Study on the Shear Strength and Durability of Ionic Soil Stabilizer-Modified Soft Soil in Acid Alkali Environments

Abstract

1. Introduction

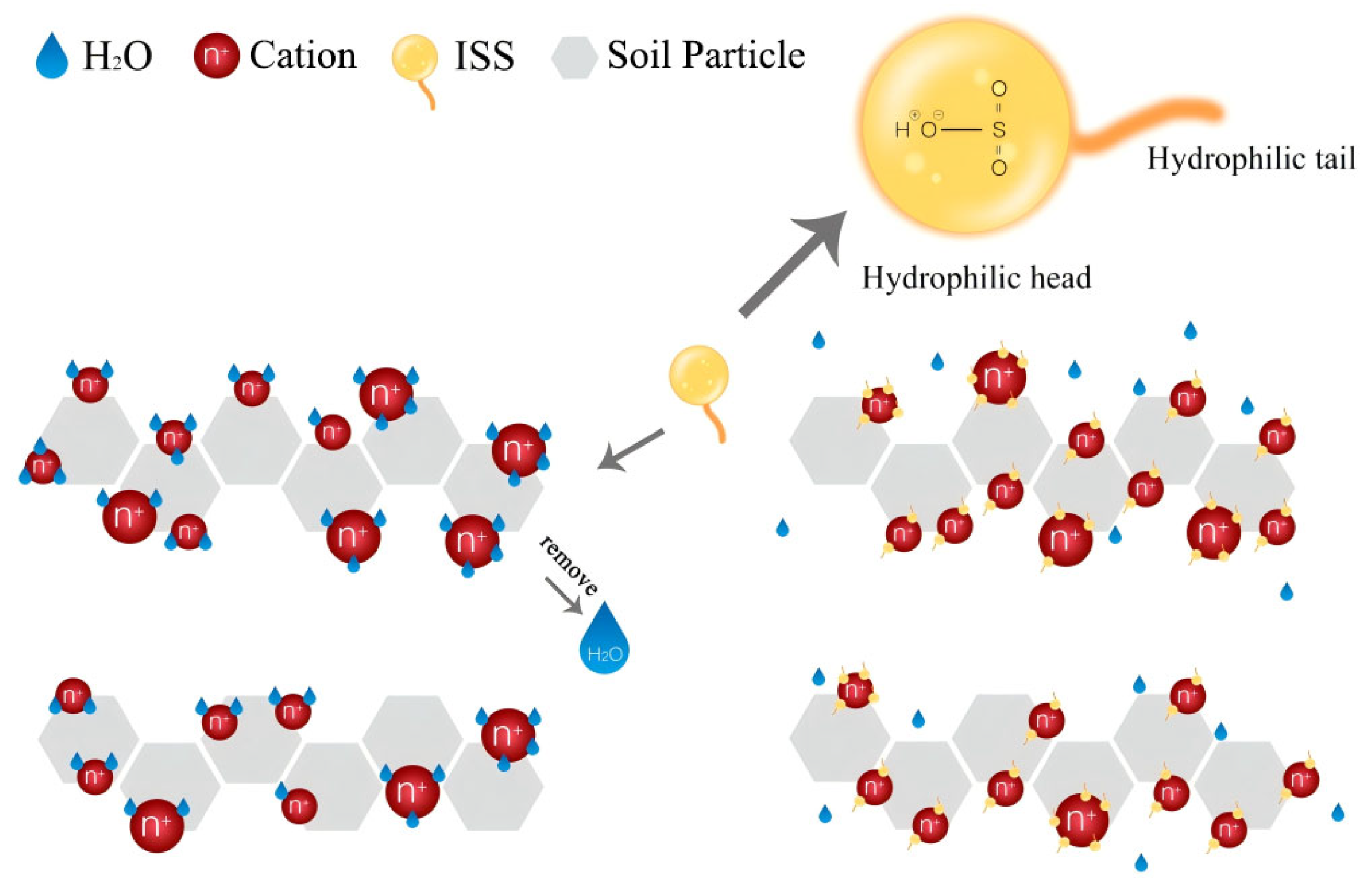

2. Materials and Methods

2.1. Test Material

2.2. Experimental Content and Methods

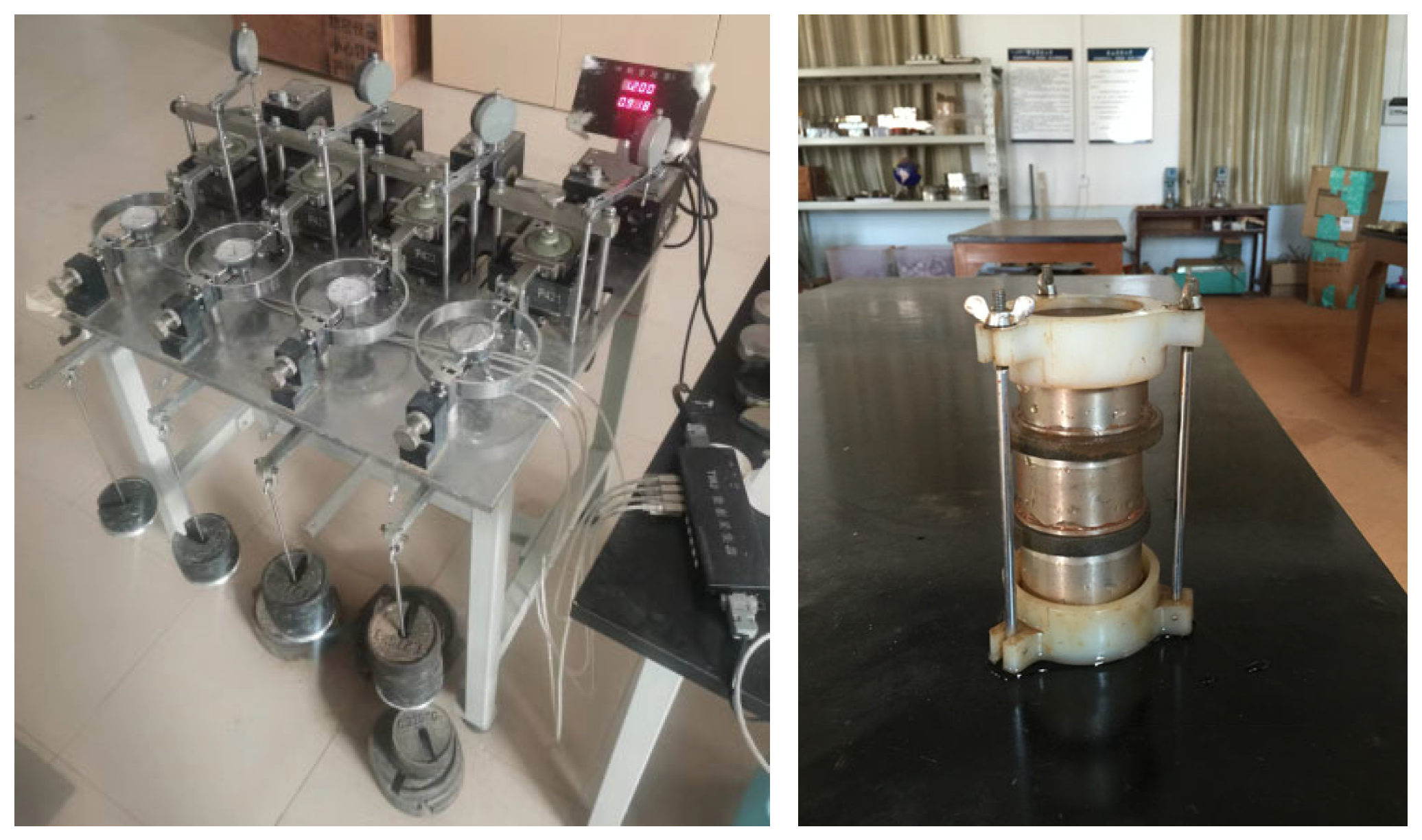

2.2.1. Direct Shear Test

2.2.2. Permeability Test

2.2.3. Direct Shear Test Under Acid–Alkali Wetting–Drying Cycles

3. Results and Discussion

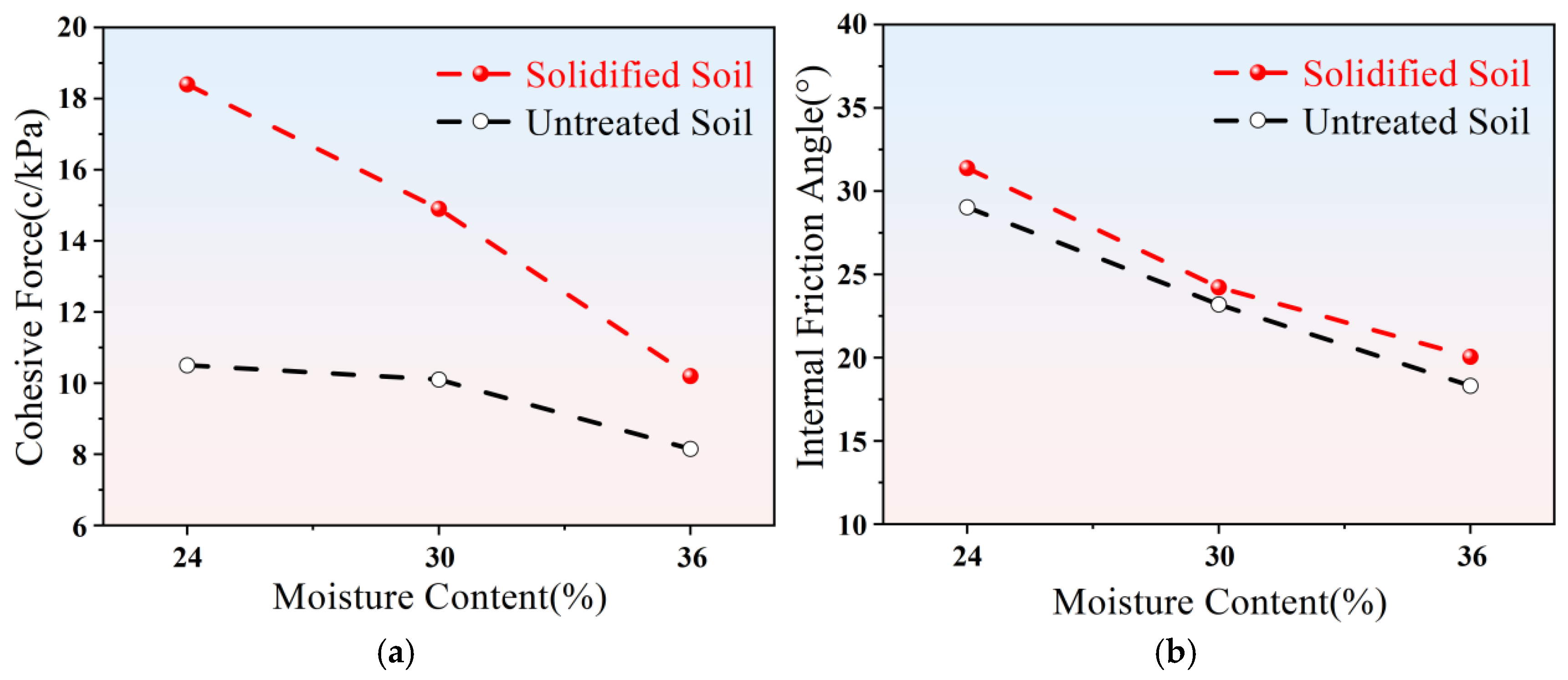

3.1. Effect of Moisture Content on Strength of Solidified Soft Soil

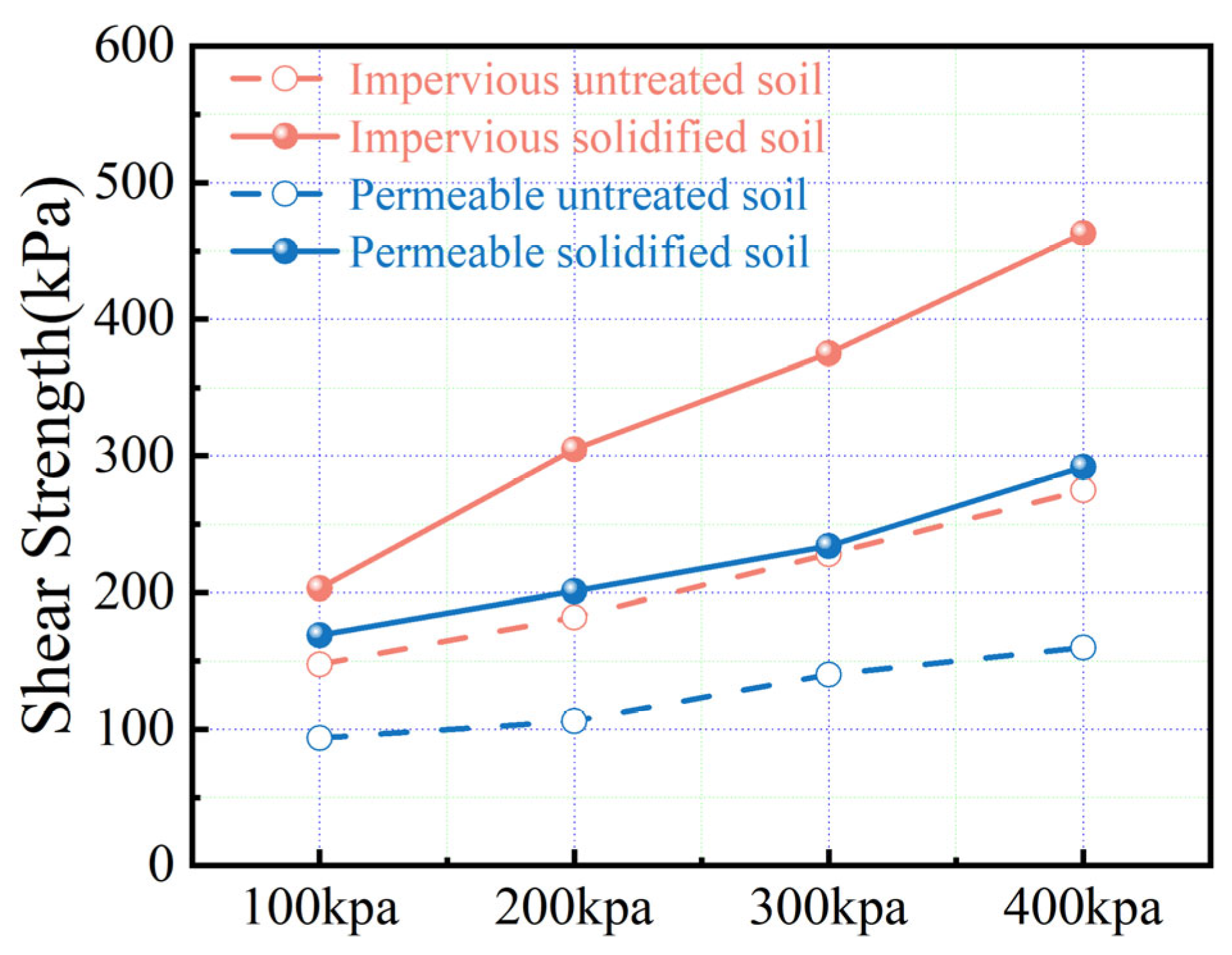

