Abstract

Straw fiber curtain contains a plant fiber blanket woven from crop straw, which is mainly used to protect embankment slopes from rainwater erosion. To investigate the erosion control performance of slopes covered with straw fiber curtains of different structural configurations, physical model tests were conducted in a 95 cm × 65 cm × 50 cm (length × height × width) test box with a slope ratio of 1:1.5 under controlled artificial rainfall conditions (20 mm/h, 40 mm/h, and 60 mm/h). The study evaluated the runoff characteristics, sediment yield, and key hydrodynamic parameters of slopes under the coverage of different straw fiber curtain types. The results show that the A-type straw fiber curtain (woven with strips of straw fiber) has the best effect on water retention and sediment reduction, while the B-type straw fiber curtain (woven with thicker straw strips) with vertical straw fiber has a better effect regarding water retention and sediment reduction than the B-type transverse straw fiber curtain. The flow of rainwater on a slope covered with straw fiber curtain is mainly a laminar flow. Straw fiber curtain can promote the conversion of water flow from rapids to slow flow. The Darcy-Weisbach resistance coefficient of straw fiber curtain increases at different degrees with an increase in rainfall time.

1. Introduction

Traditional crop straw is often burned or abandoned, which can easily pollute the environment and damage the land. Reusing crop straw is a challenging problem in agriculture. In recent years, straw materials have been gradually used for slope protection. Loose straw or woven straw is laid on the slope to prevent the slope from being washed by rain and reduce dust pollution. Many scholars have conducted experiments and simulation studies on straw materials used for slope protection.

In the study of protecting slope erosion using unshaped straw fiber, Katdare et al. [1] tested the tensile properties of a geogrid made of different varieties of rice straw, and they found that the tensile strength of a manual rice straw geogrid was 5.4 kN/m. According to Javellonar et al. [2], the rainfall model experiments of rice straw mat (RSM) and rice straw net (RSN) under different rainfall intensities and slopes demonstrated that the soil loss of RSM was significantly lower than that of RSN. Donjadee et al. [3] conducted field anti-erosion experiments using rice straw mulching (RC) and vetiver straw mulching (VGM), and both VGM and RC demonstrated excellent anti-erosion abilities. Yang et al. [4] and Wang et al. [5] studied the effects of wheat straw length and coverage on rainfall infiltration, slope runoff, and soil loss. Rice straw mulch can effectively improve the anti-erosion ability of the slope, and the anti-erosion ability of rice straw mulch is mainly related to rainfall, rice straw length, and mulch amount [6,7,8,9,10,11].

Numerical simulations of straw mainly focus on the mechanical analysis of rice straw, soil, and agronomic machine interaction. Ma et al. [12] modeled rice straw as a rigid rod by arranging discrete element method (DEM) spheres in a row and studied its movement in a combine harvester. A flexible DEM straw model [13,14,15,16] was also developed to investigate the grain–straw separation process in harvesters, thereby providing methodological foundations for straw modeling. Jia et al. [17] established a numerical model of rice straw using the discrete element method and studied and analyzed the interaction between rice straw and agricultural machinery parts. Zeng et al. [18] established a model of soil-tool-rice straw interaction by using the discrete element method, in which soil, cleaning tool, and straw were modeled by spherical particles, walls, and clumps, respectively. Zhang et al. [19] provided an improved DEM modeling method based on a flexible coupling boundary. Experiments and simulations [20,21] show that this method can effectively improve the modeling accuracy of the straw discrete element model. Mao et al. [22] proposed a bonded granular straw model (BSM) with flexible hollow cylindrical bonds and simulated the mechanical properties of BSM. Wang et al. [23] established a two-dimensional model of root water uptake and soil infiltration based on the dynamic equation of soil water, and they simulated soil infiltration under full straw mulching.

At present, the research on straw mainly focuses on the anti-erosion characteristics of loose straw, whereas research on the anti-erosion effect of fixed straw fiber curtain-protected slopes is not as prevalent. Straw fiber curtain ecological slope protection technology belongs to a new type of ecological slope protection technology. The design and construction of this technology lack theoretical support and normative guidance, so it is necessary to carry out related research on the anti-erosion characteristics and mechanisms of straw fiber curtain. Therefore, this study draws lessons from relevant rainfall model test experience and independently designed a straw fiber curtain anti-erosion test device. Based on this test device, a series of physical model tests were conducted under three rainfall intensities (20 mm/h, 40 mm/h, and 60 mm/h) on four slope conditions: an exposed slope, a slope protected by A-type straw fiber curtain, a slope with B-type transverse fiber curtain, and a slope with a B-type vertical fiber curtain. The study primarily aimed to evaluate the erosion resistance performance of different straw fiber curtain configurations, with a focus on runoff production, sediment yield, and key hydrodynamic characteristics. This research offers a comprehensive investigation into the anti-erosion effectiveness of each curtain type, thereby clarifying their distinct functional mechanisms in protecting embankment slopes. The test results can provide a reference for the design theory and construction optimization of straw fiber curtain ecological slope protection technology.

