Design Issues and Value Analysis of Modern Stone Slab Coverings

Abstract

1. Introduction

1.1. Research Background

1.2. Research Propose

1.3. Research Aim

2. Literature Review

2.1. General Information and Requirements

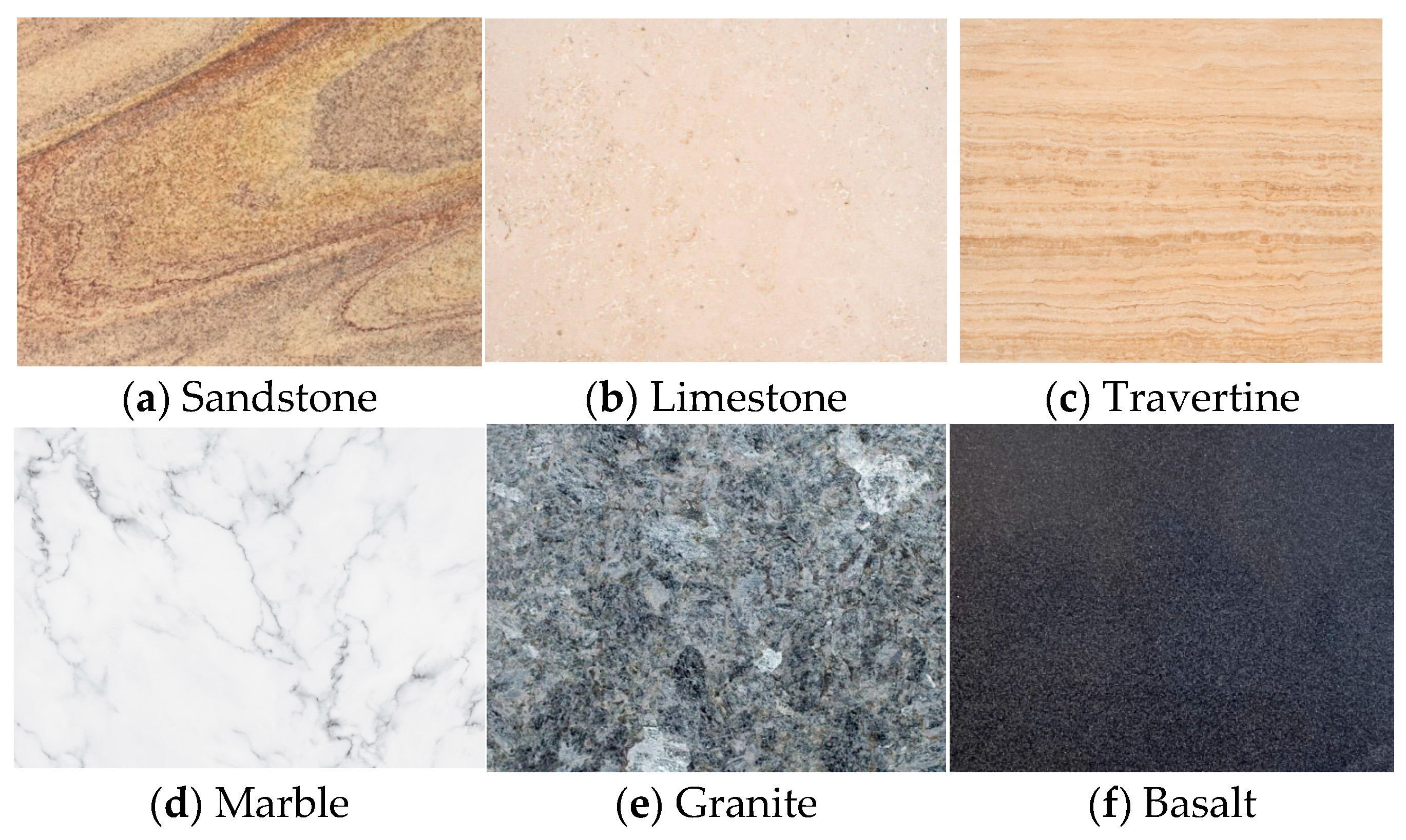

2.2. Stone Types Used

2.3. Air Pollution in Urban Environments

- sulfur dioxide,

- nitrogen oxide,

- ozone,

- hydrogen fluoride, hydrogen chloride, hydrogen sulfide

- dust and soot particles,

- carbon dioxide, if its concentration significantly exceeds the natural proportion in the air (0.029%).