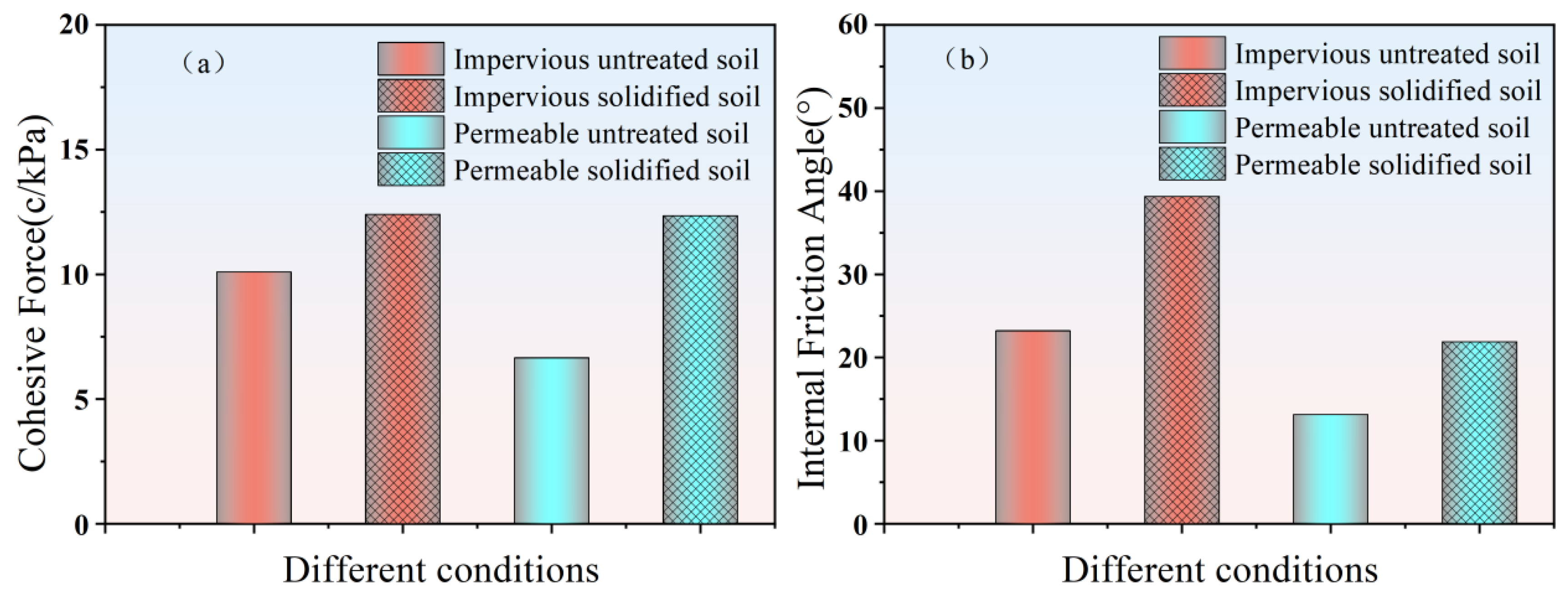

3.2. Effect of Permeability on Strength of Solidified Soft Soil

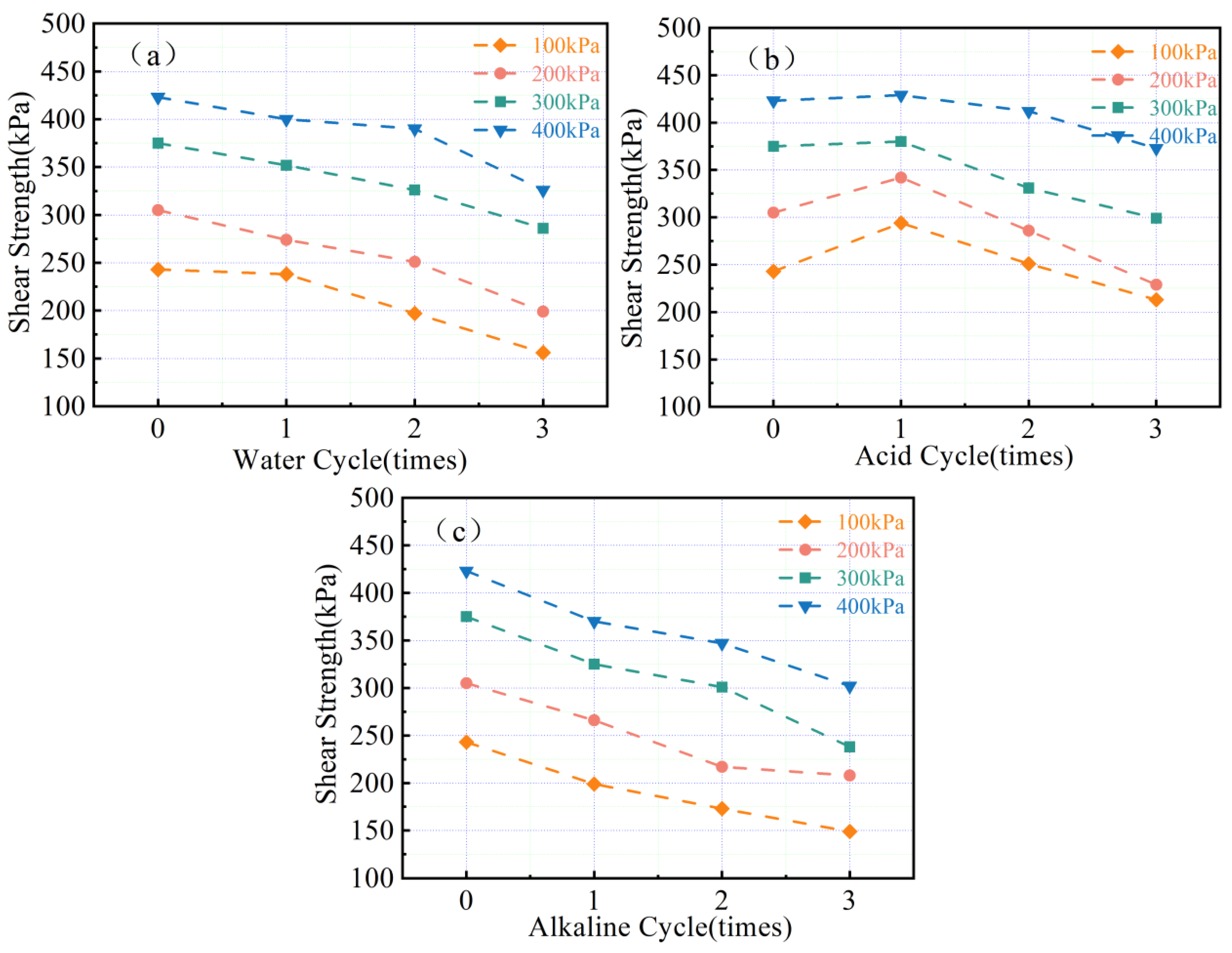

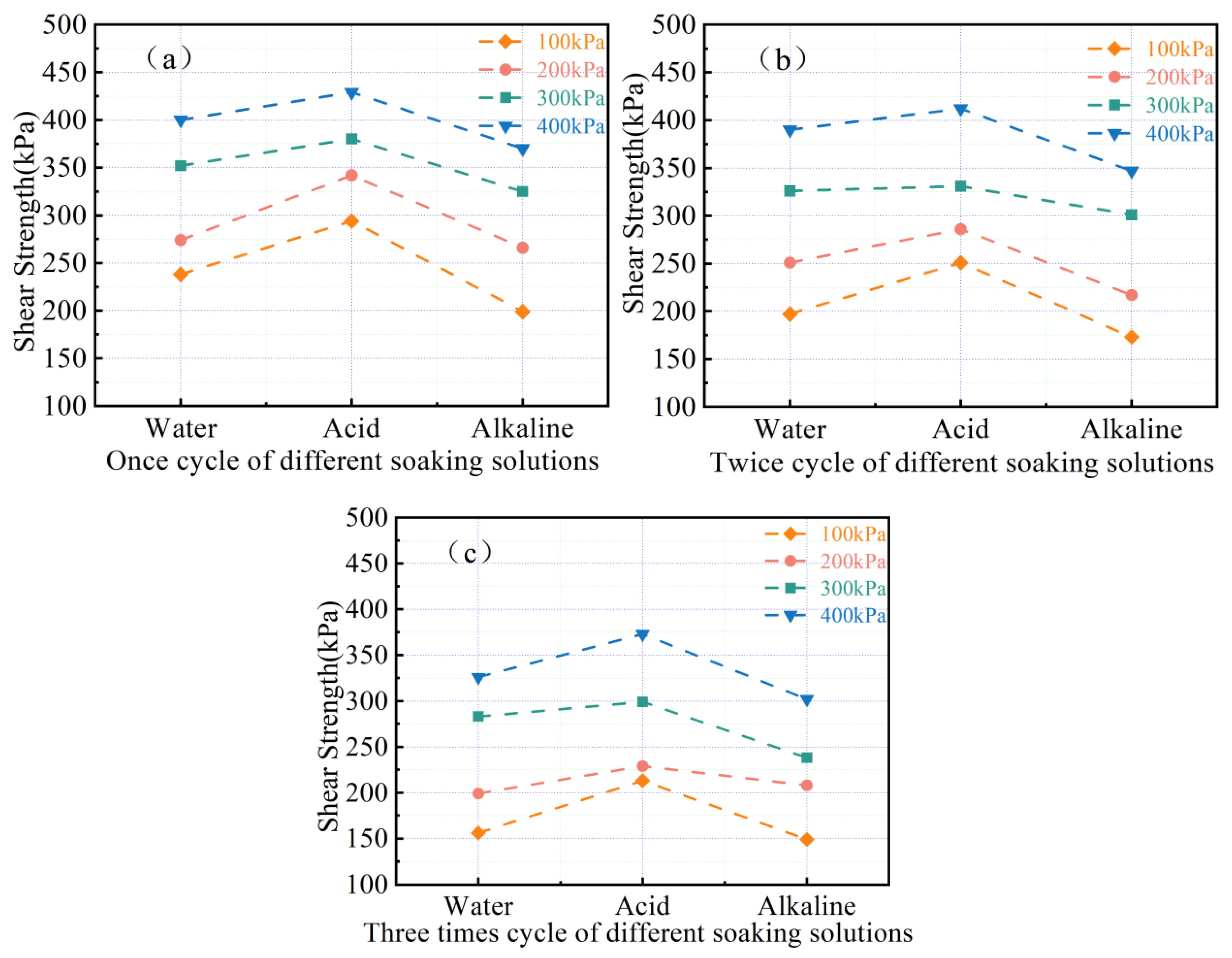

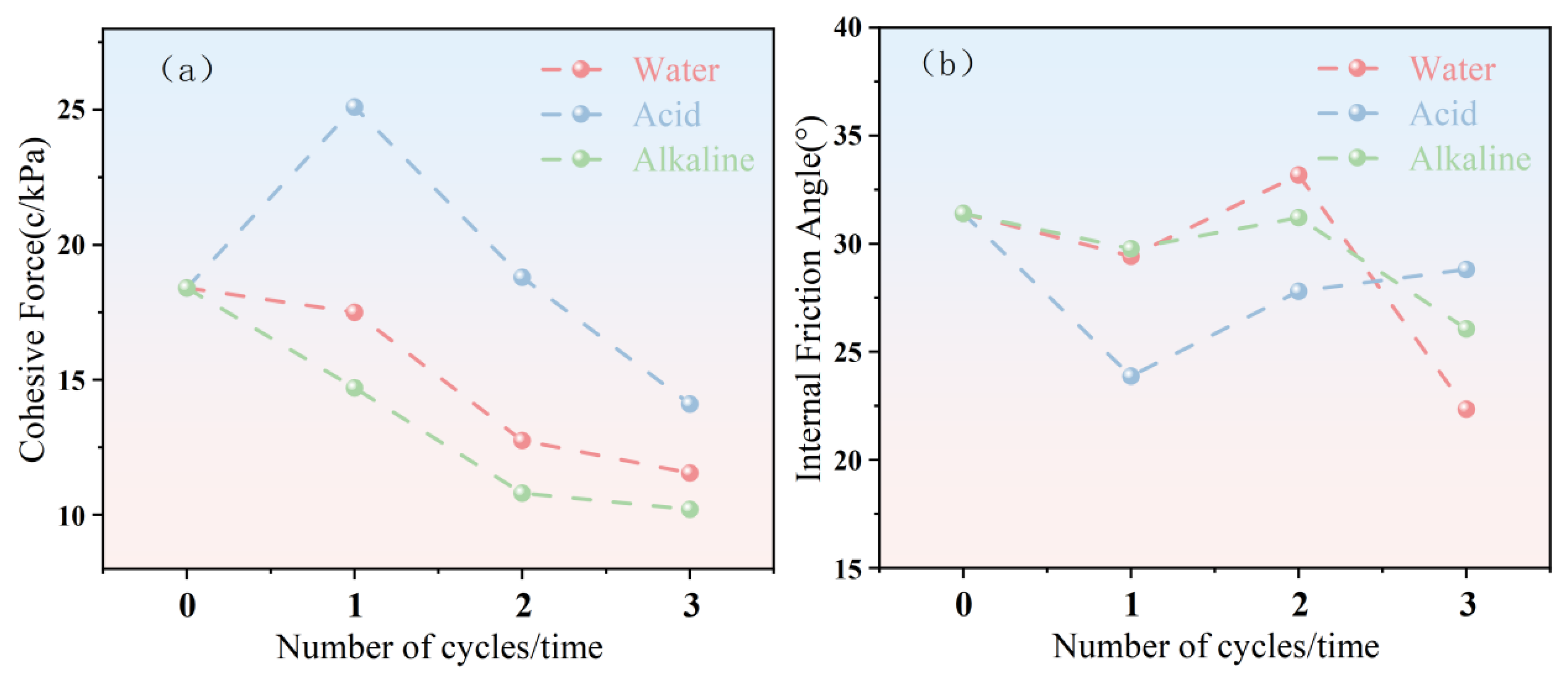

3.3. Effect of Acid–Alkali Drying and Wetting Cycles on Shear Strength of Solidified Soft Soil

4. Conclusions

- After ISS treatment, the soil’s cohesive strength increased by up to 75.24% and the internal friction angle improved by up to 9.50%, particularly when the moisture content was reduced to 24%. This indicates the treatment is most effective in relatively drier conditions.