2. Materials and Methods

2.1. Experimental Design

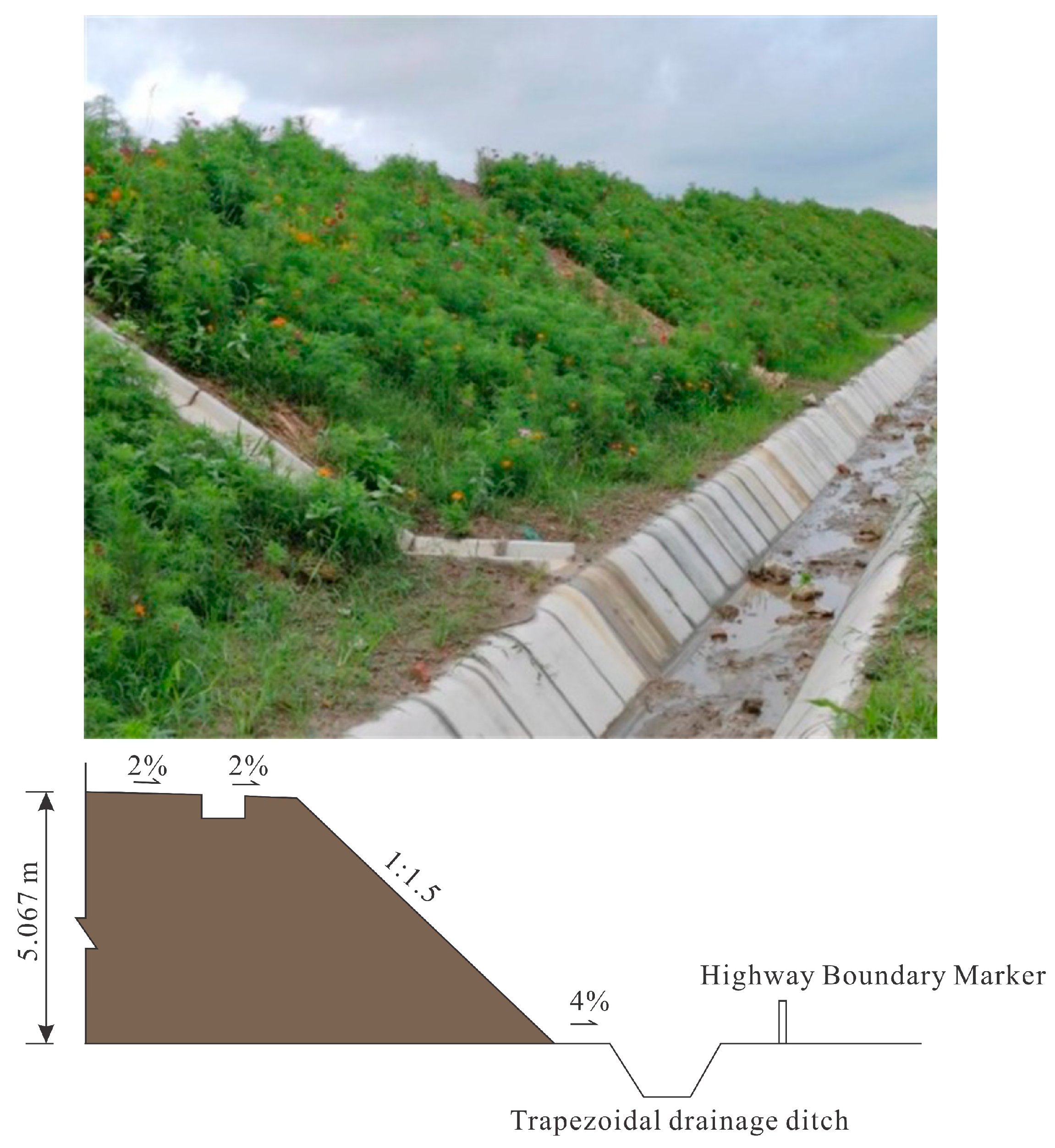

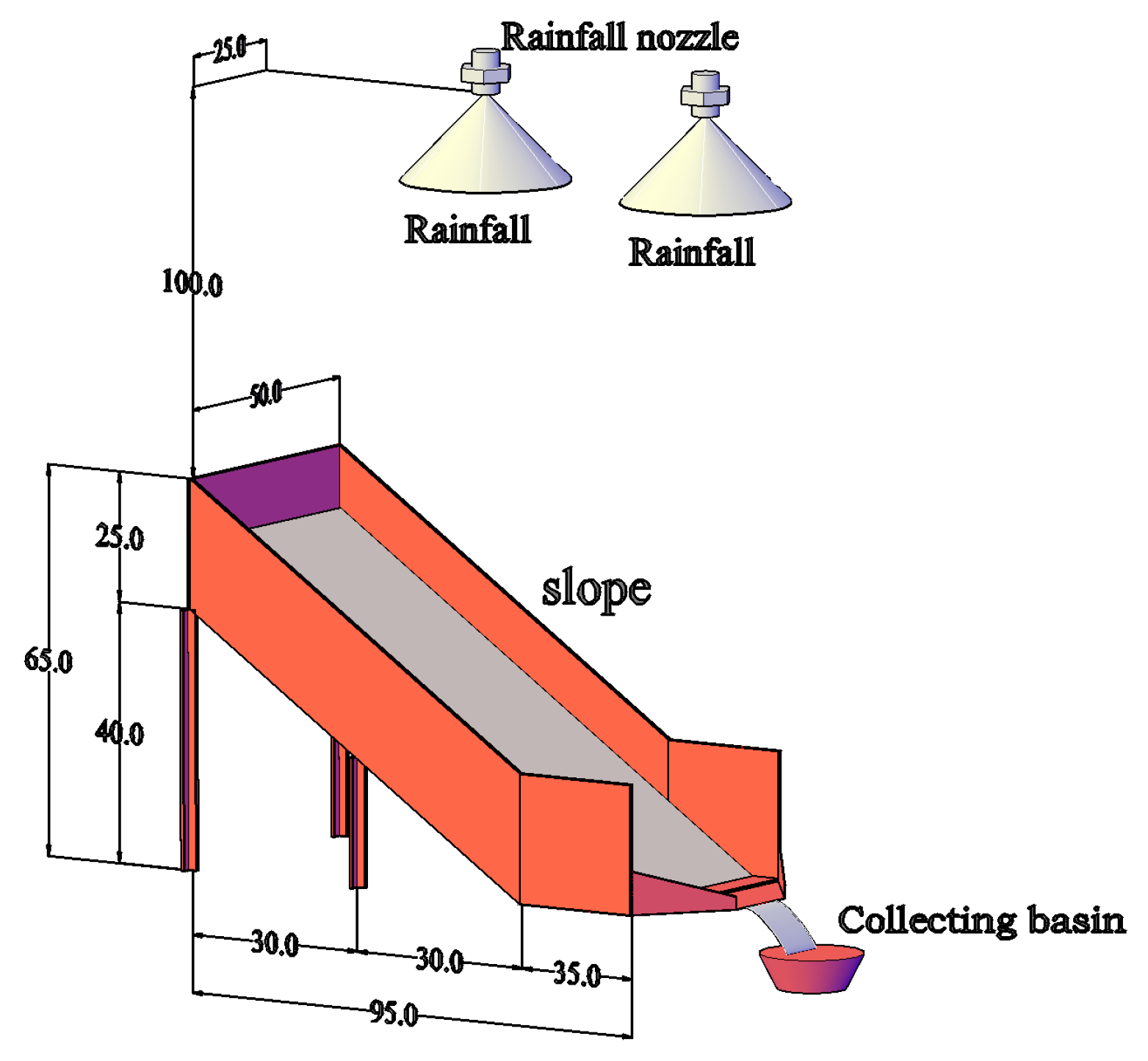

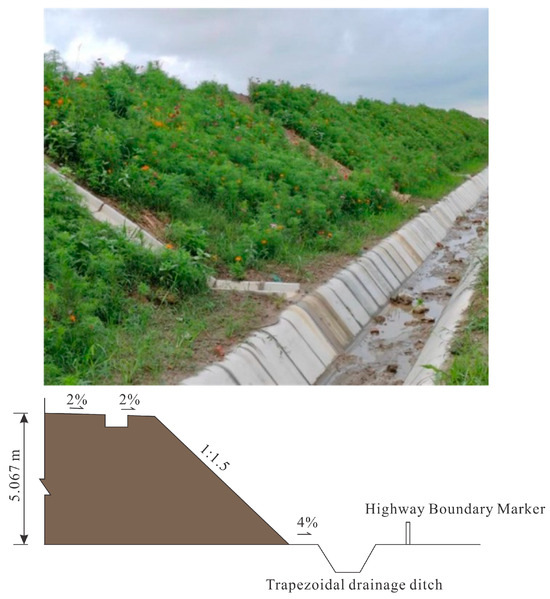

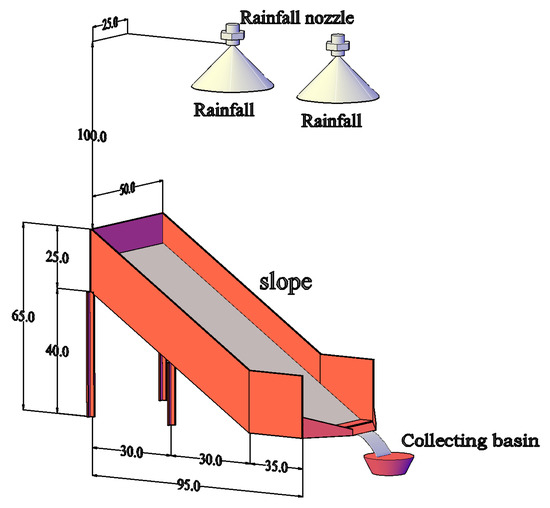

To compare the erosion resistance of different straw fiber curtain configurations under varying rainfall conditions, physical model tests were performed on a bare slope and slopes protected by A-type, B-type transverse, and B-type vertical straw fiber curtains under three levels of simulated rainfall. The elevation profile of the test embankment is illustrated in Figure 1. The slope was constructed with a gradient of 1:1.5, representing a typical fill embankment commonly encountered in transportation infrastructure. Therefore, a model box with a slope ratio of 1:1.5 and dimensions of 95 cm × 65 cm × 50 cm (length × height × width) was made based on actual field conditions, as shown in Figure 2.

Figure 1.

The elevation profile of the test terrain.

Figure 2.

Schematic diagram of the model test (unit: cm).

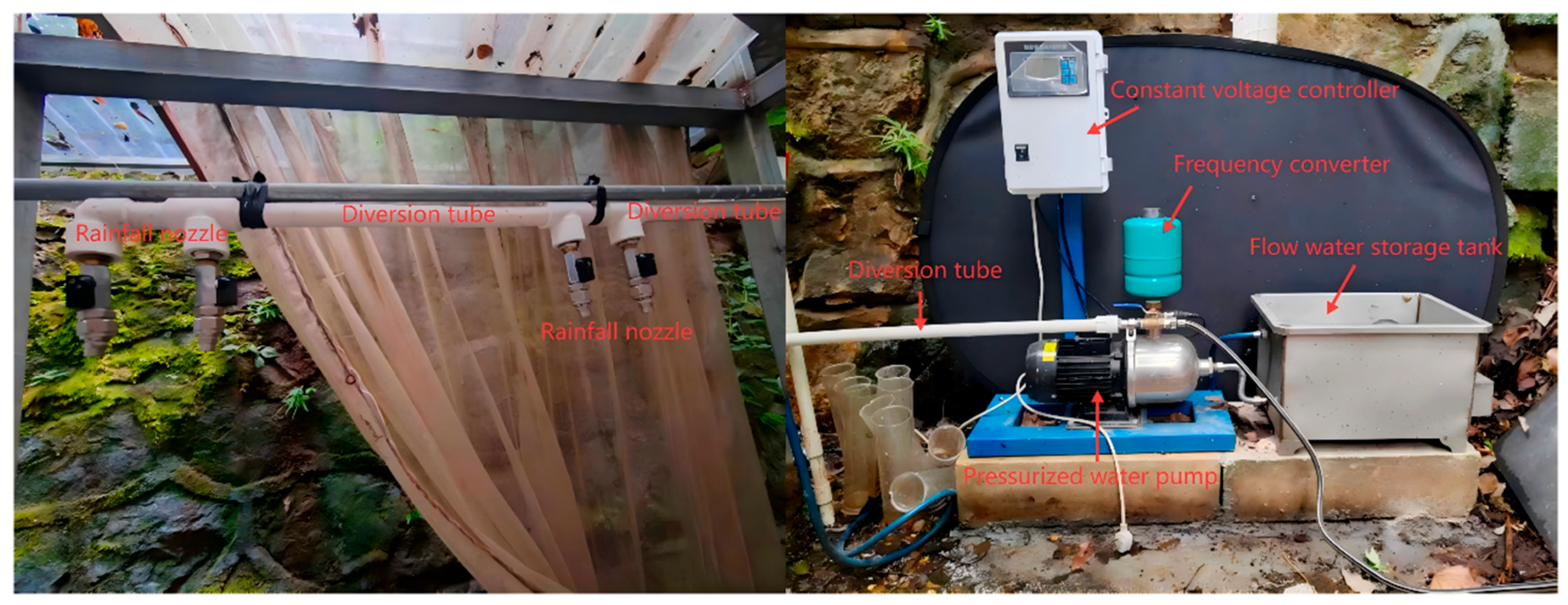

An artificial rainfall simulation system was established, comprising a flow water storage tank, a pressurized water pump, a frequency converter, a constant voltage controller, diversion tubes, and multiple interchangeable rainfall nozzles, as shown in Figure 3. Water was first stored in a flow water storage tank and then delivered by the pressurized water pump, which operates under the control of the frequency converter to adjust the flow rate. The constant voltage controller ensures that the water pressure remains stable throughout the system. The water is subsequently distributed through the diversion tube to the rainfall nozzles, which are evenly spaced and vertically oriented to provide uniform rainfall coverage over the slope surface. By regulating the pump output, the system reliably produced three target rainfall intensities: 20 mm/h, 40 mm/h, and 60 mm/h. These intensities were selected based on typical rainfall levels observed at the construction site during the rainy season.

Figure 3.

Schematic of the artificial rainfall system used in the model tests.

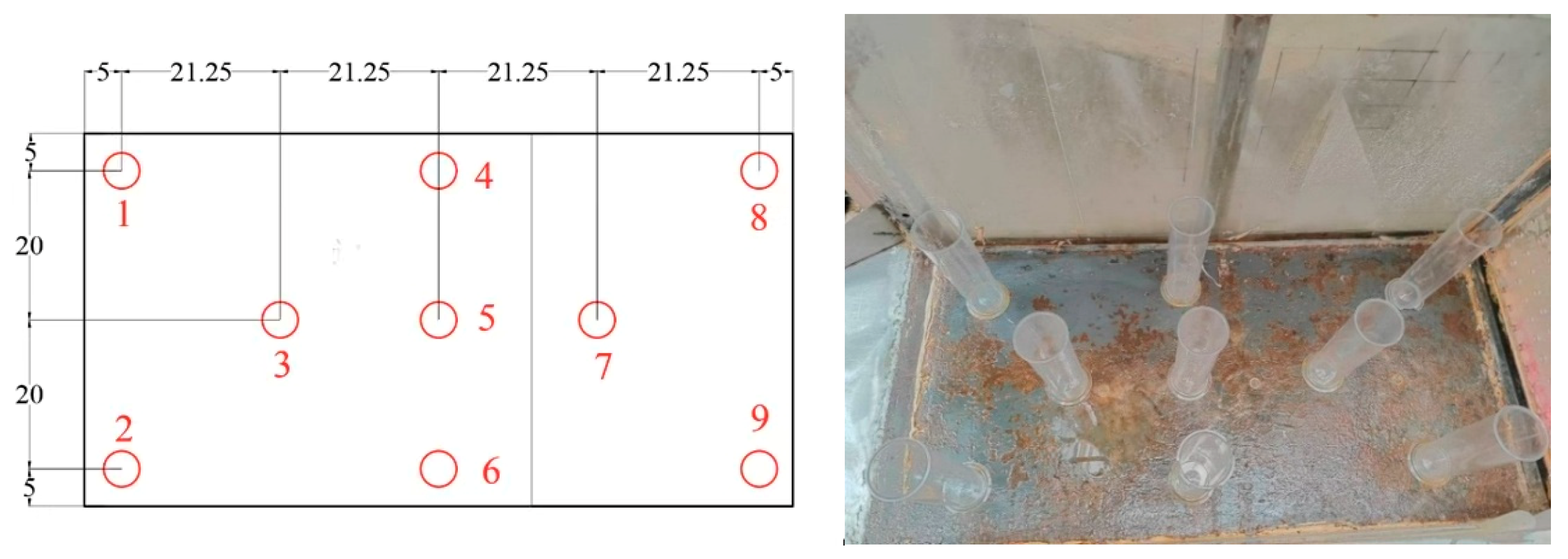

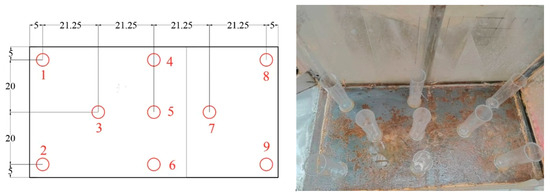

Rainfall intensity and uniformity were calibrated using nine graduated cylinders placed across the top, middle, and bottom of the slope, as shown in Figure 4. The calibration procedure followed the Technical Code for Sprinkler Engineering (GB/T 50085-2007) [24], which defines the rainfall uniformity coefficient as

where Cu is the rainfall uniformity coefficient (%), and hi is the rainfall depth (mm) collected by the i-th graduated cylinder.

is the average rainfall depth across all graduated cylinders. n is the total number of graduated cylinders. This coefficient quantitatively reflects the spatial uniformity of the simulated rainfall across the test slope. According to the standard, a rainfall uniformity of Cu ≥ 80% is required to ensure acceptable consistency for artificial rainfall experiments. The rainfall intensity test data are shown in Table 1. The rainfall uniformity coefficients were 83.59%, 89.83%, and 85.76% for the respective intensities, all of which meet the uniformity requirements specified in the technical standards.

Figure 4.

Plan view of the layout of graduated cylinders for rainfall uniformity testing.

Table 1.

Measured rainfall intensities.

