. Predicting moisture content in kiln-dried timbers using machine learning. Eur. J. Wood Wood Prod. 2022, 80, 681–692. [Google Scholar] [CrossRef]

- Avramidis, S.; Lazarescu, C.; Rahimi, S. Niemz, P., Teischinger, A., Sandberg, D., Eds.; Basics of wood drying. In Springer Handbook of Wood Science and Technology; Springer International Publishing: Cham, Switzerland, 2023; pp. 679–706. [Google Scholar] [CrossRef]

- Rahimi, S.; Nasir, V.; Avramidis, S.; Sassani, F. The role of drying schedule and conditioning in moisture uniformity in wood: A machine learning approach. Polymers 2023, 15, 792. [Google Scholar] [CrossRef]

- Salas, C.; Moya, R. Kiln, solar, and air-drying behavior of lumber of Tectona grandis and Gmelina arborea from fast-grown plantations: Moisture content, wood color, and drying defects. Dry. Technol. 2014, 32, 301–310. [Google Scholar] [CrossRef]

- Shahverdi, M.; Oliveira, L.; Avramidis, S. Kiln-drying optimization for quality Pacific coast hemlock timber. Dry. Technol. 2017, 35, 1867–1873. [Google Scholar] [CrossRef]

- Bharati, M.; MacGregor, J.; Tropper, W. Softwood lumber grading through on-line multivariate image analysis techniques. Ind. Eng. Chem. Res. 2003, 42, 5345–5353. [Google Scholar] [CrossRef]

- Gazo, R.; Wells, L.; Krs, V.; Benes, B. Validation of automated hardwood lumber grading system. Comput. Electron. Agric. 2018, 155, 496–500. [Google Scholar] [CrossRef]

- Kline, D.E.; Surak, C.; Araman, P.A. Automated hardwood lumber grading utilizing a multiple sensor machine vision technology. Comput. Electron. Agric. 2003, 41, 139–155. [Google Scholar] [CrossRef]

- Thomas, E. An artificial neural network for real-time hardwood lumber grading. Comput. Electron. Agric. 2017, 132, 71–75. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, W.; Gao, R.; Jin, Z.; Wang, X. Recent advances in the application of deep learning methods to forestry. Wood Sci. Technol. 2021, 55, 1171–1202. [Google Scholar] [CrossRef]

- Ji, M.; Zhang, W.; Diao, X.; Wang, G.; Miao, H. Intelligent automation manufacturing for Betula solid timber based on machine vision detection and optimization grading system applied to building materials. Forests 2023, 14, 1510. [Google Scholar] [CrossRef]

- Australian Government. Accelerate Adoption of Wood Processing Innovation Program. 2025. Available online: https://www.communitygrants.gov.au/grants/2021-6106 (accessed on 9 August 2025).

- Ministerial Plantations Industry Growth for Australian and National Forest Industries Steering Committee. Australia’s State of the Forests Report: Synthesis 2023; Australian Bureau of Agricultural and Resource Economics and Sciences (ABARES): Canberra, Australia, 2024. Available online: https://www.agriculture.gov.au/abares/forestsaustralia/sofr/sofr-synthesis (accessed on 9 July 2025).

- Whittle, L. Effects of Bushfires and COVID-19 on the Forestry and Wood Processing Sectors (ABARES Insights, Issue 6); Department of Agriculture, Water and the Environment; Australian Bureau of Agricultural and Resource Economics and Sciences (ABARES): Canberra, Australia, 2020. Available online: https://www.agriculture.gov.au/abares/products/insights/effects-of-bushfires-and-covid19-forestry-wood-processing-sectors (accessed on 19 July 2025).