- efflorescence,

- material deterioration, thickness reduction, rust, weathering,

- cracking and peeling, frosting,

- corrosion of fastening elements,

2.4. Typical Damage to Stone Elements on Facades

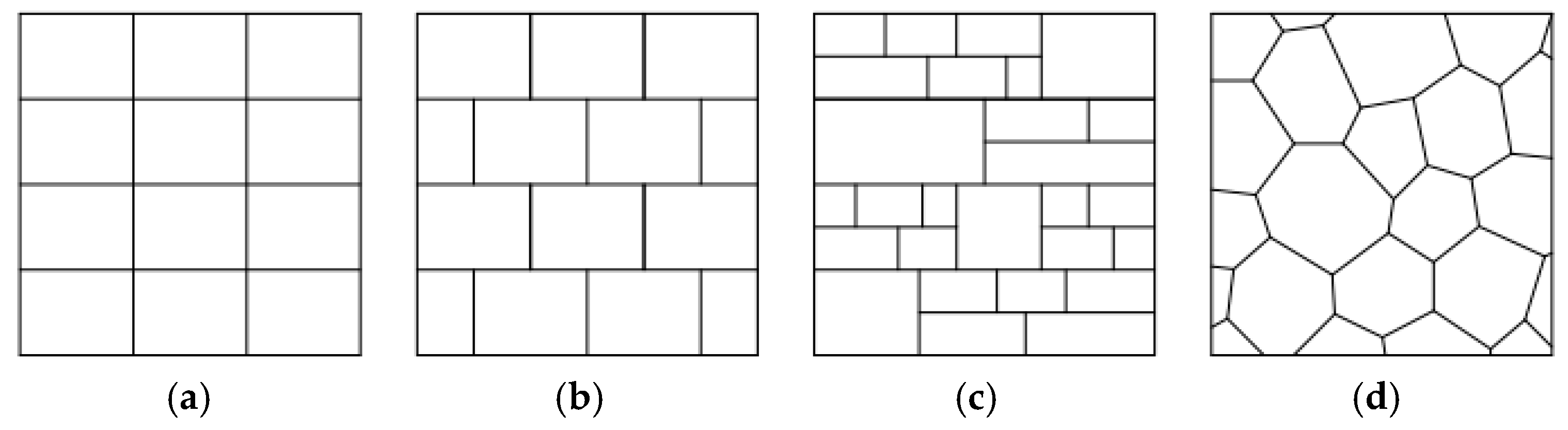

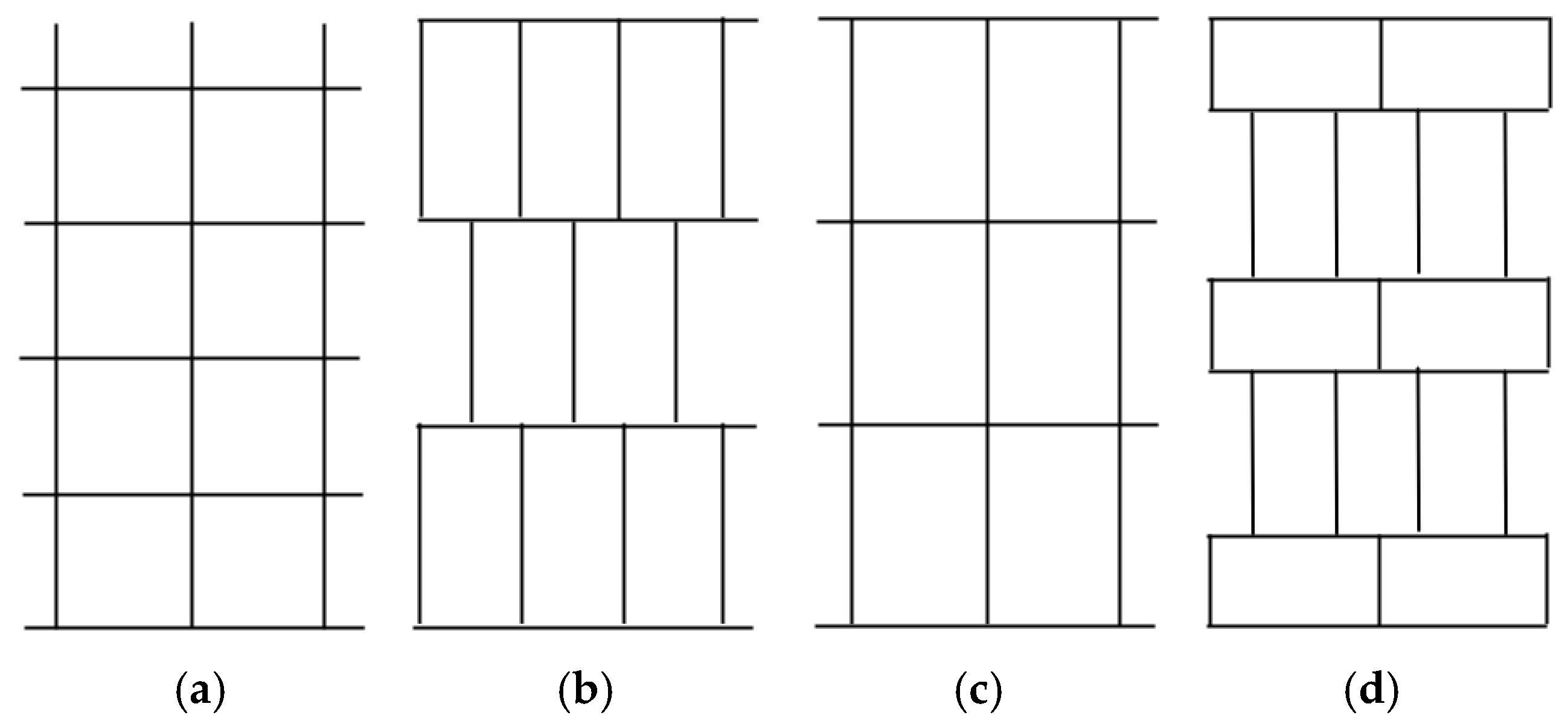

2.5. Traditional Paving Joints

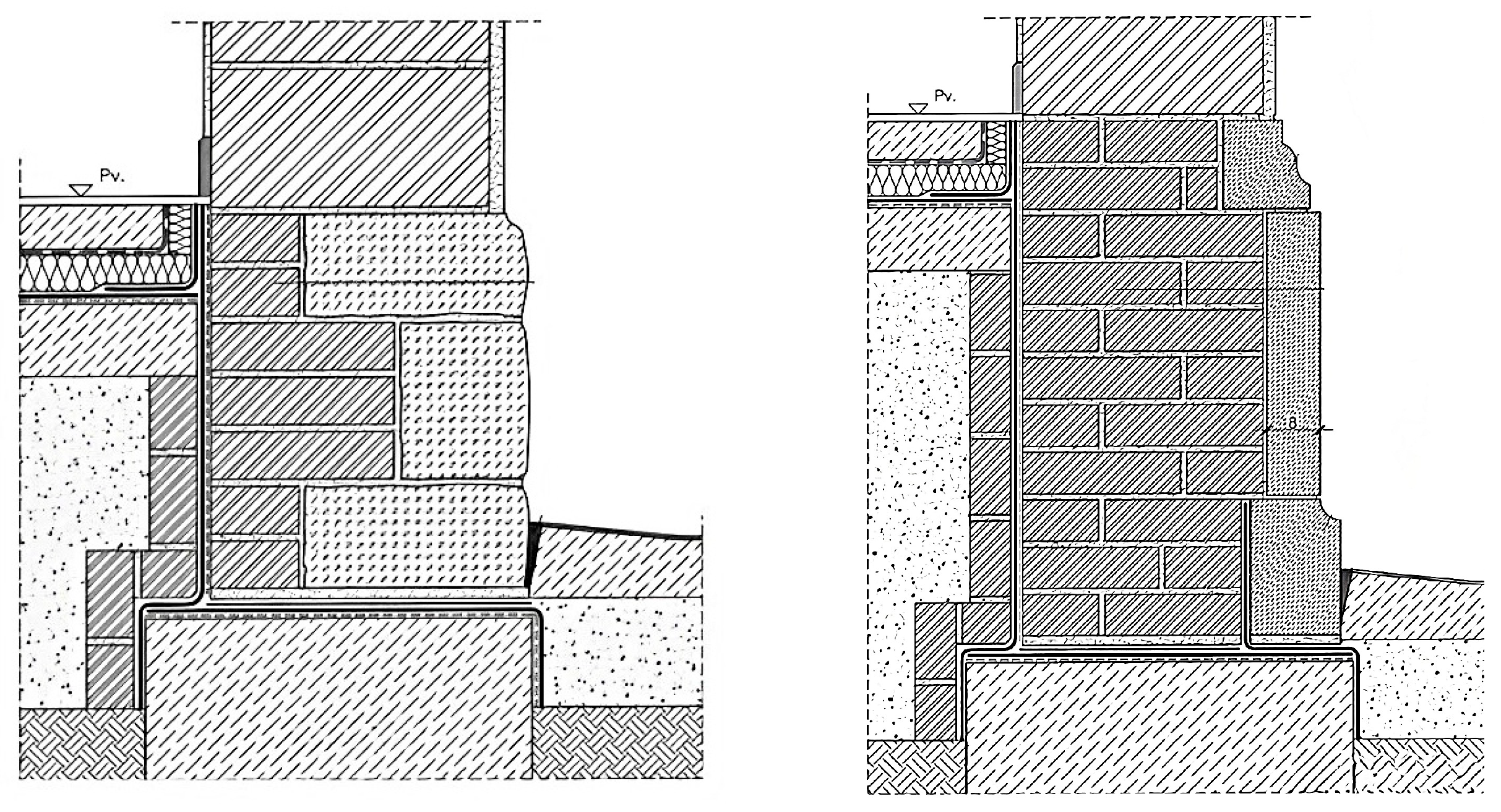

2.6. Building Physics and Fastening of Traditional Stone Cladding