2.2. Experimental Materials

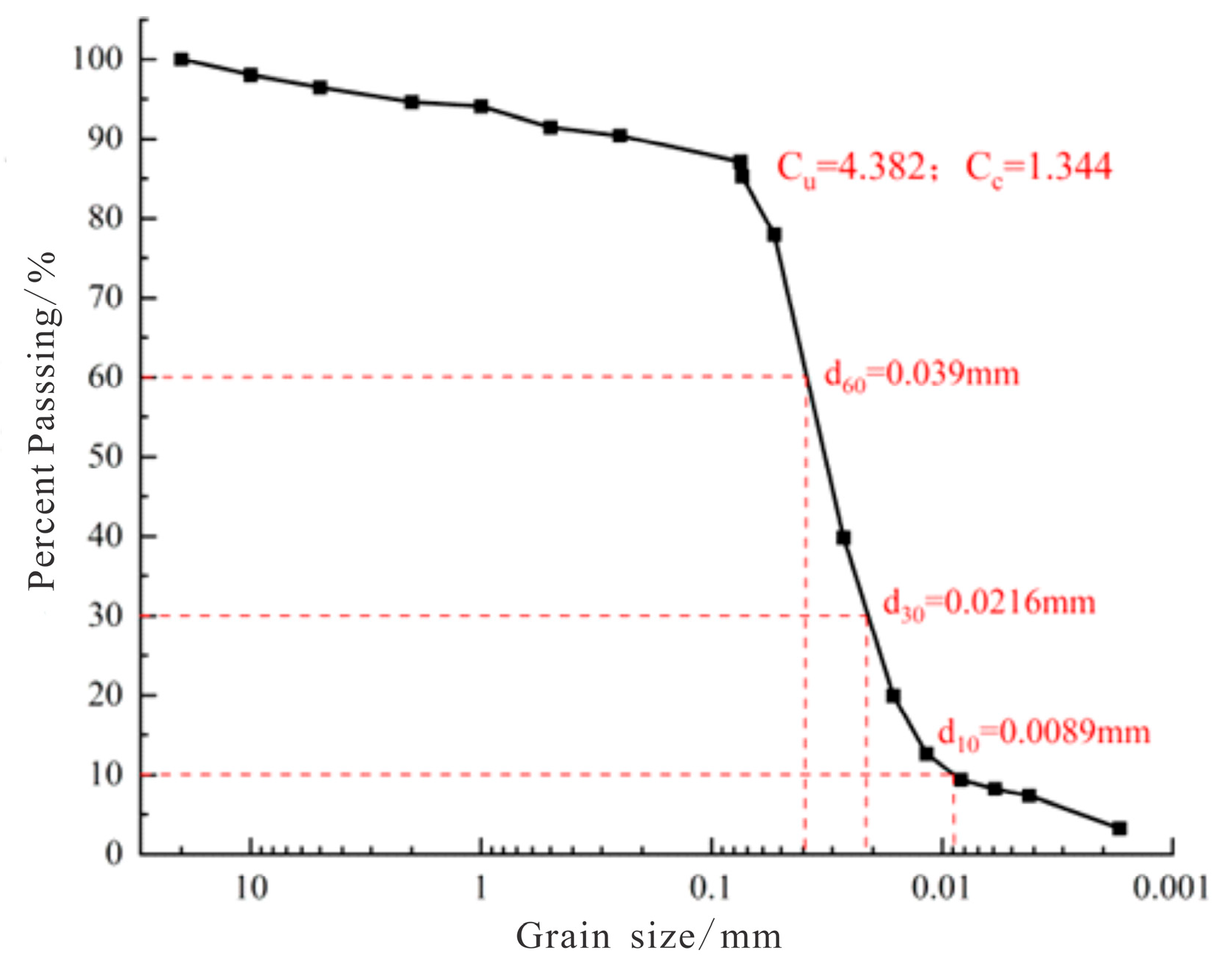

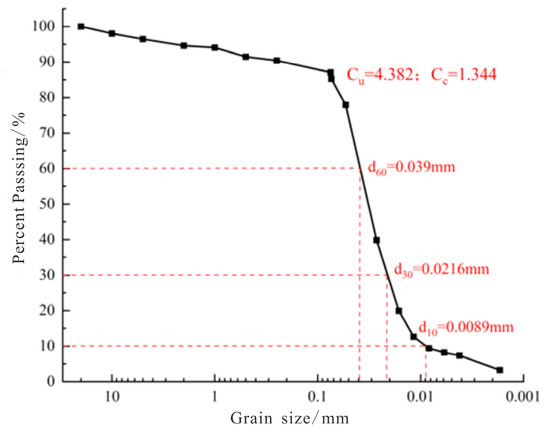

The soil used in this anti-erosion test is mainly used for the filling embankment of the Nantong Ring Expressway Project in Jiangsu Province, China. The ecological slope protection technology of straw fiber curtains with flowers and plants has been successfully realized on the embankment of the project. The soil used in this project is low-liquid-limit clay, and the specific physical and mechanical parameters of the soil are shown in Table 2. The particle size distribution of the soil used in model tests is shown in Figure 5.

Table 2.

The basic physical and mechanical parameters of the soil used for the test.

Figure 5.

Particle size distribution of soil used in model tests.

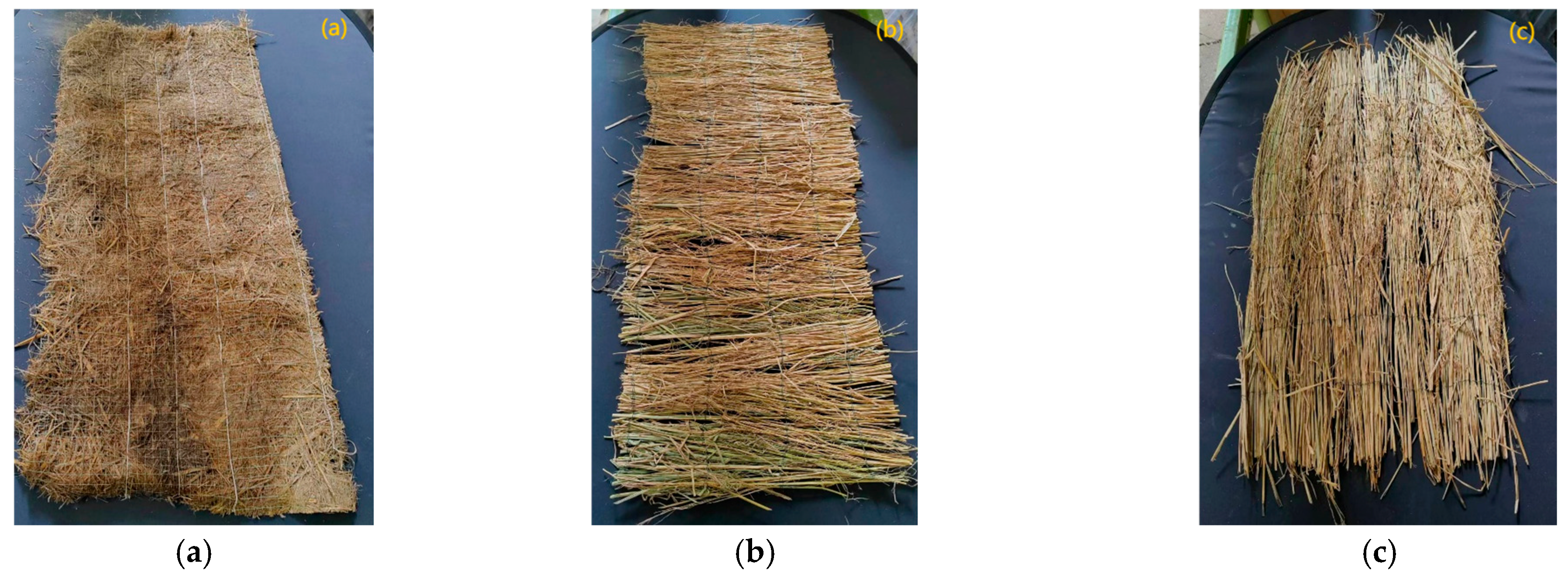

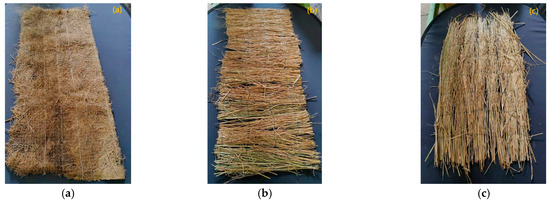

The three straw fiber curtains used in the experiment are A-type straw fiber curtain, B-type transverse straw fiber curtain, and B-type vertical straw fiber curtain, as shown in Figure 6. Among them, the A-type straw fiber curtain is well-made, and the production process mainly involves the processing of straw using rice, wheat, and other crops into strip fibers, weaving them into blankets after combination, and then consolidating them with upper and lower layers of reinforced nets, thus forming a whole plant fiber blanket. The B-type horizontal straw fiber curtain and the B-type vertical straw fiber curtain are simple to make, mainly by simply pruning and arranging straw from rice, wheat, and other crops, and then binding and fixing with string, thus forming a simple plant fiber blanket.

Figure 6.

Actual drawings of three kinds of straw fiber curtains. (a) A-type straw fiber curtain. (b) B-type transverse straw fiber curtain. (c) B-type vertical straw fiber curtain.

The average sizes of the three straw fiber curtains used in the test are shown in Table 3. The curtain length (105 cm) corresponds to the actual surface length of the compacted slope to ensure full coverage and anchoring at both the upper and lower ends. The width was set to 48 cm, matching the internal width of the model box after accounting for the 1 cm thickness of each steel sidewall (total 2 cm), allowing the curtain to be neatly installed without folding or deformation at the edges.

Table 3.

Physical configuration of straw fiber curtains.

2.3. Model Test Flow

(1) Soil preparation and compaction: The test soil was adjusted to optimum water content and left to stand for 24 h to ensure homogeneity. The compaction degree was set to 0.8, and the slope was constructed in three compacted layers, each 5 cm thick, to ensure uniformity and stability.

(2) Rainfall simulation and sampling schedule: Rainfall intensities were set at 20 mm/h, 40 mm/h, and 60 mm/h. During each 60 min test, runoff and sediment samples were collected at regular intervals: every 1 min during the first 10 min, every 2 min from 10 to 30 min, and every 3 min from 30 to 60 min. Each sampling period lasted for 10 s.

(3) Sediment and flow velocity measurement: After sampling, runoff containers were allowed to stand for 12 h to allow complete sedimentation of suspended soil particles. The supernatant was removed, and the sediment was dried in an oven for more than 12 h before weighing. Flow velocity was measured using a potassium permanganate tracer method, and a correction coefficient of 0.75 was applied to estimate the average flow velocity due to the overland flow pattern [25]. Each rainfall simulation test was conducted three times under identical conditions, and the average values of the runoff and sediment yield were used for analysis.

(4) Data processing: Runoff rate (mm/min) and sediment yield rate [g/(m2·min)] were calculated as indicators of runoff intensity and erosion intensity, respectively, using the formulas presented in Equations (2) and (3). Equation (4) is used to calculate the overall water retention and sediment reduction capacity of straw fiber curtain. Hydrodynamic parameters are mainly calculated by runoff and sediment yield parameters, as shown in Equations (6)–(8) [25,26].

where the following notations apply:

—runoff yield (mm/min);

—sediment yield (g/(m2·min));

—total mass of muddy water with sediment (g), sampling time: 10 s;

—dry sediment weight (g);

—density of water (g/cm3);

—slope area (mm2);

—rainfall time (min);

—capacity of stagnant water and sediment reduction;

—runoff yield of slope covered with straw fiber curtain (mm/min);

—runoff yield of exposed slope (mm/min);

—sediment yield of slope covered with straw fiber curtain (g/(m2·min));

—sediment yield of bare slope (g/(m2·min)); V—the average flow rate (cm/s);

—width of the sink (cm);

—runoff sampling time (s);

—the runoff viscosity coefficient (cm2/s);

—hydraulic radius (cm), and the average runoff depth

can be approximately replaced by the thin layer flow on the slope;

—hydraulic gradient, which can be approximately replaced by the sine value of the gradient.