- Lopez, R.; Chong, H.-Y.; Pereira, C. Obstacles preventing the off-site prefabrication of timber and MEP services: Qualitative analyses from builders and suppliers in Australia. Buildings 2022, 12, 1044. [Google Scholar] [CrossRef]

- Wortmann, J.C. Wortmann, J.C., Muntslag, D.R., Timmermans, P.J.M., Eds.; Introduction to customer driven manufacturing. In Customer Driven Manufacturing; Chapman & Hall: London, UK, 1997; pp. 1–2. [Google Scholar]

- Gueimonde Canto, A.; Benito, J.; García-Vázquez, J. Competitive effects of co-operation with suppliers and buyers in the sawmill industry. J. Bus. Ind. Mark. 2011, 26, 58–69. [Google Scholar] [CrossRef]

- Eingartner, V.; González-Benito, J.; García-Vázquez, J.M. Kohl, H., Seliger, G., Dietrich, F., Vien, H.T., Eds.; Integrating Digital Value Chains for Timber Construction. In Decarbonizing Value Chains; GCSM 2024; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2025. [Google Scholar] [CrossRef]

- Vukman, K.; Klarić, K.; Greger, K.; Perić, I. Driving efficiency and competitiveness: Trends and innovations in ERP systems for the wood industry. Forests 2024, 15, 230. [Google Scholar] [CrossRef]

- Reinders, J.; Orozco, S.; Eingartner, V.; Feldhaus, A.; Yang, Y.; Borrego, I. Kohl, H., Seliger, G., Dietrich, F., Vien, H.T., Eds.; Digital Integration and Optimization Workflows in Timber Construction with Prefabricated Components: A Business Intelligence-Driven Application for Optimizing Carbon Footprints and Project Performance. In Decarbonizing Value Chains; GCSM 2024; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2025. [Google Scholar] [CrossRef]

- Nanayakkara, S.; Perera, S.; Senaratne, S.; Weerasuriya, G.T.; Bandara, H.M. Blockchain and smart contracts: A solution for payment issues in construction supply chains. Informatics 2021, 8, 36. [Google Scholar] [CrossRef]

- Ma, C.; Gao, X.; Zhang, L.; Kang, W. Optimizing timber supply chains: Exploring the potential of digital collaboration. Sustainability 2025, 17, 15. [Google Scholar] [CrossRef]

- Teixeira, J.E.; Tavares-Lehmann, A.T.C.P. Industry 4.0 in the European Union: Policies and national strategies. Technol. Forecast. Social. Change 2022, 180, 121664. [Google Scholar] [CrossRef]

- Lock, P.; Whittle, L. Future Opportunities for Using Forest and Sawmill Residues in Australia; Australian Bureau of Agricultural and Resource Economics and Sciences (ABARES): Canberra, Australia, 2018. Available online: https://www.agriculture.gov.au/abares/research-topics/forests/forest-economics/forest-economic-research/forest-sawmill-residues-report (accessed on 9 August 2025).

- Tucker, S.N.; Tharumarajah, A.; May, B.; England, J.; Paul, K.; Hall, M.; Mitchell, P.; Rouwette, R.; Seo, S.; Syme, M. Life Cycle Inventory of Australian Forestry and Wood Products; Forest & Wood Products Australia: Collingwood, Australia, 2009; Available online: https://www.fwpa.com.au/wp-content/uploads/2008/12/PNA008-0708_Research_Report_LCI_Timber_0.pdf (accessed on 9 August 2025).

- Binderholz. Solid Timber Manual: Sustainable Timber Products for Modern Construction; Binderholz GmbH & Saint-Gobain Rigips Austria GesmbH. 2023. Available online: https://www.binderholz.com/fileadmin/user_upload/pdf/products/solid-timber-manual.pdf (accessed on 9 August 2025).

- ForestWorks. Forestry Workforce Training Program: Scoping Study (Prepared for the Department of Agriculture, Fisheries and Forestry); Australian Bureau of Agricultural and Resource Economics and Sciences (ABARES): Canberra, Australia, 2023. Available online: https://www.agriculture.gov.au/sites/default/files/documents/forestry-workforce-training-program-scoping-study.pdf (accessed on 9 August 2025).

- URS Australia Pty, Ltd. Australia’s Forest Industry in the Year 2020 (Prepared for Department of Agriculture, Fisheries and Forestry); Australian Government: Canberra, Australia, 2007. Available online: https://www.agriculture.gov.au/sites/default/files/sitecollectiondocuments/forestry/publications/2020-report-final.pdf (accessed on 31 July 2025).

- Timberlink. Sa Premier Officially Opens Nextimber Facility and Tarpeena Green Mill Upgrade. 2024. Available online: https://nextimber.com.au/sa-premier-officially-opens-nextimber-facility/ (accessed on 9 August 2025).