2.7. Fire Resistance of Ventilated Stone Cladding

3. Results

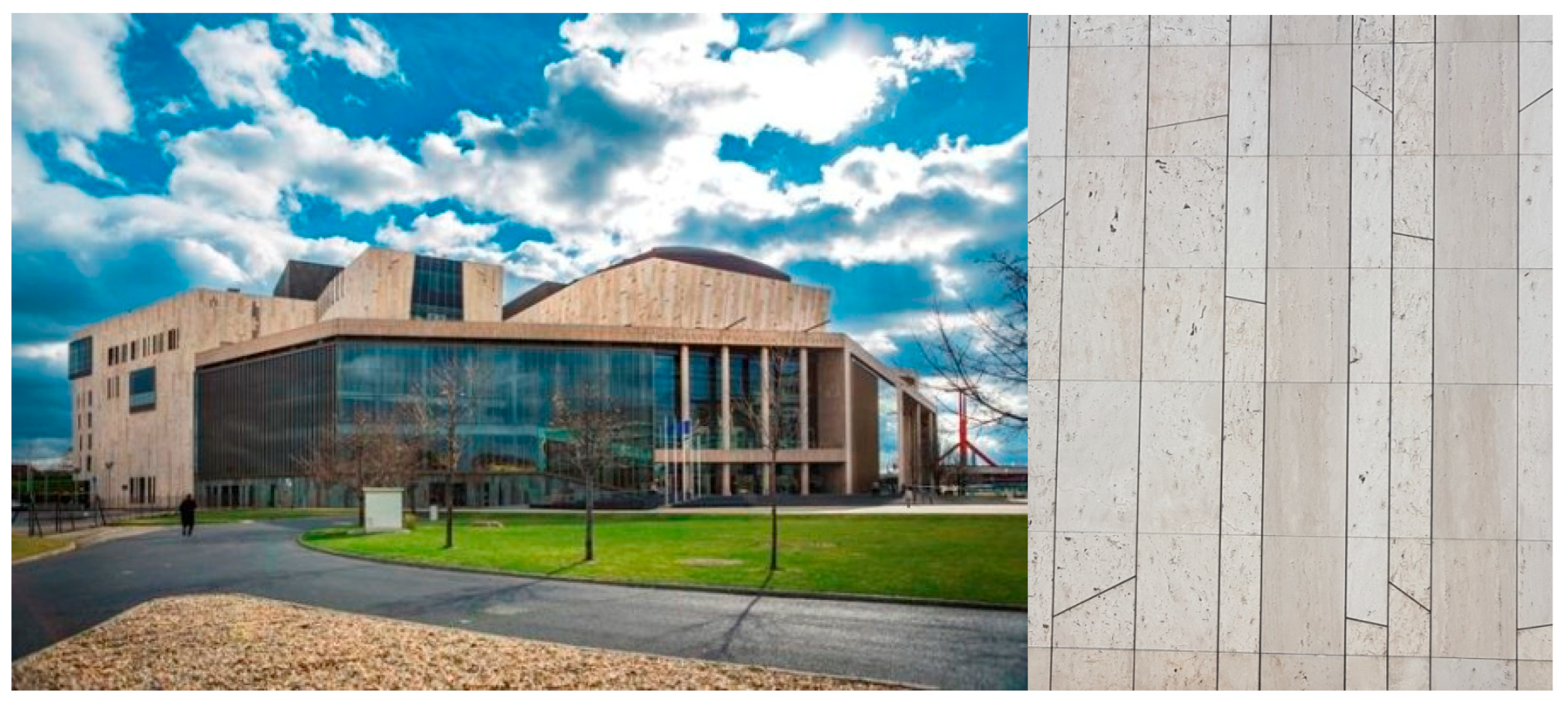

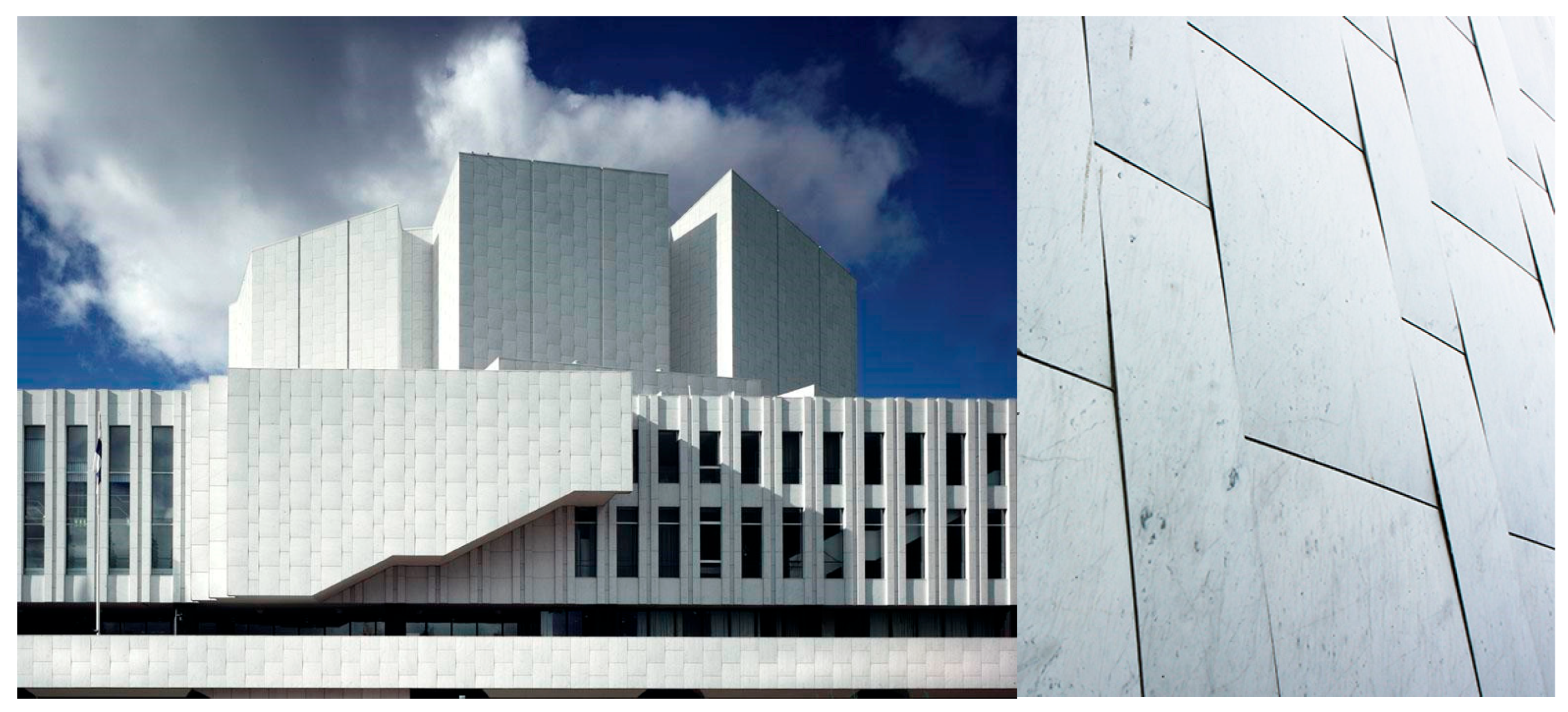

3.1. Modern Assembled Stone Cladding

- the facade stone cladding is made with a free ventilation air gap,

- the thermal cross-section of the boundary facade wall—without cladding—satisfies basic thermal insulation and moisture protection requirements,