3. Results

3.1. Erosion Morphology Analysis of Different Slopes After Rainfall

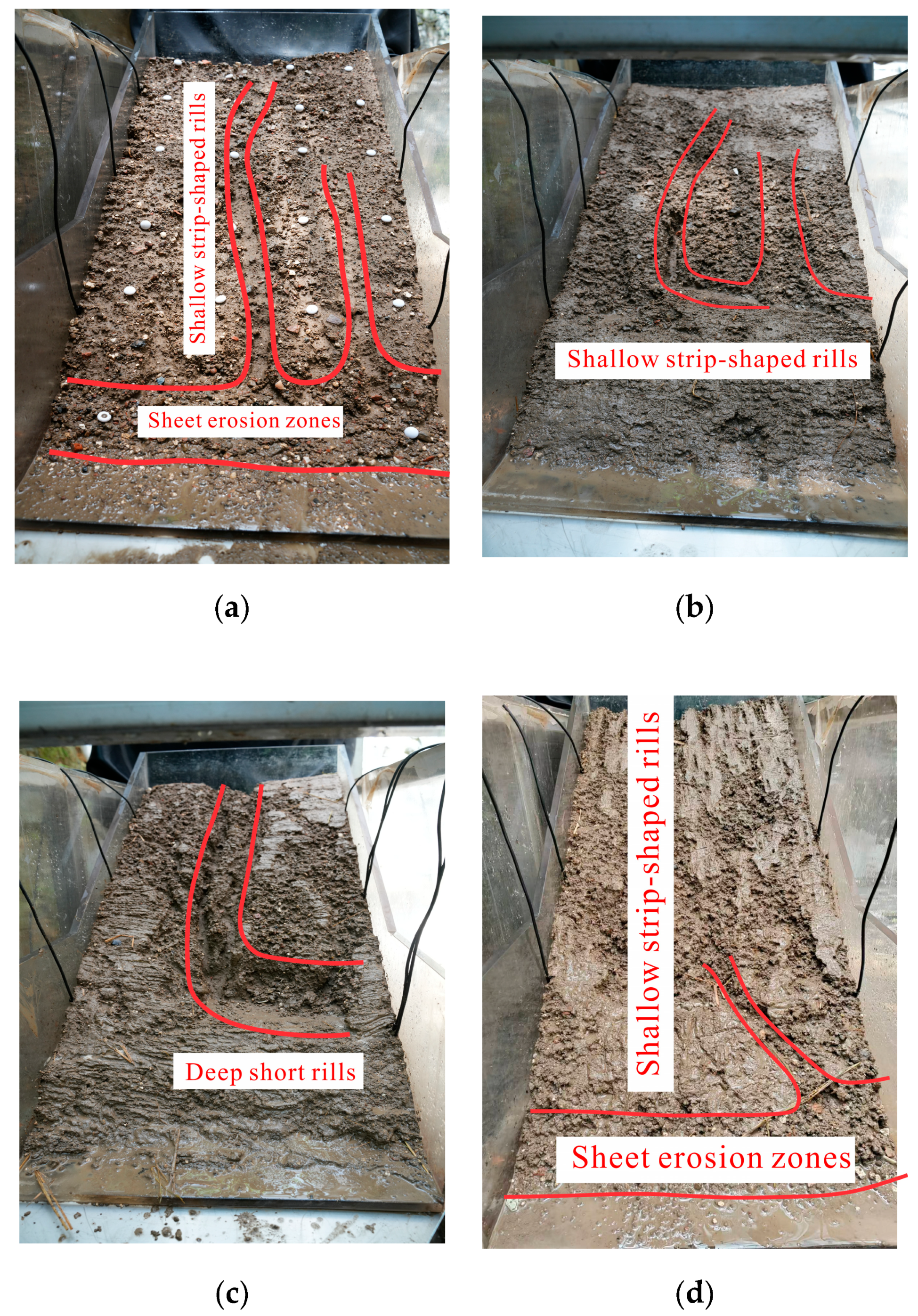

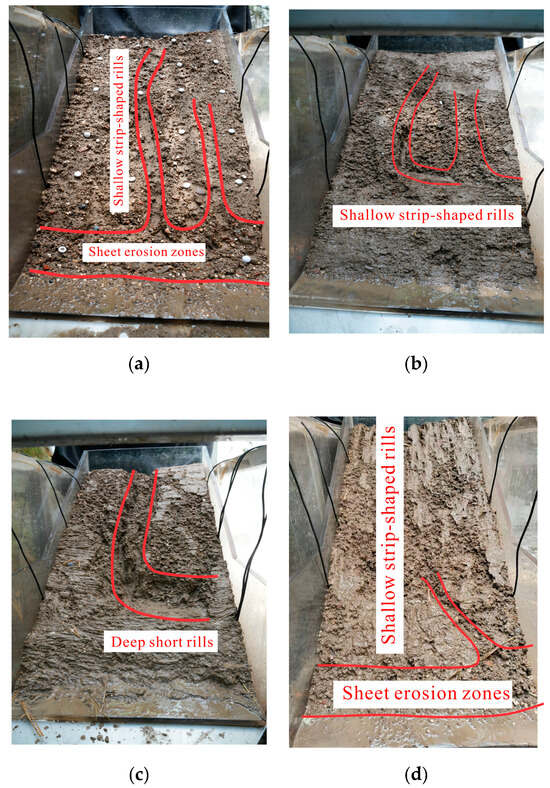

Based on post-rainfall morphological observations, as shown in Figure 7, the erosion patterns were classified into three typical forms: shallow, strip-shaped rills, sheet erosion zones, and deep, short rills. Under the rainfall intensity of 60 mm/h, the exposed slope and the slope protected with the A-type straw fiber curtain predominantly exhibited shallow and elongated rills accompanied by surface sheet erosion. In contrast, the B-type transverse straw fiber curtain-protected slope developed deeper and shorter rills, indicating more intense localized erosion. The slope reinforced with the B-type vertical straw fiber curtain displayed similar erosion morphology to the A-type, with primarily shallow, strip-shaped rills and sheet erosion.

Figure 7.

Pattern of typical slope erosion under 60 mm/h rainfall intensity. (a) Exposed slope. (b) Slope with A-type straw fiber curtain. (c) Slope with B-type transverse curtain. (d) Slope with B-type vertical curtain.

These findings suggest that both the A-type and B-type vertical straw fiber curtain configurations are effective in reducing rill width and depth, thereby attenuating the erosive force of rainfall and suppressing the downward progression of rill development. Although the B-type transverse curtain also demonstrates a certain capacity to mitigate surface erosion, it may facilitate concentrated infiltration and scouring, ultimately leading to the formation of deeper rills.

3.2. Runoff and Sediment Yield Behavior of Straw Fiber Curtains Against Erosion

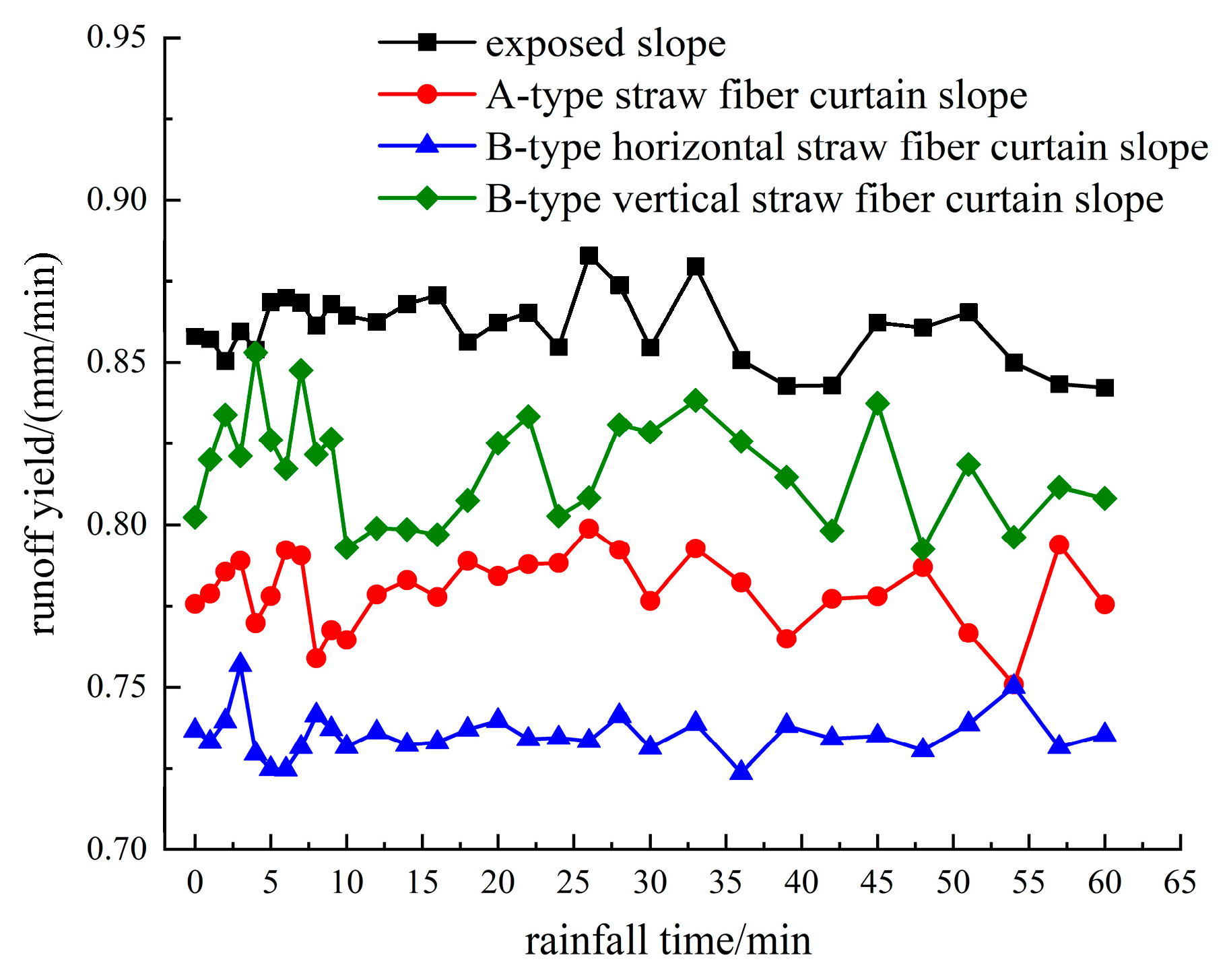

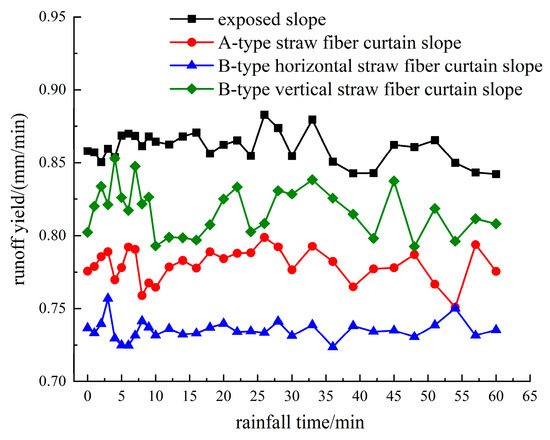

The runoff and sediment yields were similar under each rainfall intensity. This paper takes the experimental results under 60 mm/h rainfall intensity as an example to analyze the anti-erosion characteristics and mechanism of straw fiber curtain. As shown in Figure 8, rainfall time refers to the elapsed duration since the initiation of artificial rainfall. Under the rainfall intensity of 60 mm/h, the runoff rate of the exposed slope and slope covered with A-type and B-type straw fiber curtains is mainly exposed slope > B-type vertical straw fiber curtain slope covering > A-type straw fiber curtain slope covering > B-type horizontal straw fiber curtain slope covering within 0–60 min. The experiments show that A-type and B-type straw fiber curtains have the functions of intercepting rainfall raindrops and slowing down the flow of rainfall raindrops, both of which can reduce slope runoff. Because B-type vertical straw strips are approximately parallel to the flow direction of rainfall raindrops, compared with the other two types of straw fiber curtains, the B-type vertical straw fiber curtain can promote the rapid collection of rainfall raindrops and rainwater flow.