- Timberlink Australia Pty Ltd. NeXTimber® Environmental Product Declaration: Cross Laminated Timber (CLT) and Glue Laminated Timber (GLT) (Version 1.1); EPD Australasia: Sydney, Australia, 2024; Available online: https://nextimber.com.au/app/uploads/2025/05/NeXTimber-EPD.pdf (accessed on 10 August 2025).

- Timberlink Australia & New Zealand. Sustainability Report 2022. 2023. Available online: https://www.timberlinkaustralia.com.au/app/uploads/2023/06/Sustainability-Report-June-2023.1.pdf (accessed on 10 August 2025).

- Binderholz. The New Industry 4.0 Computer System Installed at the Binderholz Glulam Factory in JENBACH, Austria. 2023. Available online: https://www.binderholz.com/en-us/news/details/the-new-industry-40-computer-system-installed-at-the-binderholz-glulam-factory-in-jenbach-austria/ (accessed on 9 August 2025).

- SCM Group. Technologies for Houses and Construction Elements: Binderholz Timber Construction. 2023. Available online: https://www.scmgroup.com/en/scmwood/news-events/case-studies/h46417/binderholz-timber-construction (accessed on 9 August 2025).

- Tietoevry. Setting the Speed Record with First SAP S/4HANA Implementation in the Nordics. Available online: https://www.tietoevry.com/en/success-stories/2018/setting-the-speed-record-with-first-sap-s4-hana-implementation-in-the-nordics/ (accessed on 9 August 2025).

- Binderholz. Volume Increase and Expansion of Setting Capacity in Binderholz Cross-Laminated Timber CLT BBS Production Completed. 2023. Available online: https://www.binderholz.com/en-us/news/details/volume-increase-and-expansion-of-setting-capacity-in-binderholz-cross-laminated-timber-clt-bbs-production-completed/ (accessed on 9 August 2025).

| Process | Technique | Description | Ref. |

|---|---|---|---|

| Initial Log breakdown to produce a flat surface | Split Sawing | Split sawing is commonly used as the first step in log processing. It cuts through the centre of the log, creating two halves with flat faces. The pith ends up near the board edge, increasing risks of checking and strength variations. Cutting through the pith leads to radial shrinkage and splits. | [32] |

| Cant Sawing | Cant sawing removes outer sections and retains the core as a boxed-heart cant. This minimises surface defects but can introduce internal stresses and long-term instability. It typically improves recovery. | [32] | |

| Breakdown into timber products (resaw) | Quarter Sawing | Quarter sawing produces boards with vertical grain orientation, reducing tangential shrinkage and enhancing dimensional stability. It has a lower yield and slower cutting speed but results in even drying, less cupping and warp and is preferred for flooring and joinery. | [32] |

| Rift Sawing | Rift sawing produces boards with grain at a consistent diagonal (typically 30–60° to the face), offering excellent dimensional stability and a uniform, linear grain pattern. It yields less wood and produces more waste but is valued for aesthetic and structural consistency. | [33] | |

| Back Sawing or Plain Sawing | Back sawing or Plain sawing provides high recovery of wide boards but results in tangential grain that is prone to shrinkage, cupping, and warping. Less prone to splitting when nailing. This method is common in Australia and often develops drying stresses and deformation. | [32] | |

| Radial Sawing | Radial sawing involves slicing the log like wedges from the centre outward. This method offers a good balance between yield and dimensional performance but is less commonly adopted due to equipment requirements. | [32] | |

| Through-and-Through or Live Sawing | Through-and-through or live sawing makes parallel cuts along the full log length without rotating it. While it maximises yield and is efficient, it can produce boards with mixed grain orientations, leading to varying shrinkage behaviours. | [28] |

| Type | Technology | Description | References |

|---|---|---|---|

| Log CT Scanning | CT and laser scanning for log breakdown and defect detection | Enhances log breakdown precision and defect detection; reduces variability in board quality | [52,53,54] |

| Precision cutting | Laser scanning, CNC cutting | Improves dimensional accuracy and consistency in sawn boards | [52] |

| Sawing Monitoring | Sensor-based monitoring of cutting parameters and tool conditions | Reduces inconsistencies due to tool wear, misalignment, and sawdust-related issues | [55,56,57,58,59] |

| Smart Kiln-Drying | Machine learning and sensor integration for kiln-drying process optimisation. | Ensures uniform drying, mitigates internal stresses and reduces variability in moisture content | [60,61,62,63,64] |