- the thickness of the stone slab cladding is at least 2.5 cm, and the largest panel size is not larger than 30 times the thickness,

- the suspension connection of the lower and expansion panels is solved,

- the intermediate anchorages—inside the expansion panel—are flexible,

- the connection and fastening elements are partially or completely resistant to oxidation—rainwater hitting the facade can be perfectly drained from the surface,

- the movements and forces resulting from solar radiation and variable heat load are equalized 50% within the element suspension and 50% within the expansion panel,

- the facade doors and windows must be closed with the inverted casing in such a way that the results of their mechanical movements remain within the casing field without reducing the quality of the window installation,

- defective elements can be replaced without opening the facade.

3.2. Relationship Between Porosity and Density and the Excretory System

3.3. Surface Treatment of Facade Stone Coverings

- Honed—the surface of the stone is ground to a flat, even finish. In the case of stones that contain natural luster, such as granite or marble, the lens or shine is removed, creating a matte (unpolished) surface that is less reflective and has no protrusions or ridges.

- Honed and unfilled—imperfections and pores are left unfilled, giving the product a more rustic feel, especially in outdoor applications.

- Honed and filled—imperfections and pores are filled, and the surface is left honed.

- Polished—a mirror-like finish that creates a high-gloss finish.

- Polished—this finish provides an antique, rough appearance. Hard plastic or metal brushes are used to achieve the final shape.

- Flamed—a process in which granite or other stone is exposed to high temperatures and then cooled suddenly. This process results in cracks and texture on the surface of the stone, creating a rough, non-slip surface.

3.4. Impregnation of Stone Coverings

- The chance of moss and algae growth outdoors.

- Easier cleaning—Treated surfaces absorb less dirt, making cleaning easier and faster.

- Longer life—Impregnation protects the stone against environmental influences, freezing, temperature fluctuations, and chemicals.

- Aesthetic protection—Preserves the original color and texture of the stone, avoiding premature fading.