- The permeability of soft soil was reduced by 88.4% after ISS treatment. This densification of the soil matrix effectively inhibited water penetration and resulted in a strength retention of over 85% post-saturation. In contrast, untreated soils suffered a 40–50% loss in shear strength, highlighting the crucial role of permeability control in long-term mechanical performance.

- Under repeated wet–dry cycles, ISS-modified soil maintained good mechanical stability. The cohesion dropped only by ~26.53% in alkaline conditions, and even increased initially under acid exposure due to ion interactions. In comparison, untreated soils exhibited more severe degradation. The order of durability was acid > neutral > alkaline.

- Although this study focused primarily on the macroscopic strength and durability characteristics, a key limitation is the absence of microstructural and compositional analyses (e.g., SEM and EDX), which will be addressed in future work to further elucidate the underlying stabilization mechanisms.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abdel-Rahman, M.M. Advancements in Geotechnical Engineering. In Review of Soil Improvement Techniques; Shehata, H., Badr, M., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 175–199. [Google Scholar]

- Bian, X.; Xia, J.; Liu, H.; Xiao, T. Strength, Durability, and Microscopic Analysis of Silt Solidified with Two-Phase Phosphogypsum and Cement Fiber. Materials 2025, 18, 1960. [Google Scholar] [CrossRef] [PubMed]

- Ren, Z.; Zheng, Y.; Li, B.; Liu, J.; Wei, P.; Yao, Z. Characterization and quantitative analysis of unfrozen water at ultra-low temperatures: Insights from NMR and MD study. J. Hydrol. 2025, 647, 132354. [Google Scholar] [CrossRef]

- Cyriaque Kaze, R.; Naghizadeh, A.; Tchadjie, L.; Adesina, A.; Noel Yankwa Djobo, J.; Deutou Nemaleu, J.G.; Kamseu, E.; Chinje Melo, U.; Tayeh, B.A. Lateritic soils based geopolymer materials: A review. Constr. Build. Mater. 2022, 344, 128157. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, L.; Tu, C. Experimental Investigation on the Improvement of Dredged Sludge Using Air–Booster Vacuum Preloading with Polyacrylamide Addition. Materials 2025, 18, 2065. [Google Scholar] [CrossRef] [PubMed]

- Lei, H.; Wang, L.; Zhang, W.; Jiang, M.; Bo, Y.; Song, W.; Cao, Q. Geotechnical properties of the South China Sea soft soil: A comparative study with the soils from Bohai Sea and Yellow Sea. Bull. Eng. Geol. Environ. 2023, 82, 158. [Google Scholar] [CrossRef]