Figure 8.

Analysis of the runoff yield of a slope covered with straw fiber curtain.

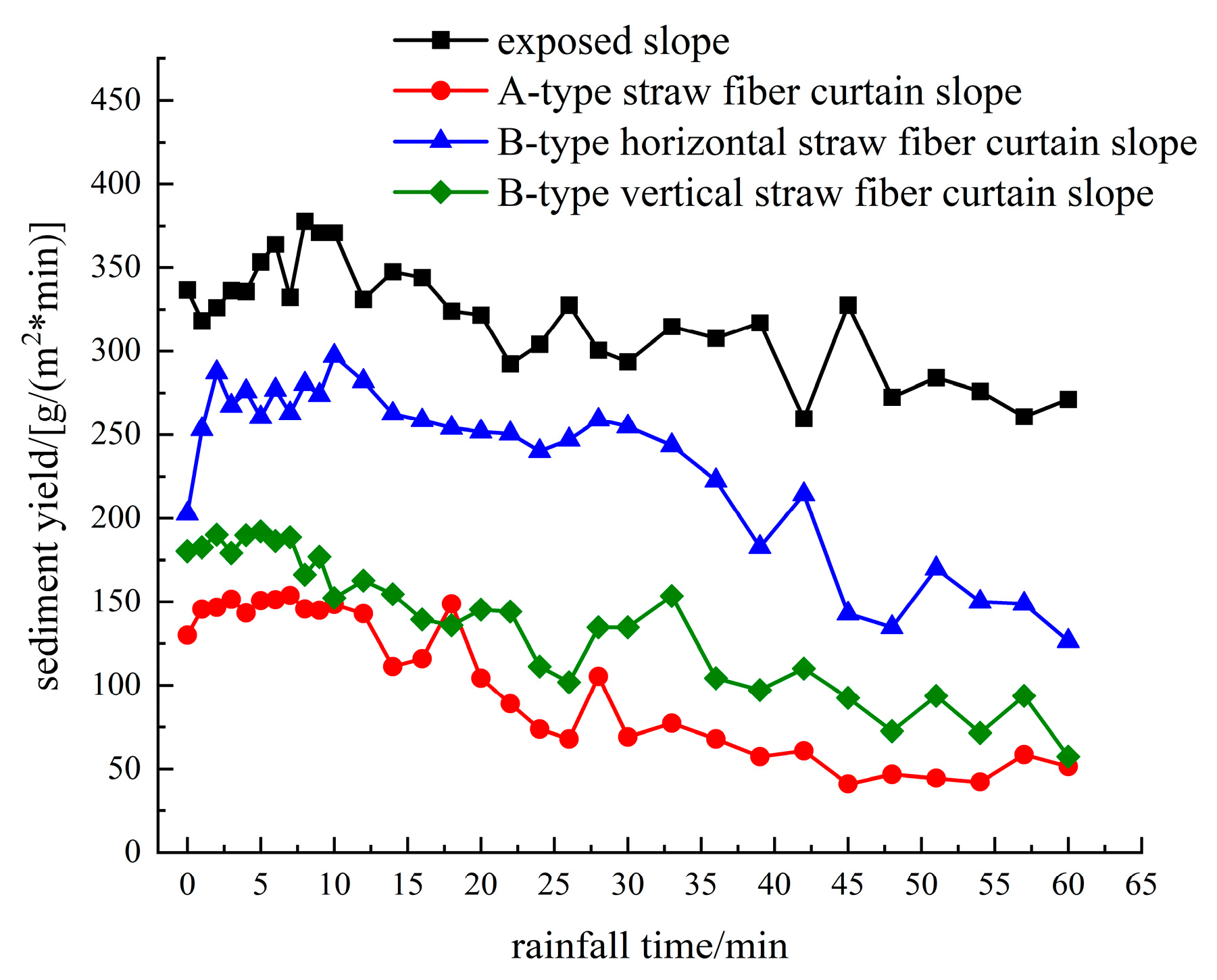

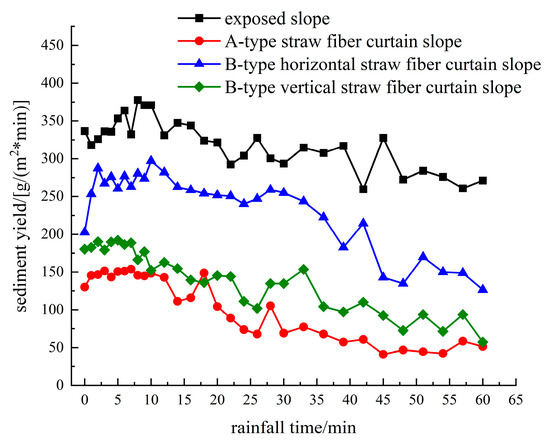

As shown in Figure 9, under 60 mm/h rainfall intensity, the sediment yield and cumulative sediment yield of the bare slope and the slopes covered with A-type and B-type straw fiber curtains show that bare slope > slope covered with B-type transverse straw fiber curtain > slope covered with B-type vertical straw fiber curtain > slope covered with A-type straw fiber curtain within 0–60 min. The experiments show that covering with A-type and B-type straw fiber curtains can effectively reduce rainwater erosion and sediment loss of a slope. Among them, the A-type straw fiber curtain features a compact surface and is well-made, woven from fine strip straw fiber, and has the best effect in reducing slope sediment loss. B-type horizontal and vertical straw fiber curtains are formed by weaving thick straw strips, and there are many pores over the whole slope. The ability to reduce sediment loss of B-type vertical straw fiber curtains is better than that of B-type horizontal straw fiber curtains.

Figure 9.

Analysis of the sediment yield of a slope covered with straw fiber curtain.

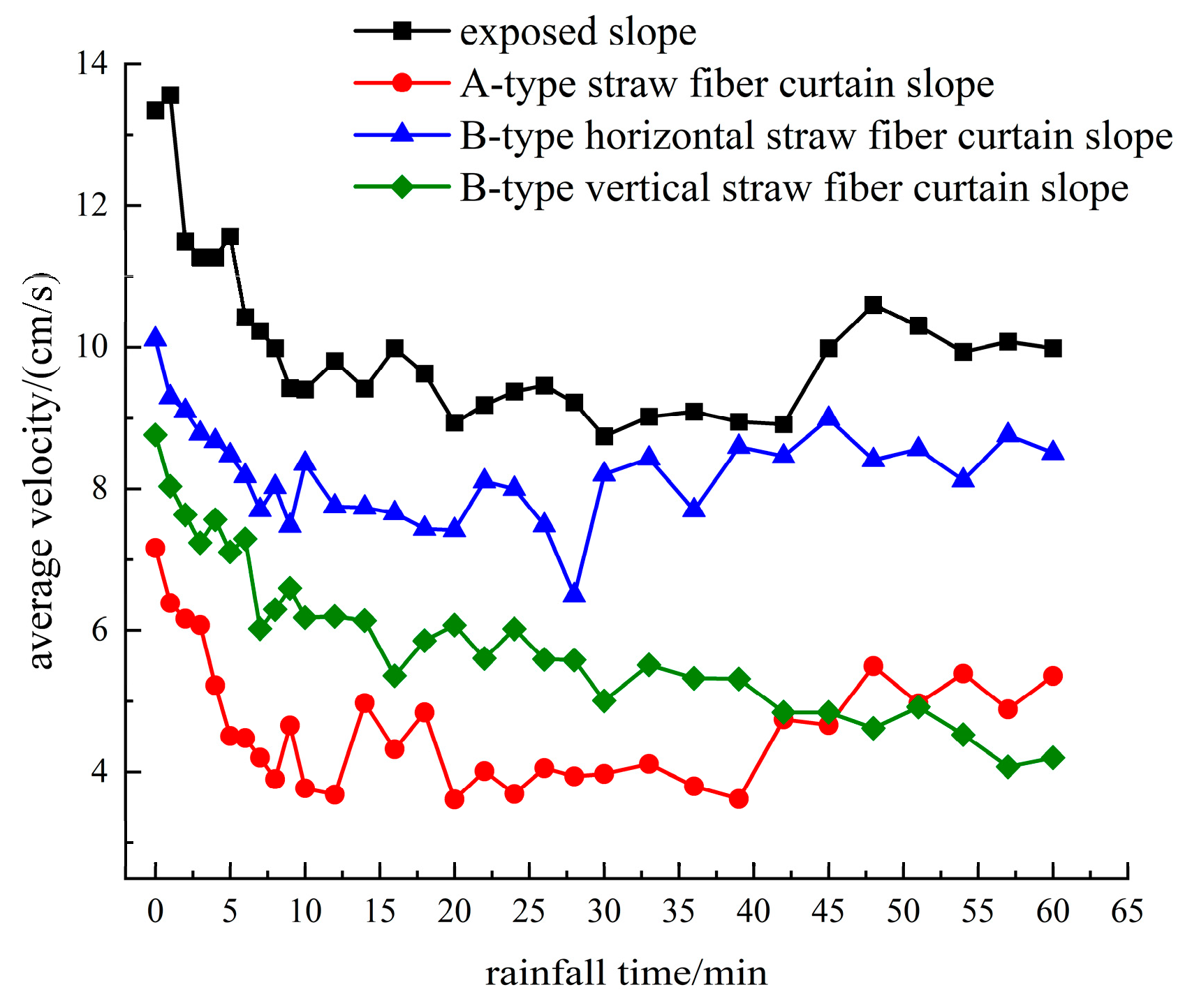

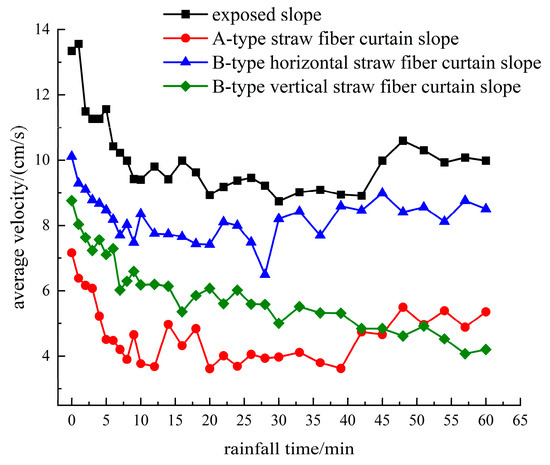

As shown in Figure 10, the average flow velocity of various slopes under 60 mm/h rainfall intensity is mainly exposed slope > B-type transverse straw fiber curtain slope > B-type vertical straw fiber curtain slope > A-type straw fiber curtain slope within 0–60 min, indicating that covering with A-type and B-type straw fiber curtains can change slope surface roughness, intercept rainfall raindrops, slow down rainfall raindrop kinetic energy, and reduce slope fluid flow velocity. Under 60 mm/h rainfall intensity, the average flow velocity of the exposed slope and the slope covered with A-type and B-type transverse straw fiber curtains increased to a certain extent in the later period of rainfall, mainly due to the emergence of a gully, which is beneficial to rainfall flow. This gully is not deep, but parallel to the slope surface, and rainfall easily concentrates in the gully and flows rapidly.