3.5. Modern Joint Design

3.6. Dehumidification of Installed Stone Slab Cladding

3.7. Thermal Expansion of Stone Slabs

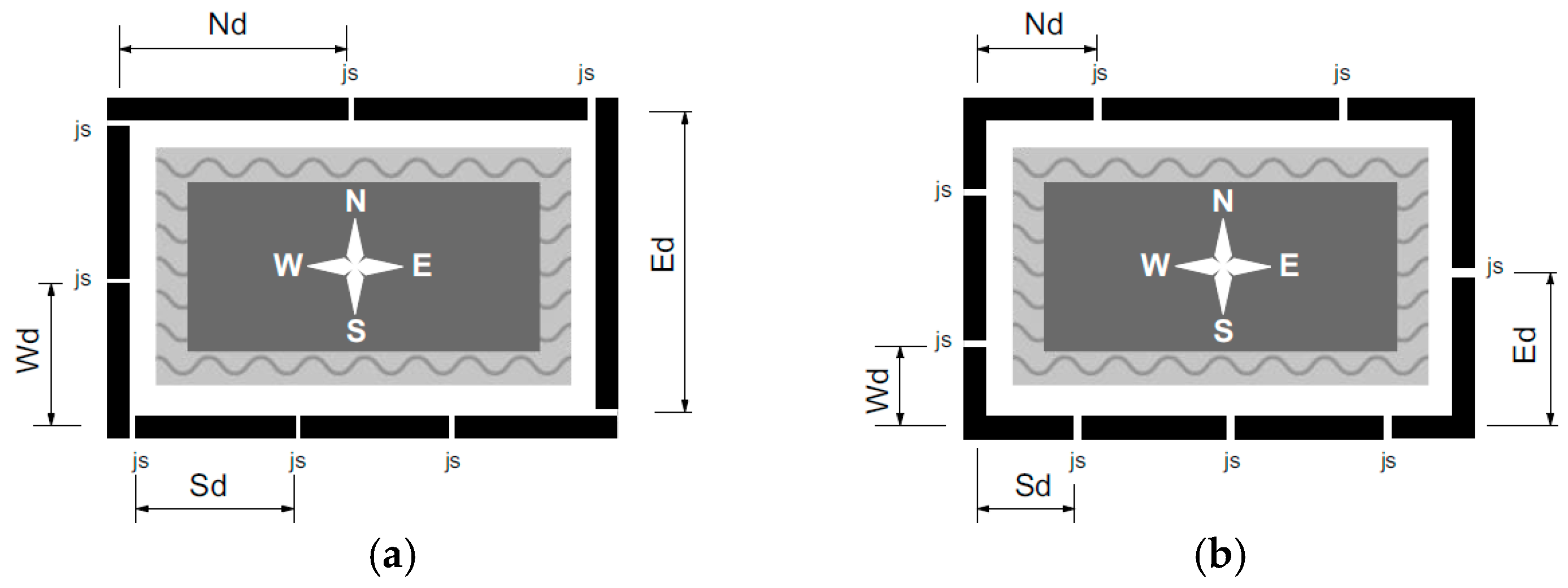

3.8. Summer and Winter Thermal Conditions

3.9. Fire Resistance of Ventilated Stone Cladding

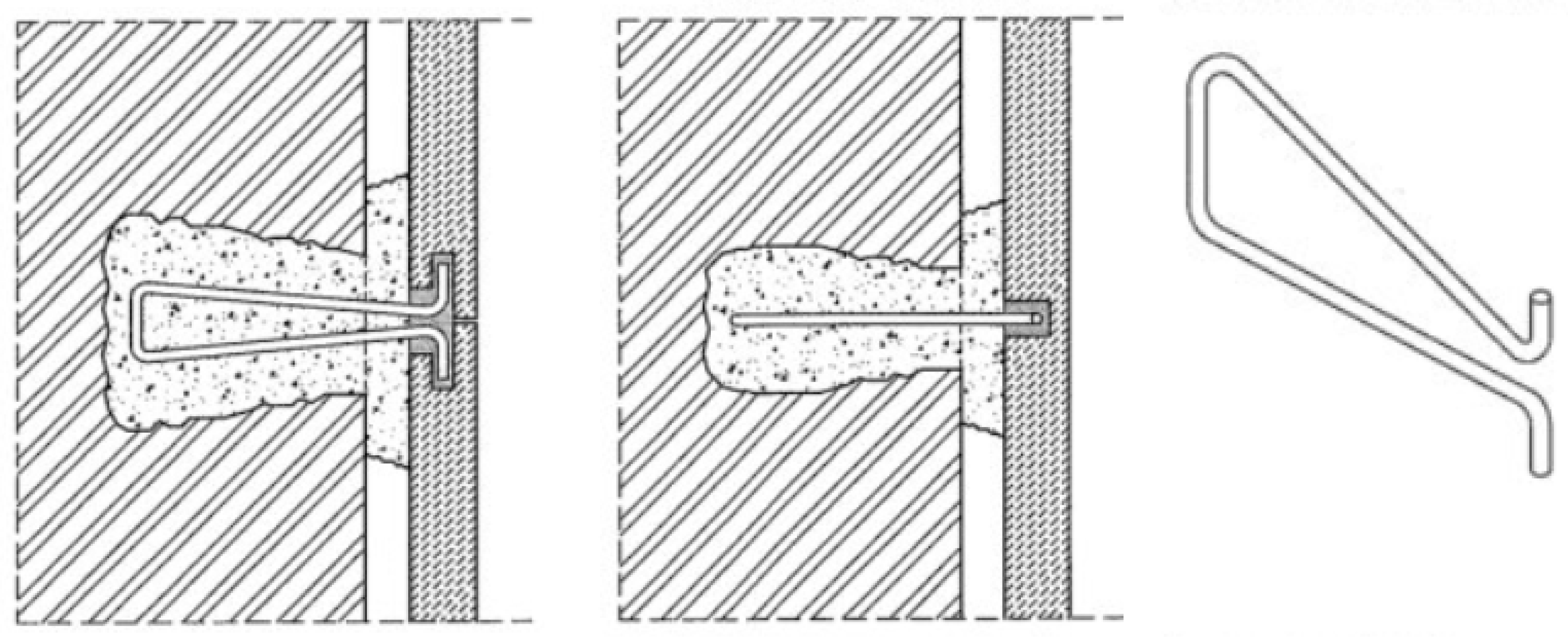

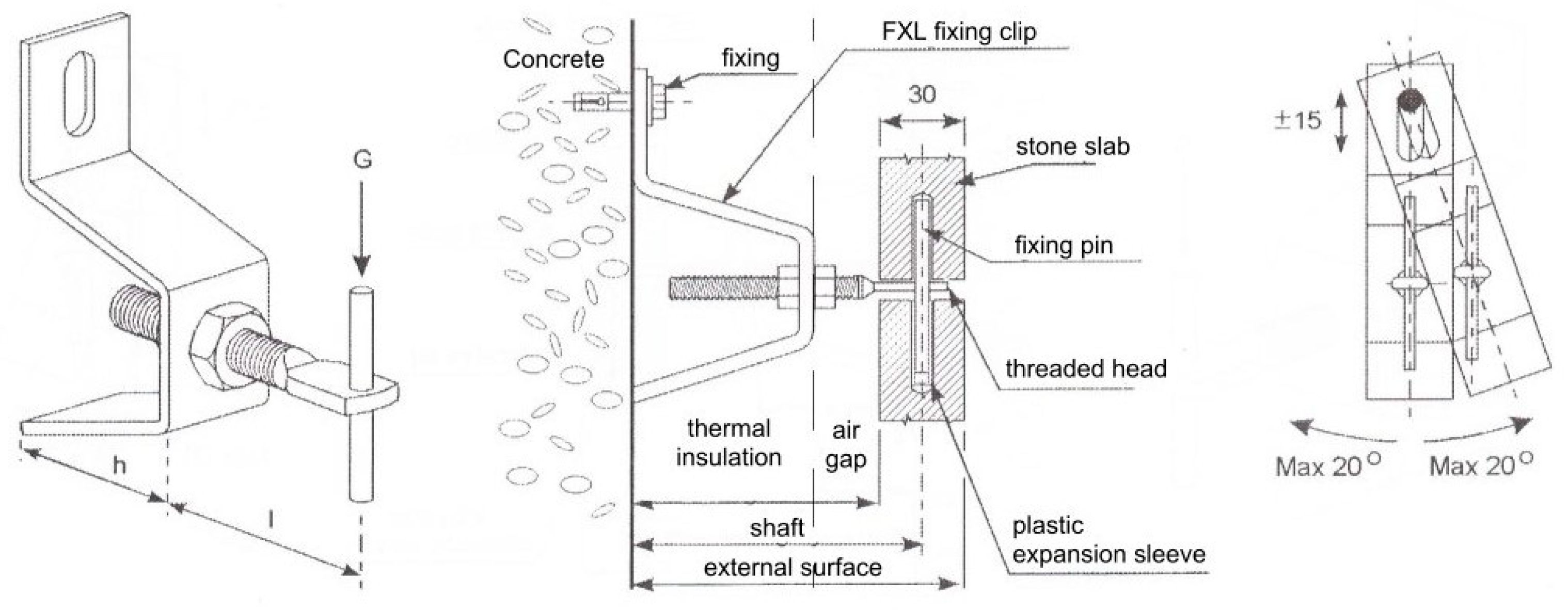

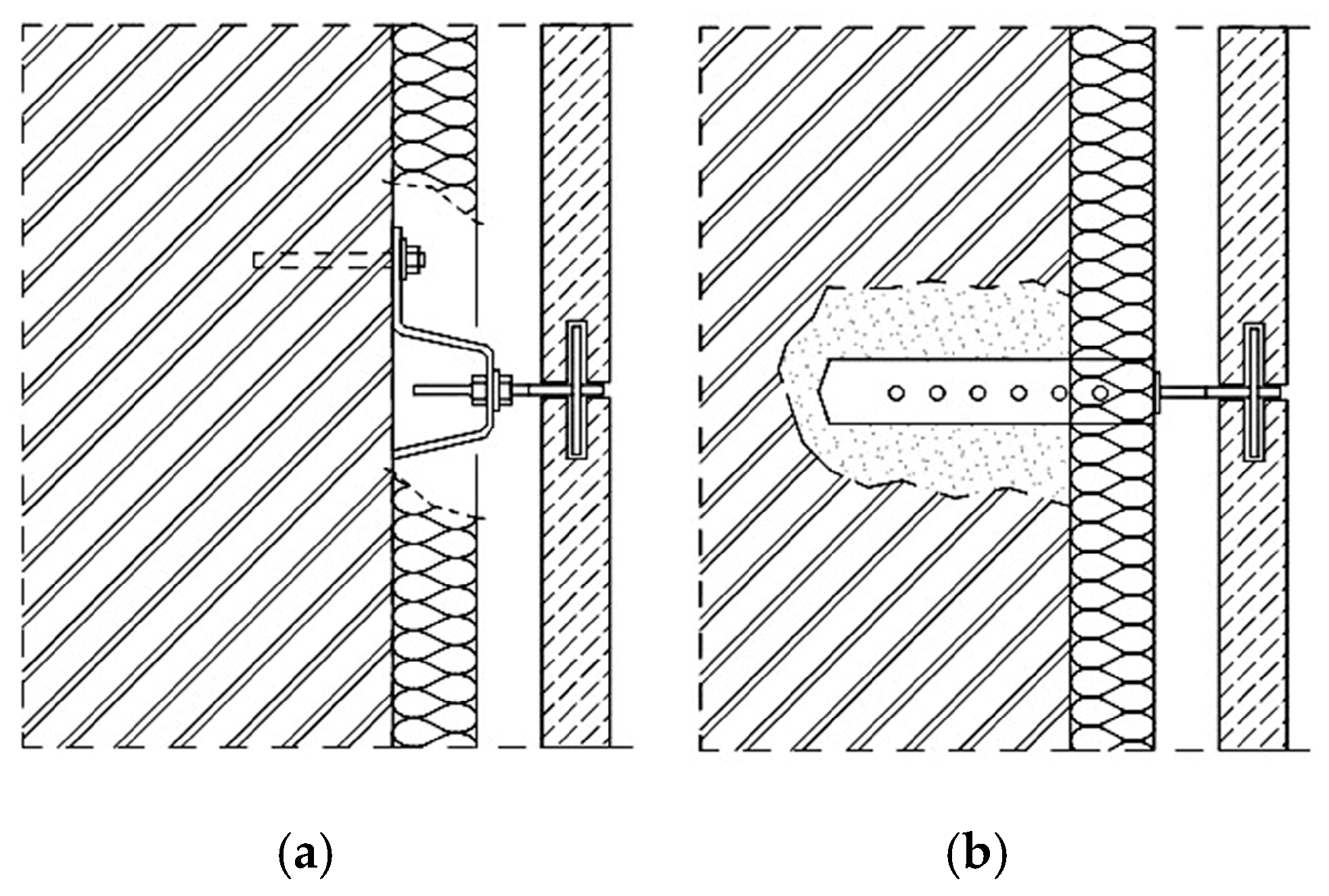

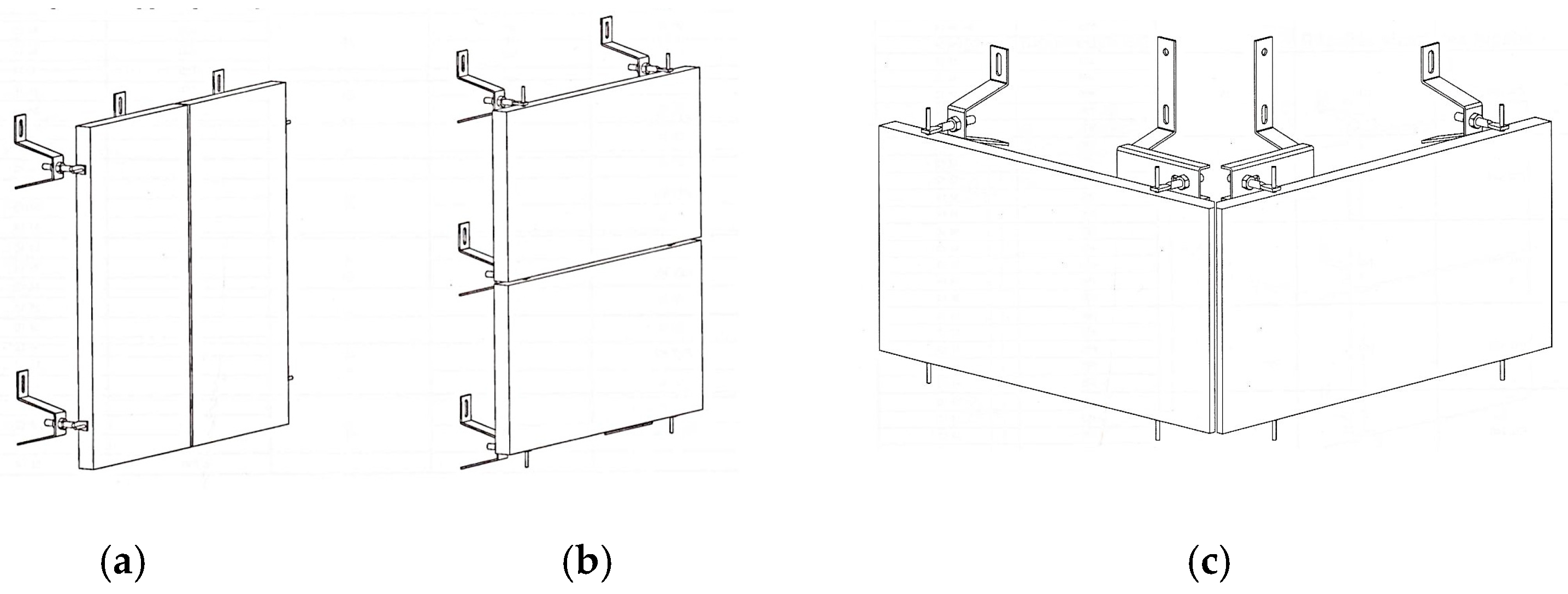

3.10. Fixing the Assembled Stone Slab

3.11. Modern Fastening Methods

- 2–6 cm stone slab cladding,

- 3–5 cm ventilation gap,

- 12–20 cm thermal insulation (thickness varies depending on the climate),

- load-bearing wall structure.

3.12. Fasteners

3.13. Fixing Methods

4. Conclusions

4.1. When Selecting the Stone Materials for Cladding, the Following Considerations Should Be Made

4.2. Technical Aspects to Check When Designing Modern Air-Gap Wall Structures

4.3. Building Physics Considerations in the Case of Modern Assembled Stone Cladding

4.4. The Following Requirements Must Be Observed When Attaching the Supports of Modern Mounted Stone Facades

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ferreira, C.; Silva, A.; de Brito, J.; Dias, I.S.; Flores-Colen, I. Definition of a condition-based model for natural stone claddings. J. Build. Eng. 2021, 33, 101643. [Google Scholar] [CrossRef]

- Fürtön, B.; Bakonyi, D. Nagy Balázs Homlokzatképzések parametrikus tervezése és modellezése BIM alapokon (Parametric design and modelling of façade constructions based on BIM). In Épületeink és Műemlékeink; Konferencia Iroda Bt.: Budapest, Hungary, 2021; p. 17. ISBN 9786155831225. (In Hungarian) [Google Scholar]

- Huang, B.; Lu, W.; Mosalam, K.M. Mosalam Shaking table testing of granite cladding with undercut bolt anchorage. Eng. Struct. 2018, 171, 488–499. [Google Scholar] [CrossRef]

- Cortés-Meseguer, L.; Bello, P.M. Methodology for the Study and Analysis of Concrete in a Heritage Façade: The Ateneu Sueco Del Socorro (Spain). Eng 2025, 6, 33. [Google Scholar] [CrossRef]