- Wijeyesekera, D.C.; Ho, M.H.; Bai, X.; Bakar, I. Strength and Stiffness Development in Soft Soils: A FESEM aided Soil Microstructure Viewpoint. IOP Conf. Ser. Mater. Sci. Eng. 2016, 136, 012041. [Google Scholar] [CrossRef]

- Cao, J.; Wang, T.; Zhou, G.; Feng, X.; Zhu, C. Parameter estimation of grouting pressure and surface subsidence on the reliability of shield tunnel excavation under incomplete probability information. Comput. Geotech. 2024, 173, 106530. [Google Scholar] [CrossRef]

- Luo, X.; Xu, W.; Qiu, X.; Yang, Q.; Xiao, S. Exploring the microstructure characteristics and mechanical behavior of the ionic soil stabilizer-treated clay. Arab. J. Geosci. 2020, 13, 729. [Google Scholar] [CrossRef]

- Wu, X.-T.; Qi, Y.; Chen, B. Solidification effect and mechanism of ionic soil stabilizer applied on high-water-content clay. Bull. Eng. Geol. Environ. 2021, 80, 8583–8595. [Google Scholar] [CrossRef]

- Jia, J.; Lu, X.; Zhu, J.; Wang, J.; Zhang, L.; Cheng, X. Effect of ionic soil stabilizer on the properties of lime and fly ash stabilized iron tailings as pavement base. Constr. Build. Mater. 2024, 450, 138558. [Google Scholar] [CrossRef]

- Luo, X.H.; Qiu, X.; Wang, Y.J.; Wu, J.H.; Xiao, S.L. Micro-Treatment Mechanism Study on Ionic Soil Stabilizer Improving Clay. Key Eng. Mater. 2016, 667, 370–375. [Google Scholar] [CrossRef]

- Tavakoli, E.; He, S.; Yu, X.; Hoyos Laureano, R. Laboratory Evaluation of a Liquid Ionic Stabilizer for an Expansive Soil in North Texas. In PanAm Unsaturated Soils 2017; ASCE Press: Reston, VA, USA, 2018; pp. 190–197. [Google Scholar]

- Gautam, S.; Hoyos, L.R.; He, S.; Prabakar, S.; Yu, X. Chemical Treatment of a Highly Expansive Clay Using a Liquid Ionic Soil Stabilizer. Geotech. Geol. Eng. 2020, 38, 4981–4993. [Google Scholar] [CrossRef]

- Niu, W.; Guo, B.; Li, K.; Ren, Z.; Zheng, Y.; Liu, J.; Lin, H.; Men, X. Cementitous material based stabilization of soft soils by stabilizer: Feasibility and durabiliy assessment. Constr. Build. Mater. 2024, 425, 136046. [Google Scholar] [CrossRef]

- Rao, S.M.; Reddy, B.V.V.; Muttharam, M. The impact of cyclic wetting and drying on the swelling behaviour of stabilized expansive soils. Eng. Geol. 2001, 60, 223–233. [Google Scholar] [CrossRef]

- Das, G.; Razakamanantsoa, A.; Herrier, G.; Deneele, D. Physicochemical and Microstructural Evaluation in Lime-Treated Silty Soil Exposed to Successive Wetting-Drying Cycles Submitted to Different Testing Conditions. J. Mater. Civ. Eng. 2023, 35, 04022458. [Google Scholar] [CrossRef]

- Xiong, Y.; Meng, F.; Qu, D.; Mao, M.; Zhang, J. Study on the Bonding Performance of Reinforced Concrete with Reef Limestone Under the Combined Effects of Dry and Wet Carbonation. Materials 2025, 18, 1963. [Google Scholar] [CrossRef] [PubMed]

- Piao, M.; Wang, Q.; Zha, F.; Meng, L.; Zhang, H. Stability of Lignosulphonate-modified expansive soil under wet-dry cycles: Utilizing industrial waste for sustainable soil improvement. Bull. Eng. Geol. Environ. 2025, 84, 161. [Google Scholar] [CrossRef]

- Zhang, J.; Yao, B.; Sun, Y.; Wang, M.; Sun, Q.; Sun, C.; Wang, B.; Lin, Z. Study of the effects of an ionic stabilizer on the permeability of gangue bonding material. Constr. Build. Mater. 2022, 345, 128325. [Google Scholar] [CrossRef]

- Song, X.; Wang, P.; Van Zwieten, L.; Bolan, N.; Wang, H.; Li, X.; Cheng, K.; Yang, Y.; Wang, M.; Liu, T.; et al. Towards a better understanding of the role of Fe cycling in soil for carbon stabilization and degradation. Carbon Res. 2022, 1, 5. [Google Scholar] [CrossRef]

- Hou, Y.; Li, P.; Wang, J. Review of chemical stabilizing agents for improving the physical and mechanical properties of loess. Bull. Eng. Geol. Environ. 2021, 80, 9201–9215. [Google Scholar] [CrossRef]

- Gan, J.K.M.; Fredlund, D.G.; Rahardjo, H. Determination of the shear strength parameters of an unsaturated soil using the direct shear test. Can. Geotech. J. 1988, 25, 500–510. [Google Scholar] [CrossRef]

- Daniel, D.E. Permeability Test for Unsaturated Soil. Geotech. Test. J. 1983, 6, 81–86. [Google Scholar] [CrossRef]

- Zhang, B.; Zhao, Q.G.; Horn, R.; Baumgartl, T. Shear strength of surface soil as affected by soil bulk density and soil water content. Soil Tillage Res. 2001, 59, 97–106. [Google Scholar] [CrossRef]