Figure 10.

Average velocity analysis of a slope covered with straw fiber curtain.

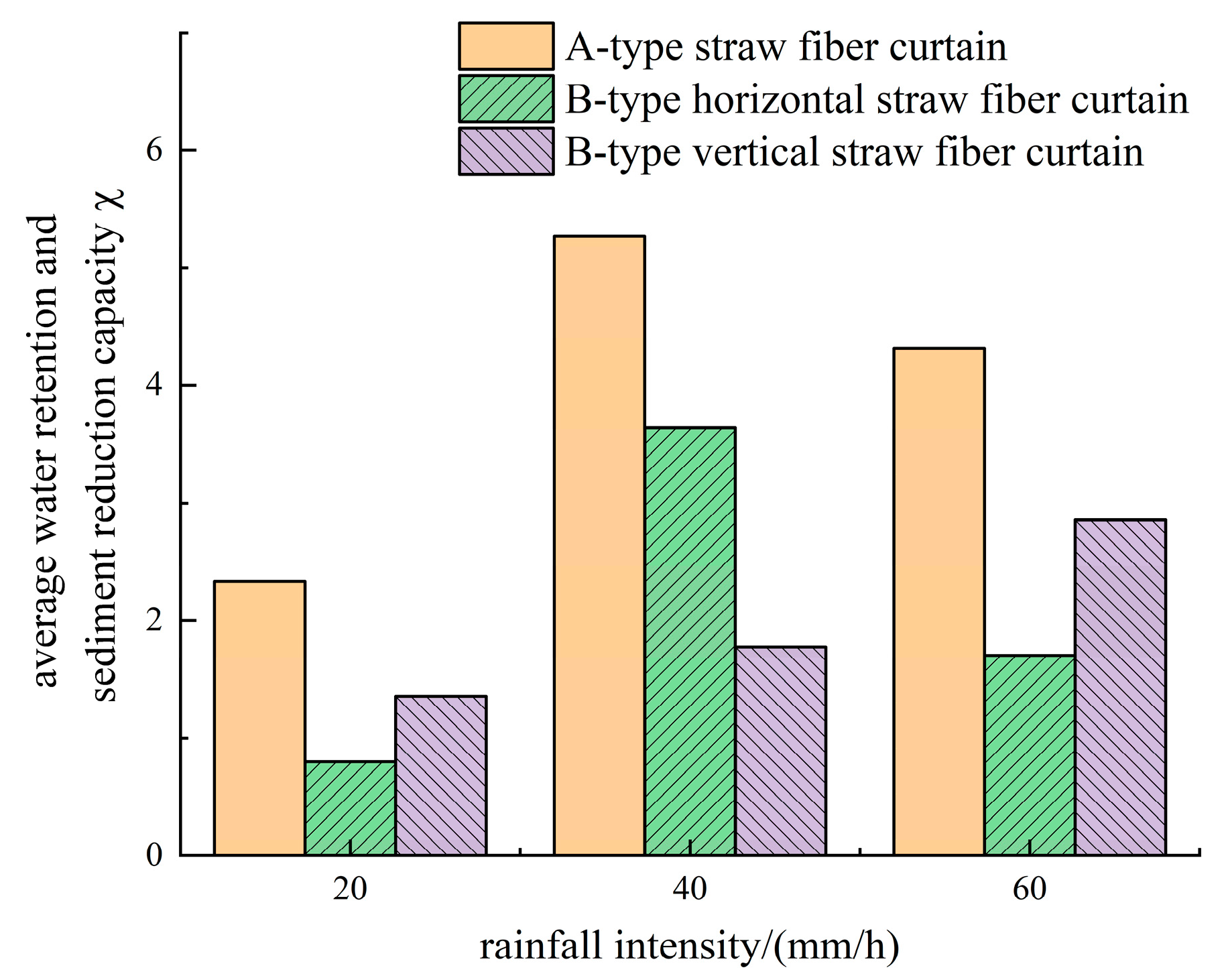

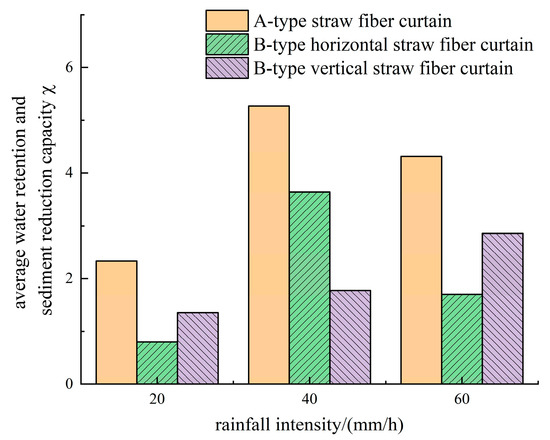

From Figure 11, it can be seen that the average water retention and sediment reduction capacity of A-type and B-type horizontal straw fiber curtains mainly shows a parabola trend with the increase in rainfall intensity under 20, 40 and 60 mm/h rainfall intensity, while the average water retention and sediment reduction capacity of B-type vertical straw fiber curtains gradually increases with the increase in rainfall intensity. Among them, the A-type straw fiber curtain can play a better role in water retention and sediment reduction under different rainfall intensities, but its processing cost is higher than that of the B-type straw fiber curtain, so it is recommended to use it mainly on a low embankment slope. The results of the B-type transverse straw fiber curtain under 20 mm/h rainfall intensity are close to 4 under 40 mm/h rainfall intensity and close to 1 under 60 mm/h rainfall intensity, which shows that the overall anti-erosion ability of the B-type transverse straw fiber curtain fluctuates greatly with rainfall intensity and is not suitable for large-scale use. The B-type vertical straw fiber curtain’s performance in reducing stagnant water and sediment under different rainfall intensities is average, but its overall performance is relatively stable. As rainfall intensity increases, the stagnant water and sediment reduction capacity also increases, making it a suitable option for high embankment areas.

Figure 11.

Analysis of the relationship between average water retention and sediment reduction capacity of straw fiber curtains and rainfall intensity.

3.3. Variation of Hydrodynamic Parameters

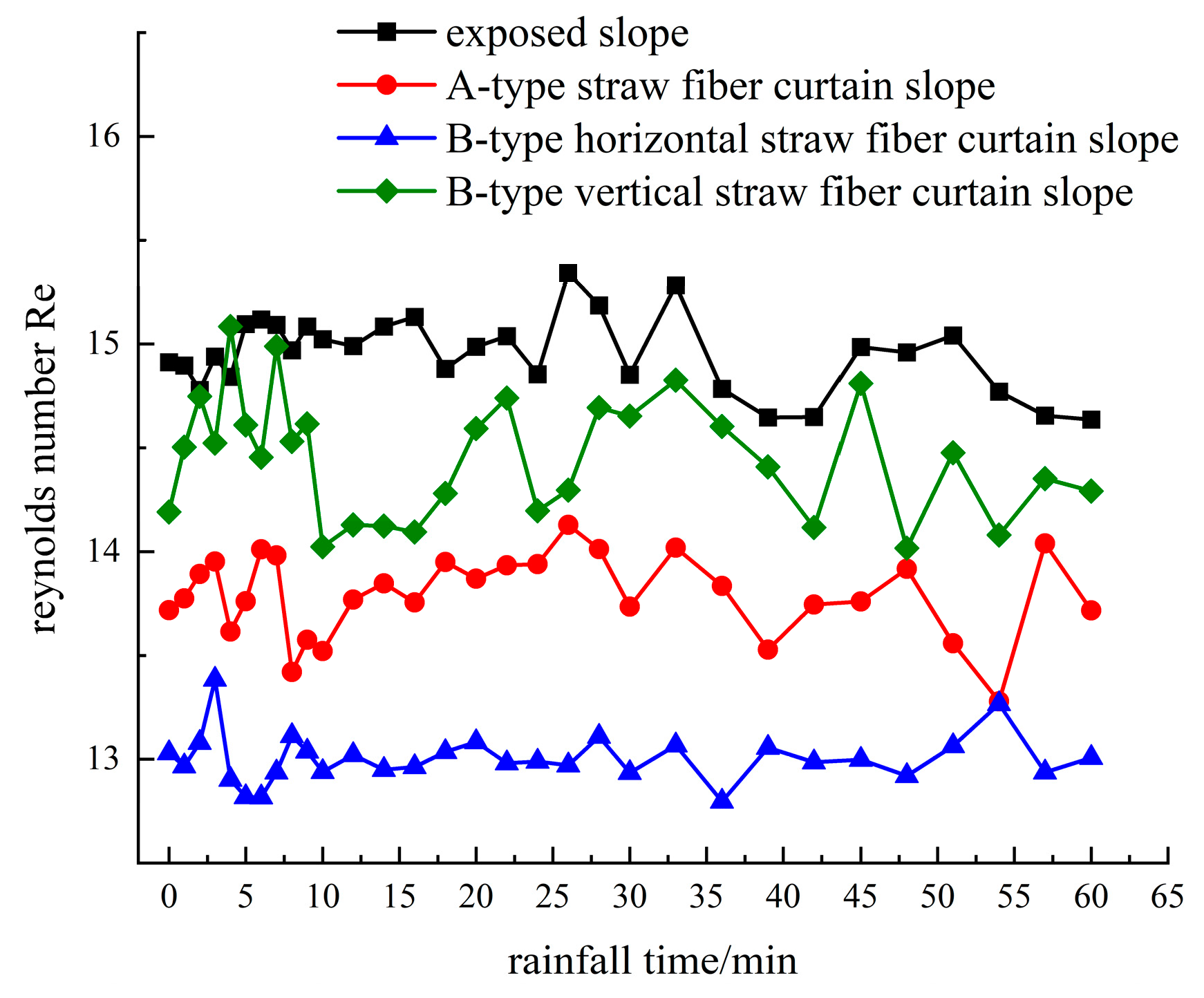

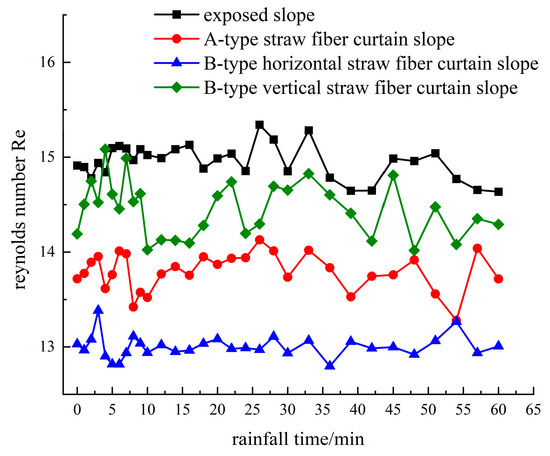

From Figure 12, under 60 mm/h rainfall intensity, the Reynolds numbers of exposed slopes and slopes covered with A-type and B-type straw fiber curtains are mainly in the order of bare slopes > slopes covered with B-type vertical straw fiber curtain > slopes covered with A-type straw fiber curtain > slopes covered with B-type transverse straw fiber curtain within 0–60 min. The Reynolds numbers of the three types of slopes fluctuate mainly in the range of 13–15, which is basically consistent with the variation of runoff yield. The Reynolds number of the three types of slopes under 60 mm/h rainfall intensity is small, and the rainwater flow is mainly laminar flow. With an increase in rainfall time, the Reynolds number of slopes covered with A-type and B-type straw fiber curtains is relatively stable, from which it can be concluded that both A-type and B-type straw fiber curtains effectively play a role in stagnating flow and reducing sediment during a rainfall period under 60 mm/h rainfall intensity.

Figure 12.

Reynolds number analysis.