- Farmer, M.C.; Lyons, S.P. Stone Cladding Failure: The Cause and Consequences. In Proceedings of the Second Forensic Engineering Congress, San Juan, Puerto Rico, 21–23 May 2000. [Google Scholar] [CrossRef]

- Lluis-Teruel, C.; i Ginovart, J.L. Construction of Structures with Thin-Section Ceramic Masonry. Buildings 2025, 15, 2042. [Google Scholar] [CrossRef]

- Assadimoghadam, A.; Banihashemi, S.; Muminovic, M.; Lemckert, C.; Sanders, P. Adaptive Façades for High-Rise Residential Buildings: A Qualitative Analysis of the Design Parameters and Methods. Buildings 2025, 15, 2072. [Google Scholar] [CrossRef]

- Barbero-Barrera, M.d.M.; Tendero-Caballero, R.; de Viedma-Santoro, M.G. Impact of Solar Shading on Façades’ Surface Temperatures under Summer and Winter Conditions by IR Thermography. Architecture 2024, 4, 221–246. [Google Scholar] [CrossRef]

- Neto, N.; de Brito, J. Validation of an inspection and diagnosis system for anomalies in natural stone cladding (NSC). Constr. Build. Mater. 2012, 30, 224–236. [Google Scholar] [CrossRef]

- Sousa, H.; Sousa, R. Durability of Stone Cladding in Buildings: A Case Study of Marble Slabs Affected by Bowing. Buildings 2019, 9, 229. [Google Scholar] [CrossRef]

- Åkesson, U.; Lindqvist, J.E.; Schouenborg, B.; Grelk, B. Relationship between microstructure and bowing properties of calcite marble claddings Bull. Eng. Geol. Environ. 2006, 65, 73–79. [Google Scholar] [CrossRef]

- Zuo, S.; Xiao, J.; Yuan, Q. Comparative study on the new-old mortar interface deterioration after wet-dry cycles and heat-cool cycles. Construct. Build. Mater. 2020, 244, 118374. [Google Scholar] [CrossRef]

- Greelane. Közönséges Kőzetek és Ásványok Sűrűsége (Density of Common Stones and Minerals); Tudomány Technika Matematika: Budapest, Hungary, 2020. [Google Scholar]

- Burján, B. A Nyugati pályaudvar építő- és díszítőkövei (Building and decorative stones of the Nyugati railway station). Építés Építészettudomány 2018, 46, 57–91. (In Hungarian) [Google Scholar] [CrossRef]

- Burján, B.; Török, Á. Az Akadémia székházához felhasznált kőzetek (Stones used for the Academy’s headquarters). Építés Építészettudomány 2016, 44, 187–225. (In Hungarian) [Google Scholar] [CrossRef][Green Version]

- Turi, N.; Török, Á.; Nemes, R. A Prágai Károly-Híd Homokköveinek Laboratóriumi Vizsgálata: Vízfelvételi Tulajdonságok és a Hőtágulás Változásának Elemzése (Laboratory Testing of the Sandstones of the Charles Bridge in Prague: Analysis of Water Absorption Properties and Thermal Expansion Variation). In Mérnökgeológia-Kőzetmechanika; Török, Á., Vásárhelyi, B., Eds.; Műegyetemi Kiadó: Budapest, Hungary, 2008; pp. 215–224. (In Hungarian) [Google Scholar]

- Rosso, F.; Pisello, A.L.; Jin, W.; Ghandehari, M.; Cotana, F.; Ferrero, M. Cool Marble Building Envelopes: The Effect of Aging on Energy Performance and Aesthetics. Sustainability 2016, 8, 753. [Google Scholar] [CrossRef]

- Marini, P.; Bellopede, R. The Influence of the Climatic Factors on the Decay of Marbles: An Experimental Study. Am. J. Environ. Sci. 2007, 3, 143–150. [Google Scholar] [CrossRef]

- Ferreira, C.; Dias, I.S.; Silva, A.; de Brito, J.; Flores-Colen, I. Criteria for selection of cladding systems based on their maintainability. J. Build. Eng. 2021, 39, 102260. [Google Scholar] [CrossRef]

- Gherardi, F.; Kapridaki, C.; Roveri, M.; Gulotta, D.; Maravelaki, P.N.; Toniolo, L. The deterioration of Apuan white marble in contemporary architectural context. J. Cult. Herit. 2019, 35, 297–306. [Google Scholar] [CrossRef]

- Silva, A.; Dias, J.; Gaspar, P.; Brito, J. Service life prediction models for exterior stone cladding. Build. Res. Inf. 2011, 39, 637–653. [Google Scholar] [CrossRef]

- Chew, M.Y.L.; Samarakoon, W.; Asmone, A.S. Tile Delamination on Façades of Tall Buildings. Buildings 2025, 15, 1054. [Google Scholar] [CrossRef]

- Prieto, A.J.; Silva, A.; de Brito, J.; Macias-Bernal, J.M. Serviceability of facade claddings. Build. Res. Inf. 2018, 46, 179–190. [Google Scholar] [CrossRef]

- Pitzurra, L.; Moroni, B.; Nocentini, A.; Sbaraglia, G.; Poli, G.; Bistoni, F. Microbial growth and air pollution in carbonate stone weathering. Int. Biodet. Biodegr. 2003, 52, 63–68. [Google Scholar] [CrossRef]

- Török, Á.; Hajnal, G.; Emszt, G.; Árpás, E.A. A Mátyás-templom kőzetanyagának állapota (The state of the stone of the Matthias Church). Építőanyag J. Silic. Based Compos. Mater. 2005, 57, 74–80. (In Hungarian) [Google Scholar]

- Országgyűlés Évfordulók—10 Éve Adták át az Országház Megújult Homlokzatát (Anniversaries—10 Years Since the Inauguration of the Renewed Façade of the Parliament), Budapest 2023. Available online: https://www.parlament.hu/-/evfordulok-10-eve-adtak-at-az-orszaghaz-megujult-homlokzatat (accessed on 20 June 2025). (In Hungarian).

- MTI. Befejeződött az Országház Homlokzatának Felújítása (Renovation of the Façade of the Parliament House Completed). Available online: https://www.galamus.hu/index.php?option=com_content&view=article&id=347374:befejezodott-az-orszaghaz-homlokzatanak-felujitasa-347374&catid=228&Itemid=232 (accessed on 20 June 2025). (In Hungarian).

- Santo, A.P.; Cuzman, O.A.; Petrocchi, D.; Pinna, D.; Salvatici, T.; Perito, B. Black on White: Microbial Growth Darkens the External Marble of Florence Cathedral. Appl. Sci. 2021, 11, 6163. [Google Scholar] [CrossRef]

- Dan Hill Finlandia: The Greatest Architectural Mistake Ever Made? Aalto’s Benign Errors. Available online: https://medium.com/iamacamera/finlandia-the-greatest-architectural-mistake-ever-made-aaltos-benign-errors-be3e9533d3e6 (accessed on 25 June 2025.).