| Moisture Control and Monitoring | Embedded sensors, wireless monitoring, AI prediction models | Monitors moisture content in real time or predicts internal gradients, enhancing timber stability and reducing drying defects. Enables feedback loops between drying, handling, and grading stages | [63] |

| Smart Grading | AI and machine vision for automated lumber grading and defect detection. | Provides consistent classification of stress grades and defects, improving quality reliability | [65,66,67,68,69] |

| Handling Systems | Automated handling systems capable of processing various grading standards | Standardises material flow, reducing handling-related distortions | [51] |

| Optimisation planning | Machine learning, AI algorithms, and data analytics for system-level coordination, Digital twins | Enables predictive maintenance, production scheduling, and resource efficiency across sawmill operations. Digital twins offer significant potential for enhancing production planning and control in the sawmill industry by enabling real-time data integration, predictive analytics, and system-wide optimisation | [70] |

| Strengths | Weaknesses |

|

|

| Opportunities | Threats |

|

|

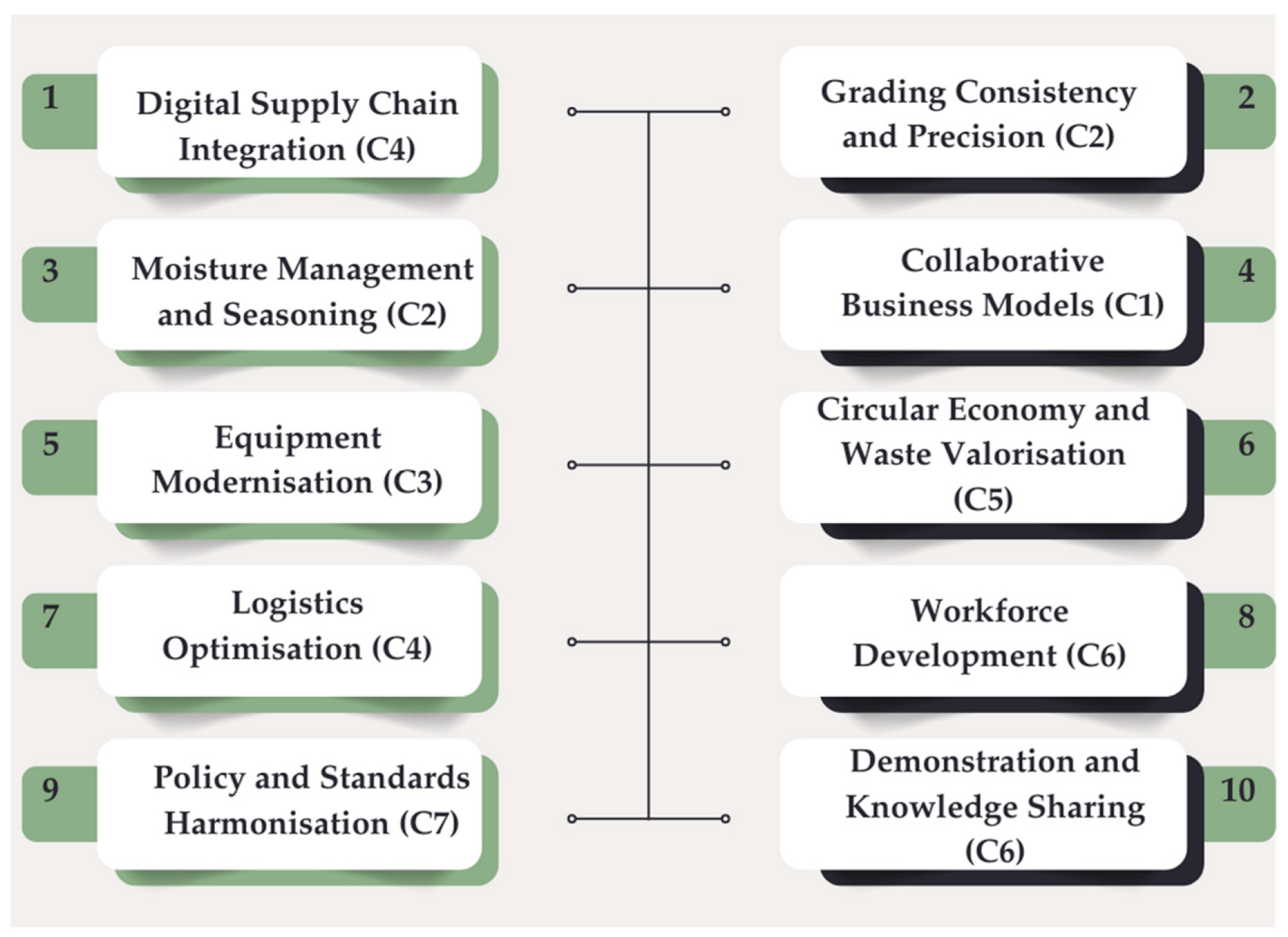

| Focus Area | Strategic Recommendation | Key Actions/Initiatives |

|---|---|---|

| Collaborative Business Models | Establish stable, long-term supply partnerships between sawmills and prefabricators. | Vertical Integration Models, Business Collaboration Mechanisms, Cross-Functional Integration Committees, Prefabricator Involvement in Log Selection |

| Grading Consistency and Precision | Standardise and modernise grading practices using AI and national verification protocols. | Grading Equipment, Grading Harmonisation Initiatives, In-line QA Monitoring Systems, Standard Operating Procedures, Training Programs for Graders and Operators |

| Equipment Modernisation | Drive uptake of digital and automated sawmilling technologies. | Sawing Equipment, Kilns with Moisture Equalisation, Automated Defect Detection Systems, In-line QA Monitoring Systems |

| Moisture Management and Seasoning | Implement moisture control from sawing through to assembly. | Moisture Meters and MC Sensors, Kilns with Moisture Equalisation, Moisture Equalisation and Post-Kiln Handling Protocols, Sensor-Embedded Timber |