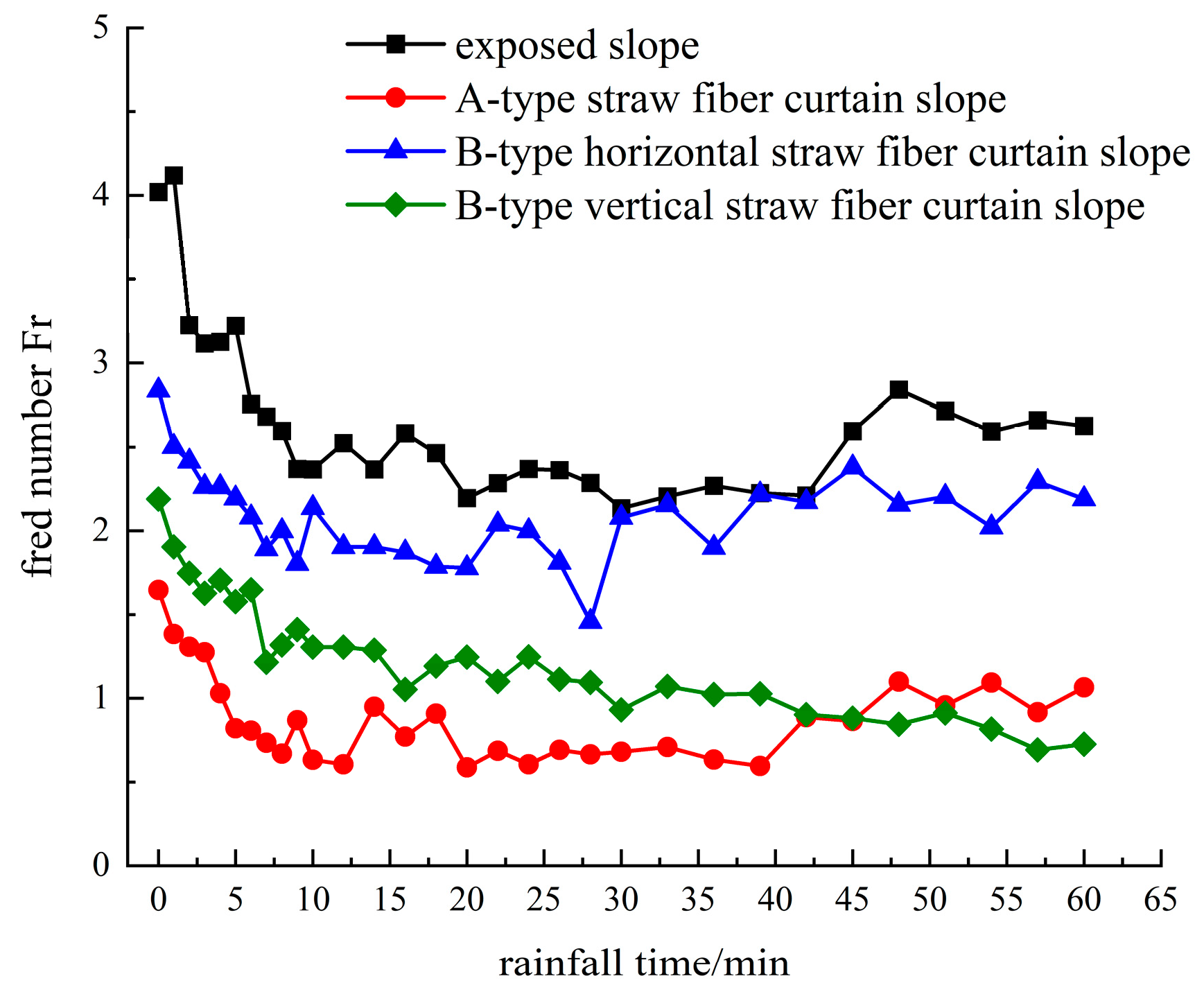

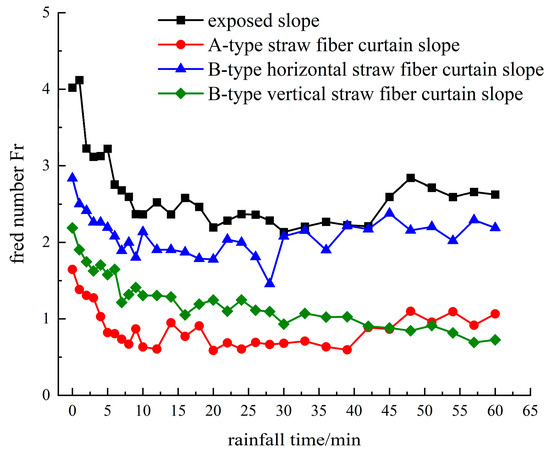

As shown in Figure 13, under 60 mm/h rainfall intensity, the Fred number Fr of A-type is greater than 1 in 0–5 min, less than 1 in 5–45 min, and greater than 1 in 45–60 min, showing the change trend of slow jet stream and flow jet stream. The experiment shows that the slope covered with A-type straw fiber curtain can effectively intercept and collect raindrops under 60 mm/h rainfall intensity, but with the increase in rainfall time, the slope is eroded and has a gully, which is beneficial to rainwater flow to a certain extent, leading to an increase in the average velocity and Fred number in the later period of rainfall. Under 60 mm/h rainfall intensity, the Fred number Fr for the B-type transverse direction curtain is greater than 1 in 0–60 min, which is dominated by a jet stream, and the Fred number decreases at first and then increases. The experiments show that the ability to reduce kinetic energy and the velocity of raindrops by using the B-type transverse straw fiber curtain is less than that of the A-type and B-type vertical straw fiber curtains. Under the rainfall intensity of 60 mm/h, the Fred number Fr of B-type vertical curtain cover is greater than 1 in 0–45 min (mainly jet stream) and less than 1 in 45–60 min (mainly slow stream). The experiments show that the slope covered with the B-type vertical straw fiber curtain has no obvious ability to reduce the kinetic energy and velocity of raindrops before and during the middle period of rainfall, but after an increase in rainfall time and the appearance of a slope gully (caused by rainfall erosion), the B-type vertical straw fiber curtain can still play a better role in reducing the kinetic energy and velocity of raindrops.

Figure 13.

Fred number analysis.

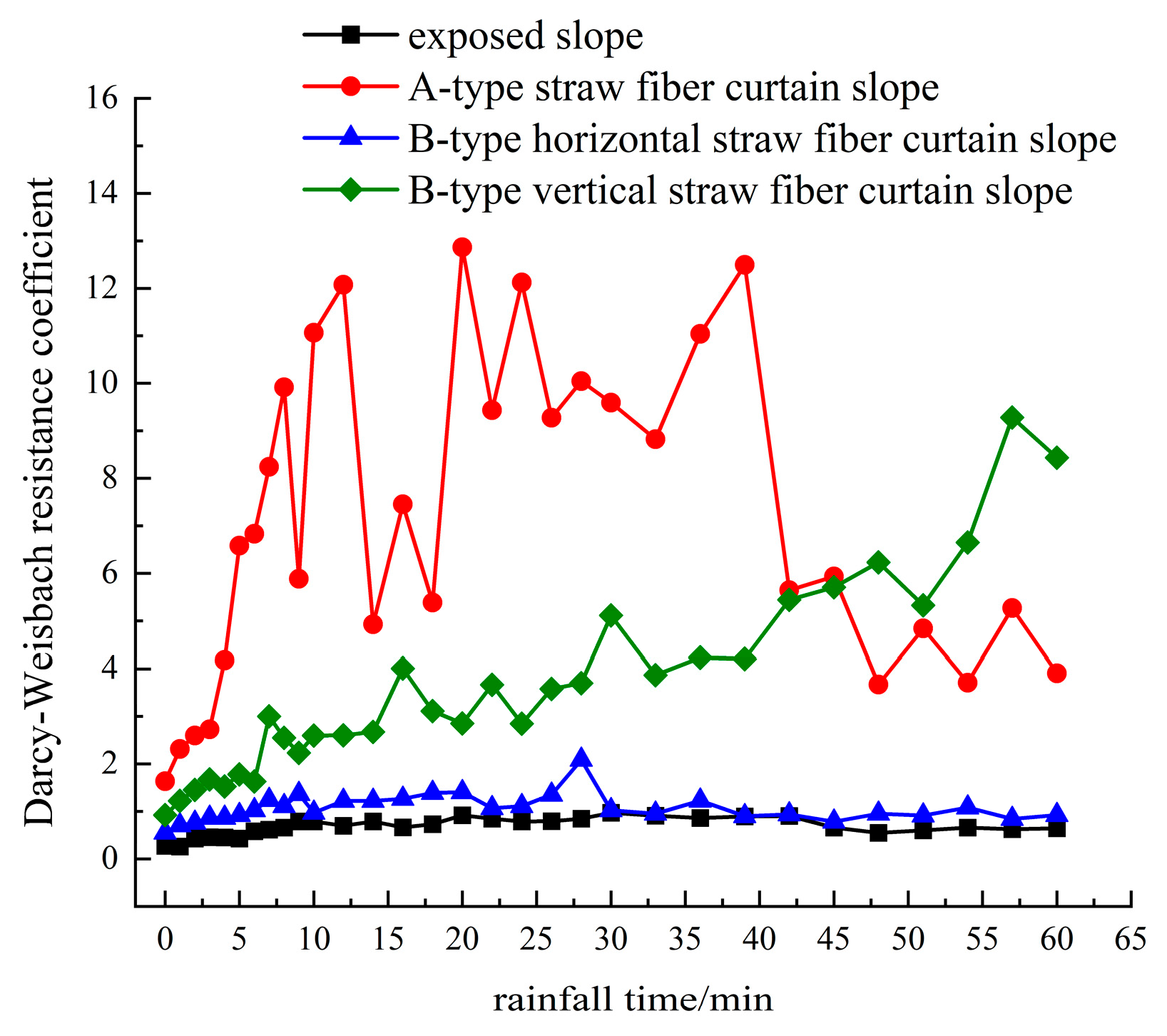

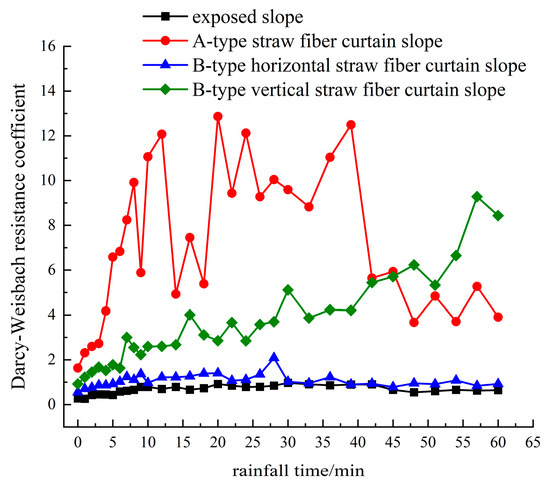

As shown in Figure 14, under 60 mm/h rainfall intensity, the Darcy-Weisbach resistance coefficients of the bare slope and the slope covered with the A-type and B-type straw fiber curtains are mainly in the order of A-type straw fiber curtain slope covering > B-type vertical straw fiber curtain slope covering > B-type transverse straw fiber curtain slope covering > bare slope over 0–60 min. The experiment shows that the A-type and B-type vertical straw fiber curtains have a greater interception effect on rainwater flow under a 60 mm/h rainfall intensity, while the B-type transverse straw fiber curtain has a lesser interception effect on rainwater flow.

Figure 14.

Darcy-Weisbach resistance coefficient analysis.