- SR Architect. Ageing Gracefully—Alvar Aalto’s Finlandia Hall, Helsinki. Available online: https://www.sra-architects.co.uk/blog-posts/25/8/2015/ageing-gracefully-alvar-aaltos-finlandia-hall-in-helsinki (accessed on 25 June 2025.).

- Bakonyi, D. New method for simplified consideration of thermal bridges in facades. In Proceedings of the Metszet Építész Tervezői Napok 2014, Budapest, Hungary, 12 June 2014. [Google Scholar]

- Pires, V.; Rosa, L.G.; Dionisio, A. Implications of exposure to high temperatures for stone cladding requirements of three Portuguese granites regarding the use of dowel–hole anchoring systems. Constr. Build. Mater. 2014, 64, 440–450. [Google Scholar] [CrossRef]

- Chakrabarti, B.; Yates, T.; Lewry, A. Effect of fire damage on natural stonework in buildings. Constr. Build. Mater. 1996, 10, 539–544. [Google Scholar] [CrossRef]

- Dionisío, A. Stone decay induced by fire on historical buildings: The case of the cloister of Lisbon Cathedral (Portugal). In Building Stone Decay: From Diagnosis to Conservation; Prikryl, R., Smith, B.J., Eds.; Geological Society, Special Publications: London, UK, 2007; pp. 87–98. [Google Scholar]

- Hajpal, M.; Torok, A. Mineralogical and colour changes of quartz sandstone by heat. Environ. Geol. 2004, 46, 311–322. [Google Scholar] [CrossRef]

- Lubloy, E. How does concrete strength affect the fire resistance? J. Struct. Fire Eng. 2020, 11, 311–324. [Google Scholar] [CrossRef]

- Almadani, R.; Fu, F. Parametric Analysis of a Steel Frame under Fire Loading Using Monte Carlo Simulation. Fire 2022, 5, 25. [Google Scholar] [CrossRef]

- Hajpál, M. Burning Effect on Sandstones of Historic Buildings and their Petrophysical and Mineralogical Studies. Period. Polytech. Civ. Eng. 1999, 43, 207–218. [Google Scholar]

- MET. A Levegőszennyezés Jelentése és Következményei Globálisan (The Meaning and Consequences of Air Pollution Globally); MET Central Europe/MET Magyarország: Budapest, Hungary, 2021. (In Hungarian) [Google Scholar]

- UrbUrbanek, M.; Gil-Díaz, T.; Lützenkirchen, J.; Castelvetro, V. Nano-Zirconia as a Protective and Consolidant Material for Marble in Architectural Surfaces. Buildings 2025, 15, 492. [Google Scholar] [CrossRef]

- López, A.J.; Ramil, A.; Pozo-Antonio, J.S.; Rivas, T.; Pereira, D. Ultrafast Laser Surface Texturing: A Sustainable Tool to Modify Wettability Properties of Marble. Sustainability 2019, 11, 4079. [Google Scholar] [CrossRef]

- Versiegelung Kőlapok Impregnálása És Tömítése (Impregnation and Sealing of Stone Slabs), Budapest. 2020. Available online: https://www.versiegelung24.com/hu/fel%C3%BCletek/ko-csempe (accessed on 21 June 2025). (In Hungarian).

- Paládi-Kovács, Á.; Maxi, T. HR Profix Konzol Rendszer, Profix rendszerű trapézkapocs kőlap homlokzathoz (HR Profix Console System, Profix system trapezoidal staples for stone facades), Dunaújváros 2020. Catalogues in English. Available online: https://www.hrprofix.com/prospectus (accessed on 21 June 2025).

- Ghodousian, O.; Ghodousian, A.; Shafaie, V.; Hajiloo, S.; Rad, M.M. Study of Bonding between Façade Stones and Substrates with and without Anchorage Using Shear-Splitting Test—Case Study: Travertine, Granite, and Marble. Buildings 2023, 13, 1229. [Google Scholar] [CrossRef]

- Paládi-Kovács, Á. Principles of designing facade cladding brick walls. J. Fac. Civ. Eng. Subot. 2024, 45, 21–36. [Google Scholar] [CrossRef]

- Kocsis, L. Hőhídak homlokzati hőszigetelések dűbeleinél (Thermal bridges of façade insulation). Építés Spektrum Épületek és Szerkezeteik 2010, 9, 10–13. (In Hungarian) [Google Scholar]

| Stone Type | Density [kg/m3] | Min. Thickness [cm] | Porosity [%] |

|---|---|---|---|

| Sandstone | 2000–2600 | 4–5 | 20–24 |

| Limestone | 2600–2700 | 3–4 | 0.25–1 |

| Travertine | 2100–2500 | 3–4 | 3–11 |

| Marble | 2600–2900 | 2–3 | 0.5–2 |

| Granite | 2600–2800 | 2 | 0.3–1 |

| Basalt | 2800–3000 | 2 | 0.5–25 |

| Type | Corner Design | North [m] | North [m] | South [m] | South [m] | West [m] | West [m] | East [m] | East [m] |

|---|---|---|---|---|---|---|---|---|---|

| With Air Gap | Without Air Gap | With Air Gap | Without Air Gap | With Air Gap | Without Air Gap | With Air Gap | Without Air Gap | ||

| Granite | Open joint | 14 | 10 | 9 | 6 | 8 | 7 | 12 | 9 |

| Closed joint | 7 | 5 | 4 | 3 | 4 | 3 | 6 | 5 | |

| Limestone | Open joint | 10 | 8 | 8 | 7 | 7 | 6 | 9 | 8 |

| Closed joint | 6 | 5 | 5 | 5 | 5 | 4 | 6 | 5 | |

| Sandstone | Open joint | 8 | 6 | 6 | 5 | 5 | 4 | 7 | 6 |

| Closed joint | 4 | 3 | 3 | 3 | 3 | 2 | 4 | 3 |

| Recommended | Not recommended | Forbidden | |

|---|---|---|---|

| Stone type | travertine, marble, granite, basalt | sandstone * limestone * | - |

| Air gap | all types of stone | - | - |

| Dry technology | fast construction execution | highly skilled workforce required | - |

| Wet technology | slower construction execution | lack of highly skilled workers | - |

| Thermal insulation material | rock wool, mineral wool | glass wool | EPS, XPS, PIR |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paládi-Kovács, Á.; Nemes, R. Design Issues and Value Analysis of Modern Stone Slab Coverings. Eng 2025, 6, 209. https://doi.org/10.3390/eng6090209

Paládi-Kovács Á, Nemes R. Design Issues and Value Analysis of Modern Stone Slab Coverings. Eng. 2025; 6(9):209. https://doi.org/10.3390/eng6090209

Chicago/Turabian StylePaládi-Kovács, Ádám, and Rita Nemes. 2025. "Design Issues and Value Analysis of Modern Stone Slab Coverings" Eng 6, no. 9: 209. https://doi.org/10.3390/eng6090209

APA StylePaládi-Kovács, Á., & Nemes, R. (2025). Design Issues and Value Analysis of Modern Stone Slab Coverings. Eng, 6(9), 209. https://doi.org/10.3390/eng6090209