- Schellart, W.P. Shear test results for cohesion and friction coefficients for different granular materials: Scaling implications for their usage in analogue modelling. Tectonophysics 2000, 324, 1–16. [Google Scholar] [CrossRef]

- Xiang, W.; Cui, D.; Liu, Q.; Lu, X.; Cao, L. Theory and practice of ionic soil stabilizer reinforcing special clay. J. Earth Sci. 2010, 21, 882–887. [Google Scholar] [CrossRef]

- Jin, F.; Zhou, D.; Zhu, L. Analysis of the Microstructure and Macroscopic Fluid-Dynamics Behavior of Soft Soil after Seepage Consolidation. Fluid Dyn. Mater. Process. 2021, 18, 285–302. [Google Scholar] [CrossRef]

- Tavenas, F.; Leblond, P.; Jean, P.; Leroueil, S. The permeability of natural soft clays. Part I: Methods of laboratory measurement. Can. Geotech. J. 1983, 20, 629–644. [Google Scholar] [CrossRef]

- Li, J.; Pu, L.; Zhu, M.; Zhang, J.; Li, P.; Dai, X.; Xu, Y.; Liu, L. Evolution of soil properties following reclamation in coastal areas: A review. Geoderma 2014, 226, 130–139. [Google Scholar] [CrossRef]

- Lu, X.S.; Xiang, W. Experimental Study on Dynamic Characteristics of Ionic Soil Stabilizer Reinforcing Red Clay. Adv. Mater. Res. 2011, 374–377, 1391–1395. [Google Scholar] [CrossRef]

- Liu, X.; Feng, P.; Yu, X.; Huang, J. Decalcification of calcium silicate hydrate (C-S-H) under aggressive solution attack. Constr. Build. Mater. 2022, 342, 127988. [Google Scholar] [CrossRef]

- Sun, Y.; You, M.; Yin, X.; Hou, D.; Li, J.; Zhou, X. Study on the Micro-Mechanism of Corrosion Deterioration of Concrete Under Sulfate Attack Environment. Materials 2025, 18, 2904. [Google Scholar] [CrossRef] [PubMed]

| Soil Type | Specific Gravity/Gs | Optimal Moisture Content/% | Liquid Limit/% | Plastic Limit/% | Plasticity Index |

|---|---|---|---|---|---|

| Clay | 2.69 | 30.5 | 67.5 | 38.2 | 29.3 |

| Untreated Soil | |||||||

| Number | Time/s | H1/cm | H2/cm | 2.3aLA−1T−1 | lgH1/H2 | KT | Average Value |

| 1 | 16,800 | 129.5 | 91.7 | 2.442 × 10−6 | 1.499 × 10−1 | 3.660 × 10−7 | 3.364 × 10−7 |

| 2 | 6600 | 91.7 | 81.2 | 6.215 × 10−6 | 5.281 × 10−2 | 3.282 × 10−7 | |

| 3 | 56,400 | 81.2 | 30.8 | 7.273 × 10−7 | 4.210 × 10−1 | 3.062 × 10−7 | |

| 4 | 14,400 | 30.8 | 23.3 | 2.849 × 10−6 | 1.212 × 10−1 | 3.452 × 10−7 | |

| Solidified Soil | |||||||

| Number | Time/s | H1/cm | H2/cm | 2.3aLA−1T−1 | lgH1/H2 | KT | Average Value |

| 1 | 90,480 | 124.5 | 101.9 | 4.534 × 10−7 | 8.700 × 10−2 | 3.944 × 10−8 | 3.902 × 10−8 |

| 2 | 87,120 | 101.9 | 80 | 4.708 × 10−7 | 1.051 × 10−1 | 4.948 × 10−8 | |

| 3 | 87,300 | 80 | 67 | 4.699 × 10−7 | 7.702 × 10−2 | 3.619 × 10−8 | |

| 4 | 82,920 | 67 | 58 | 4.947 × 10−7 | 6.265 × 10−2 | 3.099 × 10−8 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, Z.; Lin, S.; Liu, S.; Li, B.; Liu, J.; Chen, L.; Fan, L.; Xie, Z.; Wu, L. Study on the Shear Strength and Durability of Ionic Soil Stabilizer-Modified Soft Soil in Acid Alkali Environments. Eng 2025, 6, 178. https://doi.org/10.3390/eng6080178

Ren Z, Lin S, Liu S, Li B, Liu J, Chen L, Fan L, Xie Z, Wu L. Study on the Shear Strength and Durability of Ionic Soil Stabilizer-Modified Soft Soil in Acid Alkali Environments. Eng. 2025; 6(8):178. https://doi.org/10.3390/eng6080178

Chicago/Turabian StyleRen, Zhifeng, Shijie Lin, Siyu Liu, Bo Li, Jiankun Liu, Liang Chen, Lideng Fan, Ziling Xie, and Lingjie Wu. 2025. "Study on the Shear Strength and Durability of Ionic Soil Stabilizer-Modified Soft Soil in Acid Alkali Environments" Eng 6, no. 8: 178. https://doi.org/10.3390/eng6080178

APA StyleRen, Z., Lin, S., Liu, S., Li, B., Liu, J., Chen, L., Fan, L., Xie, Z., & Wu, L. (2025). Study on the Shear Strength and Durability of Ionic Soil Stabilizer-Modified Soft Soil in Acid Alkali Environments. Eng, 6(8), 178. https://doi.org/10.3390/eng6080178