The Darcy-Weisbach resistance coefficient of the slope covered with the A-type straw fiber curtain increases at first and then decreases, indicating that the blocking effect of the A-type vertical straw fiber curtain on water flow gradually increases in the early stage of rainfall, and the flow pattern changes from rapid flow to slow flow. However, due to the appearance of a gully (caused by rainfall erosion), which is beneficial to rainwater flow, the Darcy-Weisbach resistance coefficient of the slope covered with the A-type straw fiber curtain decreases within 40–60 min. The Darcy-Weisbach resistance coefficient of the slope covered with the B-type vertical straw fiber curtain increases gradually, indicating that the obstruction effect of the B-type vertical straw fiber curtain on water flow increases gradually with an increase in rainfall time, and there is no gully beneficial to rainwater flow created by the B-type vertical straw fiber curtain, where the function of reducing kinetic energy and the velocity of raindrops is better in the later period. The Darcy-Weisbach resistance coefficient of the slope covered with the B-type transverse straw fiber curtain is small overall. This shows that the B-type transverse straw fiber curtain has a general blocking effect on water flow.

4. Discussion

Despite the effectiveness of straw fiber curtains in controlling slope erosion under simulated rainfall, several limitations must be acknowledged. The small-scale model box used in the laboratory setting cannot fully replicate the complex hydrological and geomorphological conditions found in natural slopes. Consequently, extrapolating the findings to field conditions should be approached with caution. Additionally, the experiment was conducted using a specific soil type sourced from a highway construction site in Jiangsu Province, which limits the applicability of the results to other soil textures or climatic regions.

Furthermore, the long-term durability and biodegradation performance of the straw fiber curtains were not assessed, and repeated rainfall events or seasonal variations could affect their effectiveness in real-world applications. While the A-type curtain exhibited superior erosion resistance, especially under lower rainfall intensities, its cost and construction complexity were not quantitatively analyzed. A formal economic evaluation would provide more practical value for infrastructure planning and material selection.

In terms of ecological considerations, this study focused primarily on hydrological indicators such as runoff rate and sediment yield, without examining the potential interactions between straw fiber curtains and vegetation regrowth, soil microbial activity, or habitat compatibility. Future research should address these ecological dimensions to support long-term sustainability.

Nevertheless, the study demonstrates several strengths. It provides a comparative evaluation of three structural types of straw fiber curtains under varying rainfall intensities (20, 40, and 60 mm/h) and offers hydrodynamic insights using parameters such as the Reynolds number, Fred number, and the Darcy-Weisbach coefficient. These findings can inform practical recommendations—for instance, using A-type curtains for low slopes where sediment control is critical, and adopting B-type vertical curtains on high embankments.

5. Conclusions

Through experiments on the erosion resistance of slopes covered with A-type, B-type (transverse), and B-type (vertical) straw fiber curtains, the behavior of runoff and sediment yield and hydrodynamic parameters of a roadbed slope covered with straw fiber curtains is explored in this paper, and the erosion resistance characteristics and construction application of straw fiber curtains are summarized and analyzed. The main conclusions are as follows:

- (1).

- The A-type straw fiber curtain, woven with fine and uniformly distributed straw strips, exhibited the highest effectiveness in reducing sediment yield and runoff, particularly under low to moderate rainfall intensities (20–40 mm/h). The B-type curtains, constructed with coarser straw strips, showed moderate erosion control performance. Among them, the B-type vertical curtain generally outperformed the transverse configuration, possibly due to its alignment with the slope flow direction, which helped reduce localized scouring and maintain relatively stable runoff conditions.

- (2).

- All straw fiber curtain configurations contributed to reduced surface flow velocity and transformed rainfall-induced flow from rapid to slower laminar flow. This was reflected in the increase in the Darcy-Weisbach resistance coefficients across all rainfall intensities. The A-type curtain showed the highest increase in resistance, followed by the B-type vertical curtain, indicating a strong ability to dissipate flow energy and stabilize surface runoff.

- (3).

- Curtain layout and structure played a key role in rill formation and sediment control. The A-type and B-type vertical curtains reduced rill depth and width, inhibiting the vertical development of erosion, whereas the B-type transverse curtain was prone to inducing concentrated flow paths that formed deeper rills.

- (4).

- From an application perspective, A-type curtains are recommended for low embankments where sediment control is critical, despite their higher manufacturing cost. B-type vertical curtains, with their stable performance across all rainfall intensities and simpler fabrication, are more suitable for high embankments and large-scale use in infrastructure projects.

- (5).

- The experiment was conducted in a small-scale laboratory model box under controlled conditions. While it provides valuable mechanistic insights, field-scale variability and long-term effects were not addressed and require further investigation.

Author Contributions

Investigation, Y.L.; Resources, F.X.; Writing – original draft, X.Z.; Writing–review & editing, R.N. and C.Z.; Supervision, L.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by China Construction Infrastructure Co., Ltd., grant number CSCIC-2023-KT-(02).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

Author Xiangyong Zhong, Feng Xu, Yang Li, and Long Zhang were employed by the China Construction Infrastructure Co. Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Katdare, R.C.; Shingarey, S.A. Paddy straw as natural geogrids for soil reinforcement and erosion control. In Proceedings of the Indian Geotechnical Conference, Kochi, India, 15–17 December 2011. [Google Scholar]

- Javellonar, R.P.; Taylan, V.T.; Agulto, I.C.; Aguinaldo, T.G.; Sicat, E.V.; Gavino, H.F. Rice Straw Geotextile As Ground Cover For Soil Erosion Mitigation. J. Energy Policy 2013, 3, 195–204. [Google Scholar]

- Donjadee, S.; Tingsanchali, T. Soil and water conservation on steep slopes by mulching using rice straw and vetiver grass clippings. Agric. Nat. Resour. 2016, 50, 75–79. [Google Scholar] [CrossRef]

- Yang, J.H.; Liu, H.Q.; Zhang, J.P.; Rahma, A.E.; Lei, T.W. Lab simulation of soil erosion on cultivated soil slopes with wheat straw incorporation. CATENA 2022, 210, 105865. [Google Scholar] [CrossRef]

- Wang, C.; Ma, J.; Wang, Y.; Li, Z.; Ma, B. The influence of wheat straw mulching and straw length on infiltration, runoff and soil loss. Hydrol. Process. 2022, 36, e14561. [Google Scholar] [CrossRef]

- Won, C.H.; Choi, Y.H.; Shin, M.H.; Lim, K.J.; Choi, J.D. Effects of rice straw mats on runoff and sediment discharge in a laboratory rainfall simulation. Geoderma 2012, 189, 164–169. [Google Scholar] [CrossRef]

- Dalir, P.; Naghdi, R.; Gholami, V. Assessing the rice straw effects on the soil erosion rate in forest road cut slope embankments. Casp. J. Environ. Sci. 2021, 19, 325–339. [Google Scholar]

- Parhizkar, M.; Shabanpour, M.; Lucas-Borja, M.E.; Zema, D.A.; Li, S.; Tanaka, N.; Cerdà, A. Effects of length and application rate of rice straw mulch on surface runoff and soil loss under laboratory simulated rainfall. Int. J. Sediment Res. 2021, 36, 468–478. [Google Scholar] [CrossRef]

- Abrantes, J.R.; Prats, S.A.; Keizer, J.J.; de Lima, J.L. Effectiveness of the application of rice straw mulching strips in reducing runoff and soil loss: Laboratory soil flume experiments under simulated rainfall. Soil Tillage Res. 2018, 180, 238–249. [Google Scholar] [CrossRef]

- Rahma, A.E.; Wang, W.; Tang, Z.; Lei, T.; Warrington, D.N.; Zhao, J. Straw mulch can induce greater soil losses from loess slopes than no mulch under extreme rainfall conditions. Agric. For. Meteorol. 2017, 232, 141–151. [Google Scholar] [CrossRef]

- Li, T.; Li, S.; Liang, C. The immediate effects of downslope cornstalk mulch (DCM) on sediment yield, runoff and runoff-associated dissolved carbon loss in a representative hillslope, Southwestern China. CATENA 2019, 175, 9–17. [Google Scholar] [CrossRef]

- Ma, Z.; Li, Y.; Xu, L. Discrete-element method simulation of agricultural particles’ motion in variable-amplitude screen box. Comput. Electron. Agric. 2015, 118, 92–99. [Google Scholar] [CrossRef]

- Lenaerts, B.; Aertsen, T.; Tijskens, E.; De Ketelaere, B.; Ramon, H.; De Baerdemaeker, J.; Saeys, W. Simulation of grain–straw separation by Discrete Element Modeling with bendable straw particles. Comput. Electron. Agric. 2014, 101, 24–33. [Google Scholar] [CrossRef]

- Leblicq, T.; Smeets, B.; Vanmaercke, S.; Ramon, H.; Saeys, W. A discrete element approach for modelling bendable crop stems. Comput. Electron. Agric. 2016, 124, 141–149. [Google Scholar] [CrossRef]

- Leblicq, T.; Smeets, B.; Ramon, H.; Saeys, W. A discrete element approach for modelling the compression of crop stems. Comput. Electron. Agric. 2016, 123, 80–88. [Google Scholar] [CrossRef]

- Korn, C.; Herlitzius, T. Coupled CFD-DEM simulation of separation process in combine harvester cleaning devices. Landtechnik 2017, 72, 247–261. [Google Scholar]

- Jia, H.; Deng, J.; Deng, Y.; Chen, T.; Wang, G.; Sun, Z.; Guo, H. Contact parameter analysis and calibration in discrete element simulation of rice straw. Int. J. Agric. Biol. Eng. 2021, 14, 72–81. [Google Scholar] [CrossRef]

- Zeng, Z.; Chen, Y. Simulation of straw movement by discrete element modelling of straw-sweep-soil interaction. Biosyst. Eng. 2019, 180, 25–35. [Google Scholar] [CrossRef]

- Zhang, J.; Nie, R.; Tan, Y.; Li, Y.; Li, L. Modeling of flexible coupling boundary combing discrete element method with finite difference method for drained/undrained triaxial test. Powder Technol. 2023, 427, 118680. [Google Scholar] [CrossRef]

- Zhang, J.; Nie, R.; Tan, Y.; Huang, M.; Li, Y.; Guo, Y. Investigation of the parallel gradation method based on response of ballast penetration into subgrade soil by discrete element method. Comput. Part. Mech. 2024, 12, 245–260. [Google Scholar] [CrossRef]

- Zhang, J.; Nie, R.S.; Huang, M.T.; Tan, Y.C.; Li, Y.F. Analysis of ballast penetration phenomenon in ballast track under dynamic loads: Experimental testing and DEM modeling. Rock Soil Mech. 2024, 45, 1720–1730. [Google Scholar] [CrossRef]

- Mao, H.; Wang, Q.; Li, Q. Modelling and simulation of the straw-grain separation process based on a discrete element model with flexible hollow cylindrical bonds. Comput. Electron. Agric. 2020, 170, 105229. [Google Scholar] [CrossRef]

- Wang, K.X.; Fu, Q.; Wang, Z.B.; Wu, Q. Simulation and verification of two-dimensional numerical simulation model of soil water infiltration under straw mulch. In Proceedings of the 2011 International Conference on New Technology of Agricultural, Zibo, China, 27–29 May 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 399–403. [Google Scholar]

- GB/T 50085-2007; Technical Code for Sprinkler Engineering. China Planning Press: Beijing, China, 2007.

- Micić Ponjiger, T.; Lukić, T.; Basarin, B.; Jokić, M.; Wilby, R.L.; Pavić, D.; Mesaroš, M.; Valjarević, A.; Milanović, M.M.; Morar, C. Detailed analysis of spatial–temporal variability of rainfall erosivity and erosivity density in the central and southern Pannonian basin. Sustainability 2021, 13, 13355. [Google Scholar] [CrossRef]

- Zuo, F.L.; Zhong, S.Q.; Ran, Z.L.; Wei, C.F. Characteristics of sediment and hydrodynamic parameters of new reconstructed slope soil in the hill area with purple soils. J. Soil Water Conserv. 2018, 32, 59–66. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).