| Digital Supply Chain Integration | Enable real-time data sharing and predictive planning across the timber value chain. | Digital Integration Tools, Digital Twin Platforms/BIM Integration, Real-Time Data Dashboards, Timber Batch Traceability Tools |

| Logistics Optimisation | Streamline transport and reduce delays between rural mills and urban prefab hubs. | Packaging and Transport Infrastructure, Logistics Management Tools |

| Circular Economy and Waste Valorisation | Transform sawmill residues into high-value products and promote lifecycle-based decision-making. | Off-cut Management Systems, Residue Collection and Sorting Lines, Bio-Based or Circular Product Lines, Carbon Accounting Tools/LCA Databases |

| Workforce Development | Upskill the workforce in digital, automated, and prefab-integrated timber manufacturing. | Skilled Workforce and QA Staff, Training Programs for Graders and Operators, Organisation Change Support |

| Policy and Standards Harmonisation | Align regulatory frameworks to enable smooth cross-sector operations and innovation. | Standardisation and Regulatory Support, Policy Alignment Tools |

| Demonstration and Knowledge Sharing | Showcase successful models and share lessons through open-access industry forums. | Knowledge Exchange Platforms, Demonstration Projects, Inter-firm Visits |

| National Digital Roadmap and Framework | Coordinate industry transformation through a national roadmap with defined digital milestones. | National Digital Roadmap, Feedback and Demand Forecasting Tools, Digital Twin Technology, Environmental Monitoring Tools |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dissanayake, H.; Gunawardena, T.; Mendis, P. Challenges in Integrating Australian Sawmilling with Prefabrication Manufacturing Industry. Eng 2025, 6, 215. https://doi.org/10.3390/eng6090215

Dissanayake H, Gunawardena T, Mendis P. Challenges in Integrating Australian Sawmilling with Prefabrication Manufacturing Industry. Eng. 2025; 6(9):215. https://doi.org/10.3390/eng6090215

Chicago/Turabian StyleDissanayake, Harshani, Tharaka Gunawardena, and Priyan Mendis. 2025. "Challenges in Integrating Australian Sawmilling with Prefabrication Manufacturing Industry" Eng 6, no. 9: 215. https://doi.org/10.3390/eng6090215

APA StyleDissanayake, H., Gunawardena, T., & Mendis, P. (2025). Challenges in Integrating Australian Sawmilling with Prefabrication Manufacturing Industry. Eng, 6(9), 215. https://doi.org/10.3390/eng6090215